wheel bolts SUZUKI SWIFT 2005 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

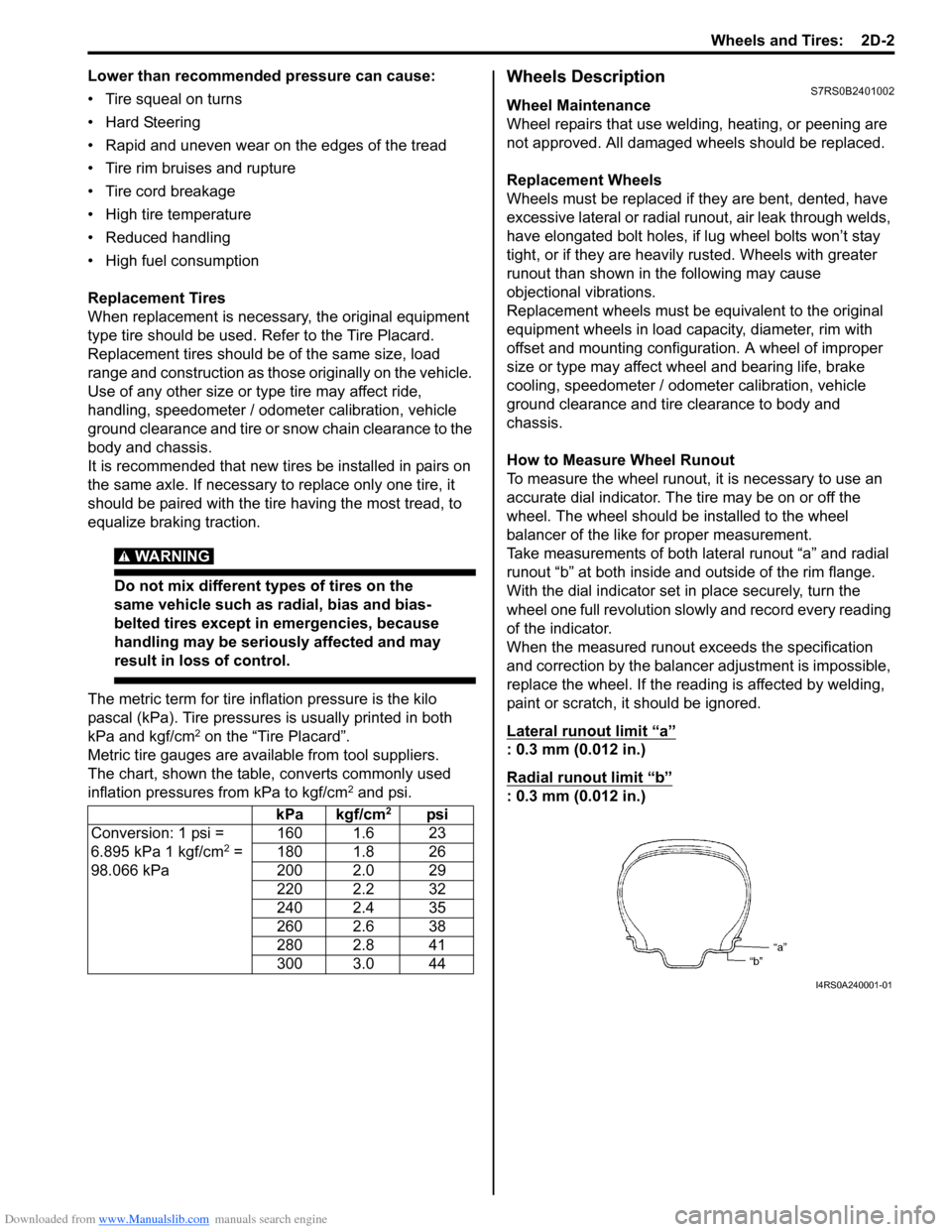

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 479 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-1

Driveline / Axle

Drive Shaft / Axle

General Description

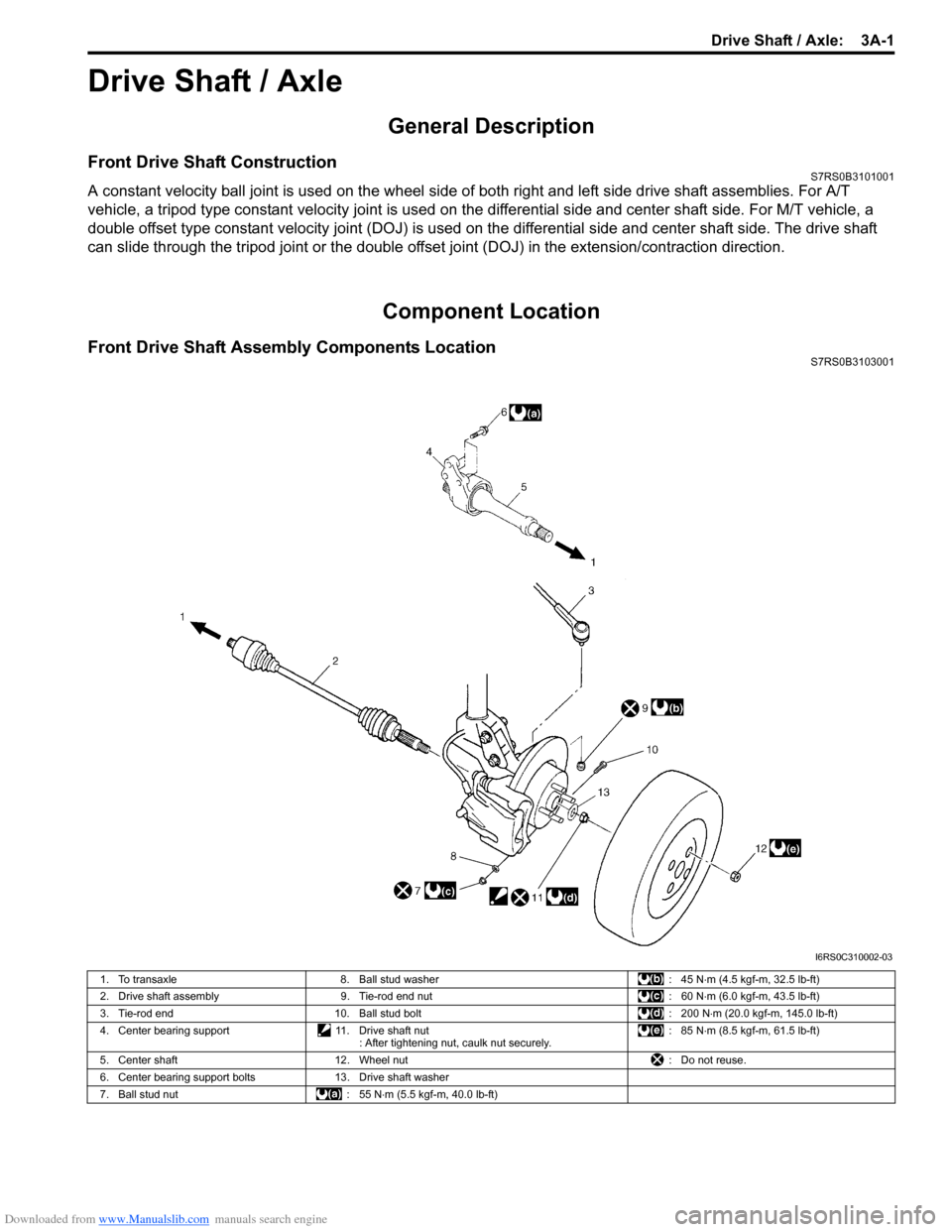

Front Drive Shaft ConstructionS7RS0B3101001

A constant velocity ball joint is used on the wheel side of both right and left side drive shaft assemblies. For A/T

vehicle, a tripod type constant velocity joint is used on the differential side and center shaft side. For M/T vehicle, a

double offset type constant velocity joint (DOJ) is used on the differential side and center shaft side. The drive shaft

can slide through the tripod joint or the double offset joint (DOJ) in the extension/contraction direction.

Component Location

Front Drive Shaft Assembly Components LocationS7RS0B3103001

I6RS0C310002-03

1. To transaxle 8. Ball stud washer : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

2. Drive shaft assembly 9. Tie-rod end nut : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Tie-rod end 10. Ball stud bolt : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

4. Center bearing support 11. Drive shaft nut

: After tightening nut, caulk nut securely. : 85 N

⋅m (8.5 kgf-m, 61.5 lb-ft)

5. Center shaft 12. Wheel nut : Do not reuse.

6. Center bearing support bolts 13. Drive shaft washer

7. Ball stud nut : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

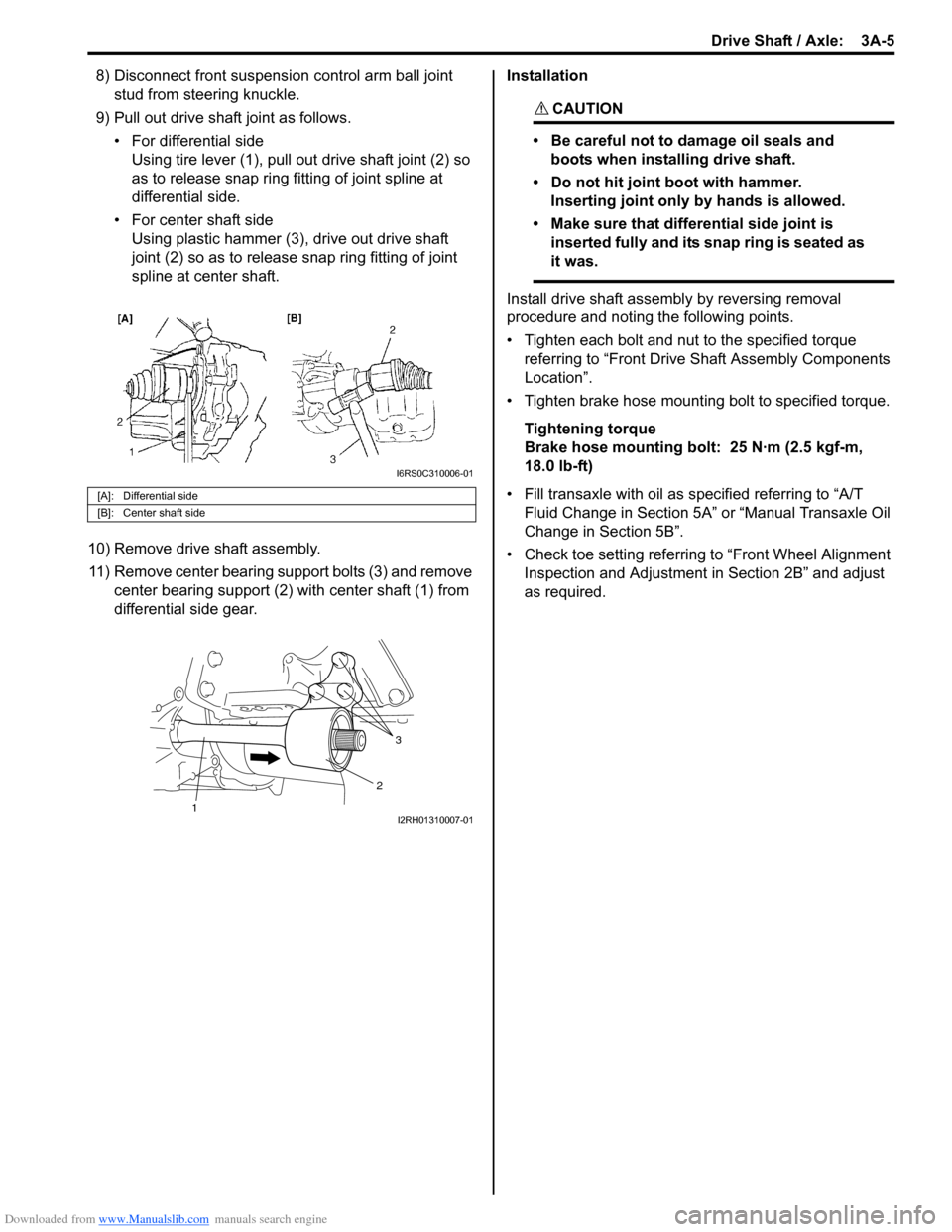

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

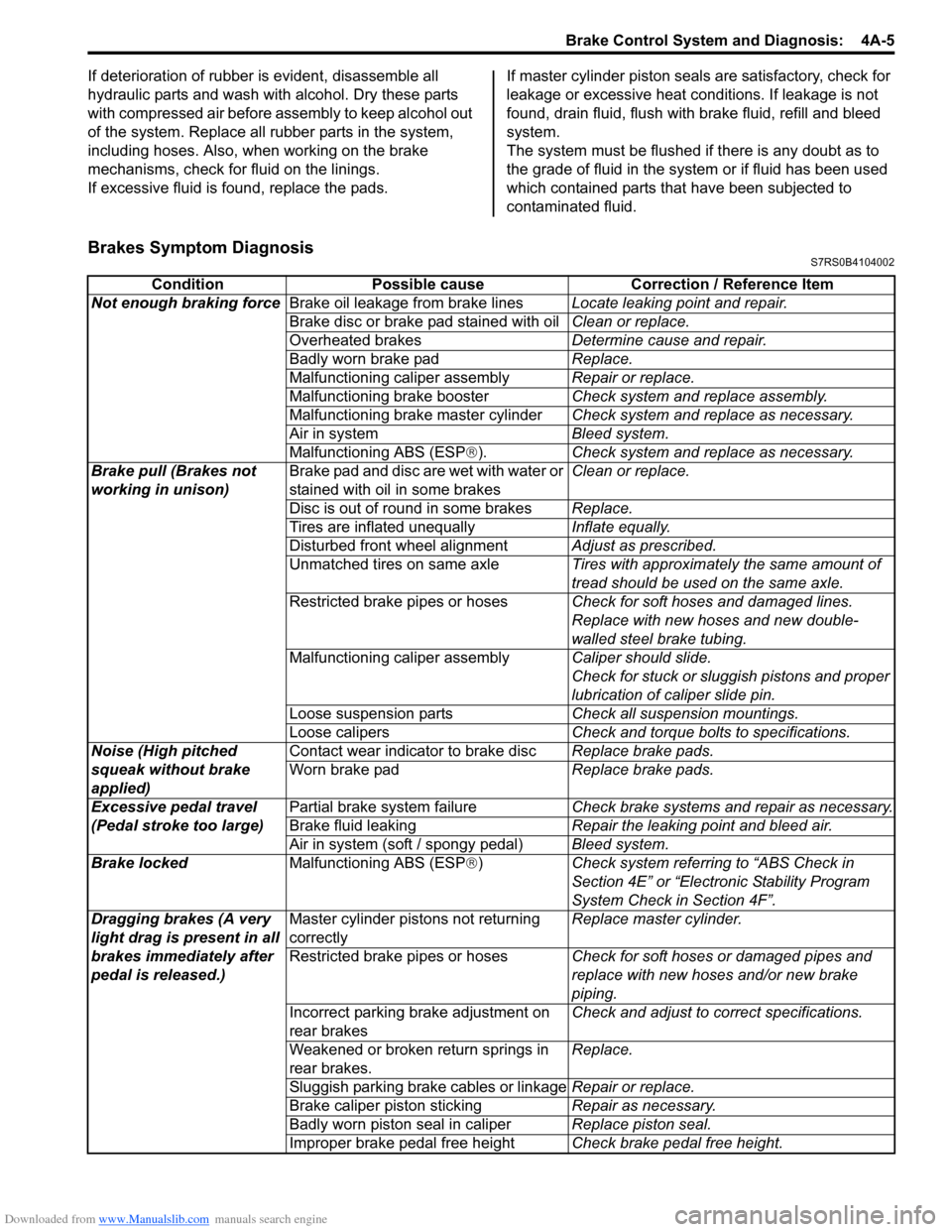

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

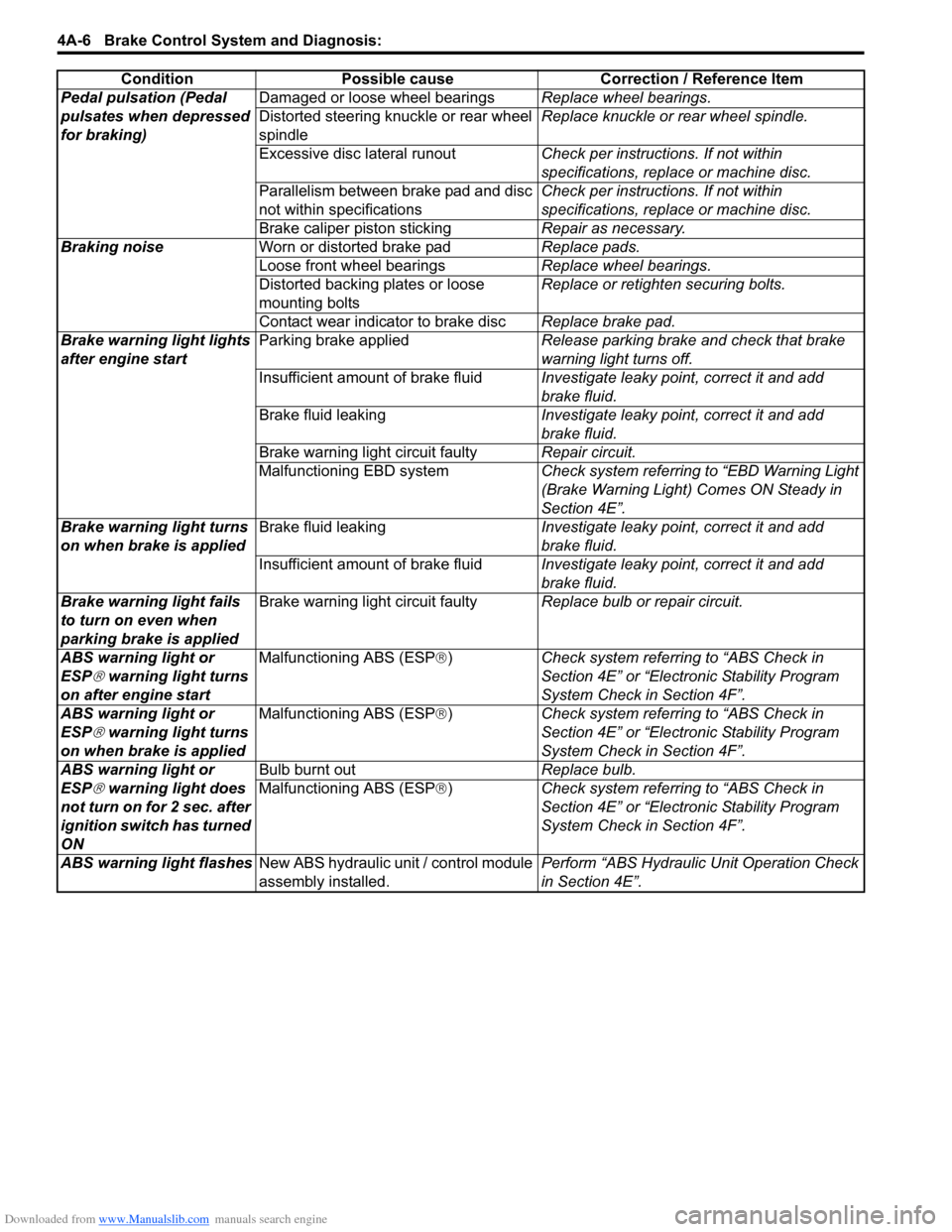

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 508 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-10 Brake Control System and Diagnosis:

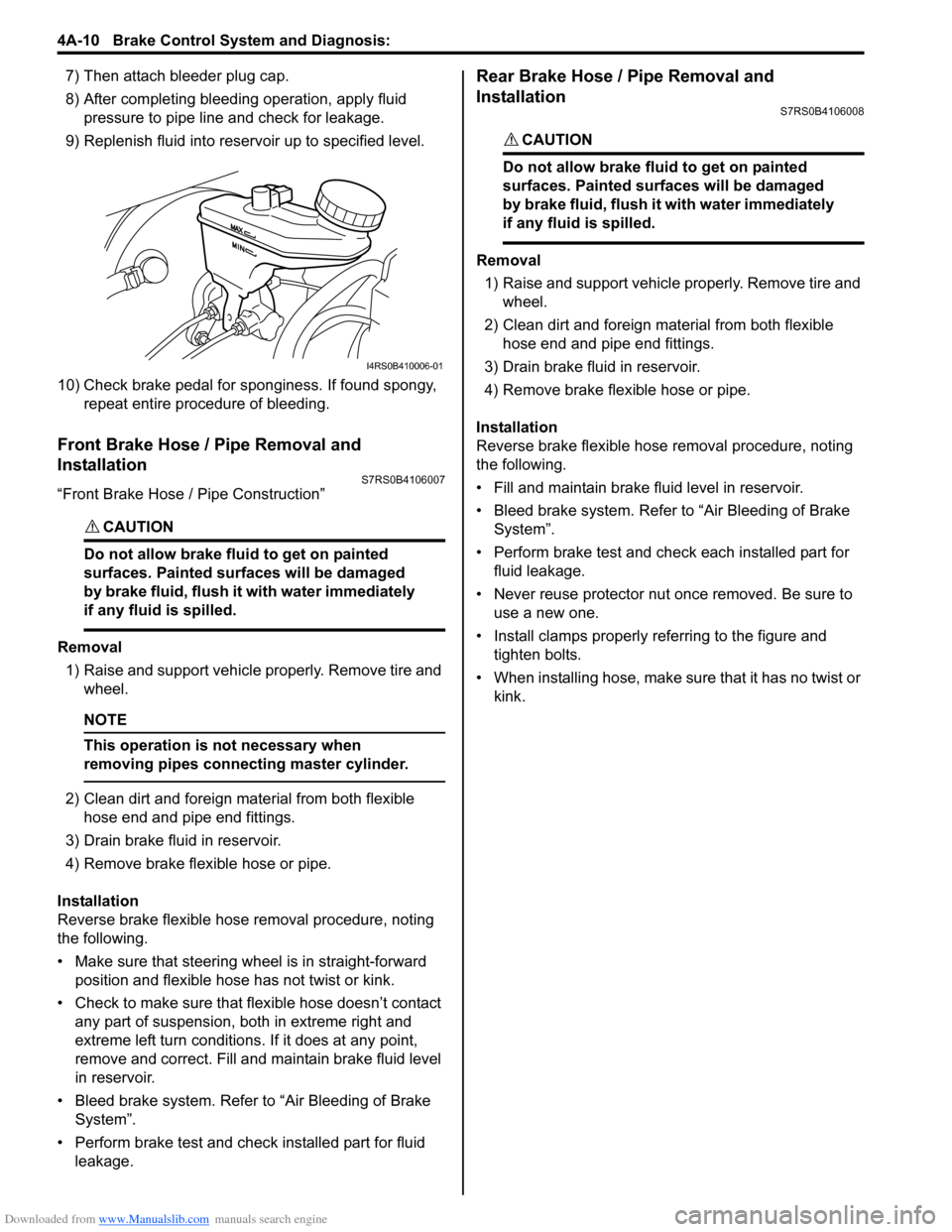

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

10) Check brake pedal for sponginess. If found spongy, repeat entire procedure of bleeding.

Front Brake Hose / Pipe Removal and

Installation

S7RS0B4106007

“Front Brake Hose / Pipe Construction”

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign mate rial from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Make sure that steering wh eel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check installed part for fluid leakage.

Rear Brake Hose / Pipe Removal and

Installation

S7RS0B4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check each installed part for fluid leakage.

• Never reuse protector nut once removed. Be sure to use a new one.

• Install clamps properly referring to the figure and tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

I4RS0B410006-01

Page 518 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-2 Front Brakes:

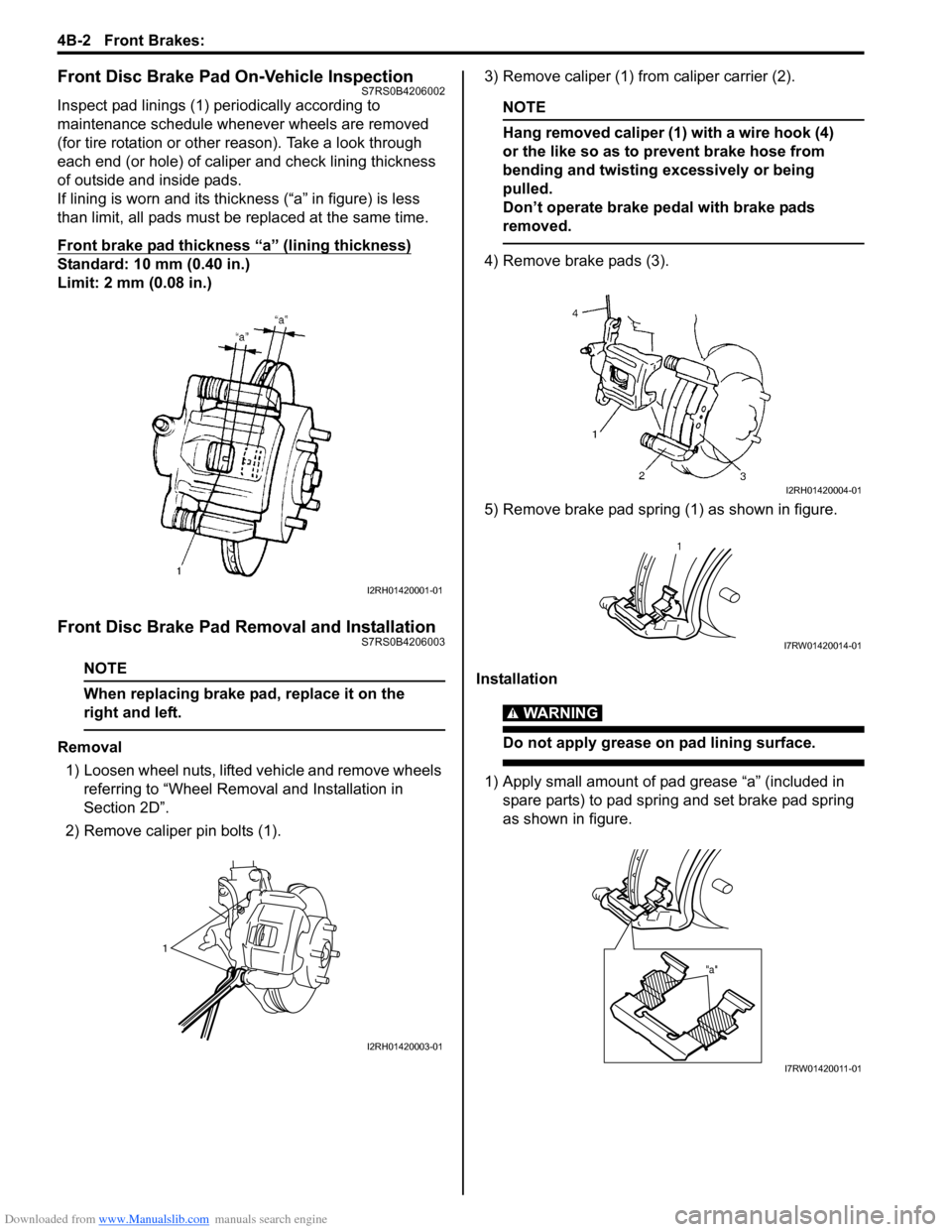

Front Disc Brake Pad On-Vehicle InspectionS7RS0B4206002

Inspect pad linings (1) periodically according to

maintenance schedule whenever wheels are removed

(for tire rotation or other reason). Take a look through

each end (or hole) of caliper and check lining thickness

of outside and inside pads.

If lining is worn and its thic kness (“a” in figure) is less

than limit, all pads must be replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

Front Disc Brake Pad Removal and InstallationS7RS0B4206003

NOTE

When replacing brake pad, replace it on the

right and left.

Removal

1) Loosen wheel nuts, lifted vehicle and remove wheels referring to “Wheel Remova l and Installation in

Section 2D”.

2) Remove caliper pin bolts (1). 3) Remove caliper (1) from caliper carrier (2).

NOTE

Hang removed caliper (1) with a wire hook (4)

or the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

4) Remove brake pads (3).

5) Remove brake pad spring (1) as shown in figure.

Installation

WARNING!

Do not apply grease on pad lining surface.

1) Apply small amount of pad grease “a” (included in spare parts) to pad spring and set brake pad spring

as shown in figure.

I2RH01420001-01

1

I2RH01420003-01

I2RH01420004-01

1

I7RW01420014-01

"a"

I7RW01420011-01

Page 519 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-3

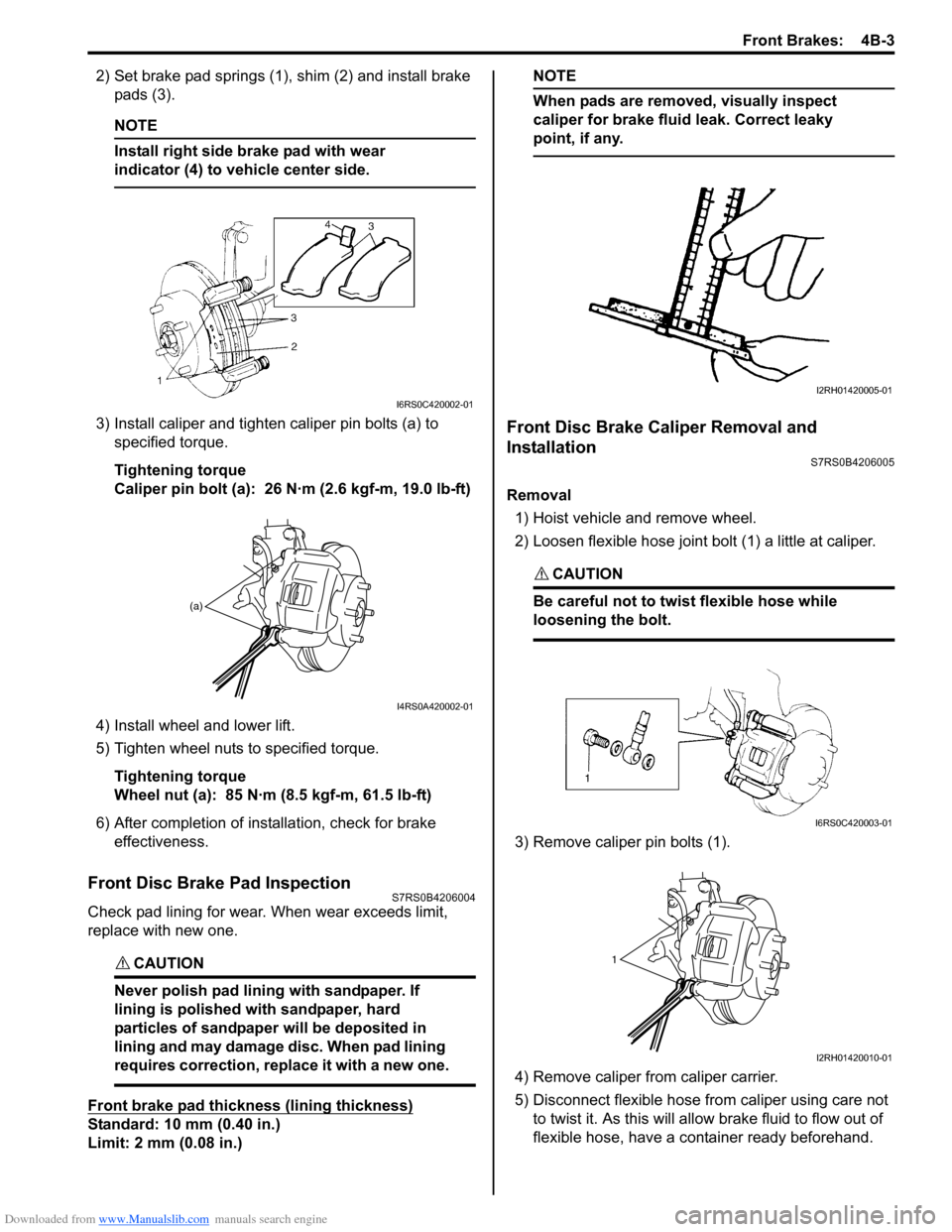

2) Set brake pad springs (1), shim (2) and install brake pads (3).

NOTE

Install right side brake pad with wear

indicator (4) to vehicle center side.

3) Install caliper and tighten caliper pin bolts (a) to specified torque.

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

4) Install wheel and lower lift.

5) Tighten wheel nuts to specified torque. Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completion of installation, check for brake effectiveness.

Front Disc Brake Pad InspectionS7RS0B4206004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Front brake pad thickness (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

Front Disc Brake Caliper Removal and

Installation

S7RS0B4206005

Removal

1) Hoist vehicle and remove wheel.

2) Loosen flexible hose joint bolt (1) a little at caliper.

CAUTION!

Be careful not to twist flexible hose while

loosening the bolt.

3) Remove caliper pin bolts (1).

4) Remove caliper fr om caliper carrier.

5) Disconnect flexible hose fr om caliper using care not

to twist it. As this will allow brake fluid to flow out of

flexible hose, have a container ready beforehand.

I6RS0C420002-01

(a)

I4RS0A420002-01

I2RH01420005-01

I6RS0C420003-01

1

I2RH01420010-01

Page 520 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-4 Front Brakes:

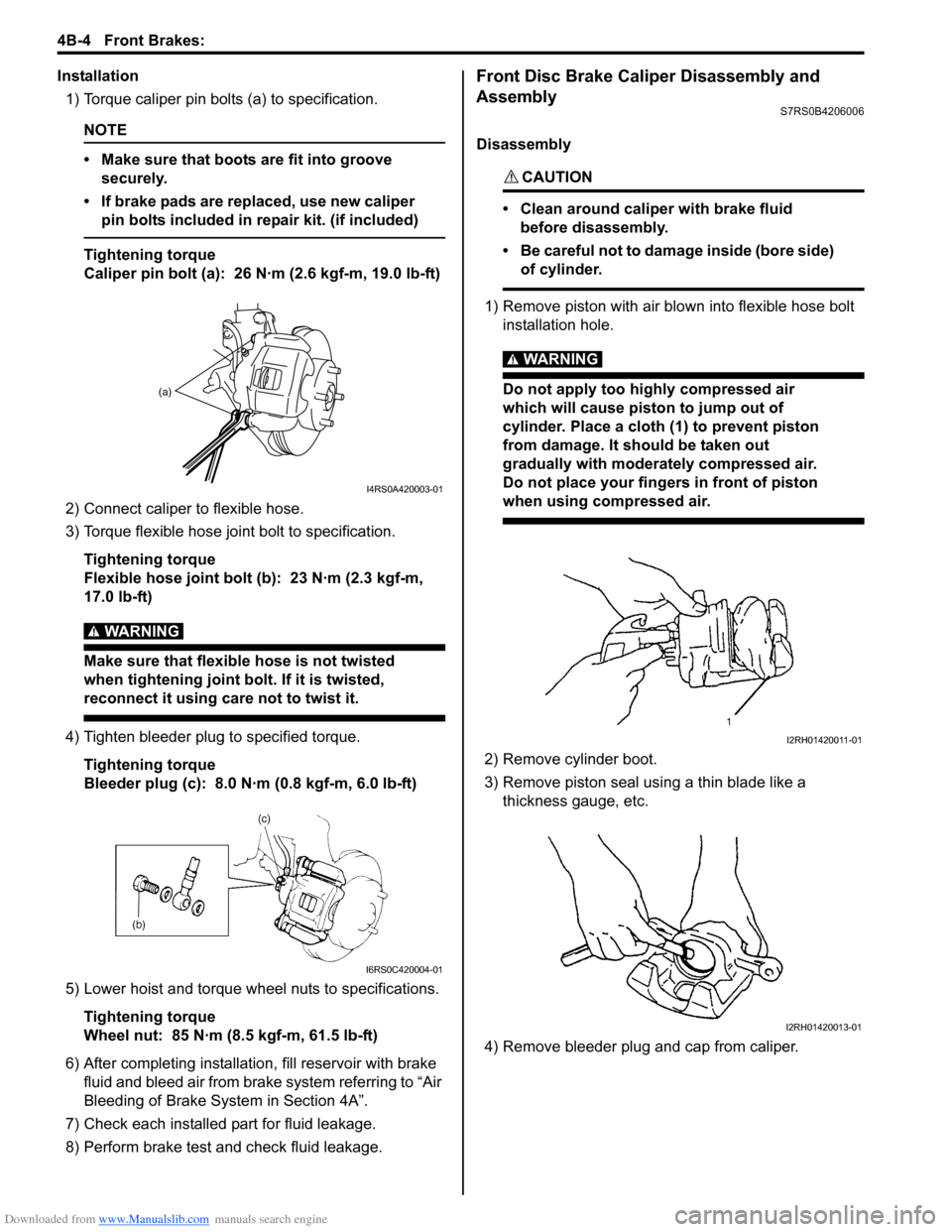

Installation1) Torque caliper pin bolts (a) to specification.

NOTE

• Make sure that boots are fit into groove securely.

• If brake pads are replaced, use new caliper pin bolts included in repair kit. (if included)

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

2) Connect caliper to flexible hose.

3) Torque flexible hose jo int bolt to specification.

Tightening torque

Flexible hose joint bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

4) Tighten bleeder plug to specified torque. Tightening torque

Bleeder plug (c): 8.0 N·m (0.8 kgf-m, 6.0 lb-ft)

5) Lower hoist and torque wheel nuts to specifications. Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completing installation, fill reservoir with brake

fluid and bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) Perform brake test and check fluid leakage.

Front Disc Brake Caliper Disassembly and

Assembly

S7RS0B4206006

Disassembly

CAUTION!

• Clean around caliper with brake fluid before disassembly.

• Be careful not to damage inside (bore side) of cylinder.

1) Remove piston with air blown into flexible hose bolt installation hole.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth (1) to prevent piston

from damage. It should be taken out

gradually with moderately compressed air.

Do not place your fingers in front of piston

when using compressed air.

2) Remove cylinder boot.

3) Remove piston seal using a thin blade like a thickness gauge, etc.

4) Remove bleeder plug and cap from caliper.

(a)

I4RS0A420003-01

I6RS0C420004-01

I2RH01420011-01

I2RH01420013-01

Page 522 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-6 Front Brakes:

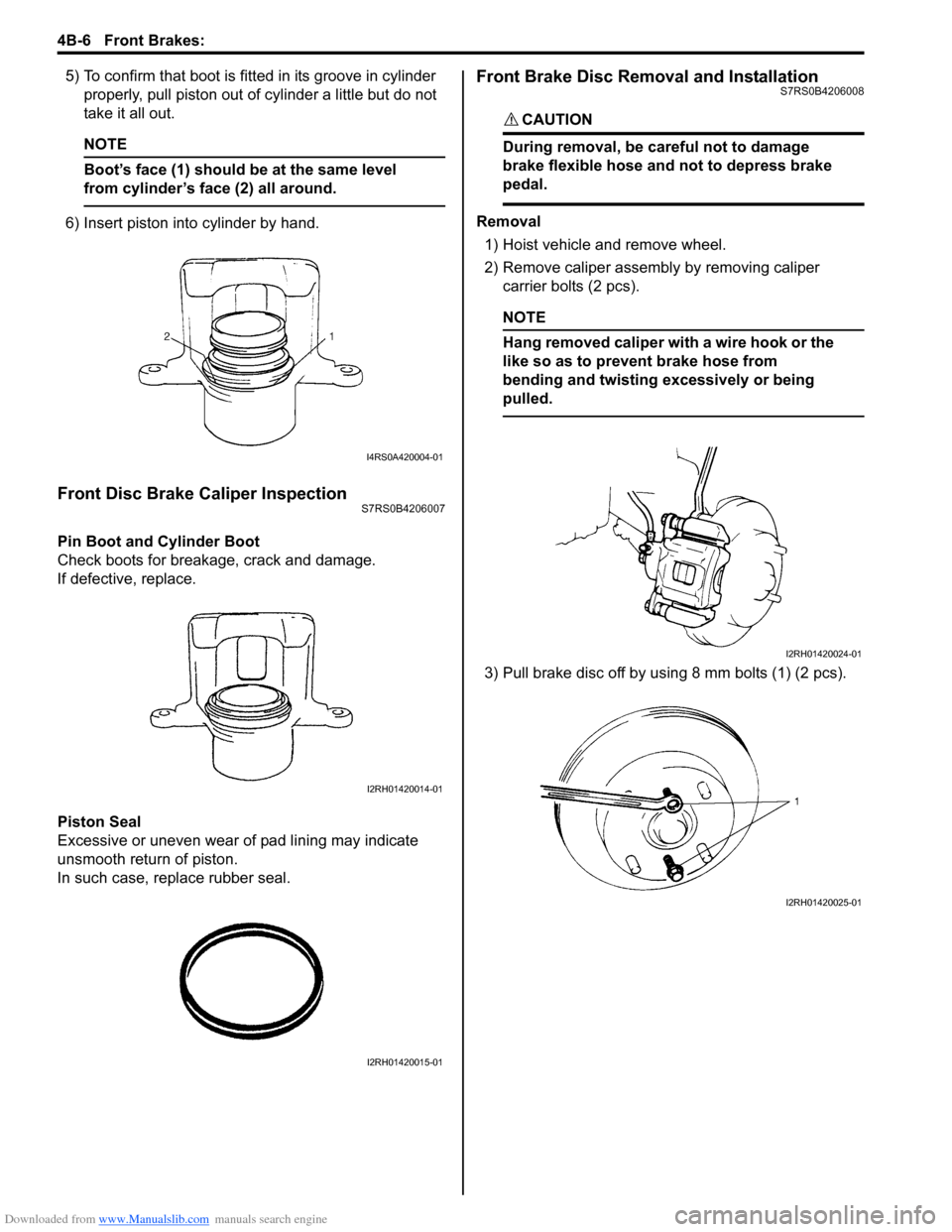

5) To confirm that boot is fitted in its groove in cylinder

properly, pull piston out of cylinder a little but do not

take it all out.

NOTE

Boot’s face (1) should be at the same level

from cylinder’s face (2) all around.

6) Insert piston into cylinder by hand.

Front Disc Brake Caliper InspectionS7RS0B4206007

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate

unsmooth return of piston.

In such case, replace rubber seal.

Front Brake Disc Removal and InstallationS7RS0B4206008

CAUTION!

During removal, be care ful not to damage

brake flexible hose and not to depress brake

pedal.

Removal

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts (2 pcs).

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

I4RS0A420004-01

I2RH01420014-01

I2RH01420015-01

I2RH01420024-01

I2RH01420025-01