wheels SUZUKI SWIFT 2005 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 472 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-5 Wheels and Tires:

Radial Tire Lead / Pull DescriptionS7RS0B2401006

“Lead / Pull” is the deviation of the vehicle from a straight

path on a level road even with no pressure on the

steering wheel.

Lead is usually caused by the following conditions.

• Improper tire and wheel alignment.

• Uneven brake assemblies.

• Tire construction.

The way in which a tire is built can produce lead in a

vehicle. An example of this is placement of the belt. Off

center belts on radial tires can cause the tire to develop

a side force while rolling straight down the road. If one

side of the tire has a little larger diameter than the other,

the tire will tend to roll to one side. This will develop a

side force which can produce vehicle lead.

The procedure in the figure (Lead Diagnosis) should be

used to make sure that wheel alignment is not mistaken

for tire lead.

• Part of the lead diagnosis procedure is different from the proper tire rotation pattern currently in the owner

and service manuals. If a medium to high mileage tire

is moved to the other side of the vehicle, be sure to

check that ride roughness has not developed.

• Rear tires will not cause lead.

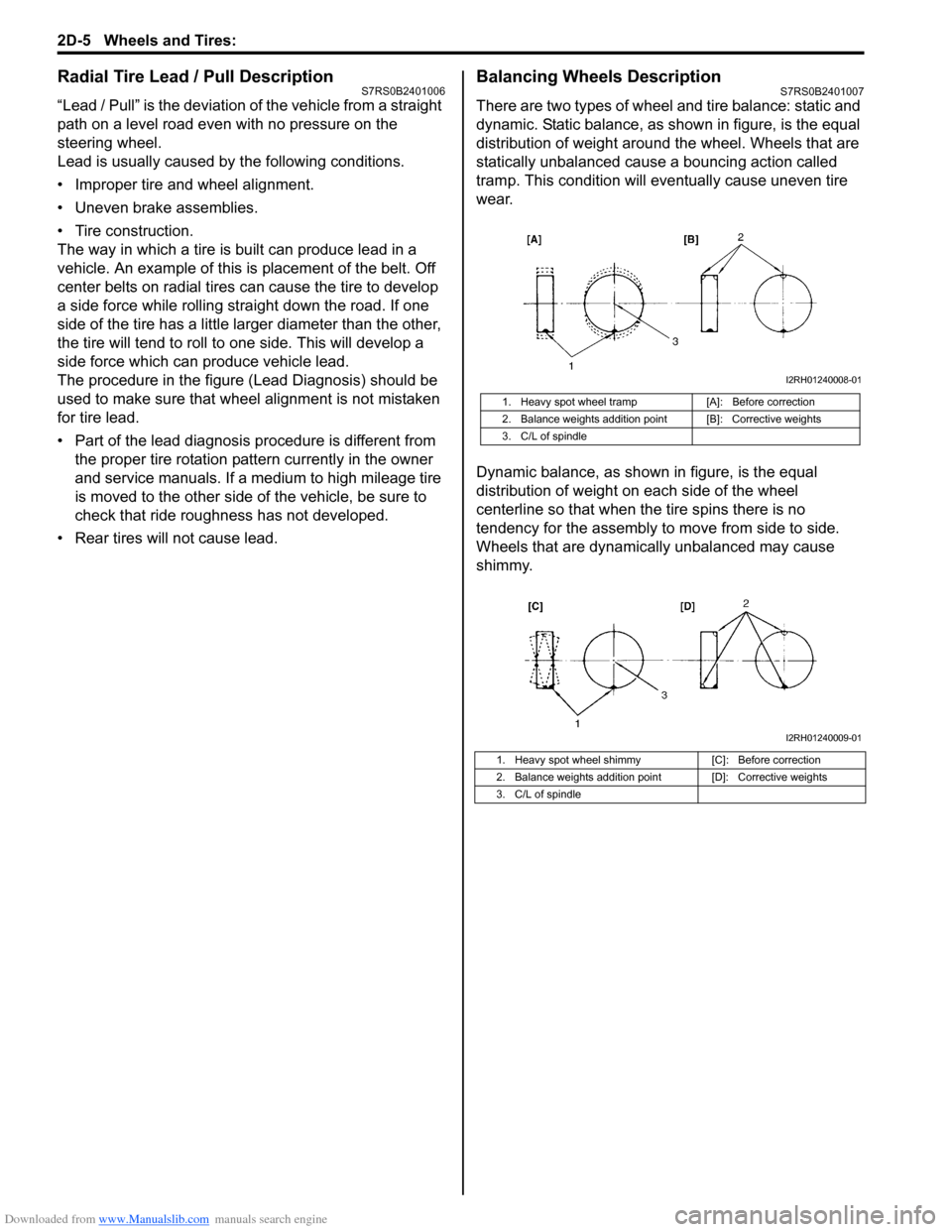

Balancing Wheels DescriptionS7RS0B2401007

There are two types of wheel an d tire balance: static and

dynamic. Static balance, as shown in figure, is the equal

distribution of weight around the wheel. Wheels that are

statically unbalanced cause a bouncing action called

tramp. This condition will eventually cause uneven tire

wear.

Dynamic balance, as shown in figure, is the equal

distribution of weight on each side of the wheel

centerline so that when the tire spins there is no

tendency for the assembly to move from side to side.

Wheels that are dynamically unbalanced may cause

shimmy.

1. Heavy spot wheel tramp [A]: Before correction

2. Balance weights addition point [B]: Corrective weights

3. C/L of spindle

1. Heavy spot wheel shimmy [C]: Before correction

2. Balance weights addition point [D]: Corrective weights

3. C/L of spindle

I2RH01240008-01

I2RH01240009-01

Page 473 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Repair Instructions

General Balance ProceduresS7RS0B2406001

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING!

Stones should be removed from the tread in

order to avoid operator injury during spin

balancing and to obtain good balance.

Each tire should be inspected for any damage, then

balanced according to equipment manufacturer’s

recommendation.

Off-Vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they

do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their

accuracy, usually to within 1/8 ounce.

On-Vehicle Balancing

On-vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer’s instructions during balancing operation.

WARNING!

Wheel spin should be limited to 55 km/h (35

mph) as indicated on speedometer.

This limit is necessary because speedometer

only indicates one-half of actual wheel speed

when one drive wheel is spinning and the

other drive wheel is stopped.

Unless care is taken in limiting drive wheel

spin, spinning wheel can reach excessive

speeds. This can result in possible tire

disintegration or differential failure, which

could cause serious personal injury or

extensive vehicle damage.

CAUTION!

Using on-vehicle balancing method with

ignition switch ON may set malfunction

diagnostic trouble code (DTC) of ESP® and

ABS even when system is in good condition.

Never turn ignition swit ch ON while spinning

wheel.

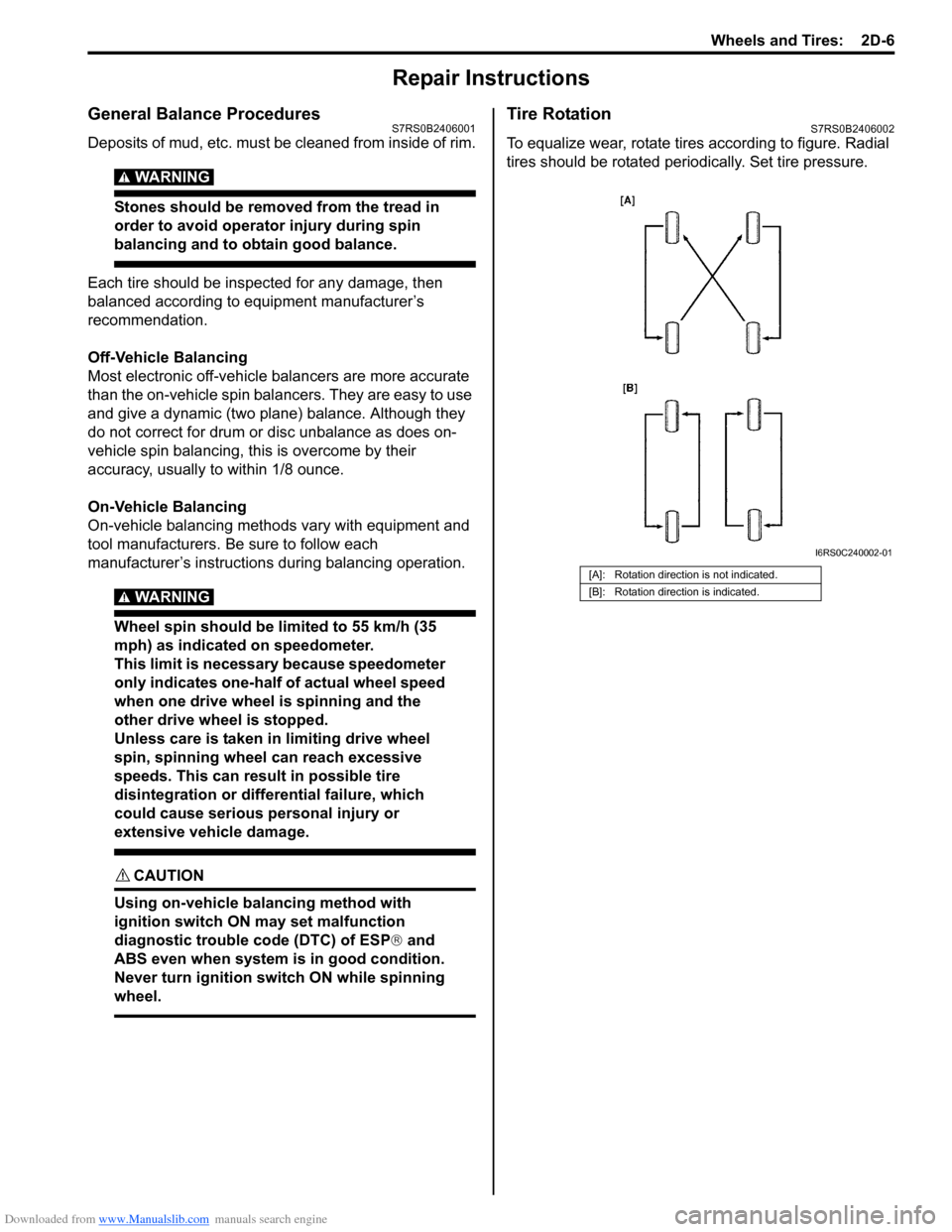

Tire RotationS7RS0B2406002

To equalize wear, rotate tires according to figure. Radial

tires should be rotated periodi cally. Set tire pressure.

[A]: Rotation direction is not indicated.

[B]: Rotation direction is indicated.

I6RS0C240002-01

Page 474 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-7 Wheels and Tires:

Wheel Removal and InstallationS7RS0B2406003

Removal

WARNING!

Do not removal all of the wheel nuts at once,

because all the wheels of this vehicle are

mounted by the wheel nuts.

Leave a nut at least not to drop the wheel.

Support the wheel and/or tire and then

remove the nut(s) left with the wheel.

1) Loosen wheel nuts by approximately 180° (half a

rotation).

2) Hoist vehicle.

3) Make sure that the vehicle will not fall off by trying to

move vehicle body in both ways.

4) Remove wheel nut except one.

5) Support the wheel and/or tire not to drop the wheel and then remove the nut left with the wheel.

CAUTION!

Never use heat to loosen tight wheel because

the application of heat to wheel causes the

wheel life shorter and the wheel bearing

damage.

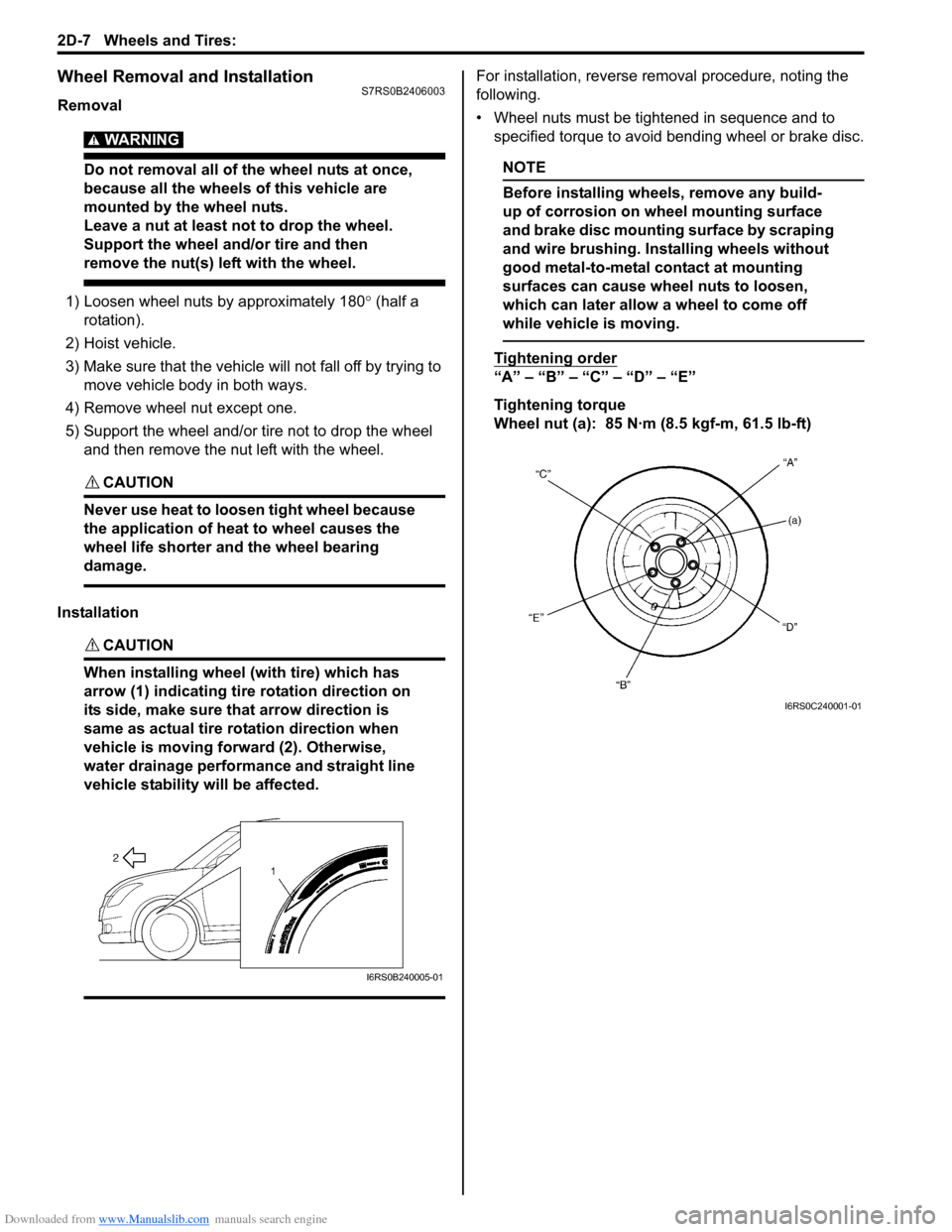

Installation

CAUTION!

When installing wheel (with tire) which has

arrow (1) indicating tire rotation direction on

its side, make sure that arrow direction is

same as actual tire ro tation direction when

vehicle is moving forw ard (2). Otherwise,

water drainage performance and straight line

vehicle stability will be affected.

For installation, reverse removal procedure, noting the

following.

• Wheel nuts must be tightened in sequence and to specified torque to avoid bending wheel or brake disc.

NOTE

Before installing wheels, remove any build-

up of corrosion on wheel mounting surface

and brake disc mounting surface by scraping

and wire brushing. Installing wheels without

good metal-to-metal contact at mounting

surfaces can cause wheel nuts to loosen,

which can later allow a wheel to come off

while vehicle is moving.

Tightening order

“A” – “B” – “C” – “D” – “E”

Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

I6RS0B240005-01

I6RS0C240001-01

Page 475 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-8

Tire Mounting and DismountingS7RS0B2406004

CAUTION!

When installing tire which has arrow

indicating tire rotation direction to wheel,

make sure that this tire rotation direction is

same as actual tire rotation direction when

vehicle is moving forward. Otherwise, it is

not possible to install wheel with tire to

vehicle in specified direction.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons al one to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate to specified pressure shown on

tire placard so that beads are completely seated.

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed 330 kpa (47.9 psi) pressure

when inflating. If 330 kpa (47.9 psi) pressure

will not seat beads, deflate, re-lubricate and

reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Install valve core and inflate to proper pressure.

Tire RepairS7RS0B2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

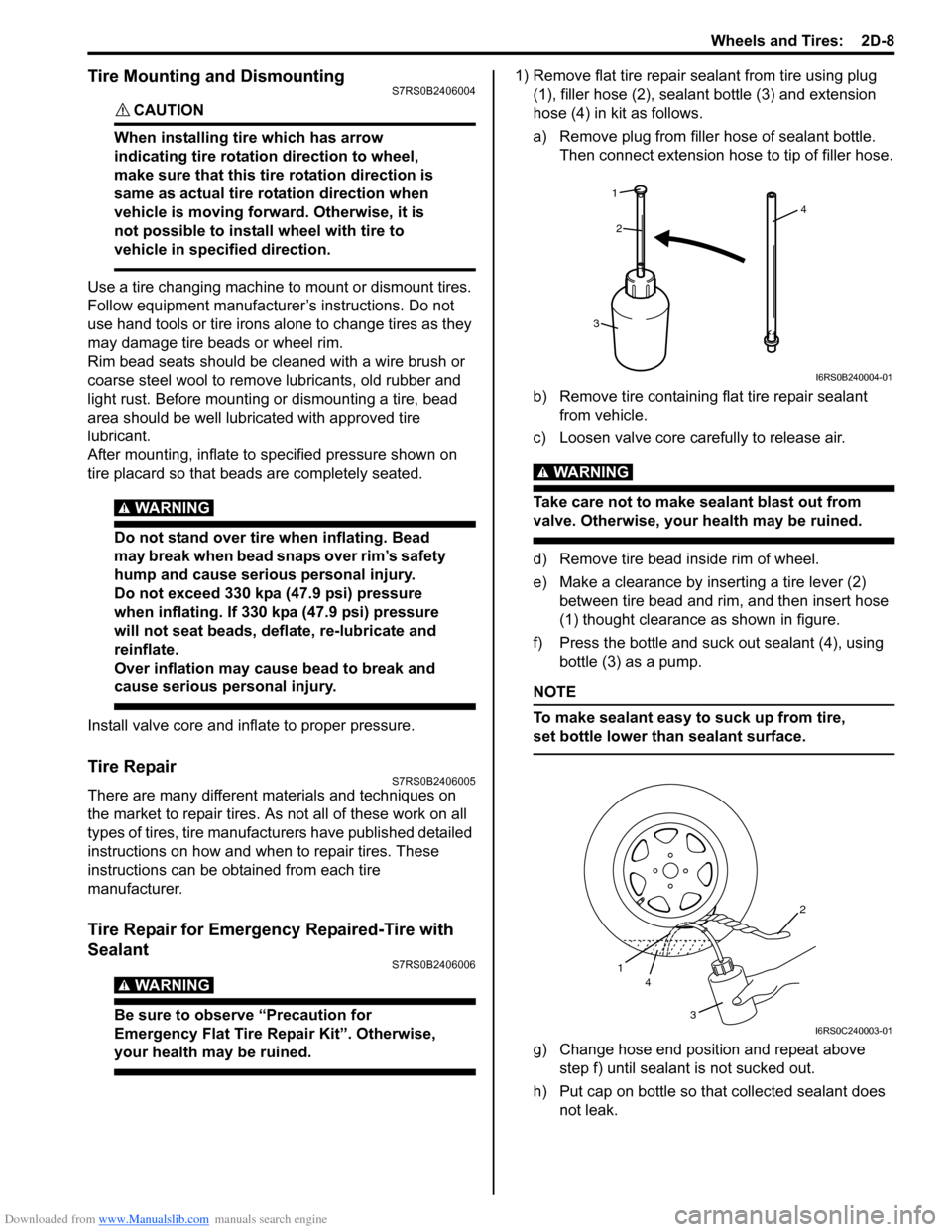

Tire Repair for Emergency Repaired-Tire with

Sealant

S7RS0B2406006

WARNING!

Be sure to observe “Precaution for

Emergency Flat Tire Repair Kit”. Otherwise,

your health may be ruined.

1) Remove flat tire repair sealant from tire using plug (1), filler hose (2), sealant bottle (3) and extension

hose (4) in kit as follows.

a) Remove plug from fille r hose of sealant bottle.

Then connect ext ension hose to tip of filler hose.

b) Remove tire containing flat tire repair sealant from vehicle.

c) Loosen valve core carefully to release air.

WARNING!

Take care not to make sealant blast out from

valve. Otherwise, your health may be ruined.

d) Remove tire bead inside rim of wheel.

e) Make a clearance by inserting a tire lever (2) between tire bead and rim, and then insert hose

(1) thought clearance as shown in figure.

f) Press the bottle and suck out sealant (4), using bottle (3) as a pump.

NOTE

To make sealant easy to suck up from tire,

set bottle lower than sealant surface.

g) Change hose end position and repeat above step f) until sealant is not sucked out.

h) Put cap on bottle so that collected sealant does not leak.

4

1

2

3

I6RS0B240004-01

1 4

3 2

I6RS0C240003-01

Page 476 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-9 Wheels and Tires:

2) Check tire if it can be repaired, referring to “Tire

Repair”. If it cannot be repaired, replace it with new

one.

3) Replace valve core of flat tire with new one if tire is reused after repairing.CAUTION!

Be sure to use new valve core. Otherwise, air

leak may occur due to sealant attached to

valve core.

4) Install tire to ri m of wheel, check that there is no air

leakage and adjust it to specified pressure shown on

tire placard.

Specifications

Wheels and Tires SpecificationsS7RS0B2407001

Tire size (Standard)

: 195/50R16 87V

Wheel size (Standard)

: 16x 6 J

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual which came

with the vehicle.

Tightening Torque SpecificationsS7RS0B2407002

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 858.5 61.5 �) / �)

Page 498 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-1 Precautions:

Brakes

Precautions

Precautions

Precautions for BrakesS7RS0B4000001

Suspension Caution

Refer to “Suspension Caution in Section 00”.

Wheels and Tires Caution

Refer to “Wheels and Tires Caution in Section 00”.

Brake Caution

Refer to “Brake Caution in Section 00”.

ESP® System Precautions

Refer to “Precaution for Vehicle Equipped with ESP ® System in Section 00”.

General Precautions

Refer to “General Precautions in Section 00”.

Vehicle Lifting Points

Refer to “Vehicle Liftin g Points in Section 0A”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Fastener Information

Refer to “Fasteners Information in Section 0A”.

Page 499 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-1

Brakes

Brake Control System and Diagnosis

Precautions

Precautions on BrakeS7RS0B4100001

Air Bag Warning

Refer to “Air Bag System Service Warning in Section 00”.

Brakes Diagnosis Note

Refer to “Brakes Diagnosis Note”.

General Description

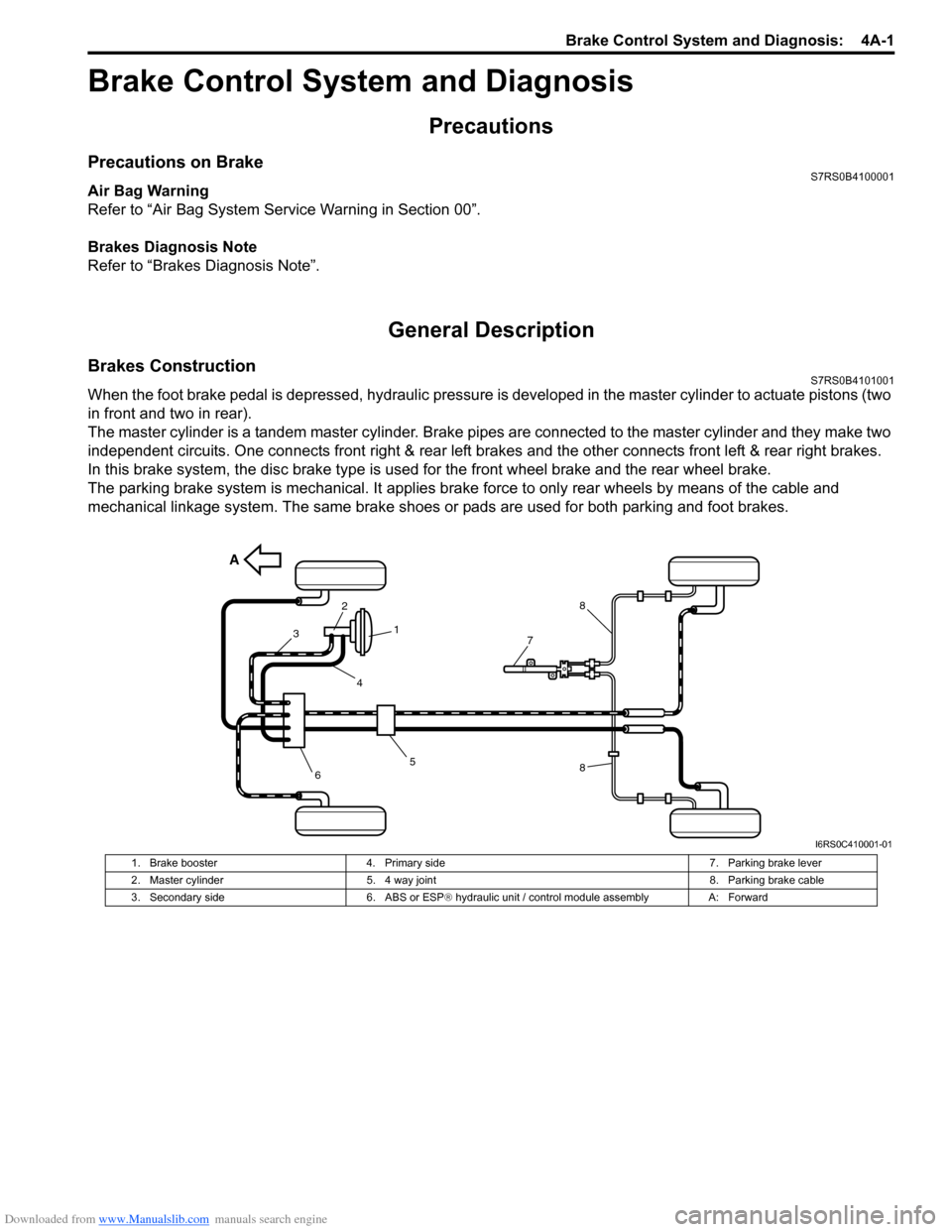

Brakes ConstructionS7RS0B4101001

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pistons (two

in front and two in rear).

The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they make two

independent circuits. One connects front right & rear left brakes and the other connects front left & rear right brakes.

In this brake system, the disc brake type is used for the front wheel brake and the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes or pads are used for both parking and foot brakes.

A

5

3

2

1

4

8

8

6

7

I6RS0C410001-01

1. Brake booster 4. Primary side 7. Parking brake lever

2. Master cylinder 5. 4 way joint 8. Parking brake cable

3. Secondary side 6. ABS or ESP® hydraulic unit / control module assembly A: Forward

Page 518 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-2 Front Brakes:

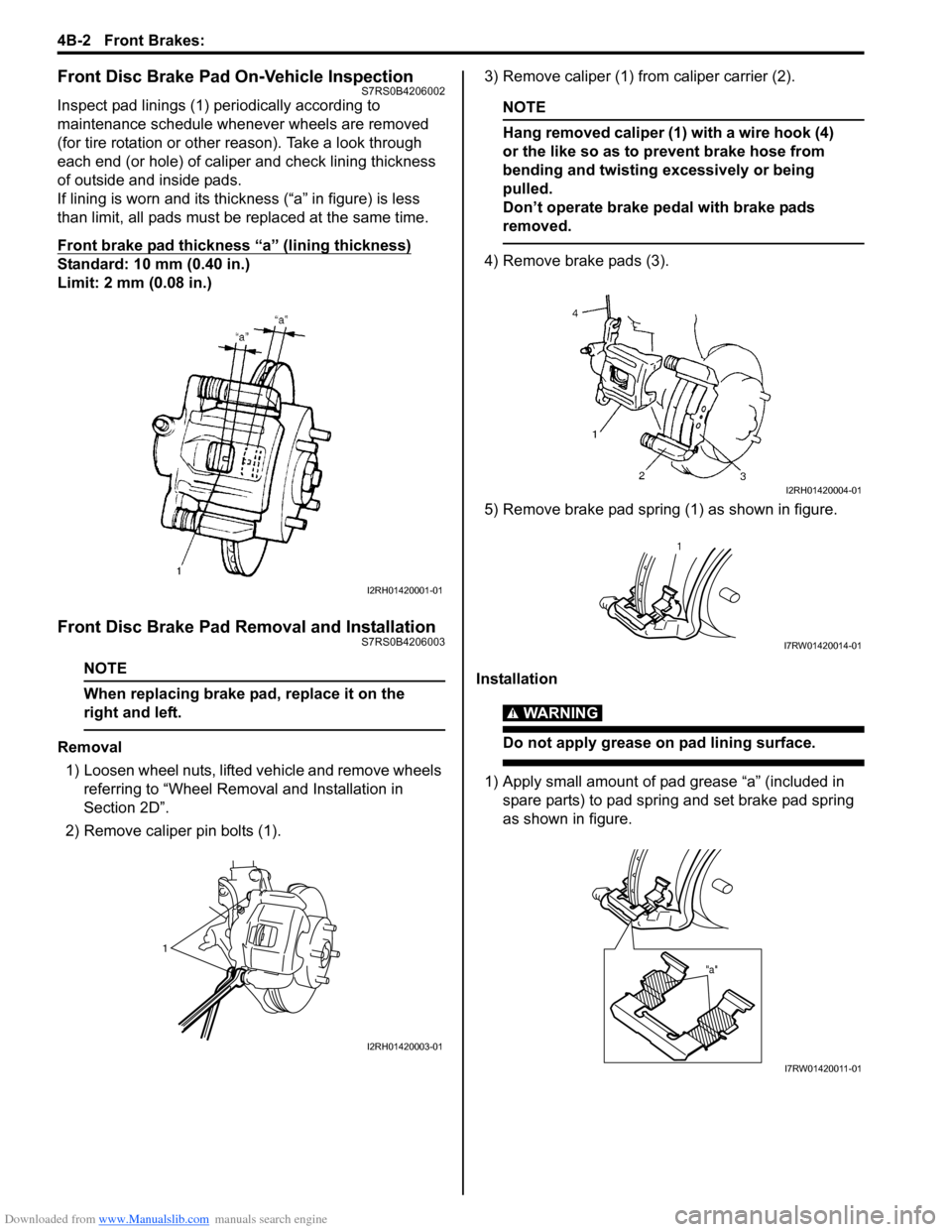

Front Disc Brake Pad On-Vehicle InspectionS7RS0B4206002

Inspect pad linings (1) periodically according to

maintenance schedule whenever wheels are removed

(for tire rotation or other reason). Take a look through

each end (or hole) of caliper and check lining thickness

of outside and inside pads.

If lining is worn and its thic kness (“a” in figure) is less

than limit, all pads must be replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

Front Disc Brake Pad Removal and InstallationS7RS0B4206003

NOTE

When replacing brake pad, replace it on the

right and left.

Removal

1) Loosen wheel nuts, lifted vehicle and remove wheels referring to “Wheel Remova l and Installation in

Section 2D”.

2) Remove caliper pin bolts (1). 3) Remove caliper (1) from caliper carrier (2).

NOTE

Hang removed caliper (1) with a wire hook (4)

or the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

4) Remove brake pads (3).

5) Remove brake pad spring (1) as shown in figure.

Installation

WARNING!

Do not apply grease on pad lining surface.

1) Apply small amount of pad grease “a” (included in spare parts) to pad spring and set brake pad spring

as shown in figure.

I2RH01420001-01

1

I2RH01420003-01

I2RH01420004-01

1

I7RW01420014-01

"a"

I7RW01420011-01

Page 537 of 1496

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-2

Repair Instructions

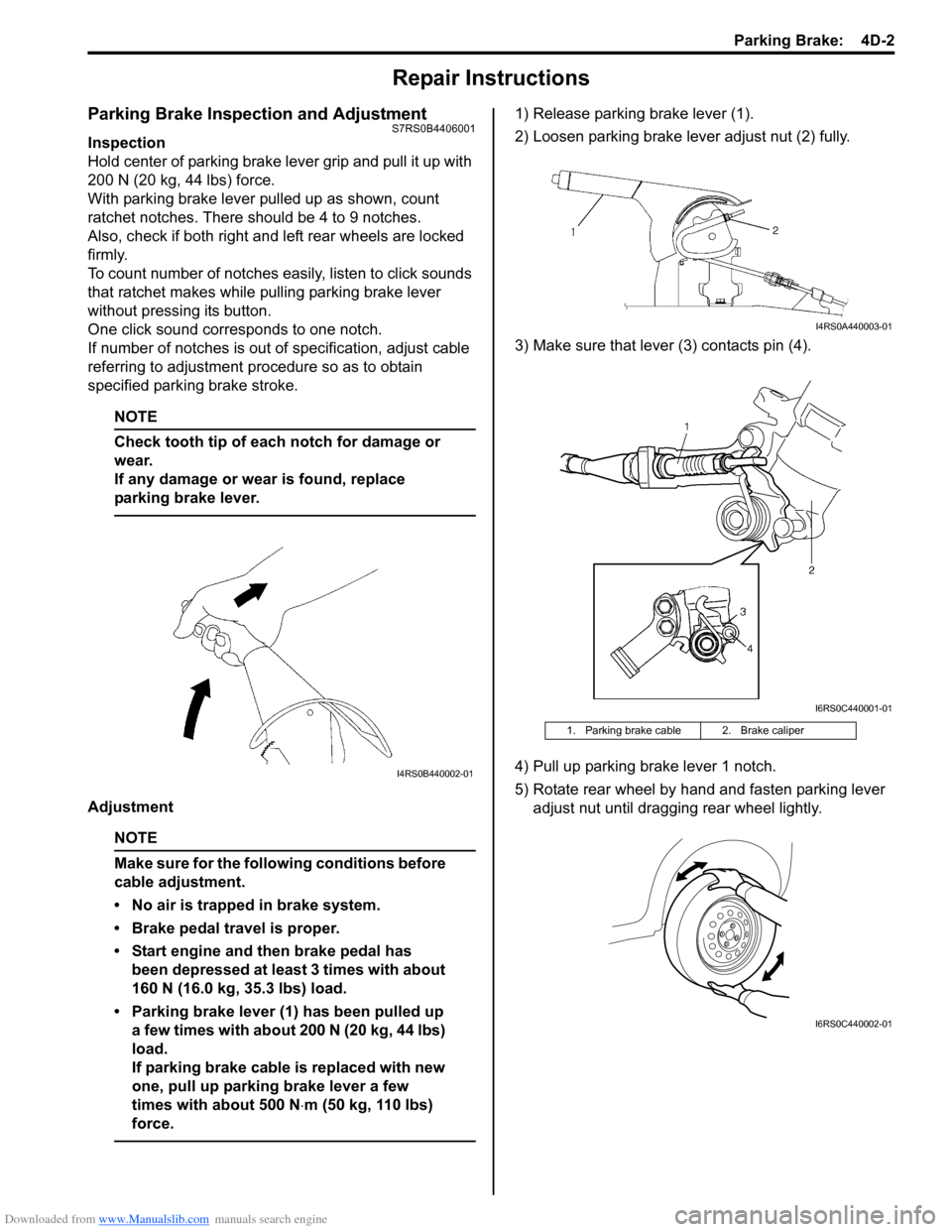

Parking Brake Inspection and AdjustmentS7RS0B4406001

Inspection

Hold center of parking brake lever grip and pull it up with

200 N (20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count

ratchet notches. There should be 4 to 9 notches.

Also, check if both right and left rear wheels are locked

firmly.

To count number of notches easily, listen to click sounds

that ratchet makes while pulling parking brake lever

without pressing its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable

referring to adjustment procedure so as to obtain

specified parking brake stroke.

NOTE

Check tooth tip of each notch for damage or

wear.

If any damage or wear is found, replace

parking brake lever.

Adjustment

NOTE

Make sure for the following conditions before

cable adjustment.

• No air is trapped in brake system.

• Brake pedal travel is proper.

• Start engine and then brake pedal has been depressed at least 3 times with about

160 N (16.0 kg, 35.3 lbs) load.

• Parking brake lever (1) has been pulled up a few times with about 200 N (20 kg, 44 lbs)

load.

If parking brake cable is replaced with new

one, pull up parking brake lever a few

times with about 500 N ⋅m (50 kg, 110 lbs)

force.

1) Release parking brake lever (1).

2) Loosen parking brake lever adjust nut (2) fully.

3) Make sure that lever (3) contacts pin (4).

4) Pull up parking brake lever 1 notch.

5) Rotate rear wheel by hand and fasten parking lever adjust nut until dragging rear wheel lightly.

I4RS0B440002-01

1. Parking brake cable 2. Brake caliper

I4RS0A440003-01

I6RS0C440001-01

I6RS0C440002-01

Page 538 of 1496

Downloaded from www.Manualslib.com manuals search engine 4D-3 Parking Brake:

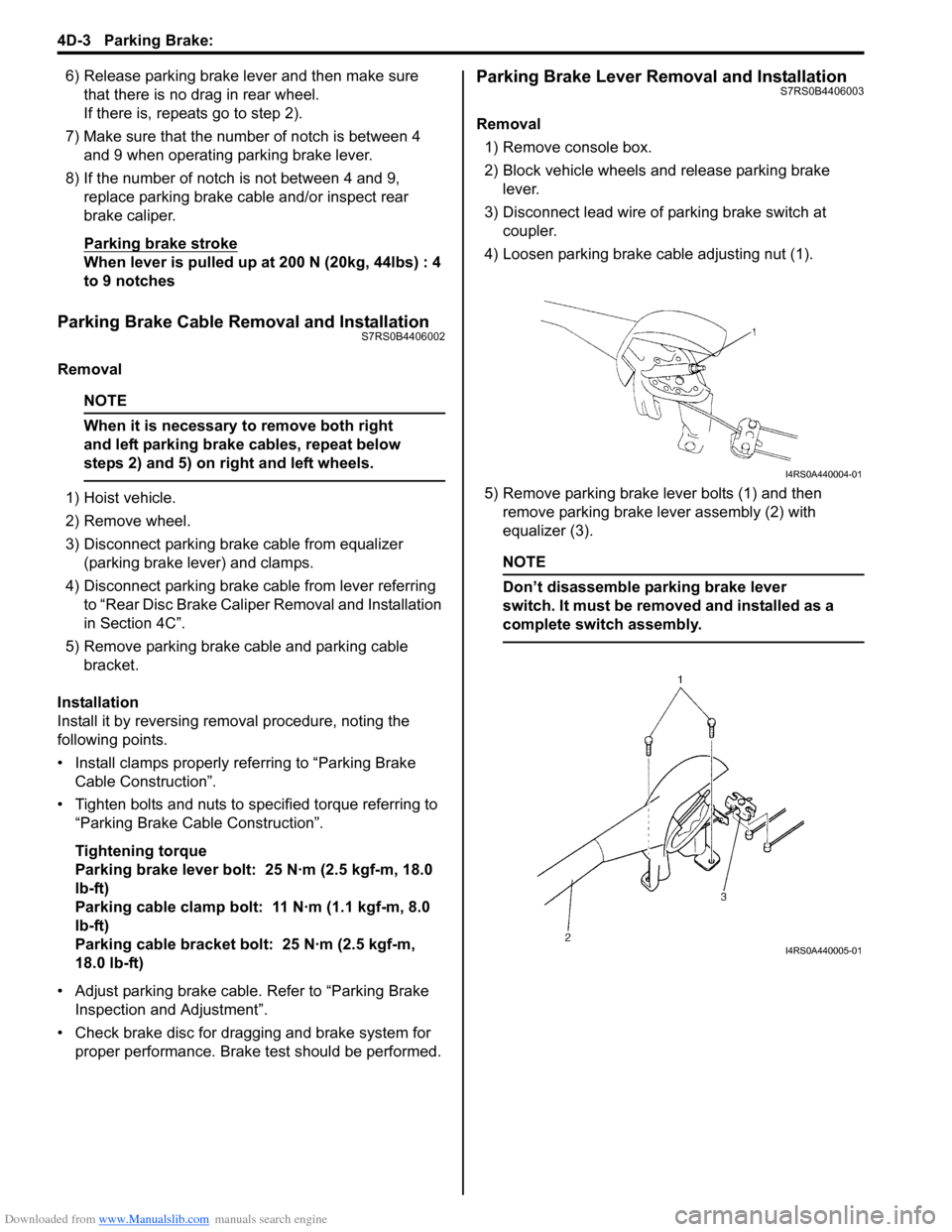

6) Release parking brake lever and then make sure that there is no drag in rear wheel.

If there is, repeats go to step 2).

7) Make sure that the number of notch is between 4 and 9 when operating parking brake lever.

8) If the number of notch is not between 4 and 9, replace parking brake cable and/or inspect rear

brake caliper.

Parking brake stroke

When lever is pulled up at 200 N (20kg, 44lbs) : 4

to 9 notches

Parking Brake Cable Removal and InstallationS7RS0B4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 5) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer (parking brake lever) and clamps.

4) Disconnect parking brake cable from lever referring to “Rear Disc Brake Caliper Removal and Installation

in Section 4C”.

5) Remove parking brake cable and parking cable bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake Cable Construction”.

• Tighten bolts and nuts to specified torque referring to “Parking Brake Cable Construction”.

Tightening torque

Parking brake lever bolt: 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Parking cable clamp bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Parking cable bracket bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Adjust parking brake cable. Refer to “Parking Brake Inspection and Adjustment”.

• Check brake disc for dragging and brake system for proper performance. Brake test should be performed.

Parking Brake Lever Removal and InstallationS7RS0B4406003

Removal

1) Remove console box.

2) Block vehicle wheels and release parking brake lever.

3) Disconnect lead wire of parking brake switch at coupler.

4) Loosen parking brake cable adjusting nut (1).

5) Remove parking brake lever bolts (1) and then remove parking brake lever assembly (2) with

equalizer (3).

NOTE

Don’t disassemble parking brake lever

switch. It must be removed and installed as a

complete switch assembly.

I4RS0A440004-01

I4RS0A440005-01