Can SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

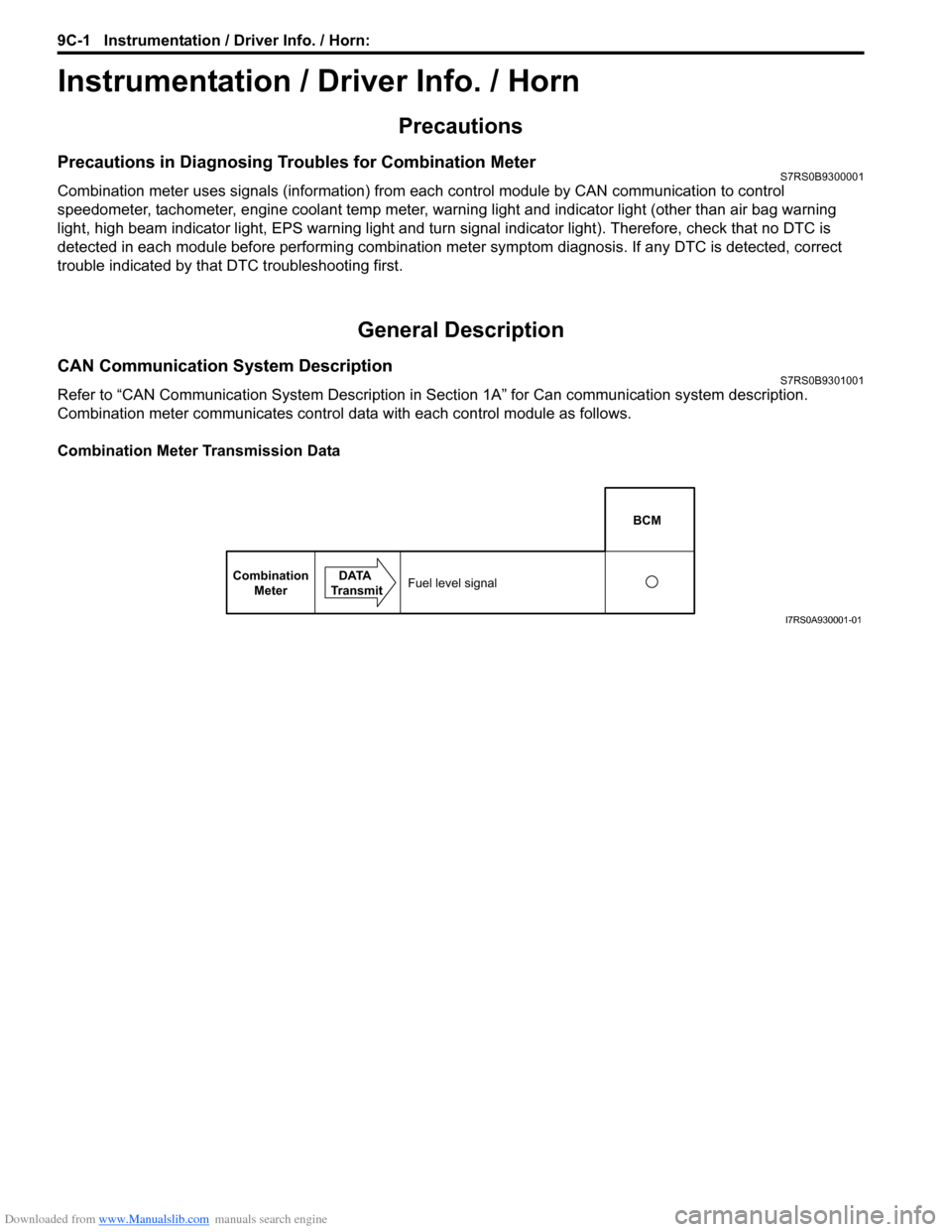

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1299 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-4

Schematic and Routing Diagram

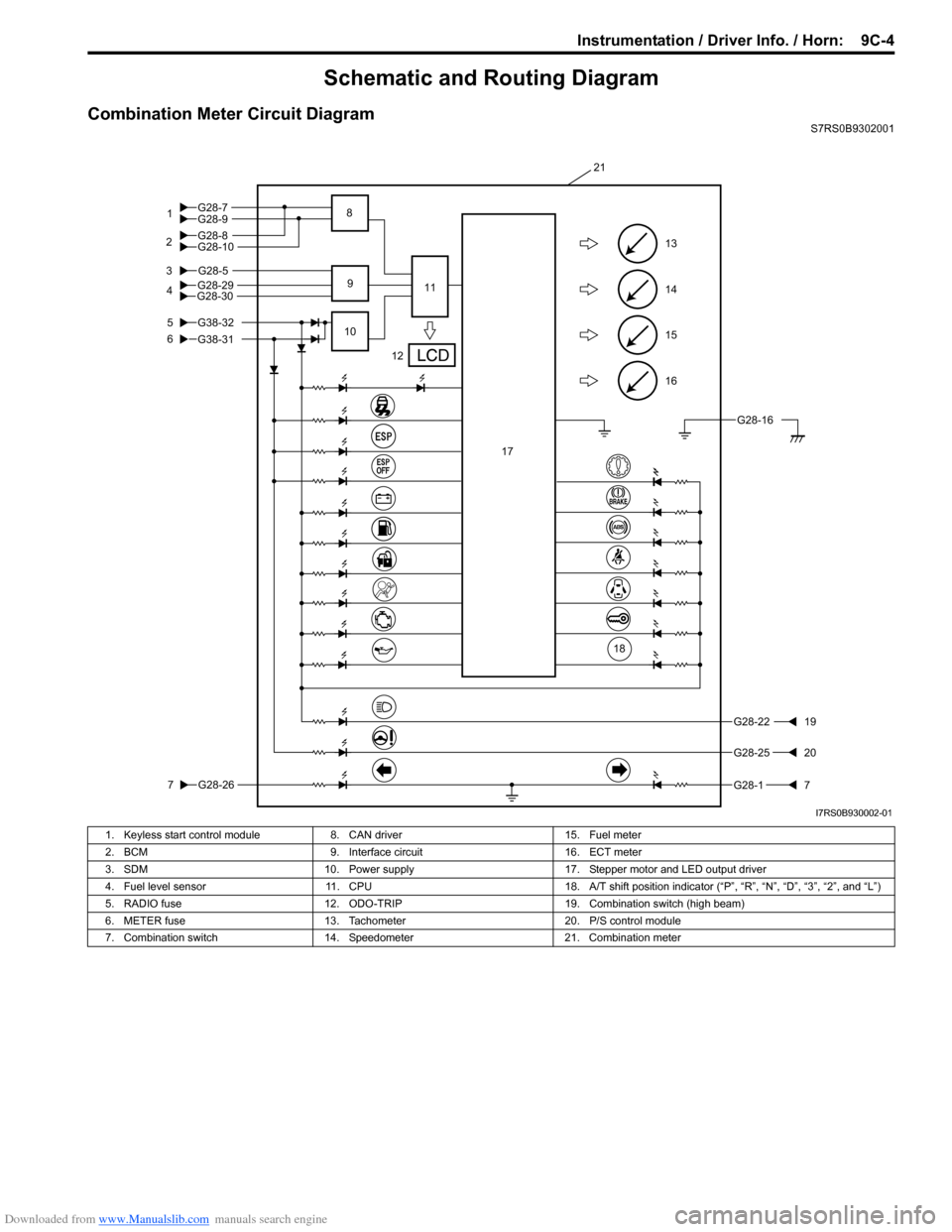

Combination Meter Circuit DiagramS7RS0B9302001

16

15

14

13

G28-5

5

6

3

G28-26

7

G28-2219

G28-2520

G28-17

12

10 11

21

9

17

G28-304G28-29

18

G28-16

G28-9

G28-10G28-8 G28-7

1

2 8

G38-31

G38-32

I7RS0B930002-01

1. Keyless start control module

8. CAN driver 15. Fuel meter

2. BCM 9. Interface circuit 16. ECT meter

3. SDM 10. Power supply 17. Stepper motor and LED output driver

4. Fuel level sensor 11. CPU 18. A/T shift position indicator (“P”, “R”, “N”, “D”, “3”, “2”, and “L”)

5. RADIO fuse 12. ODO-TRIP 19. Combination switch (high beam)

6. METER fuse 13. Tachometer 20. P/S control module

7. Combination switch 14. Speedometer 21. Combination meter

Page 1300 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-5 Instrumentation / Driver Info. / Horn:

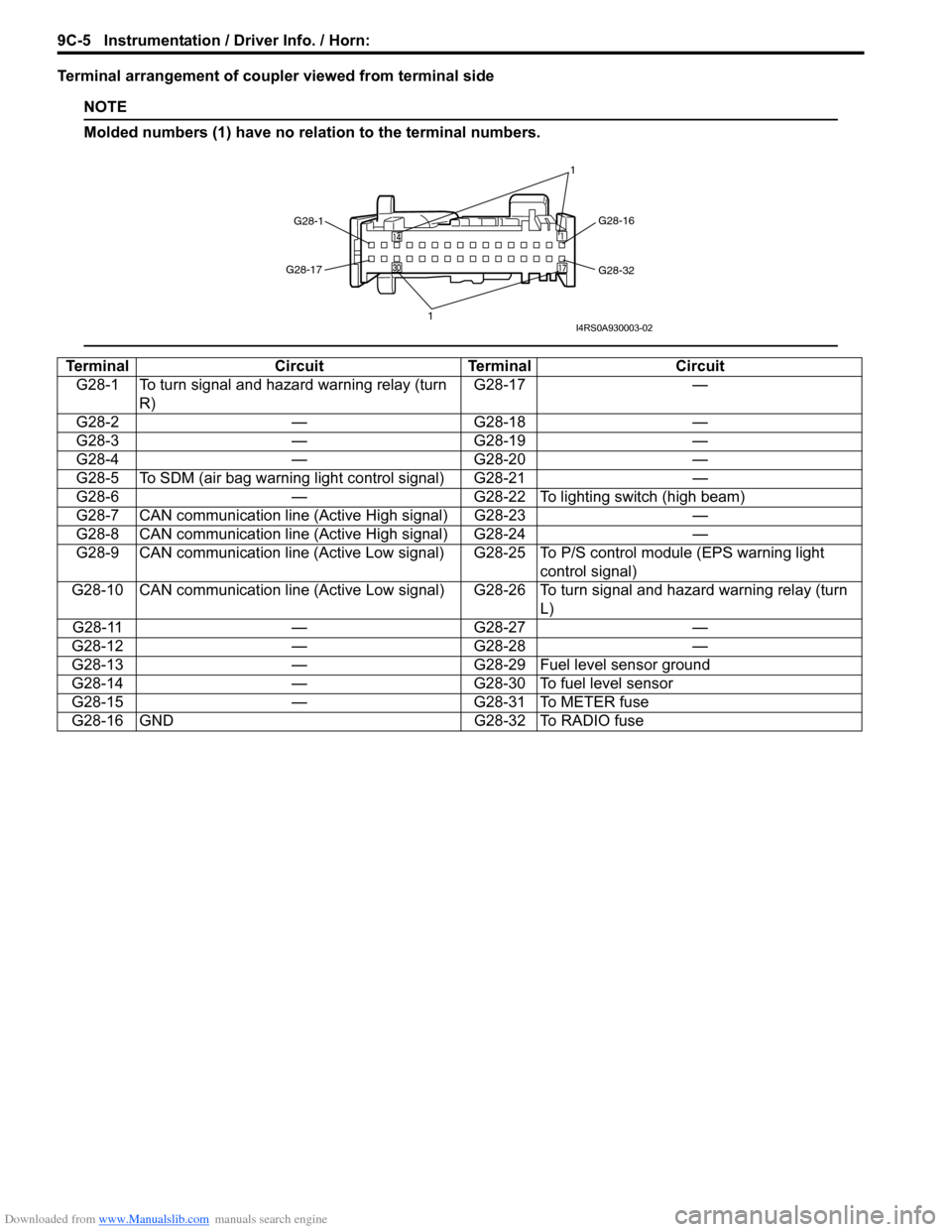

Terminal arrangement of coupler viewed from terminal side

NOTE

Molded numbers (1) have no relation to the terminal numbers.

TerminalCircuitTerminal Circuit

G28-1 To turn signal and hazard warning relay (turn R) G28-17

—

G28-2 —G28-18 —

G28-3 —G28-19 —

G28-4 —G28-20 —

G28-5 To SDM (air bag warning light control signal) G28-21 —

G28-6 —G28-22 To lighting switch (high beam)

G28-7 CAN communication line (Active High signal) G28-23 —

G28-8 CAN communication line (Active High signal) G28-24 —

G28-9 CAN communication line (Active Low signal) G 28-25 To P/S control module (EPS warning light

control signal)

G28-10 CAN communication line (Active Low signal) G28-26 To turn signal and hazard warning relay (turn L)

G28-11 —G28-27 —

G28-12 —G28-28 —

G28-13 —G28-29 Fuel level sensor ground

G28-14 —G28-30 To fuel level sensor

G28-15 —G28-31 To METER fuse

G28-16 GND G28-32 To RADIO fuse

G28-1 G28-16

G28-32

G28-17

1 1I4RS0A930003-02

Page 1305 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-10

Warning Buzzer Circuit Symptom DiagnosisS7RS0B9304012

NOTE

• Use of SUZUKI scan tool makes it easy to check wh ether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Cigarette Lighter Symptom Diagnosis (If Equipped)S7RS0B9304013

Horn Symptom DiagnosisS7RS0B9304014

Condition Possible cause Correction / Reference Item

Warning buzzer shows no

sounding Circuit fuse blown

Replace fuse and check for short circuit.

Driver side door switch faulty Check driver side door switch referring to

“Door Switch (Front / Rear Door) Inspection”.

Lighting switch faulty Check lighting switch referring to “Headlight

Switch (in Lighting Switch) Inspection in

Section 9B”.

Key reminder switch faulty Check key reminder switch referring to

“Ignition Switch Inspection”.

Seat belt switch faulty (if equipped) Check seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring and/or grounding faulty Repair as necessary.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Cigarette lighter shows

no operation Circuit fuse blown

Replace fuse and check for short circuit.

Cigarette lighter faulty Check cigarette lighter.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection”.

Wiring and/or grounding faulty Repair as necessary.

ConditionPossible cause Correction / Reference Item

Horn does not operate Circuit fuse blown Replace fuse and check for short circuit.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay referring to “Horn Relay

Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Horn faulty Check horn referring to “Horn Inspection”.

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

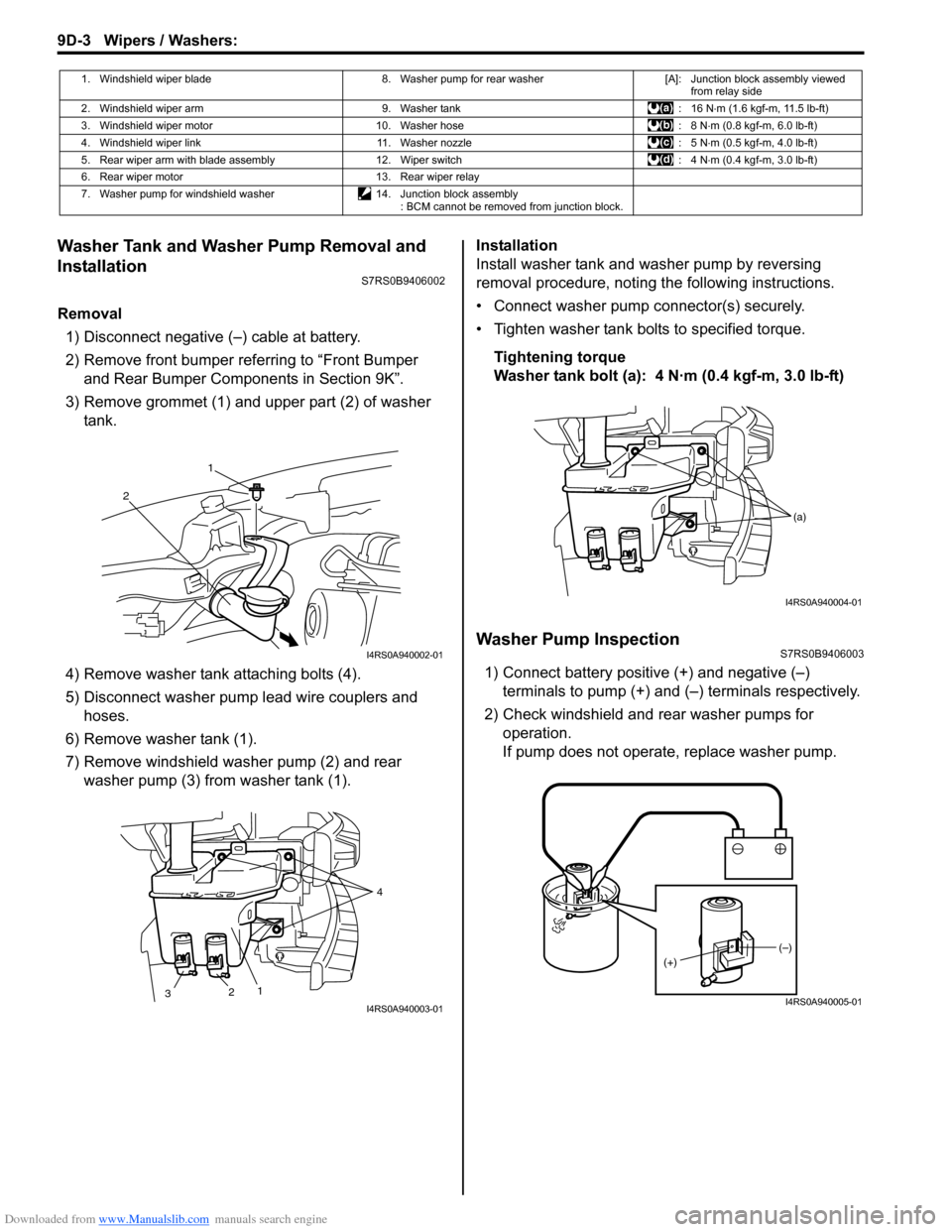

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

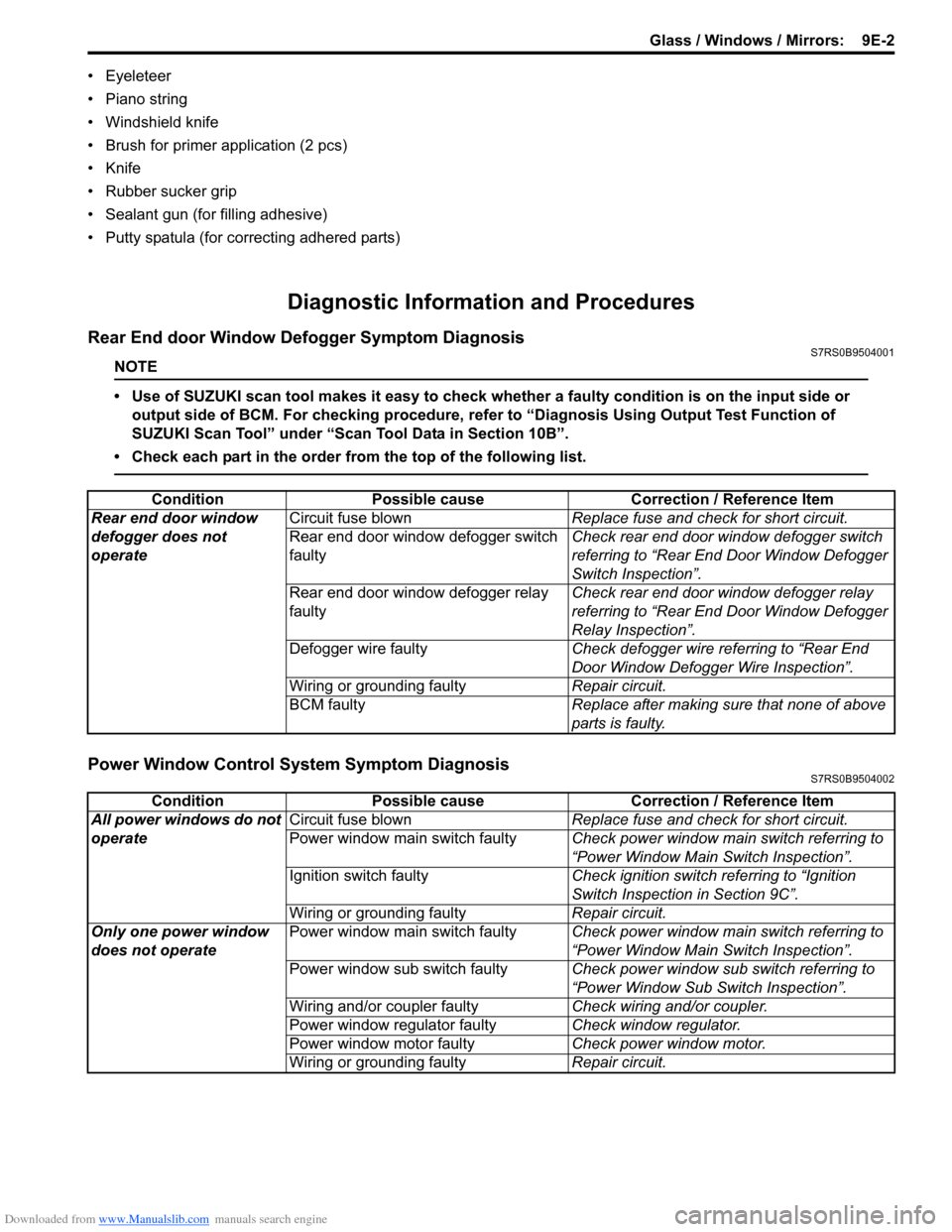

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

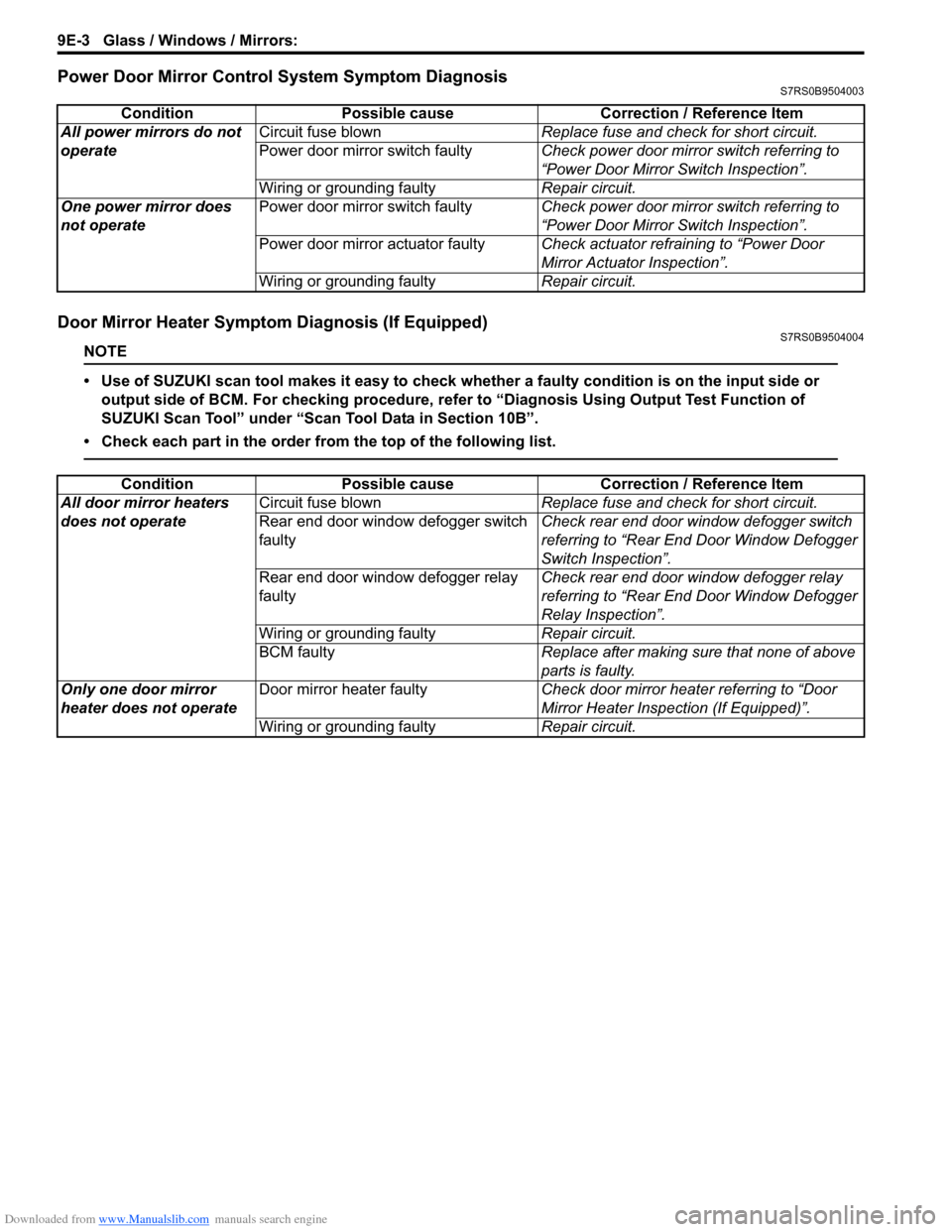

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1329 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

• Eyeleteer

• Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS7RS0B9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS7RS0B9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faulty Check defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

All power windows do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power window main switch faulty Check power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Only one power window

does not operate Power window main switch faulty

Check power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faulty Check power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faulty Check wiring and/or coupler.

Power window regulator faulty Check window regulator.

Power window motor faulty Check power window motor.

Wiring or grounding faulty Repair circuit.

Page 1330 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Power Door Mirror Control System Symptom DiagnosisS7RS0B9504003

Door Mirror Heater Symptom Diagnosis (If Equipped)S7RS0B9504004

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All power mirrors do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power door mirror switch faulty Check power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Wiring or grounding faulty Repair circuit.

One power mirror does

not operate Power door mirror switch faulty

Check power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Power door mirror actuator faulty Check actuator refraining to “Power Door

Mirror Actuator Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

All door mirror heaters

does not operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Only one door mirror

heater does not operate Door mirror heater faulty

Check door mirror heater referring to “Door

Mirror Heater Inspection (If Equipped)”.

Wiring or grounding faulty Repair circuit.

Page 1332 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-5 Glass / Windows / Mirrors:

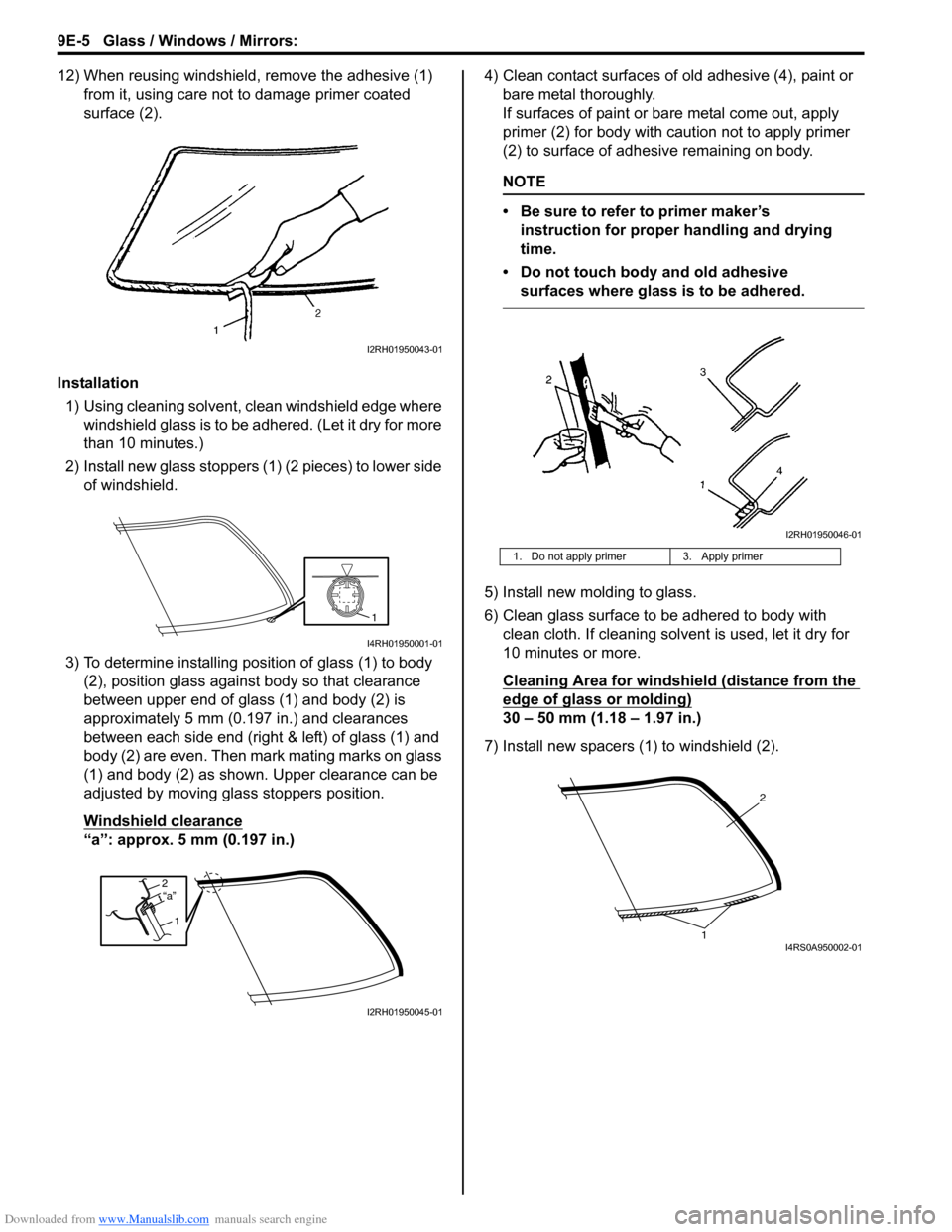

12) When reusing windshield, remove the adhesive (1) from it, using care not to damage primer coated

surface (2).

Installation 1) Using cleaning solvent, clean windshield edge where windshield glass is to be adhered. (Let it dry for more

than 10 minutes.)

2) Install new glass stoppers (1) (2 pieces) to lower side of windshield.

3) To determine installing position of glass (1) to body (2), position glass against body so that clearance

between upper end of glass (1) and body (2) is

approximately 5 mm (0.197 in.) and clearances

between each side end (right & left) of glass (1) and

body (2) are even. Then mark mating marks on glass

(1) and body (2) as shown. Upper clearance can be

adjusted by moving glass stoppers position.

Windshield clearance

“a”: approx. 5 mm (0.197 in.) 4) Clean contact surfaces of old adhesive (4), paint or

bare metal thoroughly.

If surfaces of paint or ba re metal come out, apply

primer (2) for body with caution not to apply primer

(2) to surface of adhesive remaining on body.

NOTE

• Be sure to refer to primer maker’s instruction for proper handling and drying

time.

• Do not touch body and old adhesive surfaces where glass is to be adhered.

5) Install new molding to glass.

6) Clean glass surface to be adhered to body with clean cloth. If cleaning solvent is used, let it dry for

10 minutes or more.

Cleaning Area for windshie ld (distance from the

edge of glass or molding)

30 – 50 mm (1.18 – 1.97 in.)

7) Install new spacers (1) to windshield (2).

I2RH01950043-01

1

I4RH01950001-01

2

1“a”

I2RH01950045-01

1. Do not apply primer 3. Apply primer

I2RH01950046-01

2

1I4RS0A950002-01

Page 1347 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-1

Body, Cab and Accessories

Security and Locks

General Description

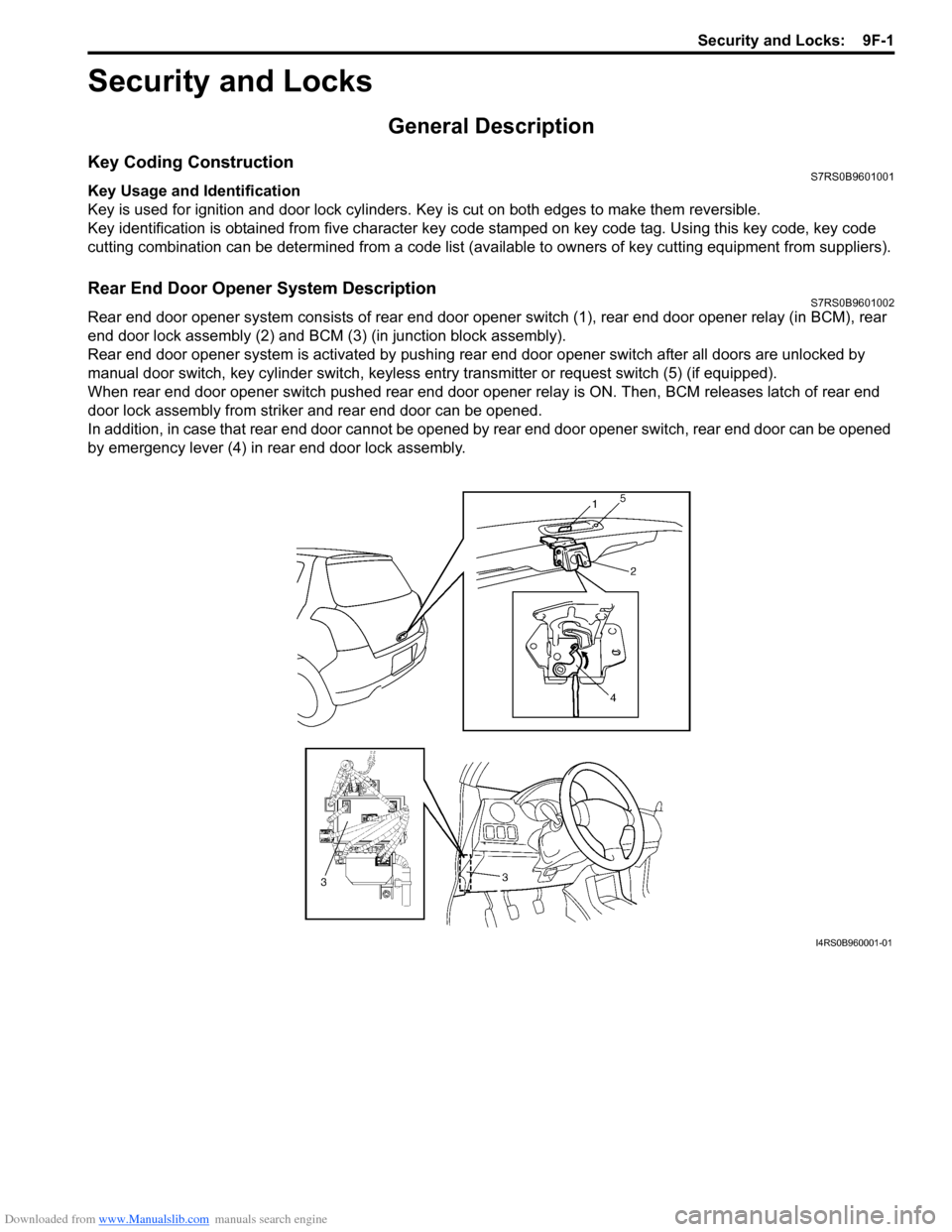

Key Coding ConstructionS7RS0B9601001

Key Usage and Identification

Key is used for ignition and door lock cylinders. Key is cut on both edges to make them reversible.

Key identification is obtained from five character key code stamped on key code tag. Using this key code, key code

cutting combination can be determined from a code list (ava ilable to owners of key cutting equipment from suppliers).

Rear End Door Opener System DescriptionS7RS0B9601002

Rear end door opener system consists of rear end door opener switch (1), rear end door opener relay (in BCM), rear

end door lock assembly (2) and BCM (3) (in junction block assembly).

Rear end door opener system is activated by pushing re ar end door opener switch after all doors are unlocked by

manual door switch, key cylinder s witch, keyless entry transmitter or request switch (5) (if equipped).

When rear end door opener switch pushed rear end door opener relay is ON. Then, BCM releases latch of rear end

door lock assembly from striker and rear end door can be opened.

In addition, in case that rear end door cannot be opened by rear end door opener switch, rear end door can be opened

by emergency lever (4) in rear end door lock assembly.

I4RS0B960001-01