Display SUZUKI SWIFT 2005 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 992 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-44 Air Conditioning System: Automatic Type

3) Light over sunload sensor vertically with an incandescent lamp approximately 100 W apart from

about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

4) Turn ignition switch to ON position.

5) Erase DTC according to instructions displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the clearance, turn ignition switch to OFF position, and then di sconnect SUZUKI scan

tool from DLC.

Not Using SUZUKI Scan Tool 1) Turn ignition switch to ON position.

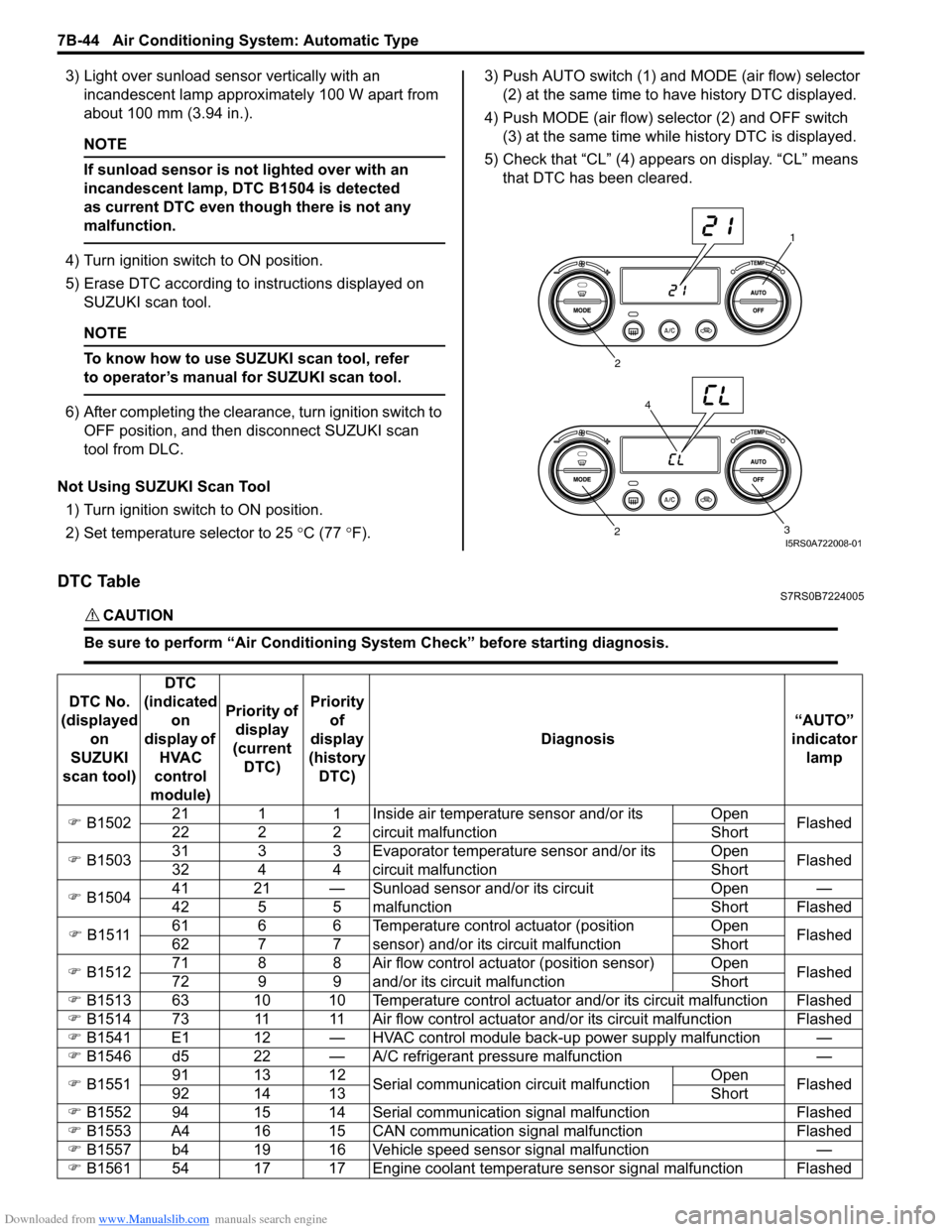

2) Set temperature selector to 25 °C (77 °F). 3) Push AUTO switch (1) and

MODE (air flow) selector

(2) at the same time to have history DTC displayed.

4) Push MODE (air flow) selector (2) and OFF switch (3) at the same time while history DTC is displayed.

5) Check that “CL” (4) appears on display. “CL” means that DTC has been cleared.

DTC TableS7RS0B7224005

CAUTION!

Be sure to perform “Air Conditioning Sy stem Check” before starting diagnosis.

1

2

3

2

4

I5RS0A722008-01

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

�) B1502 21 1 1 Inside air temperature sensor and/or its

circuit malfunction Open

Flashed

22 2 2 Short

�) B1503 31 3 3 Evaporator temperature sensor and/or its

circuit malfunction Open

Flashed

32 4 4 Short

�) B1504 41 21 — Sunload sensor and/or its circuit

malfunction Open —

42 5 5 Short Flashed

�) B1511 61 6 6 Temperature control actuator (position

sensor) and/or its circuit malfunction Open

Flashed

62 7 7 Short

�) B1512 71 8 8 Air flow control actuator (position sensor)

and/or its circuit malfunction Open

Flashed

72 9 9 Short

�) B1513 63 10 10 Temperature control actuator and/or its circuit malfunction Flashed

�) B1514 73 11 11 Air flow control actuator and/or its circuit malfunction Flashed

�) B1541 E1 12 — HVAC control module back-up power supply malfunction —

�) B1546 d5 22 — A/C refrigerant pressure malfunction —

�) B1551 91 13 12

Serial communication circuit malfunction Open

Flashed

92 14 13 Short

�) B1552 94 15 14 Serial communication signal malfunction Flashed

�) B1553 A4 16 15 CAN communication signal malfunction Flashed

�) B1557 b4 19 16 Vehicle speed sensor signal malfunction —

�) B1561 54 17 17 Engine coolant temperature sensor signal malfunction Flashed

Page 993 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-45

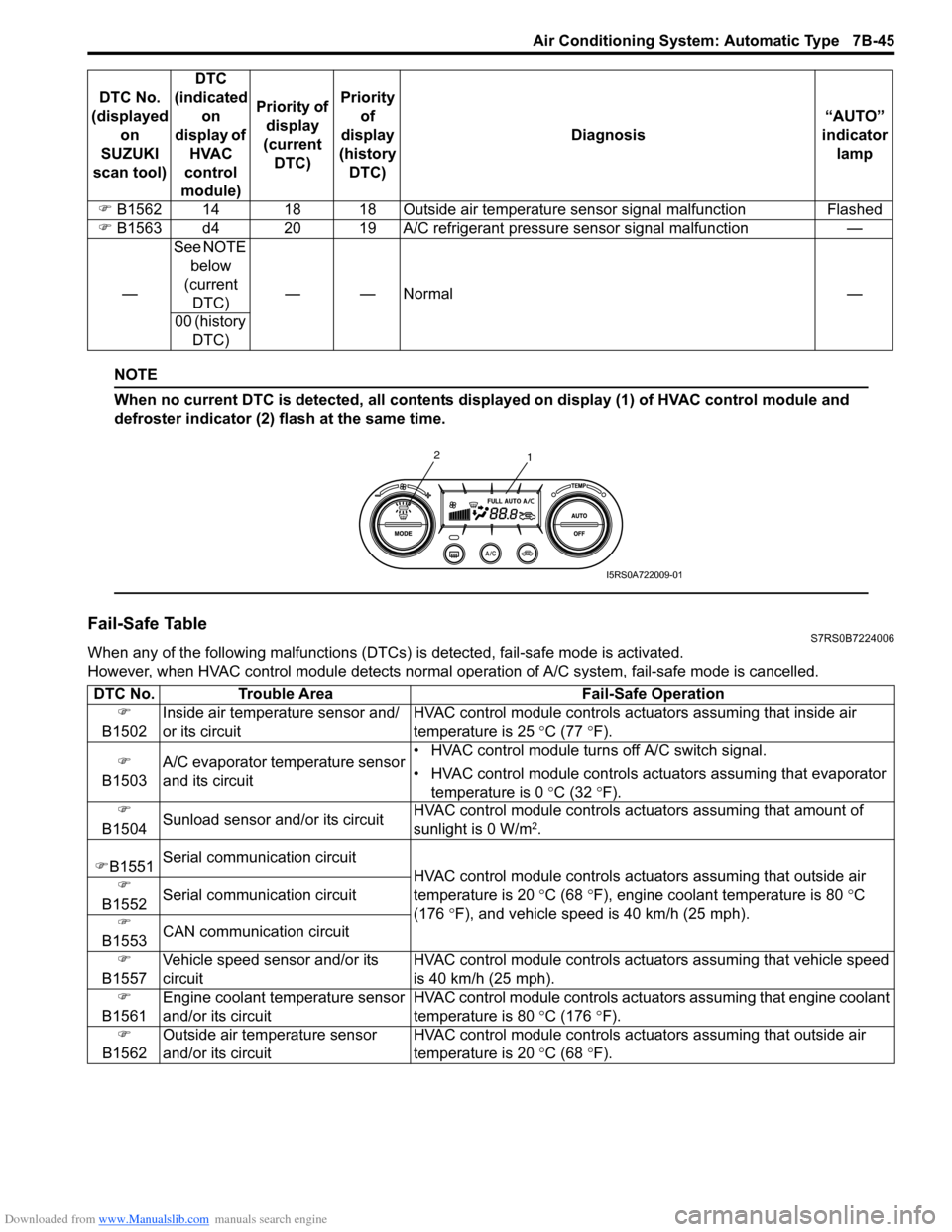

NOTE

When no current DTC is detected, all contents displayed on display (1) of HVAC control module and

defroster indicator (2) flash at the same time.

Fail-Safe TableS7RS0B7224006

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal ope ration of A/C system, fail-safe mode is cancelled.

�)

B1562 14 18 18 Outside air temperatur e sensor signal malfunction Flashed

�) B1563 d4 20 19 A/C refrigerant pressure sensor signal malfunction —

— See NOTE

below

(current DTC) ——Normal —

00 (history DTC)

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

1

2

I5RS0A722009-01

DTC No.

Trouble Area Fail-Safe Operation

�)

B1502 Inside air temperature sensor and/

or its circuit HVAC control module controls actu

ators assuming that inside air

temperature is 25 ° C (77 °F).

�)

B1503 A/C evaporator temperature sensor

and its circuit • HVAC control module turn

s off A/C switch signal.

• HVAC control module controls actu ators assuming that evaporator

temperature is 0 ° C (32 °F).

�)

B1504 Sunload sensor and/or its circuit HVAC control module controls actu

ators assuming that amount of

sunlight is 0 W/m

2.

�) B1551 Serial communication circuit

HVAC control module controls actuators assuming that outside air

temperature is 20 ° C (68 °F), engine coolant temperature is 80 °C

(176 °F), and vehicle speed is 40 km/h (25 mph).

�)

B1552 Serial communication circuit

�)

B1553 CAN communication circuit

�)

B1557 Vehicle speed sensor and/or its

circuit HVAC control module controls act

uators assuming that vehicle speed

is 40 km/h (25 mph).

�)

B1561 Engine coolant temperature sensor

and/or its circuit HVAC control module controls act

uators assuming that engine coolant

temperature is 80 ° C (176 °F).

�)

B1562 Outside air temperature sensor

and/or its circuit HVAC control module controls actu

ators assuming that outside air

temperature is 20 ° C (68 °F).

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

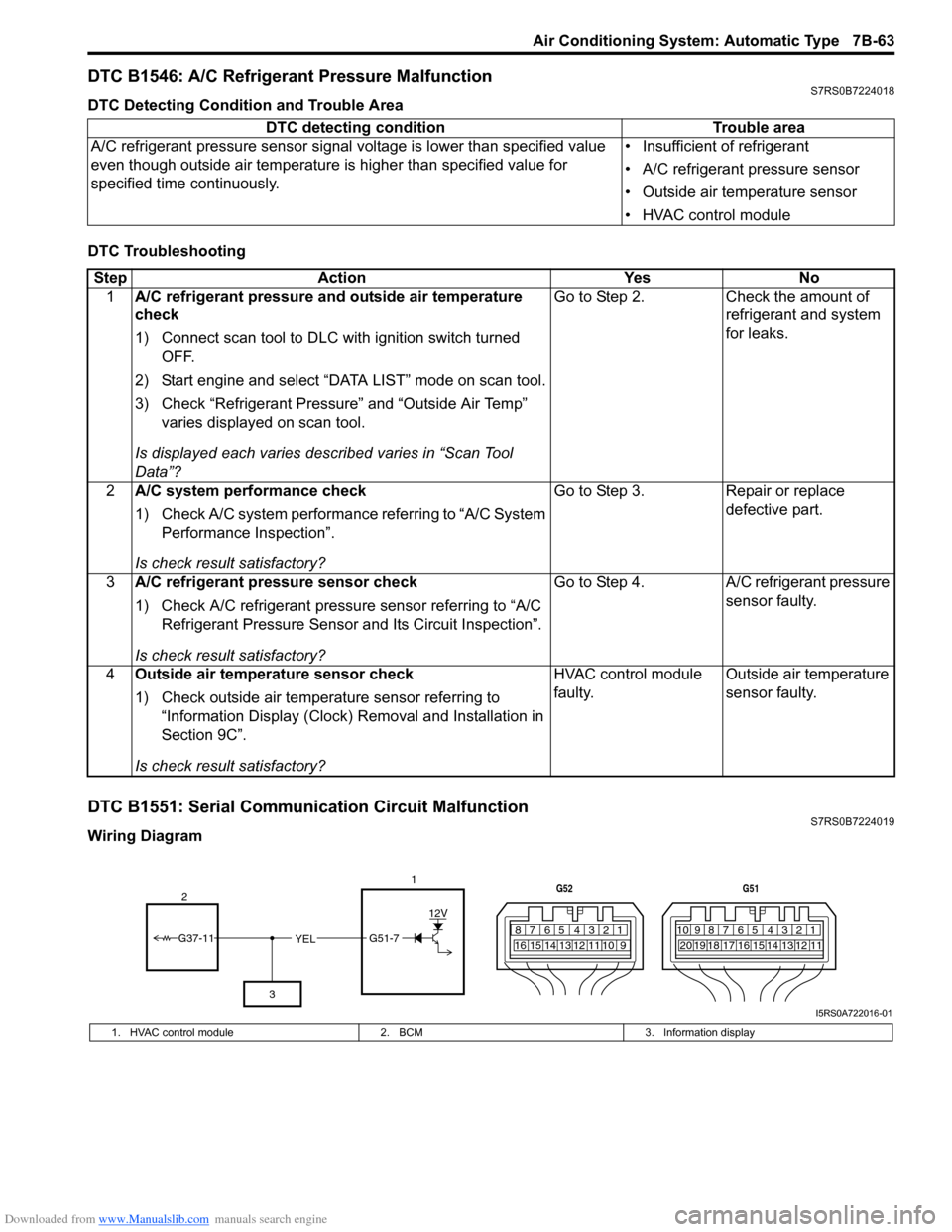

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1012 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-64 Air Conditioning System: Automatic Type

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1552: Serial Communication Signal MalfunctionS7RS0B7224020

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously. • Serial communication line of BCM

• BCM (included in junction block

assembly)

• Information display

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Disconnect connector from information display.

3) Turn ignition switch ON and check DTC.

Is there DTC B1551? Go to Step 2.

Information display

faulty.

2 Wire harness check

1) Disconnect connectors from BCM and HVAC control

module.

2) Measure resistance between “G37-11” terminal of BCM connector and “G51-7” terminal of HVAC control module

connector.

Is resistance below 5

Ω? Go to Step 3. “YEL” wire open or high

resistance circuit.

3 Wire harness check

1) Measure resistance between “G51-7” terminal of HVAC

control module connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “YEL” wire shorted to

ground circuit.

4 Wire harness check

1) Measure voltage between “G51-7” terminal of HVAC

control module connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “YEL” wire shorted to

other circuit.

5 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM (included in junction block assembly)

• HVAC control module

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

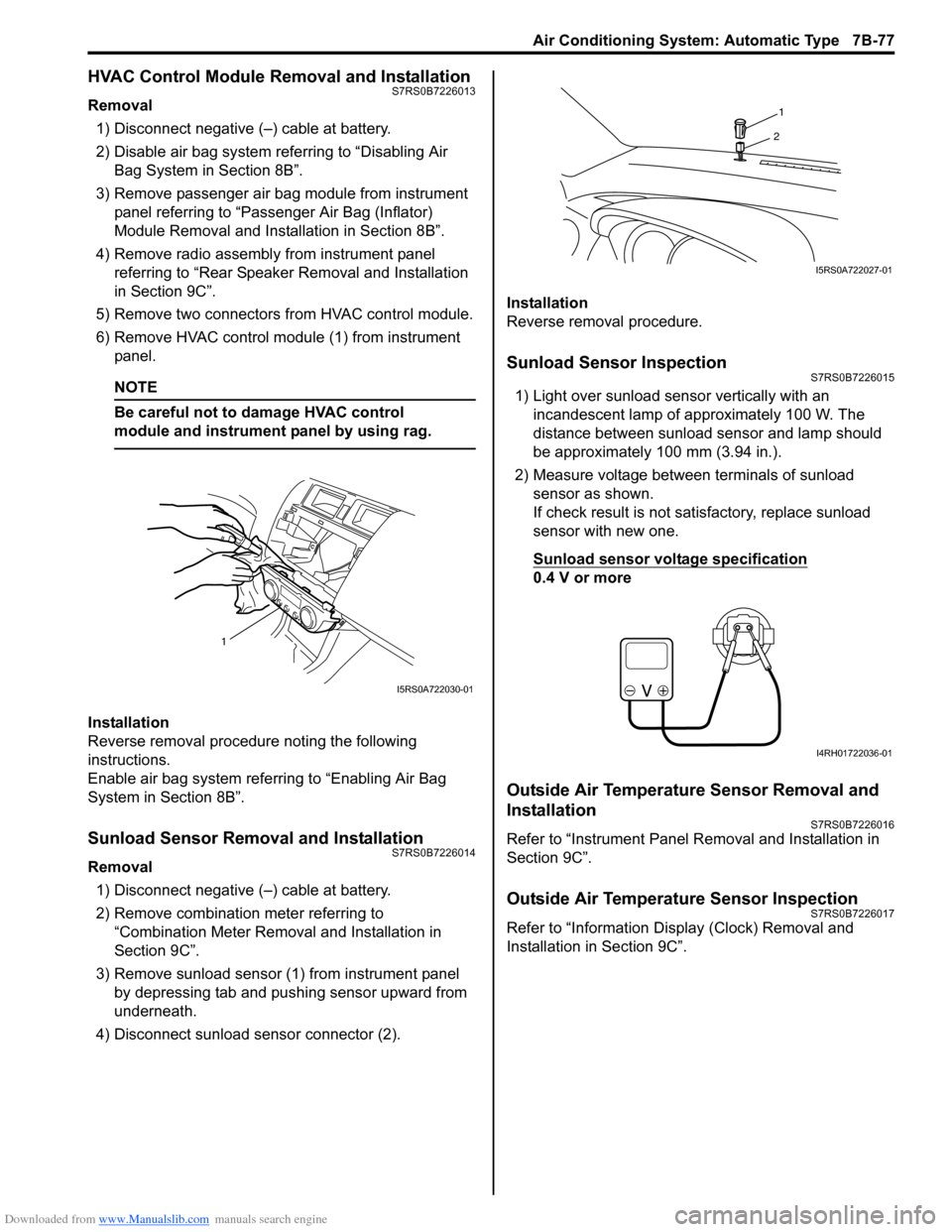

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1049 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-11

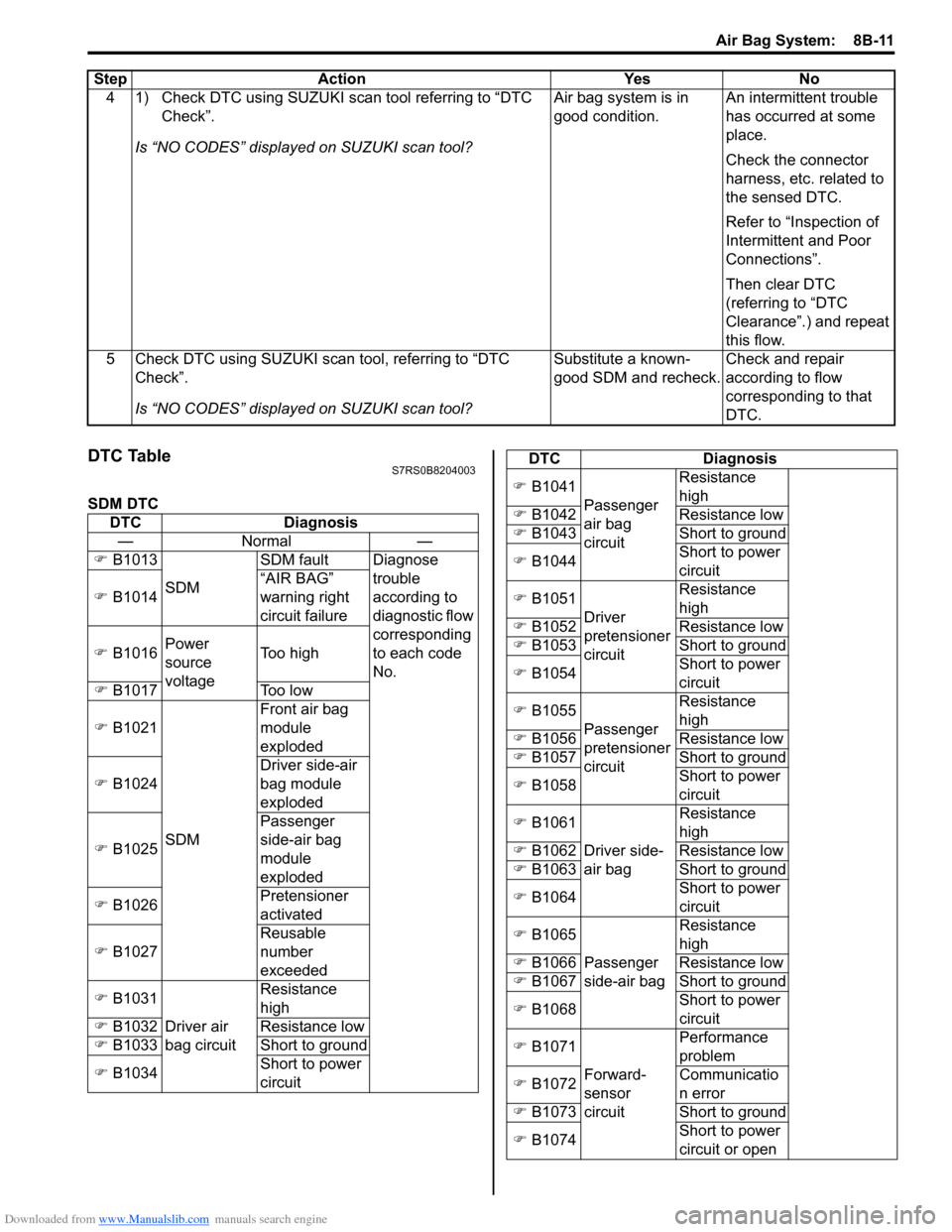

DTC TableS7RS0B8204003

SDM DTC4 1) Check DTC using SUZUKI scan tool referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool? Air bag system is in

good condition.

An intermittent trouble

has occurred at some

place.

Check the connector

harness, etc. related to

the sensed DTC.

Refer to “Inspection of

Intermittent and Poor

Connections”.

Then clear DTC

(referring to “DTC

Clearance”.) and repeat

this flow.

5 Check DTC using SUZUKI scan tool, referring to “DTC Check”.

Is “NO CODES” displayed on SUZUKI scan tool? Substitute a known-

good SDM and recheck.

Check and repair

according to flow

corresponding to that

DTC.

Step Action Yes No

DTC

Diagnosis

—N orm al —

�) B1013

SDM SDM fault Diagnose

trouble

according to

diagnostic flow

corresponding

to each code

No.

�)

B1014 “AIR BAG”

warning right

circuit failure

�) B1016 Power

source

voltage Too high

�) B1017 Too low

�) B1021

SDM Front air bag

module

exploded

�) B1024 Driver side-air

bag module

exploded

�) B1025 Passenger

side-air bag

module

exploded

�) B1026 Pretensioner

activated

�) B1027 Reusable

number

exceeded

�) B1031

Driver air

bag circuit Resistance

high

�) B1032 Resistance low

�) B1033 Short to ground

�) B1034 Short to power

circuit

�)

B1041

Passenger

air bag

circuit Resistance

high

�) B1042 Resistance low

�) B1043 Short to ground

�) B1044 Short to power

circuit

�) B1051

Driver

pretensioner

circuit Resistance

high

�) B1052 Resistance low

�) B1053 Short to ground

�) B1054 Short to power

circuit

�) B1055

Passenger

pretensioner

circuit Resistance

high

�) B1056 Resistance low

�) B1057 Short to ground

�) B1058 Short to power

circuit

�) B1061

Driver side-

air bag Resistance

high

�) B1062 Resistance low

�) B1063 Short to ground

�) B1064 Short to power

circuit

�) B1065

Passenger

side-air bag Resistance

high

�) B1066 Resistance low

�) B1067 Short to ground

�) B1068 Short to power

circuit

�) B1071

Forward-

sensor

circuit Performance

problem

�) B1072 Communicatio

n error

�) B1073 Short to ground

�) B1074 Short to power

circuit or open

DTC Diagnosis

Page 1050 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-12 Air Bag System:

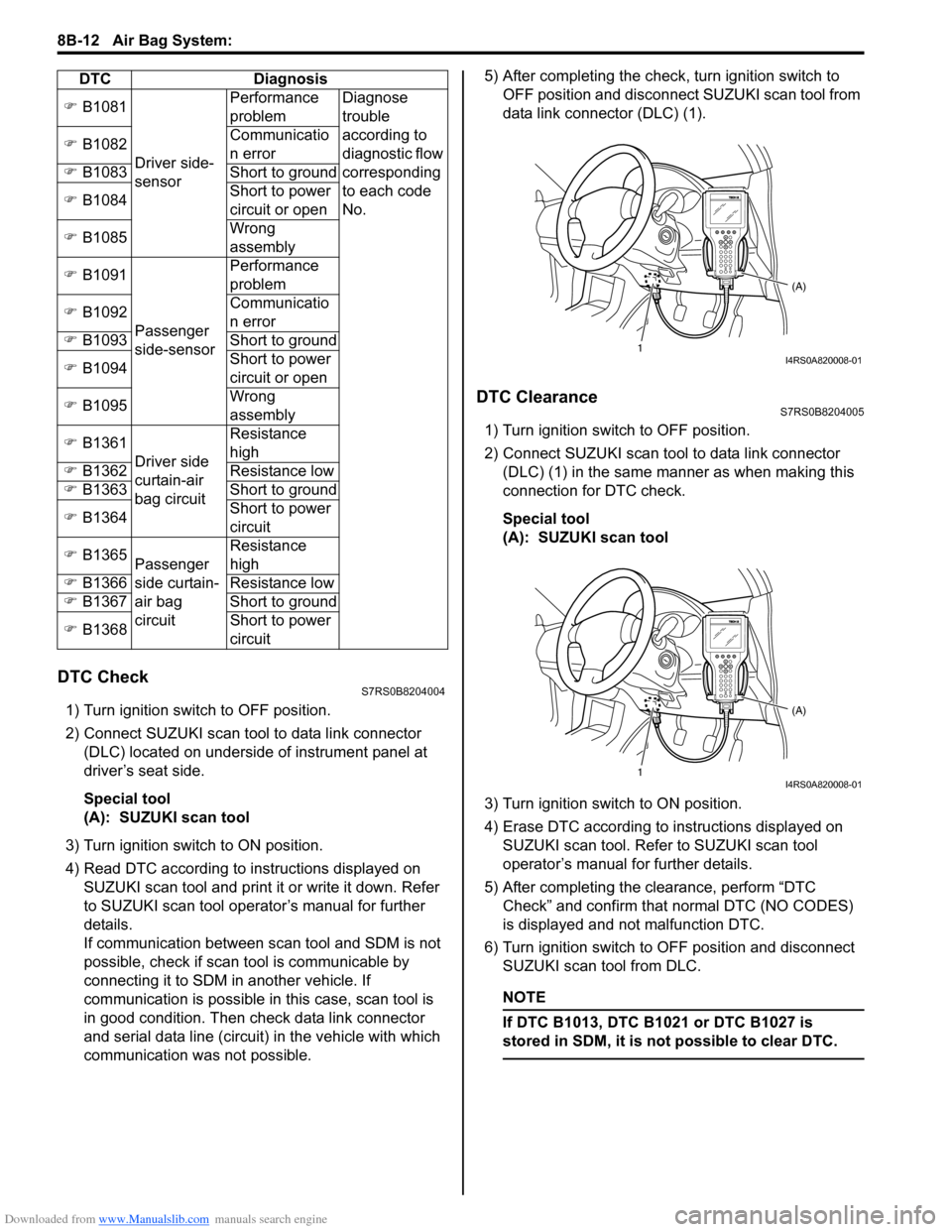

DTC CheckS7RS0B8204004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between scan tool and SDM is not

possible, check if scan tool is communicable by

connecting it to SDM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. 5) After completing the check,

turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC) (1).

DTC ClearanceS7RS0B8204005

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) in the same manner as when making this

connection for DTC check.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

5) After completing the clearance, perform “DTC Check” and confirm that normal DTC (NO CODES)

is displayed and not malfunction DTC.

6) Turn ignition switch to OFF position and disconnect SUZUKI scan tool from DLC.

NOTE

If DTC B1013, DTC B1 021 or DTC B1027 is

stored in SDM, it is not possible to clear DTC.

�) B1081

Driver side-

sensor Performance

problem

Diagnose

trouble

according to

diagnostic flow

corresponding

to each code

No.

�)

B1082 Communicatio

n error

�) B1083 Short to ground

�) B1084 Short to power

circuit or open

�) B1085 Wrong

assembly

�) B1091

Passenger

side-sensor Performance

problem

�) B1092 Communicatio

n error

�) B1093 Short to ground

�) B1094 Short to power

circuit or open

�) B1095 Wrong

assembly

�) B1361

Driver side

curtain-air

bag circuit Resistance

high

�) B1362 Resistance low

�) B1363 Short to ground

�) B1364 Short to power

circuit

�) B1365

Passenger

side curtain-

air bag

circuit Resistance

high

�) B1366 Resistance low

�) B1367 Short to ground

�) B1368 Short to power

circuit

DTC Diagnosis

1

(A)I4RS0A820008-01

1(A)I4RS0A820008-01

Page 1167 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103

Page 1168 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-ii Table of Contents

List of Connectors ........................................... 9A-103

C Connector .................................................... 9A-103

D Connector (M16A engine) ........................... 9A-104

E Connector .................................................... 9A-104

G Connector .................................................... 9A-106

J Connector ..................................................... 9A-108

K Connector .................................................... 9A-109

L Connector..................................................... 9A-109

M Connector (SPORT model) ......................... 9A-111

O Connector .................................................... 9A-111

R Connector .................................................... 9A-111

Lighting Systems .................................... 9B-1

Component Location ........... ................................9B-1

Lighting System Component s Location............... 9B-1

Interior Light System Location............................. 9B-2

Diagnostic Information and Procedures ............ 9B-2 Headlight Symptom Diagnosis ............................ 9B-2

Headlight Leveling System Symptom Diagnosis (If Equipped) ..................................... 9B-2

Turn Signal and Hazard Warning Light Symptom Diagnosis .......................................... 9B-3

Clearance, Tail and License Plate Light Symptom Diagnosis .......................................... 9B-3

Back-Up Light Symptom Diagnosis..................... 9B-4

Brake Light Symptom Diagnosis ......................... 9B-4

Front Fog Light Symptom Diagnosis (If Equipped) .......................................................... 9B-4

Interior Light Symptom Diagnosis ....................... 9B-5

Repair Instructions ..............................................9B-5 Headlight Housing Removal and Installation ...... 9B-5

Headlight Bulb Replacemen t............................... 9B-6

Headlight Aiming Adjustment with Screen .......... 9B-6

Headlight Switch (in Lighting Switch) Removal and Installation ................................... 9B-8

Headlight Switch (in Lighting Switch) Inspection .......................................................... 9B-8

Hazard Warning Switch Removal and Installation ......................................................... 9B-8

Hazard Warning Switch Inspection ..................... 9B-9

Brake Light Switch Inspection ............................. 9B-9

Turn Signal Light Switch (in Lighting Switch) Removal and Installation ................................... 9B-9

Turn Signal Light Switch (in Lighting Switch) Inspection .......................................................... 9B-9

Turn Signal and Hazard Warning Relay Removal and Installation ................................... 9B-9

Turn Signal and Hazard Warning Relay Inspection ........................................................ 9B-10

License Light Removal and Installation............. 9B-10

Front Fog Light Removal and Installation (If Equipped) ........................................................ 9B-11

Front Fog Light Bulb Replacement (If Equipped) ........................................................ 9B-11

Front Fog Light Switch Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Relay Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Aiming Adjustment with Screen (If Equipped) ....................................... 9B-12 Headlight Leveling Switch Inspection (If

Equipped) ........................................................ 9B-13

Headlight Leveling Actuator Inspection (If Equipped) ........................................................ 9B-13

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions ...........................................................9C-1 Precautions in Diagnosing Troubles for Combination Meter ............................................9C-1

General Description .............................................9C-1 CAN Communication System Description...........9C-1

Auto Volume Co ntrol System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4 Combination Meter Circuit Diagram ....................9C-4

Component Location ............ ...............................9C-6

Audio System Component Location ....................9C-6

Diagnostic Information and Procedures ............9C-6 Speedometer and VSS Symp tom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter Symptom Diagnosis ..........................................9C-7

Fuel Meter Symptom Diagnosis ..........................9C-7

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom Diagnosis ..........................................................9C-8

Brake and Parking Brake Warning Light Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis (If Equipped)......................................................9C-8

A/T Shift Position Indicator Symptom Diagnosis (A/T Model).......................................9C-9

Charge Warning Light Sy mptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Sy mptom Diagnosis ....9C-10

Cigarette Lighter Symptom Diagnosis (If Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If Equipped) ........................................................9C-11

Clock Symptom Diagnosis (If Equipped)...........9C-12

Audio System Symptom Diagnosis (If Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-14

Repair Instructions ............ ................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-15

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Remova l and Installation ..9C-15

Oil Pressure Switch Inspec tion .........................9C-16

Engine Coolant Temperature (ECT) Sensor Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspec tion.......................9C-16