combination switch SUZUKI SWIFT 2005 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1310 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-15 Instrumentation / Driver Info. / Horn:

Combination Meter Removal and InstallationS7RS0B9306003

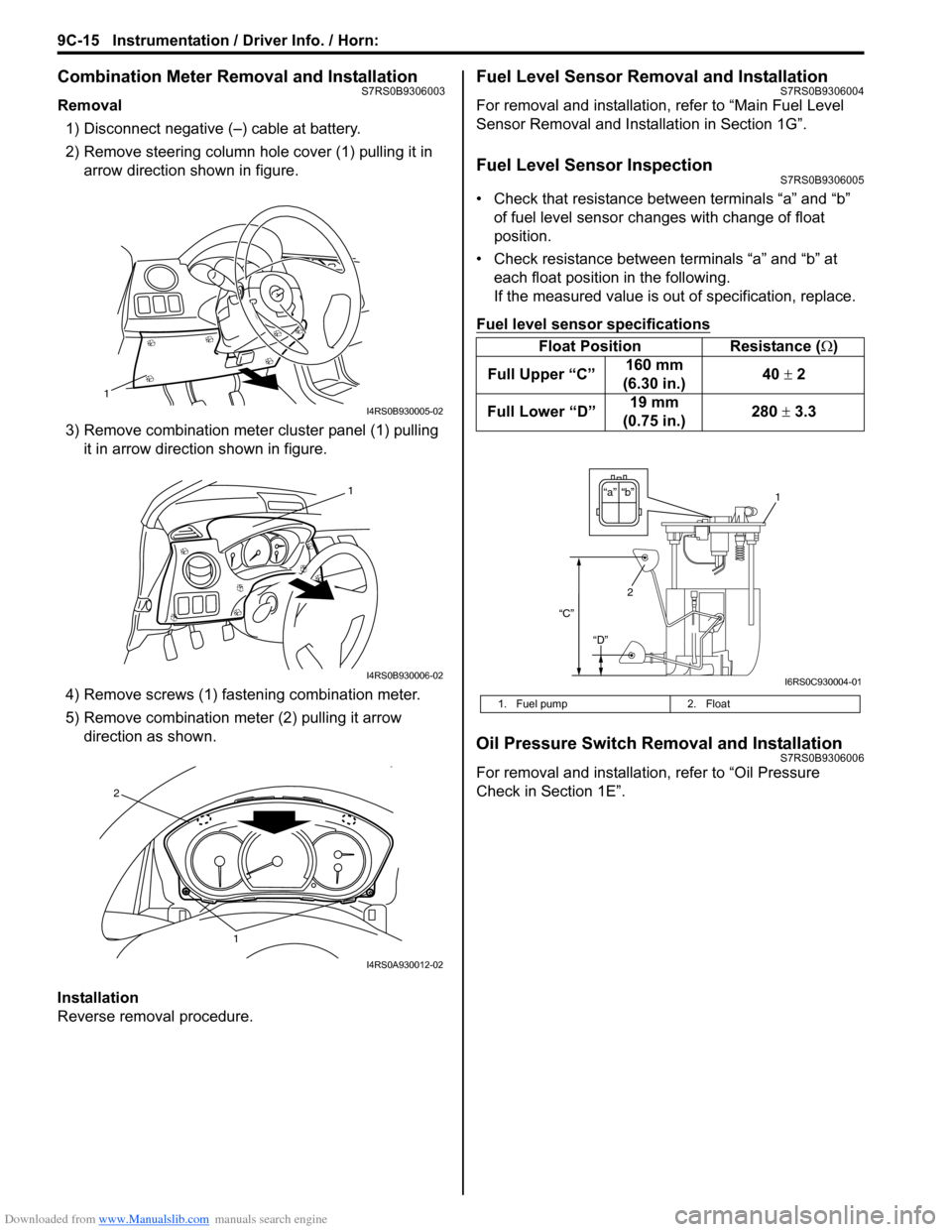

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (1) pulling it in arrow direction shown in figure.

3) Remove combination mete r cluster panel (1) pulling

it in arrow direction shown in figure.

4) Remove screws (1) fast ening combination meter.

5) Remove combination me ter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS7RS0B9306004

For removal and installation, refer to “Main Fuel Level

Sensor Removal and Installation in Section 1G”.

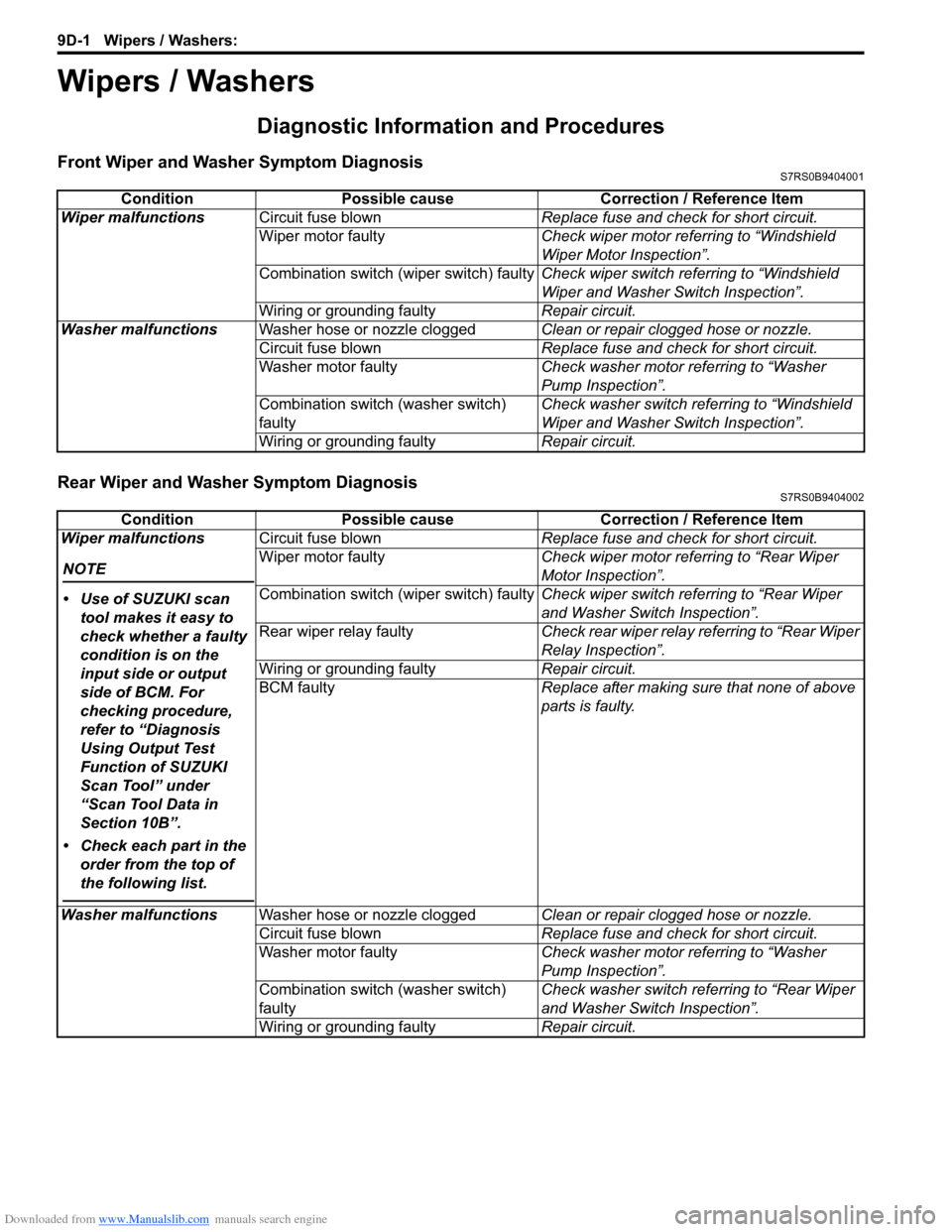

Fuel Level Sensor InspectionS7RS0B9306005

• Check that resistance between terminals “a” and “b” of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS7RS0B9306006

For removal and installation , refer to “Oil Pressure

Check in Section 1E”.

1

I4RS0B930005-02

1

I4RS0B930006-02

1

2

I4RS0A930012-02

Float Position Resistance (Ω)

Full Upper “C” 160 mm

(6.30 in.) 40

± 2

Full Lower “D” 19 mm

(0.75 in.) 280

± 3.3

1. Fuel pump 2. Float

“b”“a”

2

“C”

“D”

1

I6RS0C930004-01

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1325 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-8

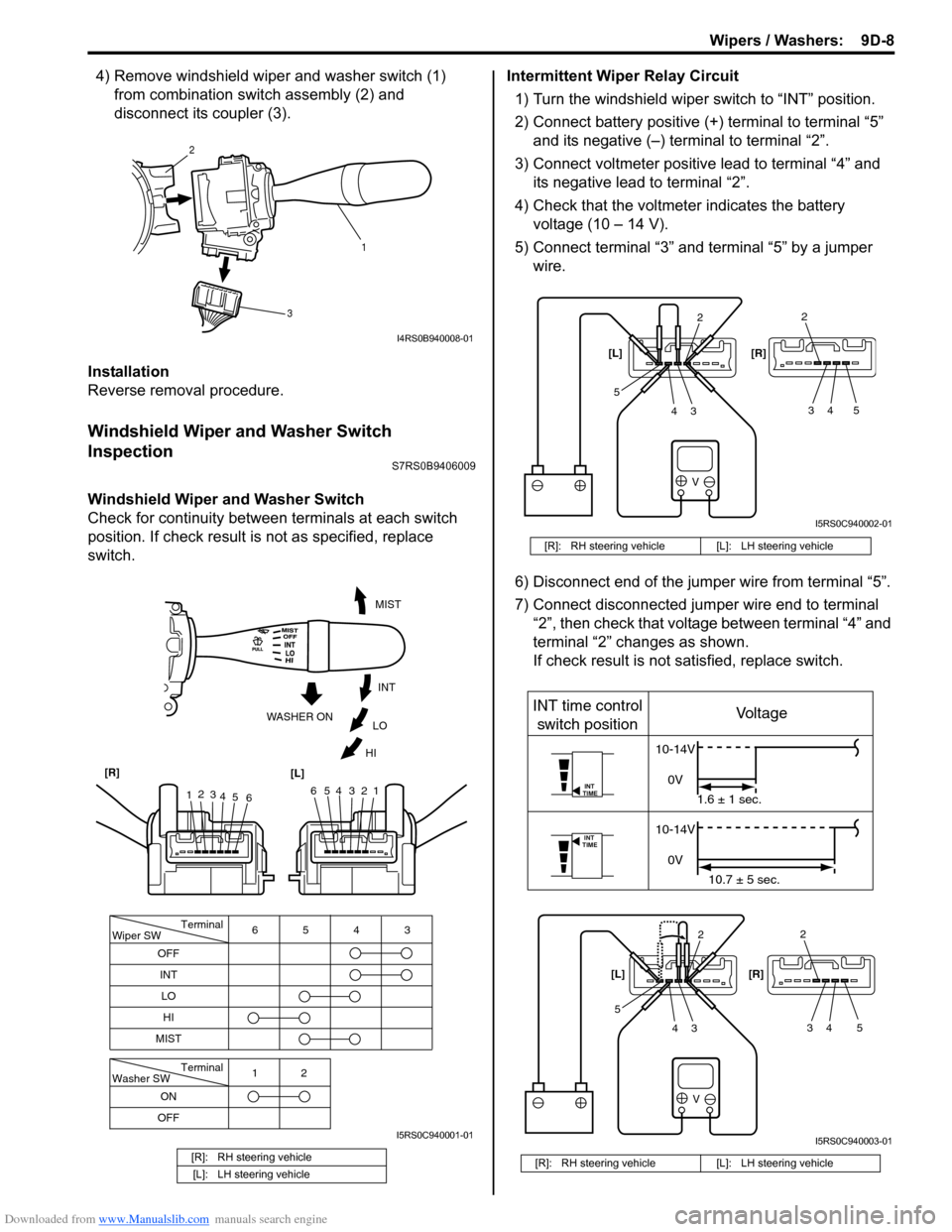

4) Remove windshield wiper and washer switch (1) from combination swit ch assembly (2) and

disconnect its coupler (3).

Installation

Reverse removal procedure.

Windshield Wiper and Washer Switch

Inspection

S7RS0B9406009

Windshield Wiper and Washer Switch

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch. Intermittent Wiper Relay Circuit

1) Turn the windshield wiper switch to “INT” position.

2) Connect battery positive (+ ) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and its negative lead to terminal “2”.

4) Check that the voltmeter indicates the battery voltage (10 – 14 V).

5) Connect terminal “3” and terminal “5” by a jumper wire.

6) Disconnect end of the jumper wire from terminal “5”.

7) Connect disconnected jumper wire end to terminal “2”, then check that voltage between terminal “4” and

terminal “2” changes as shown.

If check result is not satisfied, replace switch.

[R]: RH steering vehicle

[L]: LH steering vehicle

1

2

3

I4RS0B940008-01

Terminal

Wiper SW

OFF

INT 6543

MIST

Terminal

Washer SW

OFF 12

ONLO

HI

654321

MIST

INT

LO

HI

WASHER ON

1

2

3

4 5 6

[R]

[L]

I5RS0C940001-01

[R]: RH steering vehicle [L]: LH steering vehicle

[R]: RH steering vehicle [L]: LH steering vehicle

V

2

34

52

34 5

[L] [R]

I5RS0C940002-01

V

INT

TIME

INT

TIME

INT time control

switch position Voltage

10-14V

0V 1.6 ± 1 sec.

10-14V

0V 10.7 ± 5 sec.

2

34

52

34 5

[L]

[R]

I5RS0C940003-01

Page 1347 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-1

Body, Cab and Accessories

Security and Locks

General Description

Key Coding ConstructionS7RS0B9601001

Key Usage and Identification

Key is used for ignition and door lock cylinders. Key is cut on both edges to make them reversible.

Key identification is obtained from five character key code stamped on key code tag. Using this key code, key code

cutting combination can be determined from a code list (ava ilable to owners of key cutting equipment from suppliers).

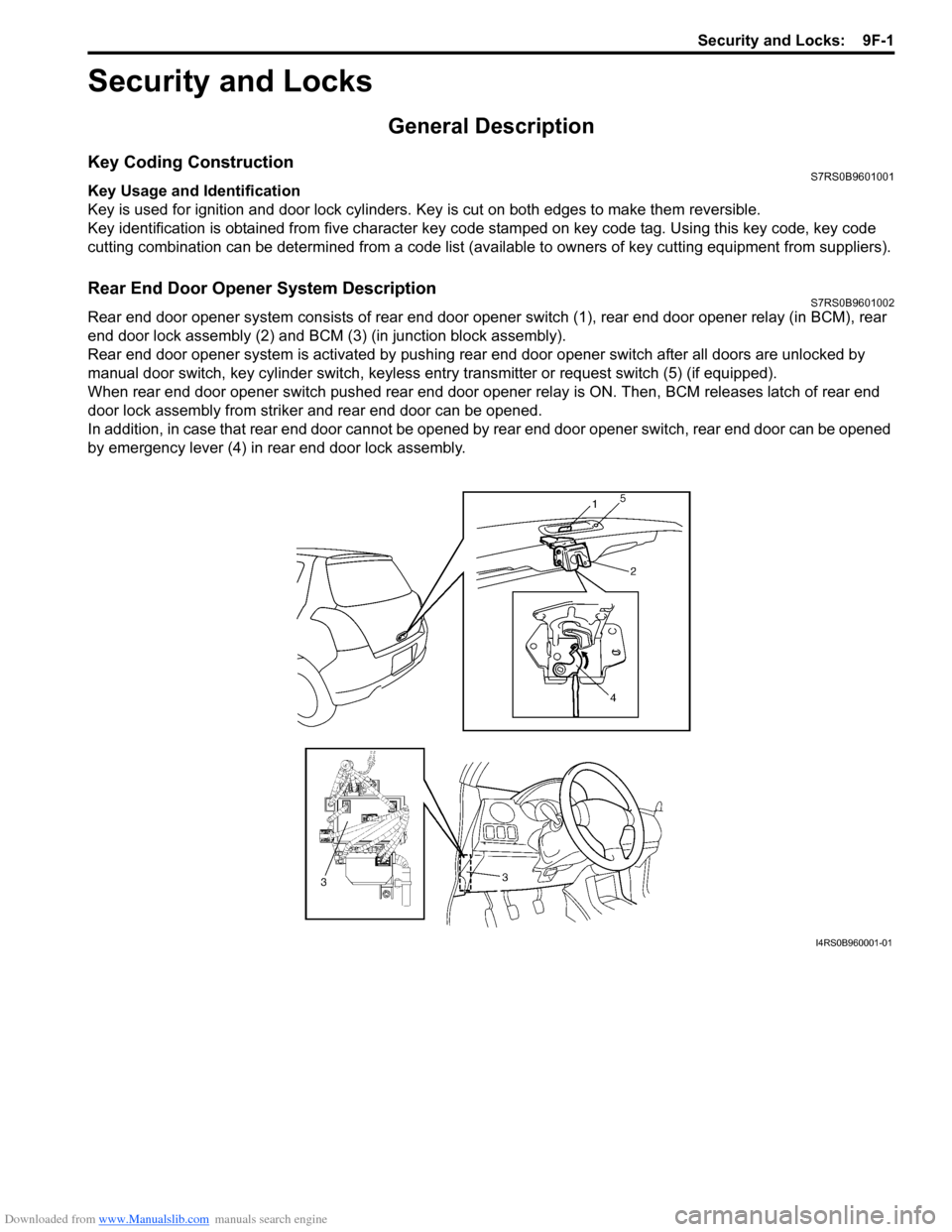

Rear End Door Opener System DescriptionS7RS0B9601002

Rear end door opener system consists of rear end door opener switch (1), rear end door opener relay (in BCM), rear

end door lock assembly (2) and BCM (3) (in junction block assembly).

Rear end door opener system is activated by pushing re ar end door opener switch after all doors are unlocked by

manual door switch, key cylinder s witch, keyless entry transmitter or request switch (5) (if equipped).

When rear end door opener switch pushed rear end door opener relay is ON. Then, BCM releases latch of rear end

door lock assembly from striker and rear end door can be opened.

In addition, in case that rear end door cannot be opened by rear end door opener switch, rear end door can be opened

by emergency lever (4) in rear end door lock assembly.

I4RS0B960001-01

Page 1405 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-2

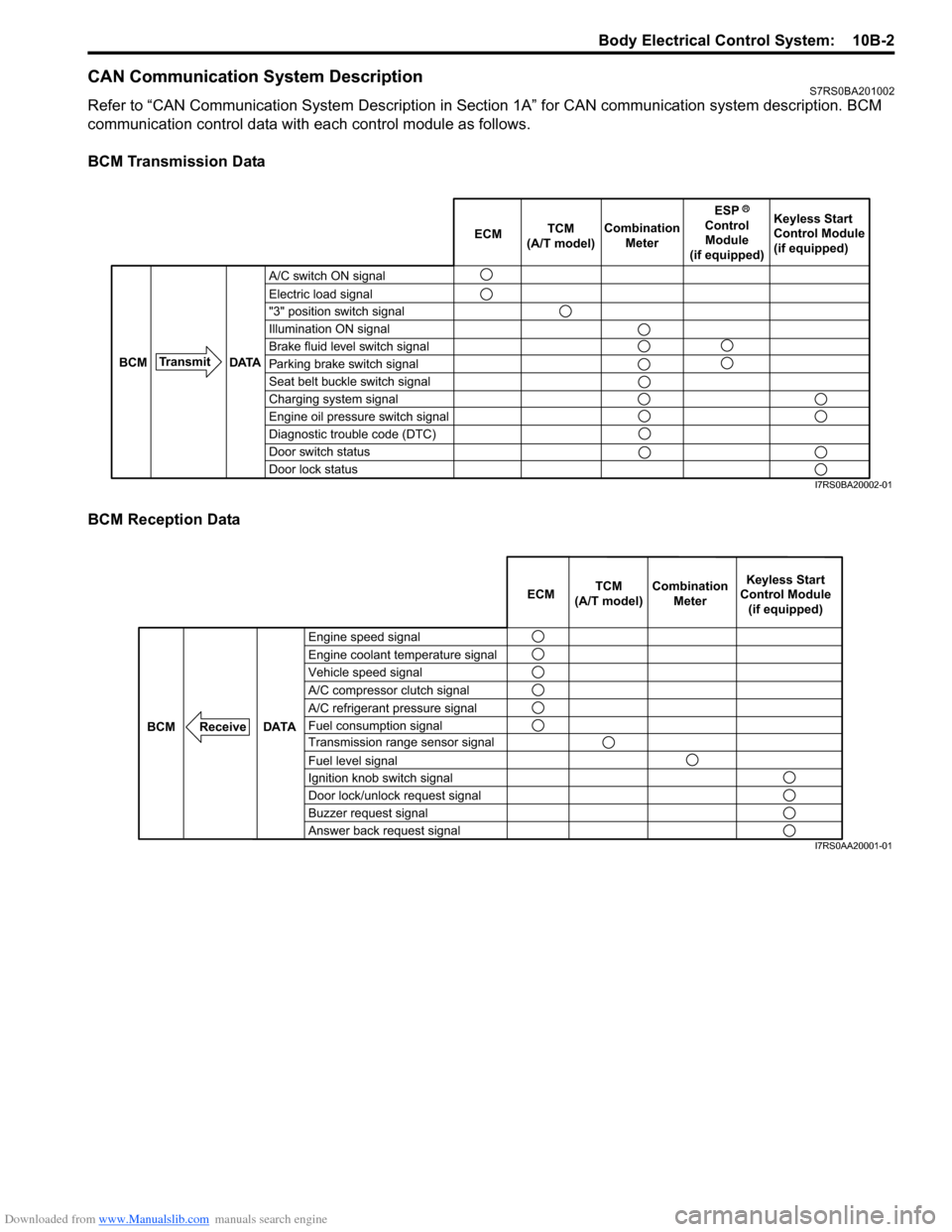

CAN Communication System DescriptionS7RS0BA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. BCM

communication control data with ea ch control module as follows.

BCM Transmission Data

BCM Reception Data

A/C switch ON signal

Electric load signal

"3" position switch signal

Illumination ON signal

Brake fluid level switch signal

Parking brake switch signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Diagnostic trouble code (DTC)

Door switch status

Door lock status ECM

TCM

(A/T model) Combination

Meter Keyless Start

Control Module

(if equipped)

Transmit DATA

BCM

ESP

Control Module

(if equipped)

I7RS0BA20002-01

Engine speed signal

Vehicle speed signal Engine coolant temperature signal

A/C refrigerant pressure signal

Fuel consumption signal A/C compressor clutch signal

Transmission range sensor signal

Fuel level signal

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal

DATA

BCM

Receive

Combination

Meter

TCM

(A/T model) Keyless Start

Control Module (if equipped)

ECM

I7RS0AA20001-01

Page 1409 of 1496

![SUZUKI SWIFT 2005 2.G Service Manual PDF Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-6

[A]: Vehicle not equipped with diagnosis connector 19. Door key cylinder switch (included in door lock a SUZUKI SWIFT 2005 2.G Service Manual PDF Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-6

[A]: Vehicle not equipped with diagnosis connector 19. Door key cylinder switch (included in door lock a](/img/20/7607/w960_7607-1408.png)

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-6

[A]: Vehicle not equipped with diagnosis connector 19. Door key cylinder switch (included in door lock actuator)40. SDM

[B]: Vehicle equipped with diagnosis conn ector 20. Manual door lock switch 41. Rear end door window defogger relay

[C]: ESP ® model 21. Rear end door window defogger switch 42. Rear end door window defogger

1. BCM (included in junction block assembly) 22. Rear end door opener switch 43. Rear end door window defogger indicator lamp

2. Rear washer motor 23. “3” position switch (A/T model)44. Horn relay

3. Rear wiper motor 24. A/C switch45. Horn switch

4. Rear wiper relay 25. Rear end door opener relay46. Horn

5. Rear wiper and washer switch 26. Rear end door opener actuator47. Lighting switch

6. Outside air temperature sensor 27. TCM (A/T model)48. Ignition switch

7. Key reminder switch 28. ECM49. Battery

8. Theft deterrent light 29. Combination meter50. To turn signal light

9. Oil pressure switch 30. Data link connector (DLC)51. Body ground

10. Generator 31. To ECM, ABS/ESP®, P/S control module 52. Engine ground

11. Information display (if equipped) 32. To SDM53. Keyless start control module (if equipped)

12. Keyless entry receiver (if equipped) 33. Door lock actuator relay 54. Right side door mirror heater (if equipped)

13. Driver side door switch 34. Driver side door lock actuator55. Left side door mirror heater (if equipped)

14. Other than driver side door switch 35. Passenger side door lock actuator56. ABS/ESP® control module

15. Rear end door switch 36. Rear door lock actuator57. To HVAC control module

16. Driver side seat belt switch 37. Turn signal and hazard warning relay 58. CAN junction connector

17. Brake fluid level switch 38. Hazard warning switch59. Steering angle sensor

18. Parking brake switch 39. Interior light

Page 1412 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-9 Body Electrical Control System:

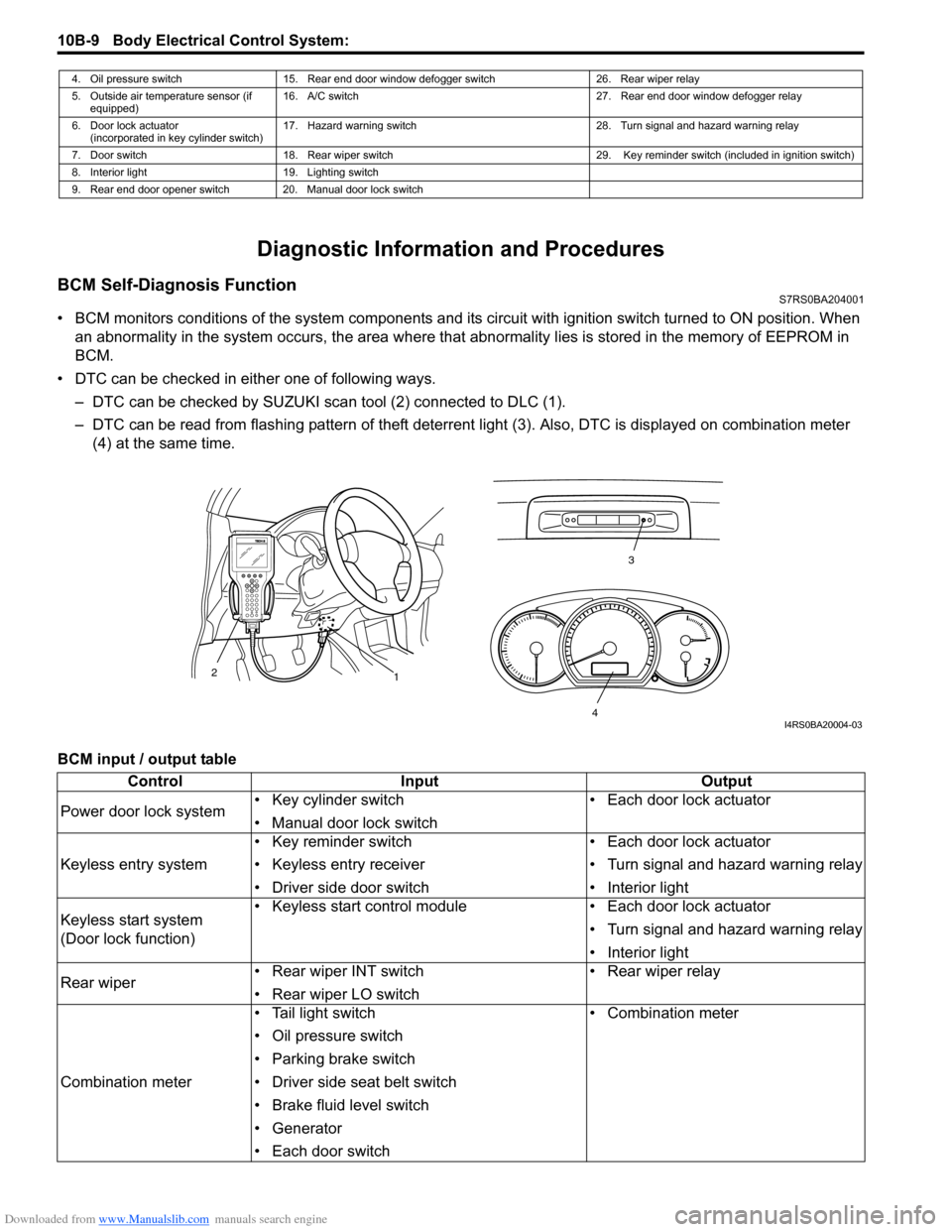

Diagnostic Information and Procedures

BCM Self-Diagnosis FunctionS7RS0BA204001

• BCM monitors conditions of the system components and its circuit with ignition switch turned to ON position. When

an abnormality in the system oc curs, the area where that abnormality lies is stored in the memory of EEPROM in

BCM.

• DTC can be checked in either one of following ways. – DTC can be checked by SUZUKI scan tool (2) connected to DLC (1).

– DTC can be read from flashing pattern of theft deterrent light (3). Also, DTC is displayed on combination meter

(4) at the same time.

BCM input / output table

4. Oil pressure switch 15. Rear end door window defogger switch 26. Rear wiper relay

5. Outside air temperature sensor (if equipped) 16. A/C switch

27. Rear end door window defogger relay

6. Door lock actuator (incorporated in key cylinder switch) 17. Hazard warning switch

28. Turn signal and hazard warning relay

7. Door switch 18. Rear wiper switch 29. Key reminder switch (included in ignition switch)

8. Interior light 19. Lighting switch

9. Rear end door opener switch 20. Manual door lock switch

3

1

2

4I4RS0BA20004-03

Control

Input Output

Power door lock system • Key cylinder switch

• Manual door lock switch • Each door lock actuator

Keyless entry system • Key reminder switch

• Keyless entry receiver

• Driver side door switch • Each door lock actuator

• Turn signal and hazard warning relay

• Interior light

Keyless start system

(Door lock function) • Keyless start control module

• Each door lock actuator

• Turn signal and hazard warning relay

• Interior light

Rear wiper • Rear wiper INT switch

• Rear wiper LO switch • Rear wiper relay

Combination meter • Tail light switch

• Oil pressure switch

• Parking brake switch

• Driver side seat belt switch

• Brake fluid level switch

• Generator

• Each door switch • Combination meter

Page 1417 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

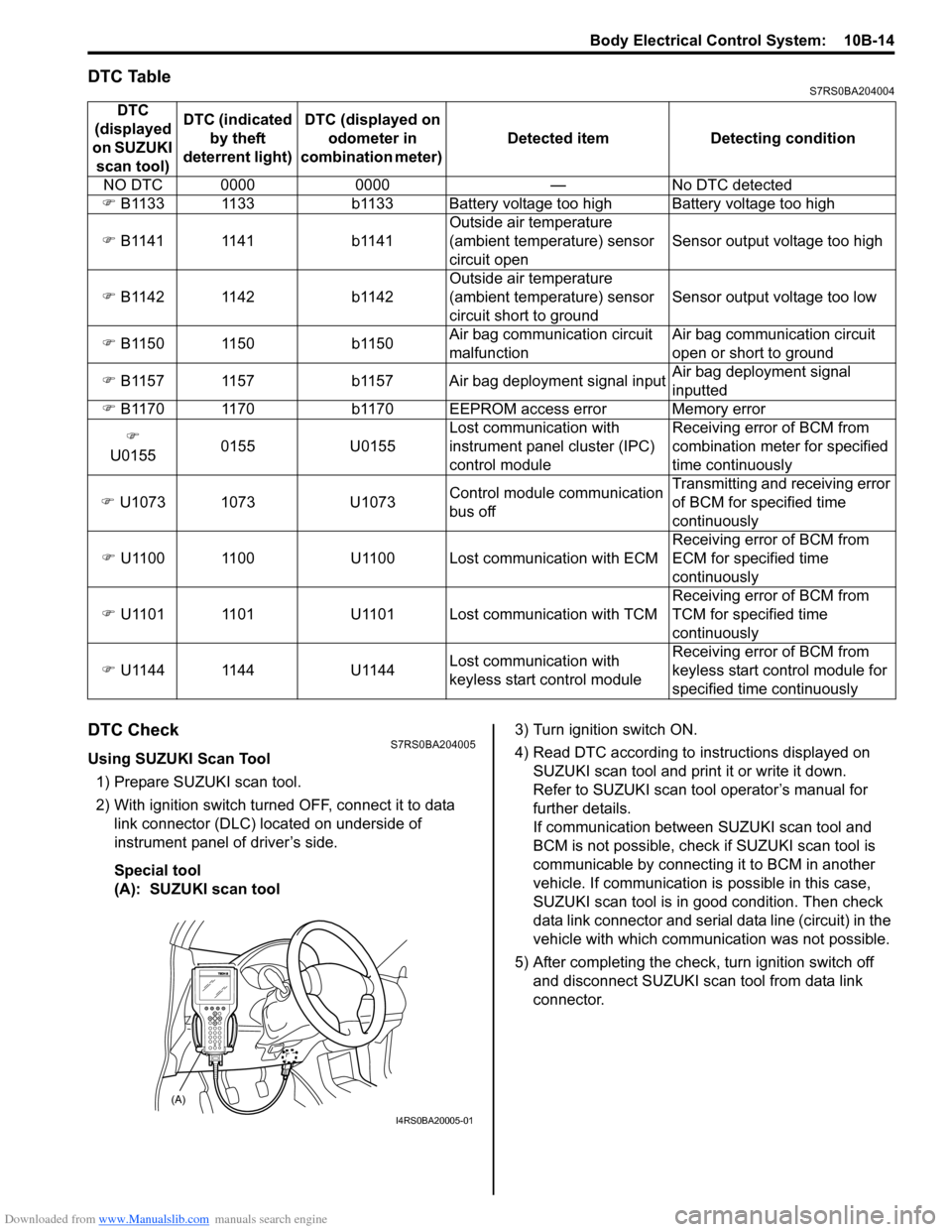

DTC TableS7RS0BA204004

DTC CheckS7RS0BA204005

Using SUZUKI Scan Tool1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of

instrument panel of driver’s side.

Special tool

(A): SUZUKI scan tool 3) Turn ignition switch ON.

4) Read DTC according to

instructions displayed on

SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for

further details.

If communication between SUZUKI scan tool and

BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another

vehicle. If communication is possible in this case,

SUZUKI scan tool is in good condition. Then check

data link connector and serial data line (circuit) in the

vehicle with which communica tion was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link

connector.

DTC

(displayed

on SUZUKI scan tool) DTC (indicated

by theft

deterrent light) DTC (displayed on

odometer in

combination meter) Detected item Detecting condition

NO DTC 0000 0000 — No DTC detected

�) B1133 1133 b1133 Battery voltage too high Battery voltage too high

�) B1141 1141 b1141 Outside air temperature

(ambient temperature) sensor

circuit openSensor output voltage too high

�) B1142 1142 b1142 Outside air temperature

(ambient temperature) sensor

circuit short to groundSensor output voltage too low

�) B1150 1150 b1150 Air bag communication circuit

malfunctionAir bag communication circuit

open or short to ground

�) B1157 1157 b1157 Air bag deployment signal input Air bag deployment signal

inputted

�) B1170 1170 b1170 EEPROM access error Memory error

�)

U0155 0155 U0155 Lost communication with

instrument panel cluster (IPC)

control moduleReceiving error of BCM from

combination mete

r for specified

time continuously

�) U1073 1073 U1073 Control module communication

bus offTransmitting and receiving error

of BCM for specified time

continuously

�) U1100 1100 U1100 Lost communication with ECM Receiving error of BCM from

ECM for specified time

continuously

�) U1101 1101 U1101 Lost communication with TCM Receiving error of BCM from

TCM for specified time

continuously

�) U1144 1144 U1144 Lost communication with

keyless start control moduleReceiving error of BCM from

keyless start control module for

specified time continuously

(A)

I4RS0BA20005-01

Page 1418 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

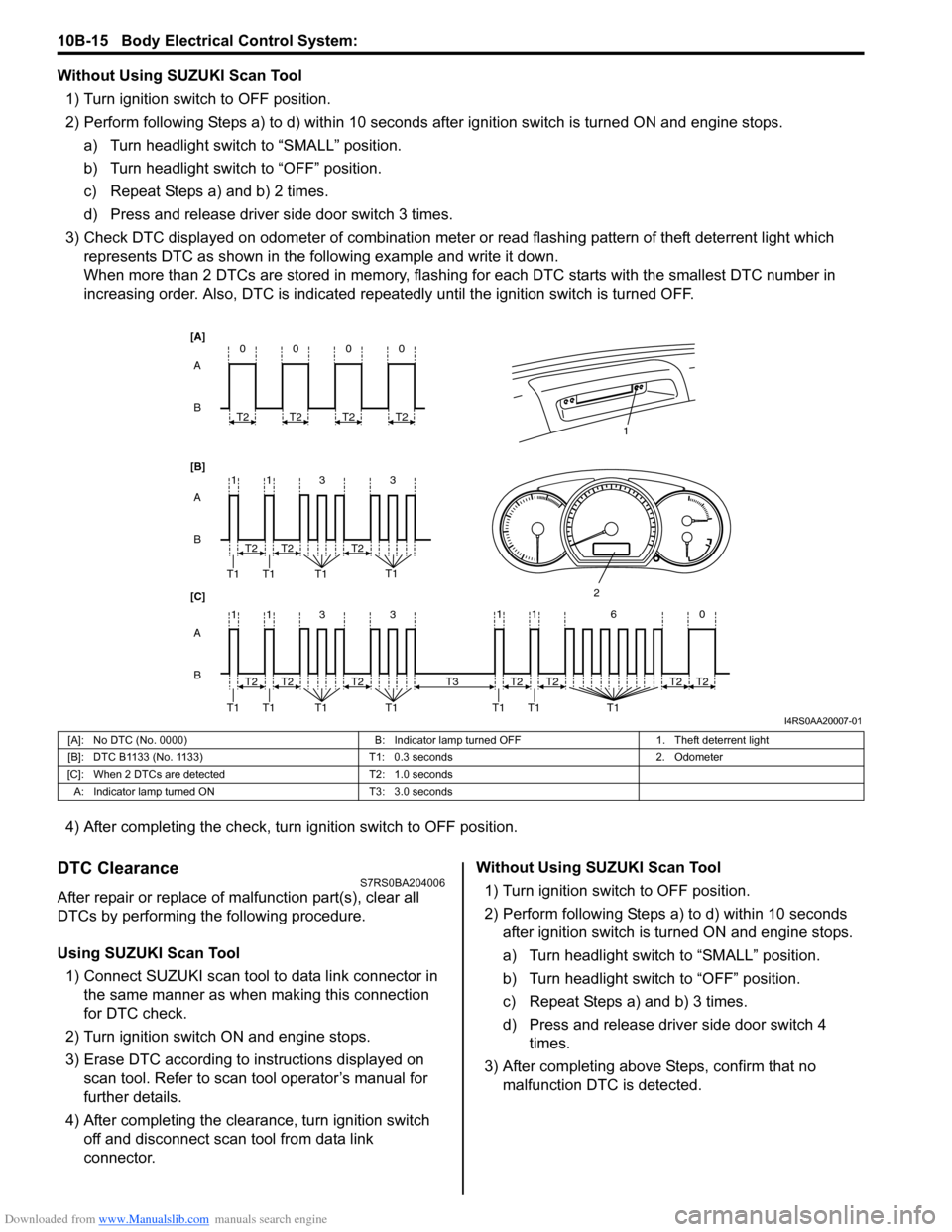

Without Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds af ter ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS7RS0BA204006

After repair or replace of malfunction part(s), clear all

DTCs by performing the following procedure.

Using SUZUKI Scan Tool 1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clear ance, turn ignition switch

off and disconnect scan tool from data link

connector. Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A

[B] [A]

[C]

B A B A

3

113

3

113

T2

T1 T1 T1 T1

1

2

T2T2

T2

T1 T1 T1 T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2

T3T2T2T2

I4RS0AA20007-01

[A]: No DTC (No. 0000) B: Indicator lamp turned OFF1. Theft deterrent light

[B]: DTC B1133 (No. 1133) T1: 0.3 seconds2. Odometer

[C]: When 2 DTCs are detected T2: 1.0 seconds

A: Indicator lamp tur ned ON T3: 3.0 seconds

Page 1424 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-21 Body Electrical Control System:

DTC B1170 (No. 1170): EEPROM Access ErrorS7RS0BA204012

DTC Detecting Condition and Possible Cause

DTC Troubleshooting

NOTE

Before performing steps below, be sure to perform “Body Electrical Control System Check”.

1) Ignition switch OFF.

2) Replace BCM.

3) Repeat BCM Check Flow Table.

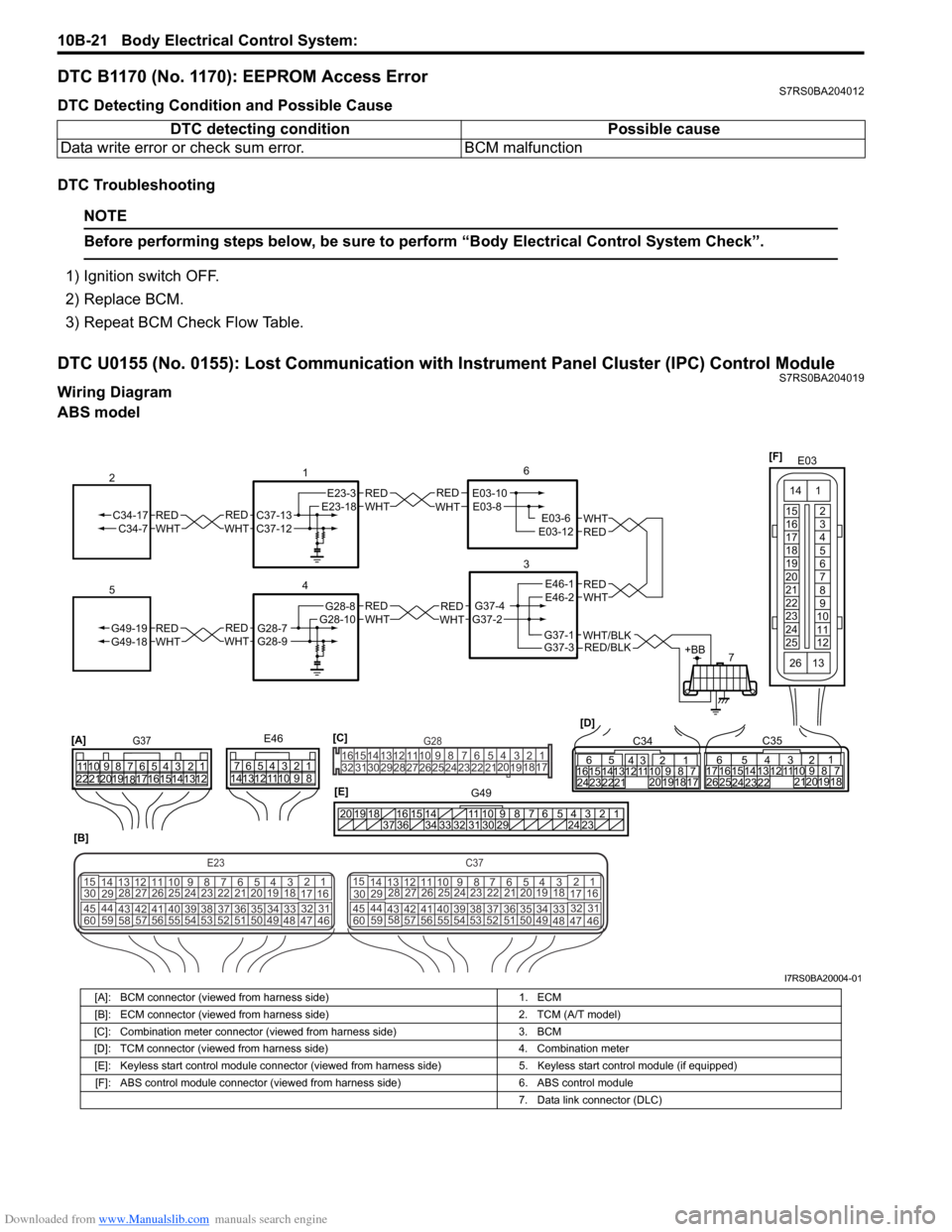

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS7RS0BA204019

Wiring Diagram

ABS model DTC detecting condition Possible cause

Data write error or check sum error. BCM malfunction

REDWHTE03-6E03-12

6

3

7

REDWHT

1

[B]

[A]

G37E46

1234567

1234567

8910

11

8910

11

121314 121314

151617

18

19202122 [D]65

1615 141312 11 43

2423 2122 10 9 8 7

21

1920 1817

C3417 16

26 2515 14

65 3

42

13 12

23 2224 1110 9

212019 87

18

1

C35

[E]

REDWHTC37-13C37-12REDWHTC34-17C34-7

2

12345678910

11

141516

36 34 33 32 31 30 29 24 23

37

181920

[C] [F]

G49

E23-3E23-18

4

REDWHTG28-7G28-9REDWHTG49-19G49-18

5

REDWHTE03-10E03-8

G37-4G37-2

REDWHTE46-1E46-2REDWHTREDWHTG28-8G28-10

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

G281234567

8

910111213141516

1718

19

20

212223242526272829303132

RED/BLKWHT/BLKG37-3G37-1+BB

I7RS0BA20004-01

[A]: BCM connector (viewed from harness side) 1. ECM

[B]: ECM connector (viewed from harness side) 2. TCM (A/T model)

[C]: Combination meter connector (viewed from harness side) 3. BCM

[D]: TCM connector (viewed from harness side) 4. Combination meter

[E]: Keyless start control module connector (viewed from harness side) 5. Keyless start control module (if equipped)

[F]: ABS control module connector (viewed from harness side) 6. ABS control module

7. Data link connector (DLC)