Clutch adjustment SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 38 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-8 Maintenance and Lubrication:

Brake Fluid InspectionS7RS0B0206035

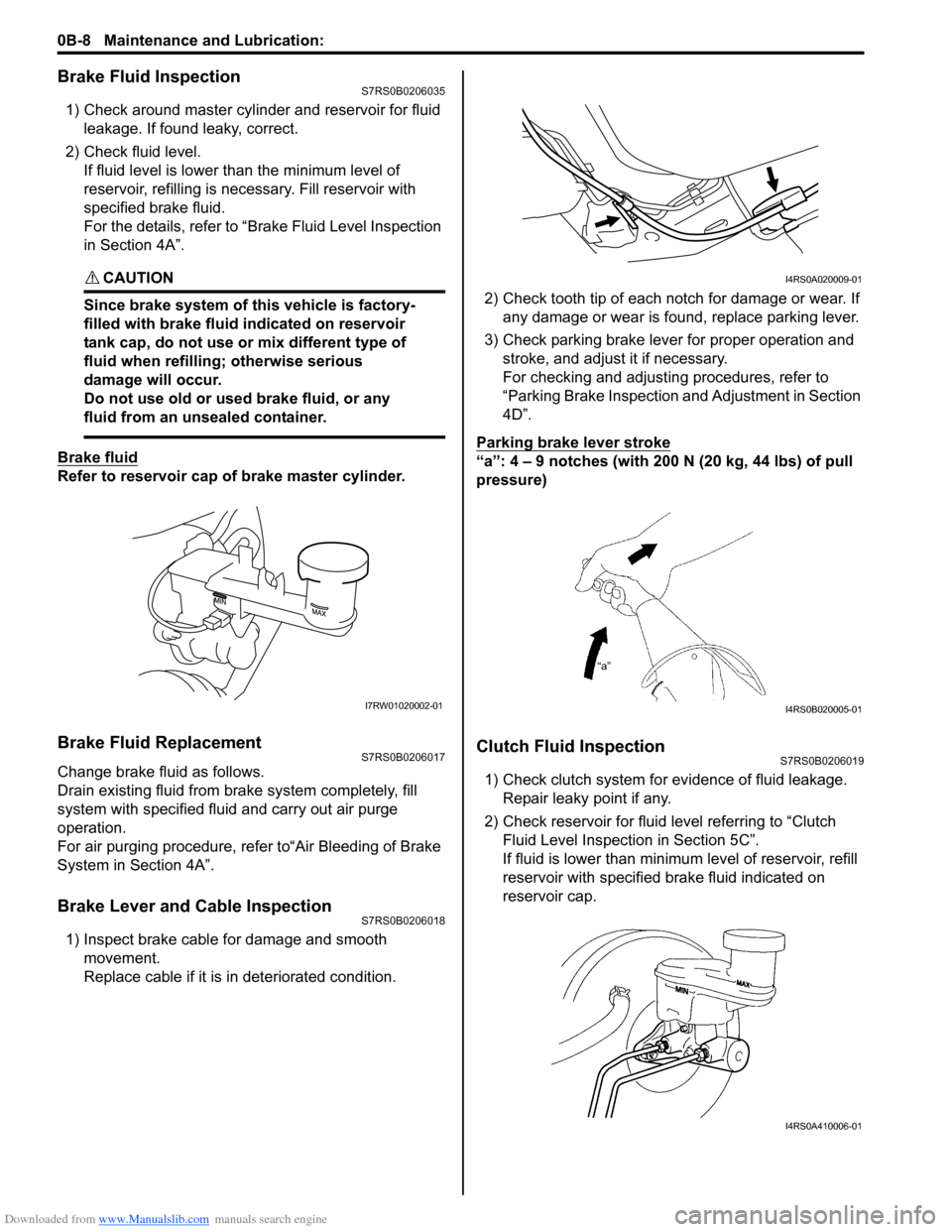

1) Check around master cylinder and reservoir for fluid leakage. If found leaky, correct.

2) Check fluid level. If fluid level is lower than the minimum level of

reservoir, refilling is necessary. Fill reservoir with

specified brake fluid.

For the details, refer to “Brake Fluid Level Inspection

in Section 4A”.

CAUTION!

Since brake system of this vehicle is factory-

filled with brake fluid indicated on reservoir

tank cap, do not use or mix different type of

fluid when refilling; otherwise serious

damage will occur.

Do not use old or used brake fluid, or any

fluid from an unsealed container.

Brake fluid

Refer to reservoir cap of brake master cylinder.

Brake Fluid ReplacementS7RS0B0206017

Change brake fluid as follows.

Drain existing fluid from brake system completely, fill

system with specified fluid and carry out air purge

operation.

For air purging procedure, refer to“Air Bleeding of Brake

System in Section 4A”.

Brake Lever and Cable InspectionS7RS0B0206018

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition. 2) Check tooth tip of each notch for damage or wear. If

any damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke, and adjust it if necessary.

For checking and adjusting procedures, refer to

“Parking Brake Inspection and Adjustment in Section

4D”.

Parking brake lever stroke

“a”: 4 – 9 notches (with 200 N (20 kg, 44 lbs) of pull

pressure)

Clutch Fluid InspectionS7RS0B0206019

1) Check clutch system for evidence of fluid leakage. Repair leaky point if any.

2) Check reservoir for fluid level referring to “Clutch

Fluid Level Inspection in Section 5C”.

If fluid is lower than minimum level of reservoir, refill

reservoir with specified brake fluid indicated on

reservoir cap.

I7RW01020002-01

I4RS0A020009-01

I4RS0B020005-01

I4RS0A410006-01

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 643 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Gear Shift Control Lever and Cable Components...................................................... 5B-5

Gear Shift Control Le ver and Cable Removal

and Installation .................................................. 5B-6

Gear Select Control Cable Adjustment ............... 5B-6

Back Up Light Switch Removal and Installation ......................................................... 5B-7

Back Up Light Switch Inspection ......................... 5B-7

Manual Transaxle Unit Components ................... 5B-8

Manual Transaxle Unit Dismounting and Remounting....................................................... 5B-9

Gear Shift and Sele ct Shaft Assembly

Components.................................................... 5B-11

Gear Shift and Sele ct Shaft Assembly

Removal and Installation................................. 5B-11

Gear Shift and Select Shaft Disassembly and Assembly ........................................................ 5B-12

Manual Transaxle Assembly Components........ 5B-13

Fifth Gear Disassembly and Assembly ............. 5B-14

Manual Transaxle Assembly Disassembly and Reassembly ............................................. 5B-16

Transaxle Right Case Disassembly and Assembly ........................................................ 5B-23

Transaxle Left Case Disassembly and Assembly ........................................................ 5B-24

Input Shaft and Countershaft Components....... 5B-25

Input Shaft Assembly Disassembly and Reassembly .................................................... 5B-26

Countershaft Assembly Disassembly and Reassembly .................................................... 5B-28

Synchronizer Parts Inspec tion .......................... 5B-31

Gear Shift Shaft Components ........................... 5B-31

5th and Reverse Gear Shift Shafts Disassembly and Assembly ............................ 5B-32

Gear Shift Shaft and Fork Inspection ................ 5B-32

Differential Components ................................... 5B-33

Differential Disassembly and Assembly ............ 5B-33

Specifications ..................................................... 5B-35

Tightening Torque Specifications ...................... 5B-35

Special Tools and Equipmen t ........................... 5B-36

Recommended Service Material ....................... 5B-36 Special Tool ...................................................... 5B-36

Clutch ................

.............................. ......... 5C-1

General Description .............................................5C-1

Clutch Construction .............................................5C-1

Diagnostic Information and Procedures ............5C-2 Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ........... ...................................5C-2

Clutch Pedal Inspection ......................................5C-2

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Pedal Position (CPP) Switch Removal and Installation ..................................................5C-4

Clutch Pedal Position (CPP) Switch Inspection and Adjustment ................................5C-5

Clutch Fluid Pipe and Hose Components ...........5C-5

Clutch Fluid Pipe Removal and Installation.........5C-6

Clutch Fluid Pipe Inspection................................5C-6

Clutch Master Cylinder Removal and Installation .........................................................5C-6

Clutch Operating Cylinder Removal and Installation .........................................................5C-7

Clutch Operating Cylinder Inspection..................5C-7

Clutch Pedal and Clutch Pedal Bracket Components ......................................................5C-7

Clutch Cover, Clutch Disc and Flywheel Components ......................................................5C-8

Clutch Cover, Clutch Disc and Flywheel Removal and Installation ...................................5C-8

Clutch Cover, Clutch Disc and Flywheel Inspection ........................................................5C-10

Clutch Release Syst em Removal and

Installation .......................................................5C-11

Clutch Release System Inspection ...................5C-13

Specifications .................... .................................5C-13

Tightening Torque Specifications ......................5C-13

Special Tools and Equipmen t ...........................5C-14

Recommended Service Material .......................5C-14

Special Tool ......................................................5C-14

Page 791 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-147

3) Install new differential side oil seal to transaxle case by using special tools.

Special tool

(A): 09924–74510

(B): 09944–88220

Differential side oil seal installing depth

“a”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

4) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

Automatic Transaxle Unit Inspection and

Adjustment

S7RS0B5106059

Inspection

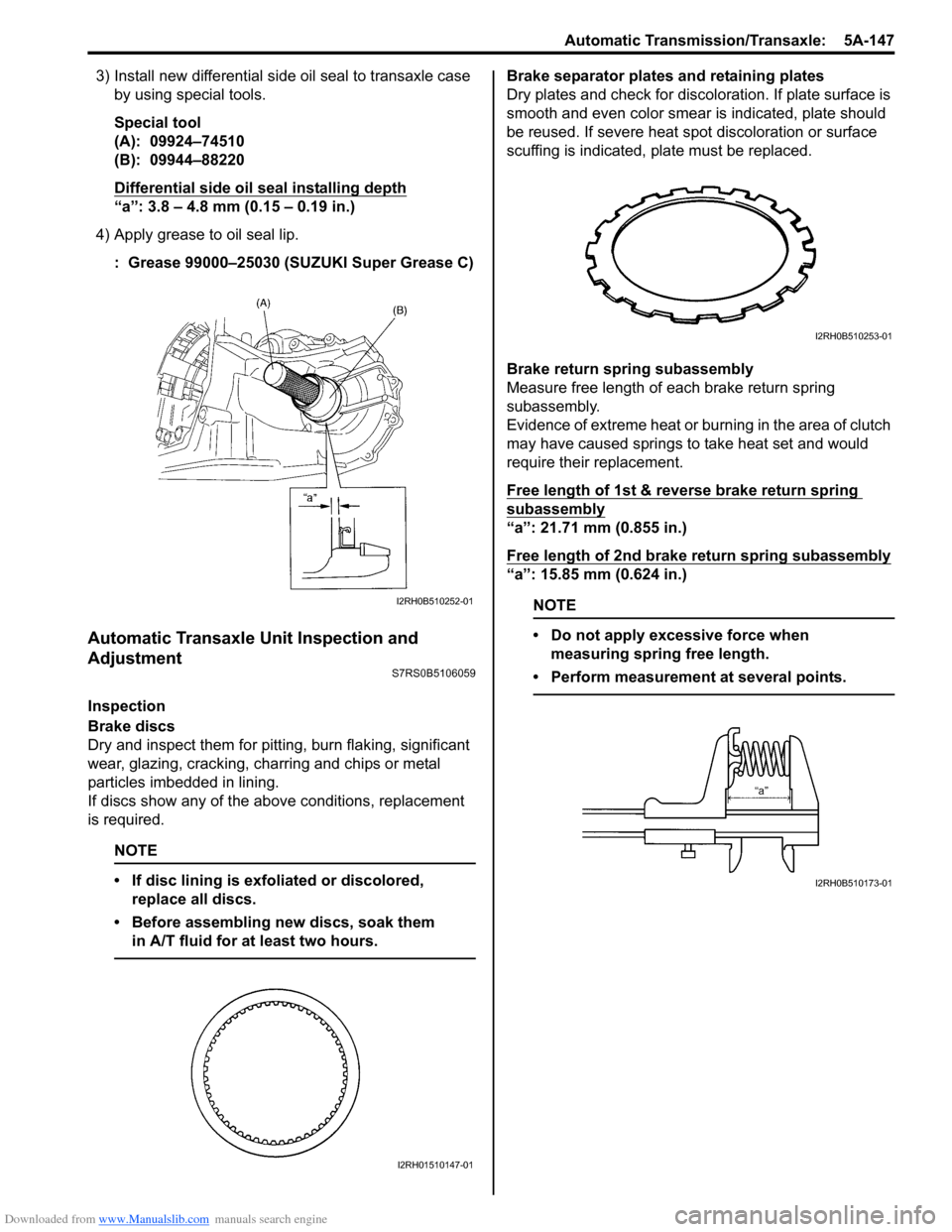

Brake discs

Dry and inspect them for pitting, burn flaking, significant

wear, glazing, cracking, charring and chips or metal

particles imbedded in lining.

If discs show any of the ab ove conditions, replacement

is required.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Brake separator plates and retaining plates

Dry plates and check for discol oration. If plate surface is

smooth and even color smear is indicated, plate should

be reused. If severe heat spot discoloration or surface

scuffing is indicated, plate must be replaced.

Brake return spring subassembly

Measure free length of each brake return spring

subassembly.

Evidence of extreme heat or burning in the area of clutch

may have caused springs to take heat set and would

require their replacement.

Free length of 1st & reverse brake return spring

subassembly

“a”: 21.71 mm (0.855 in.)

Free length of 2nd brake return spring subassembly

“a”: 15.85 mm (0.624 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

I2RH0B510252-01

I2RH01510147-01

I2RH0B510253-01

I2RH0B510173-01

Page 792 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-148 Automatic Transmission/Transaxle:

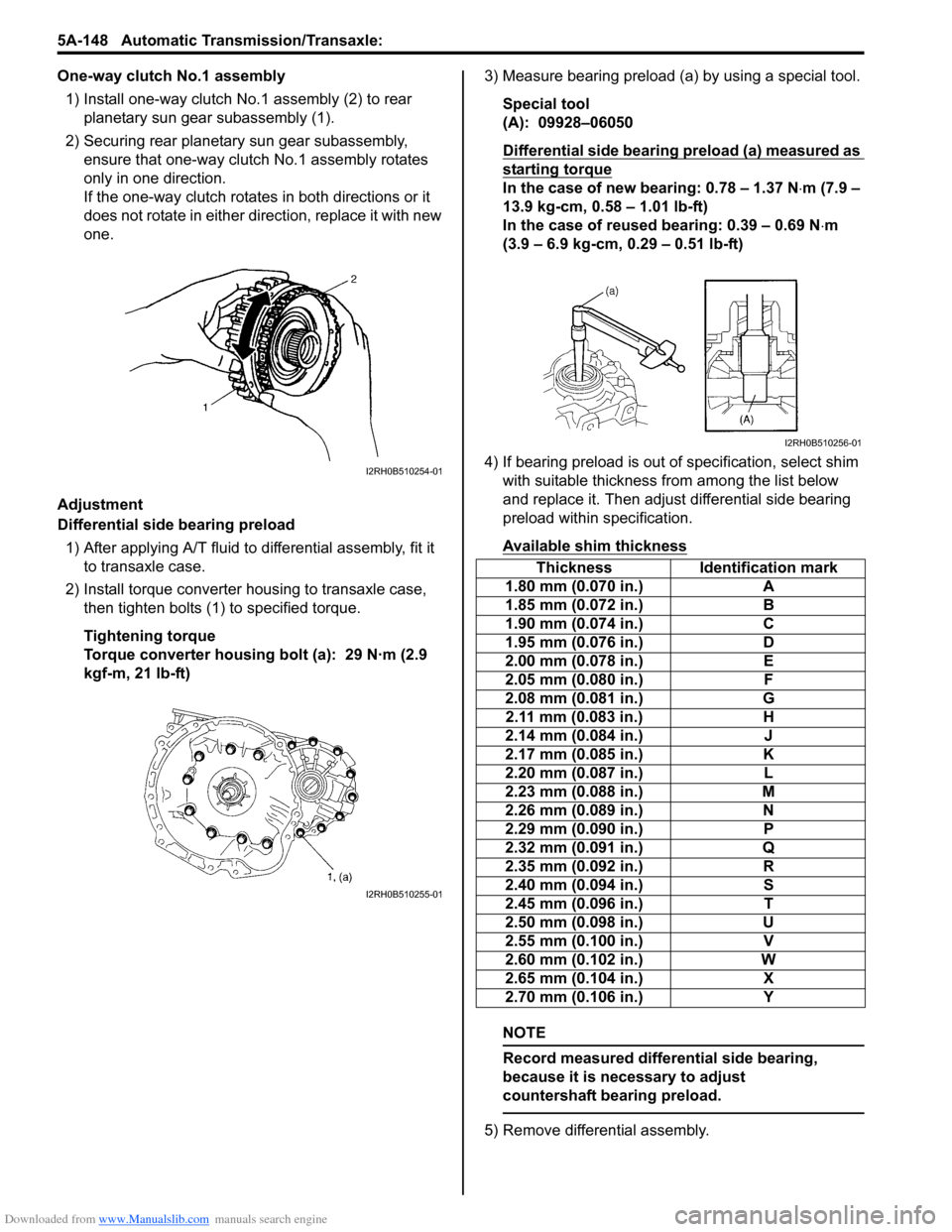

One-way clutch No.1 assembly1) Install one-way clutch No.1 assembly (2) to rear planetary sun gear subassembly (1).

2) Securing rear planetary sun gear subassembly, ensure that one-way clutch No.1 assembly rotates

only in one direction.

If the one-way clutch rotates in both directions or it

does not rotate in either direction, replace it with new

one.

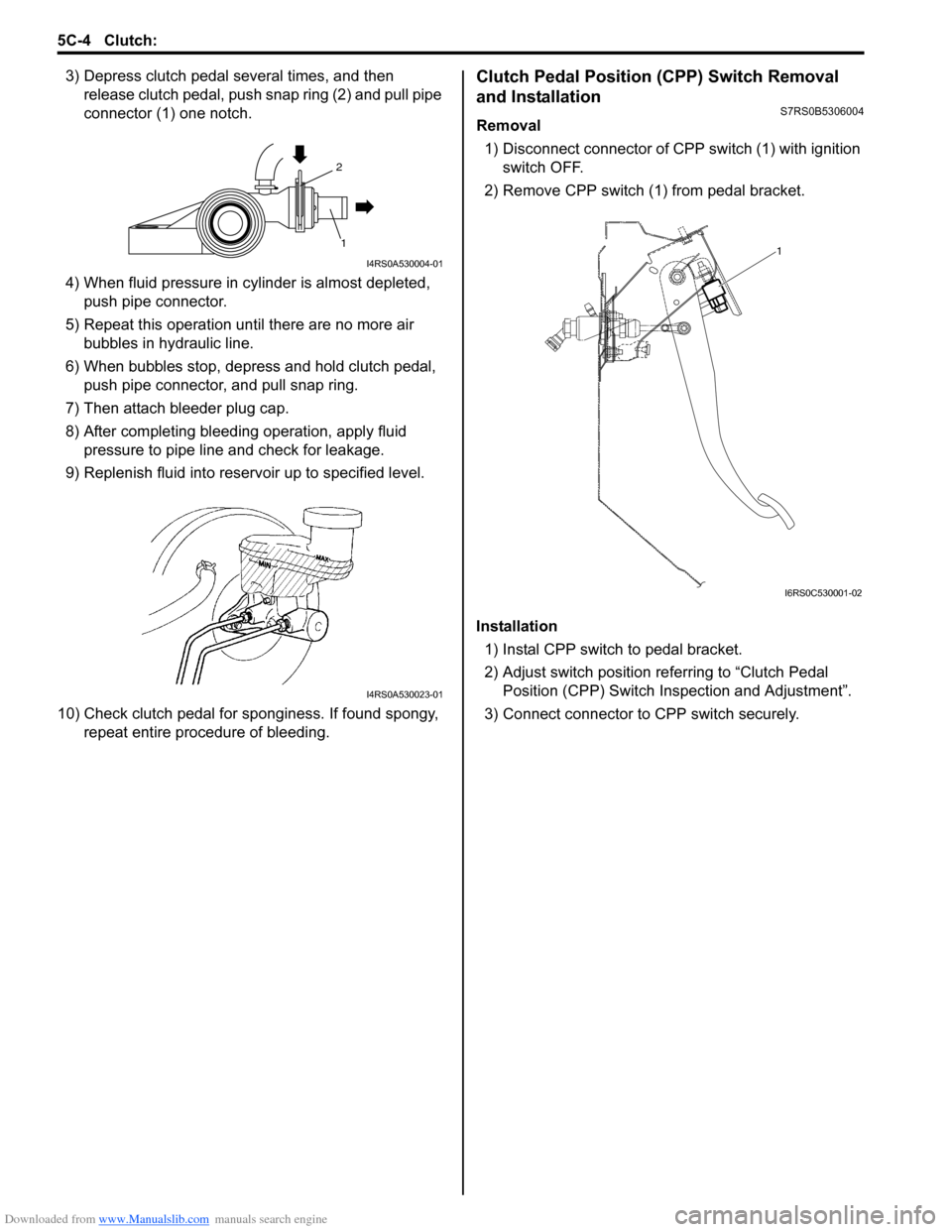

Adjustment

Differential side bearing preload 1) After applying A/T fluid to differential assembly, fit it to transaxle case.

2) Install torque converter housing to transaxle case, then tighten bolts (1) to specified torque.

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft) 3) Measure bearing preload (a) by using a special tool.

Special tool

(A): 09928–06050

Differential side bearing preload (a) measured as

starting torque

In the case of new bearing: 0.78 – 1.37 N ⋅m (7.9 –

13.9 kg-cm, 0.58 – 1.01 lb-ft)

In the case of reused bearing: 0.39 – 0.69 N ⋅m

(3.9 – 6.9 kg-cm, 0.29 – 0.51 lb-ft)

4) If bearing preload is out of specification, select shim with suitable thickness from among the list below

and replace it. Then adjust differential side bearing

preload within specification.

Available shim thickness

NOTE

Record measured differential side bearing,

because it is necessary to adjust

countershaft bearing preload.

5) Remove differential assembly.

I2RH0B510254-01

I2RH0B510255-01

Thickness Identification mark

1.80 mm (0.070 in.) A

1.85 mm (0.072 in.) B

1.90 mm (0.074 in.) C

1.95 mm (0.076 in.) D

2.00 mm (0.078 in.) E

2.05 mm (0.080 in.) F

2.08 mm (0.081 in.) G

2.11 mm (0.083 in.) H

2.14 mm (0.084 in.) J

2.17 mm (0.085 in.) K

2.20 mm (0.087 in.) L

2.23 mm (0.088 in.) M

2.26 mm (0.089 in.) N

2.29 mm (0.090 in.) P

2.32 mm (0.091 in.) Q

2.35 mm (0.092 in.) R

2.40 mm (0.094 in.) S

2.45 mm (0.096 in.) T

2.50 mm (0.098 in.) U

2.55 mm (0.100 in.) V

2.60 mm (0.102 in.) W

2.65 mm (0.104 in.) X

2.70 mm (0.106 in.) Y

I2RH0B510256-01

Page 856 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-4 Clutch:

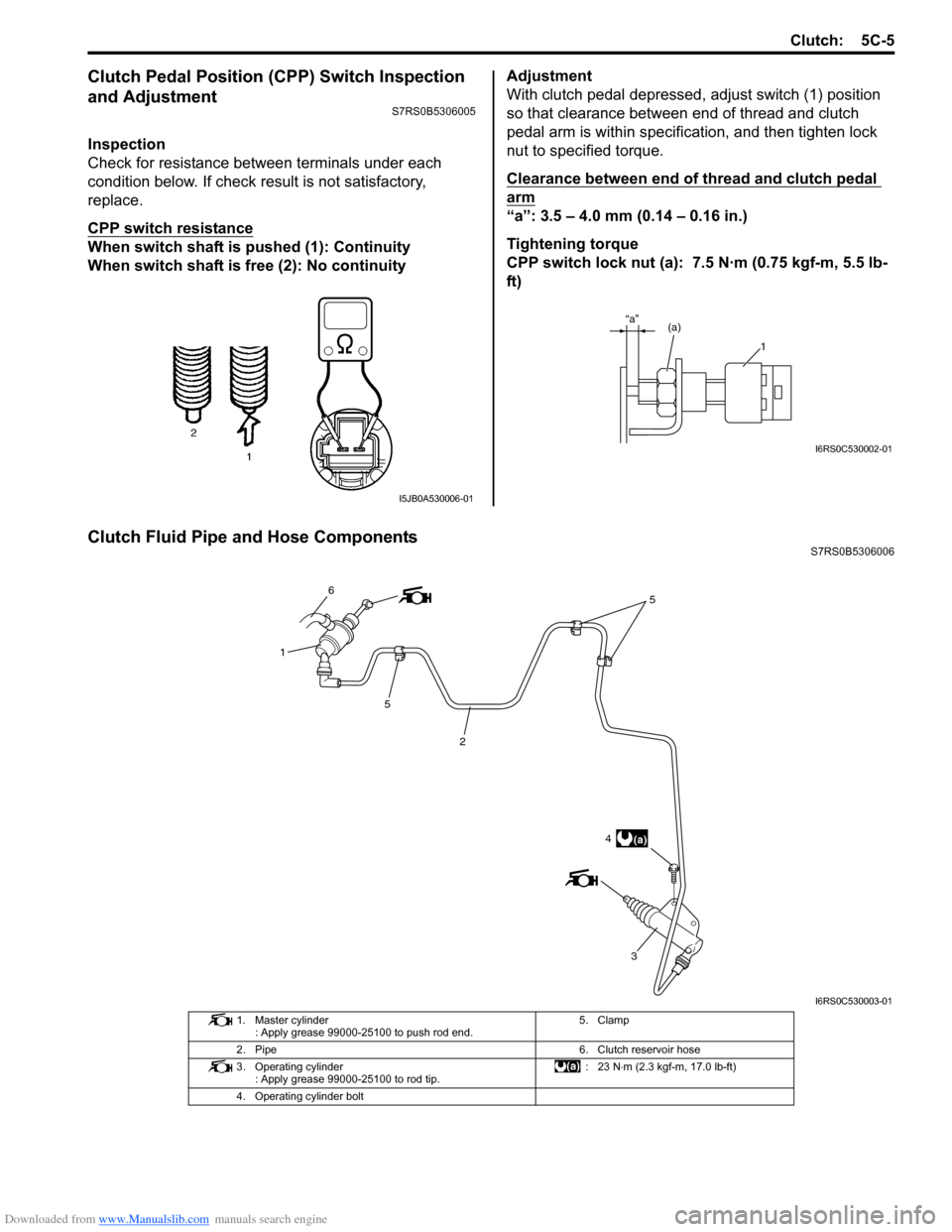

3) Depress clutch pedal several times, and then release clutch pedal, push snap ring (2) and pull pipe

connector (1) one notch.

4) When fluid pressure in cylinder is almost depleted, push pipe connector.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold clutch pedal, push pipe connector, and pull snap ring.

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

10) Check clutch pedal for sponginess. If found spongy, repeat entire procedure of bleeding.Clutch Pedal Position (CPP) Switch Removal

and Installation

S7RS0B5306004

Removal

1) Disconnect connector of C PP switch (1) with ignition

switch OFF.

2) Remove CPP switch (1 ) from pedal bracket.

Installation 1) Instal CPP switch to pedal bracket.

2) Adjust switch position re ferring to “Clutch Pedal

Position (CPP) Switch Inspection and Adjustment”.

3) Connect connector to CPP switch securely.

2

1

I4RS0A530004-01

I4RS0A530023-01

1

I6RS0C530001-02

Page 857 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-5

Clutch Pedal Position (CPP) Switch Inspection

and Adjustment

S7RS0B5306005

Inspection

Check for resistance between terminals under each

condition below. If check result is not satisfactory,

replace.

CPP switch resistance

When switch shaft is pushed (1): Continuity

When switch shaft is free (2): No continuityAdjustment

With clutch pedal depressed,

adjust switch (1) position

so that clearance between end of thread and clutch

pedal arm is within specification, and then tighten lock

nut to specified torque.

Clearance between end of thread and clutch pedal

arm

“a”: 3.5 – 4.0 mm (0.14 – 0.16 in.)

Tightening torque

CPP switch lock nut (a): 7.5 N·m (0.75 kgf-m, 5.5 lb-

ft)

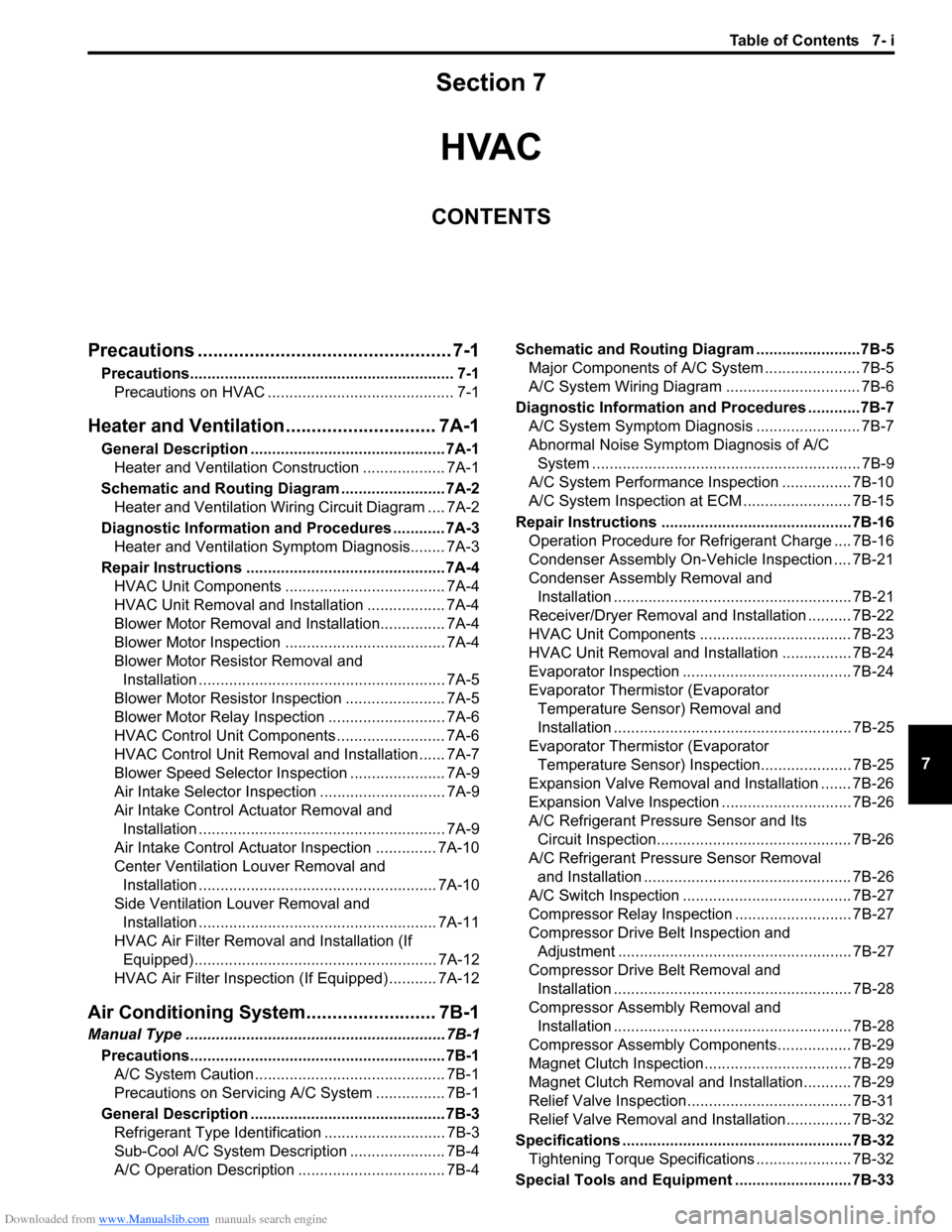

Clutch Fluid Pipe and Hose ComponentsS7RS0B5306006

I5JB0A530006-01

(a)

1

“a”

I6RS0C530002-01

6

1

5

2 5

4(a)

3

I6RS0C530003-01

1. Master cylinder

: Apply grease 99000-25100 to push rod end. 5. Clamp

2. Pipe 6. Clutch reservoir hose

3. Operating cylinder : Apply grease 99000-25100 to rod tip. : 23 N

⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Operating cylinder bolt

Page 933 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 975 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

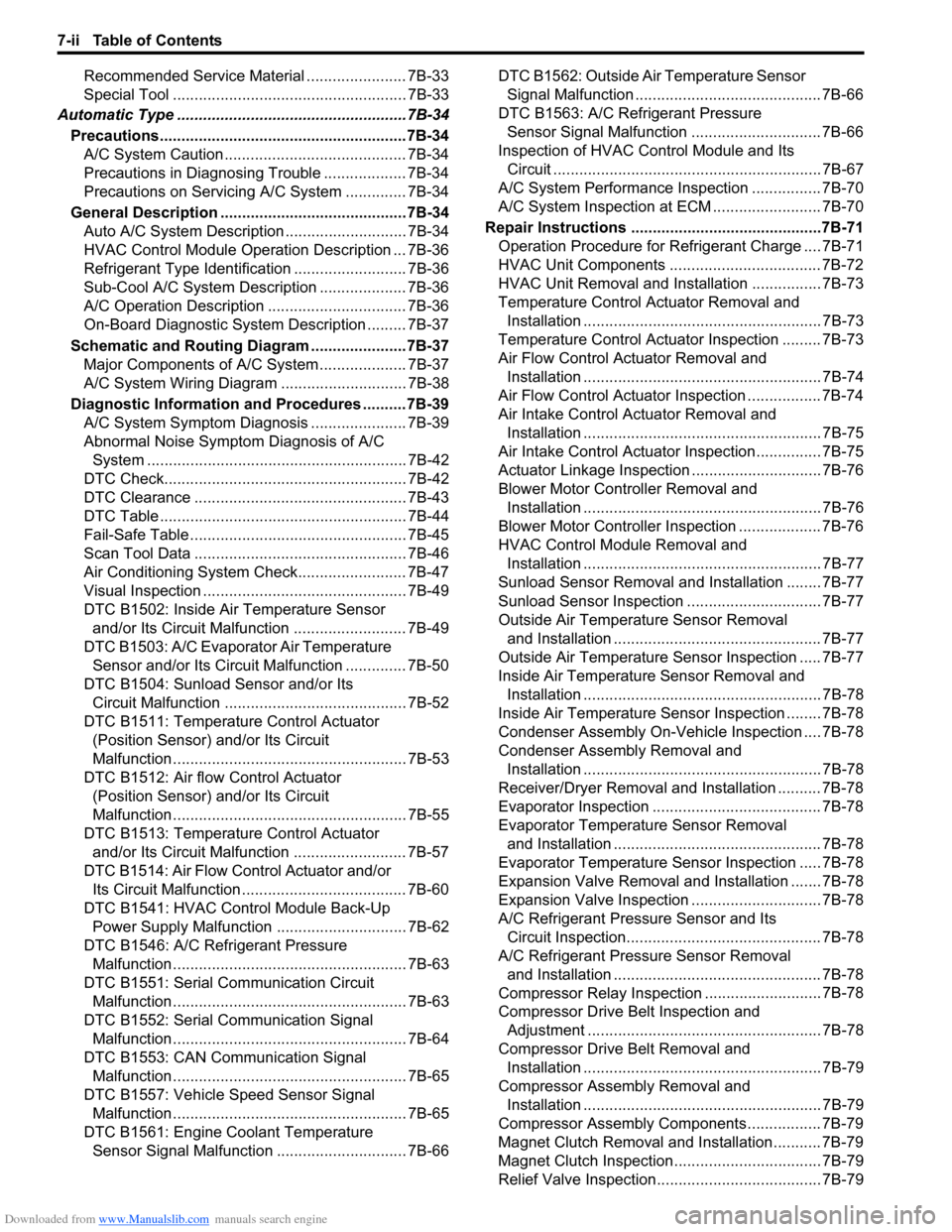

A/C Switch InspectionS7RS0B7216014

• Check that there is continuity between terminal (1) and terminal (2) when A/C s witch is at ON position.

• Check that there is no continuity between terminal (1) and terminal (2) when A/C s witch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

Compressor Relay InspectionS7RS0B7216015

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) from main fuse box.

3) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

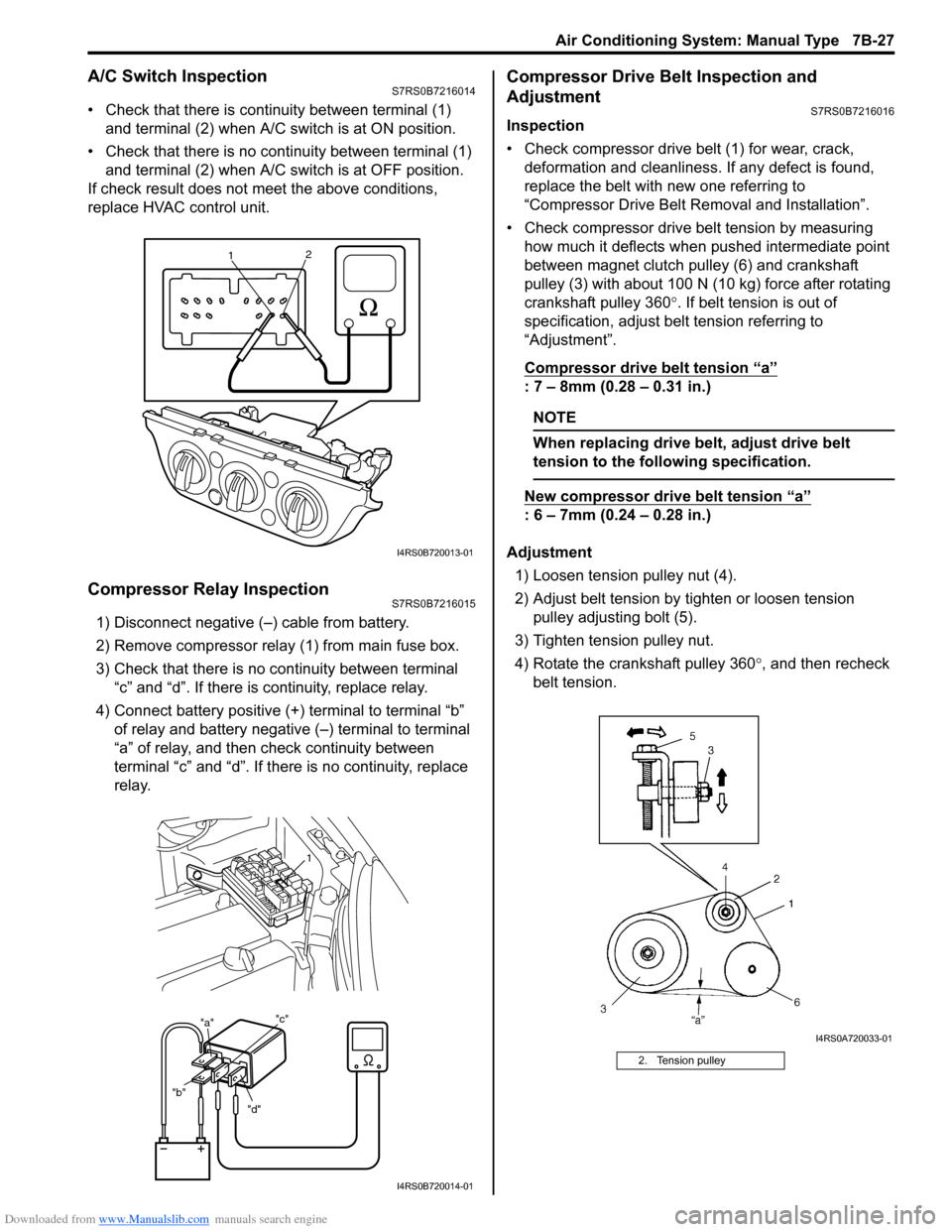

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7216016

Inspection

• Check compressor drive belt (1) for wear, crack, deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Re moval and Installation”.

• Check compressor drive belt tension by measuring how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360 °. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specification.

New compressor dr ive belt tension “a”

: 6 – 7mm (0.24 – 0.28 in.)

Adjustment 1) Loosen tension pulley nut (4).

2) Adjust belt tension by ti ghten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360 °, and then recheck

belt tension.

1 2

I4RS0B720013-01

"d"

"b" "a"

"c"

1

I4RS0B720014-01

2. Tension pulley

I4RS0A720033-01