Clutch plate torque SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 359 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-7

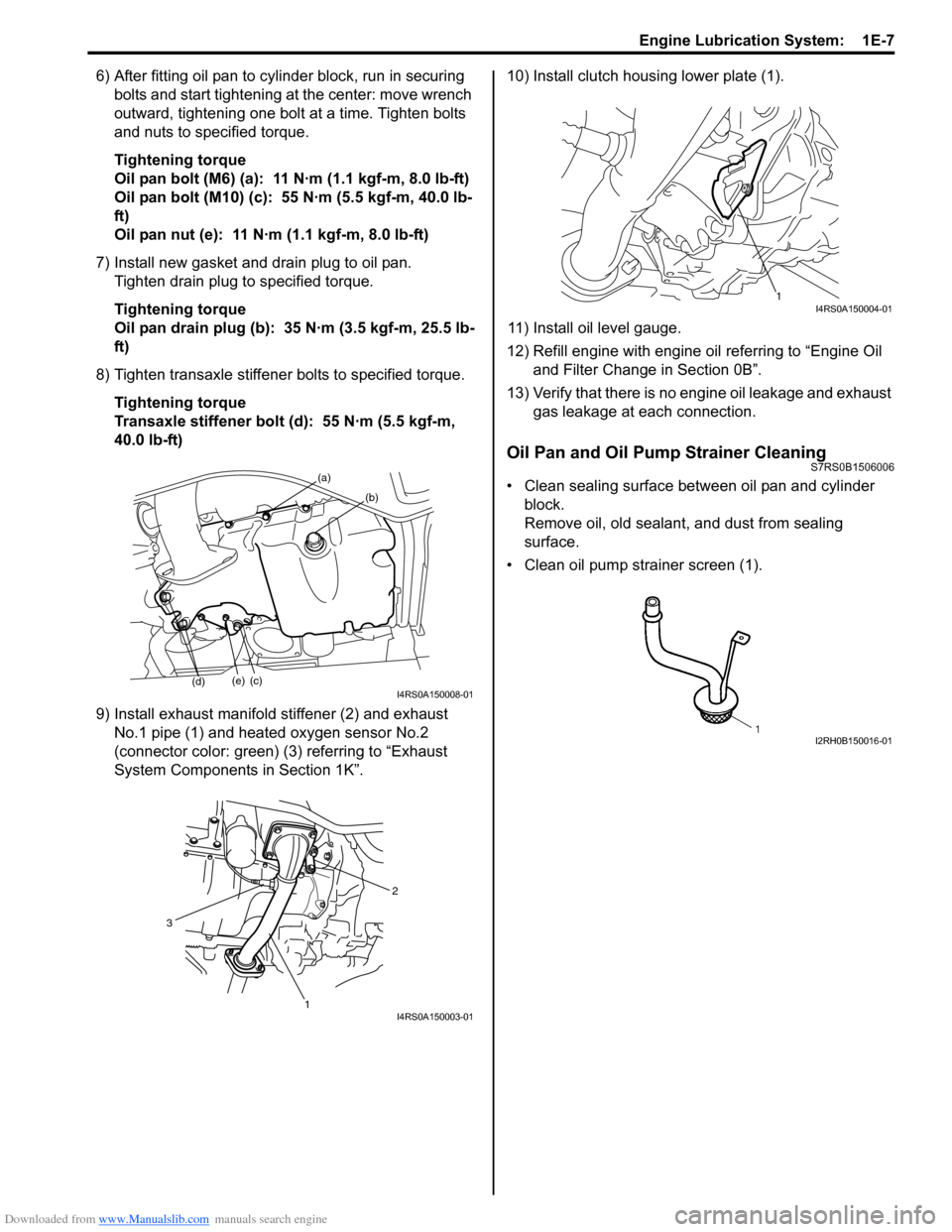

6) After fitting oil pan to cylinder block, run in securing bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) Install new gasket and drain plug to oil pan. Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque. Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)

9) Install exhaust manifold stiffener (2) and exhaust No.1 pipe (1) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 10) Install clutch housing lower plate (1).

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no en gine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS7RS0B1506006

• Clean sealing surface between oil pan and cylinder block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).(a)

(b)

(c)(e)

(d)I4RS0A150008-01

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150016-01

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

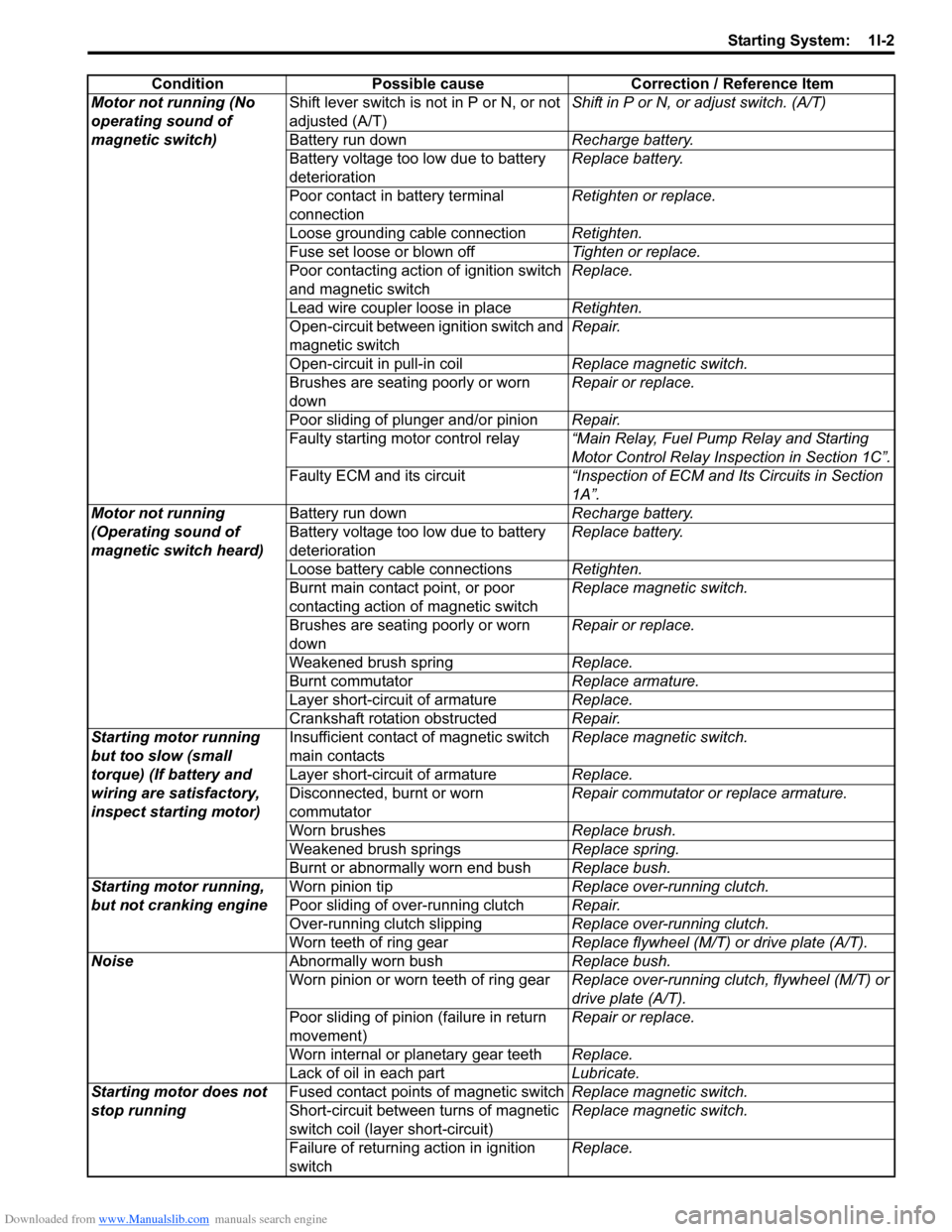

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 646 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-2 Automatic Transmission/Transaxle:

CAUTION!

• Keep component parts in group for each subassembly and avoid mixing them up.

• Clean all parts with cleaning solvent thoroughly and air dry them.

• Use kerosene or automatic transaxle fluid as cleaning solvent.

• Do not use wiping cloths or rags to clean or dry parts.

• All oil passages should be blown out and checked to make sure that they are not

obstructed.

• Keep face and eyes away from solvent spray while air blowing parts.

• Check mating surface for irregularities and remove them, if any, and clean it again.

• Soak new clutch discs and brake discs in transaxle fluid for at least 2 hours before

assembly.

• Replace all gaskets and O-ring with new ones.

• Apply automatic transaxle fluid to all O- rings.

• When installing seal ring, be careful so that it is not expanded excessively, extruded or

caught.

• Replace oil seals that are removed and apply grease to their lips.

• Before installing, be sure to apply automatic transaxle fluid to sliding, rolling

and thrusting surface of all component

part. Also after installation, make sure to

check each part for proper operation.

• Always use torque wrench when tightening bolts.

• A new discs should be soaked in ATF at least 2 hours before use.

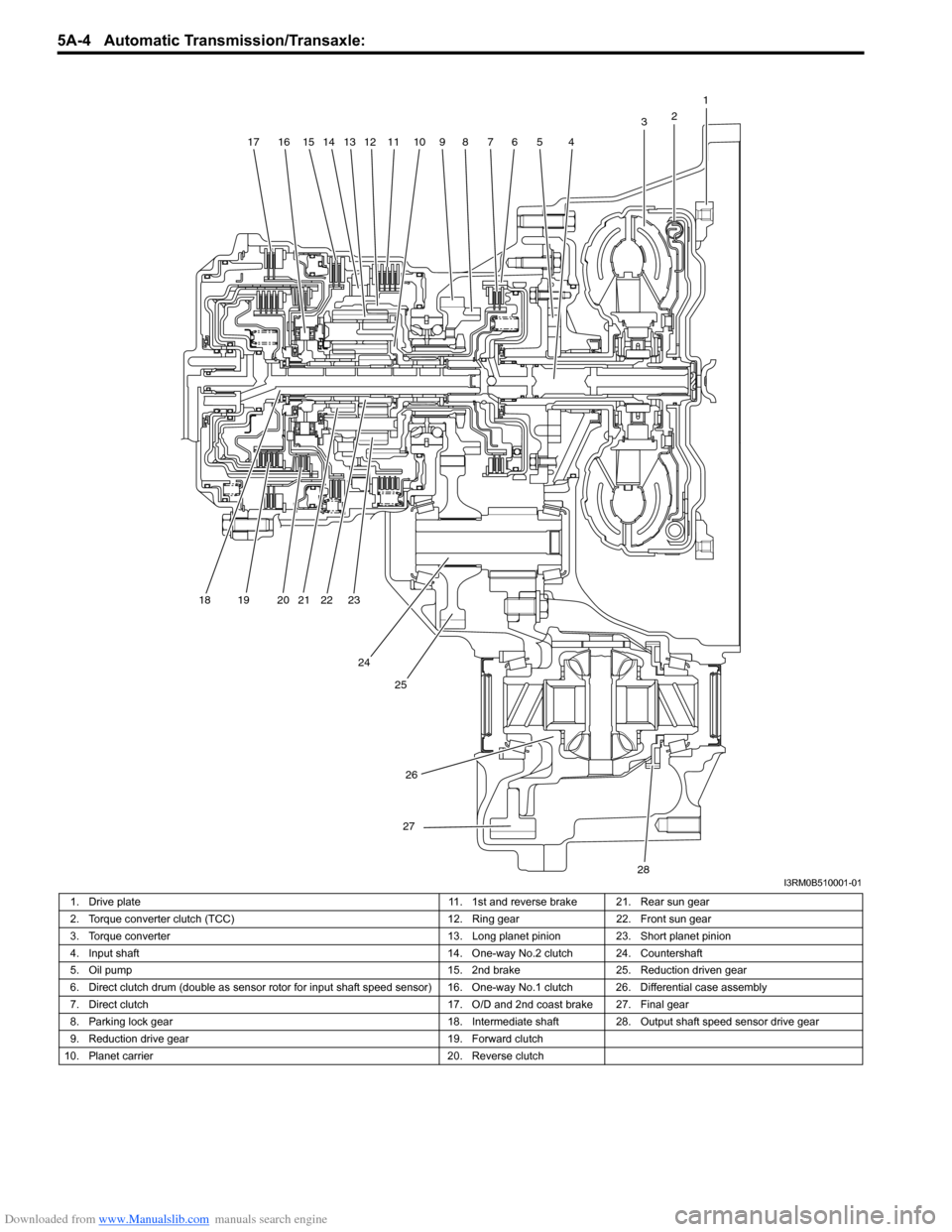

Part Inspection and Correction Table Part Inspect for Correction

Casted part,

machined part Small flaw, burr

Remove with oil

stone.

Deep or grooved

flaw Replace part.

Clogged fluid

passage Clean with air or

wire.

Flaw on installing

surface, residual

gasket Remove with oil

stone or replace

part.

Crack Replace part.

Bearing Unsmooth rotation Replace.

Streak, pitting, flaw,

crack

Replace.

Bushing, thrust

washer Flaw, burr, wear,

burning

Replace.

Oil seal, gasket Flawed or

hardened seal ring

Replace.

Worn seal ring on

its periphery or side Replace.

Piston seal ring, oil

seal, gasket, etc. Replace.

Gear Flaw, burr Replace.

Worn gear tooth Replace.

Splined part Burr, flaw, torsion Correct with oil

stone or replace.

Snap ring Wear, flaw,

distortion

Replace.

No interference Replace.

Thread Burr Replace.

Damage Replace.

Sp rin g Settling, sign of

burning Replace.

Friction plate Wear, burning,

distortion,

damaged claw Replace.

Separator plate,

retaining plate Wear, burning,

distortion,

damaged claw

Replace.

Sealing surface

(where lip

contacts) Flaw, rough

surface, stepped

wear, foreign

material

Replace.

Page 648 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-4 Automatic Transmission/Transaxle:

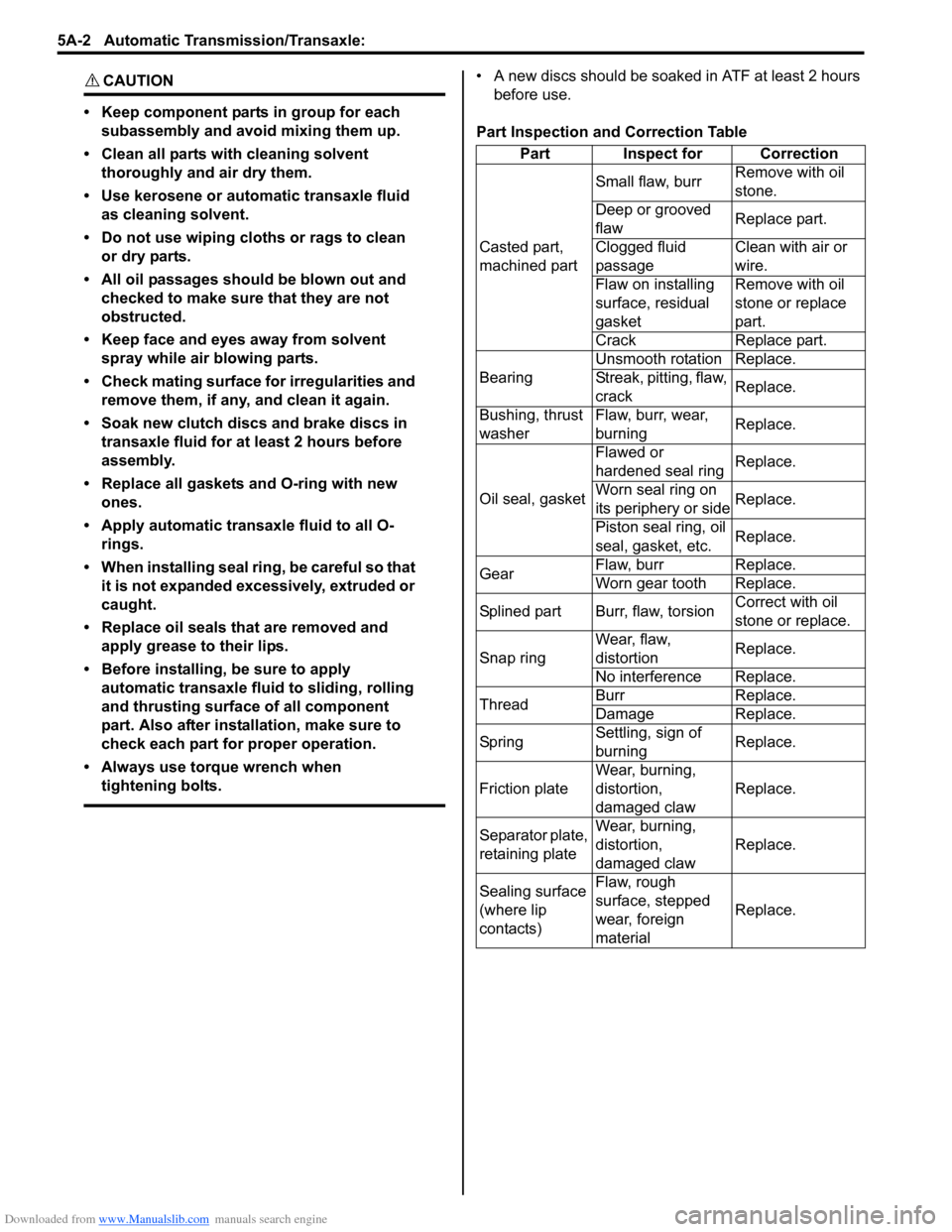

1

2

3

4567891011121314151617

18 19 20 21 22 23

24 25

26

27

28I3RM0B510001-01

1. Drive plate 11. 1st and reverse brake 21. Rear sun gear

2. Torque converter clutch (TCC) 12. Ring gear22. Front sun gear

3. Torque converter 13. Long planet pinion23. Short planet pinion

4. Input shaft 14. One-way No.2 clutch 24. Countershaft

5. Oil pump 15. 2nd brake25. Reduction driven gear

6. Direct clutch drum (double as sensor ro tor for input shaft speed sensor) 16. One-way No.1 clutch 26. Differential case assembly

7. Direct clutch 17. O/D and 2nd coast brake 27. Final gear

8. Parking lock gear 18. Intermediate shaft28.Output shaft speed sensor drive gear

9. Reduction drive gear 19. Forward clutch

10. Planet carrier 20. Reverse clutch

Page 671 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-27

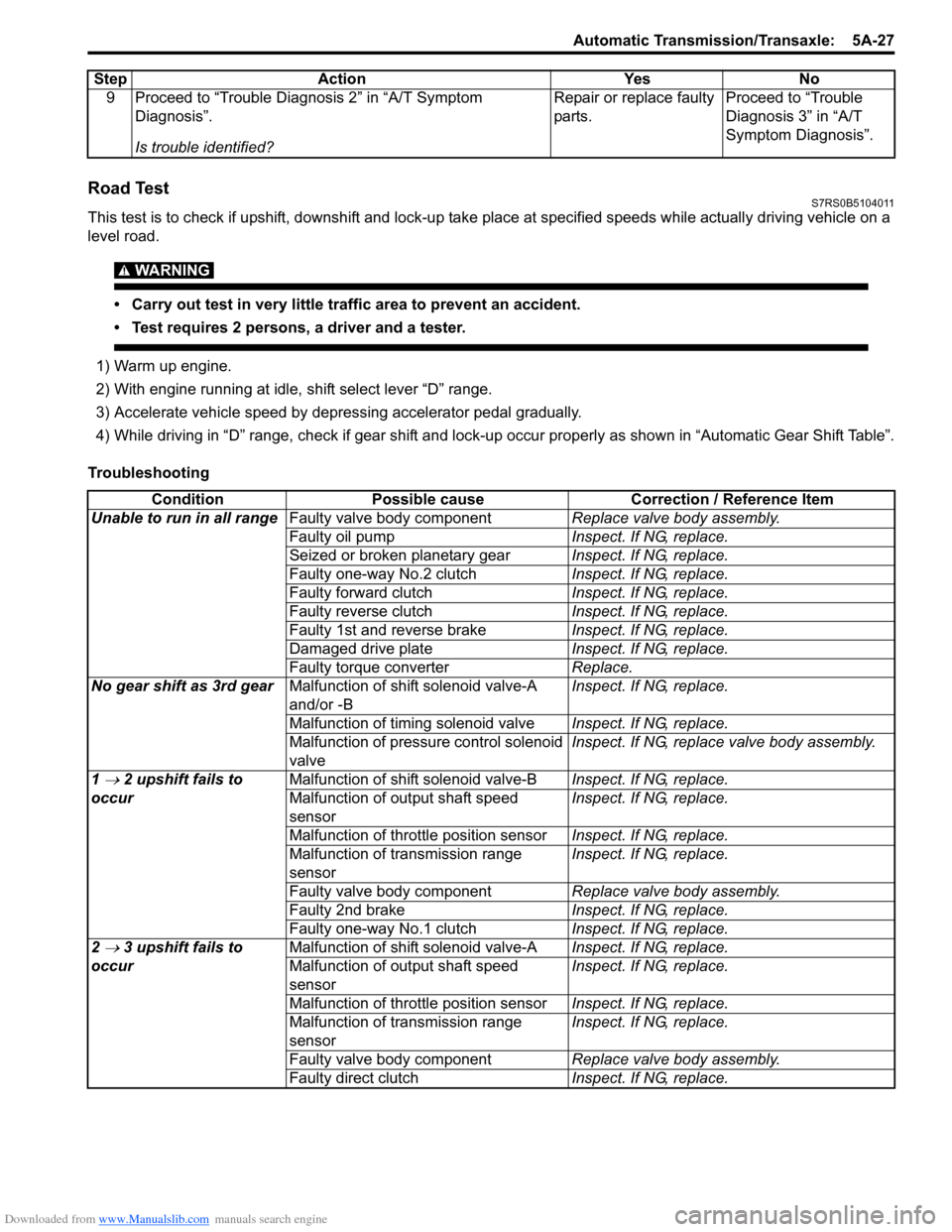

Road TestS7RS0B5104011

This test is to check if upshift, downshift and lock-up take place at specified speeds while actually driving vehicle on a

level road.

WARNING!

• Carry out test in very little traffic area to prevent an accident.

• Test requires 2 persons, a driver and a tester.

1) Warm up engine.

2) With engine running at idle, shift select lever “D” range.

3) Accelerate vehicle speed by depressing accelerator pedal gradually.

4) While driving in “D” range, check if gear shift and lock-up occur properly as shown in “Automatic Gear Shift Table”.

Troubleshooting 9 Proceed to “Trouble Diag

nosis 2” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.

Step Action Yes No

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty valve body component Replace valve body assembly.

Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty torque converter Replace.

No gear shift as 3rd gear Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

1

→ 2 upshift fails to

occur Malfunction of shif

t solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty 2nd brake Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 3 upshift fails to

occur Malfunction of shif

t solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty direct clutch Inspect. If NG, replace.

Page 684 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-40 Automatic Transmission/Transaxle:

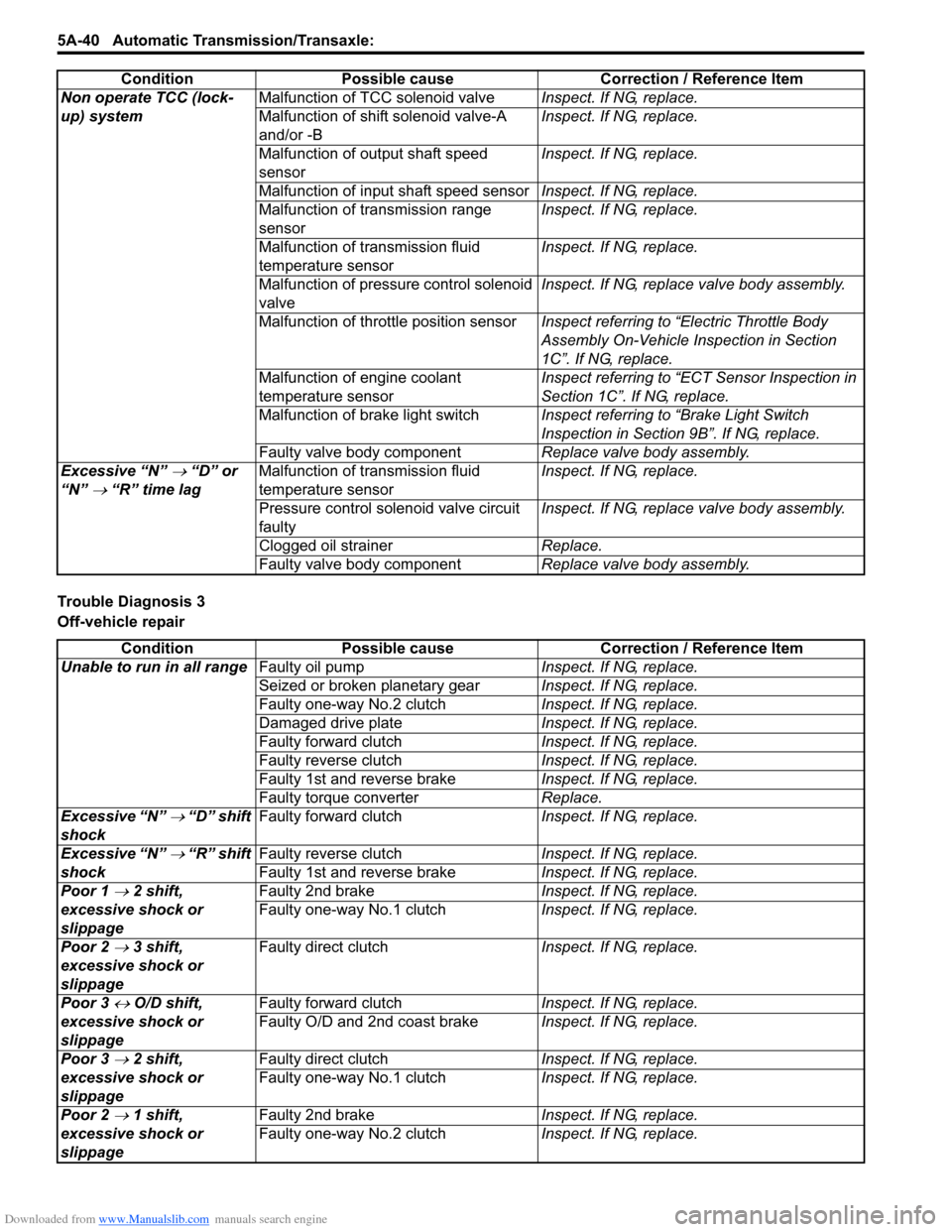

Trouble Diagnosis 3

Off-vehicle repairNon operate TCC (lock-

up) system

Malfunction of TCC solenoid valve

Inspect. If NG, replace.

Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect referring to “ECT Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of brake light switch Inspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Excessive “N”

→ “D” or

“N”

→ “R” time lag Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Pressure control solenoid valve circuit

faulty Inspect. If NG, replace valve body assembly.

Clogged oil strainer Replace.

Faulty valve body component Replace valve body assembly.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Faulty torque converter Replace.

Excessive “N”

→ “D” shift

shock Faulty forward clutch

Inspect. If NG, replace.

Excessive “N”

→ “R” shift

shock Faulty reverse clutch

Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Poor 1

→ 2 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 3 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Poor 3

↔ O/D shift,

excessive shock or

slippage Faulty forward clutch

Inspect. If NG, replace.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Poor 3

→ 2 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 1 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

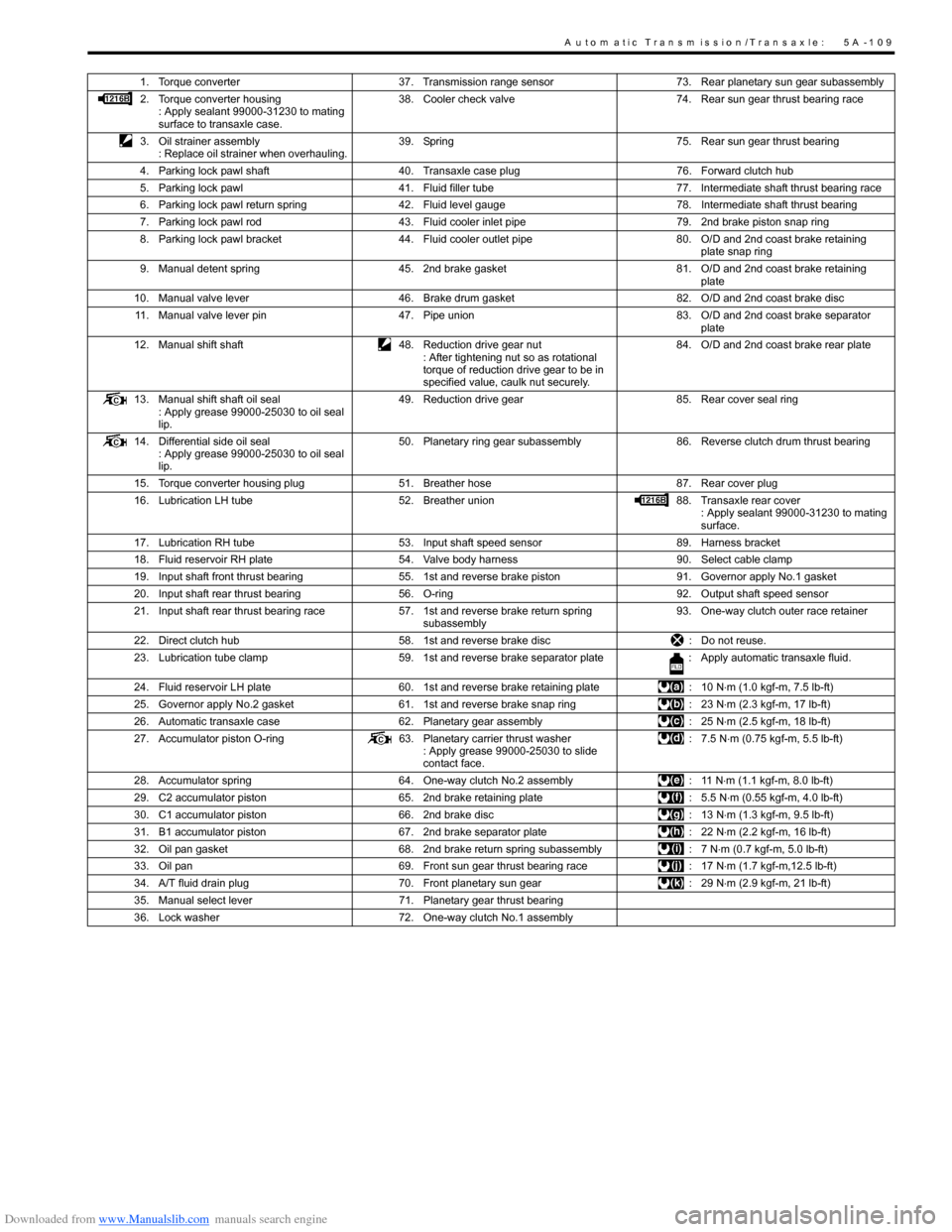

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 803 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-159

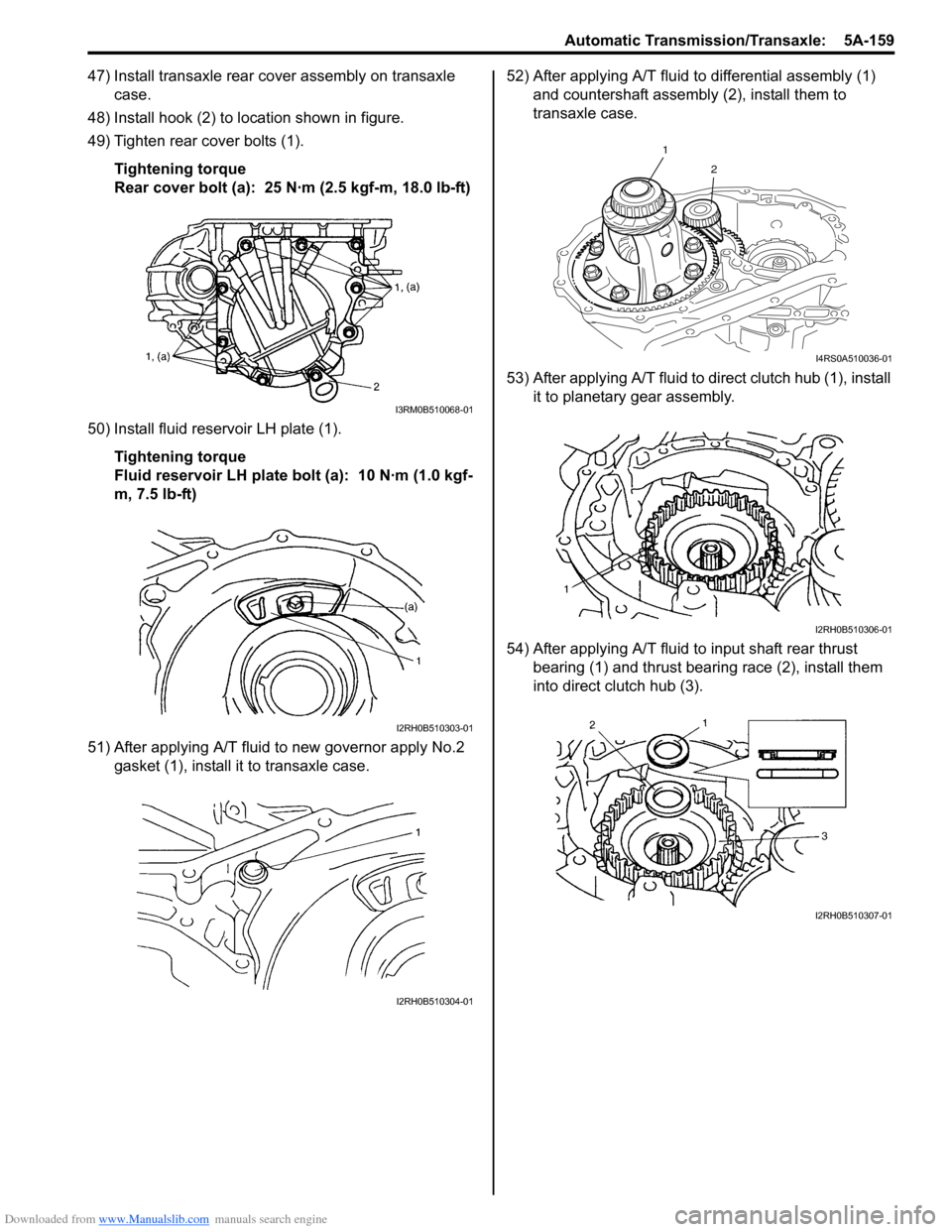

47) Install transaxle rear cover assembly on transaxle case.

48) Install hook (2) to location shown in figure.

49) Tighten rear cover bolts (1).

Tightening torque

Rear cover bolt (a): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

50) Install fluid reservoir LH plate (1). Tightening torque

Fluid reservoir LH plate bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

51) After applying A/T fluid to new governor apply No.2 gasket (1), install it to transaxle case. 52) After applying A/T fluid to differential assembly (1)

and countershaft assembly (2), install them to

transaxle case.

53) After applying A/T fluid to di rect clutch hub (1), install

it to planetary gear assembly.

54) After applying A/T fluid to input shaft rear thrust

bearing (1) and thrust bearing race (2), install them

into direct clutch hub (3).

I3RM0B510068-01

I2RH0B510303-01

I2RH0B510304-01

1

2

I4RS0A510036-01

I2RH0B510306-01

I2RH0B510307-01

Page 817 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

Diagnostic Information and Procedures

Manual Transaxle Symptom DiagnosisS7RS0B5204001

Repair Instructions

Manual Transaxle Oil ChangeS7RS0B5206001

1) Before changing or inspecting oil, be sure to stop engine and lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil. 5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

6) Pour new specified oil unt il oil level reaches bottom

of oil filler plug hole (3) as shown in figure.NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.0 liters (4.2/3.5 US/Imp. pt)

Condition Possible cause Correction / Reference Item

Gears slipping out of

mesh Worn shift fork shaft

Replace.

Worn shift fork or synchronizer sleeve Replace.

Weak or damaged locating springs Replace.

Worn bearings on input shaft or

countershaft Replace.

Worn chamfered tooth on sleeve and

gear Replace sleeve and gear.

Hard shifting Maladjusted gear select control cable Adjust.

Inadequate or insufficient lubricant Replenish.

Improper clutch pedal free travel Replace clutch master cylinder or clutch pedal

arm.

Distorted or broken clutch disc Replace.

Damaged clutch pressure plate Replace clutch cover.

Worn synchronizer ring Replace.

Worn chamfered tooth on sleeve or gear Replace sleeve or gear.

Worn gear shift / select control cables

joint Replace.

Distorted shift shaft Replace.

Worn gear shift / select control cables Replace.

Noise Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn synchronizer parts Replace.

Page 859 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-7

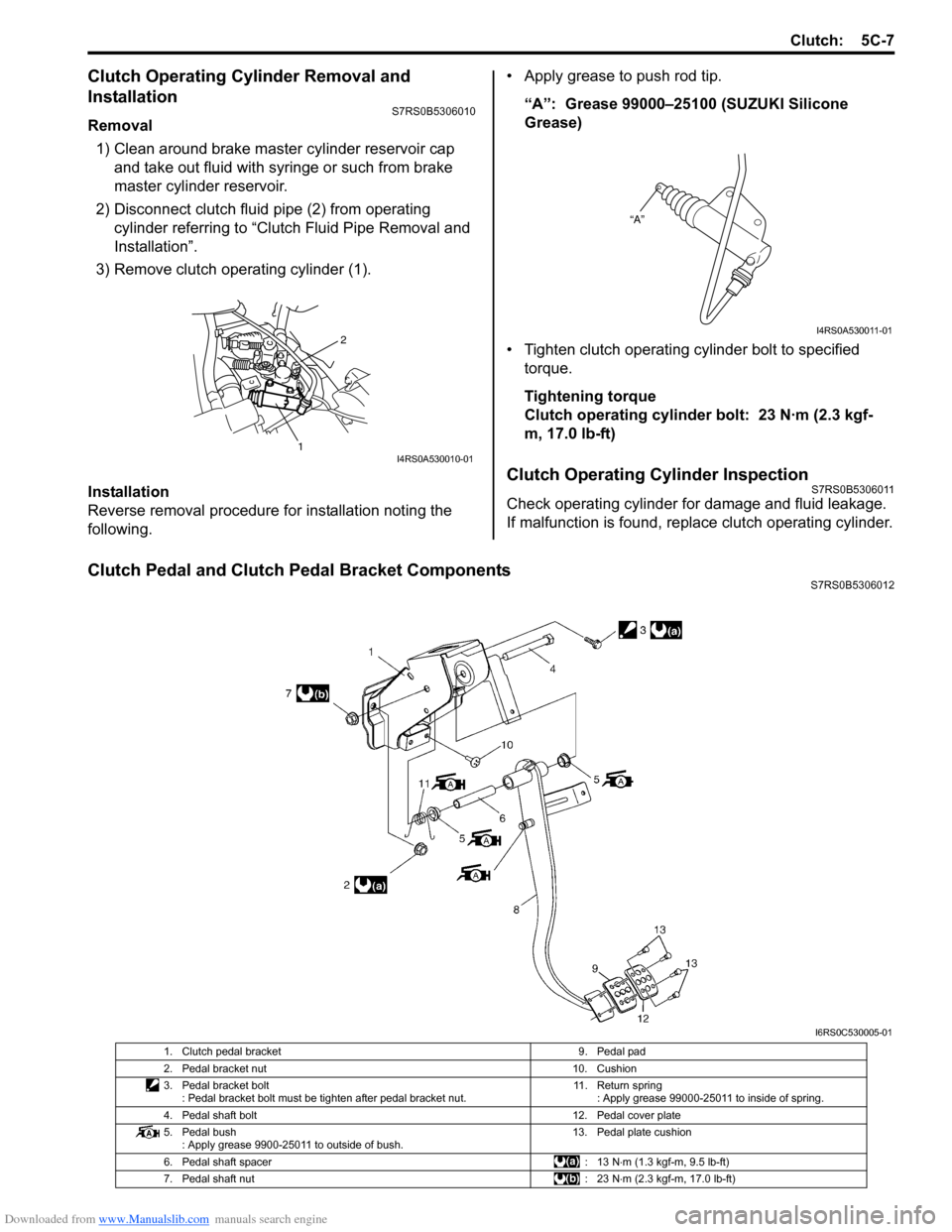

Clutch Operating Cylinder Removal and

Installation

S7RS0B5306010

Removal1) Clean around brake master cylinder reservoir cap and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe (2) from operating cylinder referring to “Clutch Fluid Pipe Removal and

Installation”.

3) Remove clutch operating cylinder (1).

Installation

Reverse removal procedure for installation noting the

following. • Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

• Tighten clutch operating cylinder bolt to specified torque.

Tightening torque

Clutch operating cylinder bolt: 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

Clutch Operating Cylinder InspectionS7RS0B5306011

Check operating cylinder for damage and fluid leakage.

If malfunction is found, repl ace clutch operating cylinder.

Clutch Pedal and Clutch Pedal Bracket ComponentsS7RS0B5306012

2

1I4RS0A530010-01

“A”

I4RS0A530011-01

I6RS0C530005-01

1. Clutch pedal bracket 9. Pedal pad

2. Pedal bracket nut 10. Cushion

3. Pedal bracket bolt : Pedal bracket bolt must be tighten after pedal bracket nut. 11. Return spring

: Apply grease 99000-25011 to inside of spring.

4. Pedal shaft bolt 12. Pedal cover plate

5. Pedal bush : Apply grease 9900-25011 to outside of bush. 13. Pedal plate cushion

6. Pedal shaft spacer : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

7. Pedal shaft nut : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)