Clutch release lever SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 42 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-12 Maintenance and Lubrication:

HVAC Air Filter (If Equipped) InspectionS7RS0B0206032

1) Remove HVAC air filter from HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

2) Check for dirt and dust. If HVAC air filter is excessively dirty, replace HVAC air filter with new

one. If not, go to next step.

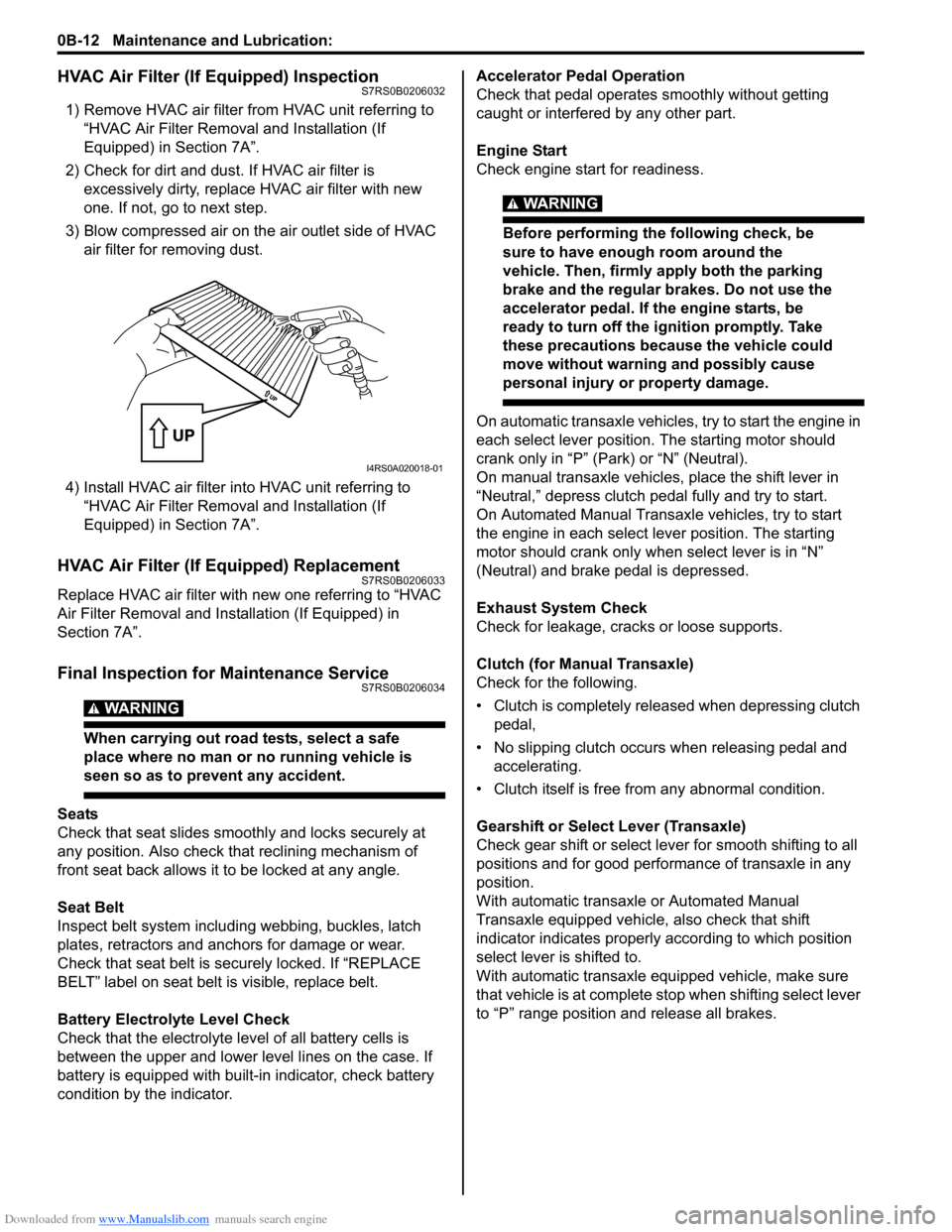

3) Blow compressed air on the air outlet side of HVAC air filter for removing dust.

4) Install HVAC air filter in to HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

HVAC Air Filter (If Equipped) ReplacementS7RS0B0206033

Replace HVAC air filter with new one referring to “HVAC

Air Filter Removal and Installation (If Equipped) in

Section 7A”.

Final Inspection for Maintenance ServiceS7RS0B0206034

WARNING!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoot hly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE

BELT” label on seat belt is visible, replace belt.

Battery Electrolyte Level Check

Check that the electrolyte le vel of all battery cells is

between the upper and lower level lines on the case. If

battery is equipped with built-in indicator, check battery

condition by the indicator. Accelerator Pedal Operation

Check that pedal operates

smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING!

Before performing th e following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On automatic transaxle vehicles, try to start the engine in

each select lever position. The starting motor should

crank only in “P” (Park) or “N” (Neutral).

On manual transaxle vehicles, place the shift lever in

“Neutral,” depress clutch pedal fully and try to start.

On Automated Manual Transaxl e vehicles, try to start

the engine in each select le ver position. The starting

motor should crank only when select lever is in “N”

(Neutral) and brake pedal is depressed.

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transaxle)

Check for the following.

• Clutch is completely released when depressing clutch pedal,

• No slipping clutch occurs when releasing pedal and accelerating.

• Clutch itself is free fr om any abnormal condition.

Gearshift or Select Lever (Transaxle)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transaxle in any

position.

With automatic transaxle or Automated Manual

Transaxle equipped vehicle, also check that shift

indicator indicates properly according to which position

select lever is shifted to.

With automatic transaxle equipped vehicle, make sure

that vehicle is at complete stop when shifting select lever

to “P” range position and release all brakes.

I4RS0A020018-01

Page 643 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Gear Shift Control Lever and Cable Components...................................................... 5B-5

Gear Shift Control Le ver and Cable Removal

and Installation .................................................. 5B-6

Gear Select Control Cable Adjustment ............... 5B-6

Back Up Light Switch Removal and Installation ......................................................... 5B-7

Back Up Light Switch Inspection ......................... 5B-7

Manual Transaxle Unit Components ................... 5B-8

Manual Transaxle Unit Dismounting and Remounting....................................................... 5B-9

Gear Shift and Sele ct Shaft Assembly

Components.................................................... 5B-11

Gear Shift and Sele ct Shaft Assembly

Removal and Installation................................. 5B-11

Gear Shift and Select Shaft Disassembly and Assembly ........................................................ 5B-12

Manual Transaxle Assembly Components........ 5B-13

Fifth Gear Disassembly and Assembly ............. 5B-14

Manual Transaxle Assembly Disassembly and Reassembly ............................................. 5B-16

Transaxle Right Case Disassembly and Assembly ........................................................ 5B-23

Transaxle Left Case Disassembly and Assembly ........................................................ 5B-24

Input Shaft and Countershaft Components....... 5B-25

Input Shaft Assembly Disassembly and Reassembly .................................................... 5B-26

Countershaft Assembly Disassembly and Reassembly .................................................... 5B-28

Synchronizer Parts Inspec tion .......................... 5B-31

Gear Shift Shaft Components ........................... 5B-31

5th and Reverse Gear Shift Shafts Disassembly and Assembly ............................ 5B-32

Gear Shift Shaft and Fork Inspection ................ 5B-32

Differential Components ................................... 5B-33

Differential Disassembly and Assembly ............ 5B-33

Specifications ..................................................... 5B-35

Tightening Torque Specifications ...................... 5B-35

Special Tools and Equipmen t ........................... 5B-36

Recommended Service Material ....................... 5B-36 Special Tool ...................................................... 5B-36

Clutch ................

.............................. ......... 5C-1

General Description .............................................5C-1

Clutch Construction .............................................5C-1

Diagnostic Information and Procedures ............5C-2 Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ........... ...................................5C-2

Clutch Pedal Inspection ......................................5C-2

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Pedal Position (CPP) Switch Removal and Installation ..................................................5C-4

Clutch Pedal Position (CPP) Switch Inspection and Adjustment ................................5C-5

Clutch Fluid Pipe and Hose Components ...........5C-5

Clutch Fluid Pipe Removal and Installation.........5C-6

Clutch Fluid Pipe Inspection................................5C-6

Clutch Master Cylinder Removal and Installation .........................................................5C-6

Clutch Operating Cylinder Removal and Installation .........................................................5C-7

Clutch Operating Cylinder Inspection..................5C-7

Clutch Pedal and Clutch Pedal Bracket Components ......................................................5C-7

Clutch Cover, Clutch Disc and Flywheel Components ......................................................5C-8

Clutch Cover, Clutch Disc and Flywheel Removal and Installation ...................................5C-8

Clutch Cover, Clutch Disc and Flywheel Inspection ........................................................5C-10

Clutch Release Syst em Removal and

Installation .......................................................5C-11

Clutch Release System Inspection ...................5C-13

Specifications .................... .................................5C-13

Tightening Torque Specifications ......................5C-13

Special Tools and Equipmen t ...........................5C-14

Recommended Service Material .......................5C-14

Special Tool ......................................................5C-14

Page 674 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-30 Automatic Transmission/Transaxle:

Troubleshooting

Engine Brake TestS7RS0B5104013

WARNING!

Before test, make sure that there is no vehicle behind so as to prevent rear-end collision.

1) While driving vehicle in 3rd gear of “D” range, shift select lever down to “2” range and check if engine brake

operates.

2) In the same way as in Step 1), check engine brake for operation when select lever is shifted down to “L” range.

3) Engine brake should operate in the test.

Troubleshooting

Stall TestS7RS0B5104014

This test is to check overall performance of automatic tr ansaxle and engine by measuring stall speed at “D” and “R”

ranges. Be sure to perform this test only when transaxle fluid is at normal operating temperature and its level is

between FULL and LOW marks.

CAUTION!

• Do not run engine at stall more than 5 seconds continuously, or fluid temperature may rise excessively high.

• After performing stall test, be su re to leave engine running at idle for longer than 1 minute before

another stall test.

1) Apply parking brake and block wheels.

2) Install tachometer.

3) Start engine with select lever shifted to “P” range.

4) Depress brake pedal fully.

5) Shift select lever to “D” range and depress accelerator pedal fully while watching tachometer. Read engine rpm quickly when it has become constant (stall speed).

6) Release accelerator pedal immediately after stall speed is checked.

7) In the same way, check stall speed in “R” range.

8) Stall speed should be withi n the following specification.

Engine stall speed

Standard: 2100 – 2400 rpm Condition Possible cause Correction / Reference Item

Operated gear is not

correct Faulty valve body component

Replace valve body assembly.

Faulty clutch or brake Inspect clutch and brake. If any parts are faulty,

replace them.

Condition Possible cause Correction / Reference Item

Failure to operate when

shifted down to “2” range Faulty valve body component

Replace valve body assembly.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Failure to operate when

shifted down to “L” range Faulty valve body component

Replace valve body assembly.

Faulty 1st and reverse brake Inspect. If NG, replace.

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

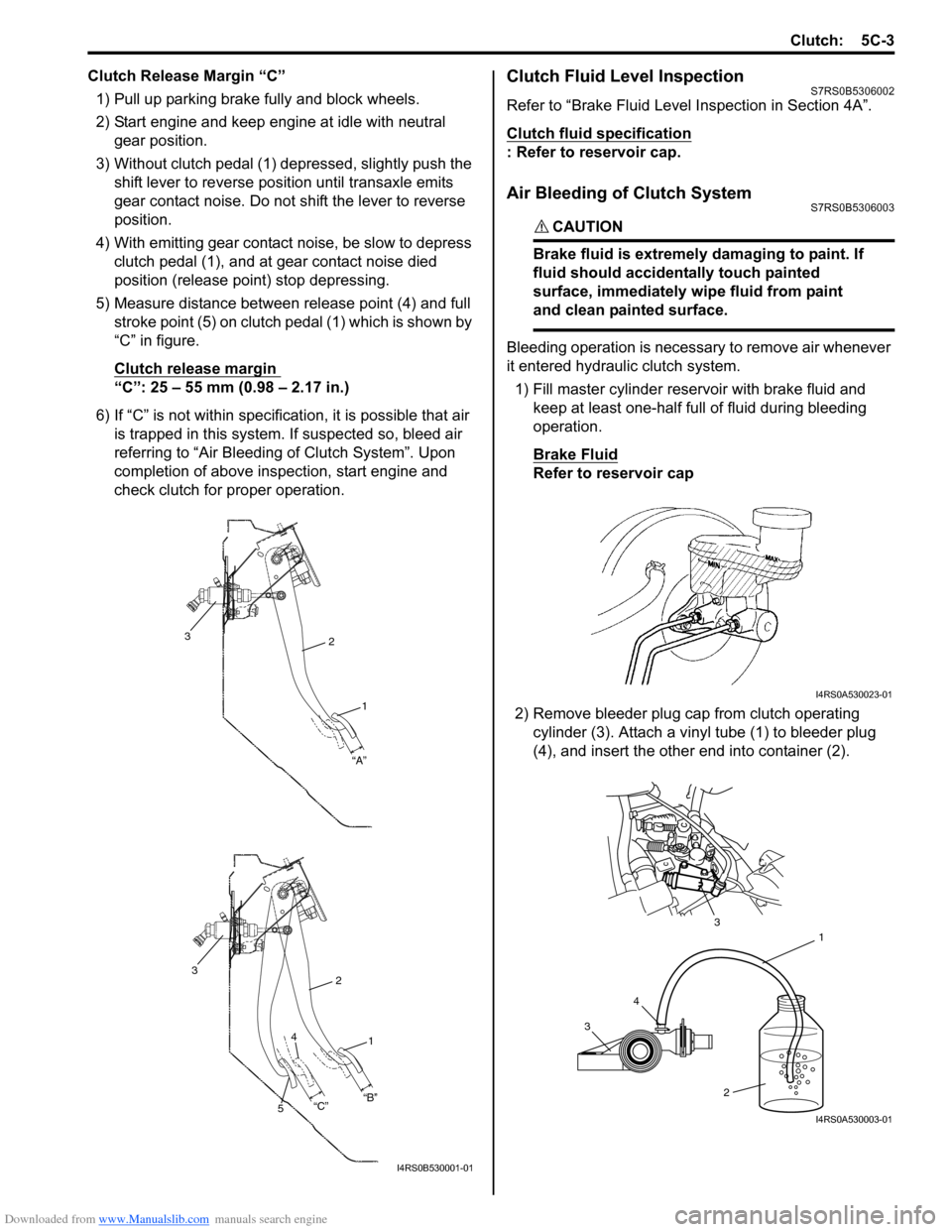

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 864 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-12 Clutch:

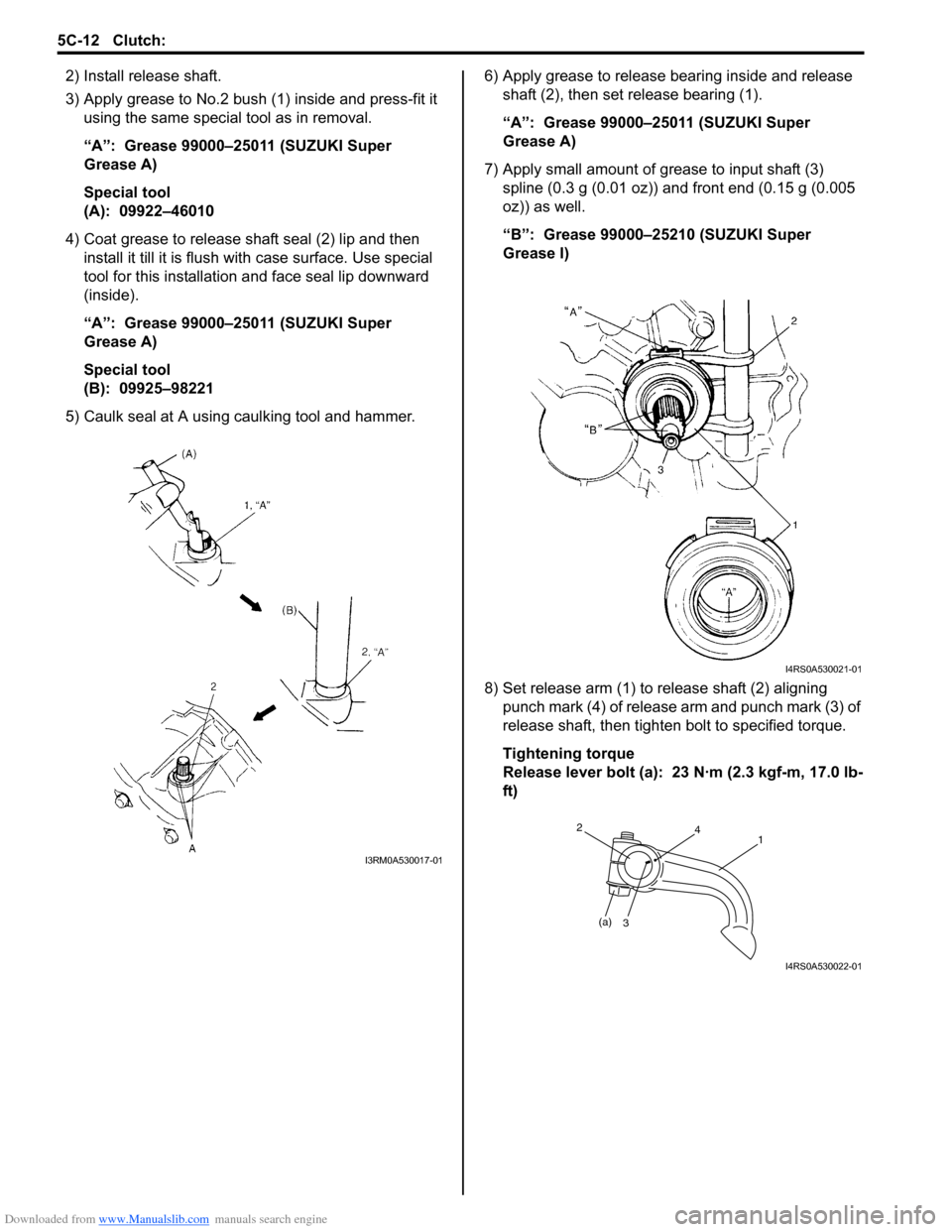

2) Install release shaft.

3) Apply grease to No.2 bush (1) inside and press-fit it using the same special tool as in removal.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(A): 09922–46010

4) Coat grease to release shaft seal (2) lip and then install it till it is flush wit h case surface. Use special

tool for this installation a nd face seal lip downward

(inside).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(B): 09925–98221

5) Caulk seal at A using caulking tool and hammer. 6) Apply grease to release bearing inside and release

shaft (2), then set release bearing (1).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

7) Apply small amount of grease to input shaft (3) spline (0.3 g (0.01 oz)) and front end (0.15 g (0.005

oz)) as well.

“B”: Grease 99000–25210 (SUZUKI Super

Grease I)

8) Set release arm (1) to release shaft (2) aligning punch mark (4) of release arm and punch mark (3) of

release shaft, then tighten bolt to specified torque.

Tightening torque

Release lever bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

I3RM0A530017-01

I4RS0A530021-01

(a)3

241

I4RS0A530022-01

Page 865 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-13

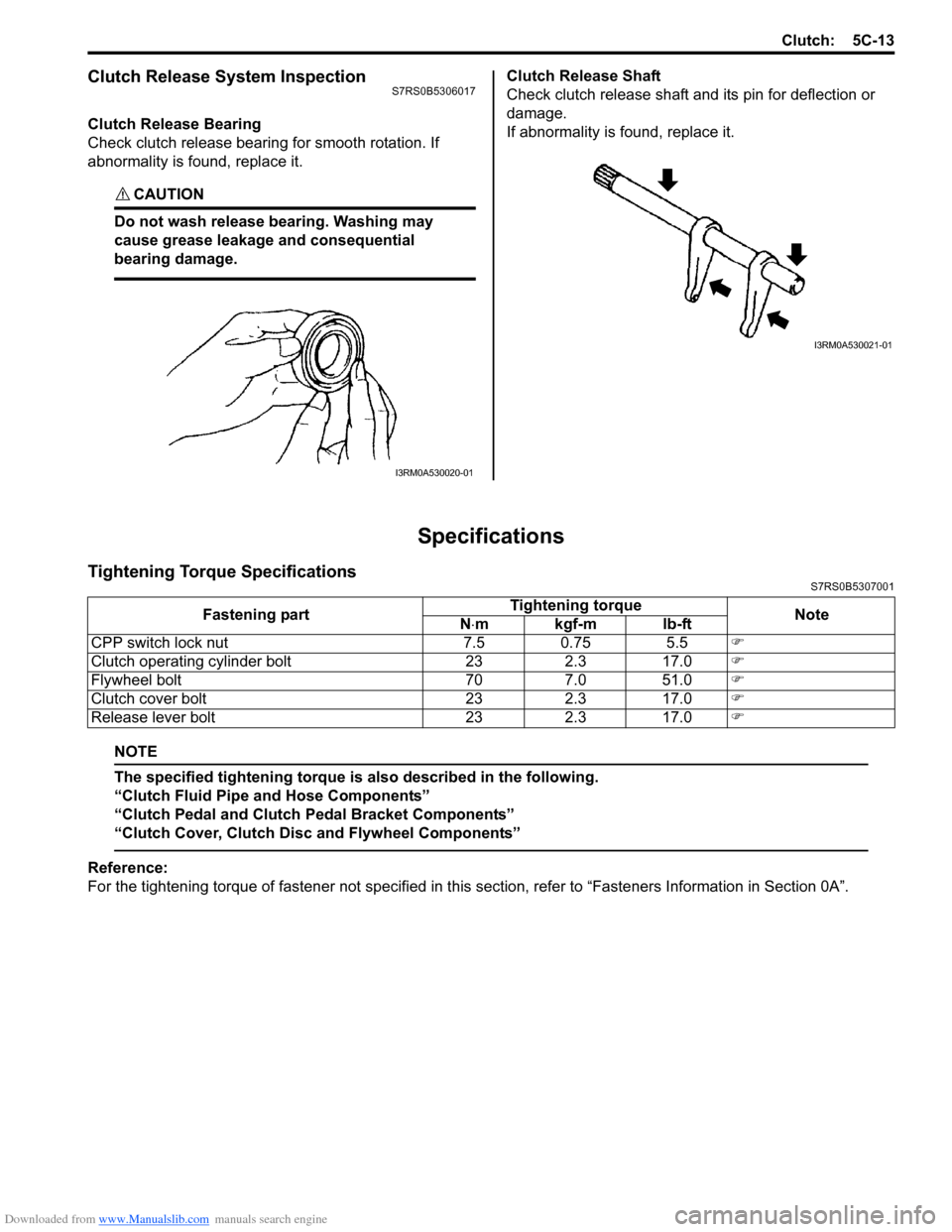

Clutch Release System InspectionS7RS0B5306017

Clutch Release Bearing

Check clutch release bearing for smooth rotation. If

abnormality is found, replace it.

CAUTION!

Do not wash release bearing. Washing may

cause grease leakage and consequential

bearing damage.

Clutch Release Shaft

Check clutch release shaft and its pin for deflection or

damage.

If abnormality is found, replace it.

Specifications

Tightening Torque SpecificationsS7RS0B5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Fluid Pipe and Hose Components”

“Clutch Pedal and Clutch Pedal Bracket Components”

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I3RM0A530020-01

I3RM0A530021-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

CPP switch lock nut 7.5 0.75 5.5 �)

Clutch operating cylinder bolt 23 2.3 17.0 �)

Flywheel bolt 70 7.0 51.0 �)

Clutch cover bolt 23 2.3 17.0 �)

Release lever bolt 23 2.3 17.0 �)