Combination meter engine speed SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 55 of 1496

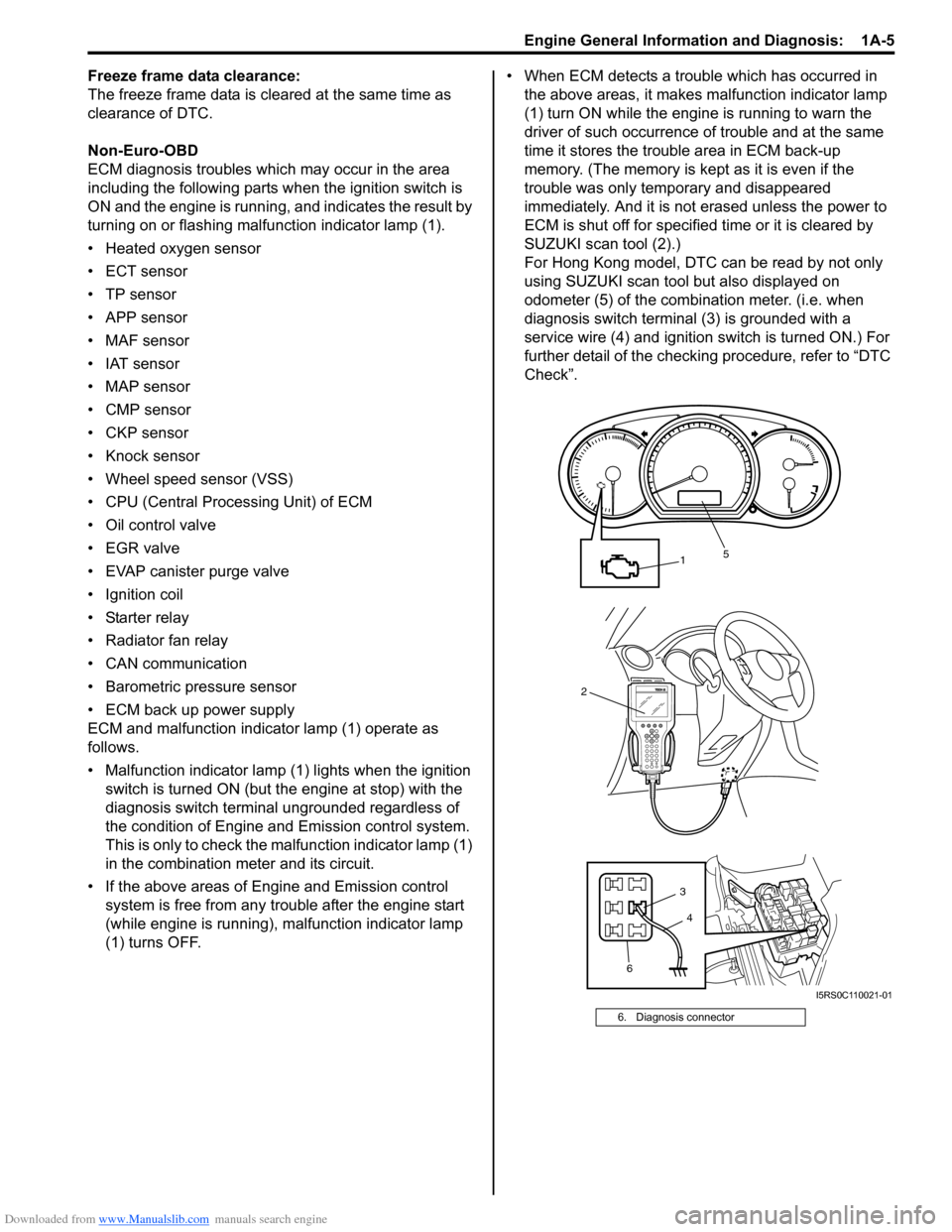

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-5

Freeze frame data clearance:

The freeze frame data is cleared at the same time as

clearance of DTC.

Non-Euro-OBD

ECM diagnosis troubles which may occur in the area

including the following parts w hen the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• Heated oxygen sensor

• ECT sensor

•TP sensor

• APP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor (VSS)

• CPU (Central Processing Unit) of ECM

• Oil control valve

• EGR valve

• EVAP canister purge valve

• Ignition coil

• Starter relay

• Radiator fan relay

• CAN communication

• Barometric pressure sensor

• ECM back up power supply

ECM and malfunction indicator lamp (1) operate as

follows.

• Malfunction indicator lamp (1) lights when the ignition switch is turned ON (but t he engine at stop) with the

diagnosis switch terminal ungrounded regardless of

the condition of Engine and Emission control system.

This is only to check the ma lfunction indicator lamp (1)

in the combination meter and its circuit.

• If the above areas of Engine and Emission control system is free from any trouble after the engine start

(while engine is running), malfunction indicator lamp

(1) turns OFF. • When ECM detects a trouble which has occurred in

the above areas, it makes malfunction indicator lamp

(1) turn ON while the engi ne is running to warn the

driver of such occurrence of trouble and at the same

time it stores the trouble area in ECM back-up

memory. (The memory is kept as it is even if the

trouble was only temporary and disappeared

immediately. And it is not erased unless the power to

ECM is shut off for specified time or it is cleared by

SUZUKI scan tool (2).)

For Hong Kong model, DTC can be read by not only

using SUZUKI scan tool but also displayed on

odometer (5) of the combination meter. (i.e. when

diagnosis switch terminal (3) is grounded with a

service wire (4) and ignition switch is turned ON.) For

further detail of the checking procedure, refer to “DTC

Check”.

6. Diagnosis connector

2

1

6 3

5

4

I5RS0C110021-01

Page 58 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-8 Engine General Information and Diagnosis:

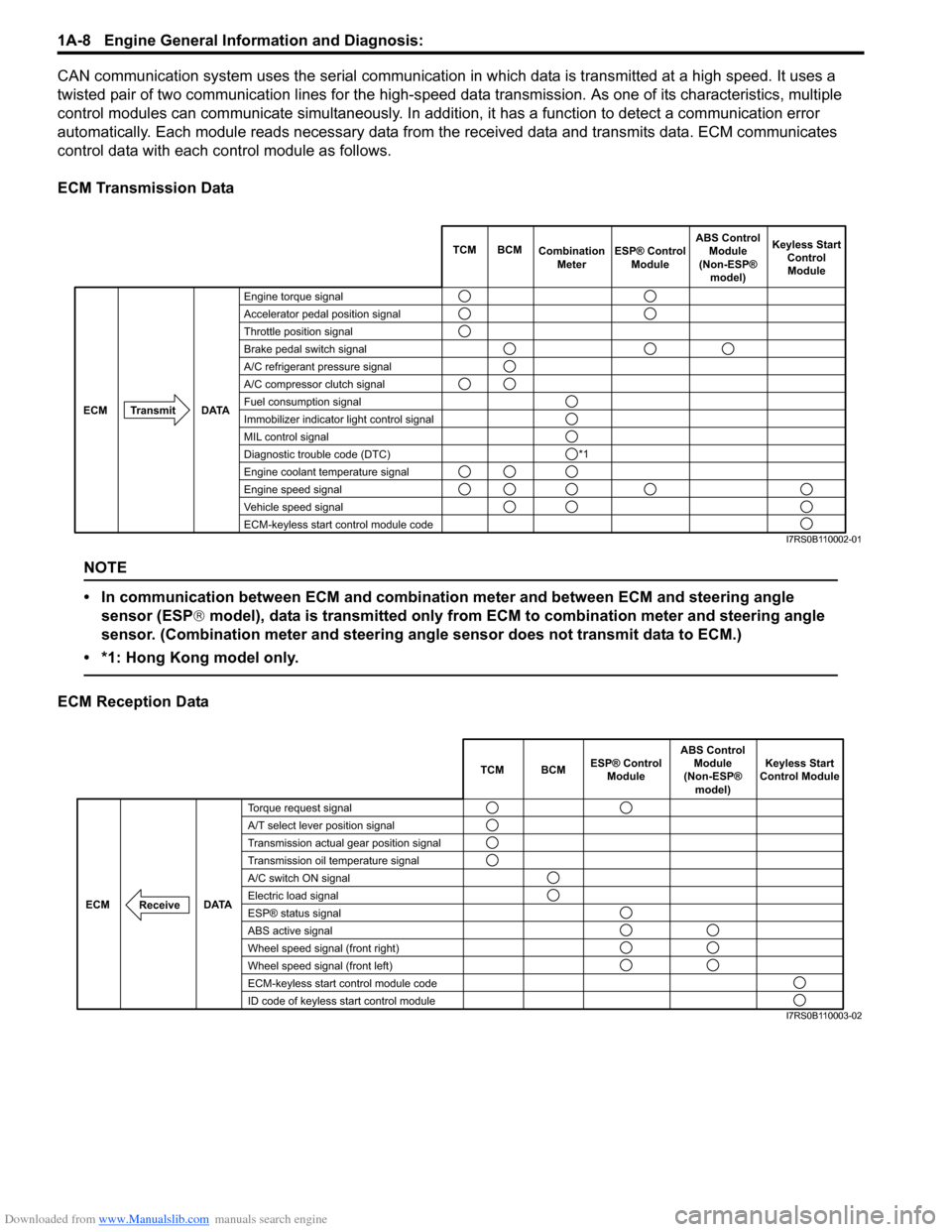

CAN communication system uses the serial communication in which data is transmitted at a high speed. It uses a

twisted pair of two communication lines for the high-speed da ta transmission. As one of its characteristics, multiple

control modules can communicate simultaneously. In addition, it has a function to detect a communication error

automatically. Each module reads necessary data from the received data and transmits data. ECM communicates

control data with each control module as follows.

ECM Transmission Data

NOTE

• In communication between ECM and combination meter and between ECM and steering angle sensor (ESP ® model), data is transmitted only from ECM to combination meter and steering angle

sensor. (Combination meter and steering angle sensor does not transmit data to ECM.)

• *1: Hong Kong model only.

ECM Reception Data

Engine torque signal

Accelerator pedal position signal

Throttle position signal

Brake pedal switch signal

A/C refrigerant pressure signal

A/C compressor clutch signal

Fuel consumption signal

Immobilizer indicator light control signal

MIL control signal

Diagnostic trouble code (DTC)

Engine coolant temperature signal

Engine speed signal

Vehicle speed signal

ECM-keyless start control module code TCM BCM

Combination

Meter Keyless Start

ControlModule

Transmit DATA

ECM

ESP® Control

Module ABS Control

Module

(Non-ESP® model)

*1

I7RS0B110002-01

TCM BCM Keyless Start

Control Module

DATA

ECM

Torque request signal

A/T select lever position signal

Transmission actual gear position signal

Transmission oil temperature signal

A/C switch ON signal

Electric load signal

ESP® status signal

ABS active signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ECM-keyless start control module code

ID code of keyless start control module

Receive

ABS Control

Module

(Non-ESP® model)

ESP® Control

Module

I7RS0B110003-02

Page 61 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-11

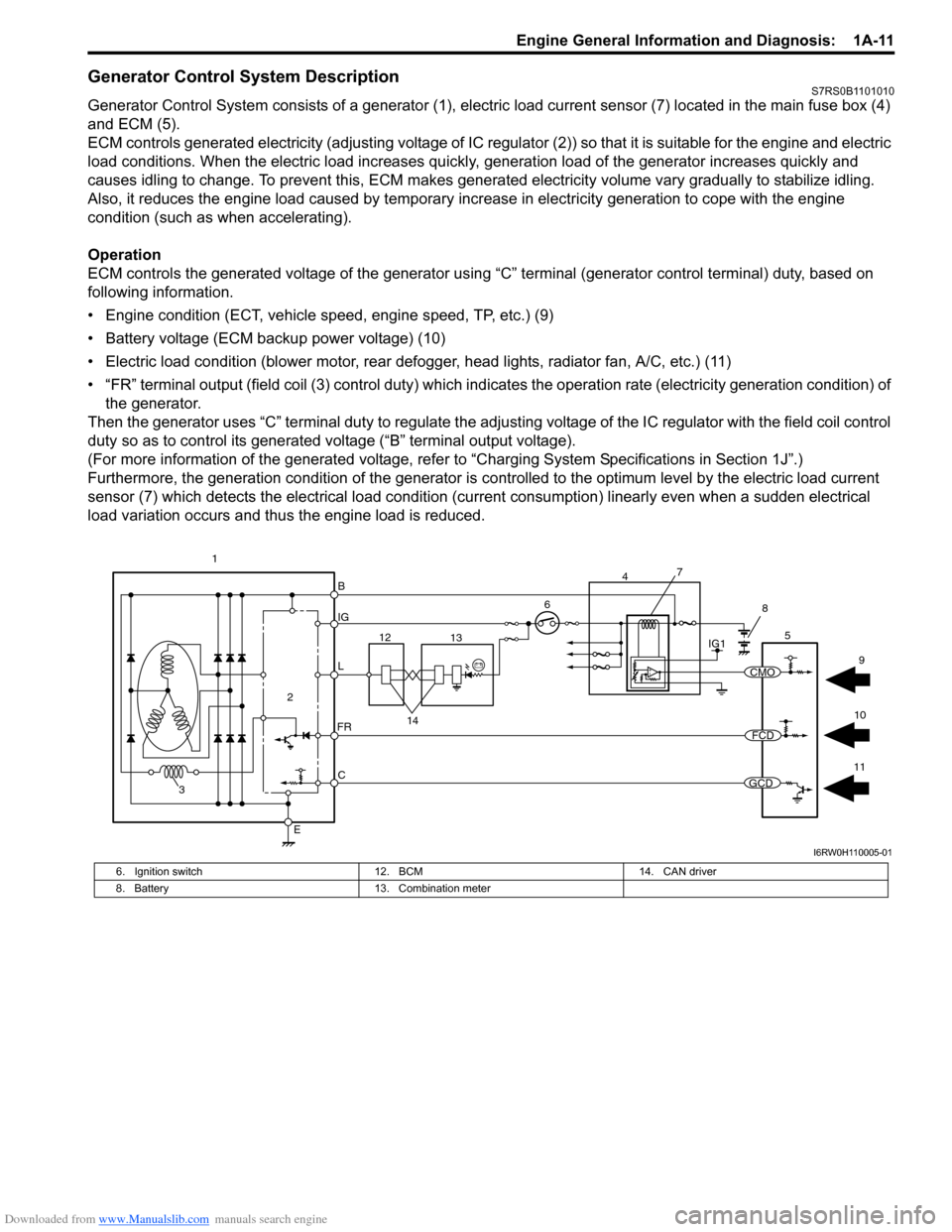

Generator Control System DescriptionS7RS0B1101010

Generator Control System consists of a generator (1), electric load current sensor (7) located in the main fuse box (4)

and ECM (5).

ECM controls generated electricity (adjusting voltage of IC regulator (2)) so that it is suitable for the engine and electric

load conditions. When the electric load increases quickly, generation load of the generator increases quickly and

causes idling to change. To prevent this, ECM makes generated electricity volume vary gradually to stabilize idling.

Also, it reduces the engine load caused by temporary incr ease in electricity generation to cope with the engine

condition (such as when accelerating).

Operation

ECM controls the generated voltage of the generator using “C” terminal (generator control terminal) duty, based on

following information.

• Engine condition (ECT, vehicle speed, engine speed, TP, etc.) (9)

• Battery voltage (ECM backup power voltage) (10)

• Electric load condition (blower motor, rear defogger, head lights, radiator fan, A/C, etc.) (11)

• “FR” terminal output (field coil (3) cont rol duty) which indicates the operation rate (electricity generation condition) of

the generator.

Then the generator uses “C” terminal duty to regulate the adju sting voltage of the IC regulator with the field coil control

duty so as to control its generated voltage (“B” terminal output voltage).

(For more information of the generated voltage, refer to “Charging System Specifications in Section 1J”.)

Furthermore, the generation condition of the generator is co ntrolled to the optimum level by the electric load current

sensor (7) which detects the electrical load condition (cur rent consumption) linearly even when a sudden electrical

load variation occurs and thus the engine load is reduced.

B

IG

L

C

E

6

2

3

FR

5

12 13

14

1IG1

7

4

8

11

10 9

CMO

FCD

GCD

I6RW0H110005-01

6. Ignition switch

12. BCM 14. CAN driver

8. Battery 13. Combination meter

Page 63 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

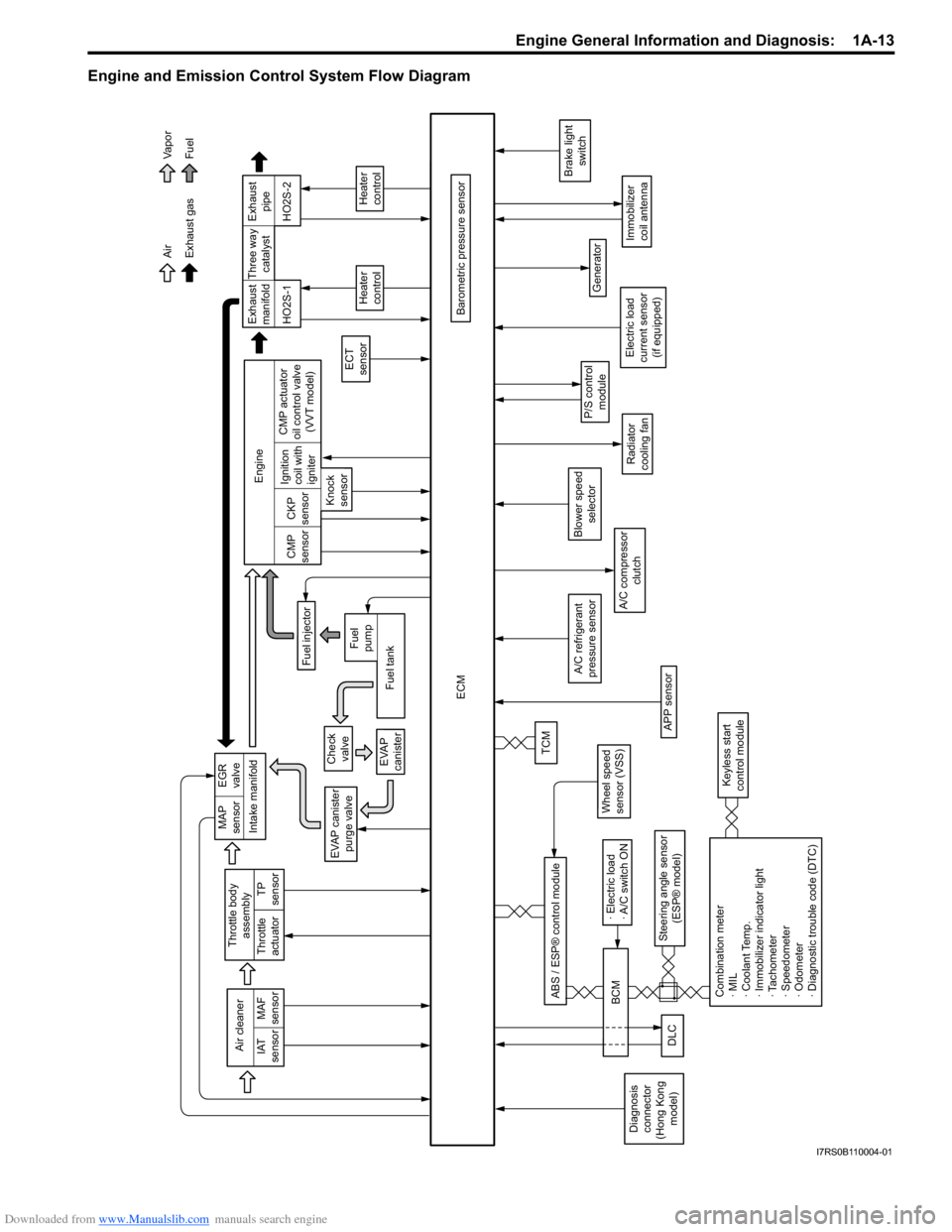

Engine and Emission Control System Flow Diagram

Intake manifold

Exhaust gas AirFuel

Va p o r

EVAP canister purge valve

ECM

Barometric pressure sensor

A/C compressor clutch

Generator

Immobilizer

coil antenna

P/S controlmodule

Brake light switch

Air cleaner

IAT

sensor MAF

sensor

A/C refrigerant

pressure sensor

TP

sensor

Throttle body

assembly

Throttle

actuator

Wheel speed

sensor (VSS)

Steering angle sensor (ESP® model)

ABS / ESP® control module

Blower speed

selector

MAP

sensor EGR

valve

Check valve

EVAP

canisterTCM

Exhaust

manifold Exhaust

pipe

Fuel injector

ECT

sensor

Heater

control

HO2S-1 HO2S-2

Engine

CMP

sensor CKP

sensor

Knock

sensor Ignition

coil with

igniter

Fuel tank

Fuel

pump CMP actuator

oil control valve (VVT model) Three way

catalyst

Heater

control

Radiator

cooling fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Odometer

· Diagnostic trouble code (DTC)

Keyless start

control module

DLC

· Electric load

· A/C switch ON

BCM

Diagnosis

connector

(Hong Kong model) Electric load

current sensor (if equipped)

APP sensor

I7RS0B110004-01

Page 67 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-17

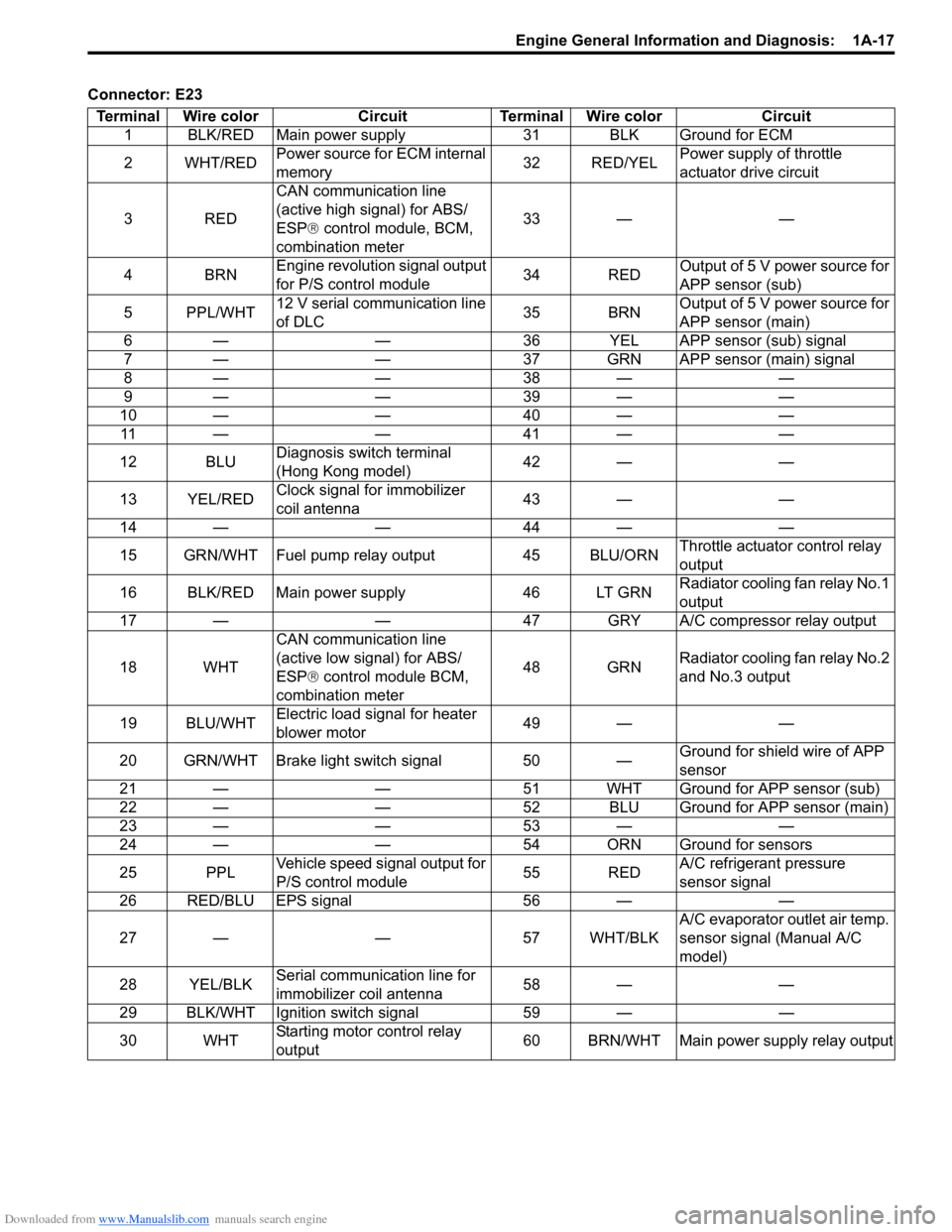

Connector: E23Terminal Wire color Circuit Terminal Wire color Circuit 1 BLK/RED Main power supply 31 BLK Ground for ECM

2WHT/RED Power source for ECM internal

memory 32 RED/YELPower supply of throttle

actuator drive circuit

3RED CAN communication line

(active high signal) for ABS/

ESP®

control module, BCM,

combination meter 33 — —

4BRN Engine revolution signal output

for P/S control module 34 REDOutput of 5 V power source for

APP sensor (sub)

5 PPL/WHT 12 V serial communication line

of DLC 35 BRNOutput of 5 V power source for

APP sensor (main)

6 — — 36 YEL APP sensor (sub) signal

7 — — 37 GRN APP sensor (main) signal

8— — 38— —

9— — 39— —

10——40—— 11——41——

12 BLU Diagnosis switch terminal

(Hong Kong model) 42 — —

13 YEL/RED Clock signal for immobilizer

coil antenna 43 — —

14——44——

15 GRN/WHT Fuel pump relay output 45 BLU/ORN Throttle actuator control relay

output

16 BLK/RED Main power supply 46 LT GRN Radiator cooling fan relay No.1

output

17 — — 47 GRY A/C compressor relay output

18 WHT CAN communication line

(active low signal) for ABS/

ESP®

control module BCM,

combination meter 48 GRN

Radiator cooling fan relay No.2

and No.3 output

19 BLU/WHT Electric load signal for heater

blower motor 49 — —

20 GRN/WHT Brake light switch signal 50 — Ground for shield wire of APP

sensor

21 — — 51 WHT Ground for APP sensor (sub)

22 — — 52 BLU Ground for APP sensor (main)

23——53——

24 — — 54 ORN Ground for sensors

25 PPL Vehicle speed signal output for

P/S control module 55 REDA/C refrigerant pressure

sensor signal

26 RED/BLU EPS signal 56 — —

27 — — 57 WHT/BLK A/C evaporator outlet air temp.

sensor signal (Manual A/C

model)

28 YEL/BLK Serial communication line for

immobilizer coil antenna 58 — —

29 BLK/WHT Ignition switch signal 59 — —

30 WHT Starting motor control relay

output 60 BRN/WHT Main power supply relay output

Page 70 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-20 Engine General Information and Diagnosis:

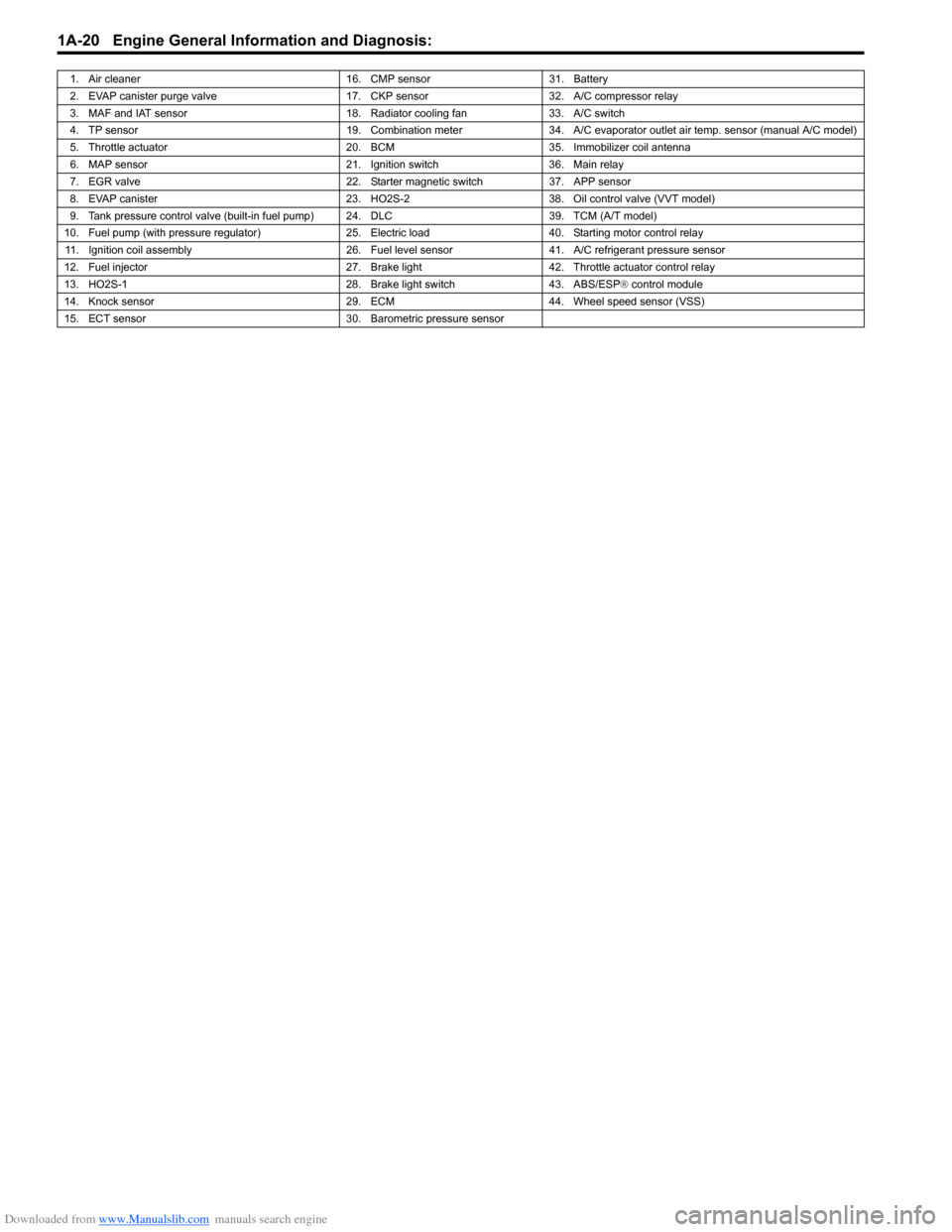

1. Air cleaner16. CMP sensor31. Battery

2. EVAP canister purge valve 17. CKP sensor32. A/C compressor relay

3. MAF and IAT sensor 18. Radiator cooling fan33. A/C switch

4. TP sensor 19. Combination meter34. A/C evaporator outlet air temp. sensor (manual A/C model)

5. Throttle actuator 20. BCM35.Immobilizer coil antenna

6. MAP sensor 21. Ignition switch36. Main relay

7. EGR valve 22. Starter magnetic switch37. APP sensor

8. EVAP canister 23. HO2S-238. Oil control valve (VVT model)

9. Tank pressure control valve (built-in fuel pump) 24. DLC 39. TCM (A/T model)

10. Fuel pump (with pressure regulator) 25. Electric load40. Starting motor control relay

11. Ignition coil assembly 26. Fuel level sensor41. A/C refrigerant pressure sensor

12. Fuel injector 27. Brake light42. Throttle actuator control relay

13. HO2S-1 28. Brake light switch43. ABS/ESP® control module

14. Knock sensor 29. ECM44. Wheel speed sensor (VSS)

15. ECT sensor 30. Barometric pressure sensor

Page 71 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-21

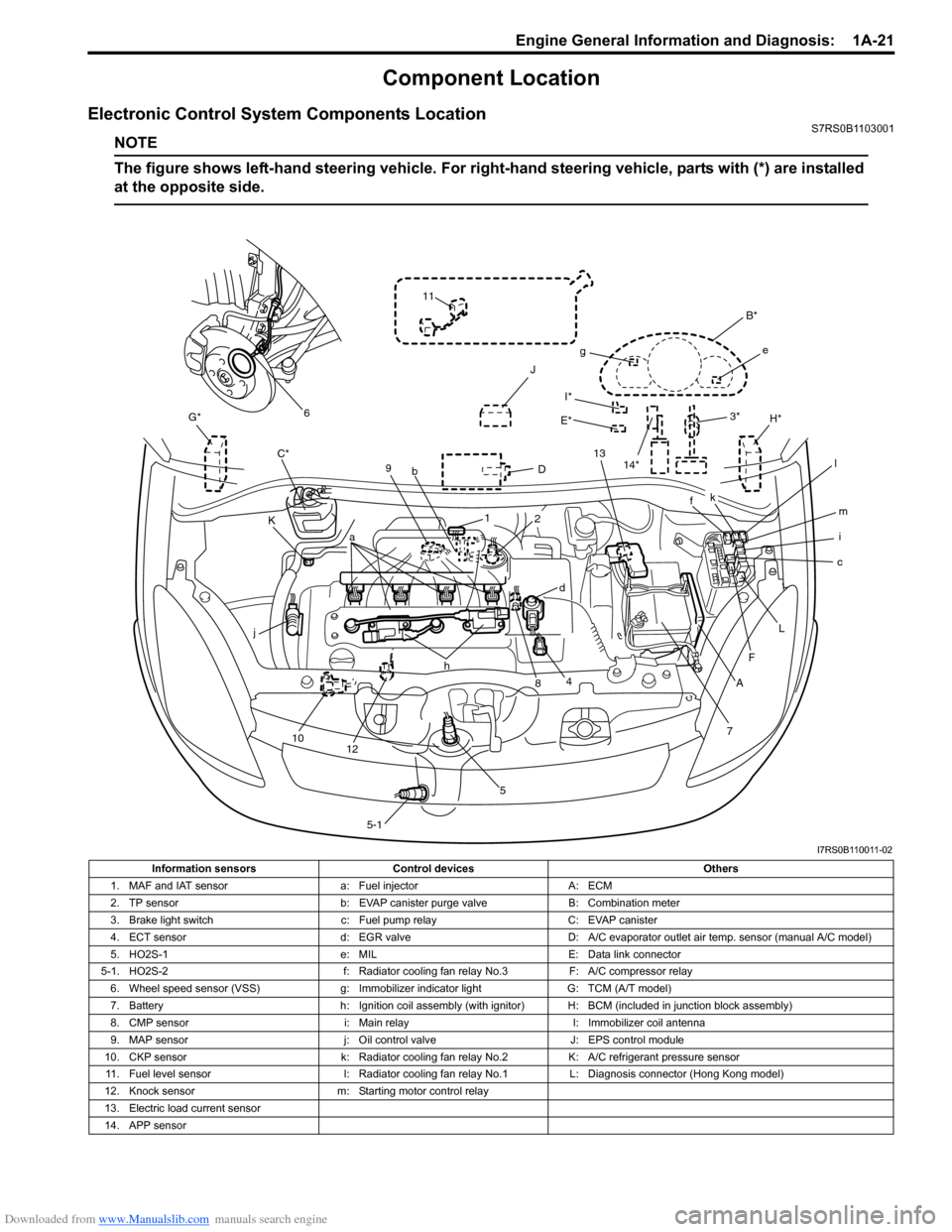

Component Location

Electronic Control System Components LocationS7RS0B1103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

I*

E*

G*

D

K H*

J

C*

7

A

F

c

L

i m

f

B*

e

g

k

l

13

3*

4

j

10 12 h

58

a

9

b

1

5-1

d

2

11

6

14*

I7RS0B110011-02

Information sensors Control devices Others

1. MAF and IAT sensor a: Fuel injectorA: ECM

2. TP sensor b: EVAP canister purge valve B: Combination meter

3. Brake light switch c: Fuel pump relayC: EVAP canister

4. ECT sensor d: EGR valveD: A/C evaporator outlet air temp. sensor (manual A/C model)

5. HO2S-1 e: MILE: Data link connector

5-1. HO2S-2 f: Radiator cooling fan relay No.3F: A/C compressor relay

6. Wheel speed sensor (VSS) g: Immobilizer indicator lightG: TCM (A/T model)

7. Battery h: Ignition coil assembly (with ignitor) H: BCM (included in junction block assembly)

8. CMP sensor i: Main relayI: Immobilizer coil antenna

9. MAP sensor j: Oil control valveJ: EPS control module

10. CKP sensor k: Radiator cooling fan relay No.2K: A/C refrigerant pressure sensor

11. Fuel level sensor l: Radiator cooling fan relay No.1L: Diagnosis connector (Hong Kong model)

12. Knock sensor m: Starting motor control relay

13. Electric load current sensor

14. APP sensor

Page 230 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-180 Engine General Information and Diagnosis:

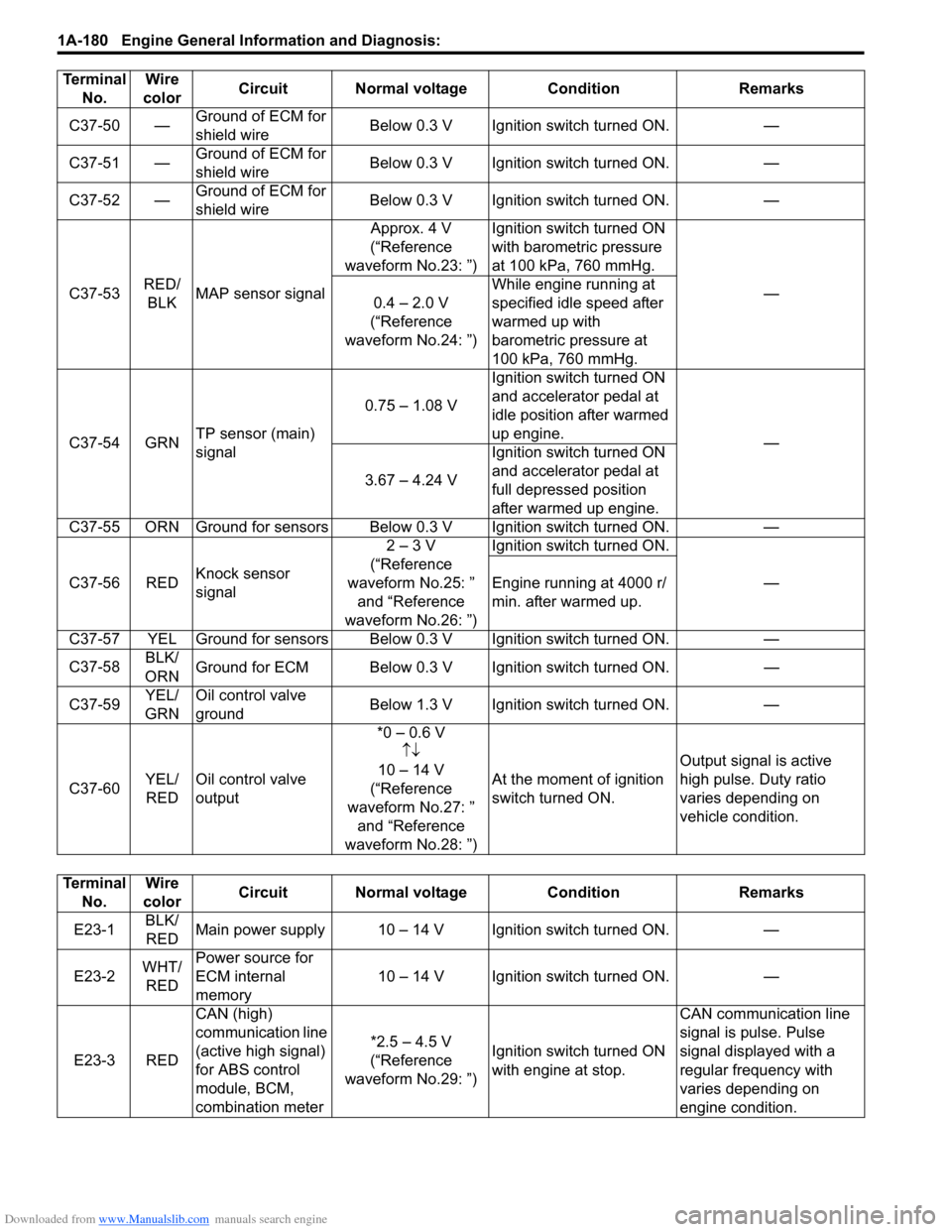

C37-50 —Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-51 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-52 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-53 RED/

BLK MAP sensor signal Approx. 4 V

(“Reference

waveform No.23: ”) Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.24: ”) While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C37-54 GRN TP sensor (main)

signal 0.75 – 1.08 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-56 RED Knock sensor

signal 2 – 3 V

(“Reference

waveform No.25: ” and “Reference

waveform No.26: ”) Ignition switch turned ON.

—

Engine running at 4000 r/

min. after warmed up.

C37-57 YEL Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-58 BLK/

ORN Ground for ECM Below 0.3 V Ignition switch turned ON.

—

C37-59 YEL/

GRN Oil control valve

ground

Below 1.3 V Ignition switch turned ON.

—

C37-60 YEL/

RED Oil control valve

output *0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.27: ” and “Reference

waveform No.28: ”) At the moment of ignition

switch turned ON.

Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

E23-1 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-2 WHT/

RED Power source for

ECM internal

memory

10 – 14 V Ignition switch turned ON. —

E23-3 RED CAN (high)

communication line

(active high signal)

for ABS control

module, BCM,

combination meter *2.5 – 4.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 231 of 1496

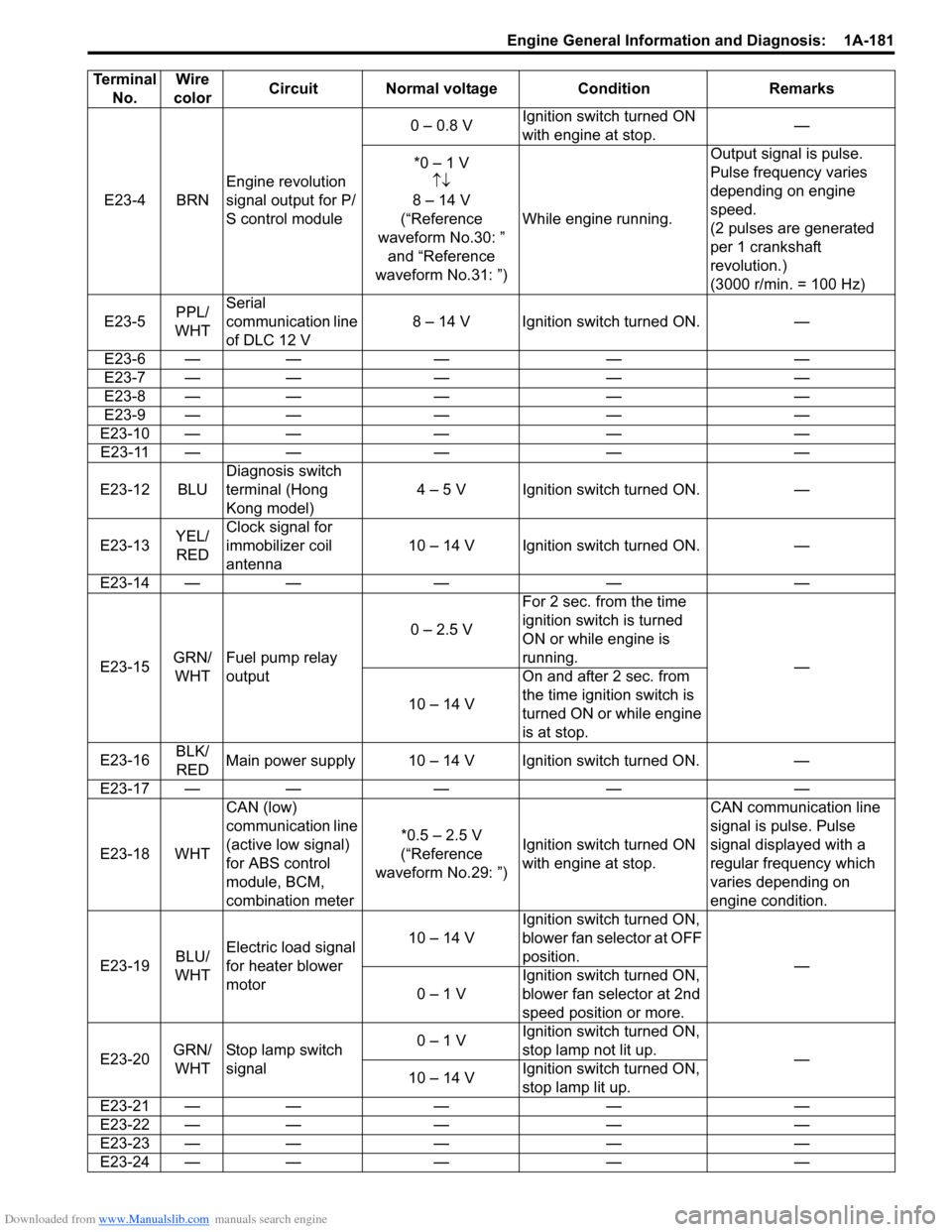

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

E23-4 BRNEngine revolution

signal output for P/

S control module 0 – 0.8 V

Ignition switch turned ON

with engine at stop. —

*0 – 1 V ↑↓

8 – 14 V

(“Reference

waveform No.30: ” and “Reference

waveform No.31: ”) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 – 14 V Ignition switch turned ON. —

E23-6 — — — — —

E23-7 — — — — —

E23-8 — — — — —

E23-9 — — — — —

E23-10 — — — — — E23-11 — — — — —

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 – 5 V Ignition switch turned ON. —

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-14 — — — — —

E23-15 GRN/

WHT Fuel pump relay

output 0 – 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-17 — — — — —

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 – 2.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 – 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

—

0 – 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 – 1 V

Ignition switch turned ON,

stop lamp not lit up.

—

10 – 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 — — — — —

E23-22 — — — — —

E23-23 — — — — —

E23-24 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 414 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

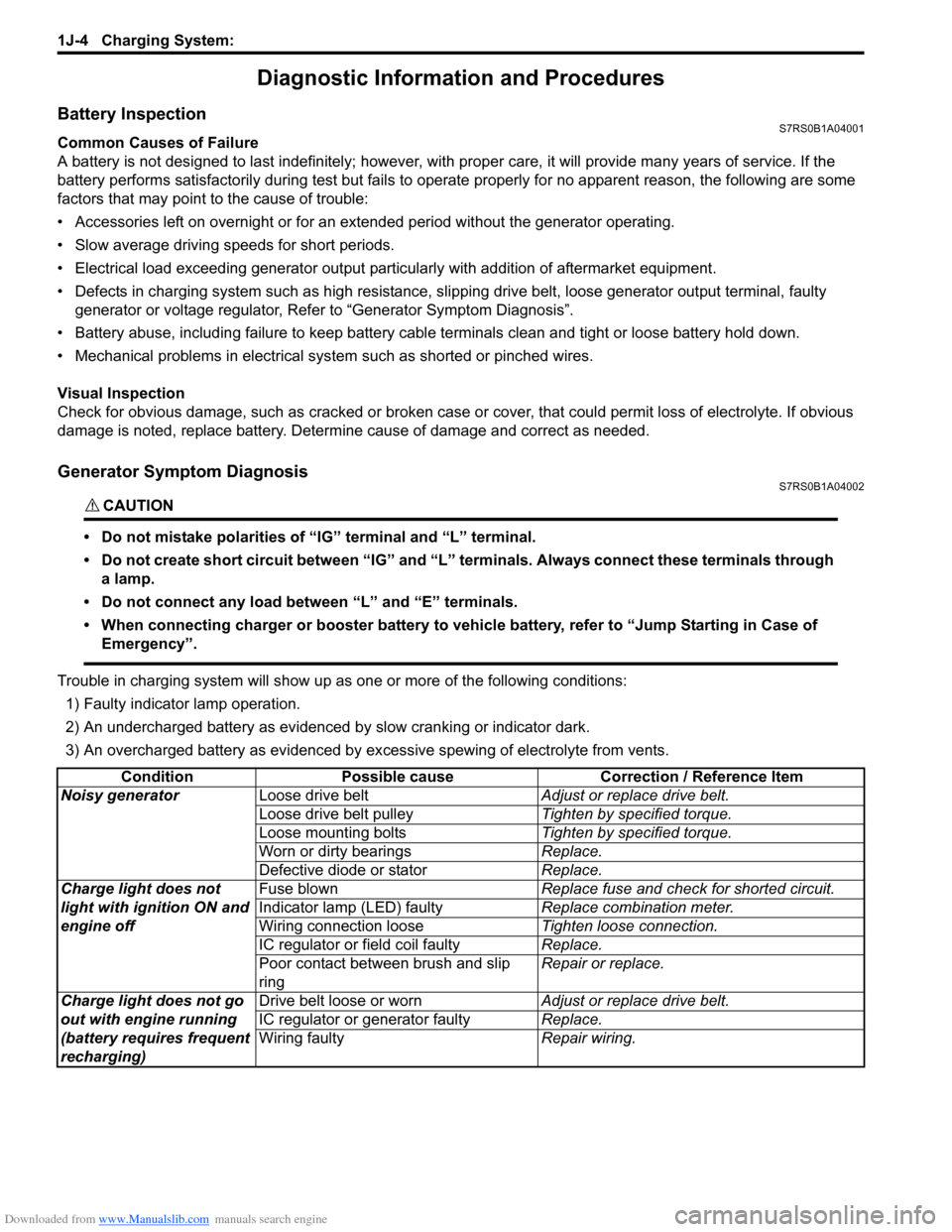

Diagnostic Information and Procedures

Battery InspectionS7RS0B1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however, with proper care, it will provide many years of service. If the

battery performs satisfactorily during te st but fails to operate properly for no apparent reason, the following are some

factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended period without the generator operating.

• Slow average driving speeds for short periods.

• Electrical load exceeding generator output partic ularly with addition of aftermarket equipment.

• Defects in charging system such as high resistance, s lipping drive belt, loose generator output terminal, faulty

generator or voltage regulator, Refer to “Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical sys tem such as shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken case or cover, that could permit loss of electrolyte. If obvious

damage is noted, replace battery. Determine cause of damage and correct as needed.

Generator Symptom DiagnosisS7RS0B1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal and “L” terminal.

• Do not create short circuit between “IG” and “L” terminals. Always connect these terminals through a lamp.

• Do not connect any load between “L” and “E” terminals.

• When connecting charger or booster battery to vehicle battery, refer to “Jump Starting in Case of Emergency”.

Trouble in charging system will show up as one or more of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or indicator dark.

3) An overcharged battery as evidenced by ex cessive spewing of electrolyte from vents.

Condition Possible cause Correction / Reference Item

Noisy generator Loose drive belt Adjust or replace drive belt.

Loose drive belt pulley Tighten by specified torque.

Loose mounting bolts Tighten by specified torque.

Worn or dirty bearings Replace.

Defective diode or stator Replace.

Charge light does not

light with ignition ON and

engine off Fuse blown

Replace fuse and check for shorted circuit.

Indicator lamp (LED) faulty Replace combination meter.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Replace.

Poor contact between brush and slip

ring Repair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging) Drive belt loose or worn

Adjust or replace drive belt.

IC regulator or generator faulty Replace.

Wiring faulty Repair wiring.