Spare SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

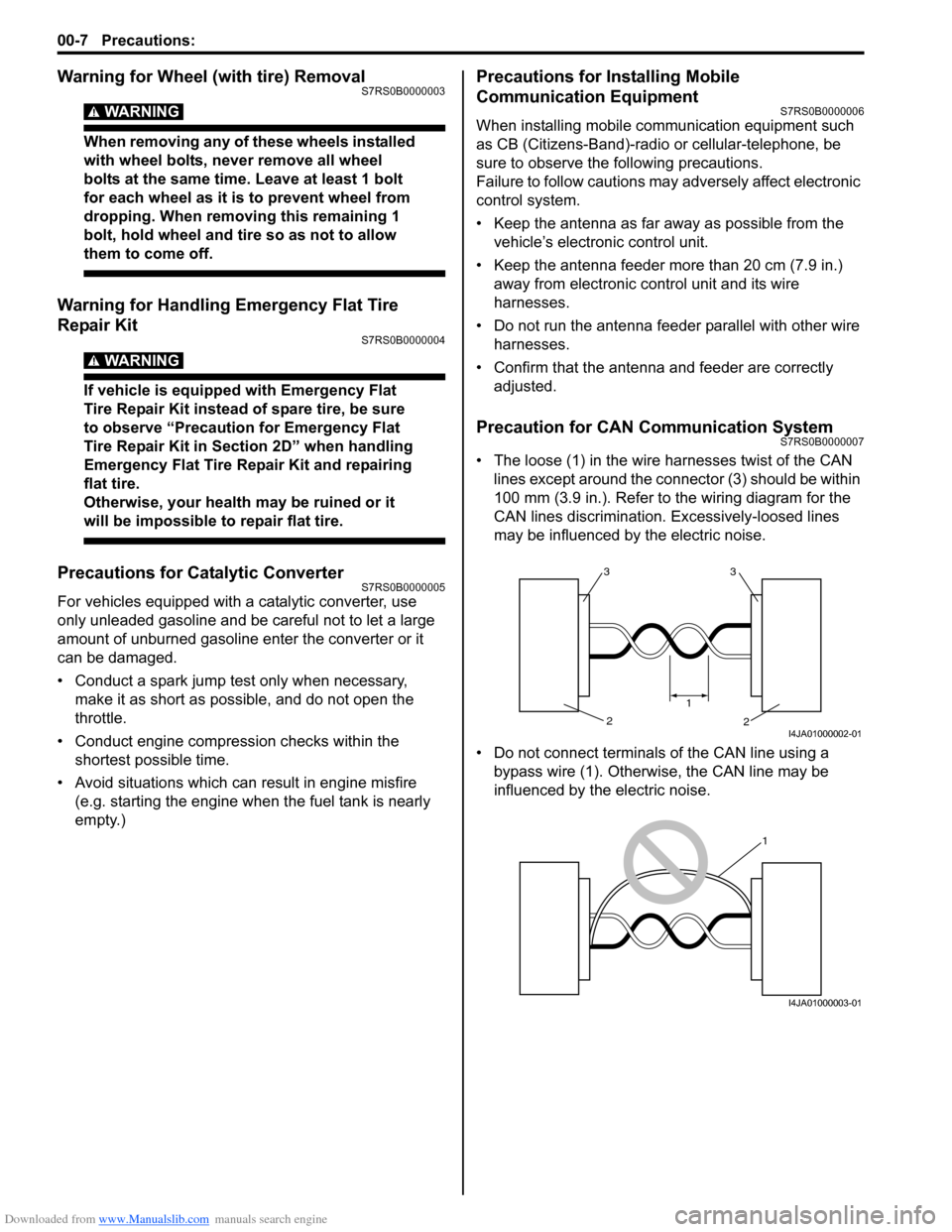

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 358 of 1496

Downloaded from www.Manualslib.com manuals search engine 1E-6 Engine Lubrication System:

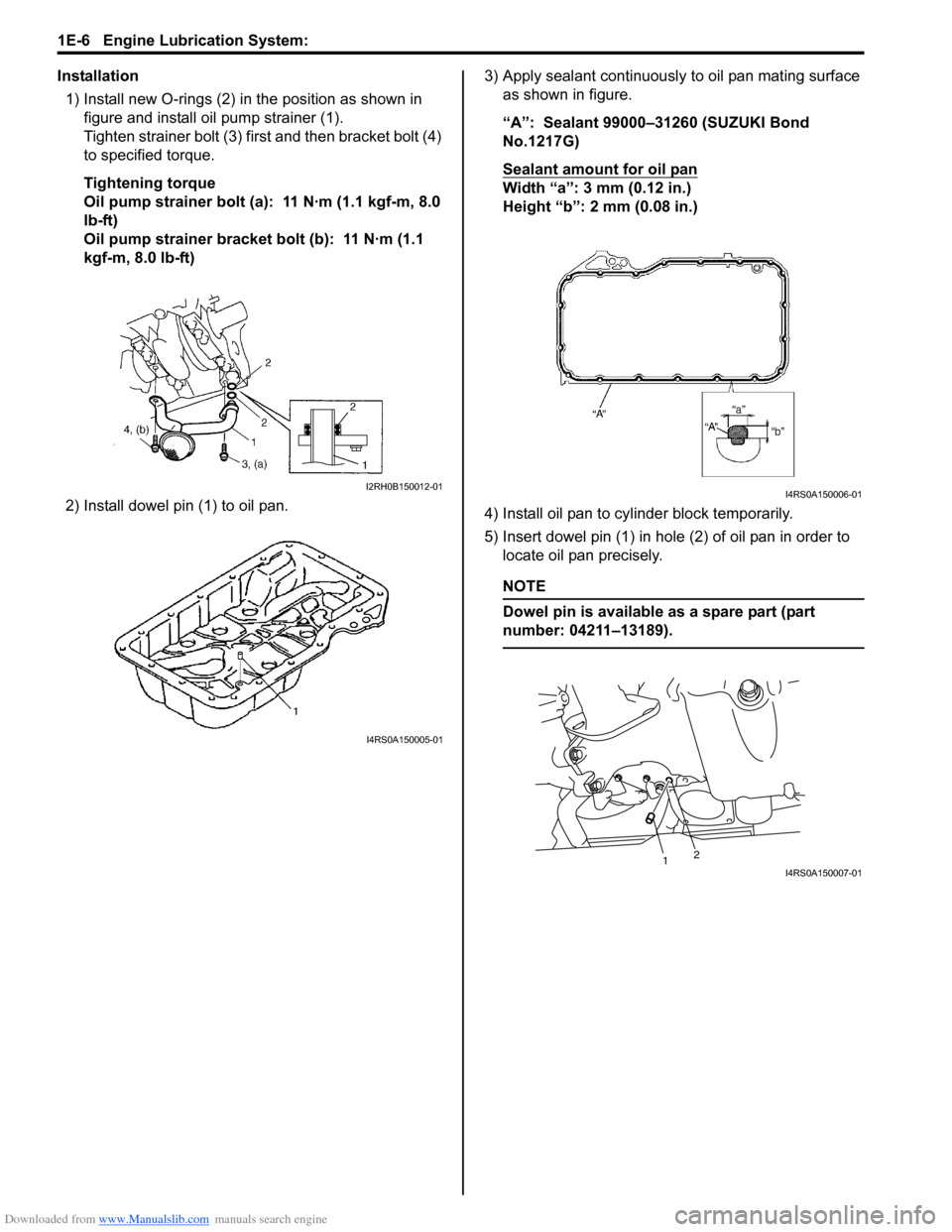

Installation1) Install new O-rings (2) in the position as shown in figure and install o il pump strainer (1).

Tighten strainer bolt (3) first and then bracket bolt (4)

to specified torque.

Tightening torque

Oil pump strainer bolt (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Oil pump strainer bracket bolt (b): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

2) Install dowel pin (1) to oil pan. 3) Apply sealant continuously to oil pan mating surface

as shown in figure.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for oil pan

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

4) Install oil pan to cy linder block temporarily.

5) Insert dowel pin (1) in hole (2) of oil pan in order to

locate oil pan precisely.

NOTE

Dowel pin is available as a spare part (part

number: 04211–13189).

I2RH0B150012-01

I4RS0A150005-01

I4RS0A150006-01

21I4RS0A150007-01

Page 482 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-4 Drive Shaft / Axle:

Front Drive Shaft Assembly On-Vehicle

Inspection

S7RS0B3106002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for smooth rotation.

If any abnormality is found, replace.

Front Drive Shaft Assembly Removal and

Installation

S7RS0B3106003

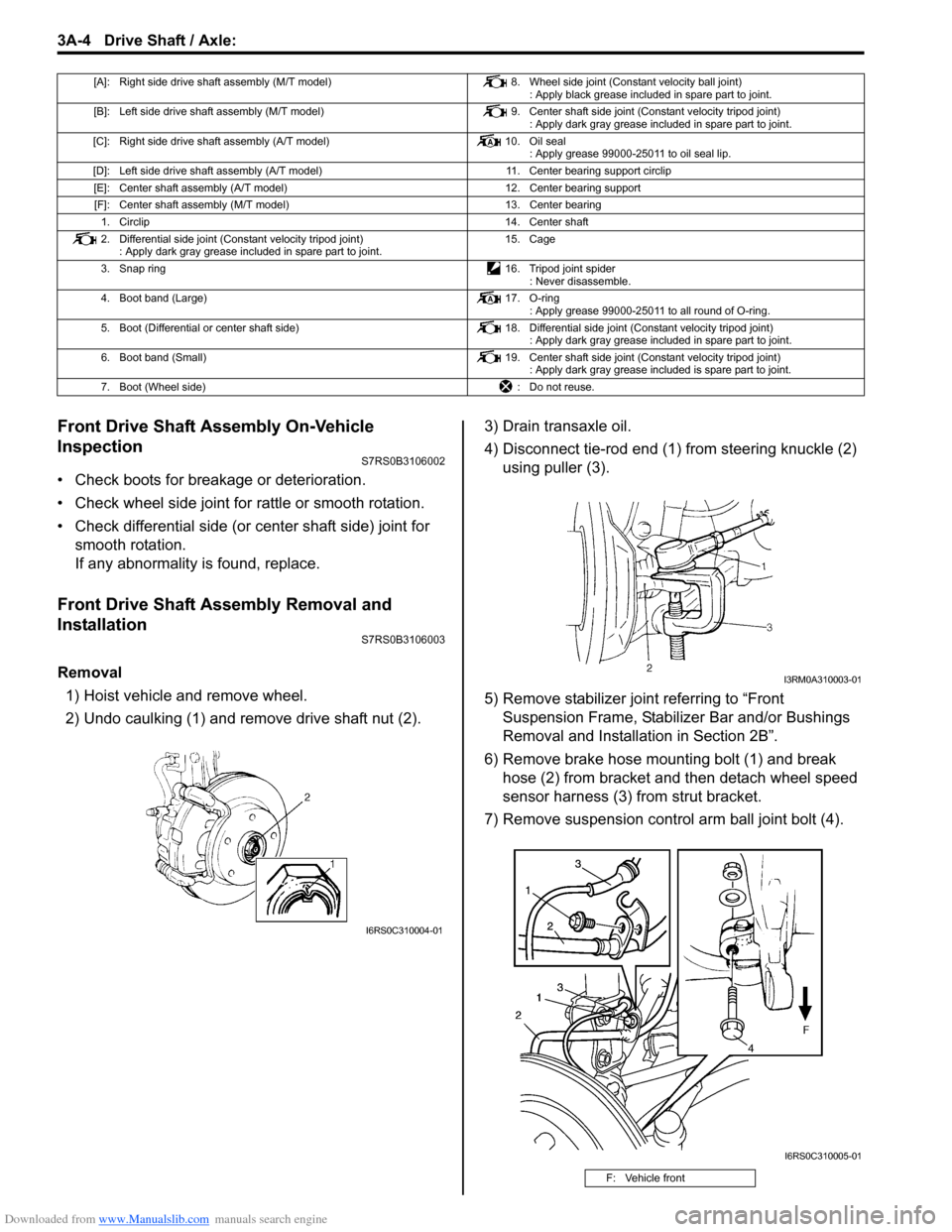

Removal

1) Hoist vehicle and remove wheel.

2) Undo caulking (1) and remove drive shaft nut (2). 3) Drain transaxle oil.

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).

5) Remove stabilizer join t referring to “Front

Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

6) Remove brake hose mounting bolt (1) and break hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

7) Remove suspension contro l arm ball joint bolt (4).

[A]: Right side drive shaft assembly (M/T model) 8. Wheel side joint (Constant velocity ball joint)

: Apply black grease included in spare part to joint.

[B]: Left side drive shaft assembly (M/T model) 9. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

[C]: Right side drive shaft assembly (A/T model) 10. Oil seal

: Apply grease 99000-25011 to oil seal lip.

[D]: Left side drive shaft assembly (A/T model) 11. Center bearing support circlip

[E]: Center shaft assembly (A/T model) 12. Center bearing support

[F]: Center shaft assembly (M/T model) 13. Center bearing

1. Circlip 14. Center shaft

2. Differential side joint (Constant velocity tripod joint) : Apply dark gray grease included in spare part to joint. 15. Cage

3. Snap ring 16. Tripod joint spider

: Never disassemble.

4. Boot band (Large) 17. O-ring

: Apply grease 99000-25011 to all round of O-ring.

5. Boot (Differential or center shaft side) 18. Differential side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

6. Boot band (Small) 19. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included is spare part to joint.

7. Boot (Wheel side) : Do not reuse.

I6RS0C310004-01

F: Vehicle front

I3RM0A310003-01

I6RS0C310005-01

Page 486 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-8 Drive Shaft / Axle:

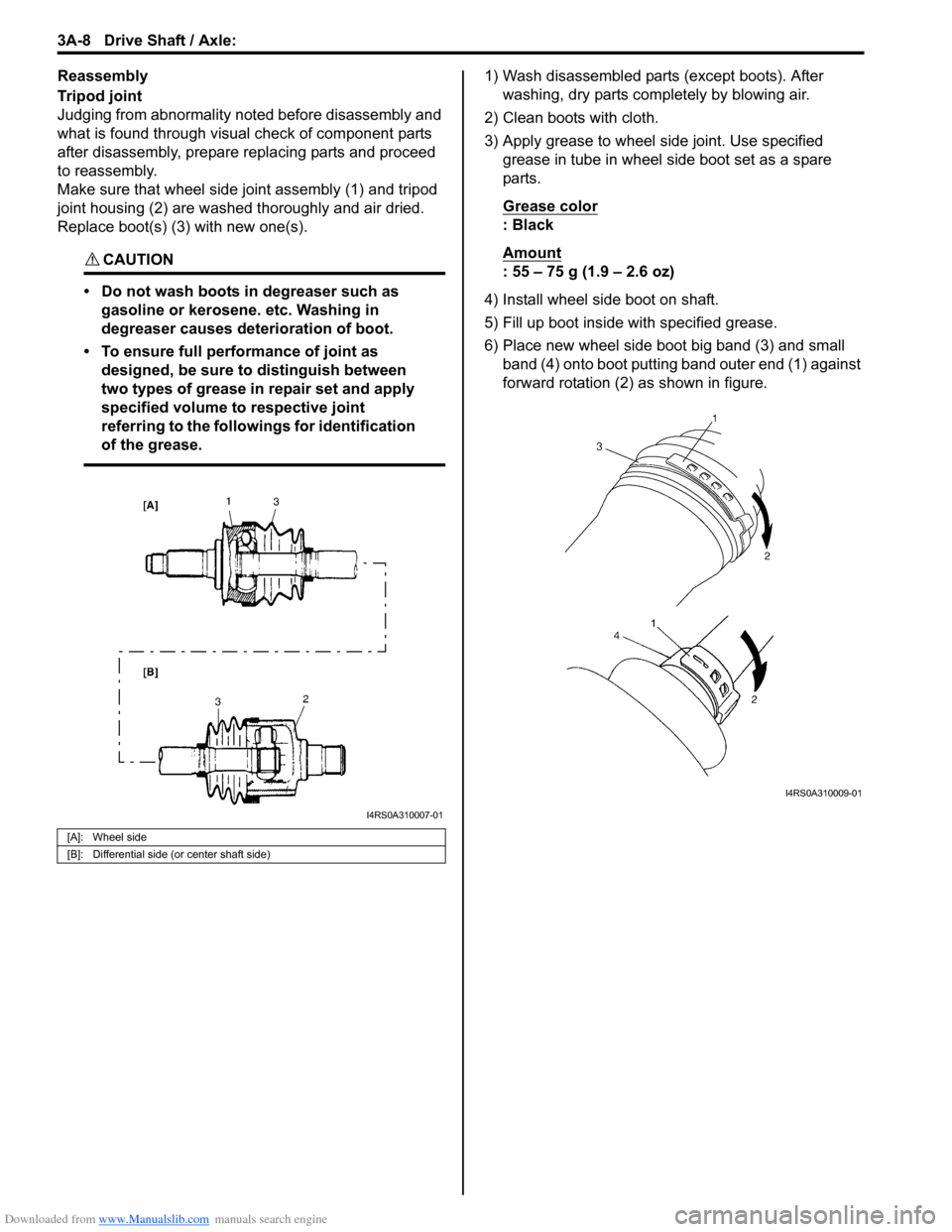

Reassembly

Tripod joint

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly (1) and tripod

joint housing (2) are washed thoroughly and air dried.

Replace boot(s) (3) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts comp letely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside with specified grease.

6) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure.

[A]: Wheel side

[B]: Differential side (or center shaft side)

I4RS0A310007-01

I4RS0A310009-01

Page 487 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-9

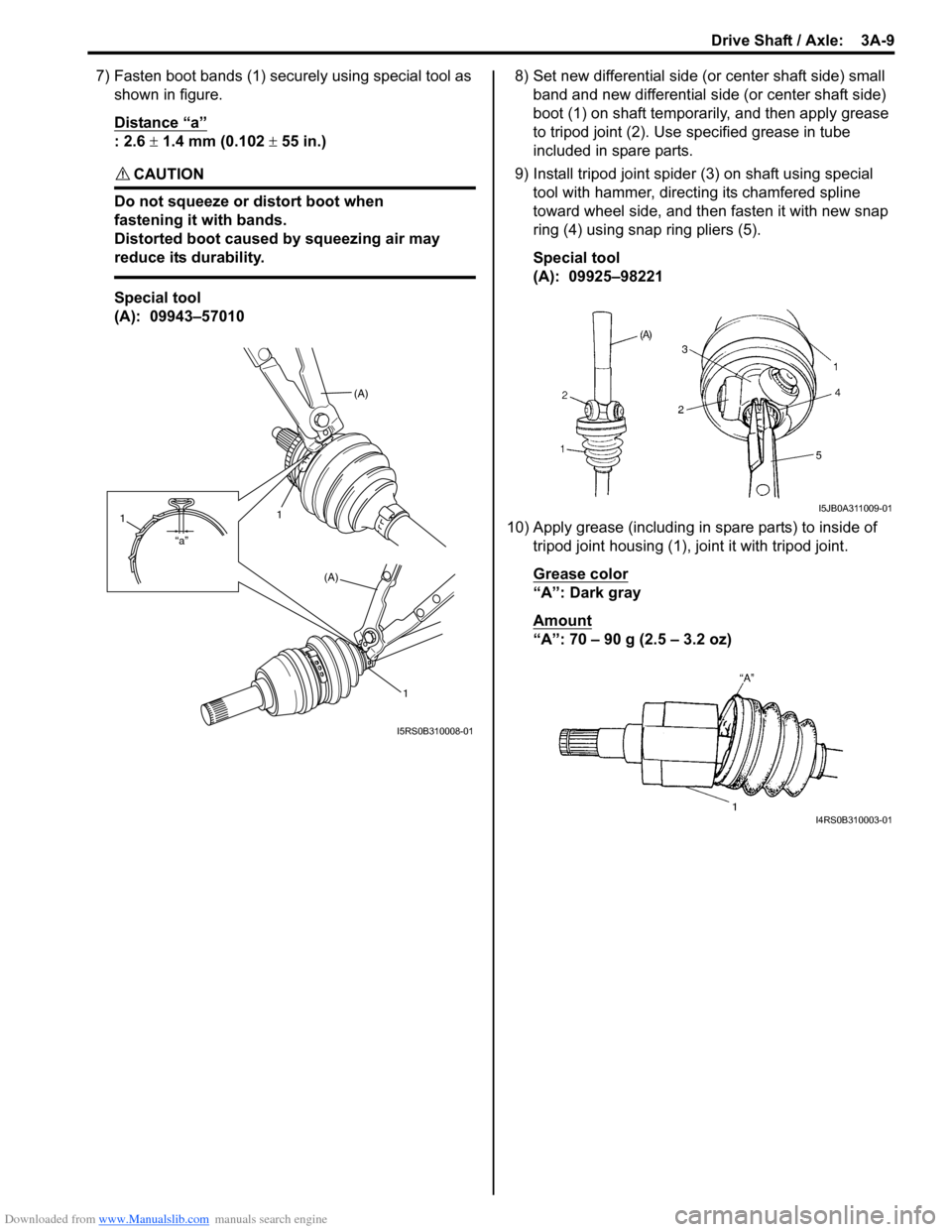

7) Fasten boot bands (1) securely using special tool as

shown in figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 55 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010 8) Set new differential side (or center shaft side) small

band and new differential side (or center shaft side)

boot (1) on shaft temporarily, and then apply grease

to tripod joint (2). Use specified grease in tube

included in spare parts.

9) Install tripod joint spider (3) on shaft using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (4) using snap ring pliers (5).

Special tool

(A): 09925–98221

10) Apply grease (including in spare parts) to inside of tripod joint housing (1), jo int it with tripod joint.

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz)

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

I5JB0A311009-01

I4RS0B310003-01

Page 489 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-11

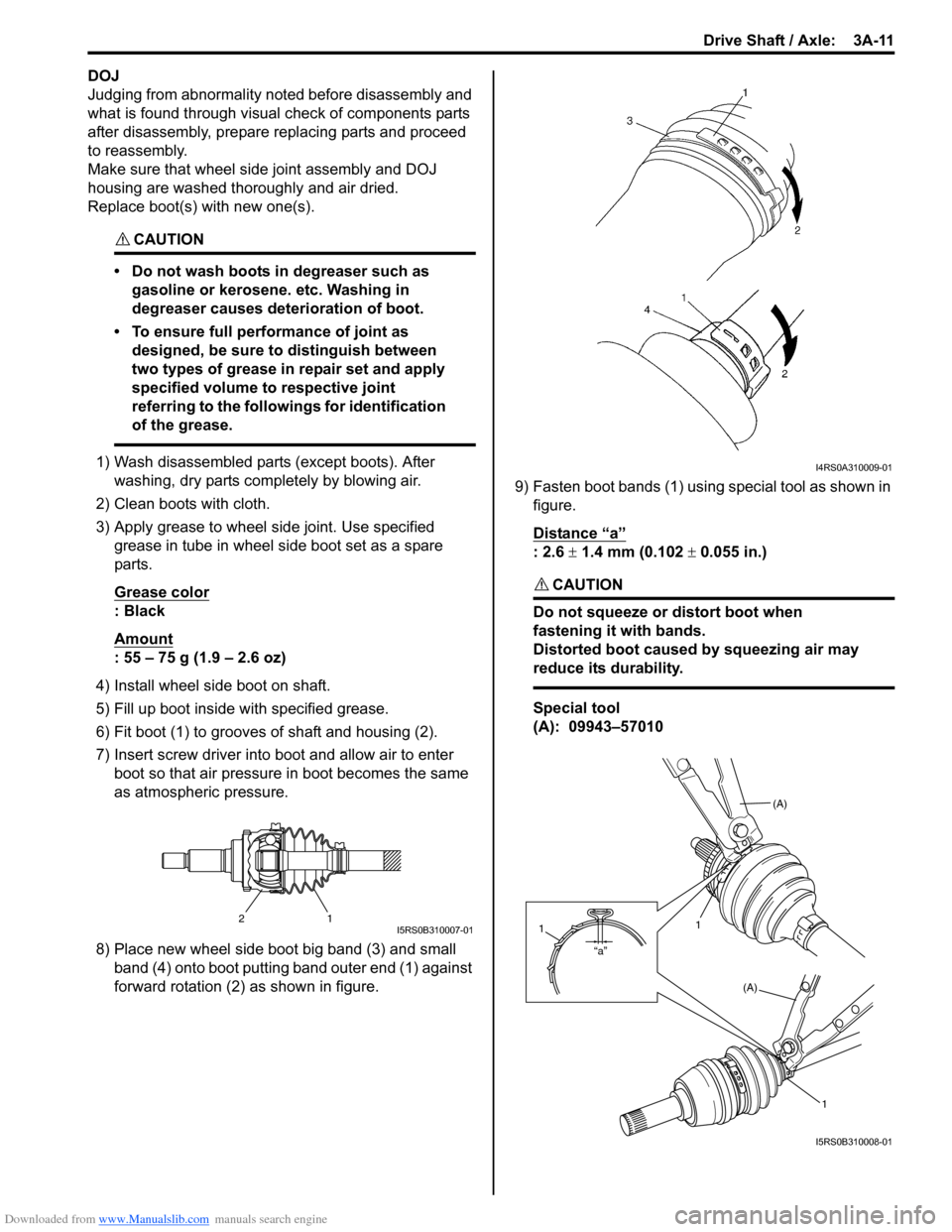

DOJ

Judging from abnormality noted before disassembly and

what is found through visual check of components parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly and DOJ

housing are washed thoroughly and air dried.

Replace boot(s) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts completely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified

grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside wi th specified grease.

6) Fit boot (1) to grooves of shaft and housing (2).

7) Insert screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

8) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure. 9) Fasten boot bands (1) using special tool as shown in

figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 0.055 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010

21I5RS0B310007-01

I4RS0A310009-01

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

Page 490 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-12 Drive Shaft / Axle:

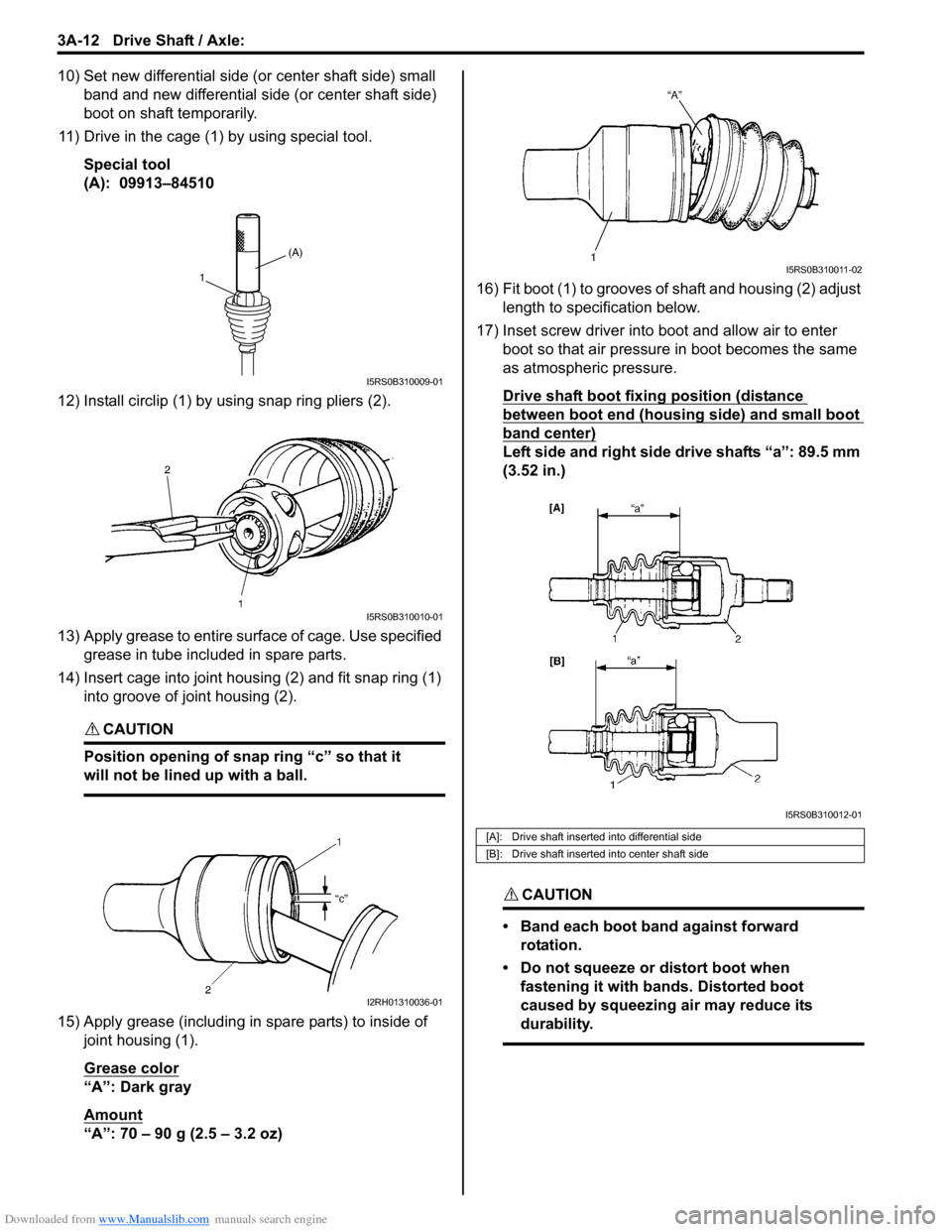

10) Set new differential side (or center shaft side) small band and new differential side (or center shaft side)

boot on shaft temporarily.

11) Drive in the cage (1) by using special tool.

Special tool

(A): 09913–84510

12) Install circlip (1) by using snap ring pliers (2).

13) Apply grease to entire su rface of cage. Use specified

grease in tube included in spare parts.

14) Insert cage into joint housing (2) and fit snap ring (1) into groove of joint housing (2).

CAUTION!

Position opening of snap ring “c” so that it

will not be lined up with a ball.

15) Apply grease (including in spare parts) to inside of joint housing (1).

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz) 16) Fit boot (1) to grooves of shaft and housing (2) adjust

length to specification below.

17) Inset screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

Drive shaft boot fixing position (distance

between boot end (housing side) and small boot

band center)

Left side and right side drive shafts “a”: 89.5 mm

(3.52 in.)

CAUTION!

• Band each boot band against forward rotation.

• Do not squeeze or distort boot when fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

(A)

1

I5RS0B310009-01

I5RS0B310010-01

I2RH01310036-01

[A]: Drive shaft inserted into differential side

[B]: Drive shaft inserted into center shaft side

I5RS0B310011-02

I5RS0B310012-01

Page 510 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-12 Brake Control System and Diagnosis:

Master Cylinder Assembly Removal and

Installation

S7RS0B4106011

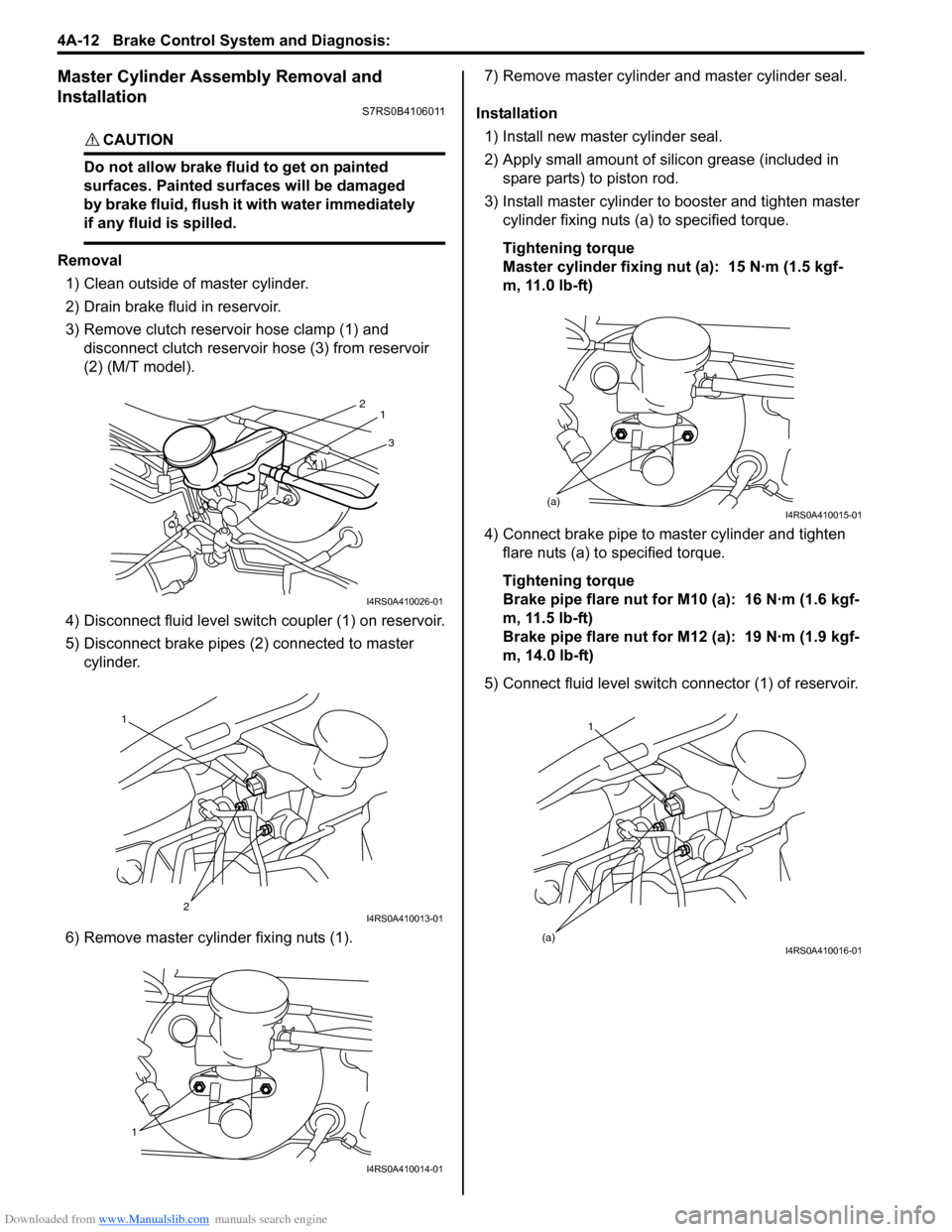

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Clean outside of master cylinder.

2) Drain brake fluid in reservoir.

3) Remove clutch reservoir hose clamp (1) and disconnect clutch reservoir hose (3) from reservoir

(2) (M/T model).

4) Disconnect fluid level switch coupler (1) on reservoir.

5) Disconnect brake pipes (2) connected to master cylinder.

6) Remove master cylinder fixing nuts (1). 7) Remove master cylinder and master cylinder seal.

Installation 1) Install new master cylinder seal.

2) Apply small amount of silic on grease (included in

spare parts) to piston rod.

3) Install master cylinder to booster and tighten master cylinder fixing nuts (a) to specified torque.

Tightening torque

Master cylinder fixing nut (a): 15 N·m (1.5 kgf-

m, 11.0 lb-ft)

4) Connect brake pipe to master cylinder and tighten flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut for M10 (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

Brake pipe flare nut for M12 (a): 19 N·m (1.9 kgf-

m, 14.0 lb-ft)

5) Connect fluid level switch connector (1) of reservoir.

3

2

1

I4RS0A410026-01

1

2

I4RS0A410013-01

1

I4RS0A410014-01

(a)I4RS0A410015-01

1

(a)

I4RS0A410016-01

Page 513 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-15

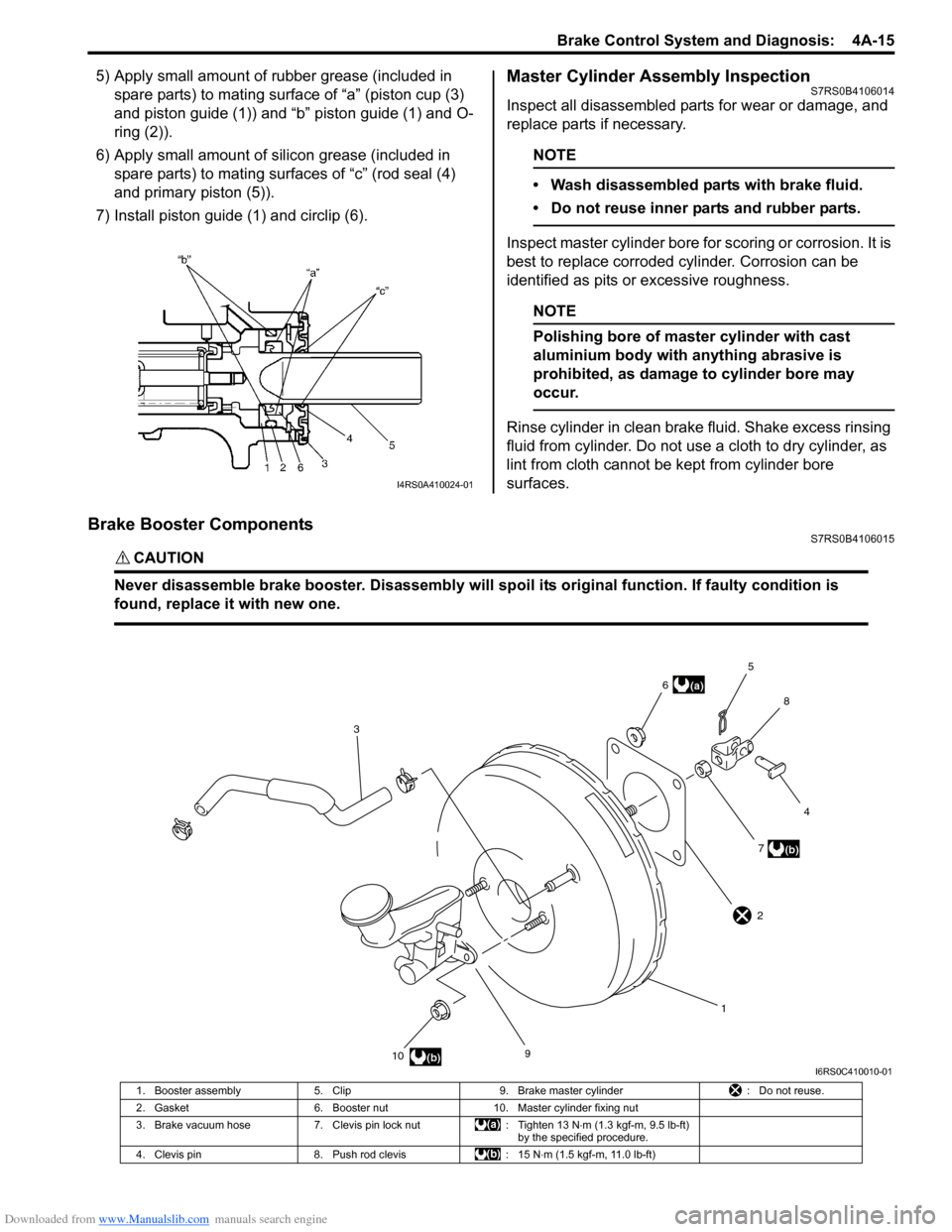

5) Apply small amount of rubber grease (included in spare parts) to mating surface of “a” (piston cup (3)

and piston guide (1)) and “b” piston guide (1) and O-

ring (2)).

6) Apply small amount of s ilicon grease (included in

spare parts) to mating surfaces of “c” (rod seal (4)

and primary piston (5)).

7) Install piston guide (1) and circlip (6).Master Cylinder Assembly InspectionS7RS0B4106014

Inspect all disassembled parts for wear or damage, and

replace parts if necessary.

NOTE

• Wash disassembled parts with brake fluid.

• Do not reuse inner parts and rubber parts.

Inspect master cylinder bore for scoring or corrosion. It is

best to replace corroded cylinder. Corrosion can be

identified as pits or excessive roughness.

NOTE

Polishing bore of master cylinder with cast

aluminium body with anything abrasive is

prohibited, as damage to cylinder bore may

occur.

Rinse cylinder in clean brake fluid. Shake excess rinsing

fluid from cylinder. Do not use a cloth to dry cylinder, as

lint from cloth cannot be kept from cylinder bore

surfaces.

Brake Booster ComponentsS7RS0B4106015

CAUTION!

Never disassemble brake booster. Disassembly will spoi l its original function. If faulty condition is

found, replace it with new one.

I4RS0A410024-01

9

10 17

4

8

5

6

3

(b)

(a)

(b)

2

I6RS0C410010-01

1. Booster assembly 5. Clip 9. Brake master cylinder : Do not reuse.

2. Gasket 6. Booster nut 10. Master cylinder fixing nut

3. Brake vacuum hose 7. Clevis pin lock nut : Tighten 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

by the specified procedure.

4. Clevis pin 8. Push rod clevis : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

Page 518 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-2 Front Brakes:

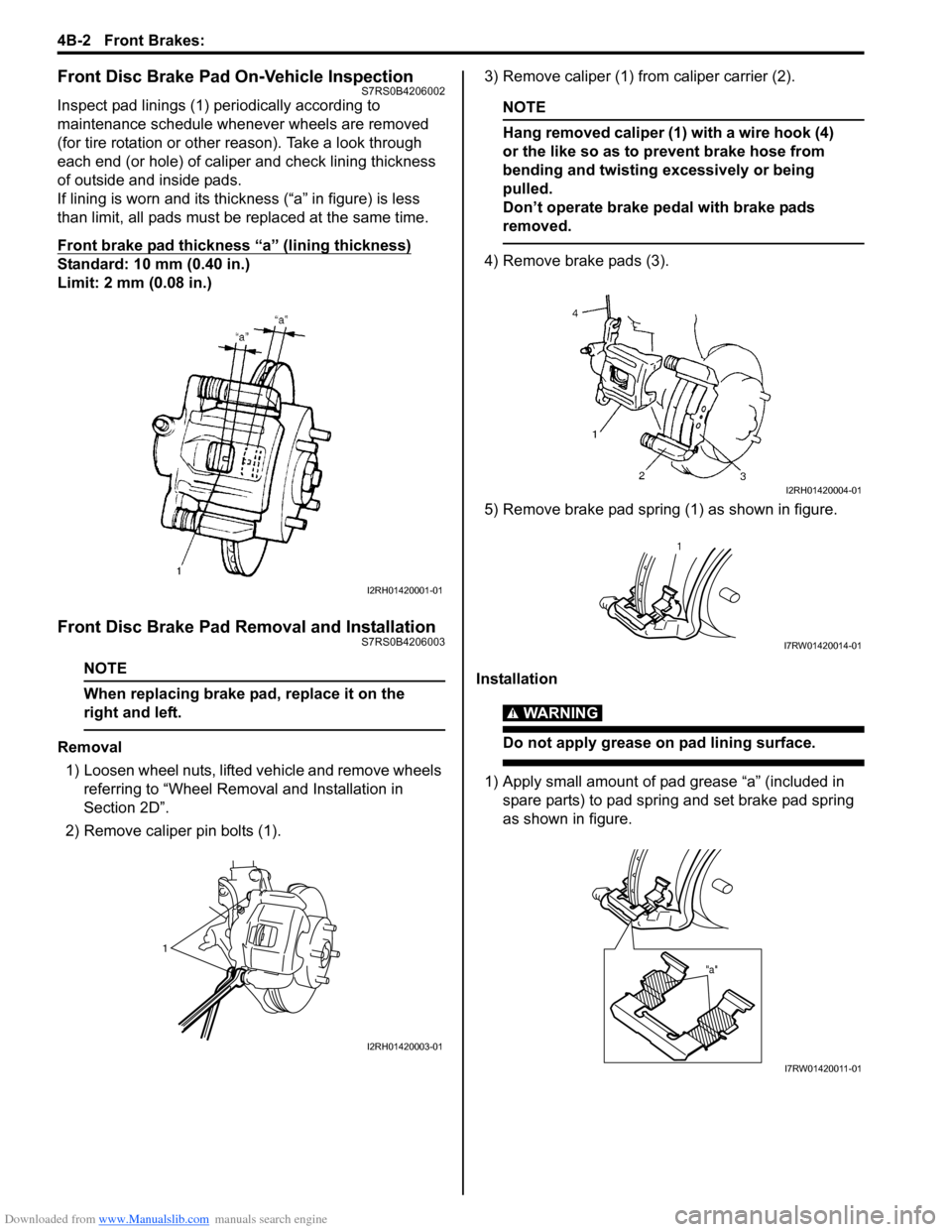

Front Disc Brake Pad On-Vehicle InspectionS7RS0B4206002

Inspect pad linings (1) periodically according to

maintenance schedule whenever wheels are removed

(for tire rotation or other reason). Take a look through

each end (or hole) of caliper and check lining thickness

of outside and inside pads.

If lining is worn and its thic kness (“a” in figure) is less

than limit, all pads must be replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

Front Disc Brake Pad Removal and InstallationS7RS0B4206003

NOTE

When replacing brake pad, replace it on the

right and left.

Removal

1) Loosen wheel nuts, lifted vehicle and remove wheels referring to “Wheel Remova l and Installation in

Section 2D”.

2) Remove caliper pin bolts (1). 3) Remove caliper (1) from caliper carrier (2).

NOTE

Hang removed caliper (1) with a wire hook (4)

or the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

4) Remove brake pads (3).

5) Remove brake pad spring (1) as shown in figure.

Installation

WARNING!

Do not apply grease on pad lining surface.

1) Apply small amount of pad grease “a” (included in spare parts) to pad spring and set brake pad spring

as shown in figure.

I2RH01420001-01

1

I2RH01420003-01

I2RH01420004-01

1

I7RW01420014-01

"a"

I7RW01420011-01