Timing belt SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 49 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-v

Ignition Timing Inspection ................................... 1H-8

Specifications ....................................................... 1H-9

Tightening Torque Specifications ........................ 1H-9

Special Tools and Equipmen t ............................. 1H-9

Special Tool ........................................................ 1H-9

Starting System ................. ........................ 1I-1

Schematic and Routing Diagram ......................... 1I-1

Cranking System Circuit Diagram ........................ 1I-1

Diagnostic Information and Procedures ............. 1I-1

Cranking System Symptom Diagnosis ................. 1I-1

Cranking System Test.......................................... 1I-3

Repair Instructions ............................................... 1I-4 Starting Motor Dismounting and Remounting ...... 1I-4

Starting Motor Components ................................. 1I-5

Starting Motor Inspection ..................................... 1I-6

Specifications ........................................................ 1I-9

Cranking System Specifications........................... 1I-9

Tightening Torque Specifications ......................... 1I-9

Special Tools and Equipment .............................. 1I-9

Recommended Service Material .......................... 1I-9

Charging System ............ .......................... 1J-1

General Description ......... .................................... 1J-1

Battery Description ...............................................1J-1

Generator Descripti on ..........................................1J-2

Diagnostic Information and Procedures ............ 1J-4 Battery Inspection ................................................1J-4

Generator Symptom Diagnosis ............................1J-4 Generator Test (Undercharged Battery

Check) ............................................................... 1J-5

Generator Test (Overcharg ed Battery Check) .... 1J-6

Repair Instructions ........... ................................... 1J-6

Jump Starting in Case of Emergency.................. 1J-6

Battery Dismounting and Remounting ................ 1J-7

Water Pump / Generator Drive Belt Tension Inspection and Adjustment ................................ 1J-7

Water Pump / Generator Drive Belt Removal and Installation .................................................. 1J-8

Generator Unit Co mponents ............................... 1J-9

Generator Dismounting a nd Remounting............ 1J-9

Generator Components........ ............................. 1J-10

Generator Insp ection......................................... 1J-11

Specifications ..................................................... 1J-13 Charging System Specifications ....................... 1J-13

Tightening Torque Specifications ...................... 1J-13

Exhaust System .............. ......................... 1K-1

General Description .............................................1K-1

Exhaust System Description ............................... 1K-1

Diagnostic Information and Procedures ............1K-1 Exhaust System Check ....................................... 1K-1

Repair Instructions ........... ...................................1K-2

Exhaust System Components ............................. 1K-2

Exhaust Manifold Removal and Installation ........ 1K-3

Exhaust Pipe and Muffler Removal and Installation ......................................................... 1K-4

Specifications .................... ...................................1K-5

Tightening Torque Specifications ........................ 1K-5

Page 305 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-20

15) Install A/C compressor to its bracket (if equipped) referring to “Compressor Assembly Removal and

Installation in Section 7B” or “Compressor Assembly

Removal and Installa tion in Section 7B”.

16) Adjust A/C compressor belt tension (if equipped) referring to “Compressor Drive Belt Inspection and

Adjustment in Section 7B” or “Compressor Drive Belt

Inspection and Adjustment in Section 7B”.

17) Check to ensure that a ll removed parts are back in

place.

Reinstall any necessary parts which have not been

reinstalled.

18) Refill cooling system with coolant referring to “Cooling System Flush and Refill in Section 1F”. 19) Refill engine with engine oil

referring to “Engine Oil

and Filter Change in Section 0B”.

20) Refill transaxle with transa xle oil referring to“Manual

Transaxle Oil Change in Section 5B” or “A/T Fluid

Change in Section 5A”.

21) Install battery and tray.

22) Connect positive and negative cable at battery.

23) Install engine hood and connect windshield washer hose.

24) Verify that there is no fu el leakage, coolant leakage,

oil leakage and exhaust gas leakage at each

connection.

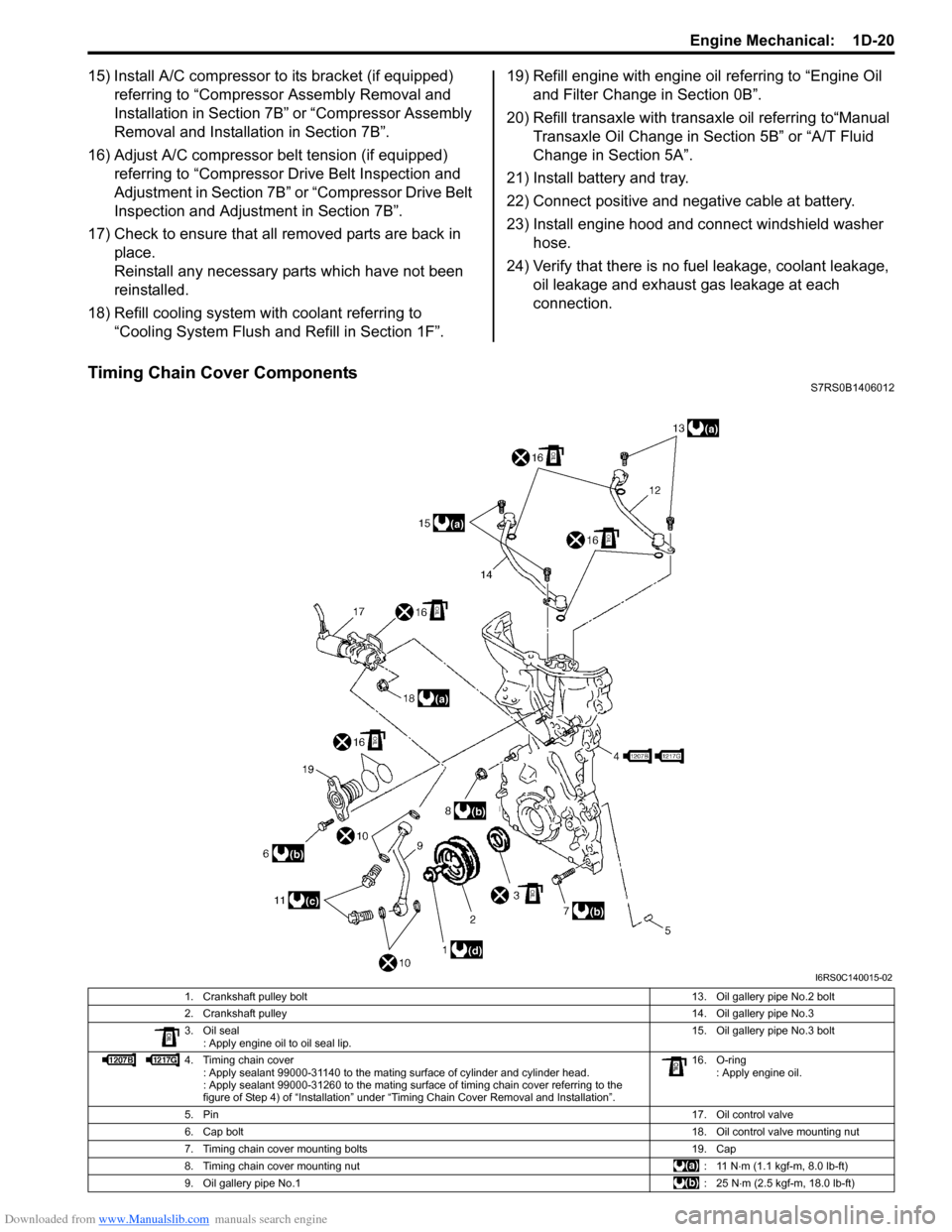

Timing Chain Cover ComponentsS7RS0B1406012

I6RS0C140015-02

1. Crankshaft pulley bolt 13. Oil gallery pipe No.2 bolt

2. Crankshaft pulley 14. Oil gallery pipe No.3

3. Oil seal : Apply engine oil to oil seal lip. 15. Oil gallery pipe No.3 bolt

4. Timing chain cover : Apply sealant 99000-31140 to the mating surface of cylinder and cylinder head.

: Apply sealant 99000-31260 to the mating surface of timing chain cover referring to the

figure of Step 4) of “Installation” under “Timing Chain Cover Removal and Installation”. 16. O-ring

: Apply engine oil.

5. Pin 17. Oil control valve

6. Cap bolt 18. Oil control valve mounting nut

7. Timing chain cover mounting bolts 19. Cap

8. Timing chain cover mounting nut : 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft)

9. Oil gallery pipe No.1 :25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

Page 306 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-21 Engine Mechanical:

Timing Chain Cover Removal and InstallationS7RS0B1406013

CAUTION!

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

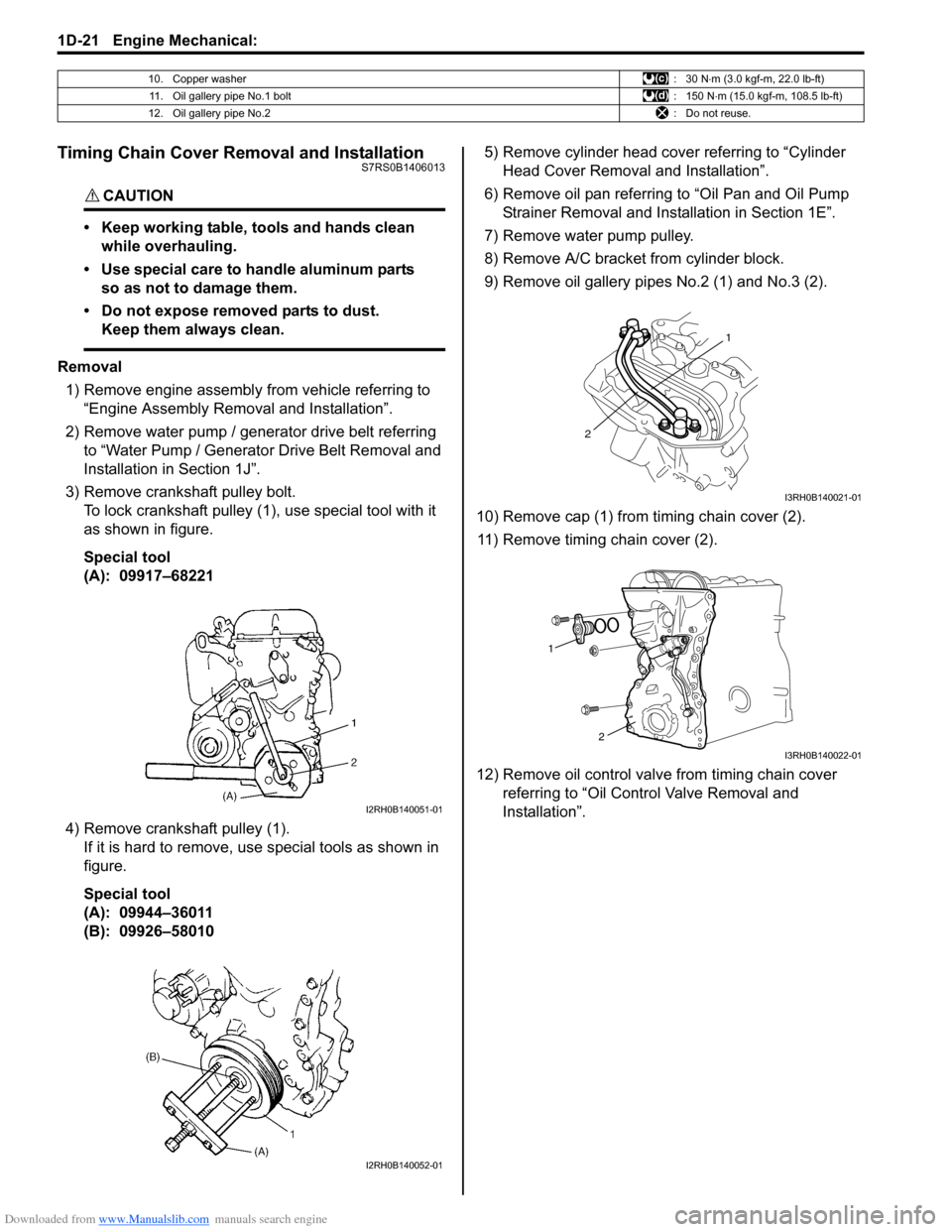

Removal

1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

3) Remove crankshaft pulley bolt. To lock crankshaft pulley (1), use special tool with it

as shown in figure.

Special tool

(A): 09917–68221

4) Remove crankshaft pulley (1). If it is hard to remove, use special tools as shown in

figure.

Special tool

(A): 09944–36011

(B): 09926–58010 5) Remove cylinder head cove

r referring to “Cylinder

Head Cover Removal and Installation”.

6) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Inst allation in Section 1E”.

7) Remove water pump pulley.

8) Remove A/C bracket from cylinder block.

9) Remove oil gallery pipe s No.2 (1) and No.3 (2).

10) Remove cap (1) from timing chain cover (2). 11) Remove timing chain cover (2).

12) Remove oil control valve from timing chain cover referring to “Oil Cont rol Valve Removal and

Installation”.

10. Copper washer :30 N⋅m (3.0 kgf-m, 22.0 lb-ft)

11. Oil gallery pipe No.1 bolt : 150 N⋅m (15.0 kgf-m, 108.5 lb-ft)

12. Oil gallery pipe No.2 : Do not reuse.

I2RH0B140051-01

I2RH0B140052-01

1

2

I3RH0B140021-01

1 2

I3RH0B140022-01

Page 367 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

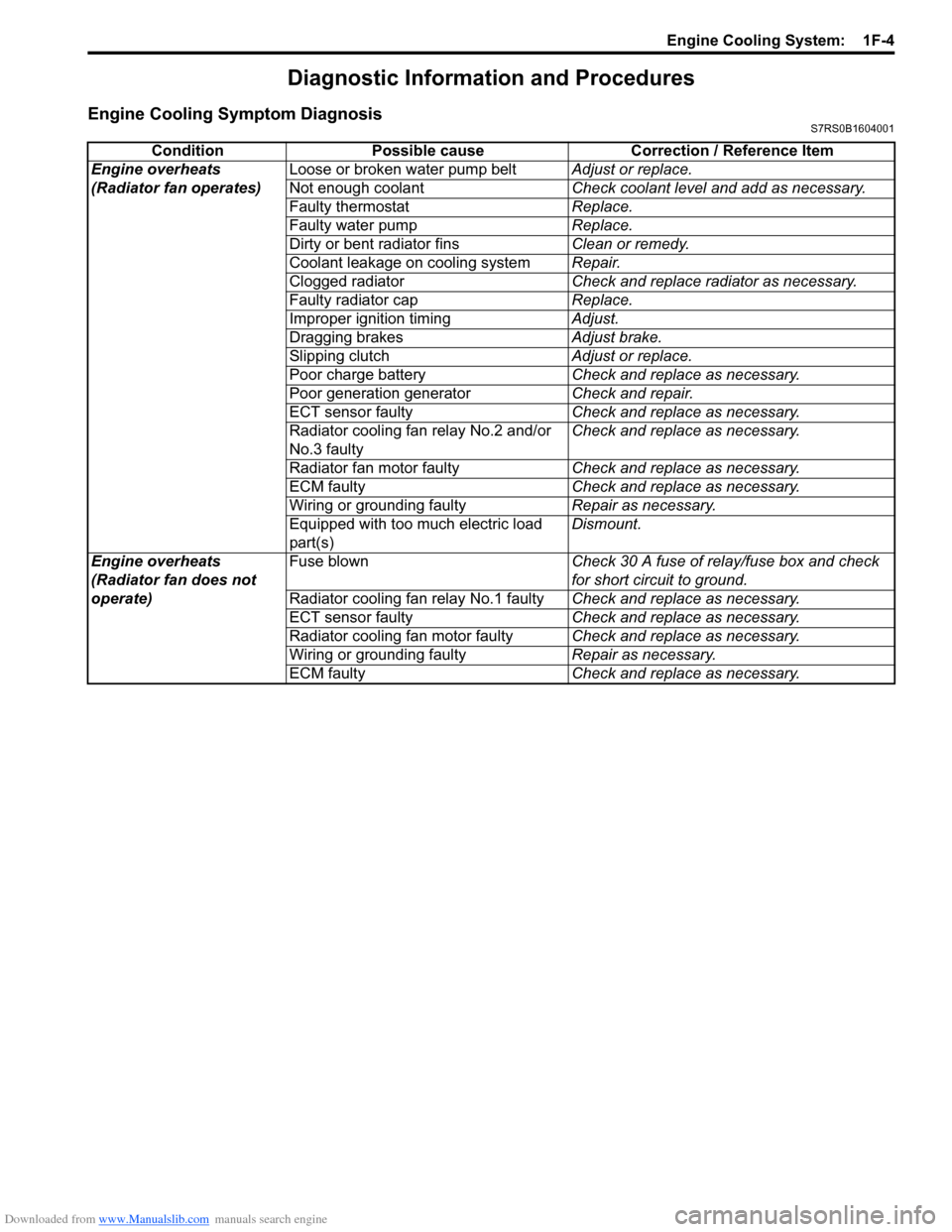

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS7RS0B1604001

ConditionPossible cause Correction / Reference Item

Engine overheats

(Radiator fan operates) Loose or broken water pump belt

Adjust or replace.

Not enough coolant Check coolant level and add as necessary.

Faulty thermostat Replace.

Faulty water pump Replace.

Dirty or bent radiator fins Clean or remedy.

Coolant leakage on cooling system Repair.

Clogged radiator Check and replace radiator as necessary.

Faulty radiator cap Replace.

Improper ignition timing Adjust.

Dragging brakes Adjust brake.

Slipping clutch Adjust or replace.

Poor charge battery Check and replace as necessary.

Poor generation generator Check and repair.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan relay No.2 and/or

No.3 faulty Check and replace as necessary.

Radiator fan motor faulty Check and replace as necessary.

ECM faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

Equipped with too much electric load

part(s) Dismount.

Engine overheats

(Radiator fan does not

operate) Fuse blown

Check 30 A fuse of relay/fuse box and check

for short circuit to ground.

Radiator cooling fan relay No.1 faulty Check and replace as necessary.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan motor faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check and replace as necessary.