Wipers SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 266 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-216 Engine General Information and Diagnosis:

Repair Instructions

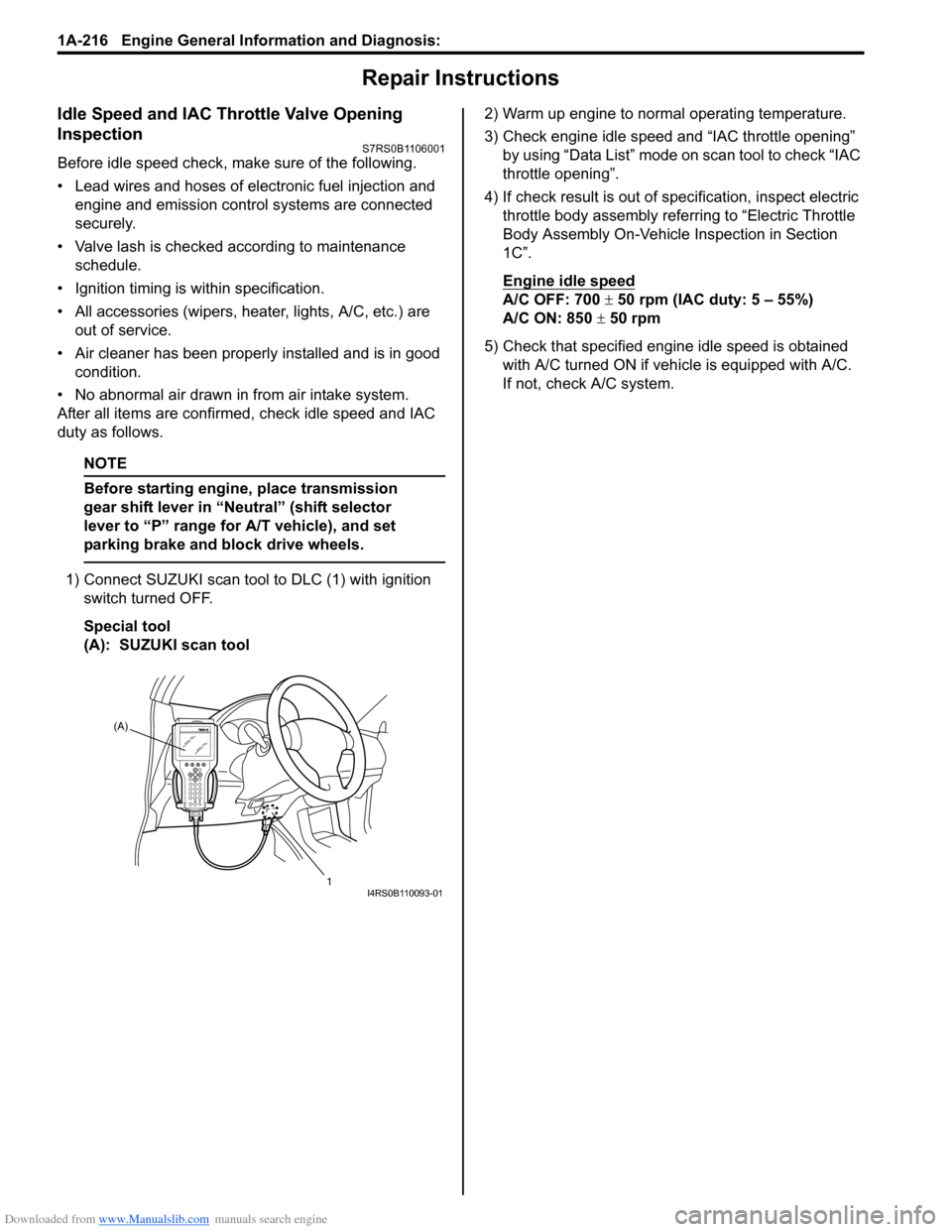

Idle Speed and IAC Throttle Valve Opening

Inspection

S7RS0B1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are out of service.

• Air cleaner has been properly installed and is in good condition.

• No abnormal air drawn in from air intake system.

After all items are confirmed, check idle speed and IAC

duty as follows.

NOTE

Before starting engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T vehicle), and set

parking brake and block drive wheels.

1) Connect SUZUKI scan tool to DLC (1) with ignition

switch turned OFF.

Special tool

(A): SUZUKI scan tool 2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC throttle opening”

by using “Data List” mode on scan tool to check “IAC

throttle opening”.

4) If check result is out of sp ecification, inspect electric

throttle body assembly referring to “Electric Throttle

Body Assembly On-Vehicle Inspection in Section

1C”.

Engine idle speed

A/C OFF: 700 ± 50 rpm (IAC duty: 5 – 55%)

A/C ON: 850 ± 50 rpm

5) Check that specified engine idle speed is obtained with A/C turned ON if vehi cle is equipped with A/C.

If not, check A/C system.

(A)

1

I4RS0B110093-01

Page 1169 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Door Switch (Front / Rear Door) Inspection ...... 9C-17

Rear End Door Switch Inspection ..................... 9C-17

Outside Air Temperature Sensor Removal and Installation (If Equipped) .......................... 9C-17

Outside Air Temperature Sensor Inspection (If Equipped) ................................................... 9C-17

Instrument Panel Removal and Installation....... 9C-18

Information Display (Clock) Removal and Installation ....................................................... 9C-19

Audio Unit Removal and In stallation ................. 9C-19

Front Speaker Removal and Installation ........... 9C-19

Rear Speaker Removal and Installation............ 9C-20

Horn Removal and Installation .......................... 9C-20

Horn Inspection ................................................. 9C-20

Horn Relay Inspection ....................................... 9C-20

Antenna Amplifier Removal and Installation ..... 9C-21

Remote Audio Control Switch Removal and Installation (If Equipped) ................................. 9C-21

Remote Audio Control Switch Inspection (If Equipped)........................................................ 9C-22

Vehicle Speed Signal Inspection (For Audio Unit) (If Equipped) ........................................... 9C-22

Specifications ..................................................... 9C-22

Tightening Torque Specifications ...................... 9C-22

Wipers / Washers............ ......................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis .... 9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions .............................................. 9D-2 Wipers and Washers Components ..................... 9D-2

Washer Tank and Washer Pump Removal and Installation .................................................. 9D-3

Washer Pump Inspection .................................... 9D-3

Windshield Wiper Removal and Installation ........ 9D-4

Windshield Wiper Motor Inspection..................... 9D-5

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection .............................. 9D-7

Windshield Wiper and Washer Switch Removal and Installation................................... 9D-7

Windshield Wiper and Washer Switch Inspection.......................................................... 9D-8

Rear Wiper and Washer Switch Removal and Installation ......................................................... 9D-9

Rear Wiper and Washer Switch Inspection......... 9D-9

Rear Wiper Relay Removal and Installation ..... 9D-10

Rear Wiper Relay Inspection ............................ 9D-10

Specifications ..................................................... 9D-10

Tightening Torque Specifications ...................... 9D-10

Glass / Windows / Mirrors.. ..................... 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System Description ........................................................ 9E-1

Windshield Construction ..................................... 9E-1

Diagnostic Information and Procedures ............ 9E-2 Rear End door Window Defogger Symptom Diagnosis .......................................................... 9E-2 Power Window Control System Symptom

Diagnosis .......................................................... 9E-2

Power Door Mirror Control System Symptom Diagnosis .......................................................... 9E-3

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-3

Repair Instructions ........... ................................... 9E-4

Windshield Removal and In stallation .................. 9E-4

Front Door Window Components ........................ 9E-8

Front Door Glass Removal and Installation ........ 9E-8

Front Door Window Re gulator Removal and

Installation ......................................................... 9E-9

Front Door Window Regula tor Inspection ......... 9E-10

Rear Door Window Components ...................... 9E-10

Rear Door Glass Removal and Installation ....... 9E-11

Rear Door Window Regulator Removal and Installation ....................................................... 9E-12

Rear Door Window Regulato r Inspection .......... 9E-12

Rear End Door Window Components ............... 9E-13

Rear End Door Glass Removal and Installation ....................................................... 9E-13

Rear End Door Window Defogger Switch Inspection ........................................................ 9E-14

Rear End Door Window Defogger Relay Inspection ........................................................ 9E-14

Rear End Door Window Defogger Wire Inspection ........................................................ 9E-15

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-15

Power Window Main Switch Inspection ............ 9E-16

Power Window Sub Switch Inspection .............. 9E-17

Door Mirror Components.. ................................. 9E-18

Door Mirror Removal and In stallation................ 9E-18

Power Door Mirror Switch Inspection ................ 9E-18

Power Door Mirror Actuator Inspection ............. 9E-19

Door Mirror Heater Switch Inspection (If Equipped) ........................................................ 9E-19

Door Mirror Heater Inspec tion (If Equipped) ..... 9E-19

Special Tools and Equipmen t ........................... 9E-19

Recommended Service Material ....................... 9E-19

Security and Locks......... ..........................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ............ ............................... 9F-2

Power Door Lock and Keyless Entry System

Component Location ......................................... 9F-2

Diagnostic Information and Procedures ............ 9F-3 Power Door Lock System Symptom Diagnosis .......................................................... 9F-3

Power Door Lock System Operation Inspection .......................................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped) .......................................................... 9F-4

Keyless Entry System Operation Inspection ....... 9F-5

Door Lock Function of Keyless Start System Symptom Diagnosis (If Equipped)..................... 9F-5

Page 1318 of 1496

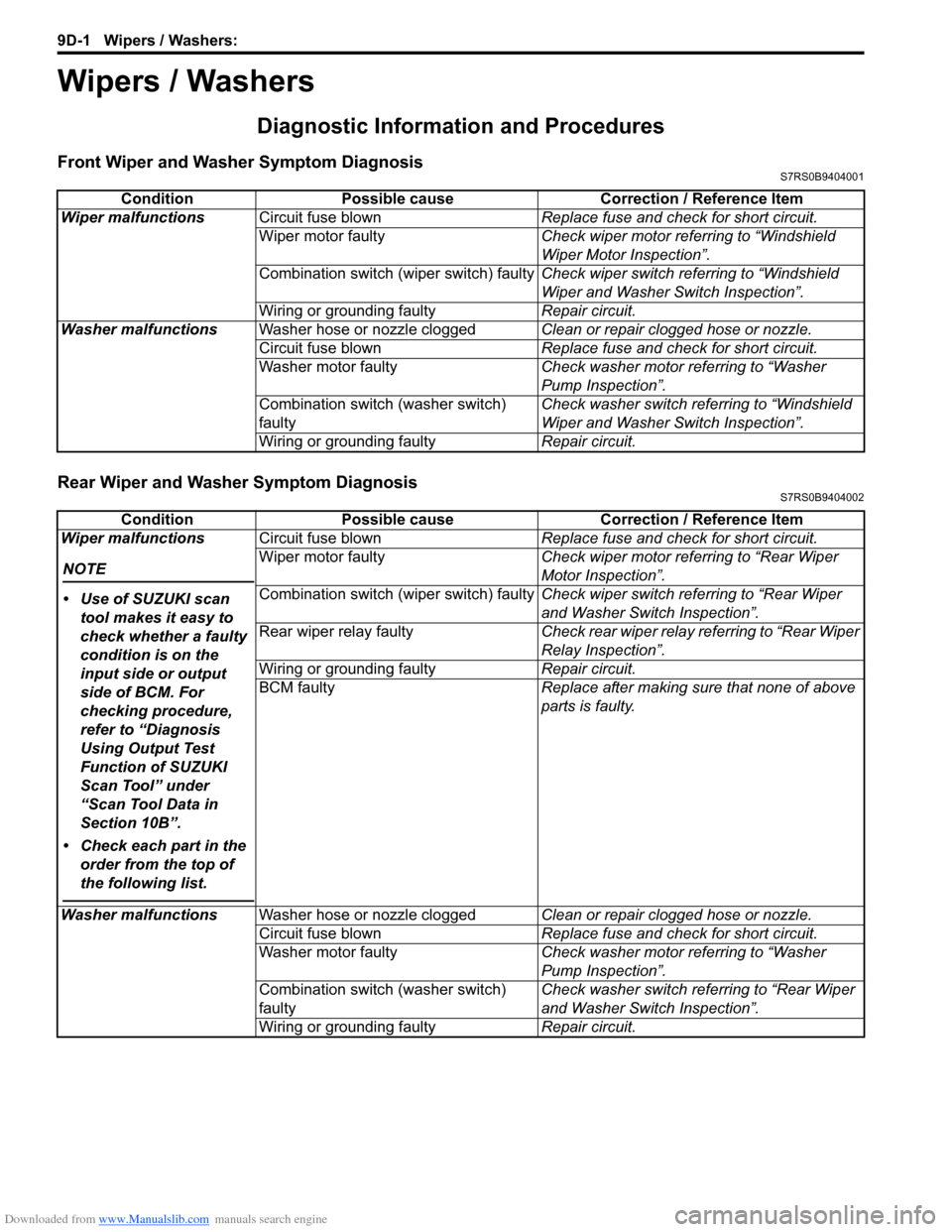

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1319 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-2

Repair Instructions

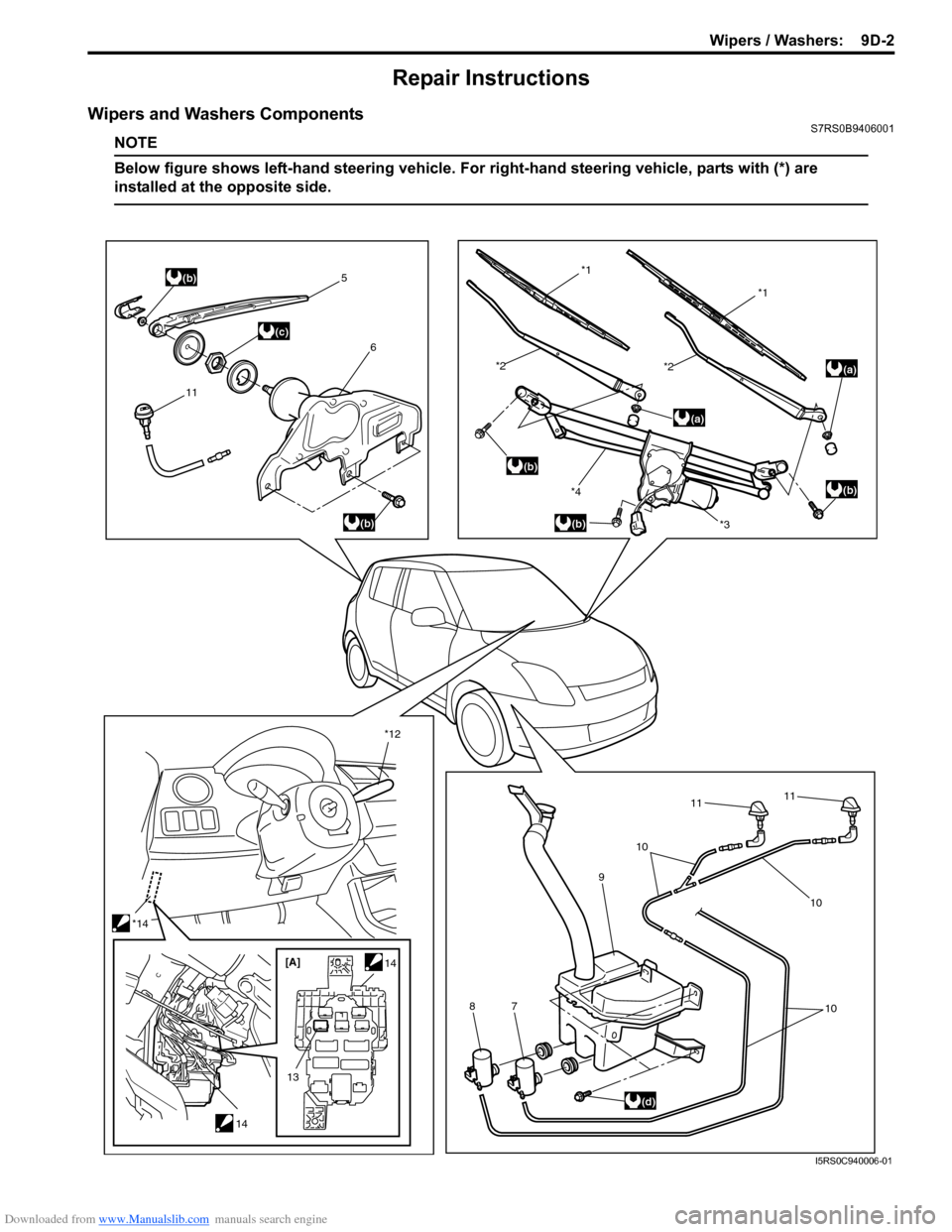

Wipers and Washers ComponentsS7RS0B9406001

NOTE

Below figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the opposite side.

11 5

6

(b)

(b)

(c)

*12

13 14

*14

14[A]

(a)

(a)

(b)

(b)

*3*1

*2

*1

*4

(b)

*2

(d)

7 9

10

10

10

11

118

I5RS0C940006-01

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

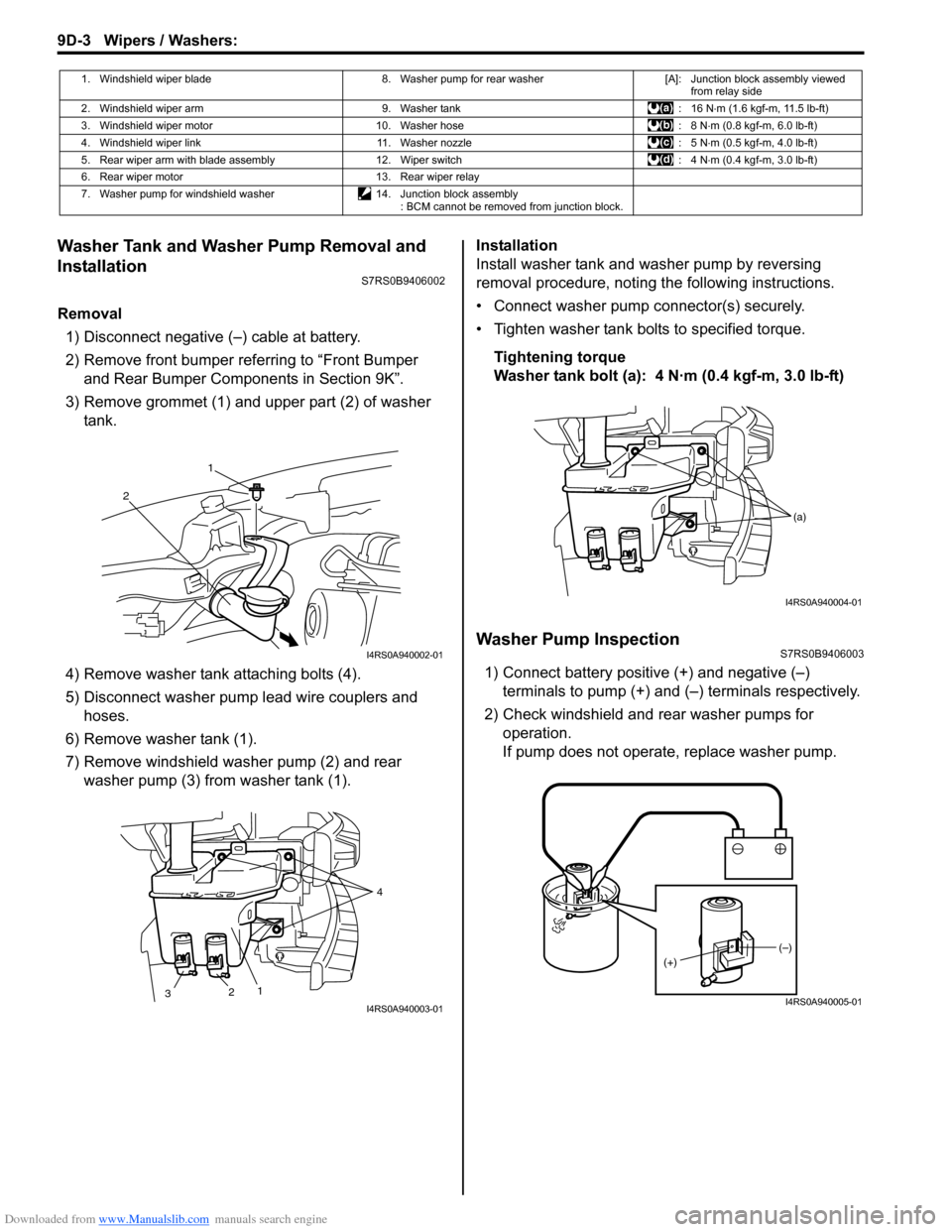

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1321 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-4

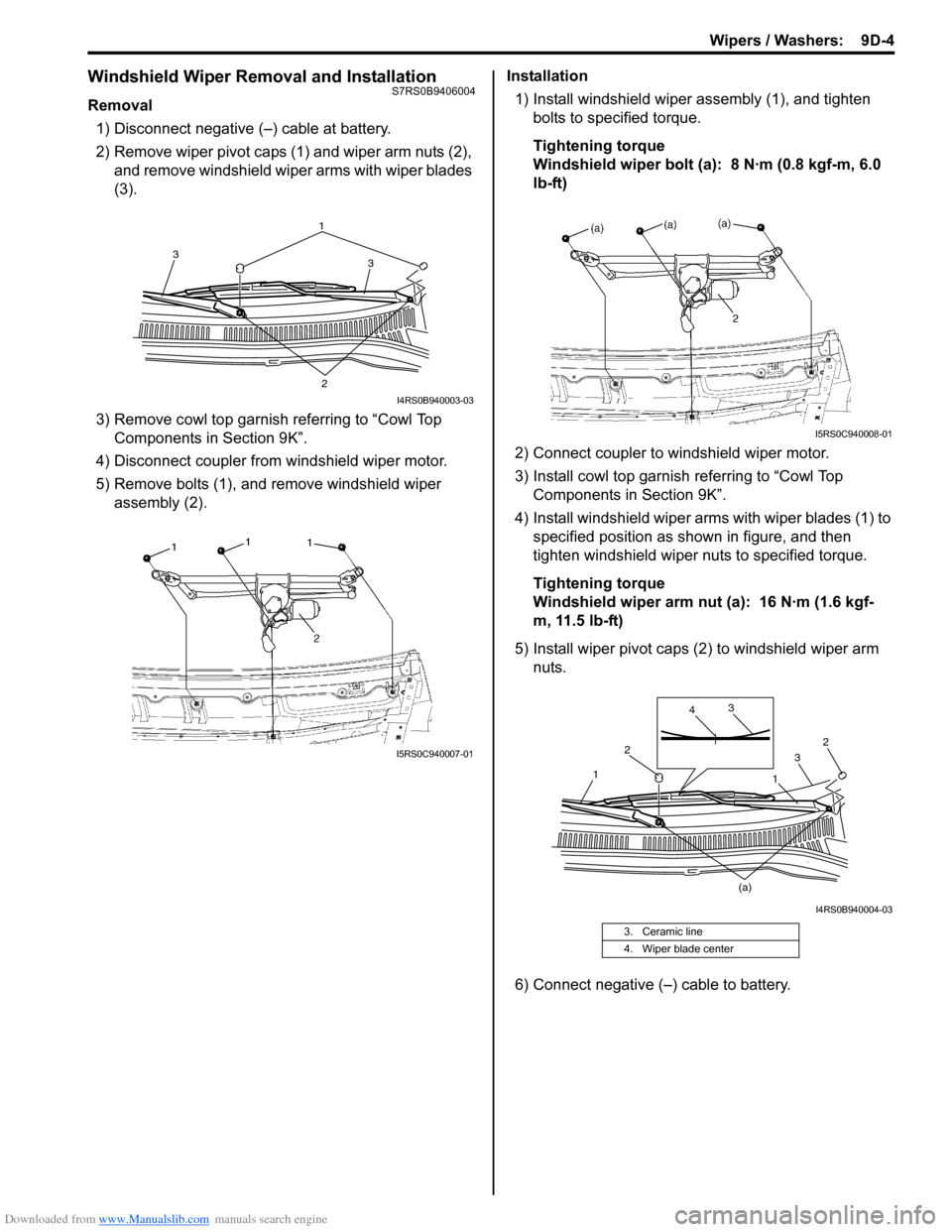

Windshield Wiper Removal and InstallationS7RS0B9406004

Removal1) Disconnect negative (–) cable at battery.

2) Remove wiper pivot caps (1) and wiper arm nuts (2), and remove windshield wiper arms with wiper blades

(3).

3) Remove cowl top garnish referring to “Cowl Top Components in Section 9K”.

4) Disconnect coupler from windshield wiper motor.

5) Remove bolts (1), and remove windshield wiper assembly (2). Installation

1) Install windshield wiper assembly (1), and tighten bolts to specified torque.

Tightening torque

Windshield wiper bolt (a): 8 N·m (0.8 kgf-m, 6.0

lb-ft)

2) Connect coupler to windshield wiper motor.

3) Install cowl top garnish referring to “Cowl Top

Components in Section 9K”.

4) Install windshield wiper arms with wiper blades (1) to specified position as shown in figure, and then

tighten windshield wiper nuts to specified torque.

Tightening torque

Windshield wiper arm nut (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

5) Install wiper pivot caps (2 ) to windshield wiper arm

nuts.

6) Connect negative (–) cable to battery.

1 3

3

2

I4RS0B940003-03

I5RS0C940007-01

3. Ceramic line

4. Wiper blade center

I5RS0C940008-01

2

2 3

3

4

1

1

(a)

I4RS0B940004-03

Page 1322 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-5 Wipers / Washers:

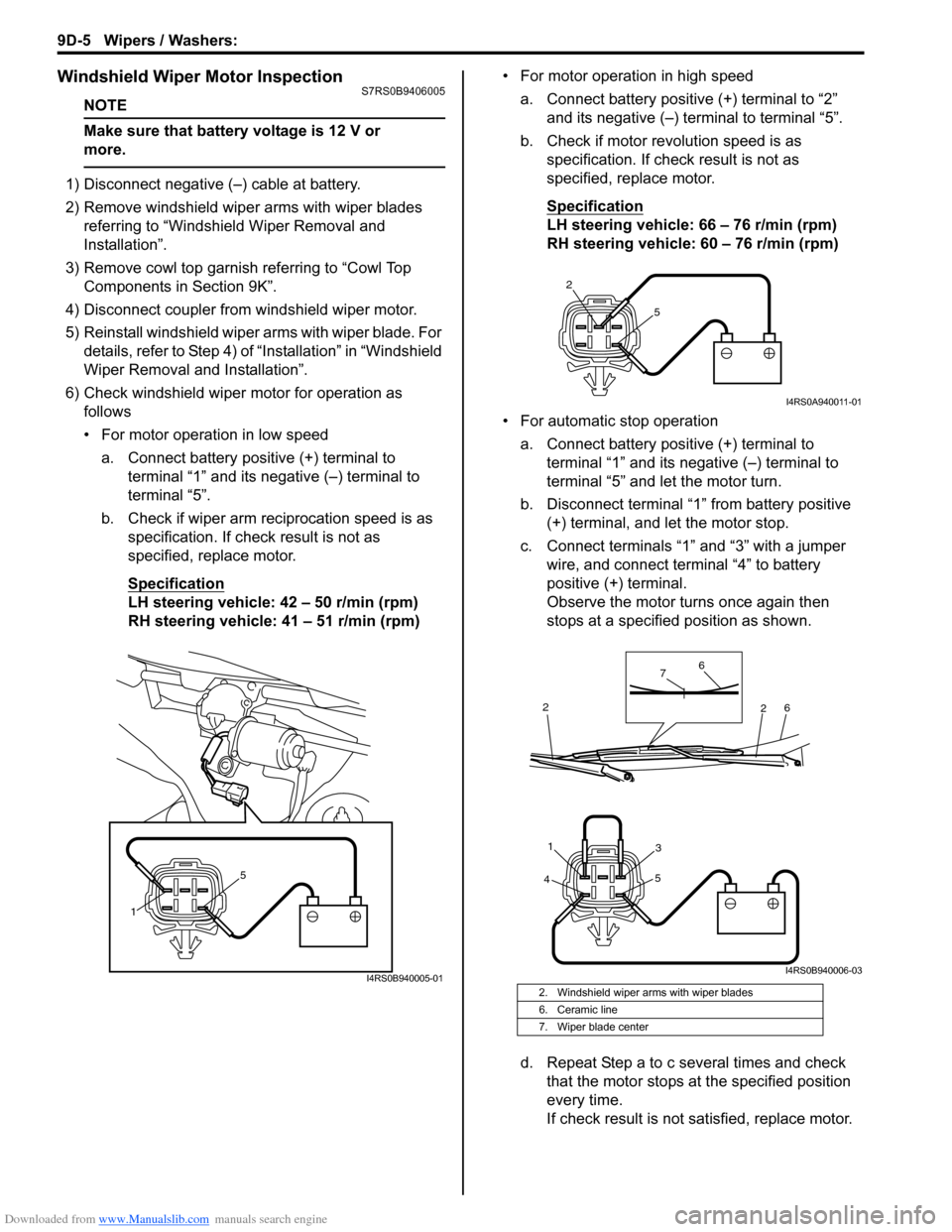

Windshield Wiper Motor InspectionS7RS0B9406005

NOTE

Make sure that battery voltage is 12 V or

more.

1) Disconnect negative (–) cable at battery.

2) Remove windshield wiper arms with wiper blades

referring to “Windshield Wiper Removal and

Installation”.

3) Remove cowl top garnish referring to “Cowl Top Components in Section 9K”.

4) Disconnect coupler from windshield wiper motor.

5) Reinstall windshield wiper arms with wiper blade. For

details, refer to Step 4) of “Installation” in “Windshield

Wiper Removal and Installation”.

6) Check windshield wiper motor for operation as

follows

• For motor operation in low speed

a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5”.

b. Check if wiper arm reciprocation speed is as specification. If check result is not as

specified, replace motor.

Specification

LH steering vehicle: 42 – 50 r/min (rpm)

RH steering vehicle: 41 – 51 r/min (rpm) • For motor operation in high speed

a. Connect battery positive (+) terminal to “2” and its negative (–) terminal to terminal “5”.

b. Check if motor revolution speed is as specification. If chec k result is not as

specified, replace motor.

Specification

LH steering vehicle: 66 – 76 r/min (rpm)

RH steering vehicle: 60 – 76 r/min (rpm)

• For automatic stop operation a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5” and let the motor turn.

b. Disconnect terminal “1” from battery positive (+) terminal, and let the motor stop.

c. Connect terminals “1” and “3” with a jumper wire, and connect terminal “4” to battery

positive (+) terminal.

Observe the motor turns once again then

stops at a specified position as shown.

d. Repeat Step a to c several times and check that the motor stops at the specified position

every time.

If check result is not satisfied, replace motor.

1 5

I4RS0B940005-012. Windshield wiper arms with wiper blades

6. Ceramic line

7. Wiper blade center

2

5

I4RS0A940011-01

4 5

31

6

6

7

2

2

I4RS0B940006-03

Page 1323 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-6

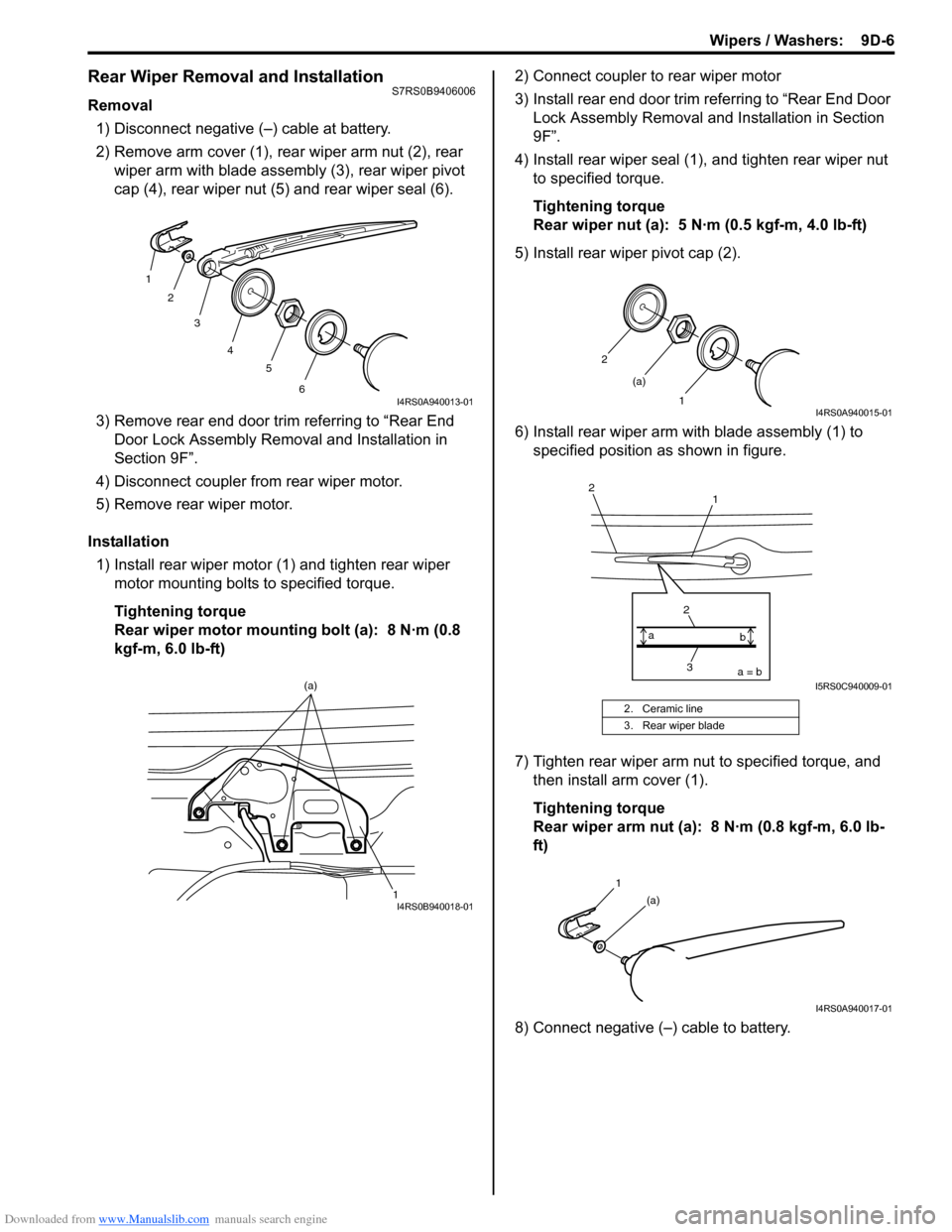

Rear Wiper Removal and InstallationS7RS0B9406006

Removal1) Disconnect negative (–) cable at battery.

2) Remove arm cover (1), rear wiper arm nut (2), rear wiper arm with blade assembly (3), rear wiper pivot

cap (4), rear wiper nut (5) and rear wiper seal (6).

3) Remove rear end door trim referring to “Rear End Door Lock Assembly Remo val and Installation in

Section 9F”.

4) Disconnect coupler from rear wiper motor.

5) Remove rear wiper motor.

Installation 1) Install rear wiper motor (1) and tighten rear wiper motor mounting bolts to specified torque.

Tightening torque

Rear wiper motor mounting bolt (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft) 2) Connect coupler to rear wiper motor

3) Install rear end door trim referring to “Rear End Door

Lock Assembly Removal and Installation in Section

9F”.

4) Install rear wiper seal (1), and tighten rear wiper nut to specified torque.

Tightening torque

Rear wiper nut (a): 5 N·m (0.5 kgf-m, 4.0 lb-ft)

5) Install rear wiper pivot cap (2).

6) Install rear wiper arm with blade assembly (1) to specified position as shown in figure.

7) Tighten rear wiper arm nut to specified torque, and then install arm cover (1).

Tightening torque

Rear wiper arm nut (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

8) Connect negative (–) cable to battery.

1 2

3

4 5

6

I4RS0A940013-01

1

(a)I4RS0B940018-01

2. Ceramic line

3. Rear wiper blade

2

1

(a)

I4RS0A940015-01

1

2

3

2a = b

a

bI5RS0C940009-01

1

(a)

I4RS0A940017-01

Page 1324 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-7 Wipers / Washers:

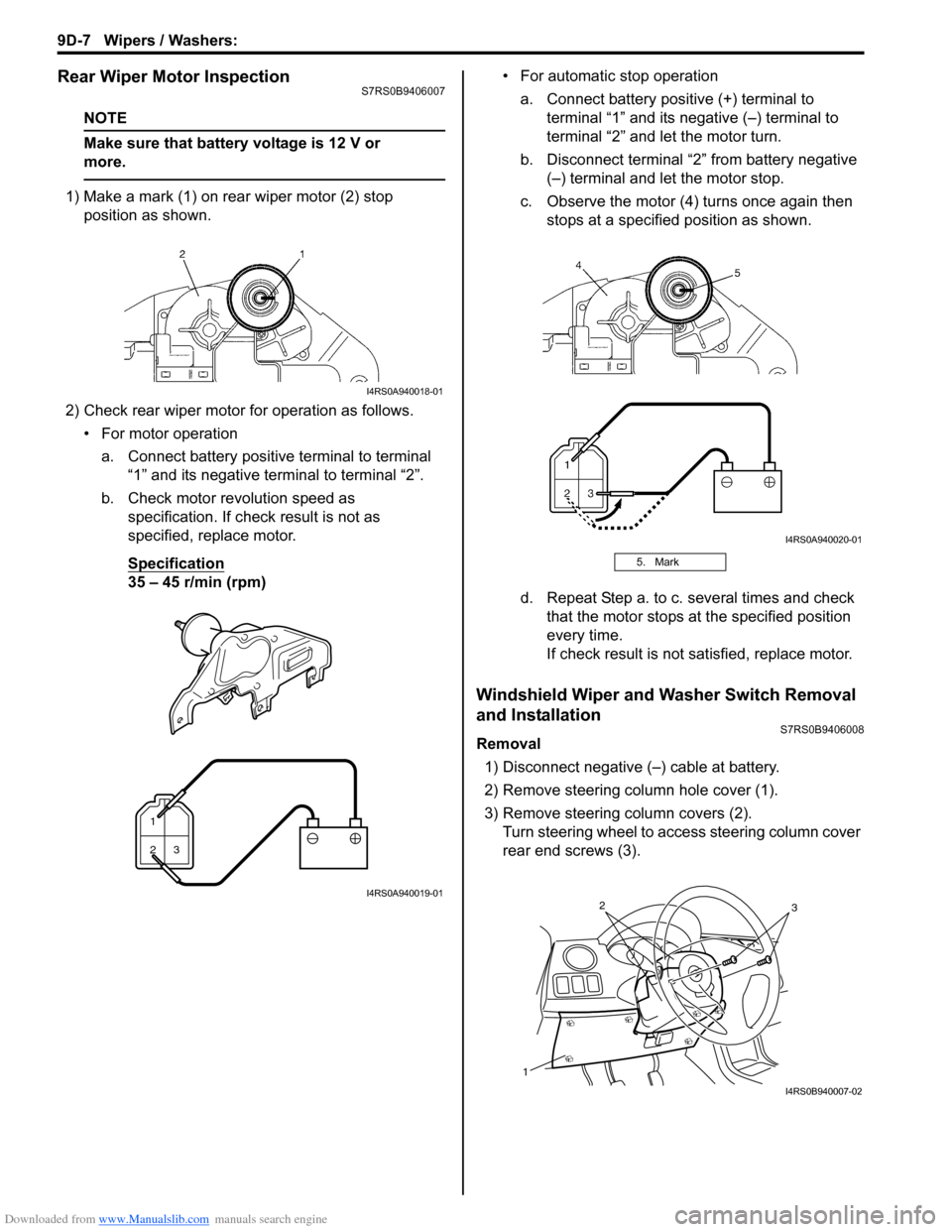

Rear Wiper Motor InspectionS7RS0B9406007

NOTE

Make sure that battery voltage is 12 V or

more.

1) Make a mark (1) on rear wiper motor (2) stop position as shown.

2) Check rear wiper motor for operation as follows. • For motor operationa. Connect battery positive terminal to terminal “1” and its negative terminal to terminal “2”.

b. Check motor revolution speed as specification. If check result is not as

specified, replace motor.

Specification

35 – 45 r/min (rpm) • For automatic stop operation

a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “2” and let the motor turn.

b. Disconnect terminal “2” from battery negative (–) terminal and let the motor stop.

c. Observe the motor (4) turns once again then stops at a specified position as shown.

d. Repeat Step a. to c. several times and check that the motor stops at the specified position

every time.

If check result is not satisfied, replace motor.

Windshield Wiper and Washer Switch Removal

and Installation

S7RS0B9406008

Removal

1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to a ccess steering column cover

rear end screws (3).

I4RS0A940018-01

1

23

I4RS0A940019-01

5. Mark

I4RS0A940020-01

1

32

I4RS0B940007-02