ELECTRIC SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 5 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions ............................................... 00-1

Precautions........................................................... 00-1

Precautions for Vehicles Equipped with a Supplemental Restraint (A ir Bag) System ........ 00-1

General Precautions ........... ................................ 00-4

Warning for Wheel (with tire) Removal ............... 00-7

Warning for Handling Emergency Flat Tire Repair Kit .......................................................... 00-7

Precautions for Catalytic Converter .................... 00-7

Precautions for Installing Mobile Communication Equipment ............................... 00-7

Precaution for CAN Communication System ...... 00-7 Precautions for Electrical Circuit Service ............ 00-8

Air Bag Warning ................................................ 00-10

Air Bag System Service Warning ...................... 00-10

Fastener Caution............................................... 00-10

Suspension Caution .......................................... 00-10

Wheels and Tires Caution ................................. 00-10

Precaution for Vehicle Equipped with ESP

®

System ............................................................ 00-11

Brake Caution ................................................... 00-11

Repair Instructions ........ .................................... 00-11

Electrical Circuit Inspection Procedure ............. 00-11

Intermittent and Poor Co nnection Inspection .... 00-13

Page 6 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-1 Precautions:

Precautions

Precautions

Precautions

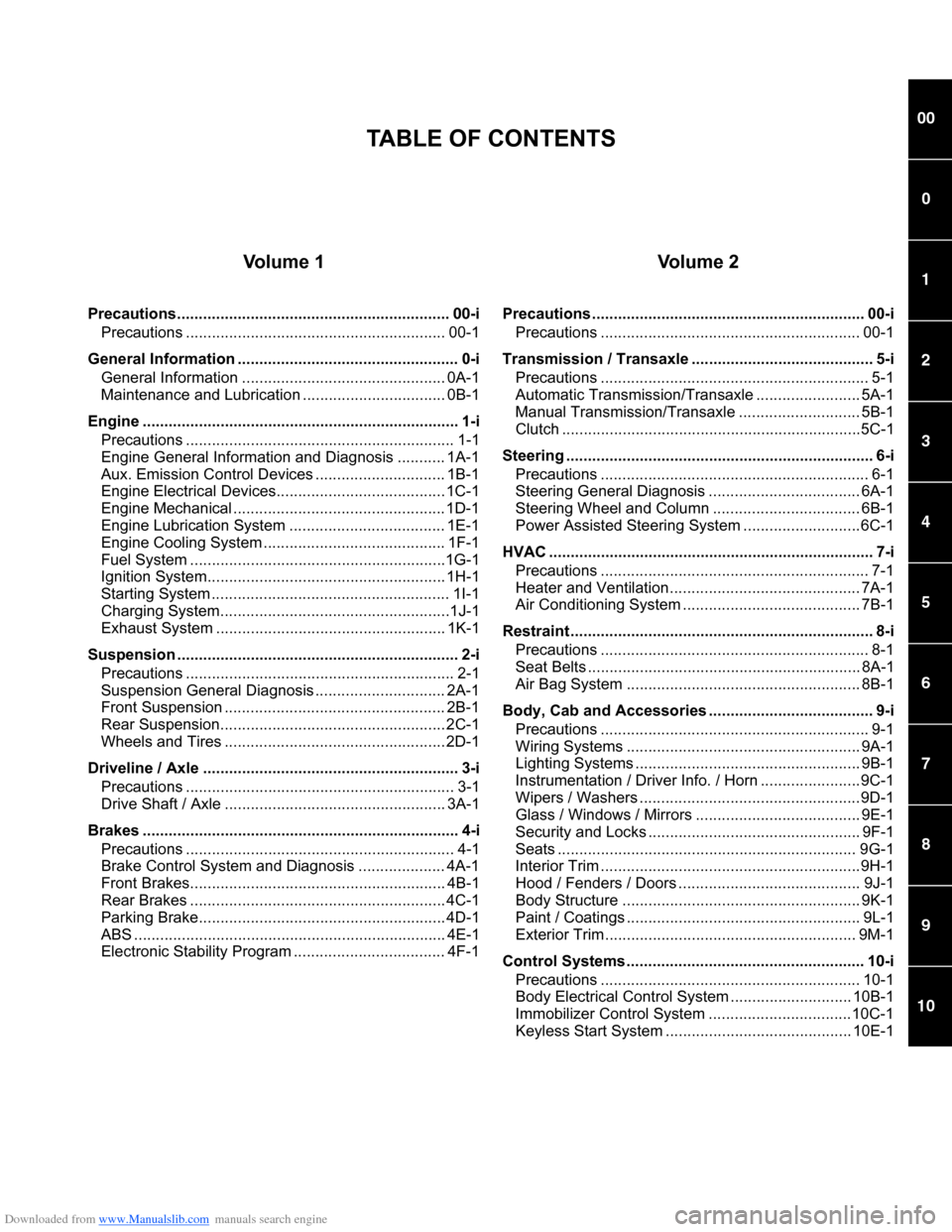

Precautions for Vehicles Equipped with a

Supplemental Restraint (Air Bag) System

S7RS0B0000001

WARNING!

• The configuration of air bag system parts are as shown in the figure. When it is

necessary to service (remove, reinstall and

inspect) these parts, be sure to follow

procedures described in Air Bag System

section. Failure to follow proper

procedures could result in possible air bag

system activation, personal injury, damage

to parts or air bag system being unable to

activate when necessary.

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, or any other air bag system

components. Modifications can adversely

affect air bag system performance and

lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F) (for

example, during a paint baking process),

remove the air bag system components

beforehand to avoid component damage

or unintended air bag system activation.

Diagnosis

• When troubleshooting air bag system, be sure to follow “Diagnosis” in Air Bag System section.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacement.

• Never use electrical test equipment other than that specified.

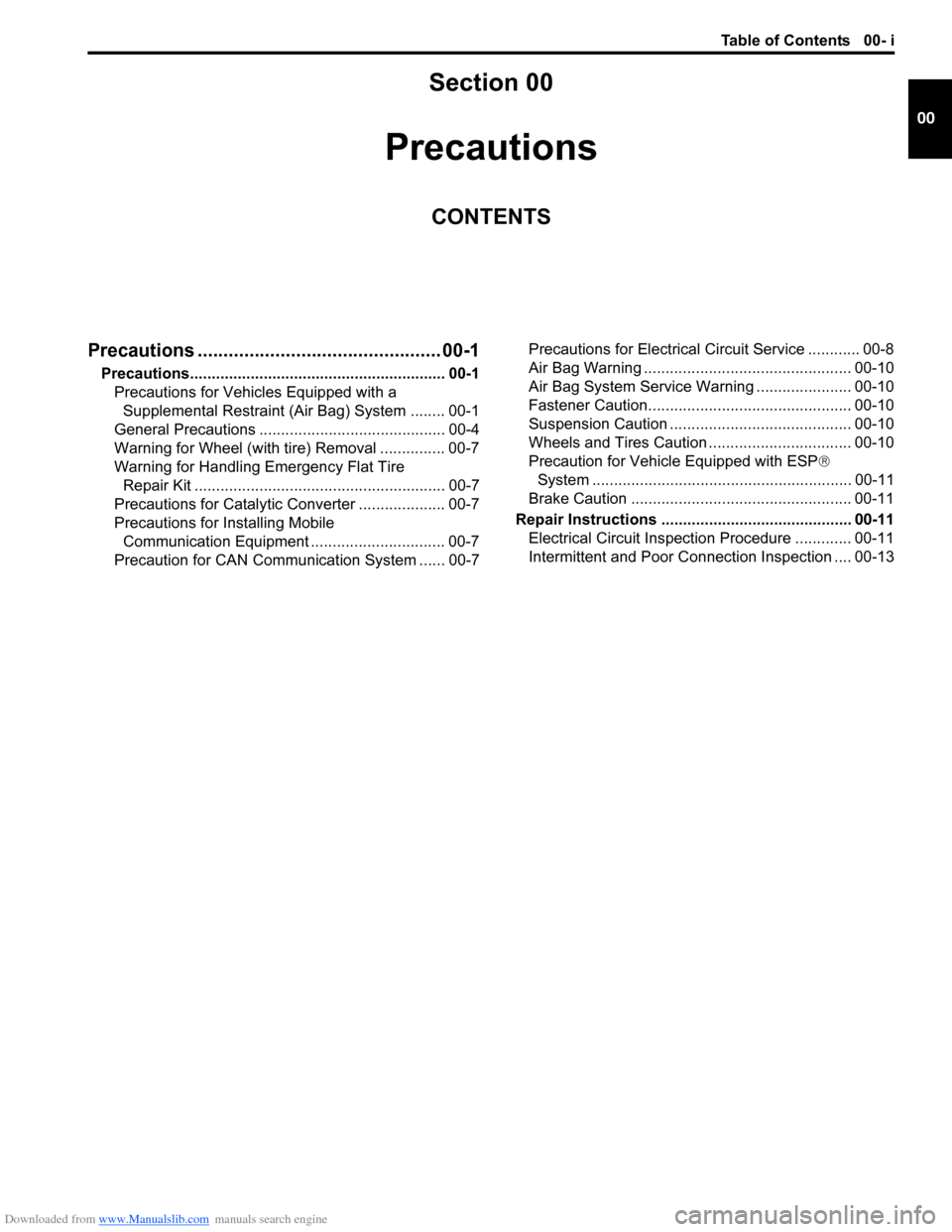

WARNING!

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger, side and curtain) and seat belt

pretensioners (driver and passenger). It is

very dangerous as the electric current from

the tester may deploy the air bag or activate

the pretensioner.

1. Air bag wire harness (in floor, main and instrument panel harness) 6. Driver air bag (inflator) module

2. Passenger air bag (inflator) module 7. Side air bag (inflator) module (if equipped)

3. SDM 8. Curtain air bag (inflator) module (if equipped)

4. Seat belt pretensioner 9. Forward sensor

5. Contact coil 10. Side sensor (if equipped)

1 2

3

4

4

5

6

7 7

8

9

10 10

I4RS0B000001-02

I4RS0A000002-02

Page 7 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-2

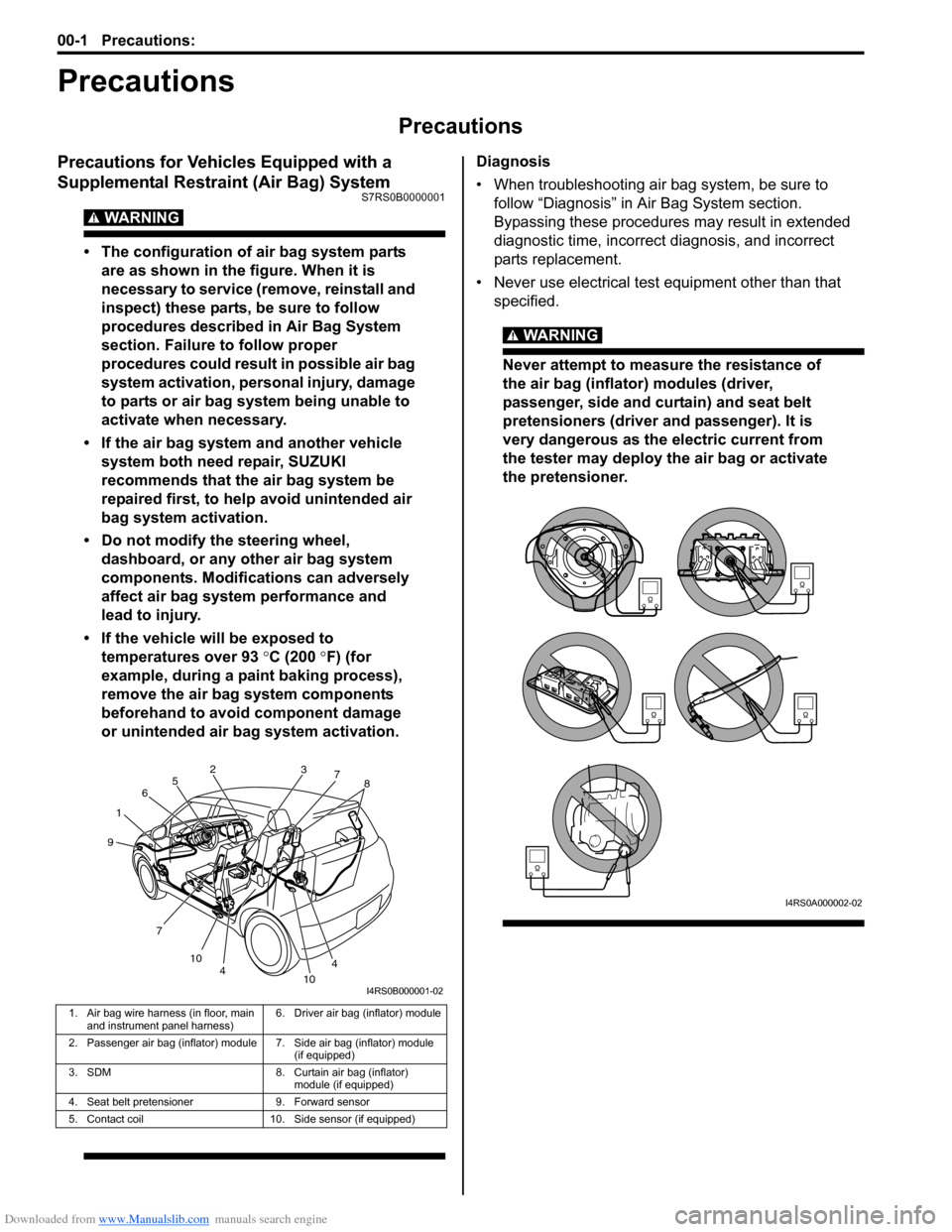

Servicing and Handling

WARNING!

Many of service procedures require

disconnection of “A/BAG” fuse and all air

bag (inflator) module(s) from initiator circuit

to avoid an accidental deployment.

Driver, Passenger, Side and Curtain Air Bag

(Inflator) Modules

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module. When placing a live air bag

(inflator) module on a bench or other

surface, always face the bag up, away from

the surface. As the live passenger air bag

(inflator) module must be placed with its

bag (trim cover) facing up, place it on the

workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment. Otherwise, personal injury

may result.

• Never dispose of live (undeployed) air bag (inflator) modules (driver, passenger, side

and curtain). If disposal is necessary, be

sure to deploy them according to

deployment procedures described in “Air

Bag (Inflator) Module and Seat Belt

Pretensioner Disposal in Section 8B”

before disposal.

• The air bag (inflator) module immediately

after deployment is very hot. Wait for at

least half an hour to cool it off before

proceeding the work.

• After an air bag (inflator) module has been deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

1

2

3

[A]

[B]

I4RS0A000003-02

Page 8 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-3 Precautions:

WARNING!

SDM

• For handling and storage of a SDM, select a place where the ambient temperature

below 65 °C (150 °F), without high humidity

and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic

Module (SDM). Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the

vehicle. All SDM and mounting bracket

fasteners must be carefully torqued and

the arrow must be pointing toward the

front of the vehicle to ensure proper

operation of the air bag system.

The SDM could be activated when powered

while not rigidly att ached to the vehicle

which could cause deployment and result

in personal injury.

WARNING!

Driver and Passenger Seat Belt

Pretensioners

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by wire or connector of pretensioner. When

placing a live seat belt pretensioner on the

workbench or some place like that, never

put something on seat belt pretensioner.

Otherwise, personal injury may result.

• Never dispose of live (inactivated) seat belt pretensioners (drive and passenger). If

disposal is necessary, be sure to activate

them according to activation procedures

described in “Air Bag (Inflator) Module and

Seat Belt Pretensioner Disposal in Section

8B” before disposal.

• The seat belt pretensioner immediately after activation is very hot. Wait for at least

half an hour to cool it off before

proceeding the work.

• With many service procedures, gloves and safety glasses should be worn to prevent

any possible irritation of the skin or eyes.

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect system

parts and other related parts according to instructions

under “Repair and Inspection Required after Accident

in Section 8B”.

• When servicing parts other than air bag system, if shocks may be applied to air bag system component

parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger, side and curtain), seat belt pretensioners

(driver and passenger), forward sensor, side sensors

or SDM, be careful not to drop it or apply an impact to

it. If an excessive impact was applied, never attempt

disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passenger, side

and curtain) or seat belt pretensioners (drive and

passenger), wipe off immediately with a dry cloth.

• Air bag wire harness is included in floor and instrument panel wire harnesses. Air bag wire

harness branched off from floor and instrument panel

wire harnesses can be identifie d easily as it is covered

with a yellow protection tube and it has yellow

connectors. Be very ca reful when handling it.

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• Never use air bag system component parts from another vehicle.

• When using electric welding, be sure to disconnect all air bag (inflator) module connectors and pretensioner

connectors from air bag wire harness respectively.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

• WARNING / CAUTION labels are attached on each

part of air bag system components. Be sure to follow

the instructions.

• After vehicle is completely repaired, perform “Air Bag Diagnostic System Check in Section 8B”.

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

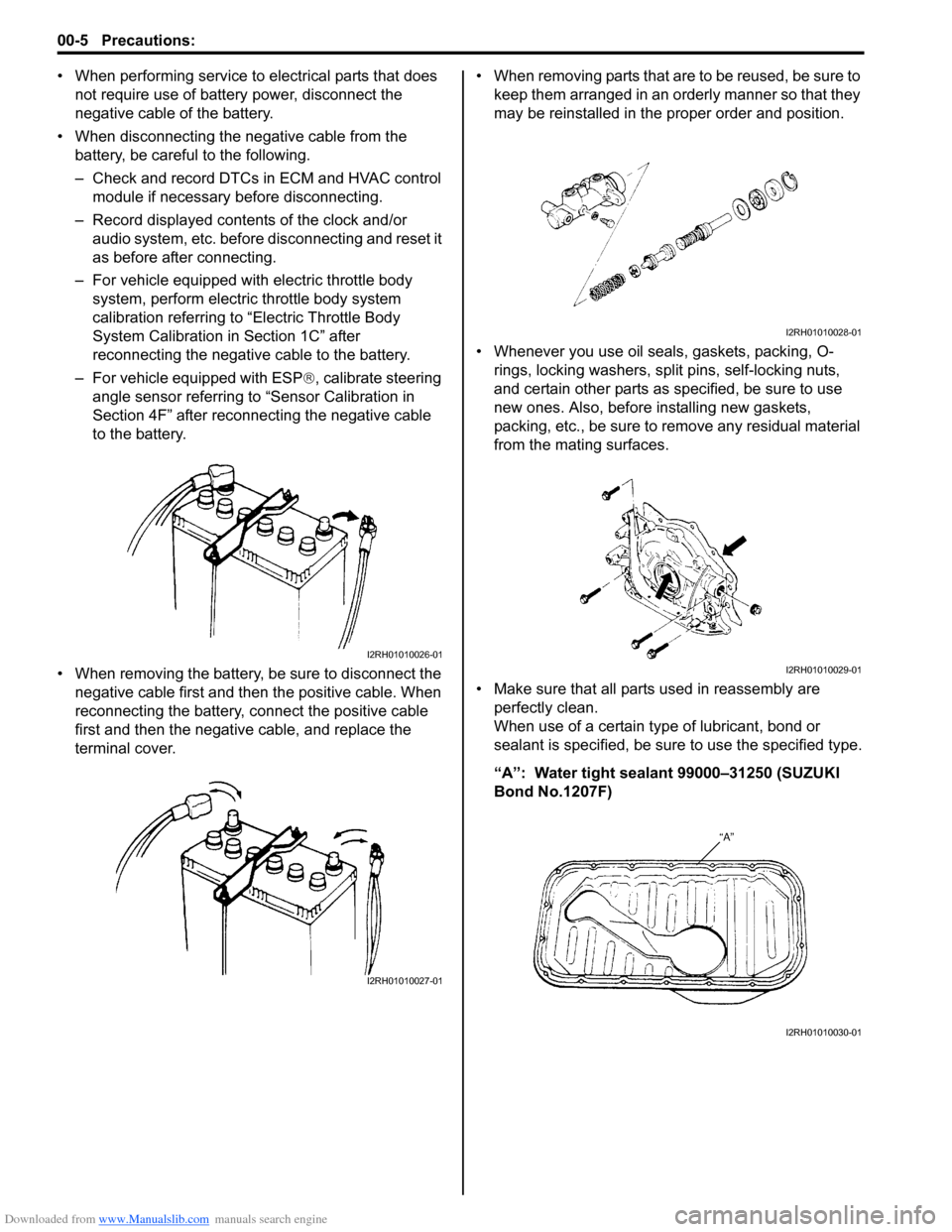

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 11 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-6

• Be sure to use special tools when instructed.Special tool

(A): 09917-98221

(B): 09916-58210

• When disconnecting vacuum hoses, attach a tag describing the correct installation positions so that the

hoses can be reinstalled correctly.

• After servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lin es related to the system

for leaks. • For vehicles equipped with fuel injection systems,

never disconnect the fuel line between the fuel pump

and injector without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

• When performing a work that produces a heat exceeding 80 °C (176 ° F) in the vicinity of the

electrical parts, remove t he heat sensitive electrical

part(s) beforehand.

• Use care not to expose connectors and electrical parts to water which will be a cause of a trouble.

• Always be careful not to handle electrical parts (computer, relay, etc.) in a rough manner or drop

them.

I2RH01010031-01

I2RH01010032-01

I2RH01010033-01

I2RH01010034-01

I2RH01010035-01

I2RH01010036-01

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

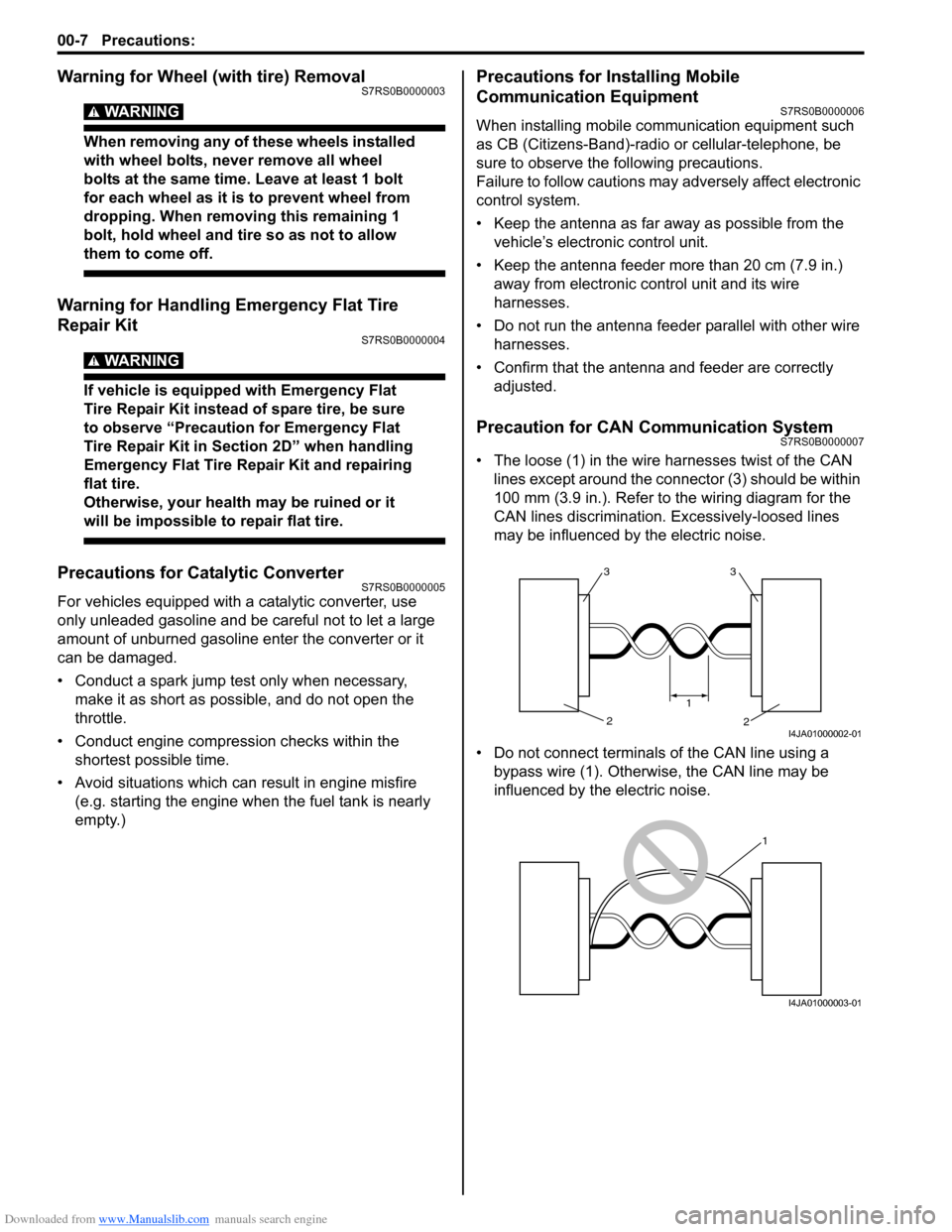

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 13 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-8

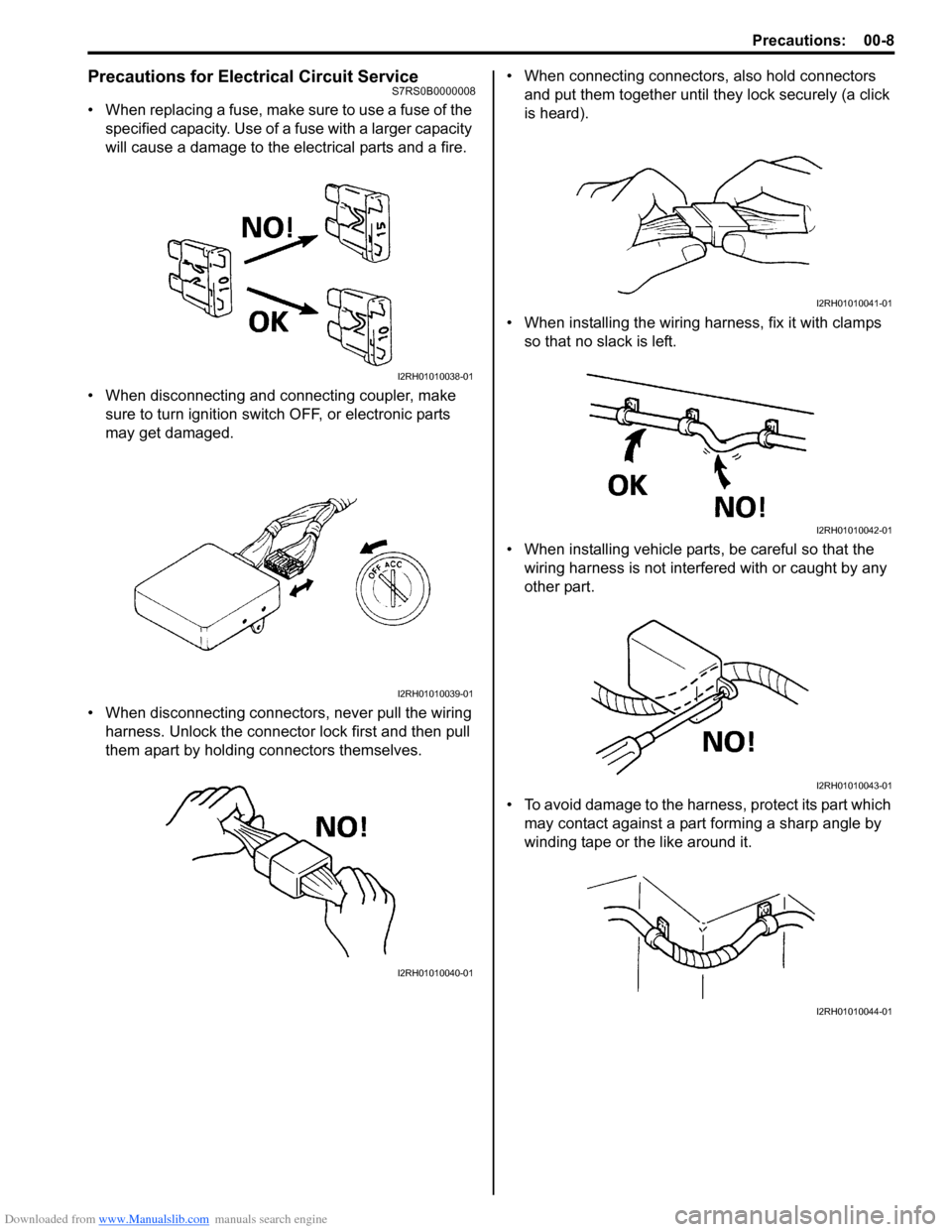

Precautions for Electrical Circuit ServiceS7RS0B0000008

• When replacing a fuse, make sure to use a fuse of the specified capacity. Use of a fuse with a larger capacity

will cause a damage to the electrical parts and a fire.

• When disconnecting and connecting coupler, make sure to turn ignition switch OFF, or electronic parts

may get damaged.

• When disconnecting connectors, never pull the wiring harness. Unlock the connecto r lock first and then pull

them apart by holding connectors themselves. • When connecting connectors, also hold connectors

and put them together until th ey lock securely (a click

is heard).

• When installing the wiring harness, fix it with clamps so that no slack is left.

• When installing vehicle parts, be careful so that the wiring harness is not interfered with or caught by any

other part.

• To avoid damage to the harnes s, protect its part which

may contact against a part forming a sharp angle by

winding tape or the like around it.

I2RH01010038-01

I2RH01010039-01

I2RH01010040-01

I2RH01010041-01

I2RH01010042-01

I2RH01010043-01

I2RH01010044-01

Page 14 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-9 Precautions:

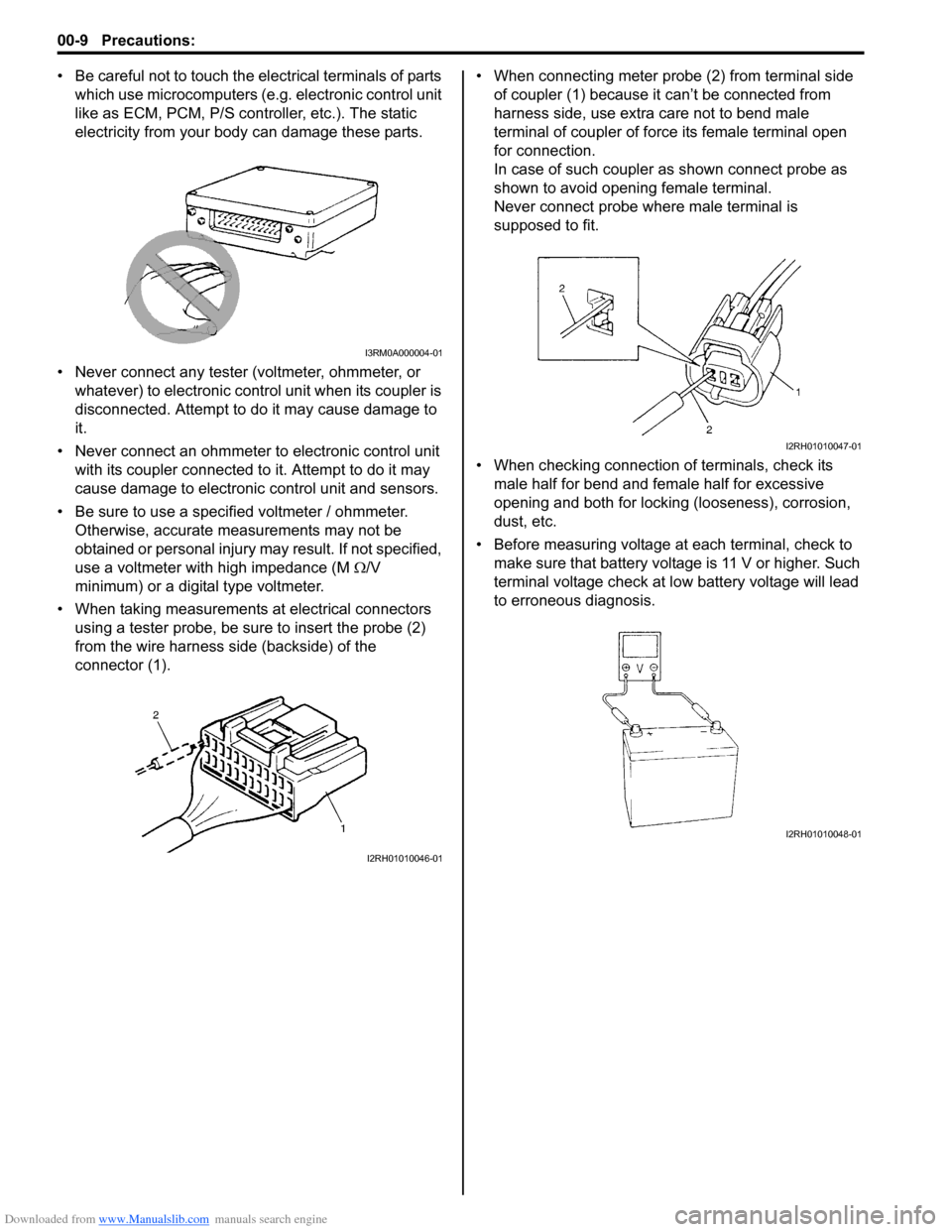

• Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter. Otherwise, accurate measurements may not be

obtained or personal injury ma y result. If not specified,

use a voltmeter with high impedance (M Ω/V

minimum) or a digital type voltmeter.

• When taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1). • When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

• Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Such

terminal voltage check at lo w battery voltage will lead

to erroneous diagnosis.

I3RM0A000004-01

I2RH01010046-01

I2RH01010047-01

I2RH01010048-01