Lever SUZUKI SWIFT 2006 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 827 of 1496

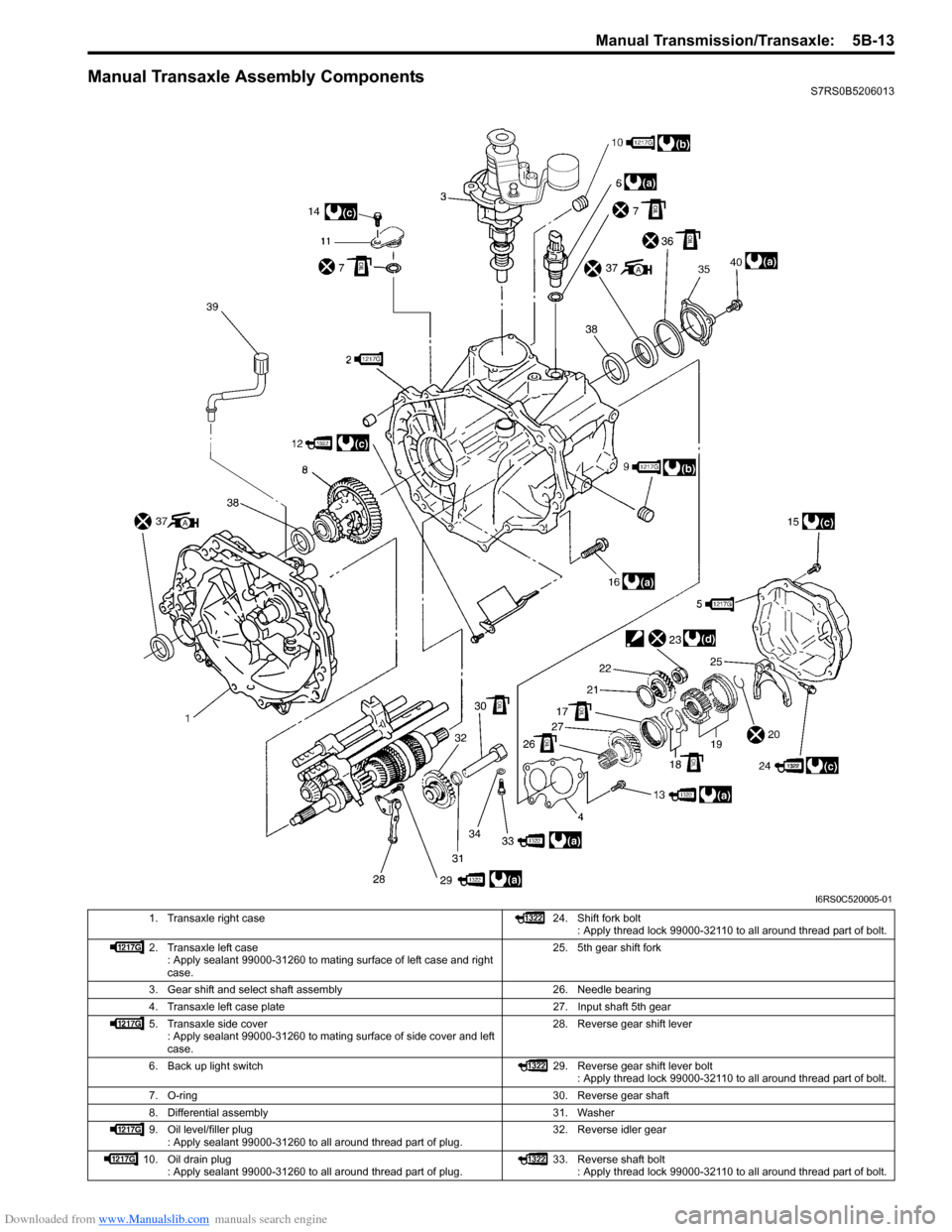

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-13

Manual Transaxle Assembly ComponentsS7RS0B5206013

I6RS0C520005-01

1. Transaxle right case 24. Shift fork bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

2. Transaxle left case : Apply sealant 99000-31260 to mating surface of left case and right

case. 25. 5th gear shift fork

3. Gear shift and select shaft assembly 26. Needle bearing

4. Transaxle left case plate 27. Input shaft 5th gear

5. Transaxle side cover : Apply sealant 99000-31260 to mating surface of side cover and left

case. 28. Reverse gear shift lever

6. Back up light switch 29. Reverse gear shift lever bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

7. O-ring 30. Reverse gear shaft

8. Differential assembly 31. Washer

9. Oil level/filler plug : Apply sealant 99000-31260 to all around thread part of plug. 32. Reverse idler gear

10. Oil drain plug : Apply sealant 99000-31260 to all around thread part of plug. 33. Reverse shaft bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

Page 828 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-14 Manual Transmission/Transaxle:

Fifth Gear Disassembly and AssemblyS7RS0B5206014

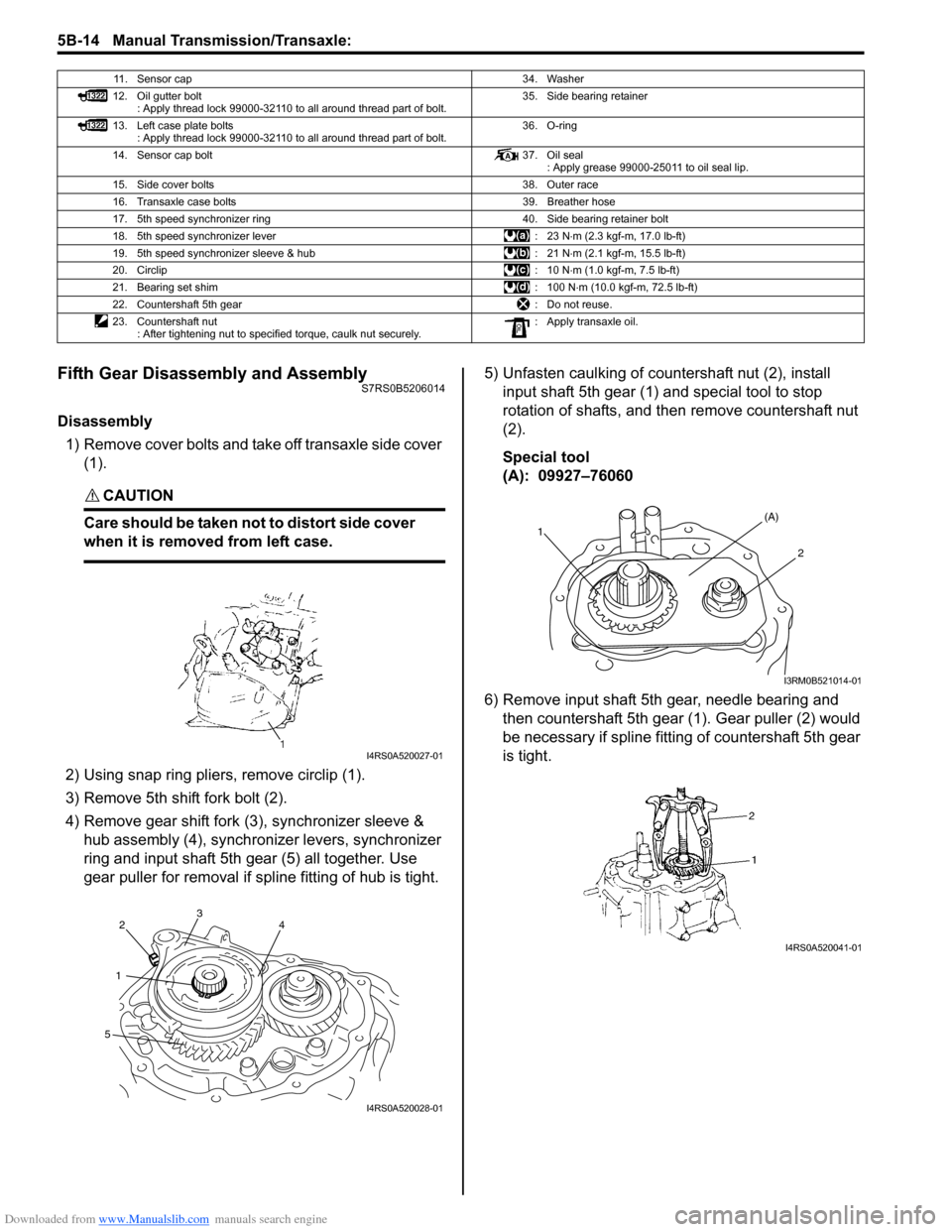

Disassembly1) Remove cover bolts and take off transaxle side cover (1).

CAUTION!

Care should be taken not to distort side cover

when it is removed from left case.

2) Using snap ring pliers, remove circlip (1).

3) Remove 5th shift fork bolt (2).

4) Remove gear shift fork (3), synchronizer sleeve &

hub assembly (4), synchron izer levers, synchronizer

ring and input shaft 5th gear (5) all together. Use

gear puller for removal if spline fitting of hub is tight. 5) Unfasten caulking of countershaft nut (2), install

input shaft 5th gear (1) and special tool to stop

rotation of shafts, and then remove countershaft nut

(2).

Special tool

(A): 09927–76060

6) Remove input shaft 5th gear, needle bearing and then countershaft 5th gear (1). Gear puller (2) would

be necessary if spline fitting of countershaft 5th gear

is tight.

11. Sensor cap 34. Washer

12. Oil gutter bolt : Apply thread lock 99000-32110 to all around thread part of bolt. 35. Side bearing retainer

13. Left case plate bolts : Apply thread lock 99000-32110 to all around thread part of bolt. 36. O-ring

14. Sensor cap bolt 37. Oil seal

: Apply grease 99000-25011 to oil seal lip.

15. Side cover bolts 38. Outer race

16. Transaxle case bolts 39. Breather hose

17. 5th speed synchronizer ring 40. Side bearing retainer bolt

18. 5th speed synchronizer lever : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

19. 5th speed synchronizer sleeve & hub : 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

20. Circlip :10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

21. Bearing set shim : 100 N⋅m (10.0 kgf-m, 72.5 lb-ft)

22. Countershaft 5th gear : Do not reuse.

23. Countershaft nut : After tightening nut to specified torque, caulk nut securely. : Apply transaxle oil.

I4RS0A520027-01

342

1

5

I4RS0A520028-01

1(A)

2

I3RM0B521014-01

I4RS0A520041-01

Page 829 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-15

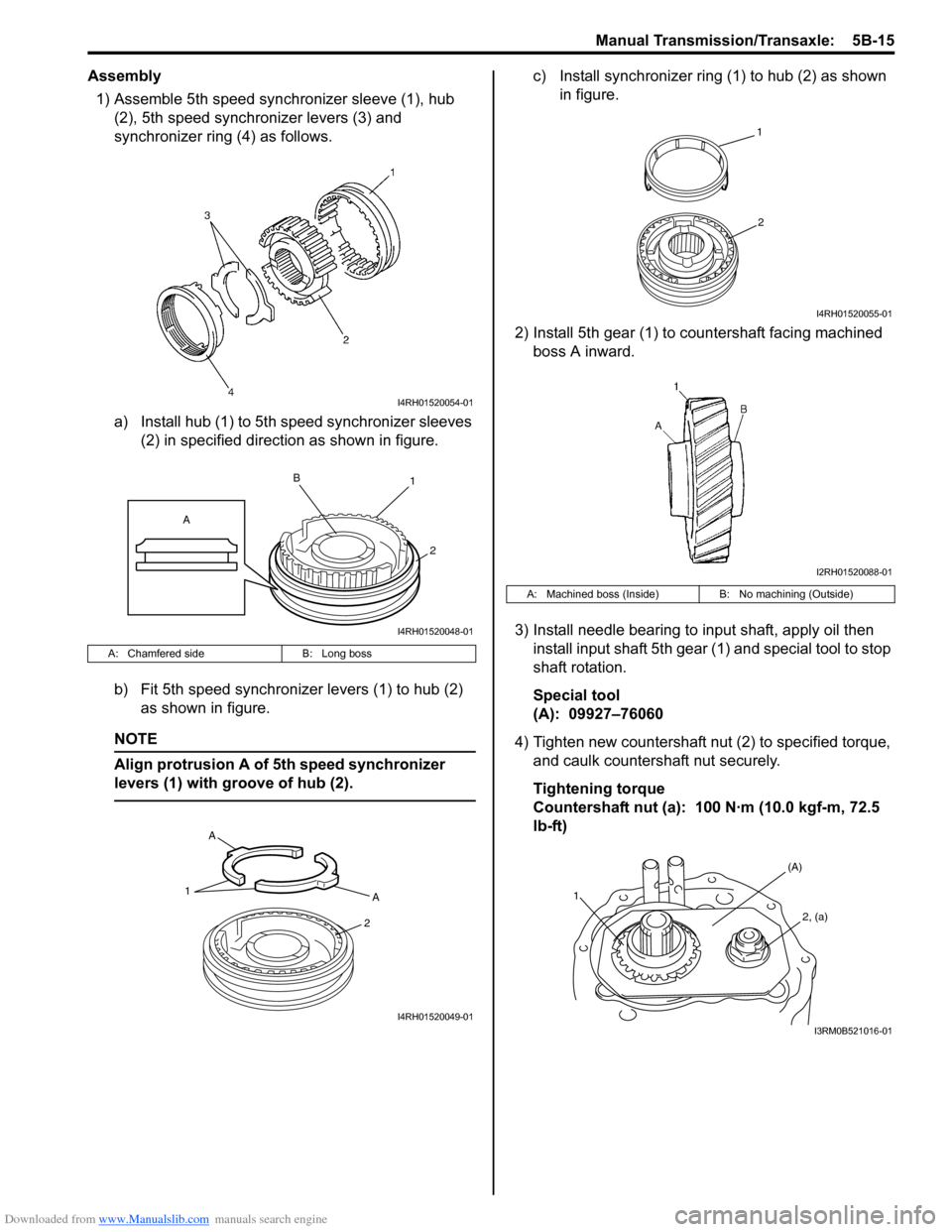

Assembly1) Assemble 5th speed synchronizer sleeve (1), hub (2), 5th speed synchronizer levers (3) and

synchronizer ring (4) as follows.

a) Install hub (1) to 5th speed synchronizer sleeves (2) in specified direction as shown in figure.

b) Fit 5th speed synchronizer levers (1) to hub (2) as shown in figure.

NOTE

Align protrusion A of 5th speed synchronizer

levers (1) with groove of hub (2).

c) Install synchronizer ring (1) to hub (2) as shown in figure.

2) Install 5th gear (1) to countershaft facing machined boss A inward.

3) Install needle bearing to input shaft, apply oil then install input shaft 5th gear (1) and special tool to stop

shaft rotation.

Special tool

(A): 09927–76060

4) Tighten new countershaft nut (2) to specified torque, and caulk countershaft nut securely.

Tightening torque

Countershaft nut (a): 100 N·m (10.0 kgf-m, 72.5

lb-ft)

A: Chamfered side B: Long boss

I4RH01520054-01

1

2

B

A

I4RH01520048-01

1A

2

A

I4RH01520049-01

A: Machined boss (Inside)

B: No machining (Outside)

1

2

I4RH01520055-01

I2RH01520088-01

1

(A)

2, (a)

I3RM0B521016-01

Page 831 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-17

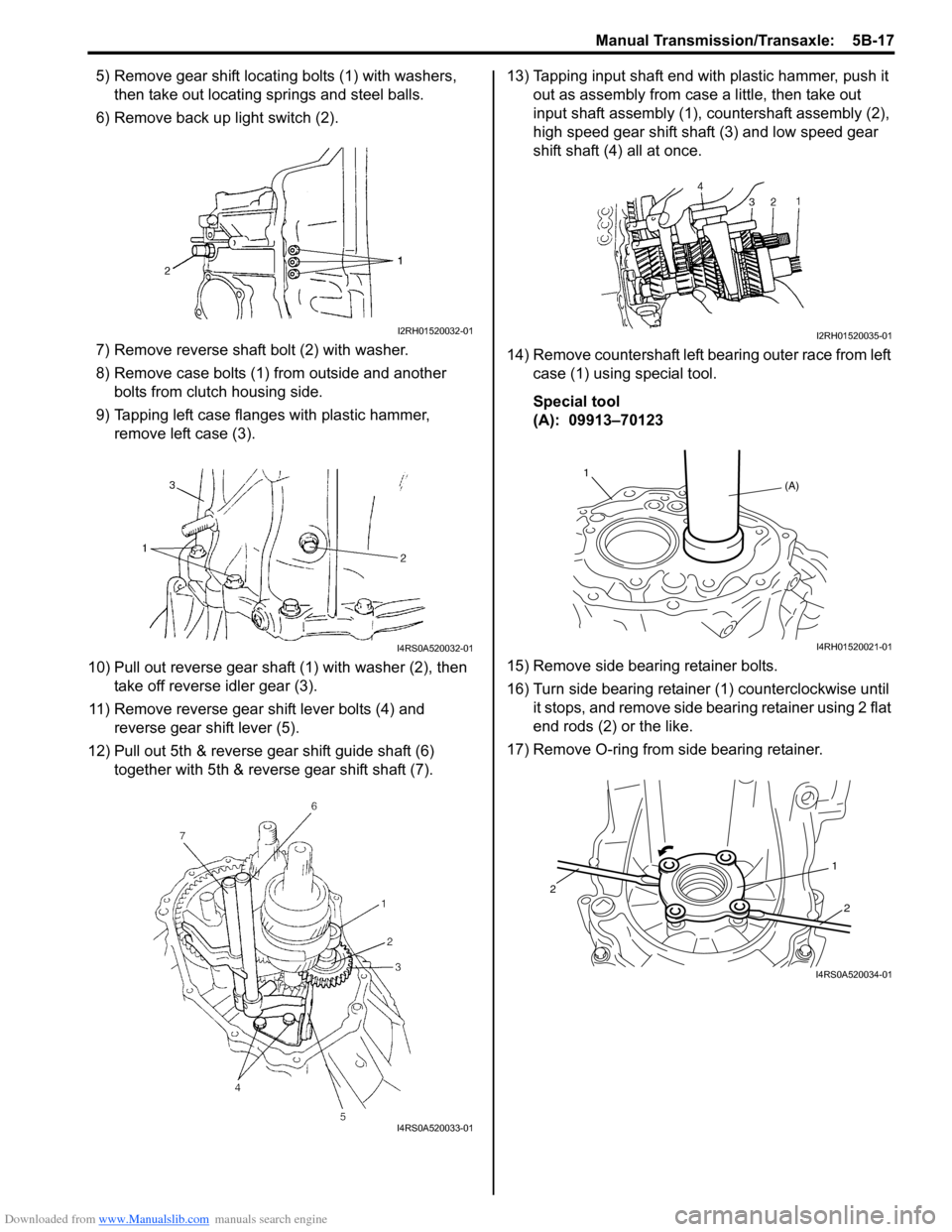

5) Remove gear shift locating bolts (1) with washers,

then take out locating springs and steel balls.

6) Remove back up light switch (2).

7) Remove reverse shaft bolt (2) with washer.

8) Remove case bolts (1) from outside and another bolts from clutch housing side.

9) Tapping left case flanges with plastic hammer, remove left case (3).

10) Pull out reverse gear shaft (1) with washer (2), then take off reverse idler gear (3).

11) Remove reverse gear shift lever bolts (4) and reverse gear shift lever (5).

12) Pull out 5th & reverse gear shift guide shaft (6) together with 5th & reverse gear shift shaft (7). 13) Tapping input shaft end with plastic hammer, push it

out as assembly from case a little, then take out

input shaft assembly (1), countershaft assembly (2),

high speed gear shift shaft (3) and low speed gear

shift shaft (4) all at once.

14) Remove countershaft left bearing outer race from left case (1) using special tool.

Special tool

(A): 09913–70123

15) Remove side bearing retainer bolts.

16) Turn side bearing retainer (1) counterclockwise until it stops, and remove side bearing retainer using 2 flat

end rods (2) or the like.

17) Remove O-ring from side bearing retainer.

I2RH01520032-01

I4RS0A520032-01

I4RS0A520033-01

I2RH01520035-01

(A)

1

I4RH01520021-01

1

2

2

I4RS0A520034-01

Page 832 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-18 Manual Transmission/Transaxle:

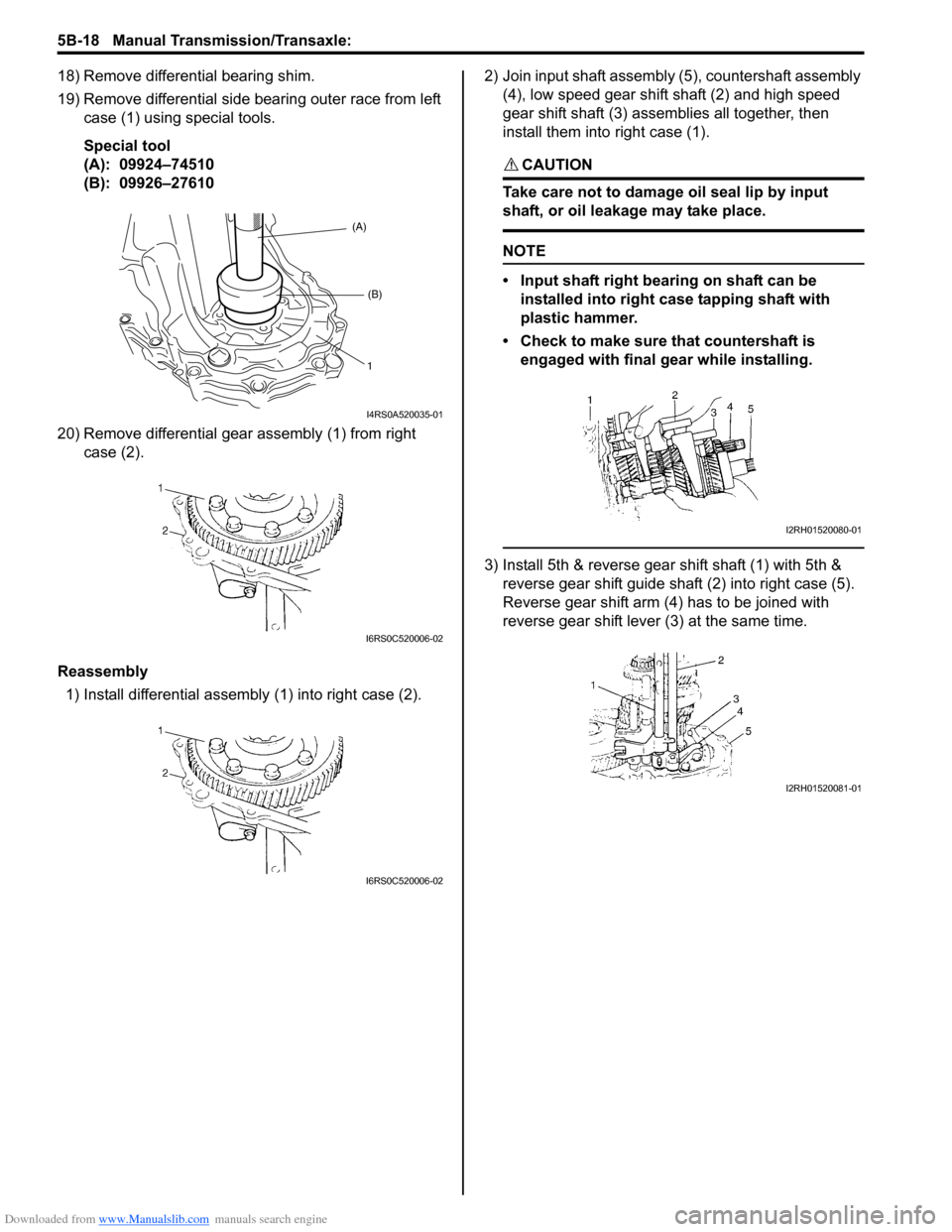

18) Remove differential bearing shim.

19) Remove differential side bearing outer race from left case (1) using special tools.

Special tool

(A): 09924–74510

(B): 09926–27610

20) Remove differential gear assembly (1) from right case (2).

Reassembly 1) Install differential assembly (1) into right case (2). 2) Join input shaft assembly (5), countershaft assembly

(4), low speed gear shift shaft (2) and high speed

gear shift shaft (3) assemblies all together, then

install them into right case (1).

CAUTION!

Take care not to damage oil seal lip by input

shaft, or oil leakage may take place.

NOTE

• Input shaft right bearing on shaft can be

installed into right case tapping shaft with

plastic hammer.

• Check to make sure that countershaft is engaged with final g ear while installing.

3) Install 5th & reverse gear shift shaft (1) with 5th &

reverse gear shift guide shaft (2) into right case (5).

Reverse gear shift arm (4) has to be joined with

reverse gear shift lever (3) at the same time.

(A)

(B)

1

I4RS0A520035-01

I6RS0C520006-02

I6RS0C520006-02

I2RH01520080-01

I2RH01520081-01

Page 833 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-19

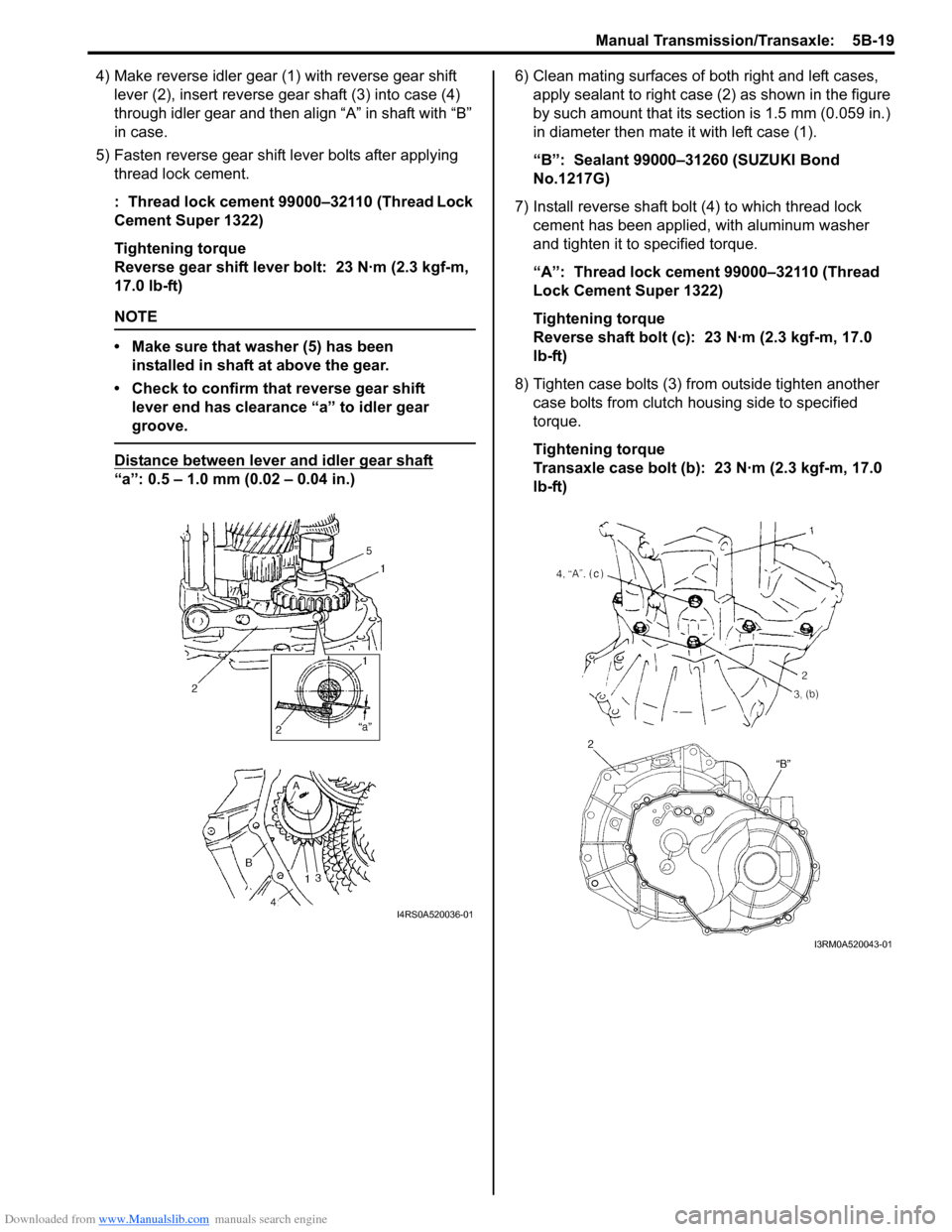

4) Make reverse idler gear (1) with reverse gear shift lever (2), insert reverse gear shaft (3) into case (4)

through idler gear and then align “A” in shaft with “B”

in case.

5) Fasten reverse gear shift lever bolts after applying thread lock cement.

: Thread lock cement 99000–32110 (Thread Lock

Cement Super 1322)

Tightening torque

Reverse gear shift lever bolt: 23 N·m (2.3 kgf-m,

17.0 lb-ft)

NOTE

• Make sure that washer (5) has been installed in shaft at above the gear.

• Check to confirm that reverse gear shift lever end has clearance “a” to idler gear

groove.

Distance between lever and idler gear shaft

“a”: 0.5 – 1.0 mm (0.02 – 0.04 in.) 6) Clean mating surfaces of both right and left cases,

apply sealant to right case (2) as shown in the figure

by such amount that its section is 1.5 mm (0.059 in.)

in diameter then mate it with left case (1).

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

7) Install reverse shaft bolt (4) to which thread lock cement has been applied, with aluminum washer

and tighten it to specified torque.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Reverse shaft bolt (c): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

8) Tighten case bolts (3) from outside tighten another case bolts from clutch housing side to specified

torque.

Tightening torque

Transaxle case bolt (b): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

I4RS0A520036-01

I3RM0A520043-01

Page 849 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-35

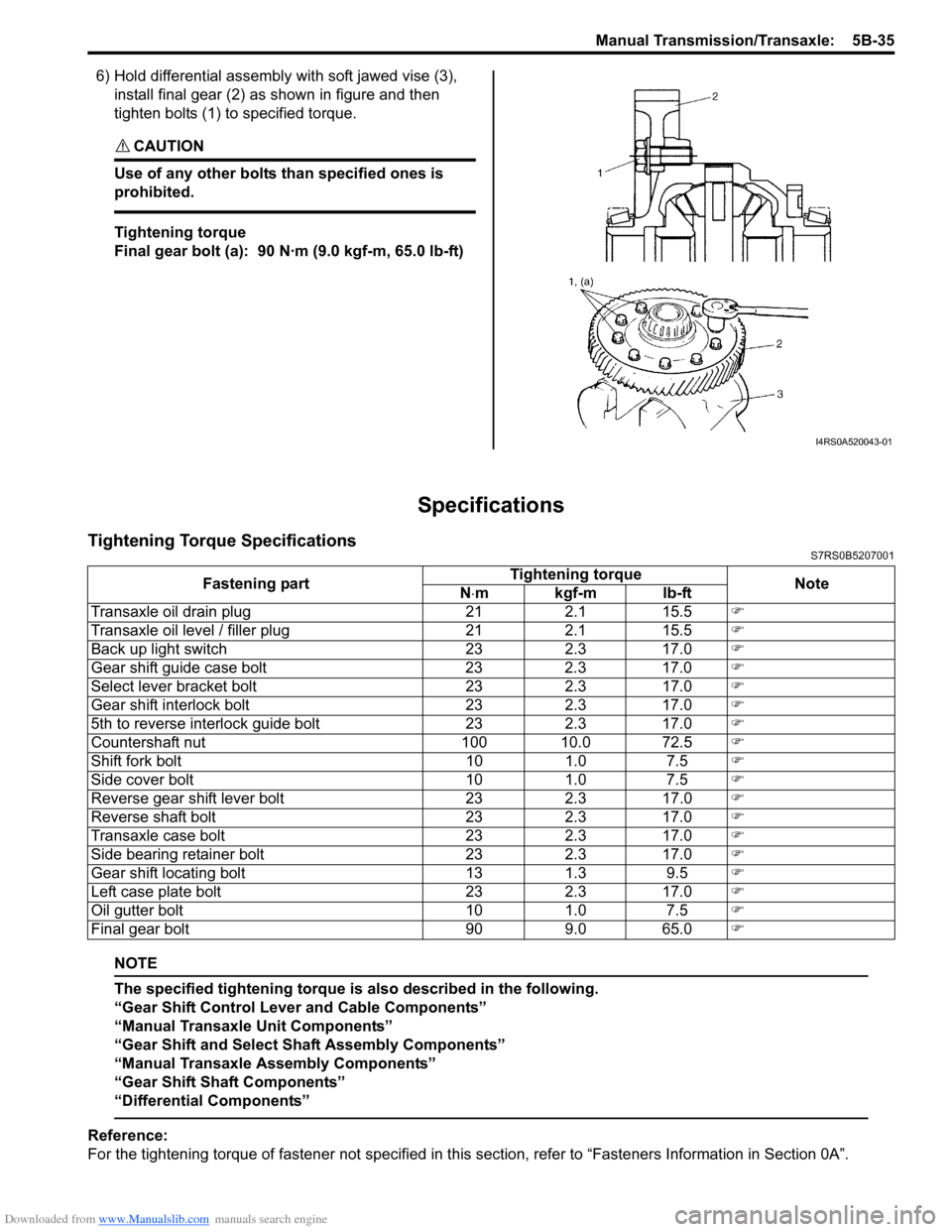

6) Hold differential assembly with soft jawed vise (3),

install final gear (2) as shown in figure and then

tighten bolts (1) to specified torque.

CAUTION!

Use of any other bolts than specified ones is

prohibited.

Tightening torque

Final gear bolt (a): 90 N·m (9.0 kgf-m, 65.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B5207001

NOTE

The specified tightening torque is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Manual Transaxle Unit Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Gear Shift Shaft Components”

“Differential Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A520043-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Transaxle oil drain plug 21 2.1 15.5 �)

Transaxle oil level / filler plug 21 2.1 15.5 �)

Back up light switch 23 2.3 17.0 �)

Gear shift guide case bolt 23 2.3 17.0 �)

Select lever bracket bolt 23 2.3 17.0 �)

Gear shift interlock bolt 23 2.3 17.0 �)

5th to reverse interlock guide bolt 23 2.3 17.0 �)

Countershaft nut 100 10.0 72.5 �)

Shift fork bolt 10 1.0 7.5 �)

Side cover bolt 10 1.0 7.5 �)

Reverse gear shift lever bolt 23 2.3 17.0 �)

Reverse shaft bolt 23 2.3 17.0 �)

Transaxle case bolt 23 2.3 17.0 �)

Side bearing retainer bolt 23 2.3 17.0 �)

Gear shift locating bolt 13 1.3 9.5 �)

Left case plate bolt 23 2.3 17.0 �)

Oil gutter bolt 10 1.0 7.5 �)

Final gear bolt 90 9.0 65.0 �)

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

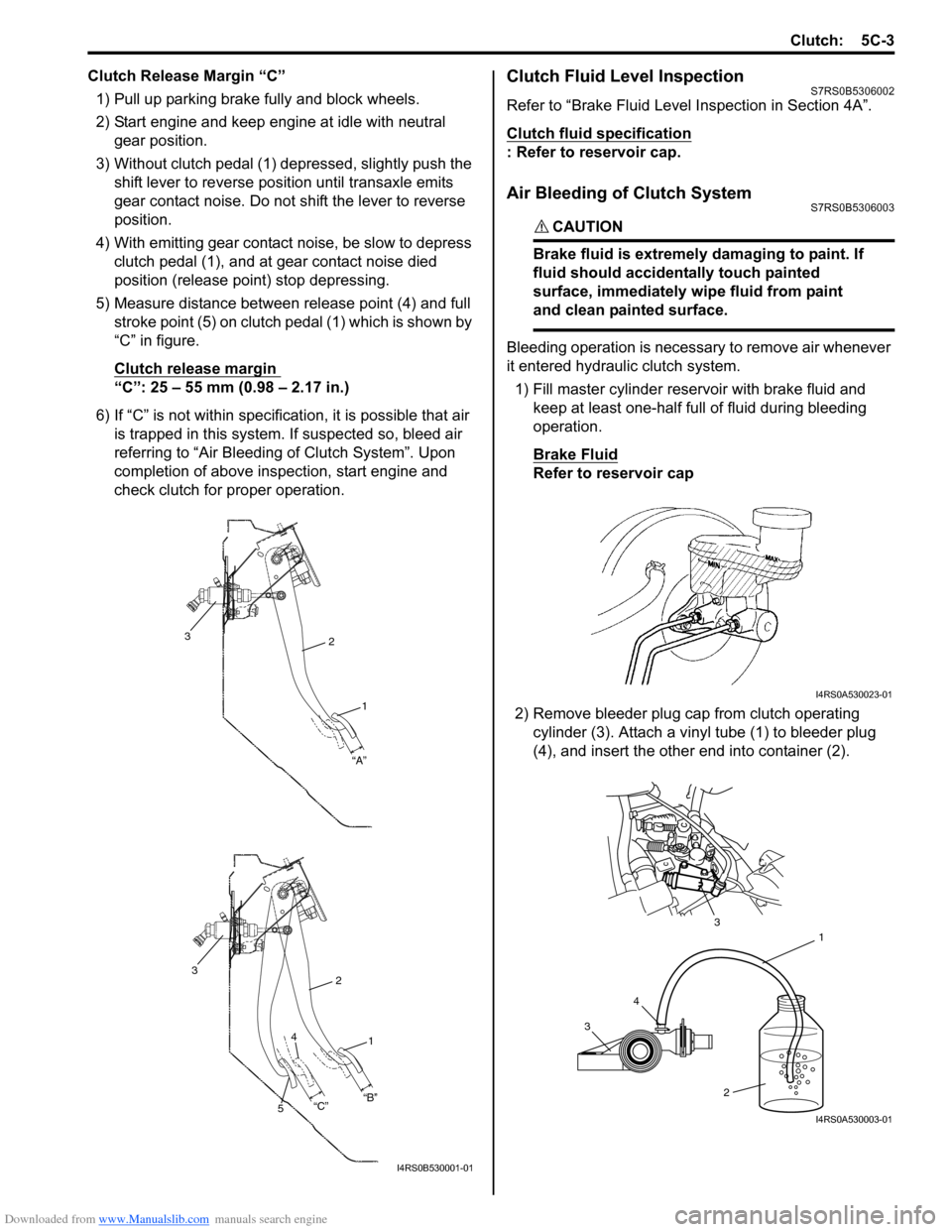

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 864 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-12 Clutch:

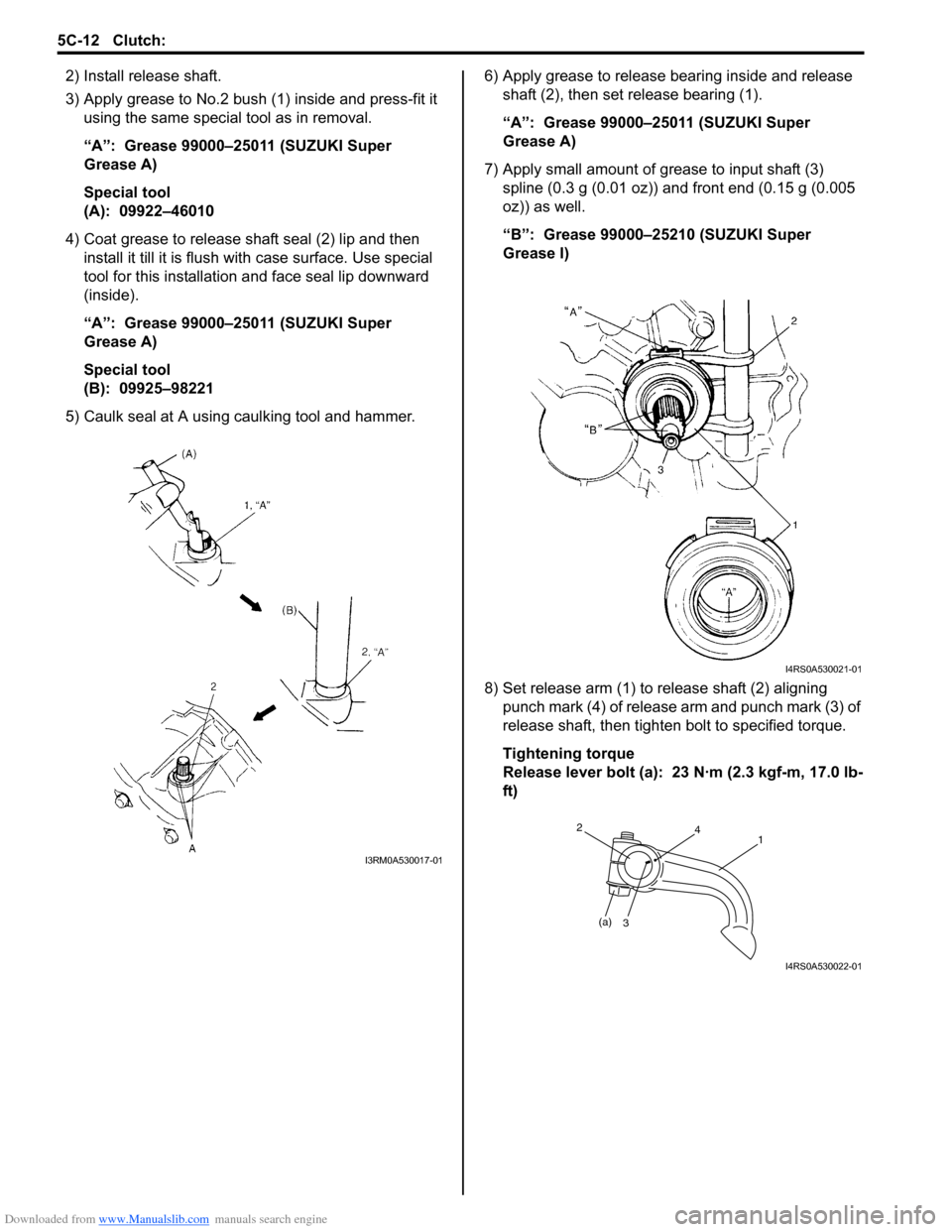

2) Install release shaft.

3) Apply grease to No.2 bush (1) inside and press-fit it using the same special tool as in removal.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(A): 09922–46010

4) Coat grease to release shaft seal (2) lip and then install it till it is flush wit h case surface. Use special

tool for this installation a nd face seal lip downward

(inside).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

Special tool

(B): 09925–98221

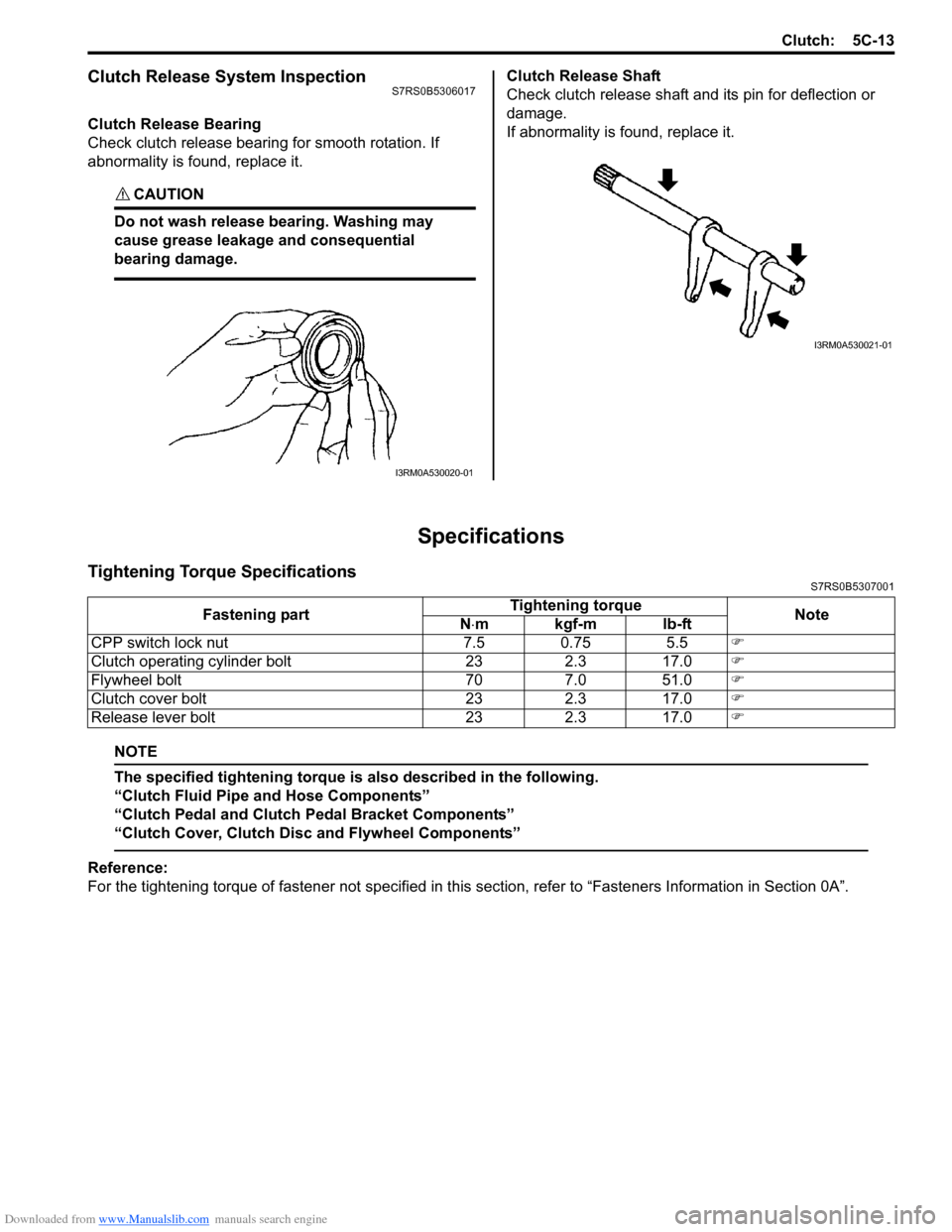

5) Caulk seal at A using caulking tool and hammer. 6) Apply grease to release bearing inside and release

shaft (2), then set release bearing (1).

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

7) Apply small amount of grease to input shaft (3) spline (0.3 g (0.01 oz)) and front end (0.15 g (0.005

oz)) as well.

“B”: Grease 99000–25210 (SUZUKI Super

Grease I)

8) Set release arm (1) to release shaft (2) aligning punch mark (4) of release arm and punch mark (3) of

release shaft, then tighten bolt to specified torque.

Tightening torque

Release lever bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

I3RM0A530017-01

I4RS0A530021-01

(a)3

241

I4RS0A530022-01

Page 865 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-13

Clutch Release System InspectionS7RS0B5306017

Clutch Release Bearing

Check clutch release bearing for smooth rotation. If

abnormality is found, replace it.

CAUTION!

Do not wash release bearing. Washing may

cause grease leakage and consequential

bearing damage.

Clutch Release Shaft

Check clutch release shaft and its pin for deflection or

damage.

If abnormality is found, replace it.

Specifications

Tightening Torque SpecificationsS7RS0B5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Fluid Pipe and Hose Components”

“Clutch Pedal and Clutch Pedal Bracket Components”

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I3RM0A530020-01

I3RM0A530021-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

CPP switch lock nut 7.5 0.75 5.5 �)

Clutch operating cylinder bolt 23 2.3 17.0 �)

Flywheel bolt 70 7.0 51.0 �)

Clutch cover bolt 23 2.3 17.0 �)

Release lever bolt 23 2.3 17.0 �)