key SUZUKI SWIFT 2006 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1425 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-22

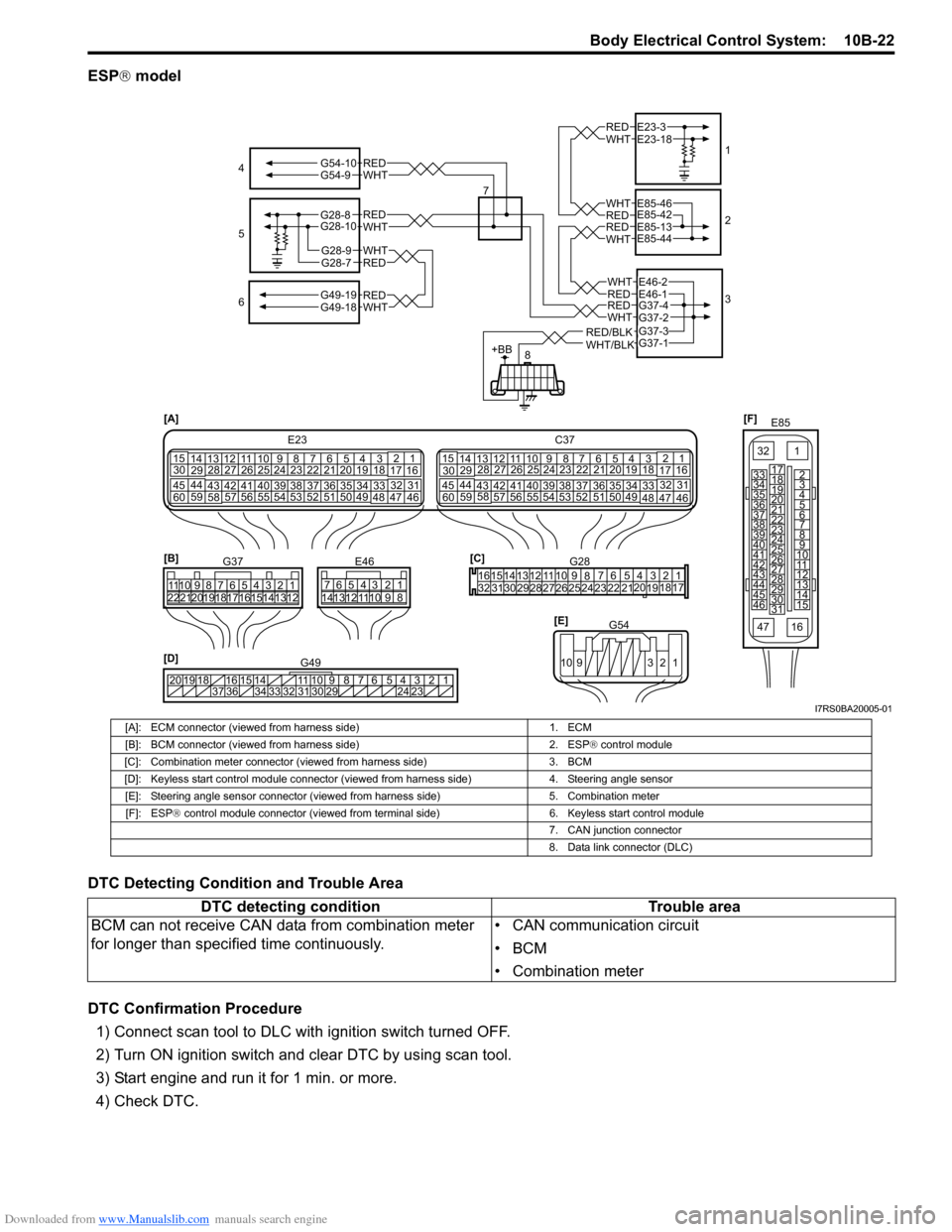

ESP® model

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

[F] E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[D] 12345678910

11

141516

36 34 33 32 31 30 29 24 23

37

181920

G49

[A]

E23

C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

[C]G28

1234567

8

910

11

1213141516

1718

19

20

212223242526272829303132

[E] G54

109 321

[B]

G37E46

1234567 1234567

8910

11

8910

11

121314 121314

1516171819202122

4

6 1

2

3

REDWHT

REDWHT

REDWHT

REDWHT

E23-3E23-18

E85-42E85-46

E85-13E85-44

G37-4G37-2

REDWHT

REDWHTG49-19G49-18

5

7

WHTG54-9REDG54-10

G28-8G28-10

G28-7REDG28-9WHT

RED/BLKWHT/BLK

REDWHTE46-1E46-2

G37-1G37-3

+BB8

I7RS0BA20005-01

[A]: ECM connector (viewed from harness side)

1. ECM

[B]: BCM connector (viewed from harness side) 2. ESP® control module

[C]: Combination meter connector (viewed from harness side) 3. BCM

[D]: Keyless start control module connector (viewed from harness side) 4. Steering angle sensor

[E]: Steering angle sensor connector (viewed from harness side) 5. Combination meter

[F]: ESP ® control module connector (viewed from terminal side) 6. Keyless start control module

7. CAN junction connector

8. Data link connector (DLC)

DTC detecting condition Trouble area

BCM can not receive CAN data from combination meter

for longer than specif ied time continuously. • CAN communication circuit

•BCM

• Combination meter

Page 1426 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

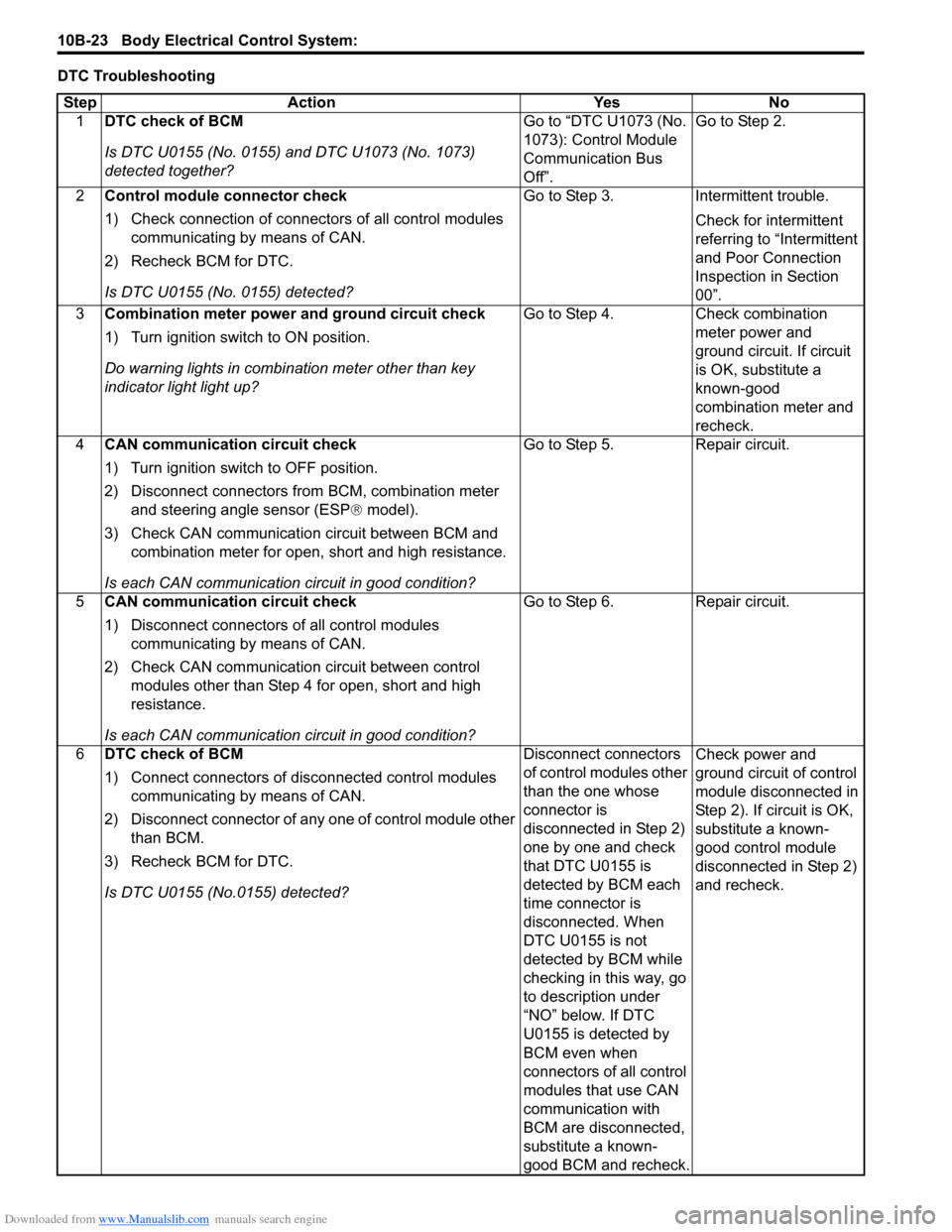

DTC TroubleshootingStep Action YesNo

1 DTC check of BCM

Is DTC U0155 (No. 0155) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U0155 (No. 0155) detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator light light up? Go to Step 4.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, combination meter

and steering angle sensor (ESP ® model).

3) Check CAN communication circuit between BCM and combination meter for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U0155 (No.0155) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U0155 is

detected by BCM each

time connector is

disconnected. When

DTC U0155 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U0155 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Page 1427 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-24

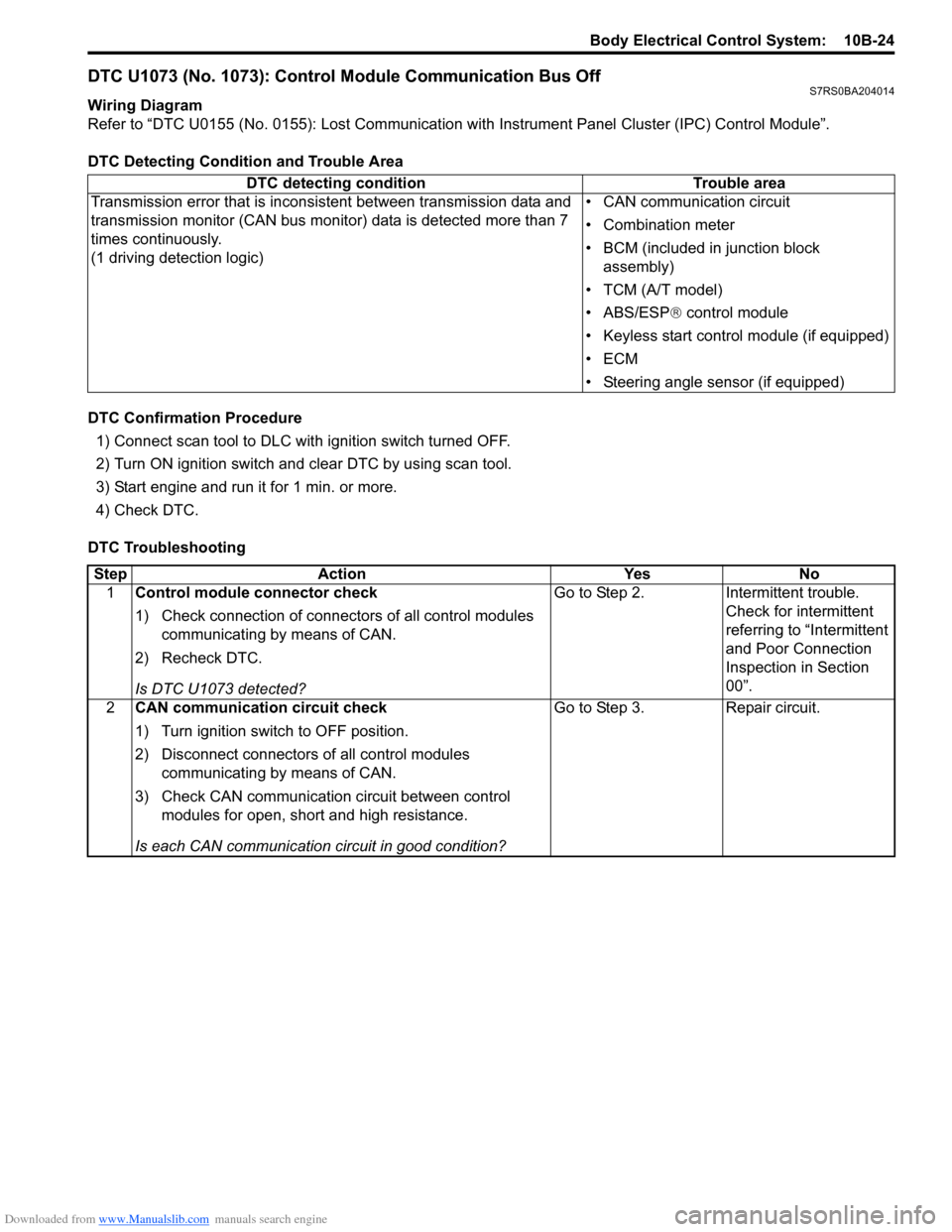

DTC U1073 (No. 1073): Control Module Communication Bus OffS7RS0BA204014

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Transmission error that is inconsistent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously.

(1 driving detection logic) • CAN communication circuit

• Combination meter

• BCM (included in junction block

assembly)

• TCM (A/T model)

• ABS/ESP ® control module

• Keyless start control module (if equipped)

•ECM

• Steering angle sensor (if equipped)

Step Action YesNo

1 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 detected? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 3.

Repair circuit.

Page 1432 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-29 Body Electrical Control System:

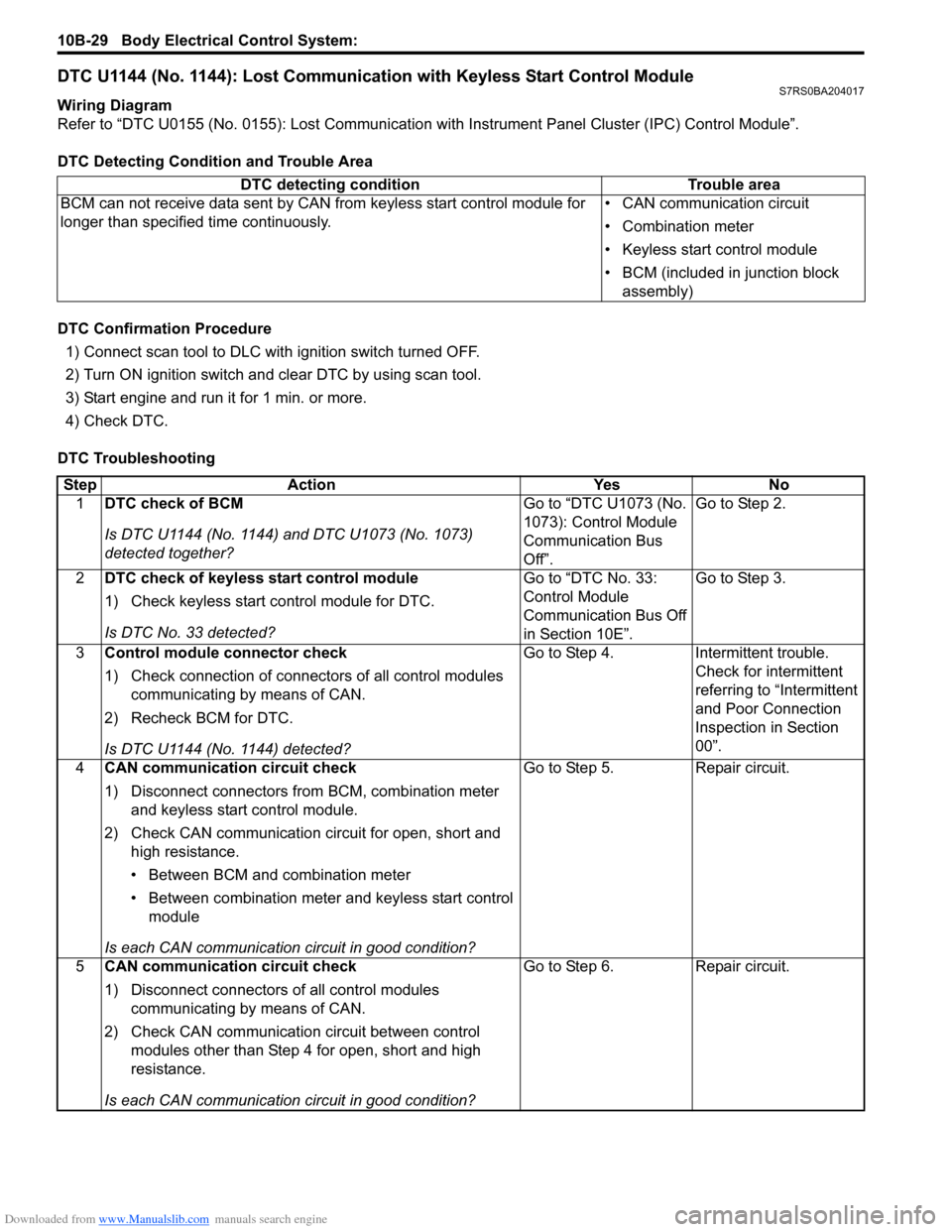

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control ModuleS7RS0BA204017

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

BCM can not receive data sent by CAN from keyless start control module for

longer than specified time continuously. • CAN communication circuit

• Combination meter

• Keyless start control module

• BCM (included in junction block

assembly)

Step Action YesNo

1 DTC check of BCM

Is DTC U1144 (No. 1144) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 DTC check of keyless start control module

1) Check keyless start co ntrol module for DTC.

Is DTC No. 33 detected? Go to “DTC No. 33:

Control Module

Communication Bus Off

in Section 10E”.Go to Step 3.

3 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1144 (No. 1144) detected? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 CAN communication circuit check

1) Disconnect connectors from BCM, combination meter

and keyless start control module.

2) Check CAN communication circuit for open, short and high resistance.

• Between BCM and combination meter

• Between combination meter and keyless start control module

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

Page 1433 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-30

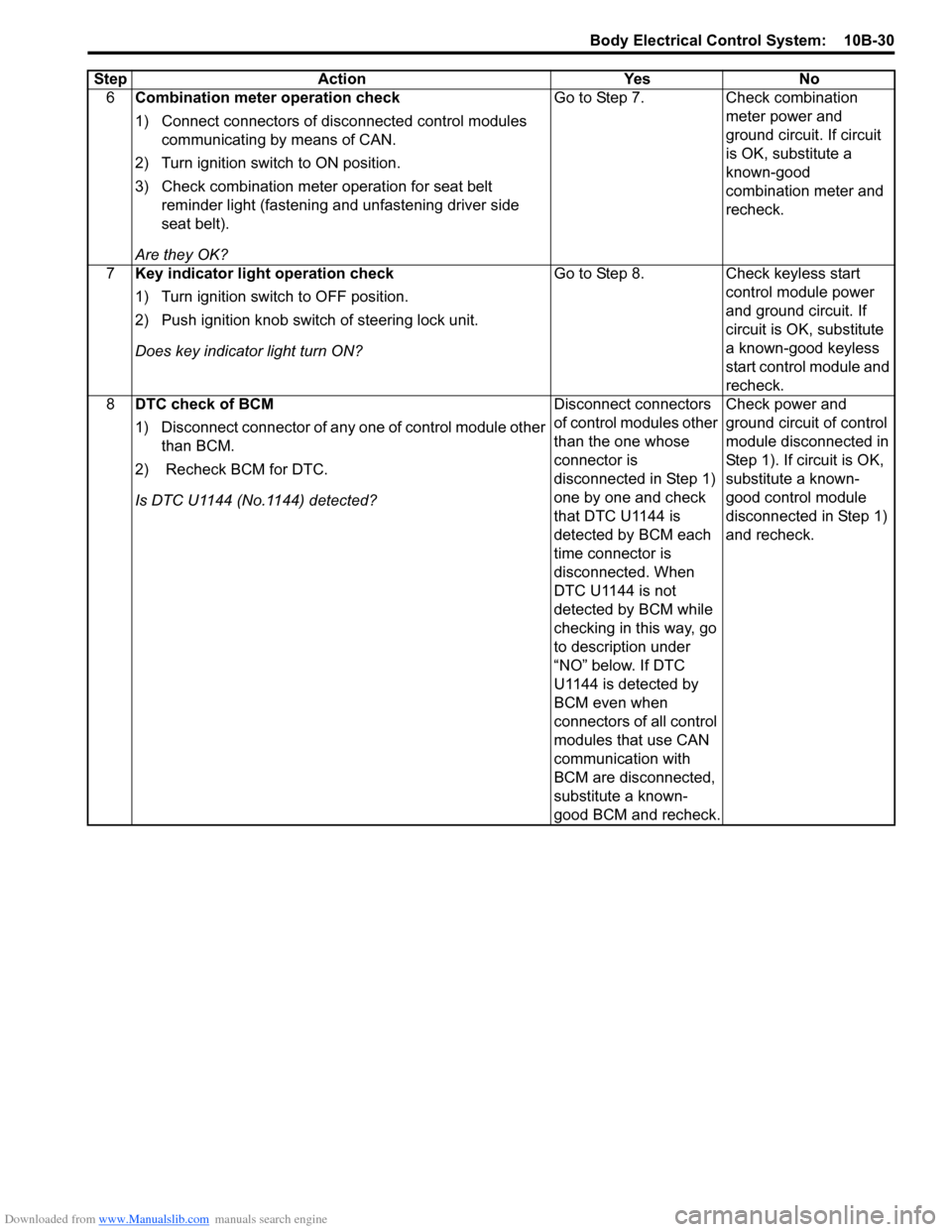

6Combination meter operation check

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Turn ignition switch to ON position.

3) Check combination meter operation for seat belt reminder light (fastening and unfastening driver side

seat belt).

Are they OK? Go to Step 7.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

7 Key indicator light operation check

1) Turn ignition switch to OFF position.

2) Push ignition knob switch of steering lock unit.

Does key indicator light turn ON? Go to Step 8.

Check keyless start

control module power

and ground circuit. If

circuit is OK, substitute

a known-good keyless

start control module and

recheck.

8 DTC check of BCM

1) Disconnect connector of any one of control module other

than BCM.

2) Recheck BCM for DTC.

Is DTC U1144 (No.1144) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 1)

one by one and check

that DTC U1144 is

detected by BCM each

time connector is

disconnected. When

DTC U1144 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U1144 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 1). If circuit is OK,

substitute a known-

good control module

disconnected in Step 1)

and recheck.

Step

Action YesNo

Page 1435 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-32

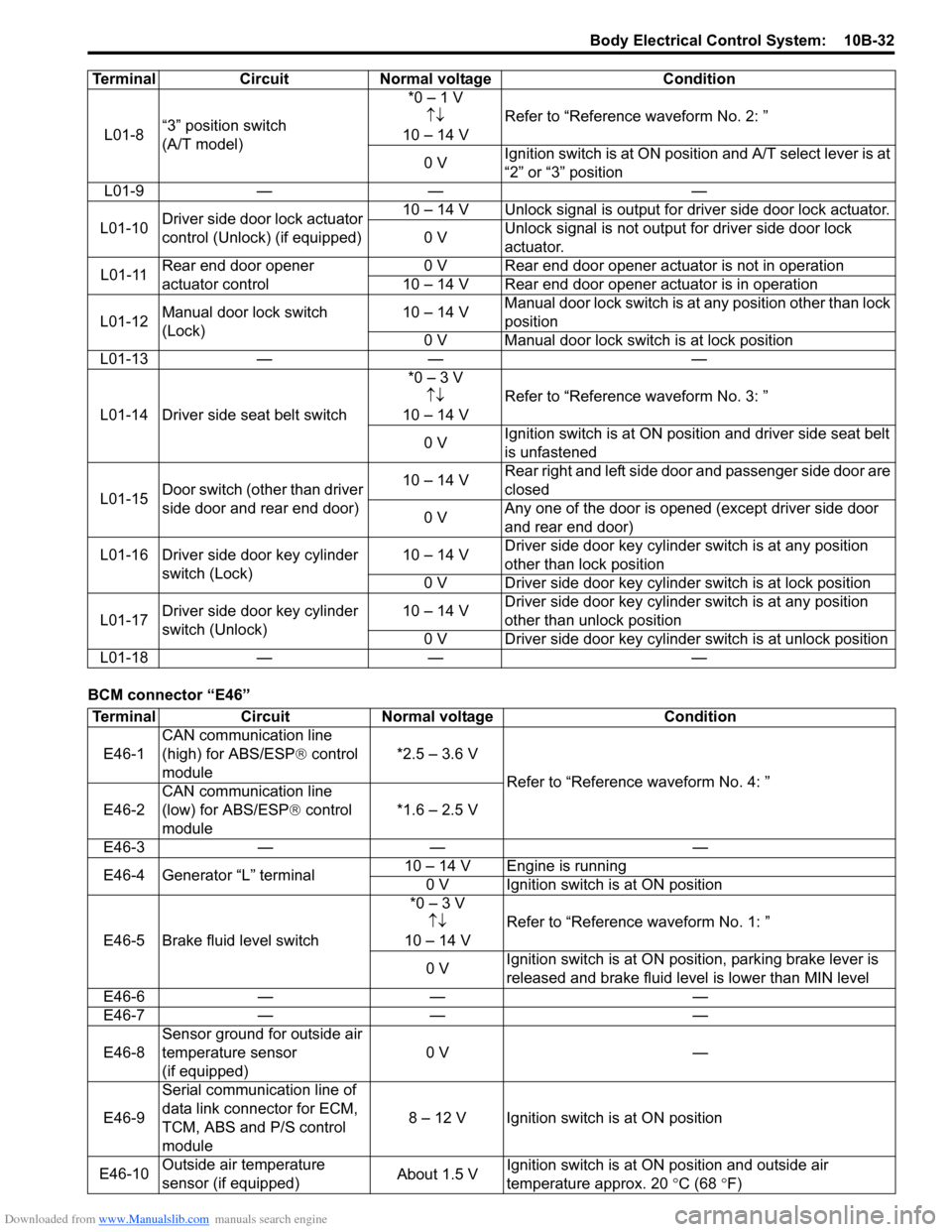

BCM connector “E46”L01-8

“3” position switch

(A/T model) *0 – 1 V

↑↓

10 – 14 V Refer to “Reference waveform No. 2: ”

0 V Ignition switch is at ON positi

on and A/T select lever is at

“2” or “3” position

L01-9 — — —

L01-10 Driver side door lock actuator

control (Unlock) (if equipped) 10 – 14 V Unlock signal is output for driver side door lock actuator.

0 V Unlock signal is not output for driver side door lock

actuator.

L01-11 Rear end door opener

actuator control 0 V Rear end door opener actuator is not in operation

10 – 14 V Rear end door opener actuator is in operation

L01-12 Manual door lock switch

(Lock) 10 – 14 V

Manual door lock switch is at any position other than lock

position

0 V Manual door lock swit ch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 3: ”

0 V Ignition switch is at ON position and driver side seat belt

is unfastened

L01-15 Door switch (other than driver

side door and rear end door) 10 – 14 V

Rear right and left side door and passenger side door are

closed

0 V Any one of the door is opened (except driver side door

and rear end door)

L01-16 Driver side door key cylinder switch (Lock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than lock position

0 V Driver side door key cylinder switch is at lock position

L01-17 Driver side door key cylinder

switch (Unlock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than unlock position

0 V Driver side door key cylinder switch is at unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

E46-1 CAN communication line

(high) for ABS/ESP

® control

module *2.5 – 3.6 V

Refer to “Reference waveform No. 4: ”

E46-2 CAN communication line

(low) for ABS/ESP

® control

module *1.6 – 2.5 V

E46-3 — — —

E46-4 Generator “L” terminal 10 – 14 V Engine is running

0 V Ignition switch is at ON position

E46-5 Brake fluid level switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON position, parking brake lever is

released and brake fluid level is lower than MIN level

E46-6 — — —

E46-7 — — —

E46-8 Sensor ground for outside air

temperature sensor

(if equipped) 0 V

—

E46-9 Serial communication line of

data link connector for ECM,

TCM, ABS and

P/S control

module 8 – 12 V Ignition switch is at ON position

E46-10 Outside air temperature

sensor (if equipped) About 1.5 VIgnition switch is at ON position and outside air

temperature approx. 20

°C (68 °F)

Page 1436 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-33 Body Electrical Control System:

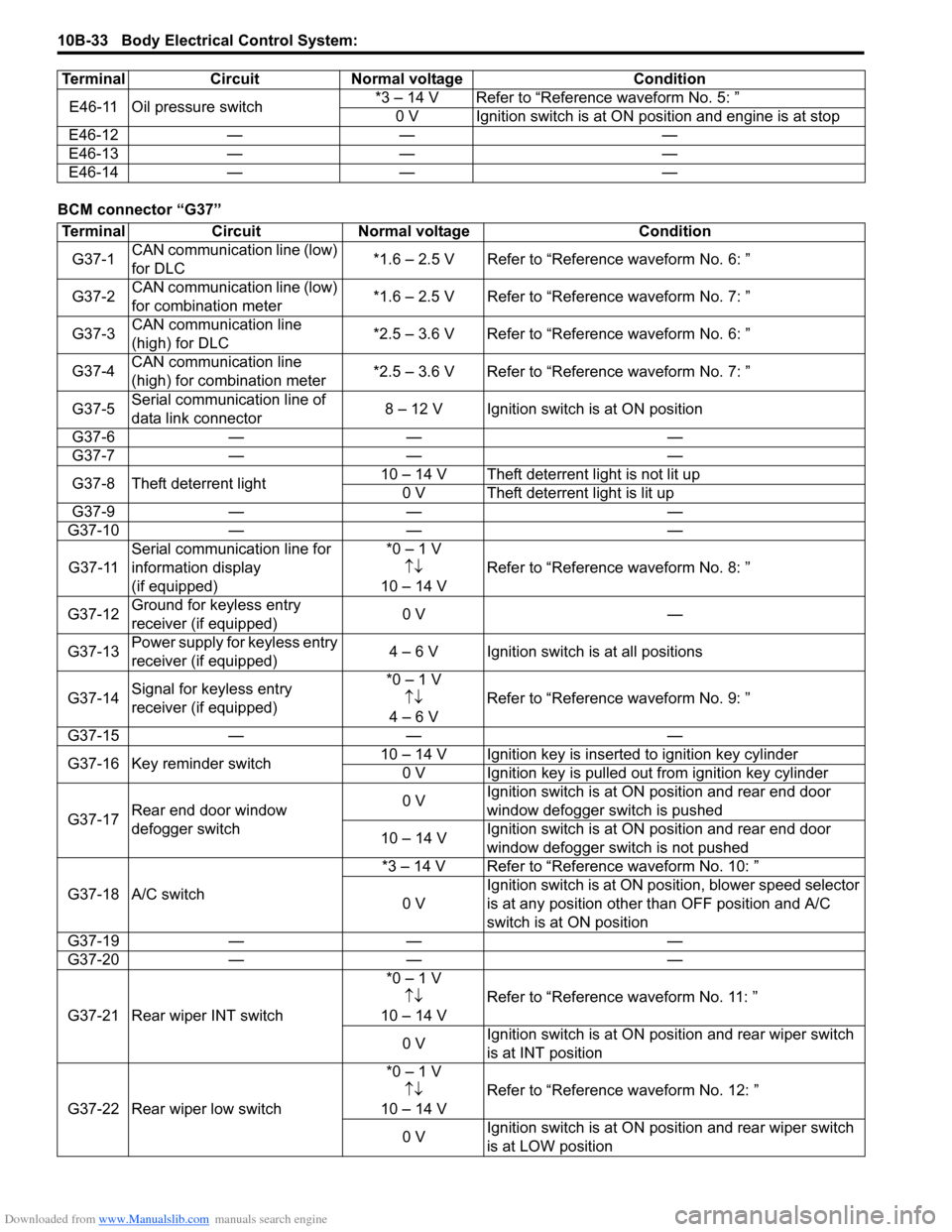

BCM connector “G37”E46-11 Oil pressure switch

*3 – 14 V Refer to “Reference waveform No. 5: ”

0 V Ignition switch is at ON position and engine is at stop

E46-12 — — —

E46-13 — — —

E46-14 — — —

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

G37-1 CAN communication line (low)

for DLC *1.6 – 2.5 V Refer to “Reference waveform No. 6: ”

G37-2 CAN communication line (low)

for combination meter *1.6 – 2.5 V Refer to “Reference waveform No. 7: ”

G37-3 CAN communication line

(high) for DLC *2.5 – 3.6 V Refer to “Reference waveform No. 6: ”

G37-4 CAN communication line

(high) for combination meter *2.5 – 3.6 V Refer to “Reference waveform No. 7: ”

G37-5 Serial communication line of

data link connector 8 – 12 V Ignition switch is at ON position

G37-6 — — —

G37-7 — — —

G37-8 Theft deterrent light 10 – 14 V Theft deterrent light is not lit up

0 V Theft deterrent light is lit up

G37-9 — — —

G37-10 — — —

G37-11 Serial communication line for

information display

(if equipped) *0 – 1 V

↑↓

10 – 14 V Refer to “Reference

waveform No. 8: ”

G37-12 Ground for keyless entry

receiver (if equipped) 0 V

—

G37-13 Power supply for keyless entry

receiver (if equipped) 4 – 6 V Ignition switch is at all positions

G37-14 Signal for keyless entry

receiver (if equipped) *0 – 1 V

↑↓

4 – 6 V Refer to “Reference

waveform No. 9: ”

G37-15 — — —

G37-16 Key reminder switch 10 – 14 V Ignition key is inserted to ignition key cylinder

0 V Ignition key is pulled out from ignition key cylinder

G37-17 Rear end door window

defogger switch 0 V

Ignition switch is at ON

position and rear end door

window defogger switch is pushed

10 – 14 V Ignition switch is at ON

position and rear end door

window defogger switch is not pushed

G37-18 A/C switch *3 – 14 V Refer to “Reference waveform No. 10: ”

0 V Ignition switch is at ON pos

ition, blower speed selector

is at any position other than OFF position and A/C

switch is at ON position

G37-19 — — —

G37-20 — — —

G37-21 Rear wiper INT switch *0 – 1 V

↑↓

10 – 14 V Refer to “Reference

waveform No. 11: ”

0 V Ignition switch is at ON pos

ition and rear wiper switch

is at INT position

G37-22 Rear wiper low switch *0 – 1 V

↑↓

10 – 14 V Refer to “Reference

waveform No. 12: ”

0 V Ignition switch is at ON pos

ition and rear wiper switch

is at LOW position

Page 1437 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-34

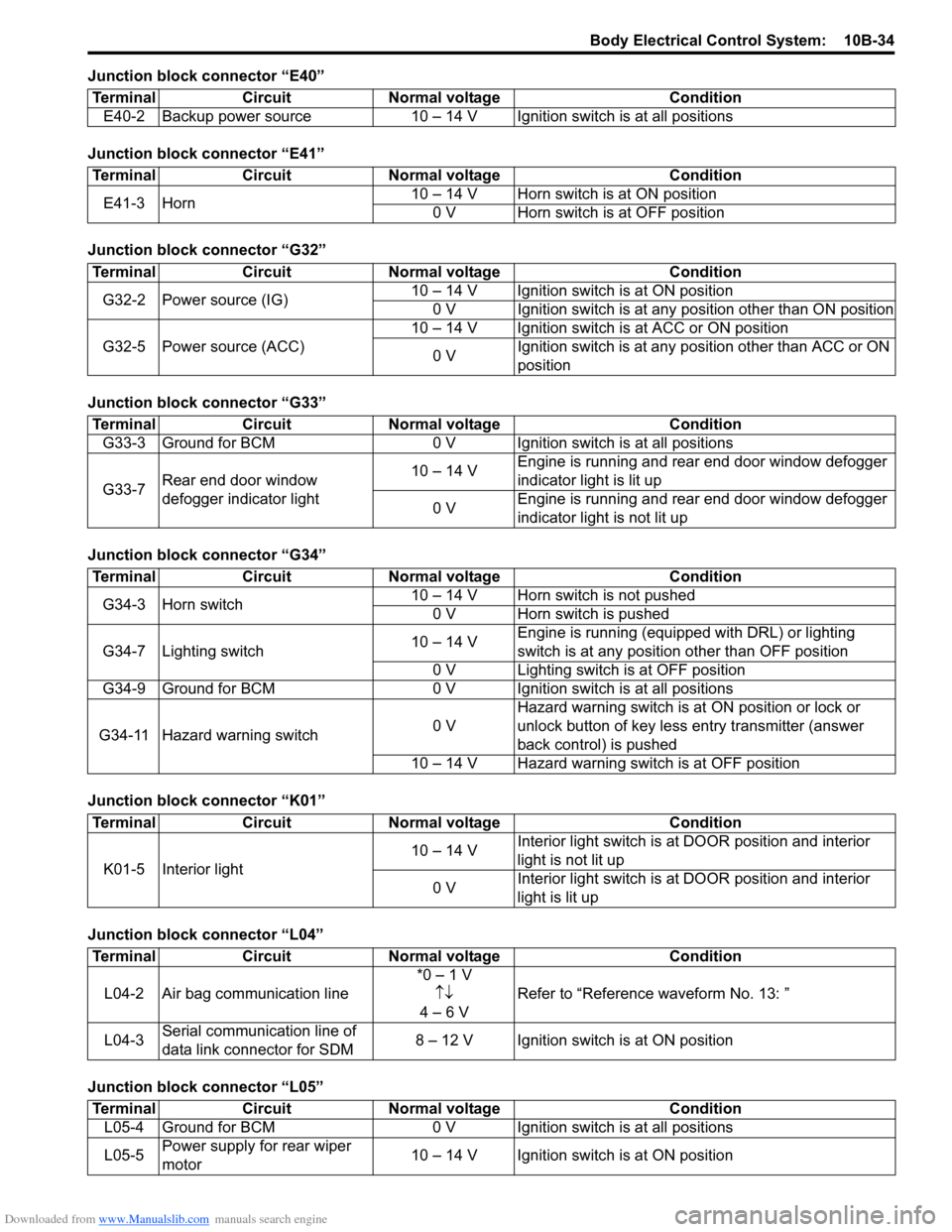

Junction block connector “E40”

Junction block connector “E41”

Junction block connector “G32”

Junction block connector “G33”

Junction block connector “G34”

Junction block connector “K01”

Junction block connector “L04”

Junction block connector “L05”Terminal Circuit Normal voltage Condition

E40-2 Backup power source 10 – 14 V Igni tion switch is at all positions

TerminalCircuitNormal voltage Condition

E41-3 Horn 10 – 14 V Horn switch is at ON position

0 V Horn switch is at OFF position

Terminal CircuitNormal voltage Condition

G32-2 Power source (IG) 10 – 14 V Ignition switch is at ON position

0 V Ignition switch is at any position other than ON position

G32-5 Power source (ACC) 10 – 14 V Ignition switch is at ACC or ON position

0 V Ignition switch is at any position other than ACC or ON

position

Terminal

CircuitNormal voltage Condition

G33-3 Ground for BCM 0 V Ignition switch is at all positions

G33-7 Rear end door window

defogger indicator light 10 – 14 V

Engine is running and rear end door window defogger

indicator light is lit up

0 V Engine is running and rear end door window defogger

indicator light is not lit up

Terminal

CircuitNormal voltage Condition

G34-3 Horn switch 10 – 14 V Horn switch is not pushed

0 V Horn switch is pushed

G34-7 Lighting switch 10 – 14 VEngine is running (equipped with DRL) or lighting

switch is at any position other than OFF position

0 V Lighting switch is at OFF position

G34-9 Ground for BCM 0 V Ignition switch is at all positions

G34-11 Hazard warning switch 0 VHazard warning switch is at

ON position or lock or

unlock button of key less entry transmitter (answer

back control) is pushed

10 – 14 V Hazard warning switch is at OFF position

Terminal CircuitNormal voltage Condition

K01-5 Interior light 10 – 14 V

Interior light switch is at

DOOR position and interior

light is not lit up

0 V Interior light switch is at

DOOR position and interior

light is lit up

Terminal CircuitNormal voltage Condition

L04-2 Air bag communication line *0 – 1 V

↑↓

4 – 6 V Refer to “Reference

waveform No. 13: ”

L04-3 Serial communication line of

data link connector for SDM 8 – 12 V Ignition switch is at ON position

Terminal

CircuitNormal voltage Condition

L05-4 Ground for BCM 0 V Ignition switch is at all positions

L05-5 Power supply for rear wiper

motor 10 – 14 V Ignition switch is at ON position

Page 1440 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-37 Body Electrical Control System:

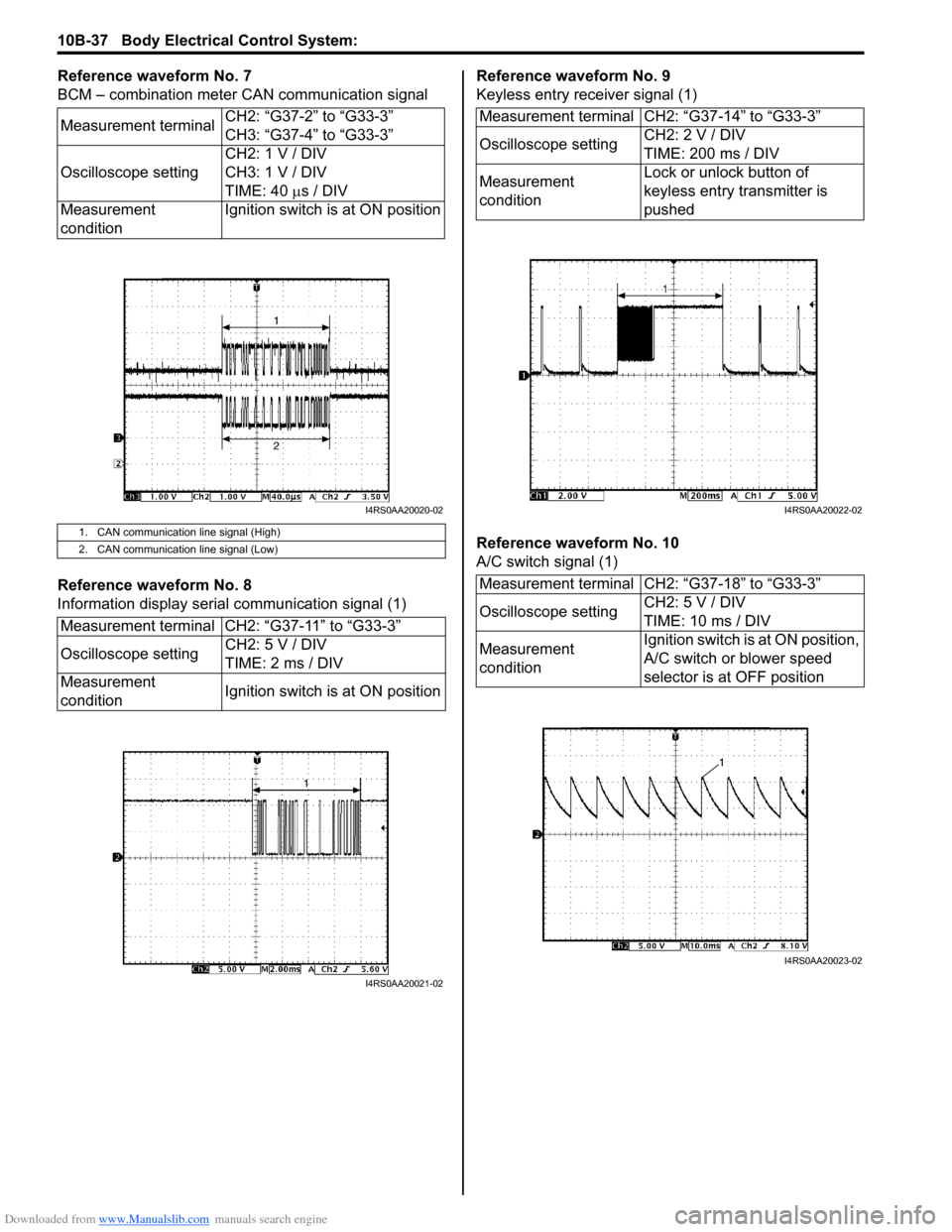

Reference waveform No. 7

BCM – combination meter CAN communication signal

Reference waveform No. 8

Information display serial communication signal (1)Reference waveform No. 9

Keyless entry receiver signal (1)

Reference waveform No. 10

A/C switch signal (1)

Measurement terminal

CH2: “G37-2” to “G33-3”

CH3: “G37-4” to “G33-3”

Oscilloscope setting CH2: 1 V / DIV

CH3: 1 V / DIV

TIME: 40

µs / DIV

Measurement

condition Ignition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

Measurement terminal CH2: “G37-11” to “G33-3”

Oscilloscope setting

CH2: 5 V / DIV

TIME: 2 ms / DIV

Measurement

condition Ignition switch is at ON position

I4RS0AA20020-02

I4RS0AA20021-02

Measurement terminal CH2: “G37-14” to “G33-3”

Oscilloscope settingCH2: 2 V / DIV

TIME: 200 ms / DIV

Measurement

condition Lock or unlock button of

keyless entry transmitter is

pushed

Measurement terminal CH2: “G37-18” to “G33-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

condition Ignition switch is at ON position,

A/C switch or blower speed

selector is at OFF position

I4RS0AA20022-02

I4RS0AA20023-02

Page 1442 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-39 Body Electrical Control System:

Repair Instructions

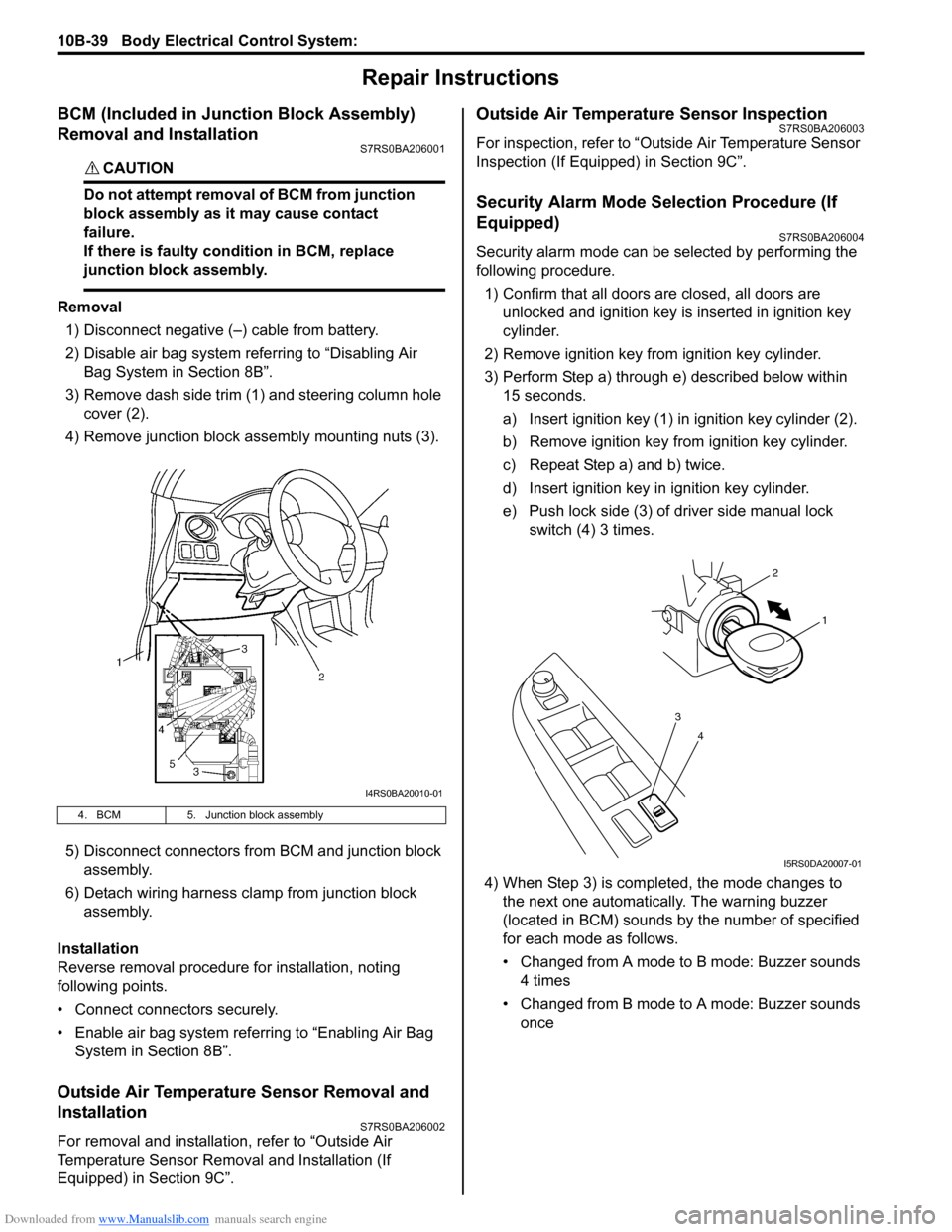

BCM (Included in Junction Block Assembly)

Removal and Installation

S7RS0BA206001

CAUTION!

Do not attempt removal of BCM from junction

block assembly as it may cause contact

failure.

If there is faulty condition in BCM, replace

junction block assembly.

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove dash side trim (1) and steering column hole cover (2).

4) Remove junction block assembly mounting nuts (3).

5) Disconnect connectors from BCM and junction block assembly.

6) Detach wiring harness clamp from junction block assembly.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Outside Air Temperature Sensor Removal and

Installation

S7RS0BA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0BA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Security Alarm Mode Selection Procedure (If

Equipped)

S7RS0BA206004

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within 15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock switch (4) 3 times.

4) When Step 3) is completed, the mode changes to the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds 4 times

• Changed from B mode to A mode: Buzzer sounds once

4. BCM 5. Junction block assembly

I4RS0BA20010-01

4

3

1

2

I5RS0DA20007-01