8B- SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1146 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-108 Air Bag System:

4) Remove side curtain-air bag (inflator) module fixing bolts (1) and clips (2).

5) Remove side curtain-air bag (inflator) module.

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live curtain air bag (inflator) module must be kept with it s bag facing up while

being stored or left standing. This is

necessary so that a free space is provided

to allow the air bag to expand in the

unlikely event of accidental deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

WARNING!

Do not install side curtain-air bag (inflator)

module while twisted or bended. Otherwise,

side curtain-air bag (inflator) module may not

deploy and injury may result.

1) Install side curtain-air bag (inflator) module (1) with

clips and new bolts.

2) Tighten side curtain-air bag (inflator) module attaching bolts (1) to specified torque.

Tightening torque

Side curtain-air bag (inflator) module attaching

bolts (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Connect side curtain-air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector wi th lock button (2).

4) Install head lining referring to “Head Lining Removal and Installation in Section 9H”.

5) Enable air bag system. Refer to “Enabling Air Bag System”.1 2

2

22

1

I4RS0A820076-01

1,(a) 1,(a)

I4RS0A820110-01

1

2

a)

b)

I4RS0A820055-01

Page 1147 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-109

Side Curtain-Air Bag (Inflator) Module

Inspection

S7RS0B8206012

WARNING!

• Never measure resistance of side curtain-air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Inflator case being damaged or having been exposed to strong impact (dropped).

Forward-Sensor Removal and InstallationS7RS0B8206013

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

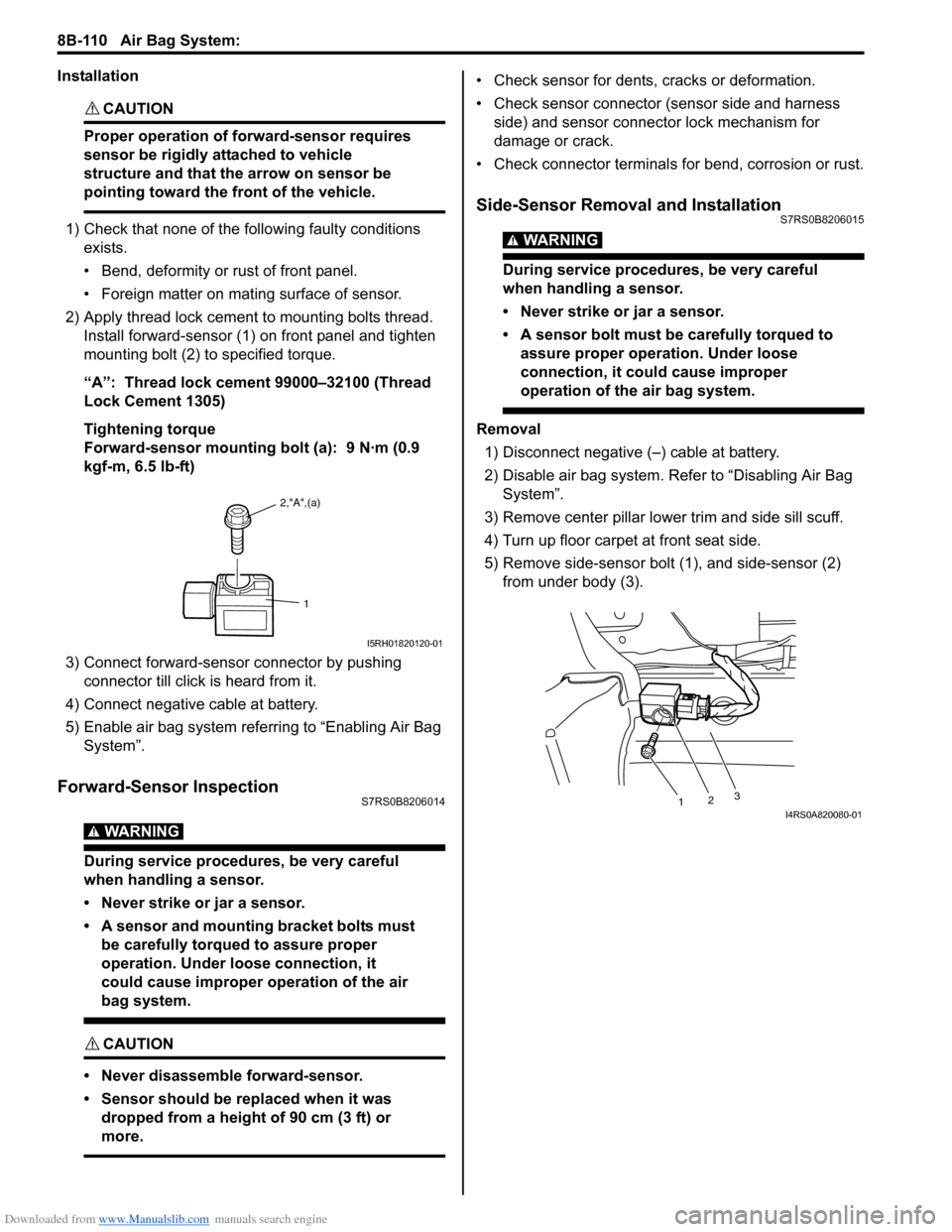

3) Disconnect forward-sensor connector sliding connector outer (2) as shown.

4) Remove forward-sensor bolt (1) and forward-sensor (2).

I4RS0A820078-03

1

2

I4RS0A820079-01

1

2

I5RH01820119-01

Page 1148 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-110 Air Bag System:

Installation

CAUTION!

Proper operation of forward-sensor requires

sensor be rigidly attached to vehicle

structure and that the arrow on sensor be

pointing toward the front of the vehicle.

1) Check that none of the following faulty conditions exists.

• Bend, deformity or rust of front panel.

• Foreign matter on mating surface of sensor.

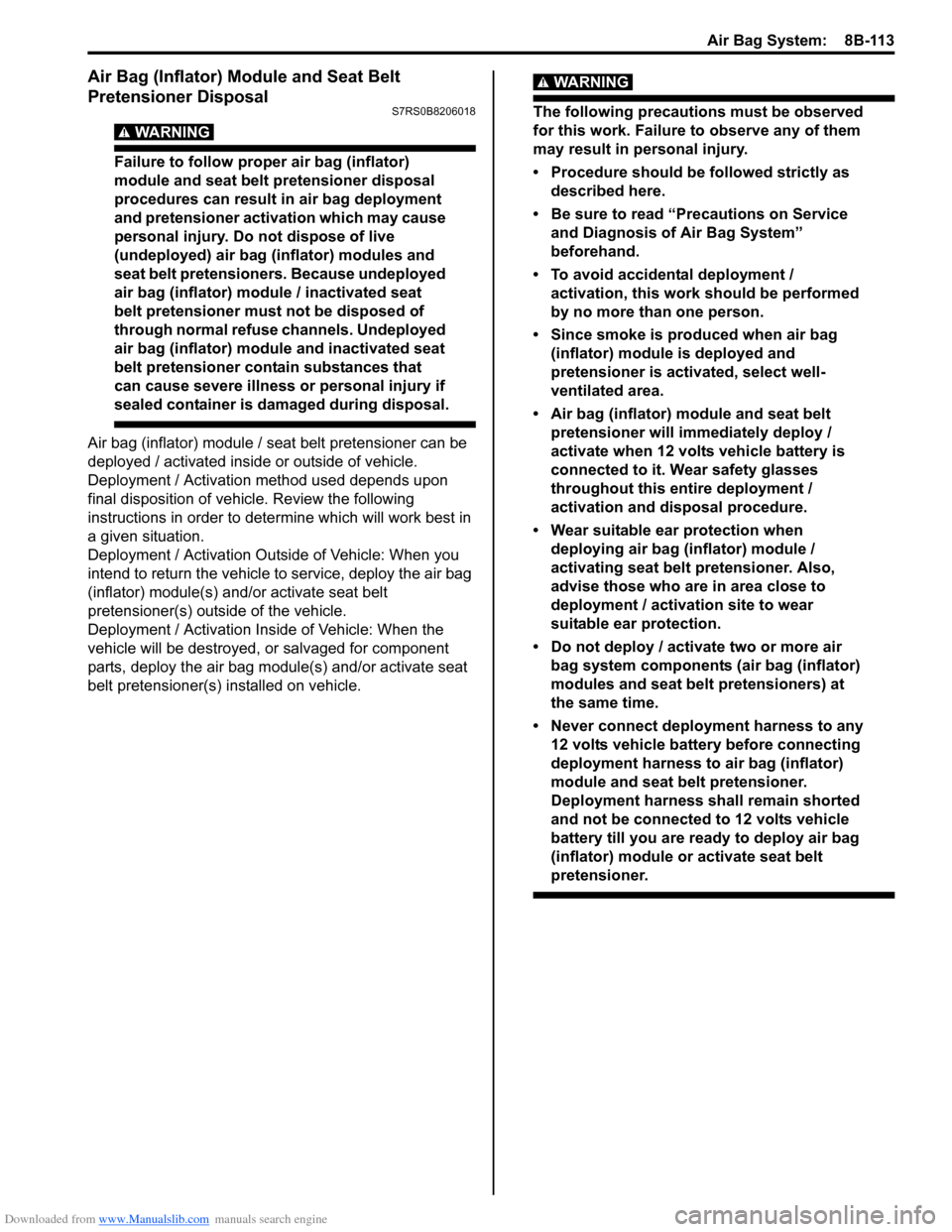

2) Apply thread lock cement to mounting bolts thread. Install forward-sensor (1) on front panel and tighten

mounting bolt (2) to specified torque.

“A”: Thread lock cement 99000–32100 (Thread

Lock Cement 1305)

Tightening torque

Forward-sensor mounting bolt (a): 9 N·m (0.9

kgf-m, 6.5 lb-ft)

3) Connect forward-sensor connector by pushing connector till click is heard from it.

4) Connect negative cable at battery.

5) Enable air bag system referring to “Enabling Air Bag System”.

Forward-Sensor InspectionS7RS0B8206014

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble forward-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

Side-Sensor Removal and InstallationS7RS0B8206015

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

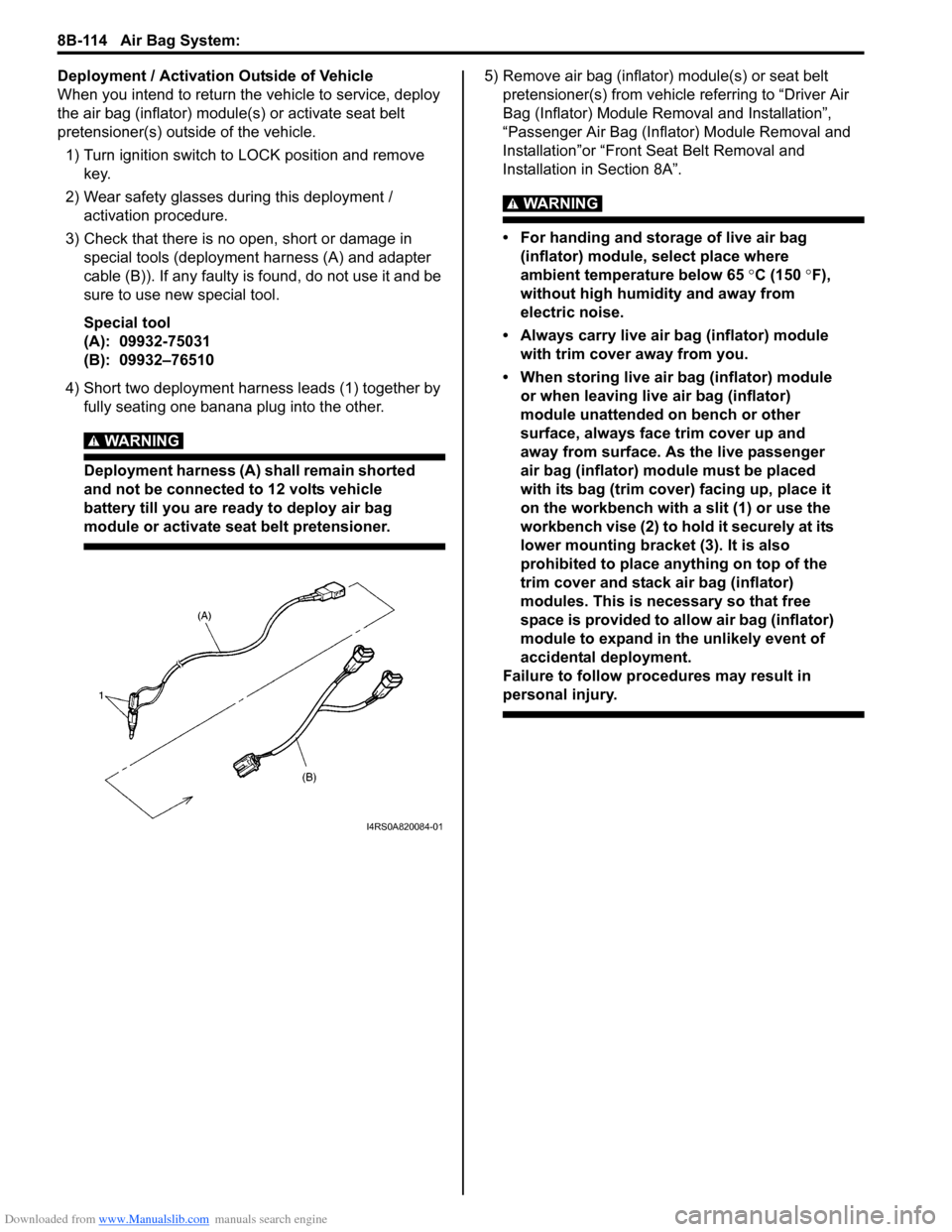

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Remove center pillar lowe r trim and side sill scuff.

4) Turn up floor carpet at front seat side.

5) Remove side-sensor bolt (1), and side-sensor (2) from under body (3).

2,"A",(a)

1

I5RH01820120-01

1 23I4RS0A820080-01

Page 1149 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-111

6) Disconnect side-sensor connector sliding connector

outer (1) as shown.

Installation

CAUTION!

Proper operation of side-sensor requires

sensor be rigidly attached to specified

position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.

2) Install side-sensor (1) on under body (2) and tighten side-sensor bolt (3) to specified torque.

Tightening torque

Side-sensor bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft) 3) Connect side-sensor connector pushing connector

inner (1) as shown.

4) Connect negative cable at battery.

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Side-Sensor InspectionS7RS0B8206016

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

1

1

I4RS0A820109-01

1 2

3, (a)I4RS0A820081-01

1

1

I4RS0A820106-01

Page 1150 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-112 Air Bag System:

• Check sensor (1) for dents, crack, deformation.

• Check sensor connector (sensor side and harness side), lock mechanism or sensor lead wire for

damage, crack, scorching or melting.

• Check connector terminals for bent, corrosion or rust. If any faulty condition is found in above checks,

replace.

Passenger Air Bag (Inflator) Module Repair

Harness Installation

S7RS0B8206017

Replace passenger air bag (inflator) module repair

harness (4) according to the following procedure when

the harness (1) connect ed with passenger air bag

(inflator) module of the air bag harness included in

instrument panel harness (2) and passenger air bag

(inflator) module connector (3) is damaged. 1) Disable air bag system. Re

fer to “Disabling Air Bag

System”.

2) Disconnect “L32” connector from floor harness located near the glove box.

3) Cut off passenger air bag (inflator) module harness (1) included in instrument panel harness (2) as

shown, and then fasten it to instrument panel

harness with vinyl tape for avoiding interference with

other parts.

4) Install passenger air bag (inflator) module repair harness (1) to floor harness (2), instrument panel

harness (3) and passenger air bag (inflator) module.CAUTION!

To avoid interference with other parts, fasten

the repair harness to in strument wire harness

with a clamp or vinyl tape as shown in figure.

5) Connect each connector securely till click is heard.

5. Driver air bag (inflator) module 7. Floor harness

6. Passenger air bag (inflator) module 8. Vinyl tape

1I4RS0A820082-01

7

4

6

6

2

28

1

3

5

5

7I4RS0A820103-01

1

I4RS0A820083-01

1

2

3

I4RS0A820085-01

Page 1151 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-113

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal

S7RS0B8206018

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. Do not dispose of live

(undeployed) air bag (inflator) modules and

seat belt pretensioners. Because undeployed

air bag (inflator) module / inactivated seat

belt pretensioner must not be disposed of

through normal refuse channels. Undeployed

air bag (inflator) module and inactivated seat

belt pretensioner contain substances that

can cause severe illness or personal injury if

sealed container is damaged during disposal.

Air bag (inflator) module / seat belt pretensioner can be

deployed / activated inside or outside of vehicle.

Deployment / Activation method used depends upon

final disposition of vehicle. Review the following

instructions in order to deter mine which will work best in

a given situation.

Deployment / Activation Ou tside of Vehicle: When you

intend to return the vehicle to service, deploy the air bag

(inflator) module(s) and/or activate seat belt

pretensioner(s) outside of the vehicle.

Deployment / Activation Insi de of Vehicle: When the

vehicle will be destroyed, or salvaged for component

parts, deploy the air bag module(s) and/or activate seat

belt pretensioner(s) installed on vehicle.

WARNING!

The following precautions must be observed

for this work. Failure to observe any of them

may result in personal injury.

• Procedure should be followed strictly as described here.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”

beforehand.

• To avoid accidental deployment / activation, this work should be performed

by no more than one person.

• Since smoke is produced when air bag (inflator) module is deployed and

pretensioner is activated, select well-

ventilated area.

• Air bag (inflator) module and seat belt pretensioner will immediately deploy /

activate when 12 volts vehicle battery is

connected to it. Wear safety glasses

throughout this entire deployment /

activation and disposal procedure.

• Wear suitable ear protection when deploying air bag (inflator) module /

activating seat belt pretensioner. Also,

advise those who are in area close to

deployment / activation site to wear

suitable ear protection.

• Do not deploy / activate two or more air bag system components (air bag (inflator)

modules and seat belt pretensioners) at

the same time.

• Never connect deployment harness to any 12 volts vehicle battery before connecting

deployment harness to air bag (inflator)

module and seat belt pretensioner.

Deployment harness sh all remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

Page 1152 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-114 Air Bag System:

Deployment / Activation Outside of Vehicle

When you intend to return the vehicle to service, deploy

the air bag (inflator) module(s) or activate seat belt

pretensioner(s) outside of the vehicle.1) Turn ignition switch to LOCK position and remove key.

2) Wear safety glasses during this deployment / activation procedure.

3) Check that there is no open, short or damage in special tools (deployment harness (A) and adapter

cable (B)). If any faulty is found, do not use it and be

sure to use new special tool.

Special tool

(A): 09932-75031

(B): 09932–76510

4) Short two deployment harness leads (1) together by fully seating one banana plug into the other.

WARNING!

Deployment harness (A) shall remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

module or activate seat belt pretensioner.

5) Remove air bag (inflator) module(s) or seat belt pretensioner(s) from vehicle referring to “Driver Air

Bag (Inflator) Module Re moval and Installation”,

“Passenger Air Bag (Inflator) Module Removal and

Installation”or “Front Seat Belt Removal and

Installation in Section 8A”.

WARNING!

• For handing and storage of live air bag (inflator) module, select place where

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Always carry live air bag (inflator) module with trim cover away from you.

• When storing live air bag (inflator) module or when leaving live air bag (inflator)

module unattended on bench or other

surface, always face trim cover up and

away from surface. As the live passenger

air bag (inflator) module must be placed

with its bag (trim cover) facing up, place it

on the workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that free

space is provided to allow air bag (inflator)

module to expand in the unlikely event of

accidental deployment.

Failure to follow procedures may result in

personal injury.

I4RS0A820084-01

Page 1153 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-115

WARNING!

• For handling and storage of seat belt pretensioner, select place where ambient

temperature is below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by webbing.

• When placing seat belt pretensioner on workbench or other surface, be sure to lay

it with its exhaust hole (1) side facing up. It

is also prohibited to put something on seat

belt pretensioner.

Otherwise, personal injury may result.

6) Set air bag (inflator) module or seat belt pretensioner

as follows.

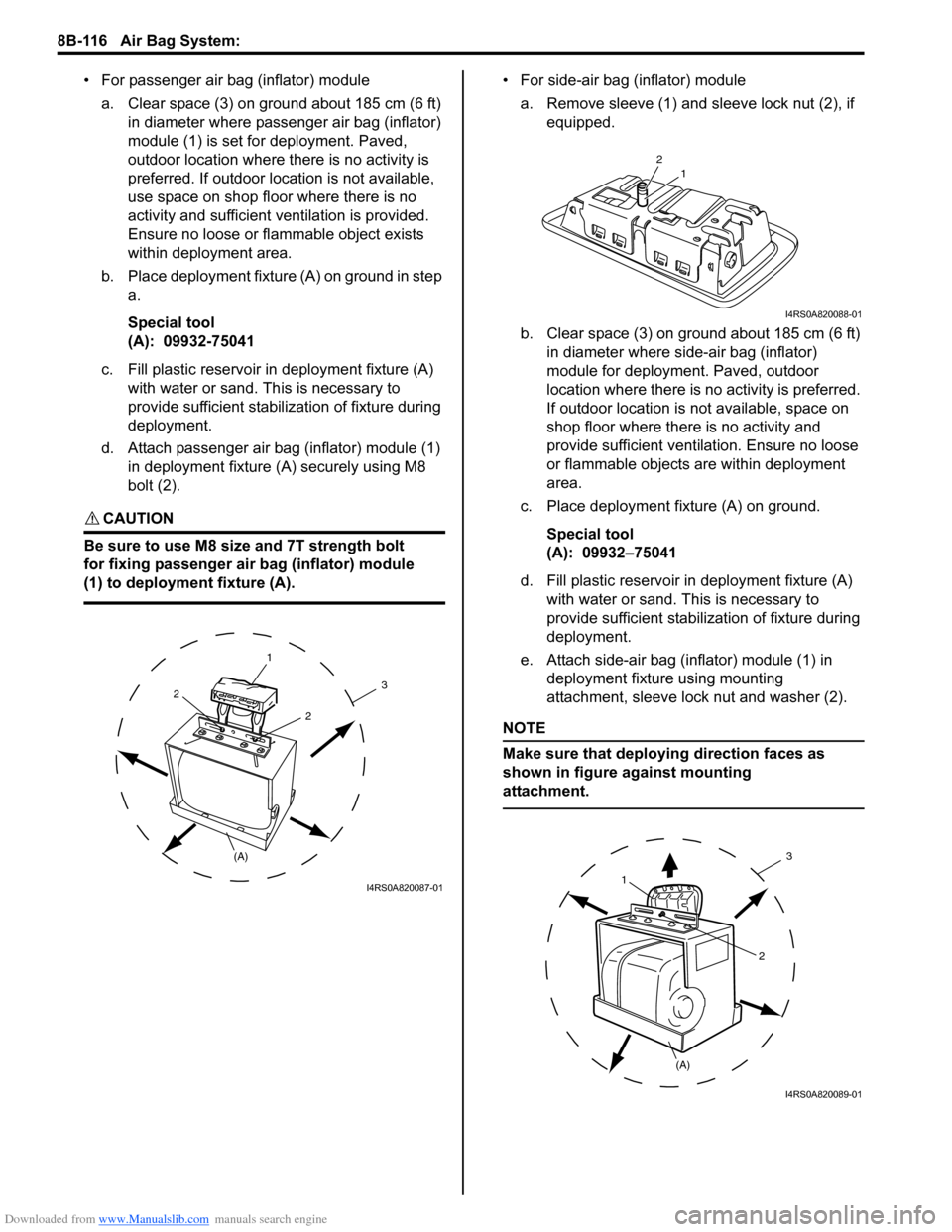

• For driver air bag (inflator) module

a. Clear space (3) on ground about 185 cm (6 ft) in diameter where driver air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place driver air bag (inflator) module (1) with its vinyl trim cover facing up (2) on ground in

step a.

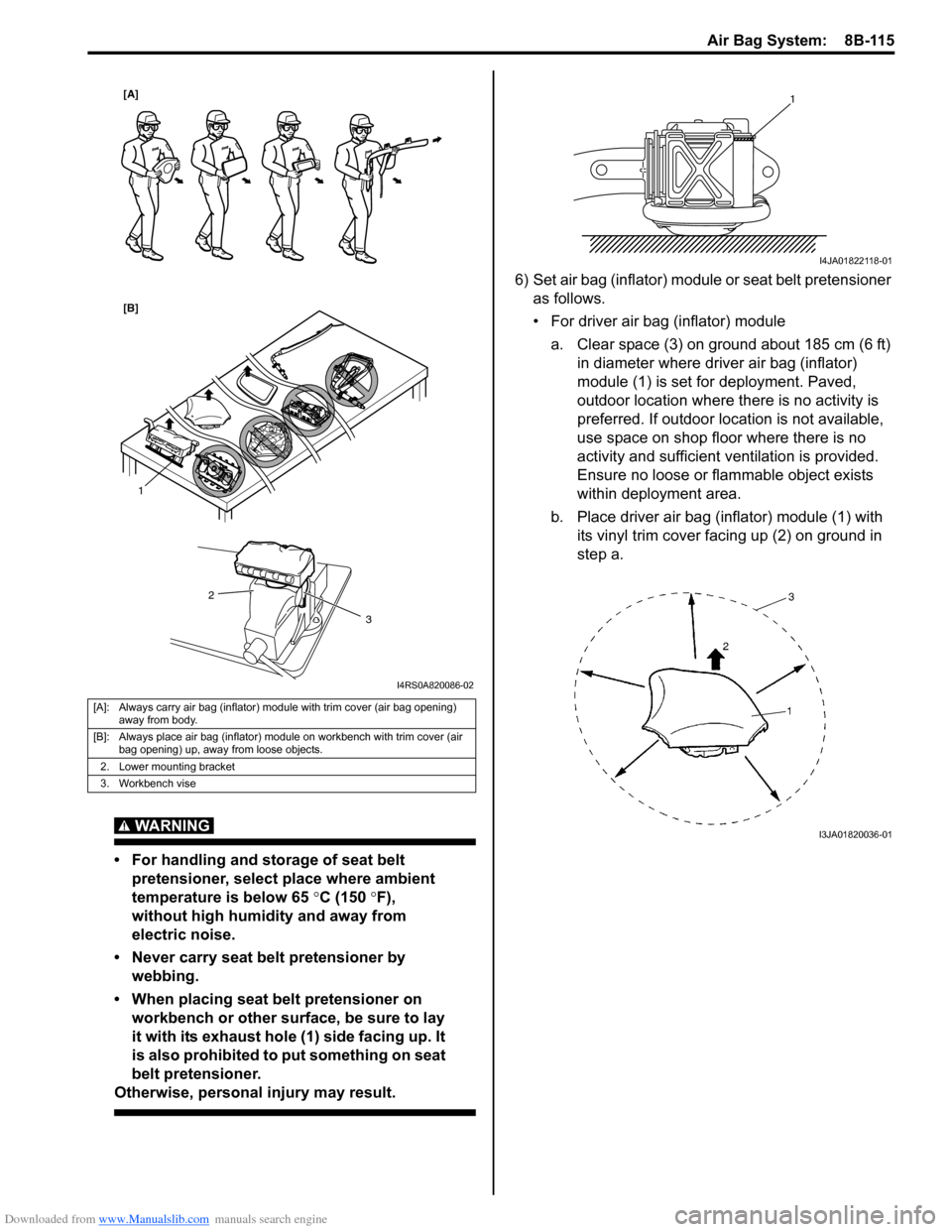

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

2. Lower mounting bracket

3. Workbench vise

1

2

3

[A]

[B]

I4RS0A820086-02

1

I4JA01822118-01

I3JA01820036-01

Page 1154 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-116 Air Bag System:

• For passenger air bag (inflator) modulea. Clear space (3) on ground about 185 cm (6 ft) in diameter where passenger air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place deployment fixture (A) on ground in step a.

Special tool

(A): 09932-75041

c. Fill plastic reservoir in deployment fixture (A) with water or sand. Th is is necessary to

provide sufficient stabilization of fixture during

deployment.

d. Attach passenger air bag (inflator) module (1) in deployment fixture (A ) securely using M8

bolt (2).

CAUTION!

Be sure to use M8 size and 7T strength bolt

for fixing passenger air bag (inflator) module

(1) to deployment fixture (A).

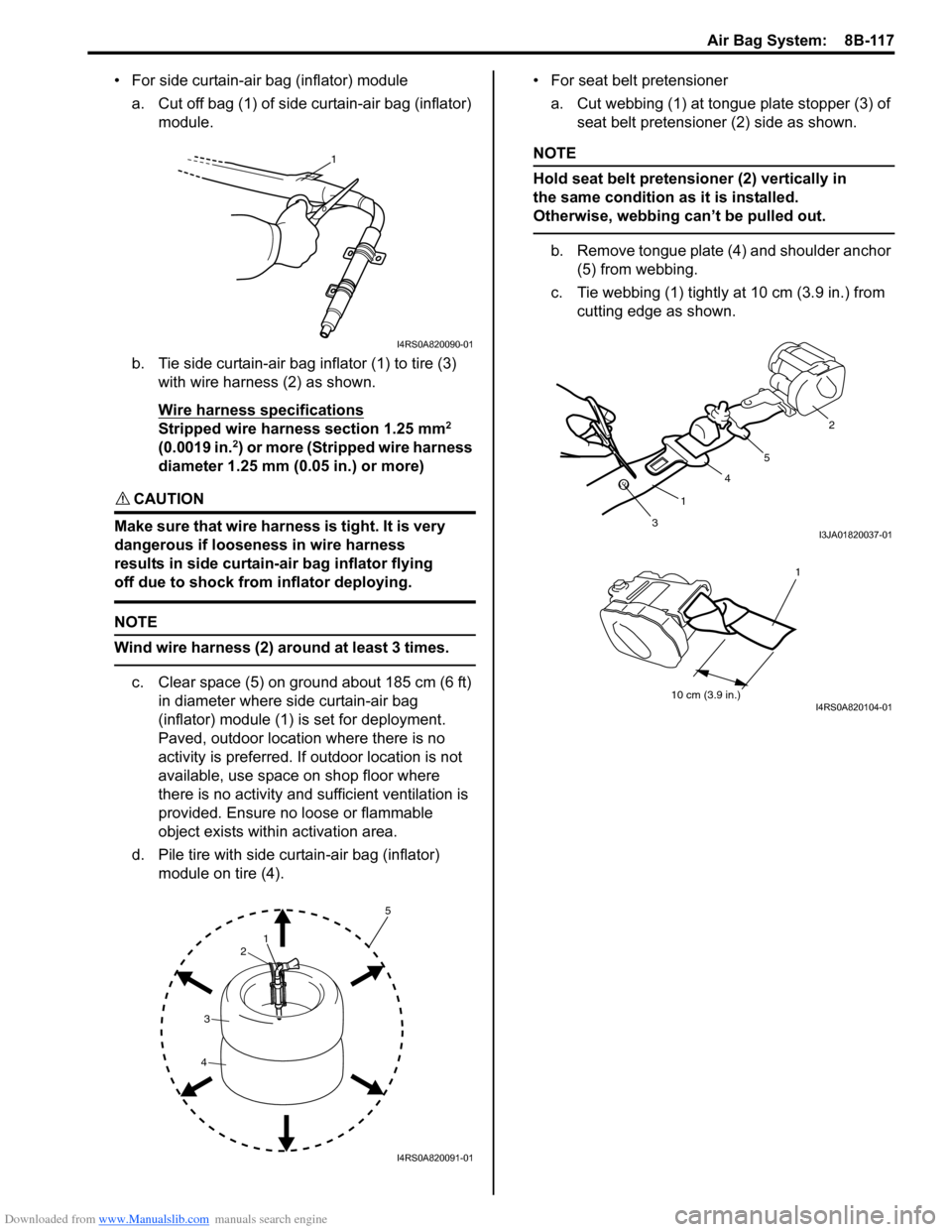

• For side-air bag (inflator) module

a. Remove sleeve (1) and sl eeve lock nut (2), if

equipped.

b. Clear space (3) on ground about 185 cm (6 ft) in diameter where side-air bag (inflator)

module for deployment. Paved, outdoor

location where there is no activity is preferred.

If outdoor location is not available, space on

shop floor where there is no activity and

provide sufficient ventilation. Ensure no loose

or flammable objects are within deployment

area.

c. Place deployment fixture (A) on ground.

Special tool

(A): 09932–75041

d. Fill plastic reservoir in deployment fixture (A) with water or sand. Th is is necessary to

provide sufficient stabiliz ation of fixture during

deployment.

e. Attach side-air bag (inflator) module (1) in deployment fixture using mounting

attachment, sleeve lock nut and washer (2).

NOTE

Make sure that deploying direction faces as

shown in figure against mounting

attachment.

1

(A)

2

2

3

I4RS0A820087-01

21

I4RS0A820088-01

1

(A) 2

3

I4RS0A820089-01

Page 1155 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-117

• For side curtain-air bag (inflator) modulea. Cut off bag (1) of side curtain-air bag (inflator) module.

b. Tie side curtain-air bag inflator (1) to tire (3) with wire harness (2) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

CAUTION!

Make sure that wire harness is tight. It is very

dangerous if looseness in wire harness

results in side curtain-air bag inflator flying

off due to shock from inflator deploying.

NOTE

Wind wire harness (2) around at least 3 times.

c. Clear space (5) on ground about 185 cm (6 ft) in diameter where side curtain-air bag

(inflator) module (1) is set for deployment.

Paved, outdoor location where there is no

activity is preferred. If outdoor location is not

available, use space on shop floor where

there is no activity and sufficient ventilation is

provided. Ensure no loose or flammable

object exists within activation area.

d. Pile tire with side curtain-air bag (inflator) module on tire (4). • For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor (5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

1

I4RS0A820090-01

1

2

3

4

5

I4RS0A820091-01

3 1 4

5 2I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01