turn light SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1415 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-12

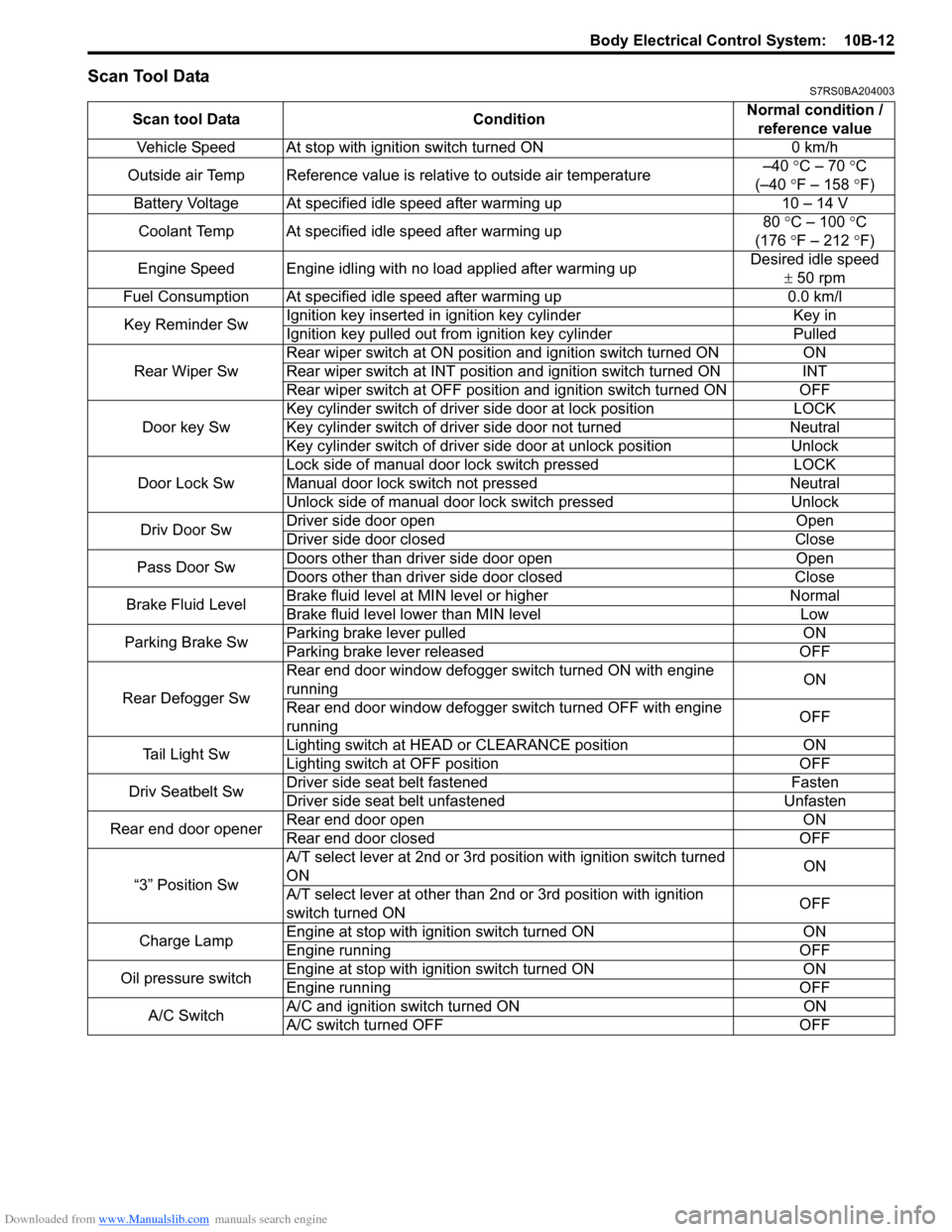

Scan Tool DataS7RS0BA204003

Scan tool DataConditionNormal condition /

reference value

Vehicle Speed At stop with ignition switch turned ON 0 km/h

Outside air Temp Reference value is relative to outside air temperature –40

°C – 70 °C

(–40 °F – 158 ° F)

Battery Voltage At specified idle speed after warming up 10 – 14 V

Coolant Temp At specified idle speed after warming up 80

°C – 100 ° C

(176 °F – 212 ° F)

Engine Speed Engine idling with no load applied after warming up Desired idle speed

± 50 rpm

Fuel Consumption At specified idle speed after warming up 0.0 km/l

Key Reminder Sw Ignition key inserted in

ignition key cylinder Key in

Ignition key pulled out from ignition key cylinder Pulled

Rear Wiper Sw Rear wiper switch at ON position and ignition switch turned ON

ON

Rear wiper switch at INT position and ignition switch turned ON INT

Rear wiper switch at OFF position and ignition switch turned ON OFF

Door key Sw Key cylinder switch of driver side door at lock position

LOCK

Key cylinder switch of driver side door not turned Neutral

Key cylinder switch of driver side door at unlock position Unlock

Door Lock Sw Lock side of manual door lock switch pressed

LOCK

Manual door lock switch not pressed Neutral

Unlock side of manual door lock switch pressed Unlock

Driv Door Sw Driver side door open

Open

Driver side door closed Close

Pass Door Sw Doors other than driver side door open

Open

Doors other than driver side door closed Close

Brake Fluid Level Brake fluid level at MIN level or higher

Normal

Brake fluid level lower than MIN level Low

Parking Brake Sw Parking brake lever pulled

ON

Parking brake lever released OFF

Rear Defogger Sw Rear end door window defogger switch turned ON with engine

running

ON

Rear end door window defogger switch turned OFF with engine

running OFF

Tail Light Sw Lighting switch at HEAD

or CLEARANCE position ON

Lighting switch at OFF position OFF

Driv Seatbelt Sw Driver side seat belt fastened

Fasten

Driver side seat belt unfastened Unfasten

Rear end door opener Rear end door open

ON

Rear end door closed OFF

“3” Position Sw A/T select lever at 2nd or 3rd position with ignition switch turned

ON

ON

A/T select lever at other than 2nd or 3rd position with ignition

switch turned ON OFF

Charge Lamp Engine at stop with ignition switch turned ON

ON

Engine running OFF

Oil pressure switch Engine at stop with ignition switch turned ON

ON

Engine running OFF

A/C Switch A/C and ignition switch turned ON

ON

A/C switch turned OFF OFF

Page 1416 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-13 Body Electrical Control System:

Scan Tool Data Definitions

Vehicle Speed (km/h, mph): It is computed based on pulse signals from vehicle speed sensor on transmission.

Outside air Temp ( °C, °F): It is detected by outside air temperature sensor.

Battery Voltage (V): This parameter indicates battery po sitive voltage inputted to BCM.

Coolant Temp (Engine coolant temperature) ( °C, °F): It is detected by engine coolant temperature sensor.

Engine Speed (RPM): It is computed by reference pulse signals from CMP sensor.

Fuel Consumption (km/l): This parameter indicates the fuel consumption computed by ECM.

Key Reminder Sw (Key reminder switch) (Pulled / Key in): This parameter indicates the state of the key reminder

switch.

Rear Wiper Sw (Rear wiper switch) (ON / INT / OFF): This parameter indicates the state of the rear wiper switch.

Door key Sw (Door key cylinder switch) (Lock / Neutral / Unlock): This parameter indicates the state of the door

key cylinder switch.

Door lock Sw (Manual door lock switch) (Lock / Neutral / Unlock): This parameter indicates the state of the

manual door lock switch.

Driv Door Sw (Driver side d oor switch) (Open / Close): This parameter indicates the state of the driver side door

switch.

Pass Door Sw (Other than driver side door switch) (Open / Close): This parameter indicates the state of the door

switches other than driver side door switch.

Brake Fluid Level (Low / Normal): Low: Brake fluid level is lower than specified level.

Normal: Brake fluid level is higher than MIN level.

Parking Brake Sw (Parking brake switch) (ON / OFF): ON: Parking brake lever is pulled up.

OFF: Parking brake lever is released.

Rear Defogger Sw (Rear end door window defogger switch) (ON / OFF): This parameter indicates the state of

the rear end door window defogger switch.

Tail Light Sw (Lighting switch) (ON / OFF): This parameter indicates the state of the lighting switch.

Driv Seatbelt Sw (Driver seat belt switch) (Fasten / Unfasten): This parameter indicates the state of the driver

side seat belt buckle switch.

Rear end Door Opener (Rear end door opener switch) (ON / OFF): This parameter indicates the state of the rear

end door opener switch.

“3” position Sw (ON/OFF): This parameter indicates the state of the “3 ” position switch included in A/T manual

selector assembly.

Charge lamp (ON / OFF): This parameter indicates the state of the charge system monitor switch.

Oil pressure switch (ON / OFF): This parameter indicates the state of the oil pressure switch.

A/C Switch (ON / OFF): This parameter indicates the state of the air conditioning switch.

Diagnosis Using Output Test Function of SUZUKI Scan Tool

SUZUKI scan tool has the output test function which can force operation of following actuators and relays of the

system controlled by BCM. When a malf unction is found in the system controlled by BCM, execute the output test

which enables easy judgment whether the malfunction is on the input side or output side of BCM. For detailed

information on operation of SUZUKI scan tool, refer to “SUZUKI Scan Tool Operator’s Manual”.

Output Teat Item Controlled Parts

Hazard Warning Light Turn signal and hazard warning relay

Interior (Dome) Light Interior (Dome) light (wh en interior light switch is at DOOR position)

Door Each door lock actuator

Rear end door open Rear end door opener relay

Warning buzzer Warning buzzer (in BCM)

Rear wiper Rear wiper relay

Alarm indicator Theft deterrent light (in information display or clock)

Rear defogger Rear end door window defogger relay

Page 1417 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

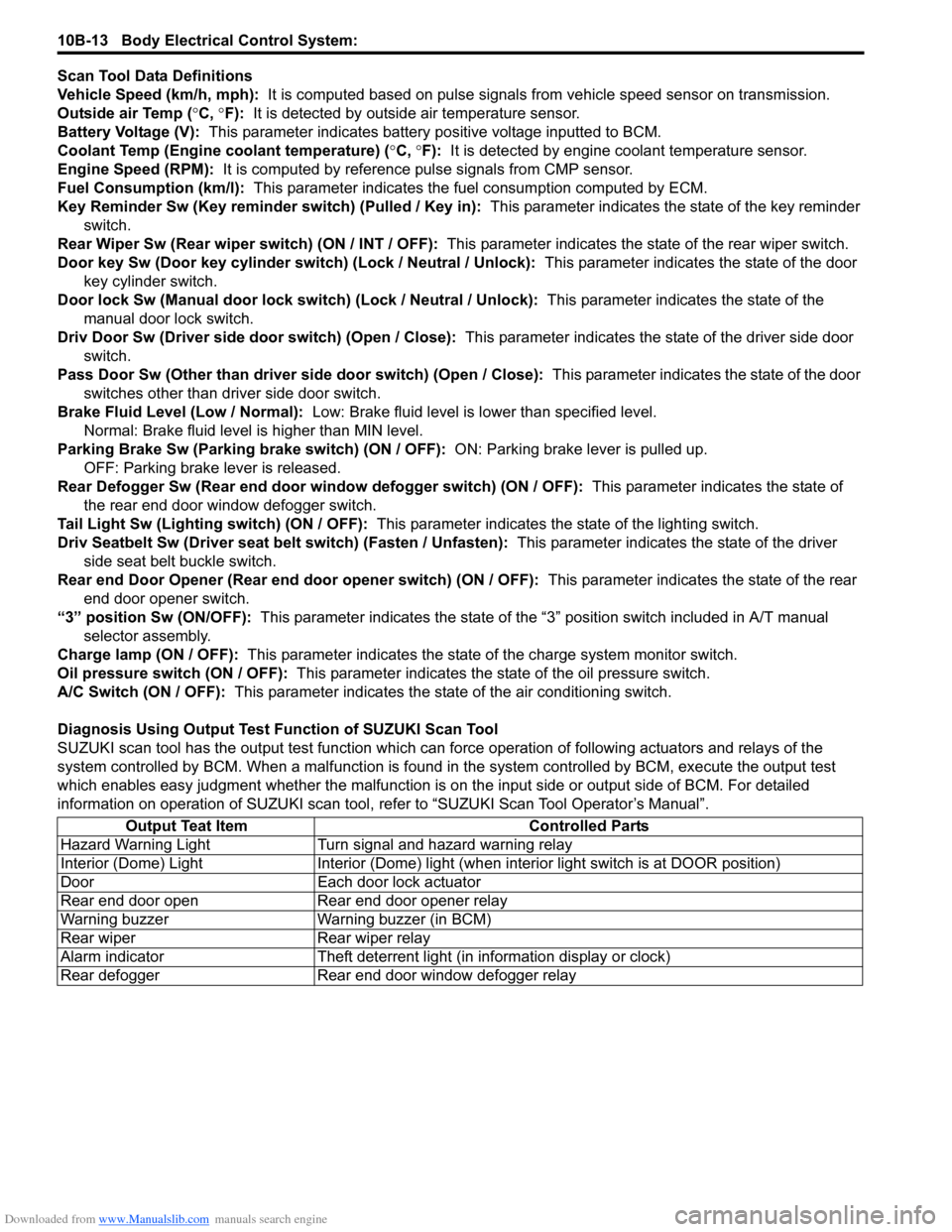

DTC TableS7RS0BA204004

DTC CheckS7RS0BA204005

Using SUZUKI Scan Tool1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of

instrument panel of driver’s side.

Special tool

(A): SUZUKI scan tool 3) Turn ignition switch ON.

4) Read DTC according to

instructions displayed on

SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for

further details.

If communication between SUZUKI scan tool and

BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another

vehicle. If communication is possible in this case,

SUZUKI scan tool is in good condition. Then check

data link connector and serial data line (circuit) in the

vehicle with which communica tion was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link

connector.

DTC

(displayed

on SUZUKI scan tool) DTC (indicated

by theft

deterrent light) DTC (displayed on

odometer in

combination meter) Detected item Detecting condition

NO DTC 0000 0000 — No DTC detected

�) B1133 1133 b1133 Battery voltage too high Battery voltage too high

�) B1141 1141 b1141 Outside air temperature

(ambient temperature) sensor

circuit openSensor output voltage too high

�) B1142 1142 b1142 Outside air temperature

(ambient temperature) sensor

circuit short to groundSensor output voltage too low

�) B1150 1150 b1150 Air bag communication circuit

malfunctionAir bag communication circuit

open or short to ground

�) B1157 1157 b1157 Air bag deployment signal input Air bag deployment signal

inputted

�) B1170 1170 b1170 EEPROM access error Memory error

�)

U0155 0155 U0155 Lost communication with

instrument panel cluster (IPC)

control moduleReceiving error of BCM from

combination mete

r for specified

time continuously

�) U1073 1073 U1073 Control module communication

bus offTransmitting and receiving error

of BCM for specified time

continuously

�) U1100 1100 U1100 Lost communication with ECM Receiving error of BCM from

ECM for specified time

continuously

�) U1101 1101 U1101 Lost communication with TCM Receiving error of BCM from

TCM for specified time

continuously

�) U1144 1144 U1144 Lost communication with

keyless start control moduleReceiving error of BCM from

keyless start control module for

specified time continuously

(A)

I4RS0BA20005-01

Page 1418 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

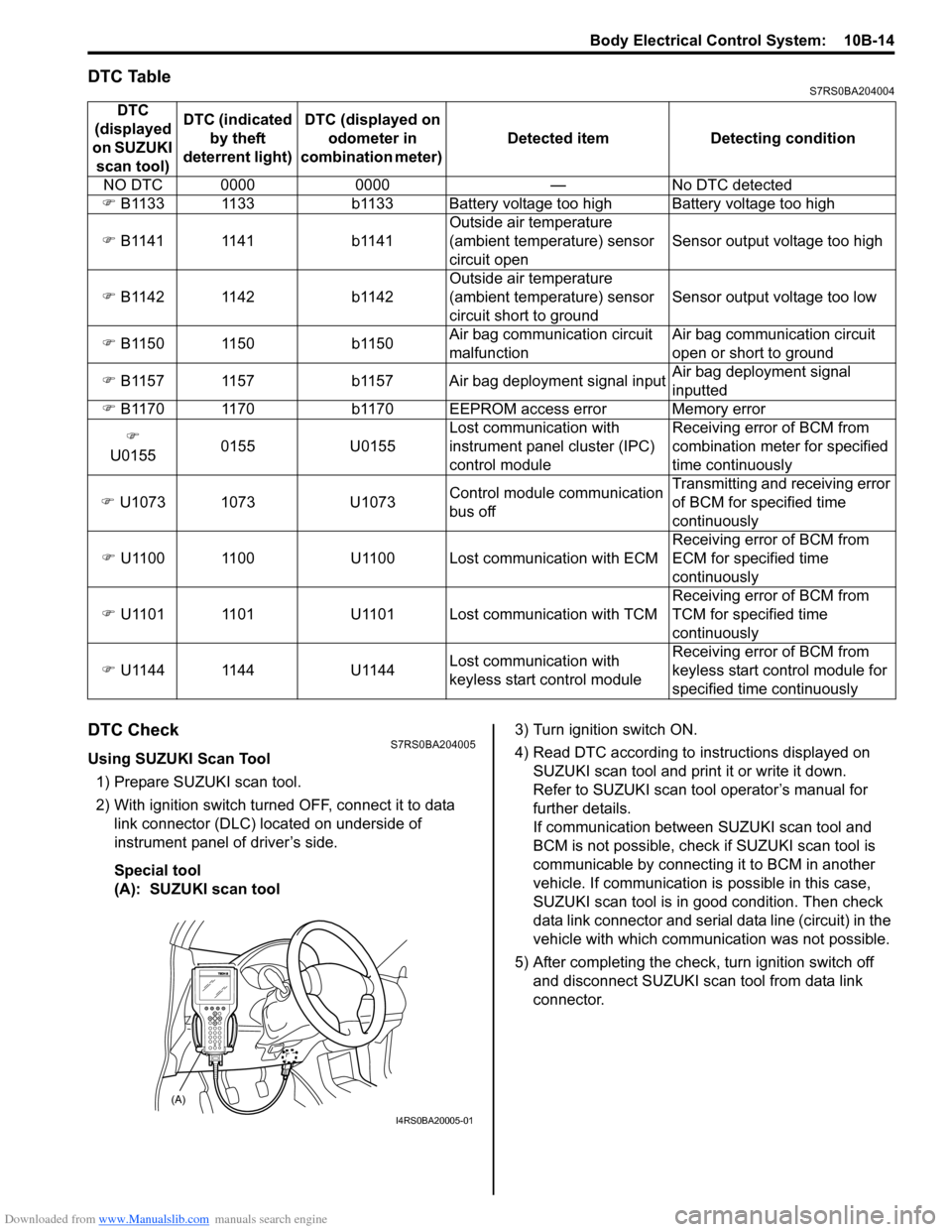

Without Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds af ter ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS7RS0BA204006

After repair or replace of malfunction part(s), clear all

DTCs by performing the following procedure.

Using SUZUKI Scan Tool 1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clear ance, turn ignition switch

off and disconnect scan tool from data link

connector. Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A

[B] [A]

[C]

B A B A

3

113

3

113

T2

T1 T1 T1 T1

1

2

T2T2

T2

T1 T1 T1 T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2

T3T2T2T2

I4RS0AA20007-01

[A]: No DTC (No. 0000) B: Indicator lamp turned OFF1. Theft deterrent light

[B]: DTC B1133 (No. 1133) T1: 0.3 seconds2. Odometer

[C]: When 2 DTCs are detected T2: 1.0 seconds

A: Indicator lamp tur ned ON T3: 3.0 seconds

Page 1426 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

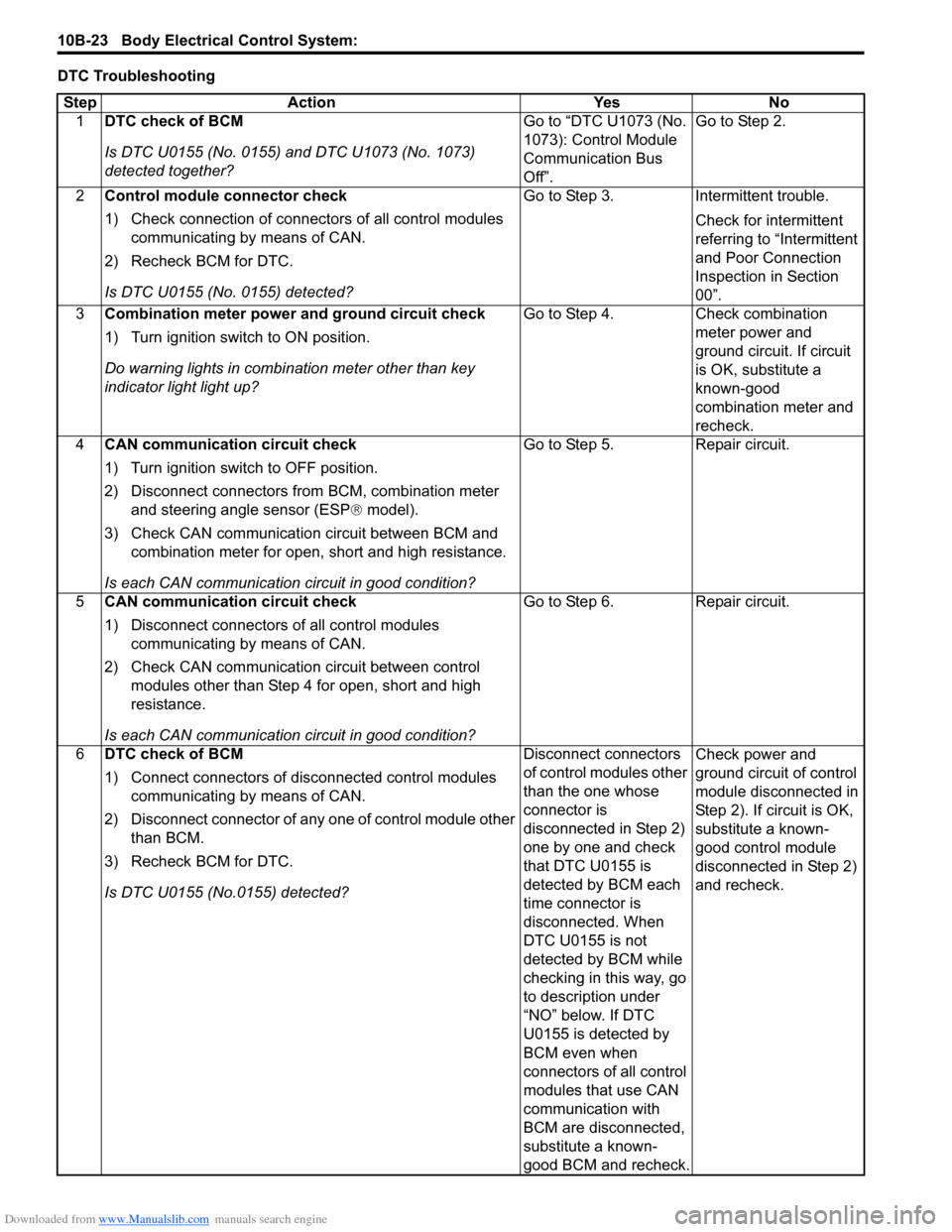

DTC TroubleshootingStep Action YesNo

1 DTC check of BCM

Is DTC U0155 (No. 0155) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U0155 (No. 0155) detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator light light up? Go to Step 4.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, combination meter

and steering angle sensor (ESP ® model).

3) Check CAN communication circuit between BCM and combination meter for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U0155 (No.0155) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U0155 is

detected by BCM each

time connector is

disconnected. When

DTC U0155 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U0155 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Page 1433 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-30

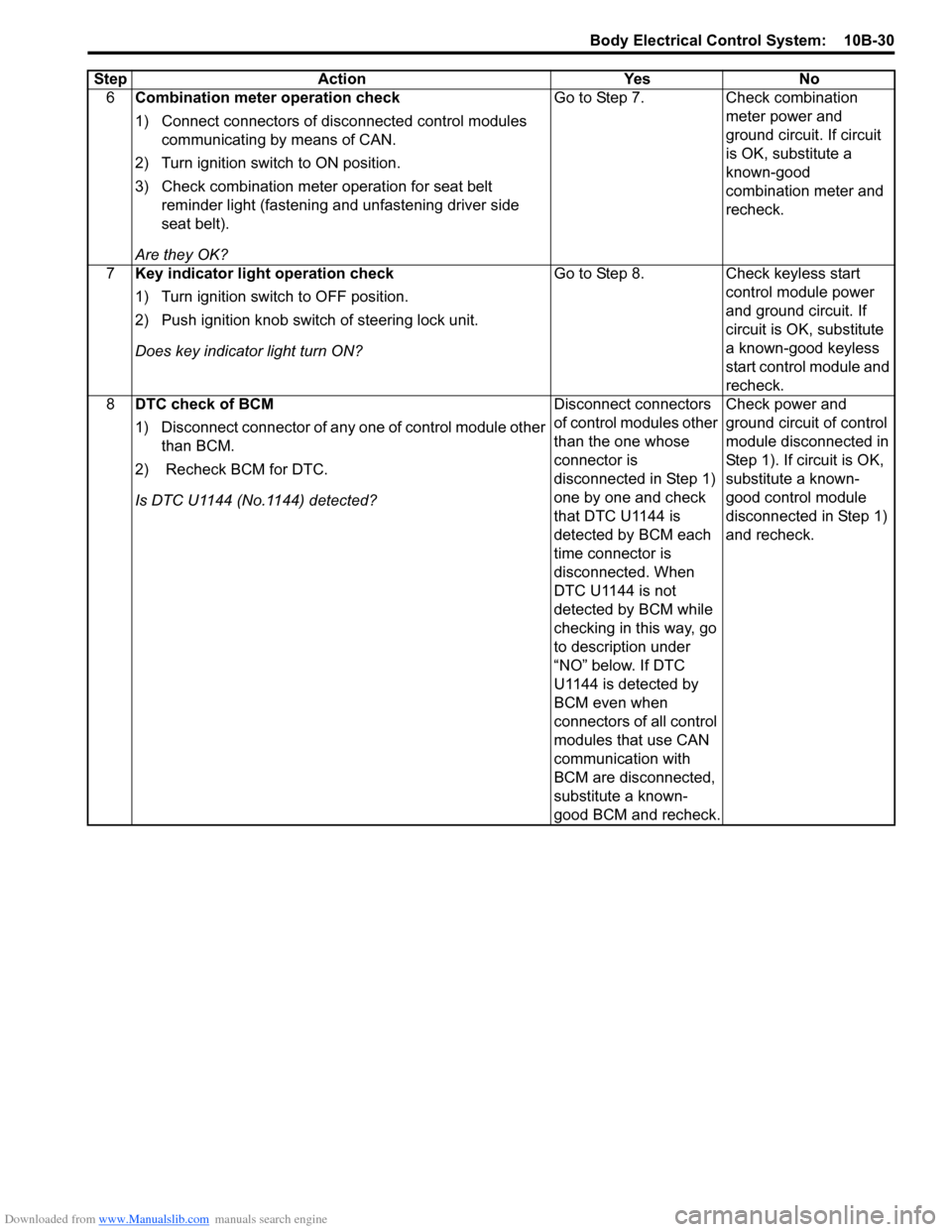

6Combination meter operation check

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Turn ignition switch to ON position.

3) Check combination meter operation for seat belt reminder light (fastening and unfastening driver side

seat belt).

Are they OK? Go to Step 7.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

7 Key indicator light operation check

1) Turn ignition switch to OFF position.

2) Push ignition knob switch of steering lock unit.

Does key indicator light turn ON? Go to Step 8.

Check keyless start

control module power

and ground circuit. If

circuit is OK, substitute

a known-good keyless

start control module and

recheck.

8 DTC check of BCM

1) Disconnect connector of any one of control module other

than BCM.

2) Recheck BCM for DTC.

Is DTC U1144 (No.1144) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 1)

one by one and check

that DTC U1144 is

detected by BCM each

time connector is

disconnected. When

DTC U1144 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U1144 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 1). If circuit is OK,

substitute a known-

good control module

disconnected in Step 1)

and recheck.

Step

Action YesNo

Page 1446 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-3 Immobilizer Control System:

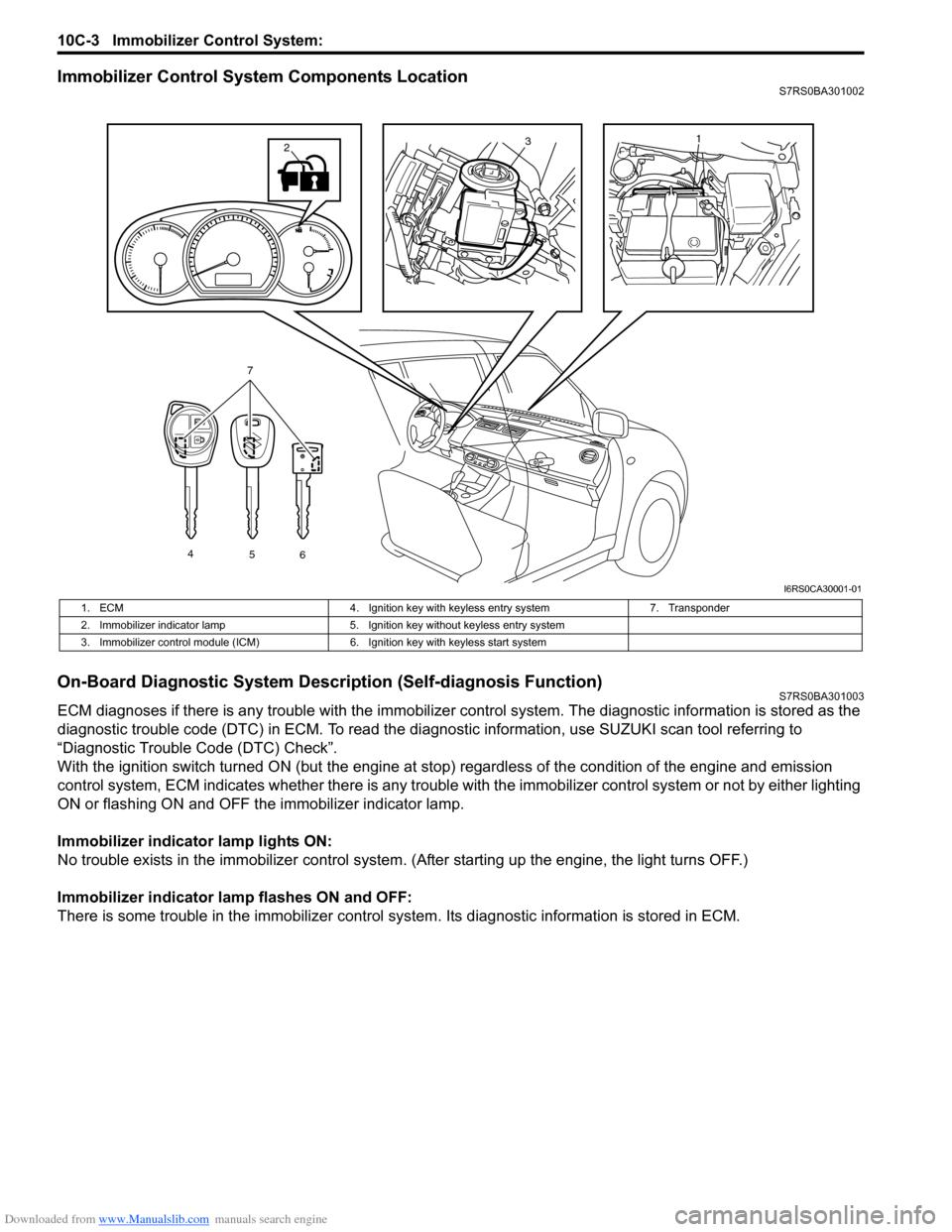

Immobilizer Control System Components LocationS7RS0BA301002

On-Board Diagnostic System Description (Self-diagnosis Function)S7RS0BA301003

ECM diagnoses if there is any trouble with the immobilizer control system. The diagnostic information is stored as the

diagnostic trouble code (DTC) in ECM. To read the di agnostic information, use SUZUKI scan tool referring to

“Diagnostic Trouble Code (DTC) Check”.

With the ignition switch turned ON (but the engine at stop) regardless of the condition of the engine and emission

control system, ECM indicates whether ther e is any trouble with the immobilizer control system or not by either lighting

ON or flashing ON and OFF t he immobilizer indicator lamp.

Immobilizer indicator lamp lights ON:

No trouble exists in the immobilizer control system. (After starting up the engine, the light turns OFF.)

Immobilizer indicator lamp flashes ON and OFF:

There is some trouble in the immo bilizer control system. Its diagnostic information is stored in ECM.

13

4

56

7

2

I6RS0CA30001-01

1. ECM 4. Ignition key with keyless entry system 7. Transponder

2. Immobilizer indicator lamp 5. Ignition key without keyless entry system

3. Immobilizer control module (ICM) 6. Ignition key with keyless start system

Page 1450 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-7 Immobilizer Control System:

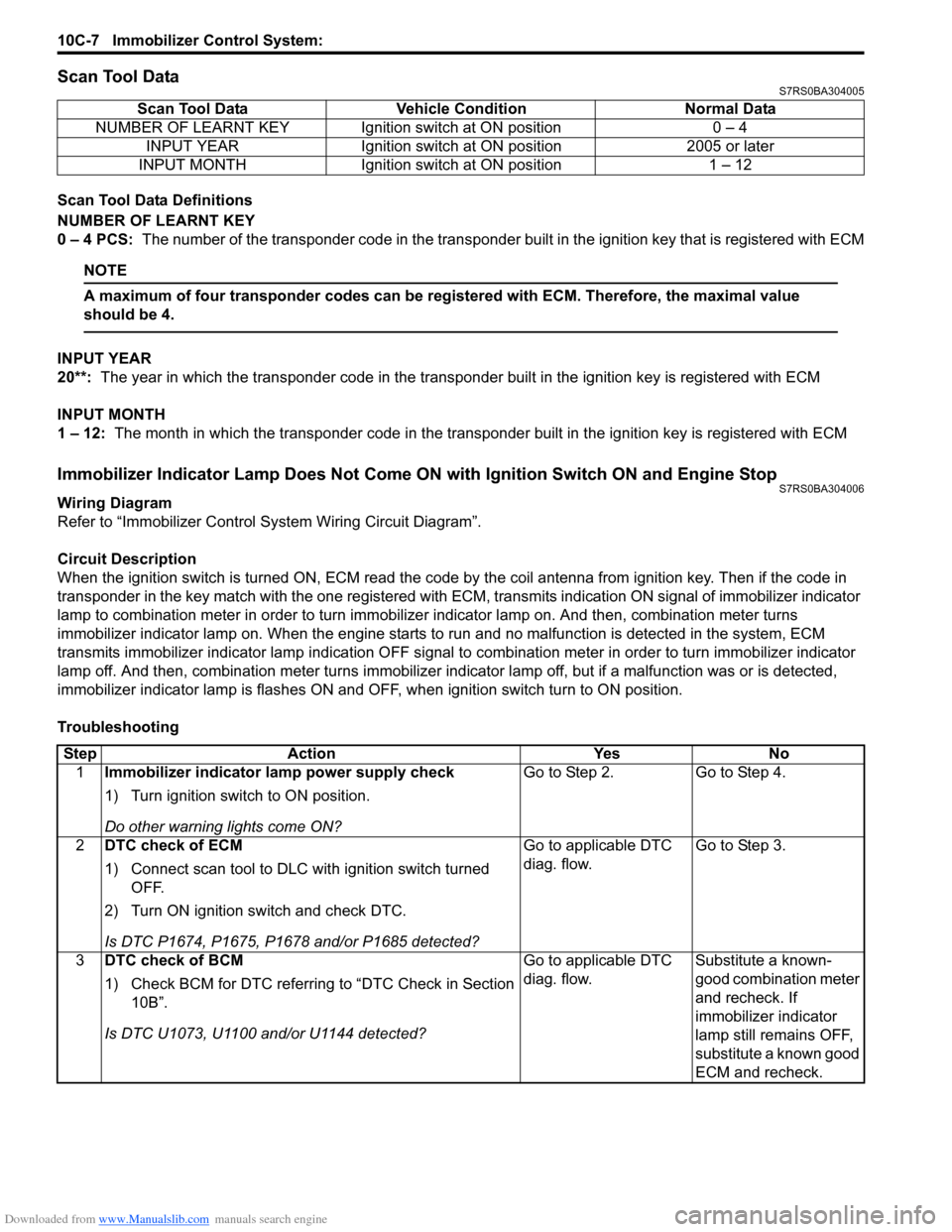

Scan Tool DataS7RS0BA304005

Scan Tool Data Definitions

NUMBER OF LEARNT KEY

0 – 4 PCS: The number of the transponder code in the transponder built in the ignition key that is registered with ECM

NOTE

A maximum of four transponder codes can be registered with ECM. Therefore, the maximal value

should be 4.

INPUT YEAR

20**: The year in which the transponder code in the transpon der built in the ignition key is registered with ECM

INPUT MONTH

1 – 12: The month in which the transponder code in the transpond er built in the ignition key is registered with ECM

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine StopS7RS0BA304006

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the ignition switch is turned ON, ECM read the code by the coil antenna from ignition key. Then if the code in

transponder in the key match with the one registered with ECM, transmits indication ON signal of immobilizer indicator

lamp to combination meter in order to turn immobilizer indicator lamp on. And then, combination meter turns

immobilizer indicator lamp on. When th e engine starts to run and no malfunction is detected in the system, ECM

transmits immobilizer indi cator lamp indication OFF signal to combination meter in order to turn immobilizer indicator

lamp off. And then, comb ination meter turns immobilizer indicator lamp off, but if a malfunction was or is detected,

immobilizer indicator lamp is flashes ON and OF F, when ignition switch turn to ON position.

Troubleshooting Scan Tool Data Vehicl

e Condition Normal Data

NUMBER OF LEARNT KEY Ignition switch at ON position 0 – 4 INPUT YEAR Ignition switch at ON position 2005 or later

INPUT MONTH Ignition switch at ON position 1 – 12

Step Action YesNo

1 Immobilizer indicator lamp power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 4.

2 DTC check of ECM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is DTC P1674, P1675, P1678 and/or P1685 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

lamp still remains OFF,

substitute a known good

ECM and recheck.

Page 1465 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-3

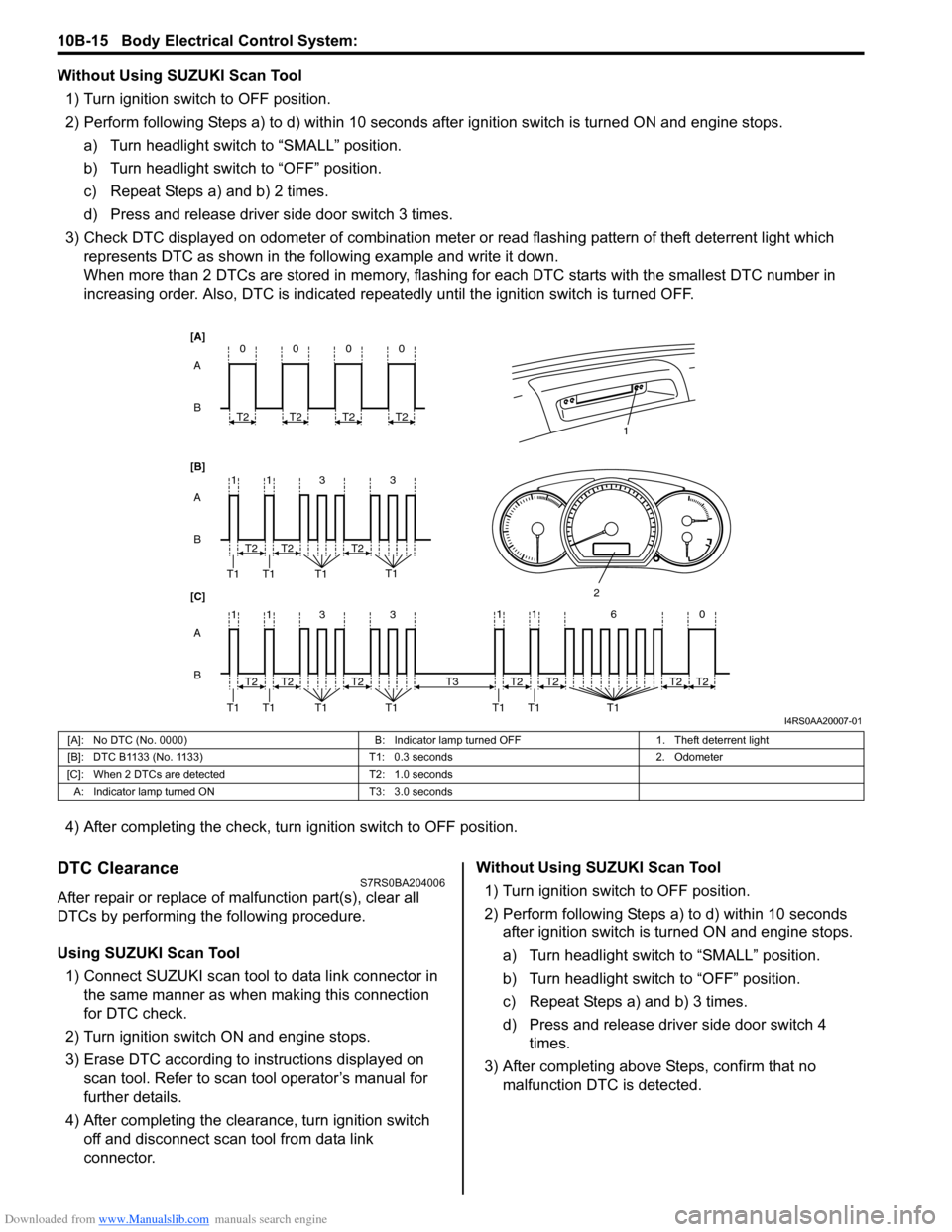

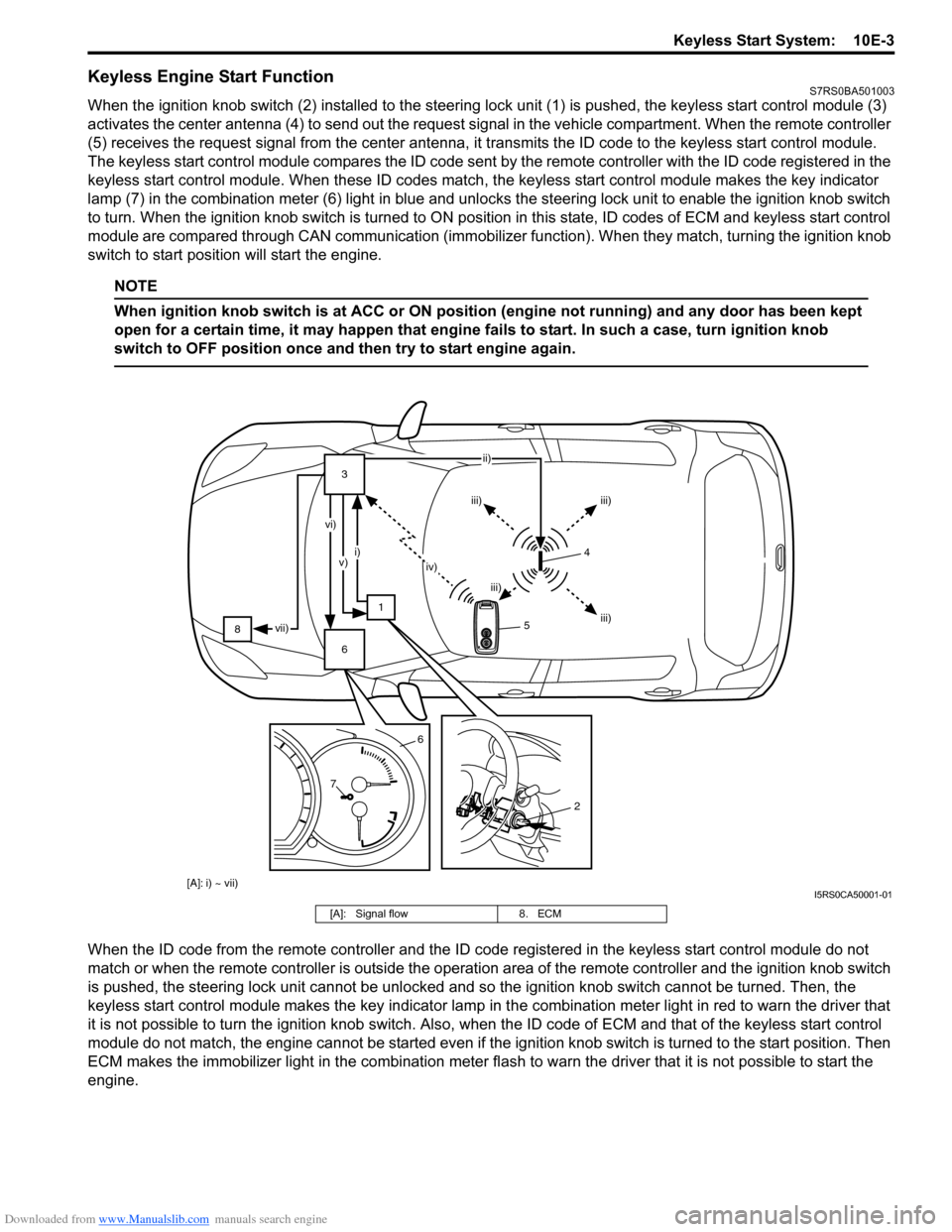

Keyless Engine Start FunctionS7RS0BA501003

When the ignition knob switch (2) installed to the steering lock unit (1) is pushed, the keyless start control module (3)

activates the center antenna (4) to send out the request signa l in the vehicle compartment. When the remote controller

(5) receives the request signal from th e center antenna, it transmits the ID code to the keyless start control module.

The keyless start control module compares the ID code sent by the remote controller with the ID code registered in the

keyless start control module. When these ID codes match, the keyless start control module makes the key indicator

lamp (7) in the combination meter (6) light in blue and unlocks the steering lock unit to enable the ignition knob switch

to turn. When the ignition knob switch is turned to ON posit ion in this state, ID codes of ECM and keyless start control

module are compared through CA N communication (immobilizer function). Wh en they match, turning the ignition knob

switch to start position will start the engine.

NOTE

When ignition knob switch is at ACC or ON position (engine not running) and any door has been kept

open for a certain time, it may happen that engine fails to start. In such a case, turn ignition knob

switch to OFF position once and then try to start engine again.

When the ID code from the remote controller and the ID code registered in the keyless start control module do not

match or when the remote controller is outside the operation area of the remote controller and the ignition knob switch

is pushed, the steering lock unit cannot be unlocked and so the ignition knob switch cannot be turned. Then, the

keyless start control module makes the key indicator lamp in t he combination meter light in red to warn the driver that

it is not possible to turn the ignition knob switch. Also, when the ID code of ECM and that of the keyless start control

module do not match, the engine cannot be started even if the ignition knob switch is turned to the start position. Then

ECM makes the immobilizer light in the combination mete r flash to warn the driver that it is not possible to start the

engine.

8 3

1

6 ii)

iii) iii)

iii)

iii)

iv)

i)

v)

vi)

vii)

7 6

2

[A]: i) ~ vii)

54

I5RS0CA50001-01

[A]: Signal flow

8. ECM

Page 1467 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-5

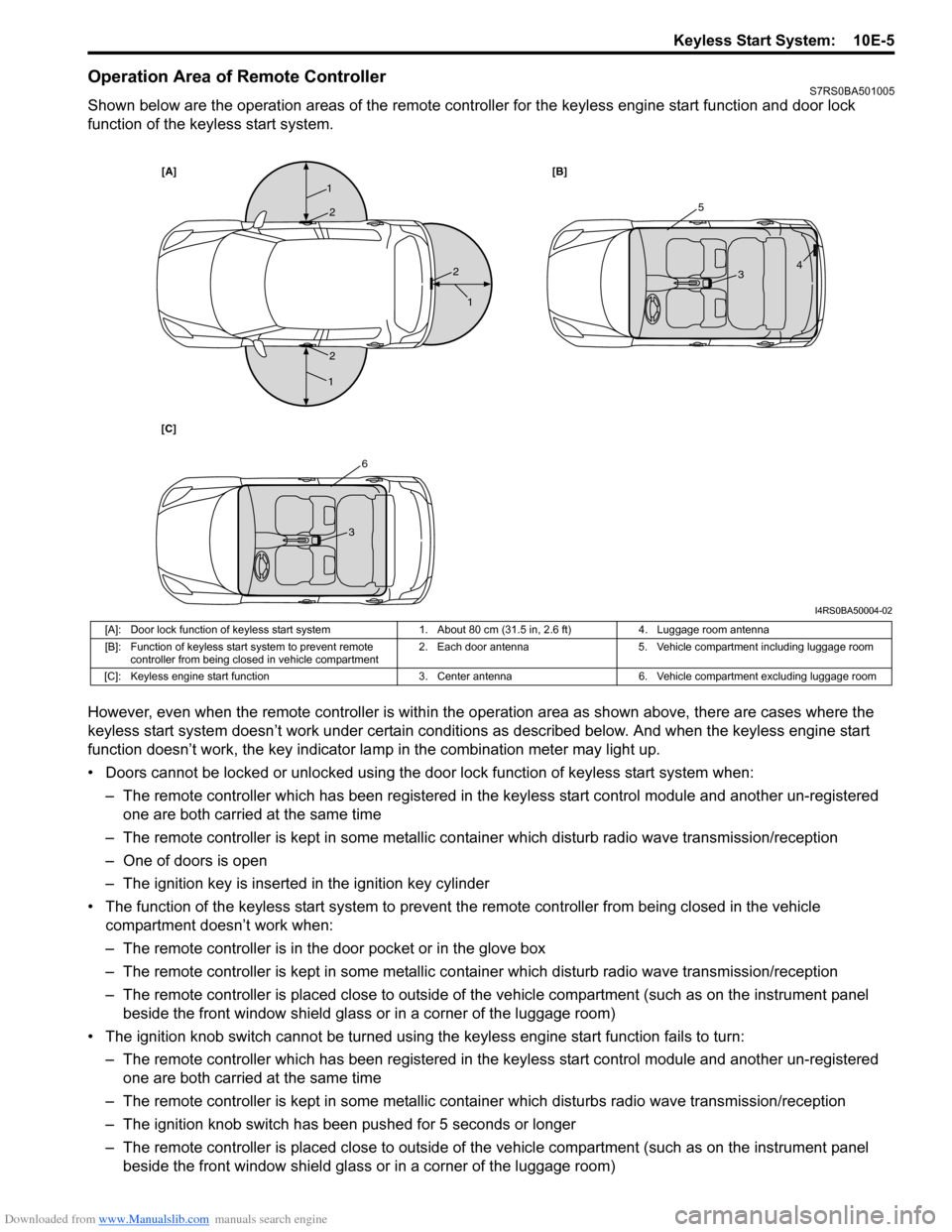

Operation Area of Remote ControllerS7RS0BA501005

Shown below are the operation areas of the remote controller for the keyless engine start function and door lock

function of the keyless start system.

However, even when the remote controller is within the operation area as shown above, there are cases where the

keyless start system doesn’t work under certain conditi ons as described below. And when the keyless engine start

function doesn’t work, the key indicator la mp in the combination meter may light up.

• Doors cannot be locked or unlocked using the doo r lock function of keyless start system when:

– The remote controller which has been registered in the keyless start control module and another un-registered one are both carried at the same time

– The remote controller is kept in some metallic co ntainer which disturb radio wave transmission/reception

– One of doors is open

– The ignition key is inserted in the ignition key cylinder

• The function of the keyless start system to prevent the remote controller from being closed in the vehicle

compartment doesn’t work when:

– The remote controller is in the door pocket or in the glove box

– The remote controller is kept in some metallic co ntainer which disturb radio wave transmission/reception

– The remote controller is placed close to outside of the vehicle compartment (such as on the instrument panel beside the front window shield glass or in a corner of the luggage room)

• The ignition knob switch cannot be turned usin g the keyless engine start function fails to turn:

– The remote controller which has been registered in the keyless start control module and another un-registered one are both carried at the same time

– The remote controller is kept in some metallic cont ainer which disturbs radio wave transmission/reception

– The ignition knob switch has been pushed for 5 seconds or longer

– The remote controller is placed close to outside of the vehicle compartment (such as on the instrument panel beside the front window shield glass or in a corner of the luggage room)

[A] [B]

[C]

1

1

1

25

6

3

3 4

2

2

I4RS0BA50004-02

[A]: Door lock function of keyless start system 1. About 80 cm (31.5 in, 2.6 ft)4. Luggage room antenna

[B]: Function of keyless start system to prevent remote controller from being closed in vehicle compartment 2. Each door antenna

5. Vehicle compartment including luggage room

[C]: Keyless engine start function 3. Center antenna6. Vehicle compartment excluding luggage room