torque SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 569 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-30

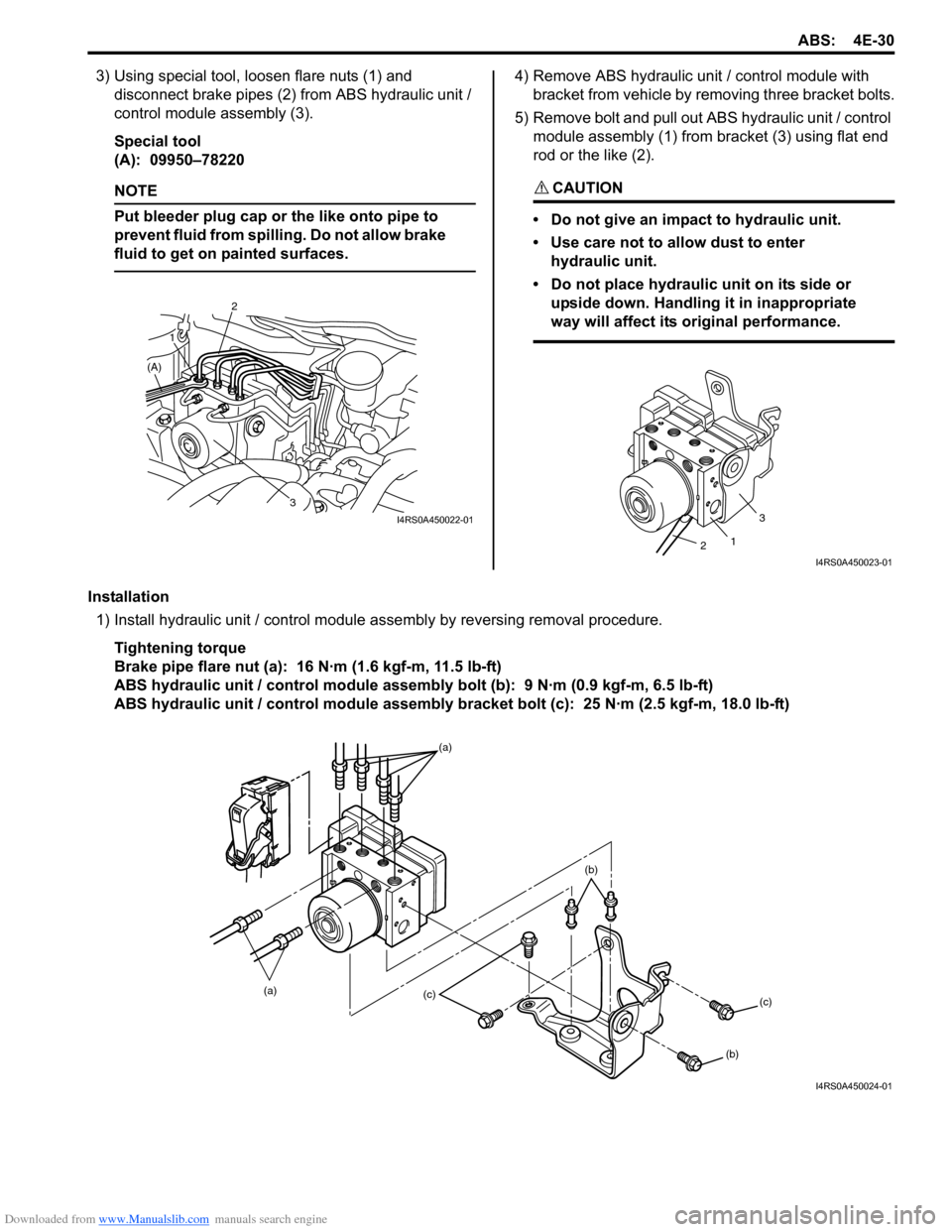

3) Using special tool, loosen flare nuts (1) and disconnect brake pipes (2) from ABS hydraulic unit /

control module assembly (3).

Special tool

(A): 09950–78220

NOTE

Put bleeder plug cap or the like onto pipe to

prevent fluid from spilli ng. Do not allow brake

fluid to get on painted surfaces.

4) Remove ABS hydraulic unit / control module with

bracket from vehicle by removing three bracket bolts.

5) Remove bolt and pull out ABS hydraulic unit / control module assembly (1) from bracket (3) using flat end

rod or the like (2).

CAUTION!

• Do not give an impact to hydraulic unit.

• Use care not to allow dust to enter hydraulic unit.

• Do not place hydraulic unit on its side or upside down. Handling it in inappropriate

way will affect its original performance.

Installation

1) Install hydraulic unit / control module assembly by reversing removal procedure.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5 lb-ft)

ABS hydraulic unit / control module assembly bolt (b): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ABS hydraulic unit / control module assembly bracket bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

3

2

1

(A)

I4RS0A450022-01

1

3

2

I4RS0A450023-01

(a) (a)(c)

(c)

(b)

(b)

I4RS0A450024-01

Page 571 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-32

Front Wheel Speed Sensor Removal and

Installation

S7RS0B4506006

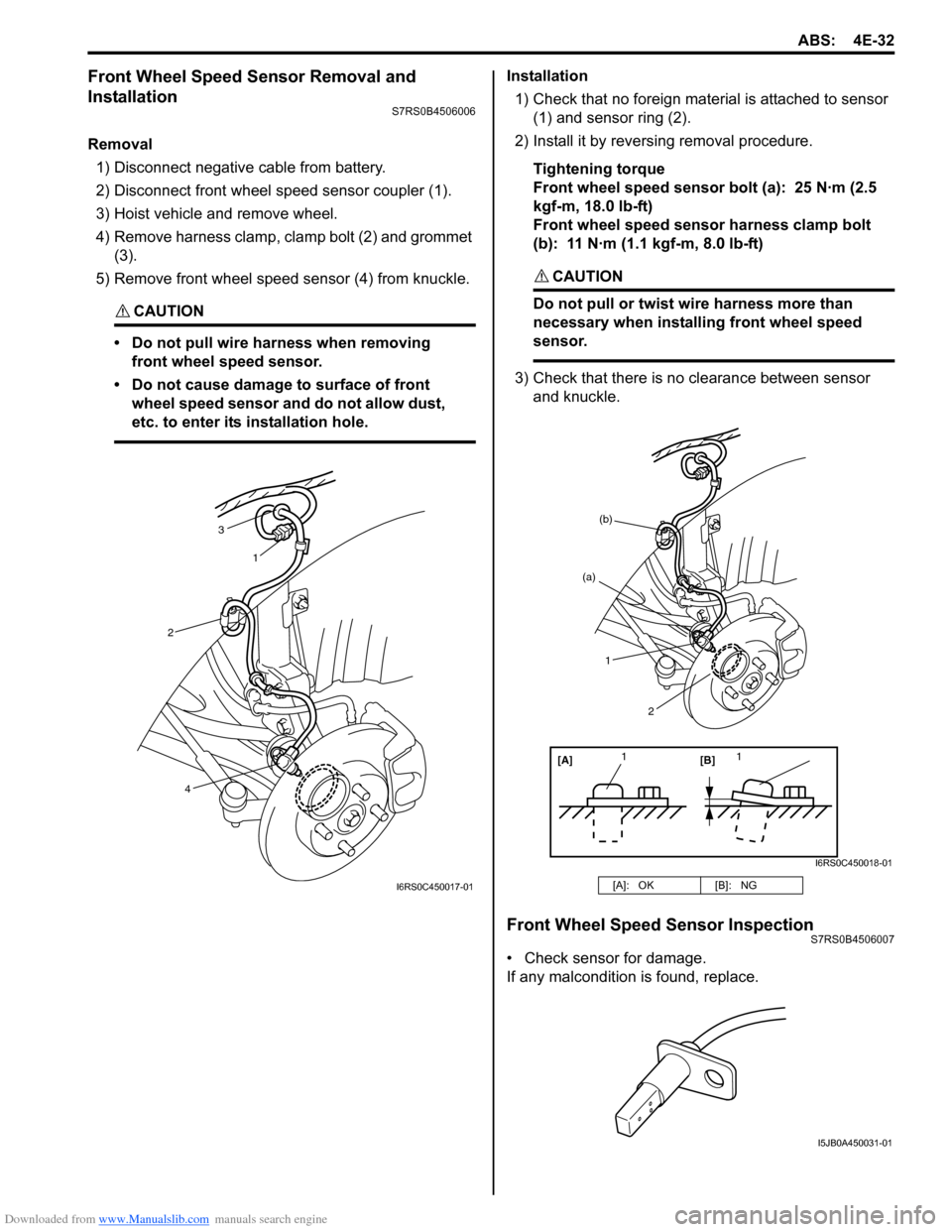

Removal1) Disconnect negative cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolt (2) and grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

CAUTION!

• Do not pull wire ha rness when removing

front wheel speed sensor.

• Do not cause damage to surface of front wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Installation

1) Check that no foreign material is attached to sensor (1) and sensor ring (2).

2) Install it by reversing removal procedure.

Tightening torque

Front wheel speed sensor bolt (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION!

Do not pull or twist wire harness more than

necessary when installing front wheel speed

sensor.

3) Check that there is no clearance between sensor

and knuckle.

Front Wheel Speed Sensor InspectionS7RS0B4506007

• Check sensor for damage.

If any malcondition is found, replace.

3

1

2

4

I6RS0C450017-01[A]: OK [B]: NG

[A][B]

11

(a)

(b)

1

2

I6RS0C450018-01

I5JB0A450031-01

Page 572 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-33 ABS:

Rear Wheel Speed Sensor Removal and

Installation

S7RS0B4506008

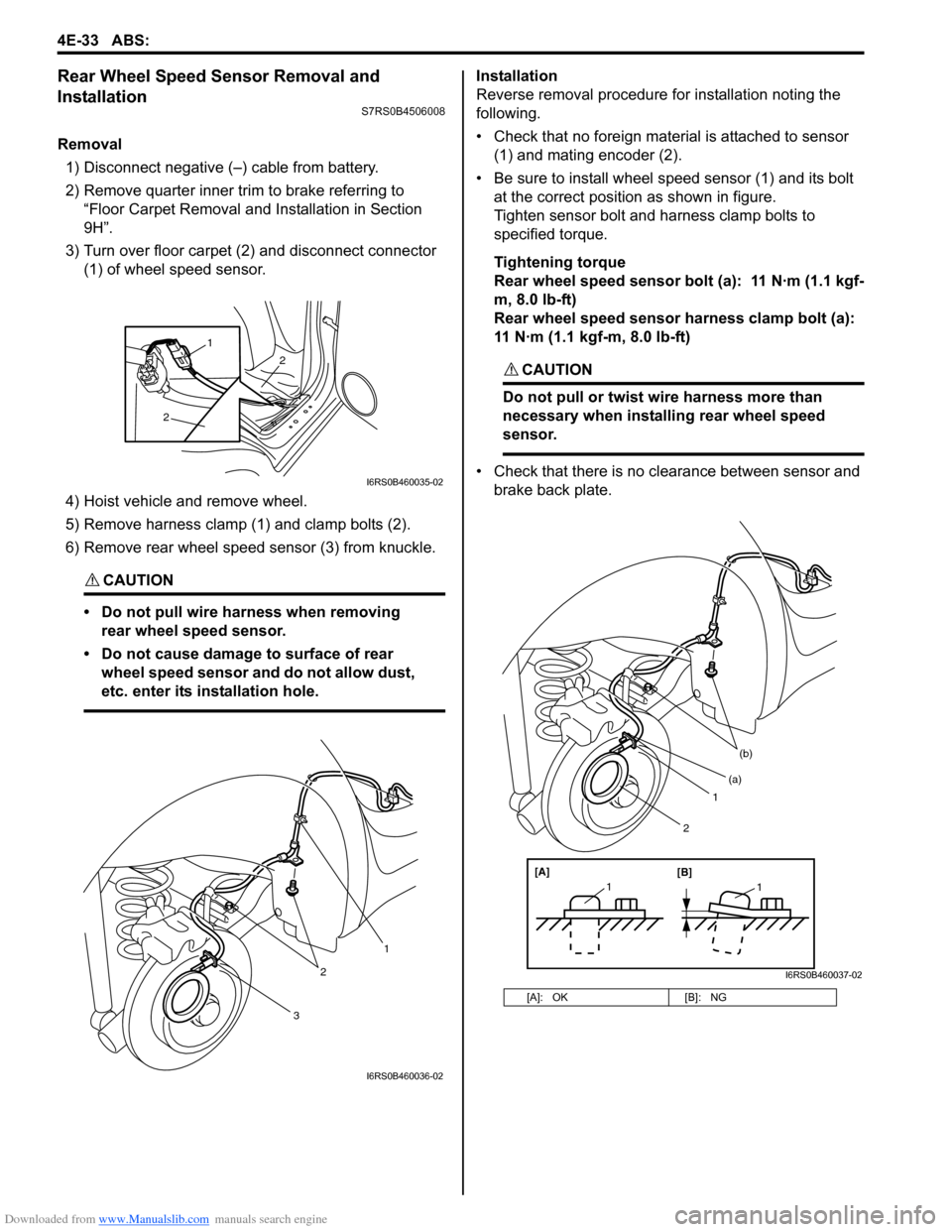

Removal1) Disconnect negative (–) cable from battery.

2) Remove quarter inner trim to brake referring to “Floor Carpet Removal a nd Installation in Section

9H”.

3) Turn over floor carpet (2) and disconnect connector (1) of wheel speed sensor.

4) Hoist vehicle and remove wheel.

5) Remove harness clamp (1) and clamp bolts (2).

6) Remove rear wheel speed sensor (3) from knuckle.

CAUTION!

• Do not pull wire harness when removing rear wheel speed sensor.

• Do not cause damage to surface of rear wheel speed sensor and do not allow dust,

etc. enter its installation hole.

Installation

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor (1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt at the correct position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt (a):

11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION!

Do not pull or twist wire harness more than

necessary when installing rear wheel speed

sensor.

• Check that there is no clearance between sensor and brake back plate.

2

2

1

I6RS0B460035-02

3

2

1

I6RS0B460036-02

[A]: OK [B]: NG

1

(b)

[A][B]

11

(a)

2

I6RS0B460037-02

Page 574 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-35 ABS:

Specifications

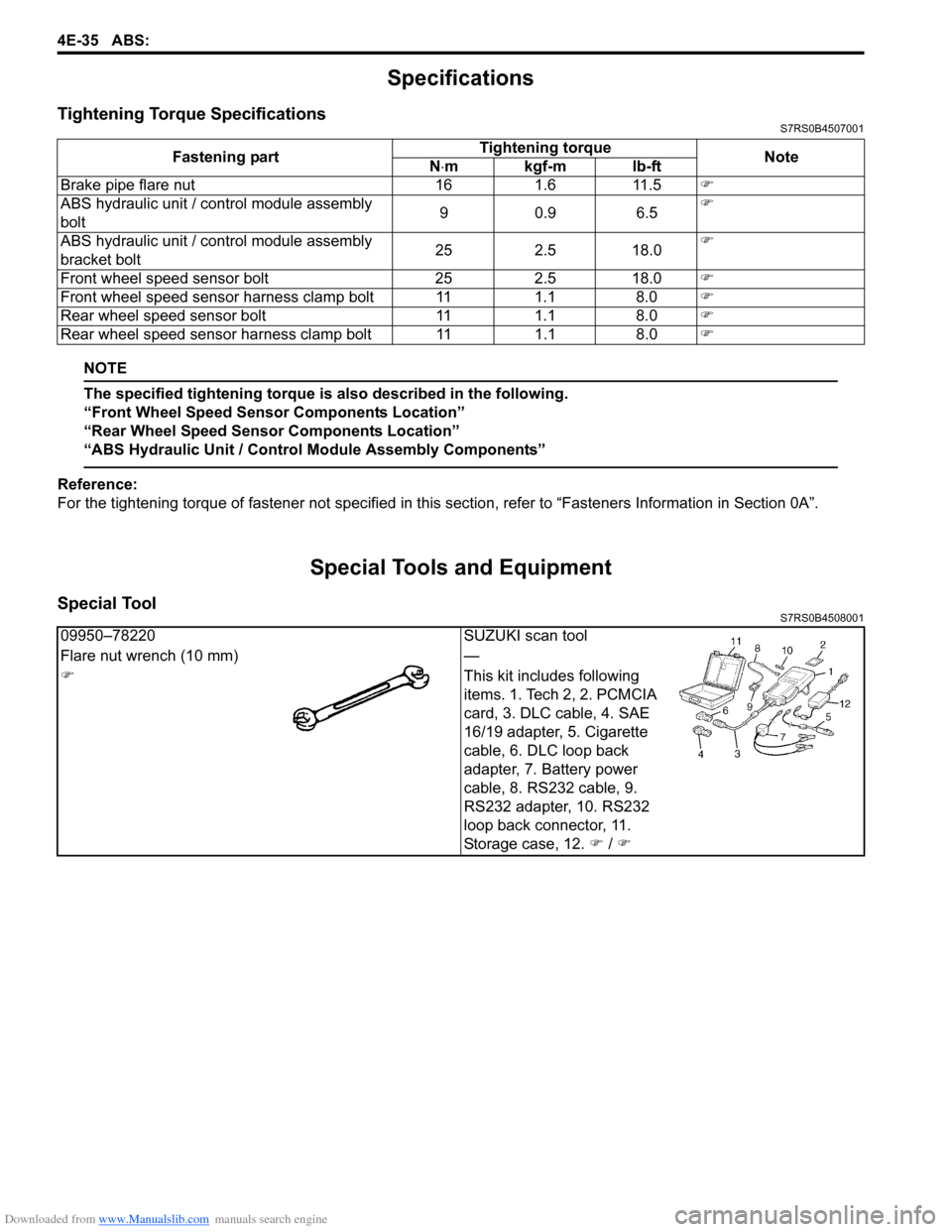

Tightening Torque SpecificationsS7RS0B4507001

NOTE

The specified tightening torque is also described in the following.

“Front Wheel Speed Sensor Components Location”

“Rear Wheel Speed Sensor Components Location”

“ABS Hydraulic Unit / Control Module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B4508001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake pipe flare nut 16 1.6 11.5 �)

ABS hydraulic unit / c ontrol module assembly

bolt 90.9 6.5�)

ABS hydraulic unit / c ontrol module assembly

bracket bolt 25 2.5 18.0�)

Front wheel speed sensor bolt 25 2.5 18.0 �)

Front wheel speed sensor harness clamp bolt 11 1.1 8.0 �)

Rear wheel speed sensor bolt 11 1.1 8.0 �)

Rear wheel speed sensor har ness clamp bolt 11 1.1 8.0 �)

09950–78220SUZUKI scan tool

Flare nut wrench (10 mm) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �) / �)

Page 576 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-2 Electronic Stability Program:

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other TestsS7RS0B4600005

When performing speedometer or other tests using speedometer tester or chassis dynamometer, ESP® function must

be deactivated by ESP ® OFF switch or using SUZUKI scan to ol to complete the tests correctly.

When using SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP ® function. Refer to SUZUKI scan tool

operator's manual for further details.

General Description

Electronic Stability Program DescriptionS7RS0B4601006

Electronic Stability Program (ESP ®) is an auxiliary function to enable the vehicle to av oid a danger safely while the

vehicle is running, stopping or turning.

Electronic Stability Program (ESP ®) consists of following functions.

ESP ® is a registered trademark of Daimler Chrysler AG.

Antilock Brake System (ABS)

This system prevents tire locking which may occur when br ake is applied suddenly or on slippery roads. With this

function, as the vehicle body is kept in the stable state an d tires unlocked, the driver can avoid any obstacle by turning

the steering wheel.

Electronic Brake force Distribution (EBD)

This function distributes braking force of front and rear wheels properly according to the vehicle load condition.

With this function, the braking force of the front and rear wheels is controlled for the optimum effect to secure the

maximum braking force regardless of the loadage.

Traction Control System (TCS)

This system controls the engine and brake to prevent the dr iving wheels from spinning at the time of starting and

accelerating. Particularly, this fu nction is helpful for safe driving on muddy or icy roads. When ESP ® control module

detects wheel spinning using information from the yaw rate sensor and wheel speed sensor, it lower the engine torque

by closing the electronic controlled thro ttle and controlling ignition. At the same time, brake is applied to the spinning

tire.

Stability Control

This function controls the vehicle body in the stable state by controlling the engine and braking so as to prevent the

vehicle from over-steering or under-steering while turning.

When under-steering occurs, this function lowers the engine torque and applies brake to the inner rear wheel in the

vehicle forward direction so as to pr event the vehicle from moving outward.

When over-steering occurs, this function applies brake to the outer front wheel in the vehicle forward direction so as to

prevent the vehicle from moving inward. Sensor Procedures required calibration

Steering angle sensor • Power is not su pplied to steering angle sensor. (battery, fuse and/or connector is

removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP ® control module. (battery, fuse and/or connector is

removed.)

• ESP® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly • Yaw rate / G sensor assembly is removed or replaced.

• ESP® hydraulic unit / control module assembly is replaced.

Page 580 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-6 Electronic Stability Program:

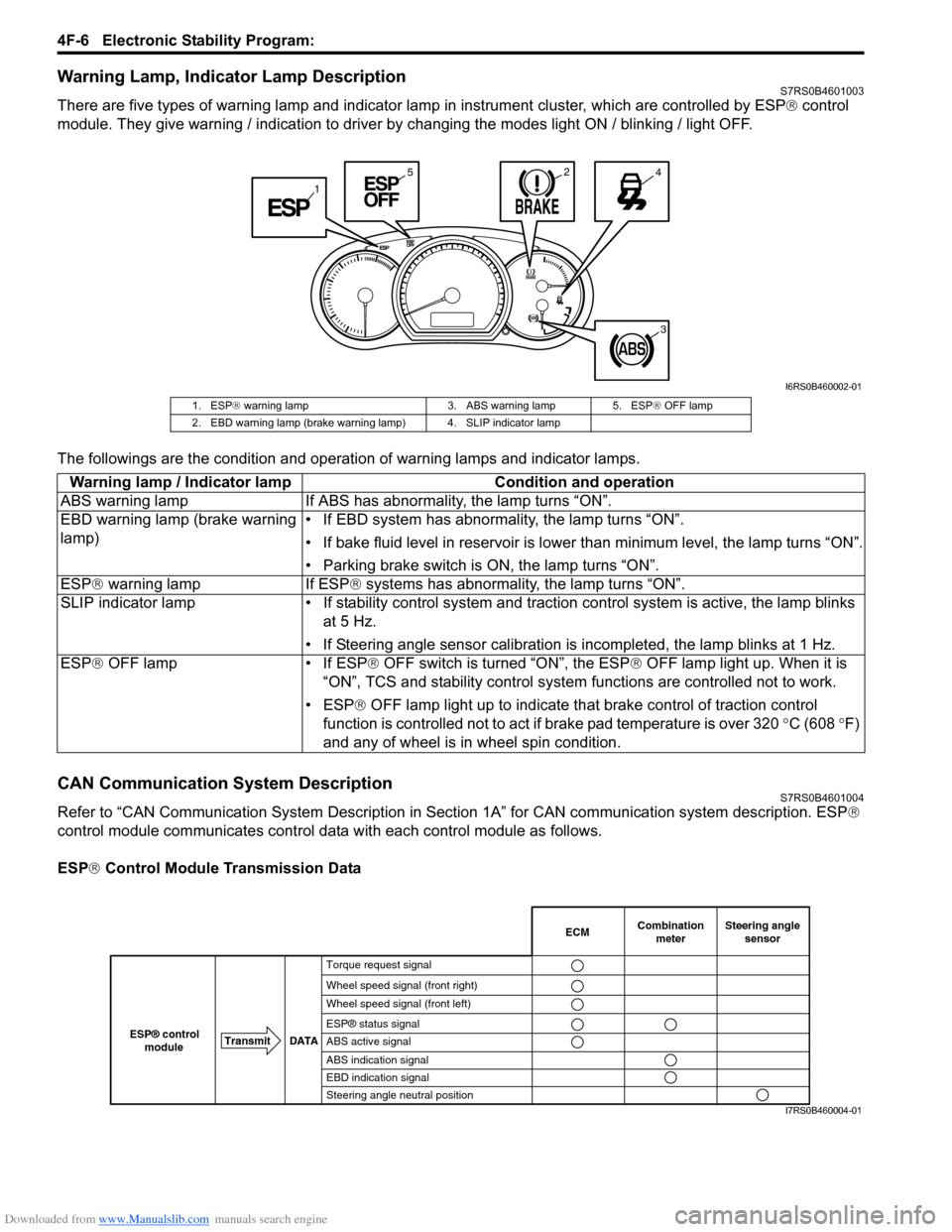

Warning Lamp, Indicator Lamp DescriptionS7RS0B4601003

There are five types of warning lamp and indicator lamp in instrument cluster, which are controlled by ESP ® control

module. They give warning / indication to driver by changing the modes light ON / blinking / light OFF.

The followings are the condition and operation of warning lamps and indicator lamps.

CAN Communication System DescriptionS7RS0B4601004

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description. ESP ®

control module communicates control data with each control module as follows.

ESP ® Control Module Transmission Data

1

245

3

I6RS0B460002-01

1. ESP ® warning lamp 3. ABS warning lamp 5. ESP ® OFF lamp

2. EBD warning lamp (brake warning lamp) 4. SLIP indicator lamp

Warning lamp / Indicator lamp Condition and operation

ABS warning lamp If ABS has abnor mality, the lamp turns “ON”.

EBD warning lamp (brake warning

lamp) • If EBD system has abnormality, the lamp turns “ON”.

• If bake fluid level in reservoir is lower

than minimum level, the lamp turns “ON”.

• Parking brake switch is ON, the lamp turns “ON”.

ESP ® warning lamp If ESP ® systems has abnormality, the lamp turns “ON”.

SLIP indicator lamp • If stability cont rol system and traction control system is active, the lamp blinks

at 5 Hz.

• If Steering angle sensor calibration is incompleted, the lamp blinks at 1 Hz.

ESP ® OFF lamp • If ESP ® OFF switch is turned “ON”, the ESP ® OFF lamp light up. When it is

“ON”, TCS and stability control system functions are controlled not to work.

• ESP® OFF lamp light up to indicate th at brake control of traction control

function is controlled not to act if brake pad temperature is over 320 °C (608 °F)

and any of wheel is in wheel spin condition.

Combination

meter

Transmit DATA

ESP® control

moduleECMSteering angle sensor

Torque request signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ESP® status signal

ABS active signal

ABS indication signal

EBD indication signal

Steering angle neutral position

I7RS0B460004-01

Page 581 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-7

ESP® Control Module Reception Data

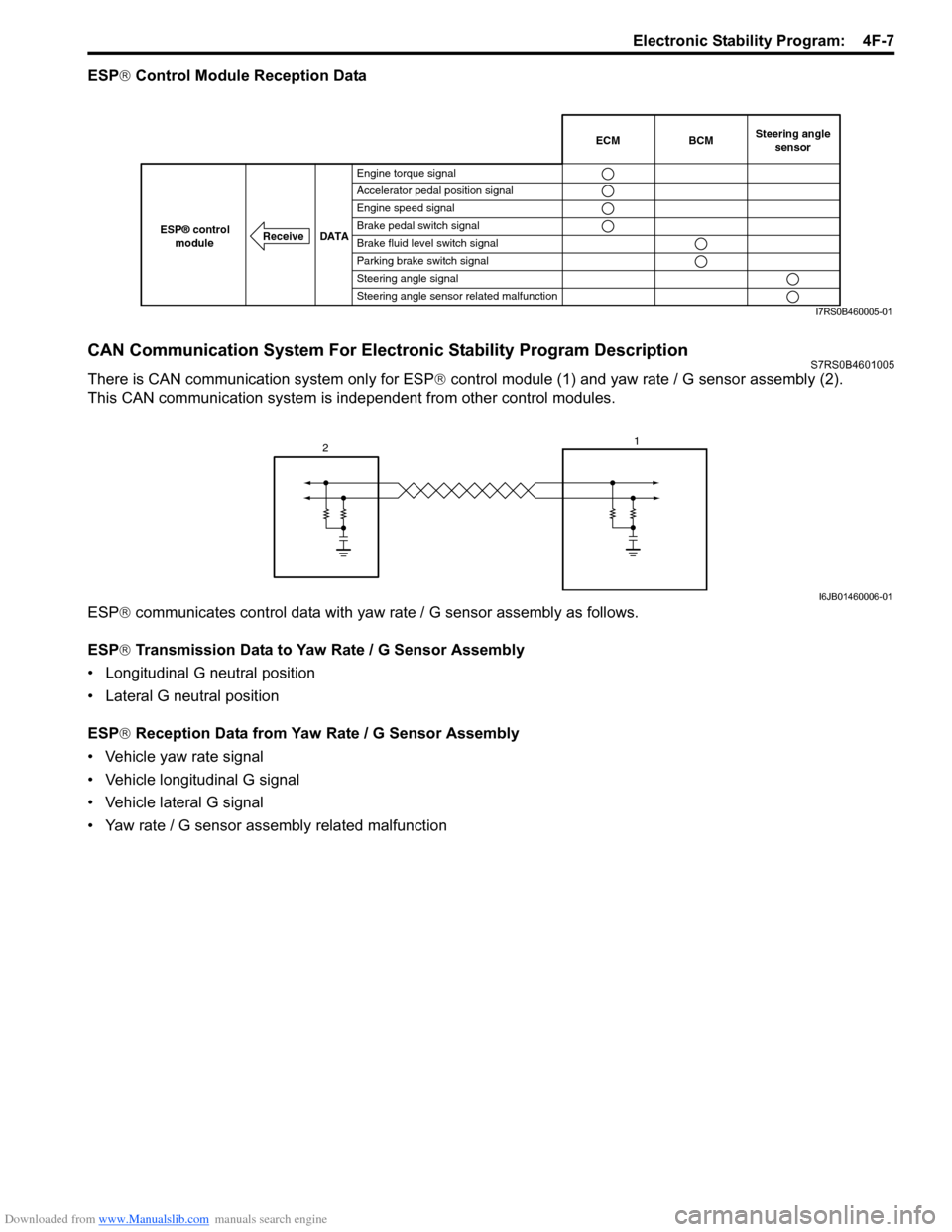

CAN Communication System For Electronic Stability Program DescriptionS7RS0B4601005

There is CAN communication system only for ESP ® control module (1) and yaw rate / G sensor assembly (2).

This CAN communication system is independent from other control modules.

ESP ® communicates control data with yaw rate / G sensor assembly as follows.

ESP ® Transmission Data to Yaw Rate / G Sensor Assembly

• Longitudinal G neutral position

• Lateral G neutral position

ESP ® Reception Data from Yaw Rate / G Sensor Assembly

• Vehicle yaw rate signal

• Vehicle longitudinal G signal

• Vehicle lateral G signal

• Yaw rate / G sensor assembly related malfunction

BCM

Receive DATA

ESP® control

moduleECMSteering angle sensor

Engine torque signal

Accelerator pedal position signal

Engine speed signal

Brake pedal switch signal

Brake fluid level switch signal

Parking brake switch signal

Steering angle signal

Steering angle sensor related malfunction

I7RS0B460005-01

2 1

I6JB01460006-01

Page 582 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-8 Electronic Stability Program:

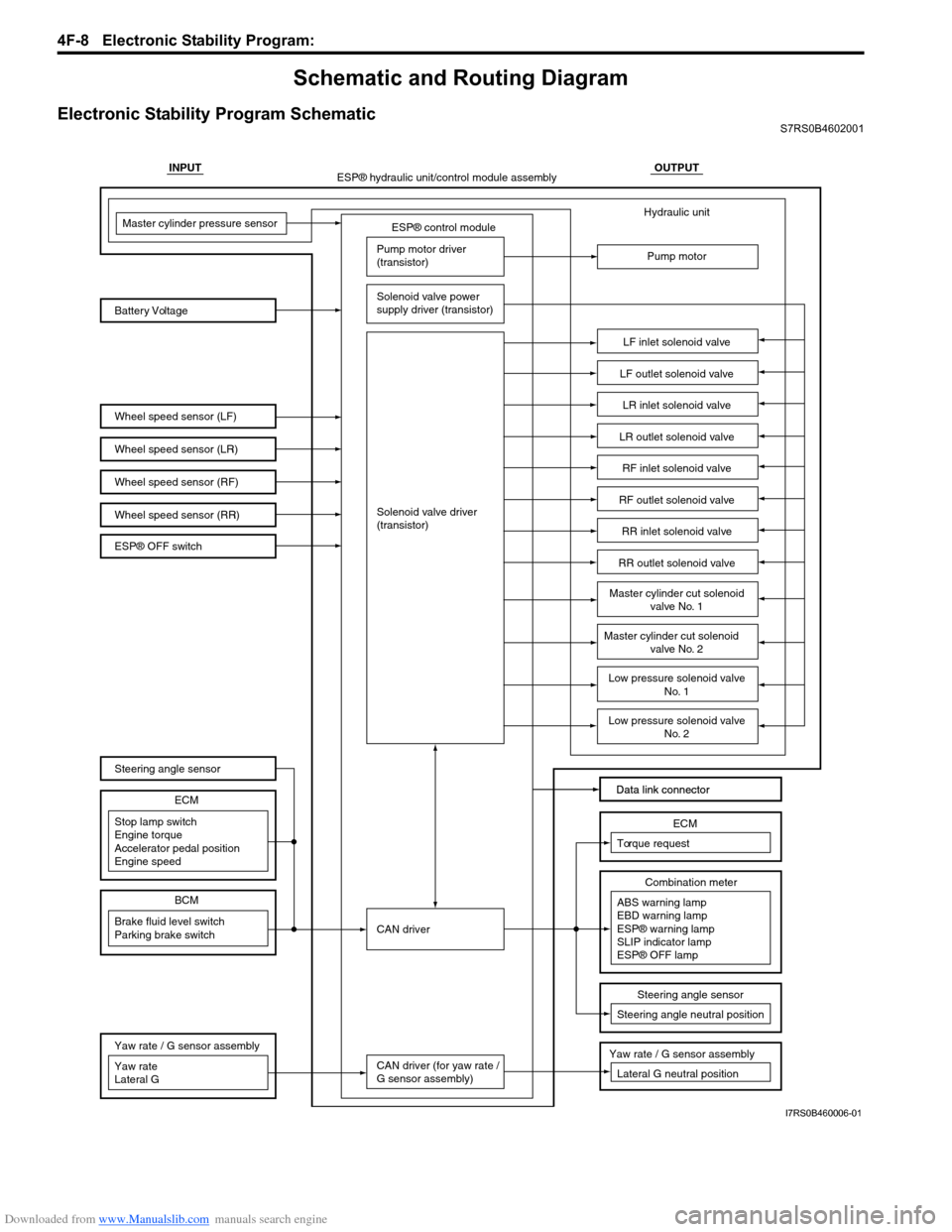

Schematic and Routing Diagram

Electronic Stability Program SchematicS7RS0B4602001

INPUTOUTPUT

ESP® control module

Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF) Battery VoltageMaster cylinder pressure sensor

Pump motor driver

(transistor)

Solenoid valve power

supply driver (transistor)

Solenoid valve driver

(transistor)

CAN driver

CAN driver (for yaw rate /

G sensor assembly) Hydraulic unit

Pump motor

LF inlet solenoid valve

LF outlet solenoid valve

LR inlet solenoid valve

LR outlet solenoid valve

RF inlet solenoid valve

RF outlet solenoid valve

RR inlet solenoid valve

RR outlet solenoid valve

Data link connector

Data link connector

ESP® hydraulic unit/control module assembly

Wheel speed sensor (RR)

Master cylinder cut solenoid valve No. 1

Master cylinder cut solenoid

valve No. 2

Low pressure solenoid valve No. 1

Low pressure solenoid valveNo. 2

Stop lamp switch

Engine torque

Accelerator pedal position

Engine speed ECM

Brake fluid level switch

Parking brake switch

BCM

Steering angle sensor

ESP® OFF switch

Yaw rate

Lateral G Yaw rate / G sensor assembly

ABS warning lamp

EBD warning lamp

ESP® warning lamp

SLIP indicator lamp

ESP® OFF lampCombination meter

Torque request

ECM

Steering angle neutral positionSteering angle sensor

Yaw rate / G sensor assembly

Lateral G neutral position

I7RS0B460006-01

Page 591 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-17

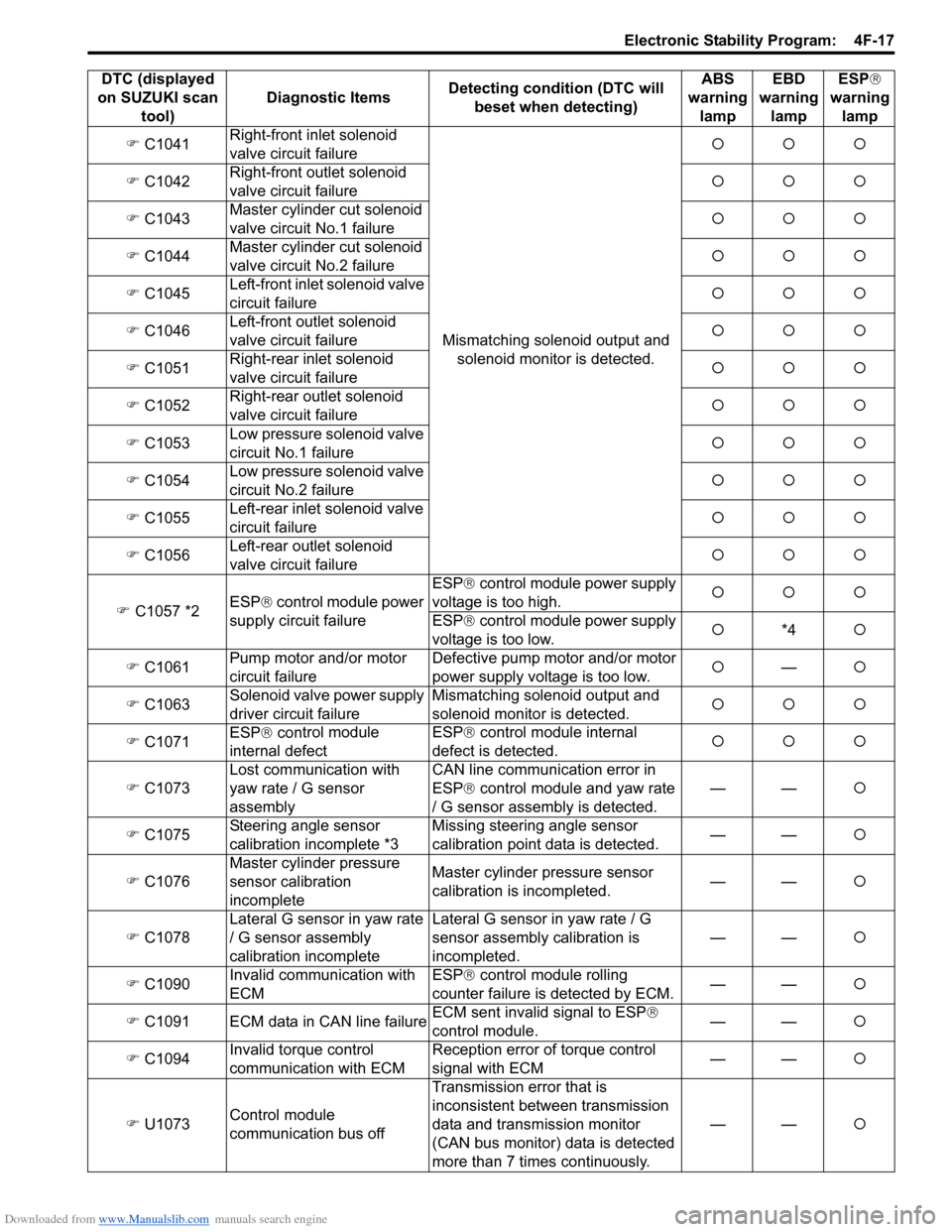

�) C1041 Right-front inlet solenoid

valve circuit failure

Mismatching solenoid output and solenoid monitor is detected. �{�{�{

�) C1042 Right-front outlet solenoid

valve circuit failure �{�{�{

�) C1043 Master cylinder cut solenoid

valve circuit No.1 failure �{�{�{

�) C1044 Master cylinder cut solenoid

valve circuit No.2 failure �{�{�{

�) C1045 Left-front inlet solenoid valve

circuit failure �{�{�{

�) C1046 Left-front outlet solenoid

valve circuit failure �{�{�{

�) C1051 Right-rear inlet solenoid

valve circuit failure �{�{�{

�) C1052 Right-rear outlet solenoid

valve circuit failure �{�{�{

�) C1053 Low pressure solenoid valve

circuit No.1 failure �{�{�{

�) C1054 Low pressure solenoid valve

circuit No.2 failure �{�{�{

�) C1055 Left-rear inlet solenoid valve

circuit failure �{�{�{

�) C1056 Left-rear outlet solenoid

valve circuit failure �{�{�{

�) C1057 *2 ESP

® control module power

supply circuit failure ESP®

control module power supply

voltage is too high. �{�{�{

ESP® control module power supply

voltage is too low. �{

*4 �{

�) C1061 Pump motor and/or motor

circuit failure Defective pump motor and/or motor

power supply voltage is too low.

�{

— �{

�) C1063 Solenoid valve

power supply

driver circuit failure Mismatching solenoid output and

solenoid monitor is detected.

�{�{�{

�) C1071 ESP

® con

trol module

internal defect ESP®

control module internal

defect is detected. �{�{�{

�) C1073 Lost communication with

yaw rate / G sensor

assembly CAN line communication error in

ESP®

control module and yaw rate

/ G sensor assembly is detected. ——

�{

�) C1075 Steering angle sensor

calibration incomplete *3 Missing steering angle sensor

calibration point data is detected.

——

�{

�) C1076 Master cylinder pressure

sensor calibration

incomplete Master cylinder pressure sensor

calibration is incompleted.

——

�{

�) C1078 Lateral G sensor in yaw rate

/ G sensor assembly

calibration incomplete Lateral G sensor in yaw rate / G

sensor assembly calibration is

incompleted.

——

�{

�) C1090 Invalid communication with

ECM ESP®

control module rolling

counter failure is detected by ECM. ——

�{

�) C1091 ECM data in CAN line failure ECM sent invalid signal to ESP

®

control module. ——

�{

�) C1094 Invalid torque control

communication with ECM Reception error of torque control

signal with ECM

——

�{

�) U1073 Control module

communication bus off Transmission error that is

inconsistent between transmission

data and transmission monitor

(CAN bus monitor) data is detected

more than 7 times continuously.

——

�{

DTC (displayed

on SUZUKI scan tool) Diagnostic Items

Detecting condition (DTC will

beset when detecting) ABS

warning lamp EBD

warning lamp ESP

®

warning lamp