ECM connector ins SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 624 of 1496

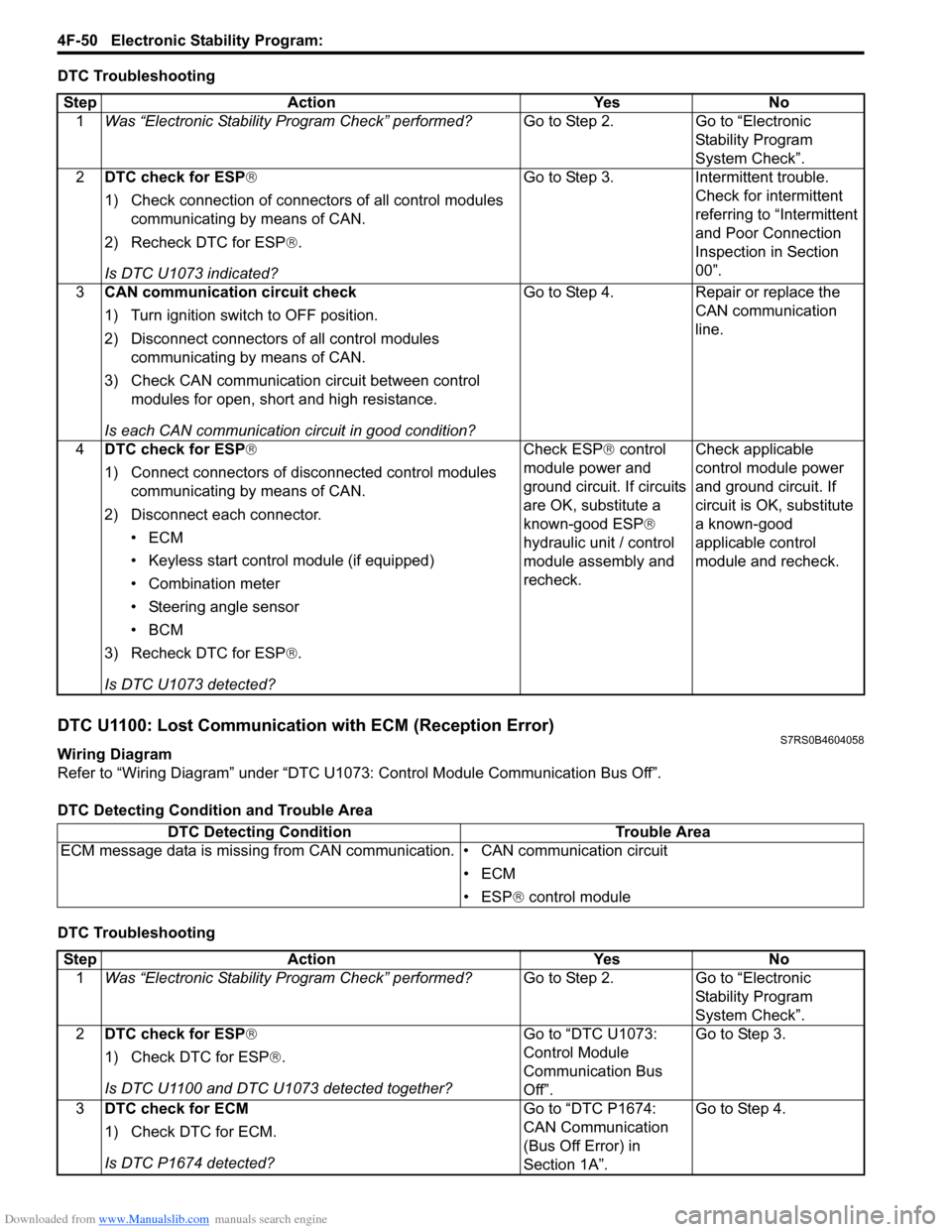

Downloaded from www.Manualslib.com manuals search engine 4F-50 Electronic Stability Program:

DTC Troubleshooting

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4604058

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC for ESP ®.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair or replace the

CAN communication

line.

4 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1073 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

DTC Detecting Condition

Trouble Area

ECM message data is missing from CAN communication. • CAN communication circuit

•ECM

• ESP® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1100 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for ECM

1) Check DTC for ECM.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

Page 625 of 1496

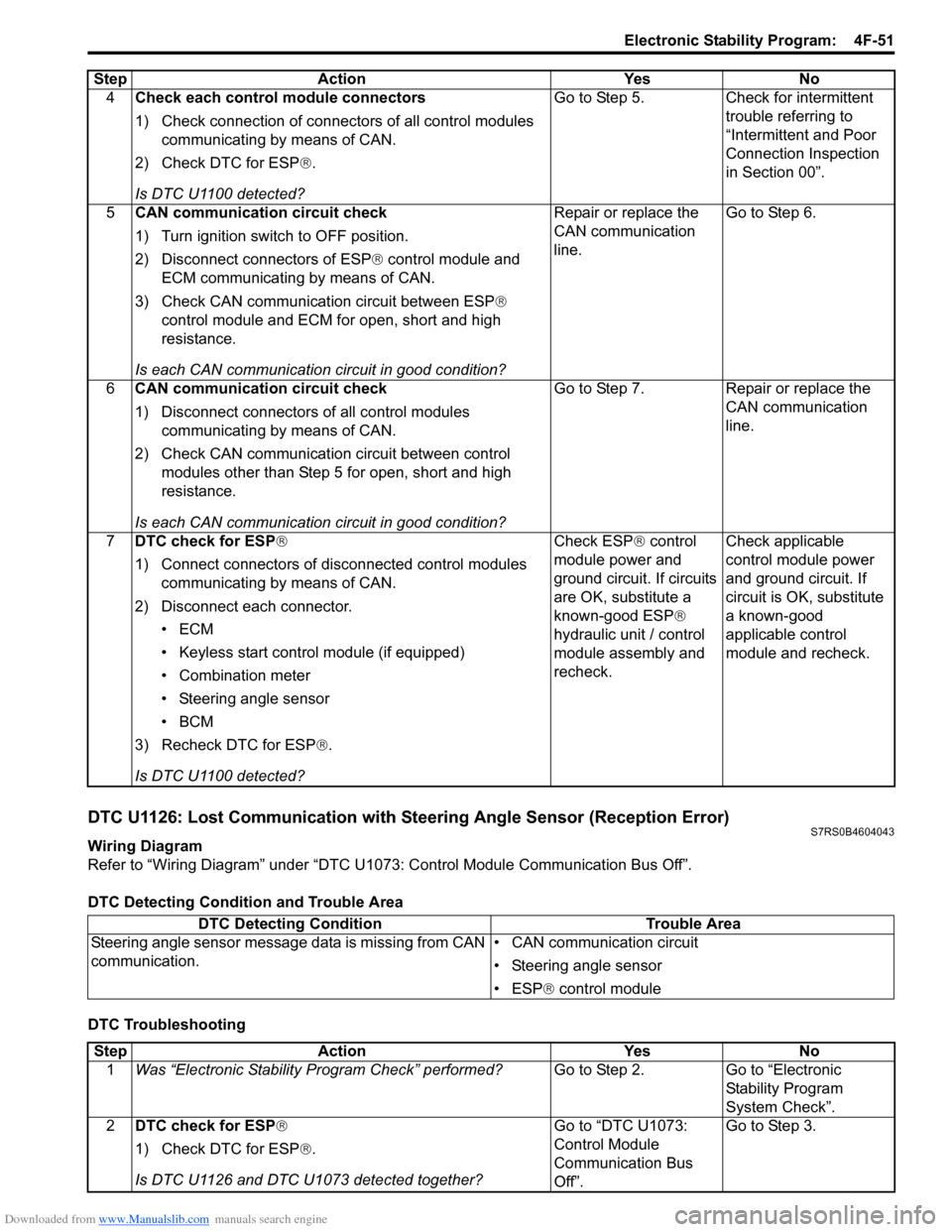

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-51

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)S7RS0B4604043

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting4

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1100 detected? Go to Step 5. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

ECM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and ECM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1100 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

Steering angle sensor message data is missing from CAN

communication. • CAN communication circuit

• Steering angle sensor

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1126 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

Page 626 of 1496

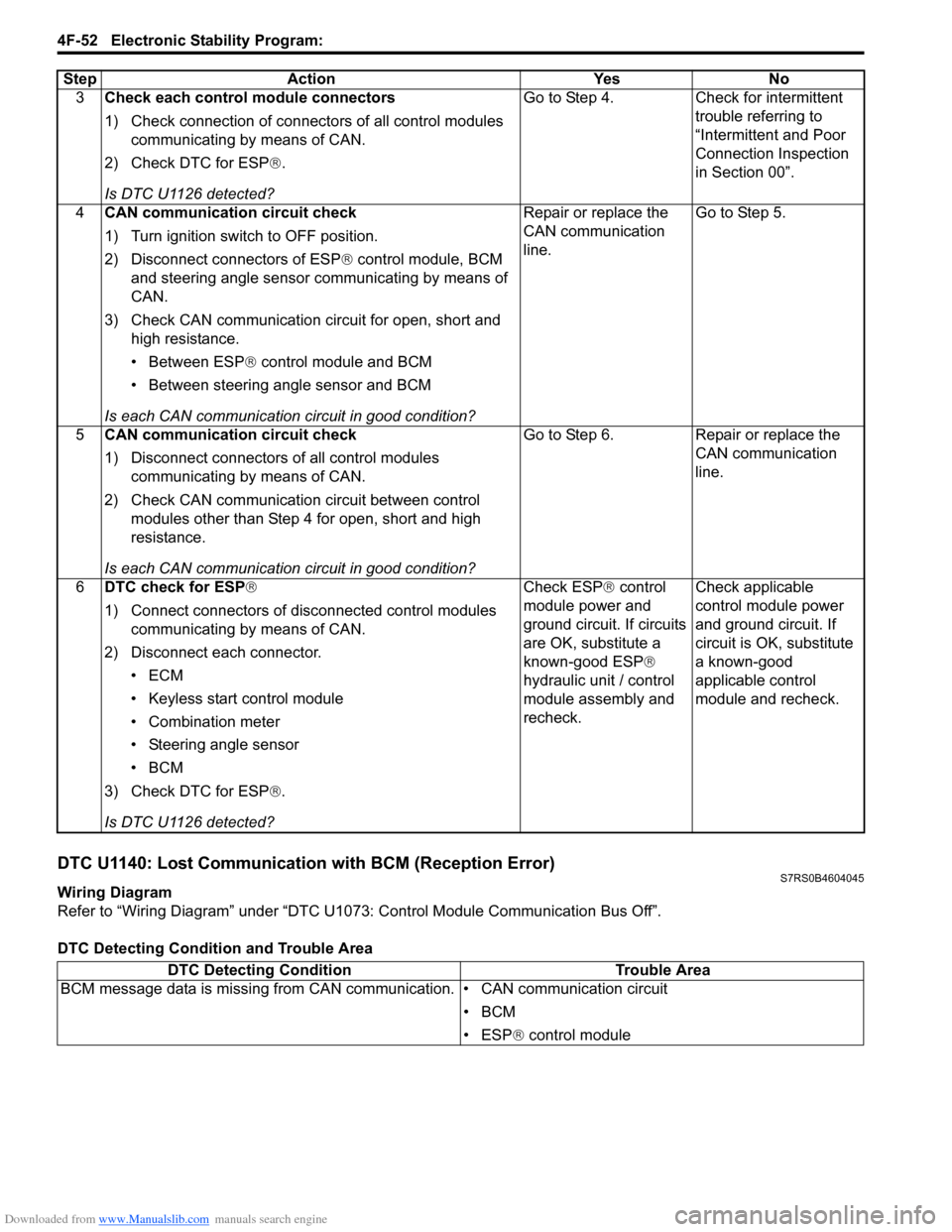

Downloaded from www.Manualslib.com manuals search engine 4F-52 Electronic Stability Program:

DTC U1140: Lost Communication with BCM (Reception Error)S7RS0B4604045

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area3

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1126 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module, BCM

and steering angle sensor communicating by means of

CAN.

3) Check CAN communication circuit for open, short and high resistance.

• Between ESP ® control module and BCM

• Between steering angle sensor and BCM

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 5.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1126 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

BCM message data is missing from CAN communication. • CAN communication circuit

•BCM

• ESP® control module

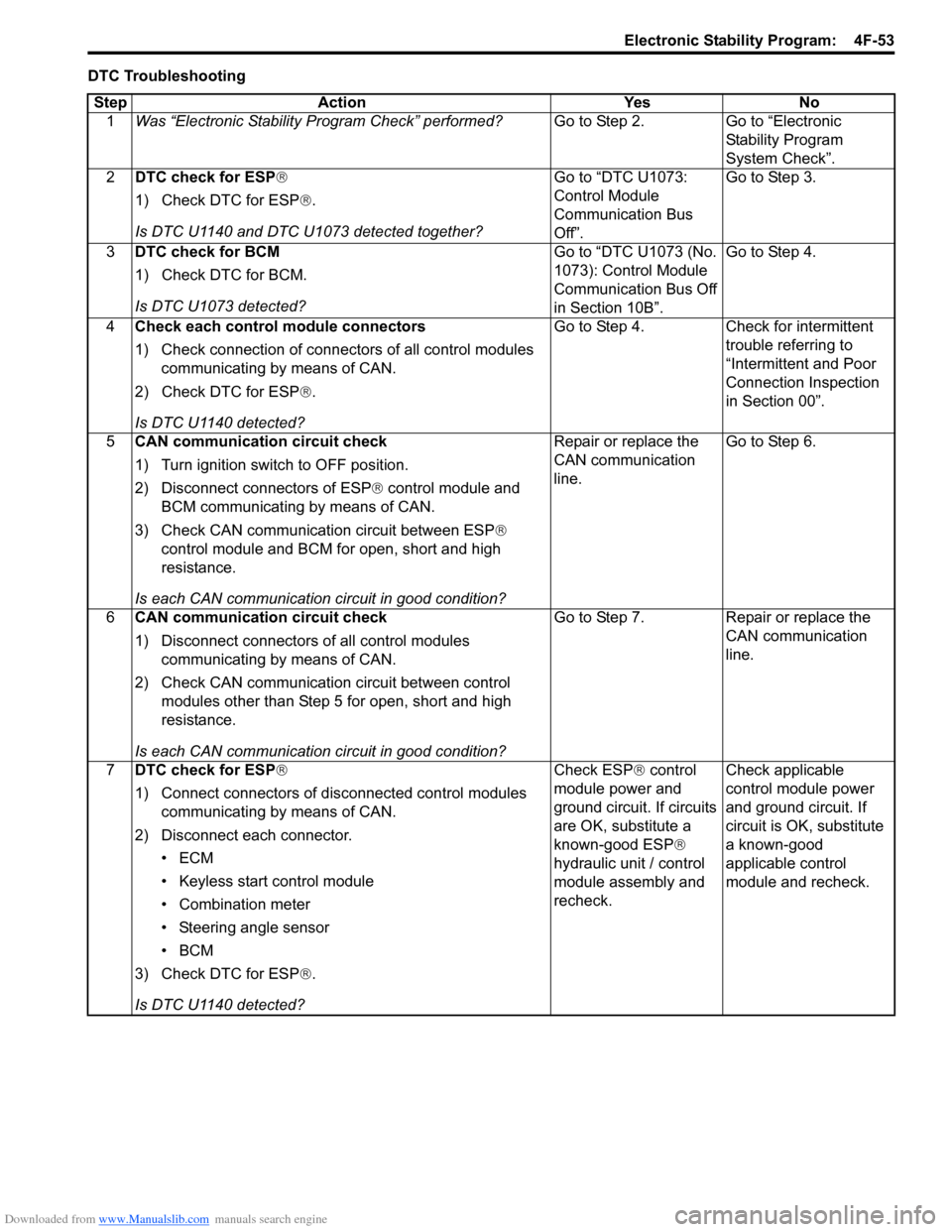

Page 627 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-53

DTC TroubleshootingStep Action Yes No 1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1140 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for BCM

1) Check DTC for BCM.

Is DTC U1073 detected? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 4.

4 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1140 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

BCM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and BCM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1140 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Page 664 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-20 Automatic Transmission/Transaxle:

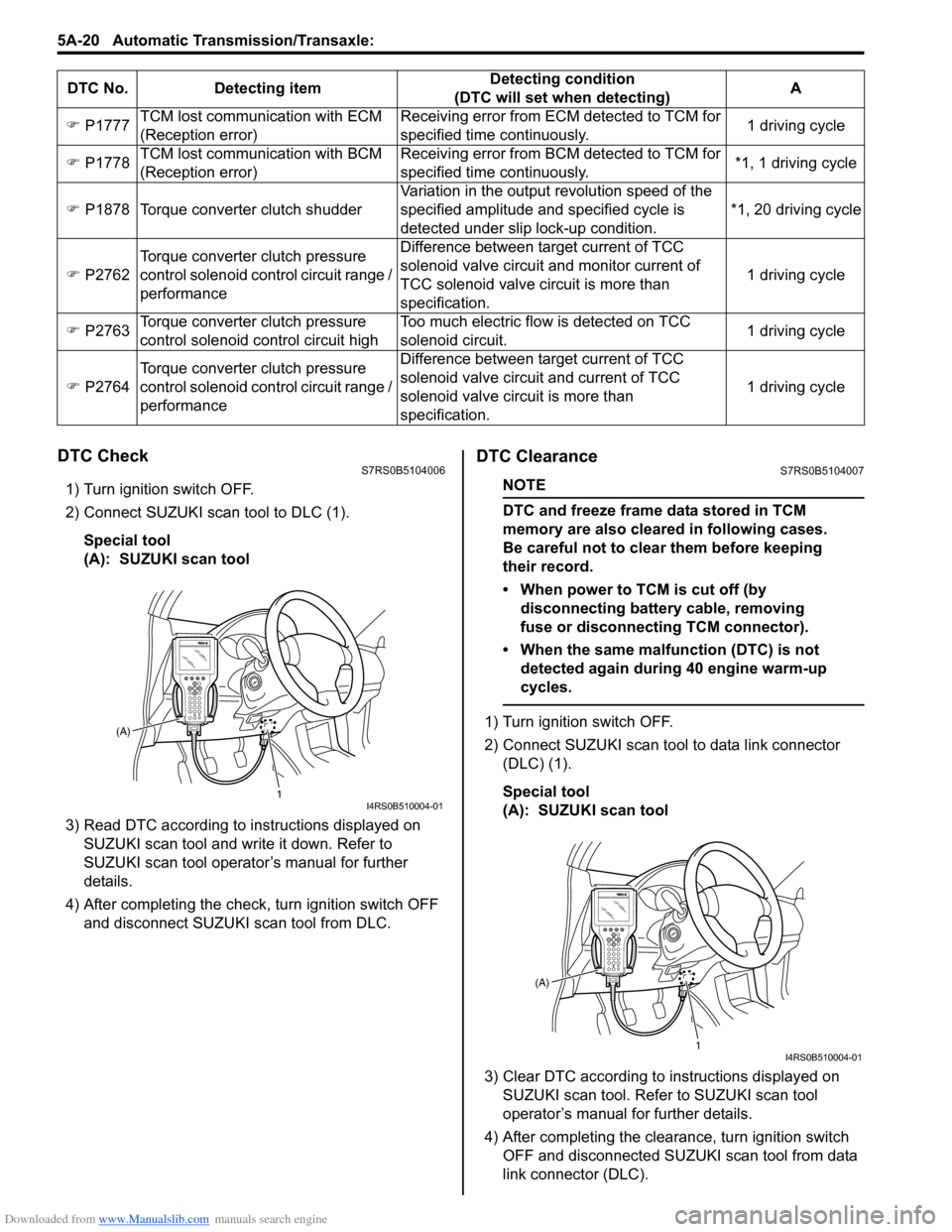

DTC CheckS7RS0B5104006

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to DLC (1).

Special tool

(A): SUZUKI scan tool

3) Read DTC according to instructions displayed on SUZUKI scan tool and wr ite it down. Refer to

SUZUKI scan tool operator’s manual for further

details.

4) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from DLC.

DTC ClearanceS7RS0B5104007

NOTE

DTC and freeze frame data stored in TCM

memory are also cleared in following cases.

Be careful not to clear them before keeping

their record.

• When power to TCM is cut off (by disconnecting battery cable, removing

fuse or disconnecting TCM connector).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles.

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to data link connector (DLC) (1).

Special tool

(A): SUZUKI scan tool

3) Clear DTC according to instructions displayed on SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

4) After completing the clearance, turn ignition switch OFF and disconnected SUZUKI scan tool from data

link connector (DLC).

�)

P1777 TCM lost communication with ECM

(Reception error) Receiving error from ECM detected to TCM for

specified time continuously.

1 driving cycle

�) P1778 TCM lost communication with BCM

(Reception error) Receiving error from BCM detected to TCM for

specified time continuously.

*1, 1 driving cycle

�) P1878 Torque converter clutch shudder Variation in the output revolution speed of the

specified amplitude and specified cycle is

detected under slip lock-up condition. *1, 20 driving cycle

�) P2762 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and monitor current of

TCC solenoid valve ci

rcuit is more than

specification. 1 driving cycle

�) P2763 Torque converter clutch pressure

control solenoid control circuit high Too much electric flow is detected on TCC

solenoid circuit.

1 driving cycle

�) P2764 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and current of TCC

solenoid valve circuit is more than

specification.

1 driving cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting) A

1

(A)I4RS0B510004-01

1

(A)I4RS0B510004-01

Page 687 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-43

Transmission Warning Light Circuit Check – Light Does Not Come “ON” at Ignition Switch ONS7RS0B5104021

Troubleshooting

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ONS7RS0B5104022

TroubleshootingStep Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check DTC

Is DTC P0705, P0707, P0712, P0713, P0717, P0722,

P0787, P0788, P0961, P0962, P0963, P0973, P0974,

P0976, P0977, P1702, P1703, P1774, P1777, P2762,

P2763 and/or P2764 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Brake light switch signal inspection

1) With ignition switch turned ON, check voltage between

terminal “C35-20” of ECM connector and ground.

Brake light switch signal specification

Brake pedal is released: 0 – 1 V

Brake pedal is depressed: 8 – 14 V

Is result as specified? Substitute a known-

good TCM and recheck.

Mis-adjusted brake light

switch or faulty brake

light switch.

Step

Action YesNo

1 Combination meter power supply check

1) Turn ignition switch ON.

Does other indicator / warnin g lights in combination meter

comes ON? Go to Step 2.

Repair combination

meter power supply

circuit referring to “C-1

Combination Meter

Circuit Diagram (Meter)

in Section 9A”.

2 TCM power and ground circuit check

1) Check referring to “TCM Power and Ground Circuit

Check”.

Is it in good condition? Go to Step 3.

Repair or replace.

3 DTC check

1) Check DTC referring to “DTC Check”.

Is there DTC P1774? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Combination meter function check

1) Turn ignition switch ON.

Does A/T selector position in dicator show correct select

lever position? Replace combination

meter.

Substitute a known-

good TCM and recheck.

Step

Action YesNo

1 Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to “DTC Check”.

Is there any DTC(s)? Perform DTC Flow to

repair and retry.

Substitute a known-

good TCM and recheck.

If OK, substitute a

known-good

combination meter and

recheck.

Page 688 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-44 Automatic Transmission/Transaxle:

DTC P0602: Control Module Programming ErrorS7RS0B5104048

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

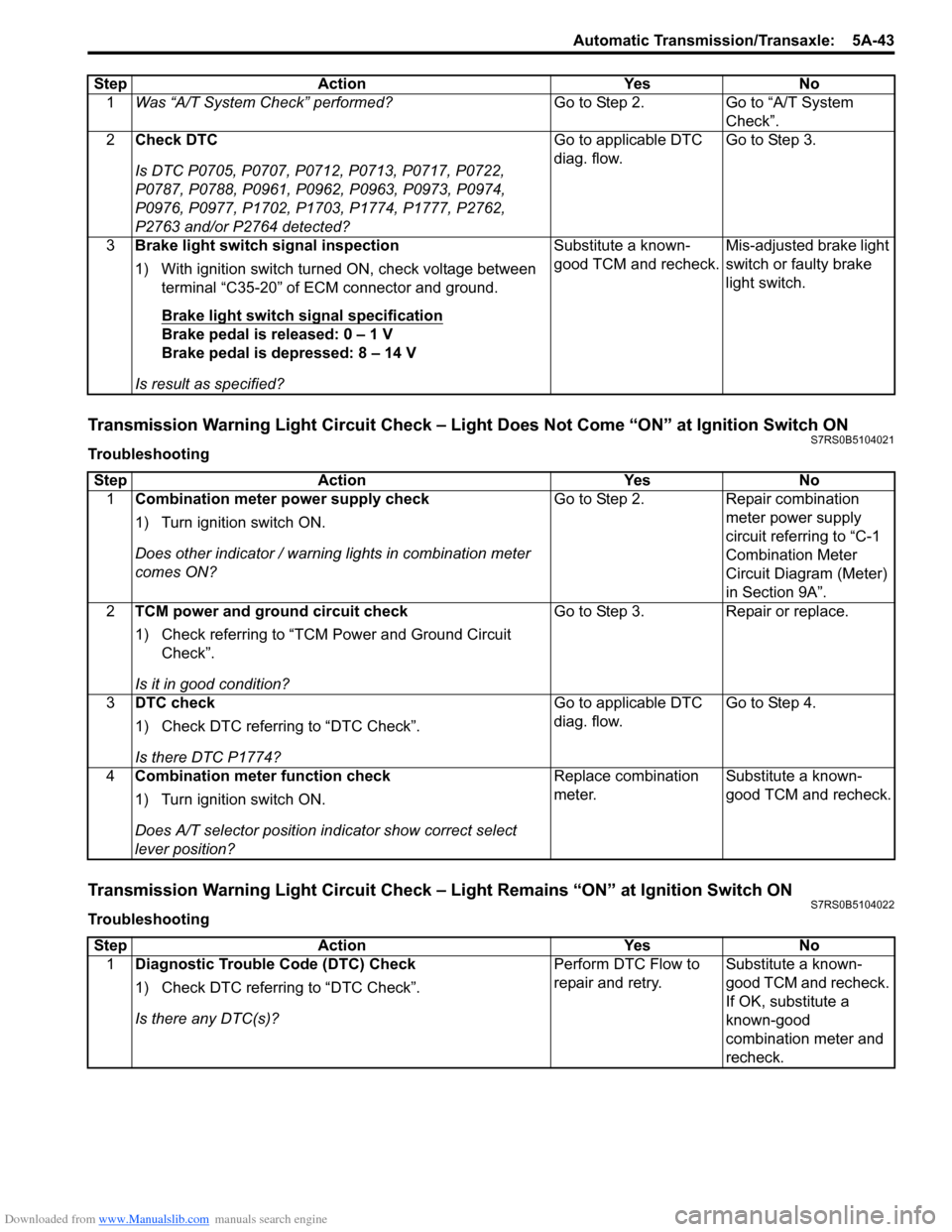

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL input)S7RS0B5104023

Wiring DiagramDTC detecting condition Trouble area

Data programming error (1 driving cycle detection logic) TCM

Step Action YesNo

1 DTC check

1) Clear DTC referring to “DTC Clearance”.

2) Turn ignition switch to OFF position.

3) Turn ignition switch to ON position and check DTC.

Is DTC P0602 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 TCM reprogramming check

Was reprogramming of TCM executed? Execute reprogramming

of TCM correctly once

again.Go to Step 3.

3 TCM power ground circuit check

1) Check TCM power supply circuit and ground circuit

referring to “TCM Power and Ground Circuit Check”.

Are check results OK? Substitute a known-

good TCM and recheck.

Repair TCM power or

ground circuit.

1. TCM

3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangem ent of TCM connector (viewed from harness side)

2P

R

N

D 2 L 3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

LT GRN/BLK

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18

C34

20 19

87

18

1

C35

[A]

I4RS0A510010-01

Page 696 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-52 Automatic Transmission/Transaxle:

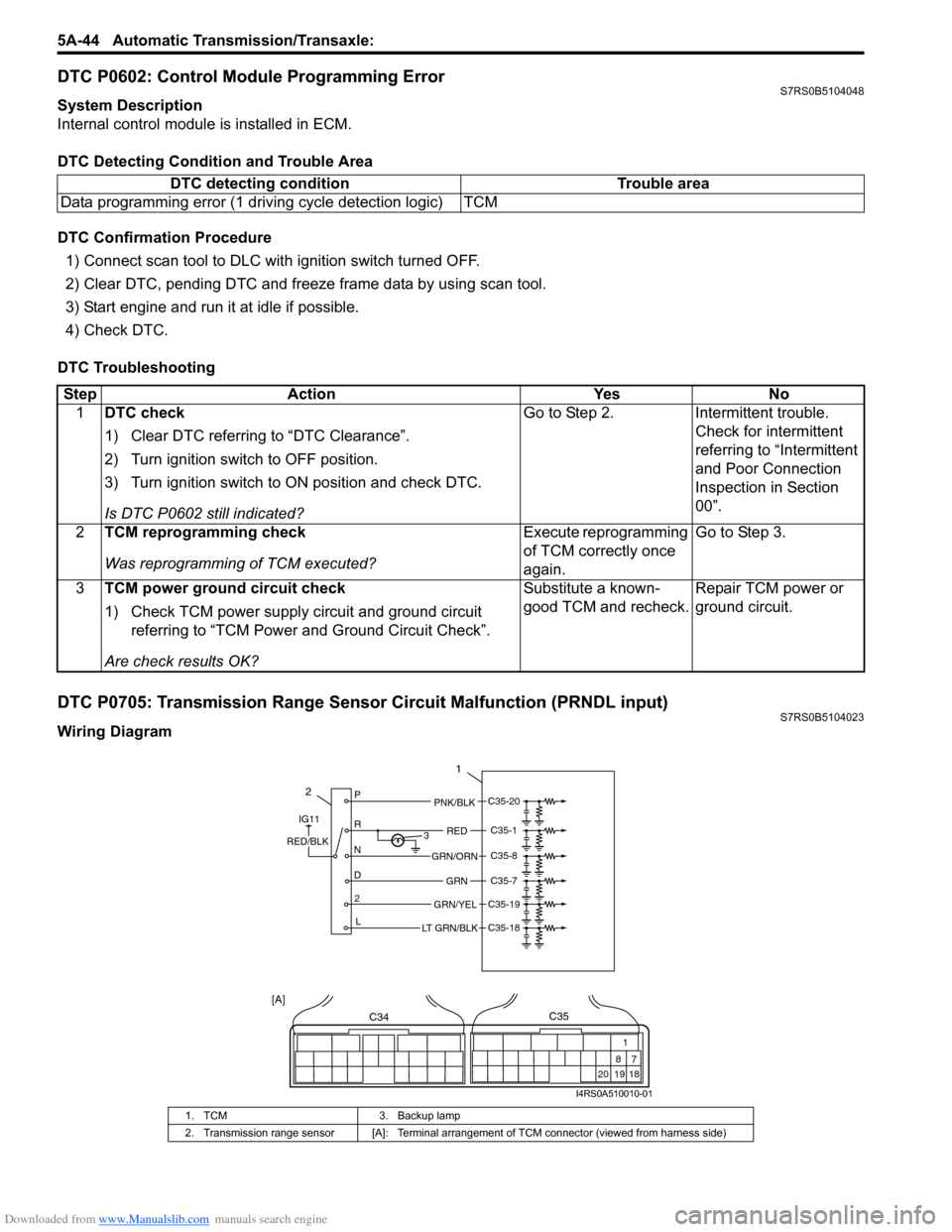

DTC P0722: Output Speed Sensor Circuit No SignalS7RS0B5104028

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

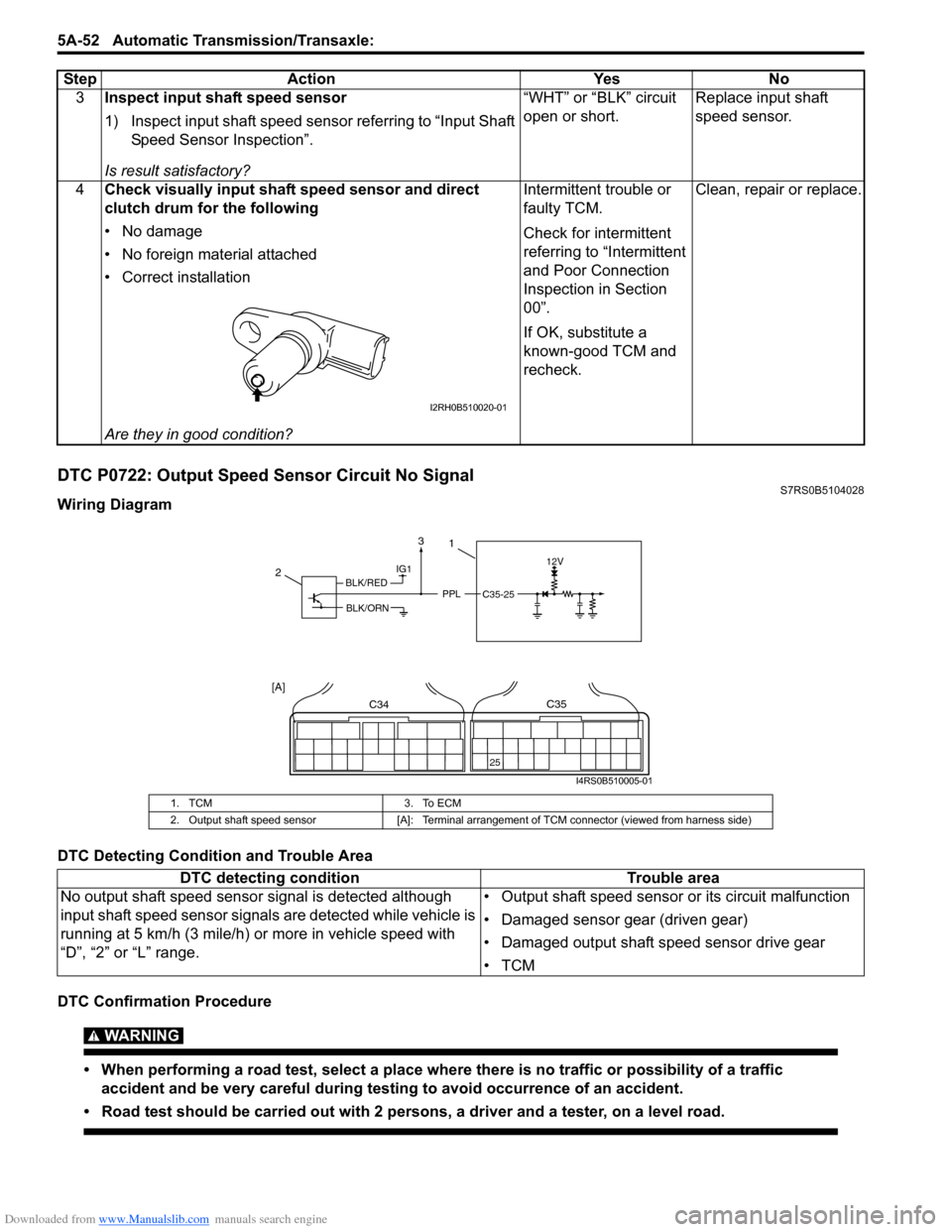

3 Inspect input shaft speed sensor

1) Inspect input shaft speed sensor referring to “Input Shaft

Speed Sensor Inspection”.

Is result satisfactory? “WHT” or “BLK” circuit

open or short.

Replace input shaft

speed sensor.

4 Check visually input shaft speed sensor and direct

clutch drum for the following

• No damage

• No foreign material attached

• Correct installation

Are they in good condition? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

Clean, repair or replace.

Step Action Yes No

I2RH0B510020-01

1. TCM

3. To ECM

2. Output shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No output shaft speed sensor signal is detected although

input shaft speed sensor signal s are detected while vehicle is

running at 5 km/h (3 mile/h) or more in vehicle speed with

“D”, “2” or “L” range. • Output shaft speed sensor or its circuit malfunction

• Damaged sensor gear (driven gear)

• Damaged output shaft speed sensor drive gear

•TCM

IG112V

PPLC35-25

2

C34

25

C35

[A]

1

BLK/RED

BLK/ORN

3

I4RS0B510005-01

Page 717 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-73

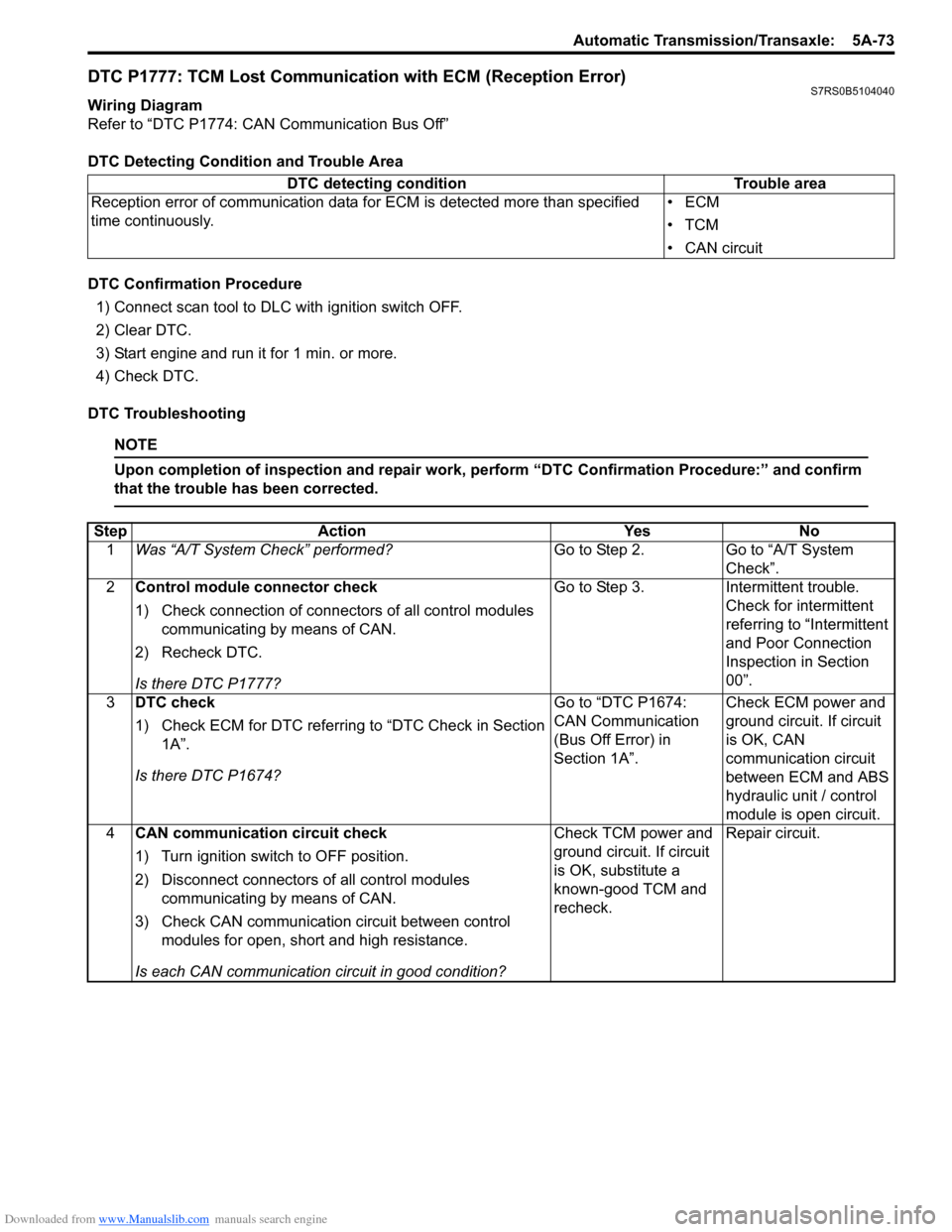

DTC P1777: TCM Lost Communication with ECM (Reception Error)S7RS0B5104040

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r ECM is detected more than specified

time continuously. •ECM

•TCM

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1777? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.

Check ECM power and

ground circuit. If circuit

is OK, CAN

communication circuit

between ECM and ABS

hydraulic unit / control

module is open circuit.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

Page 718 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

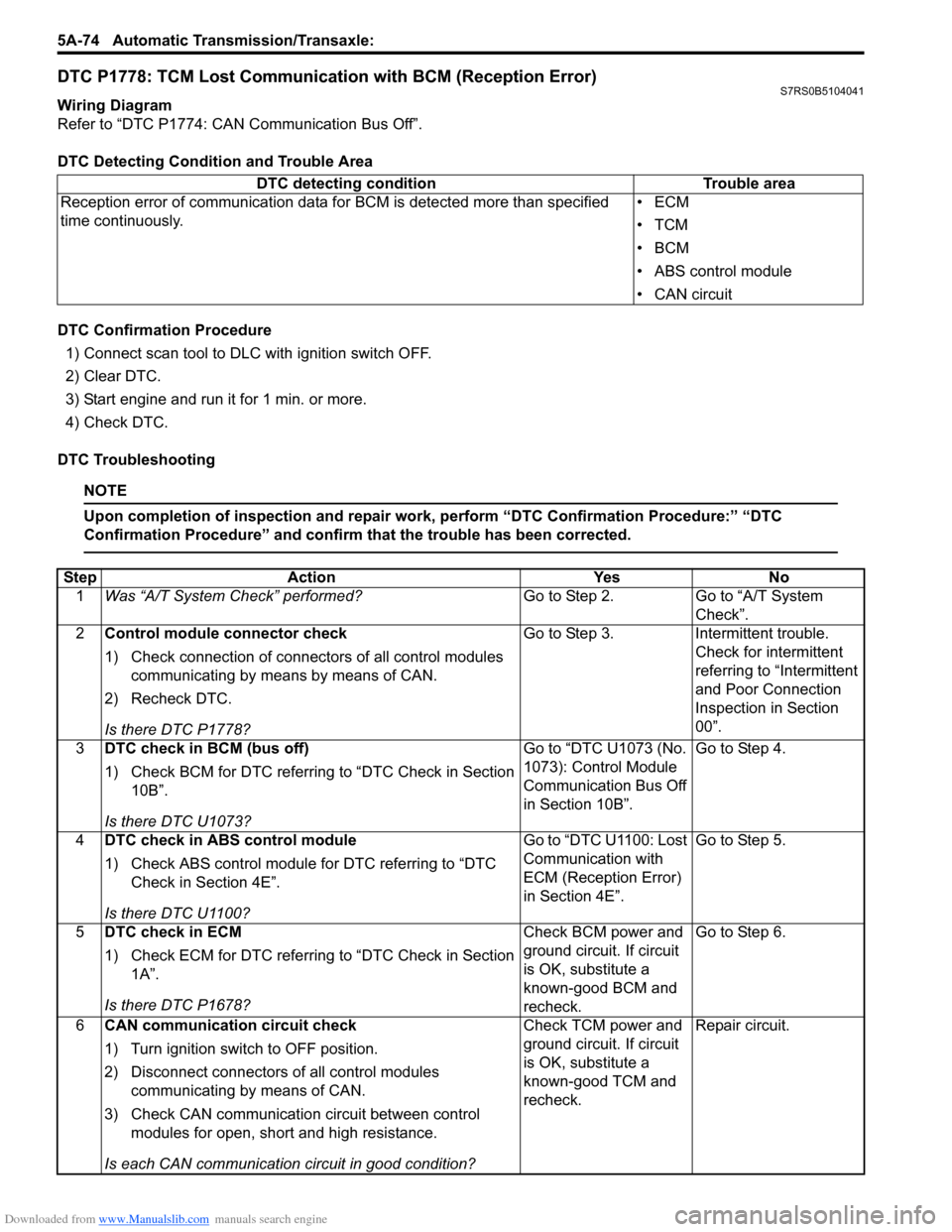

DTC P1778: TCM Lost Communication with BCM (Reception Error)S7RS0B5104041

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” “DTC

Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r BCM is detected more than specified

time continuously. •ECM

•TCM

•BCM

• ABS control module

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means by means of CAN.

2) Recheck DTC.

Is there DTC P1778? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check in BCM (bus off)

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is there DTC U1073? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.

Go to Step 4.

4 DTC check in ABS control module

1) Check ABS control module for DTC referring to “DTC

Check in Section 4E”.

Is there DTC U1100? Go to “DTC U1100: Lost

Communication with

ECM (Reception Error)

in Section 4E”.

Go to Step 5.

5 DTC check in ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1678? Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.Go to Step 6.

6 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.