Unit SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 973 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-25

Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation

S7RS0B7216008

Removal1) Disconnect negative (–) cable from battery.

2) Remove HVAC unit from vehicle body referring to “HVAC Unit Removal and Installation”.

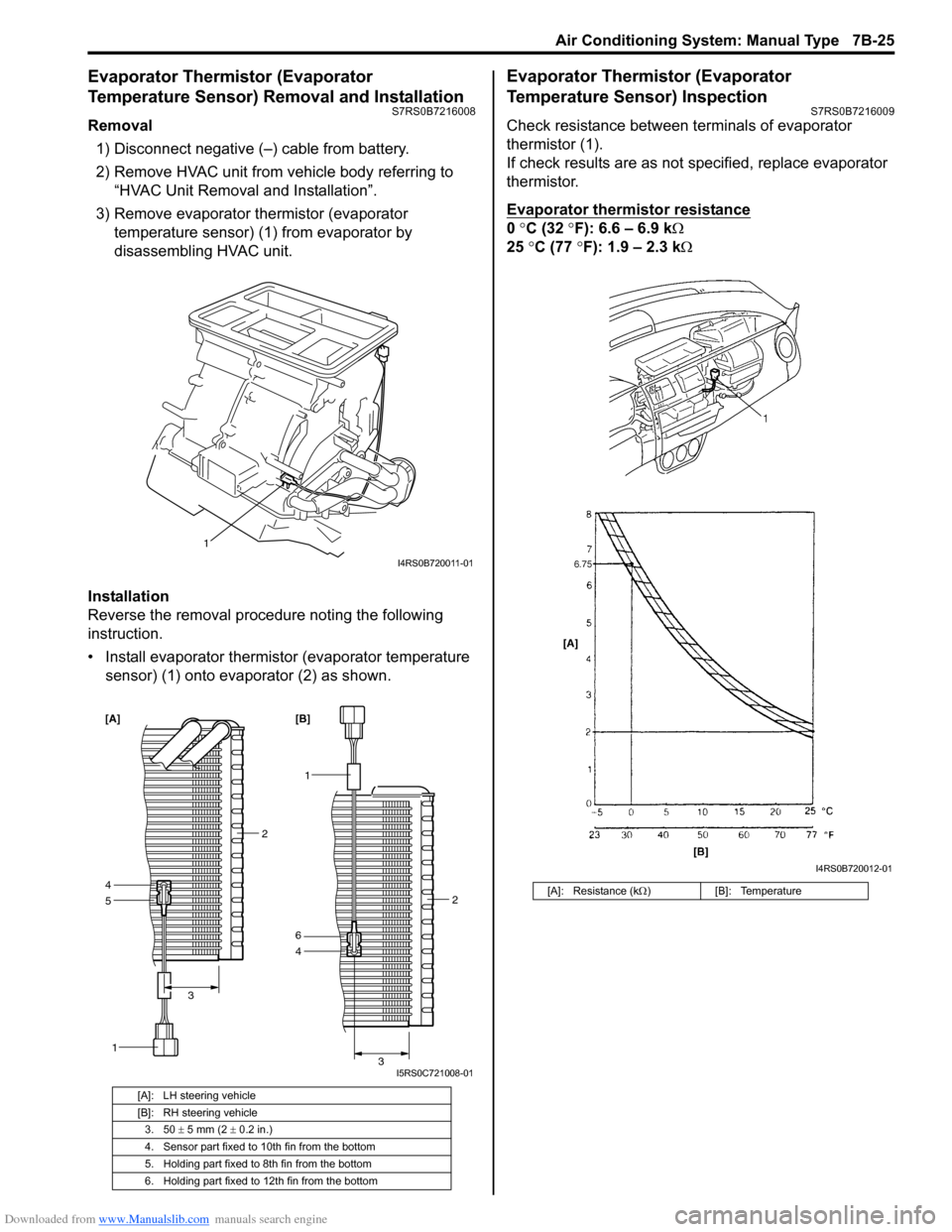

3) Remove evaporator thermistor (evaporator temperature sensor) (1) from evaporator by

disassembling HVAC unit.

Installation

Reverse the removal procedure noting the following

instruction.

• Install evaporator thermistor (evaporator temperature sensor) (1) onto evaporator (2) as shown.

Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection

S7RS0B7216009

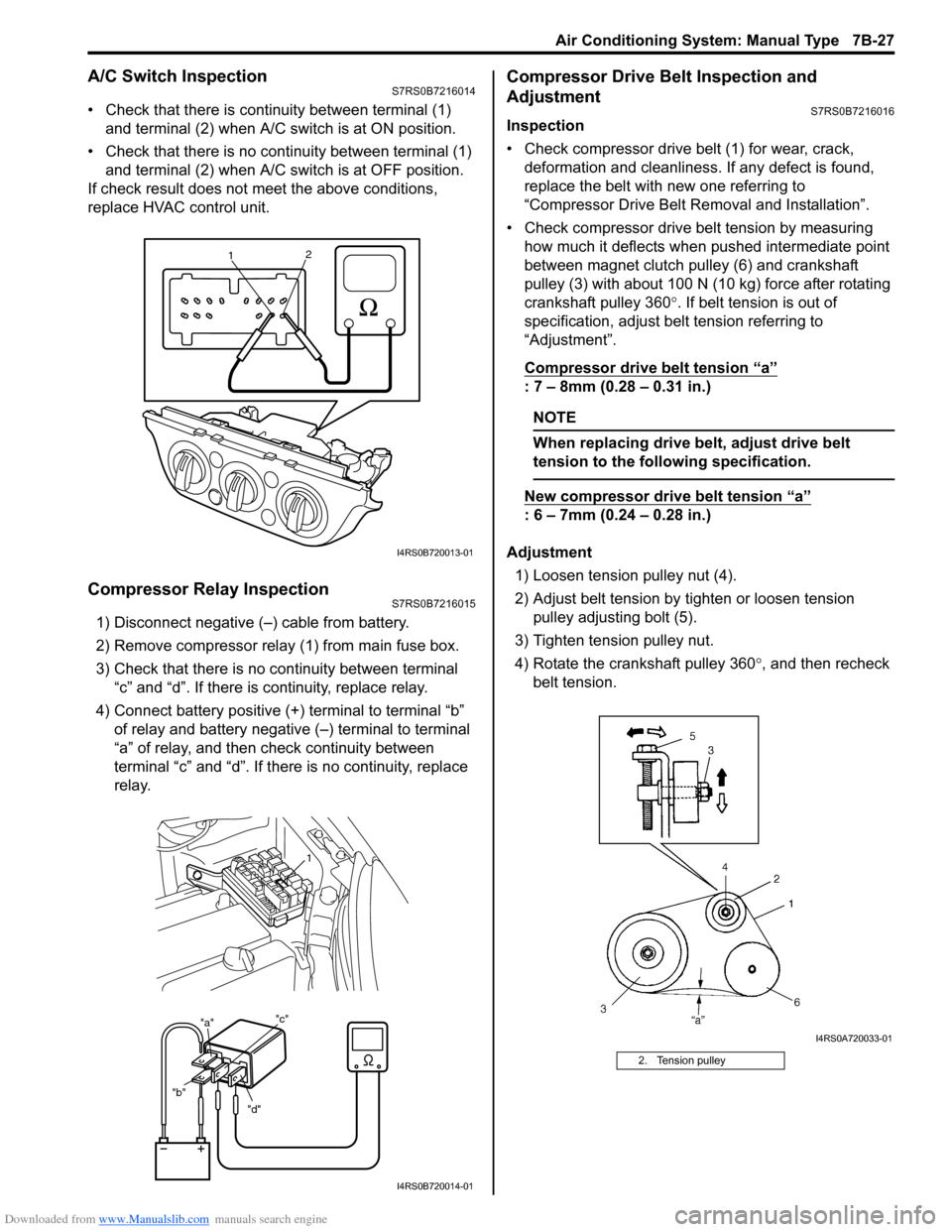

Check resistance between terminals of evaporator

thermistor (1).

If check results are as not specified, replace evaporator

thermistor.

Evaporator thermistor resistance

0 °C (32 °F): 6.6 – 6.9 k Ω

25 °C (77 °F): 1.9 – 2.3 kΩ

[A]: LH steering vehicle

[B]: RH steering vehicle

3. 50 ± 5 mm (2 ± 0.2 in.)

4. Sensor part fixed to 10th fin from the bottom

5. Holding part fixed to 8th fin from the bottom

6. Holding part fixed to 12th fin from the bottom

1

I4RS0B720011-01

5

1

4

2

3

[A]

1

4 2

3

6 [B]

I5RS0C721008-01

[A]: Resistance (k Ω) [B]: Temperature

I4RS0B720012-01

Page 975 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

A/C Switch InspectionS7RS0B7216014

• Check that there is continuity between terminal (1) and terminal (2) when A/C s witch is at ON position.

• Check that there is no continuity between terminal (1) and terminal (2) when A/C s witch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

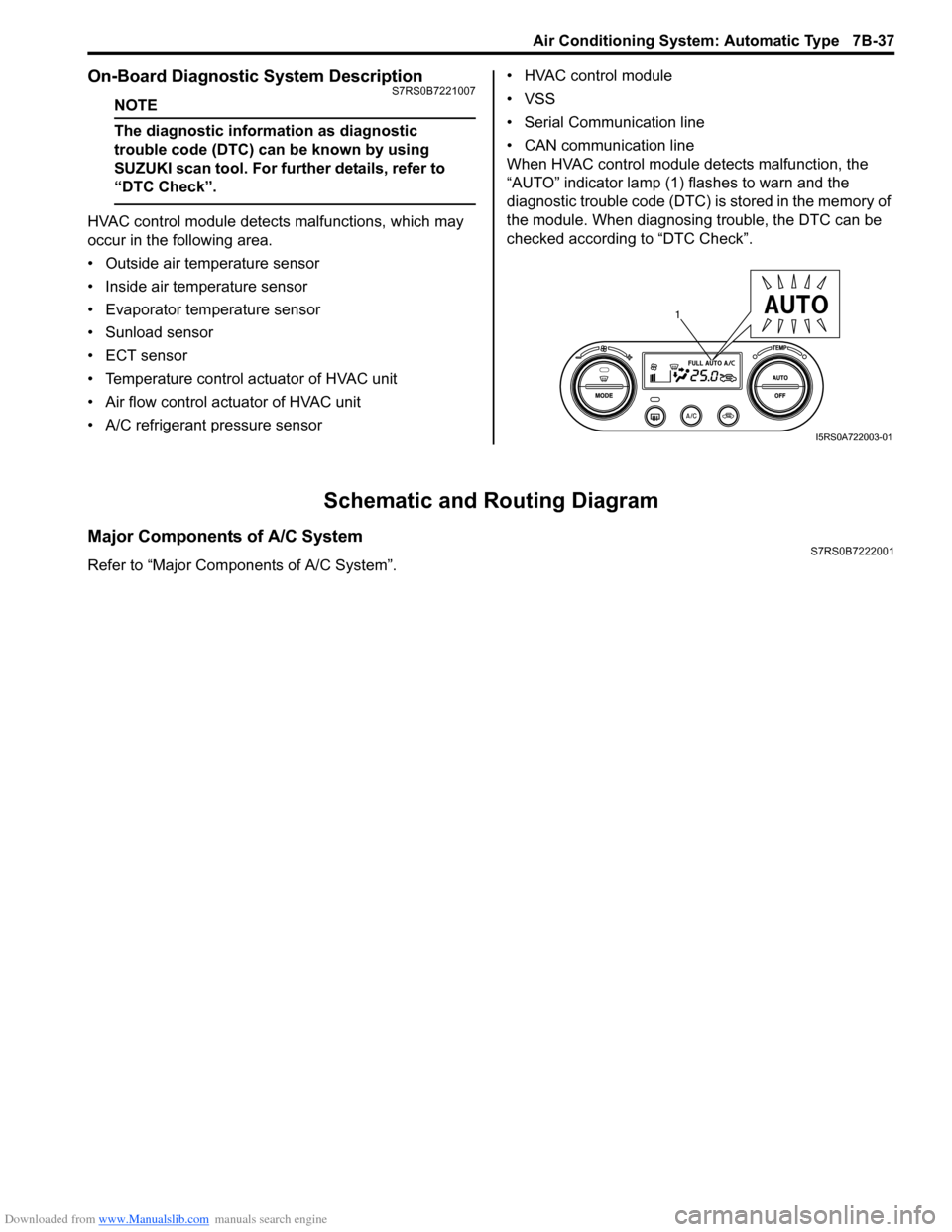

Compressor Relay InspectionS7RS0B7216015

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) from main fuse box.

3) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7216016

Inspection

• Check compressor drive belt (1) for wear, crack, deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Re moval and Installation”.

• Check compressor drive belt tension by measuring how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360 °. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specification.

New compressor dr ive belt tension “a”

: 6 – 7mm (0.24 – 0.28 in.)

Adjustment 1) Loosen tension pulley nut (4).

2) Adjust belt tension by ti ghten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360 °, and then recheck

belt tension.

1 2

I4RS0B720013-01

"d"

"b" "a"

"c"

1

I4RS0B720014-01

2. Tension pulley

I4RS0A720033-01

Page 985 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-37

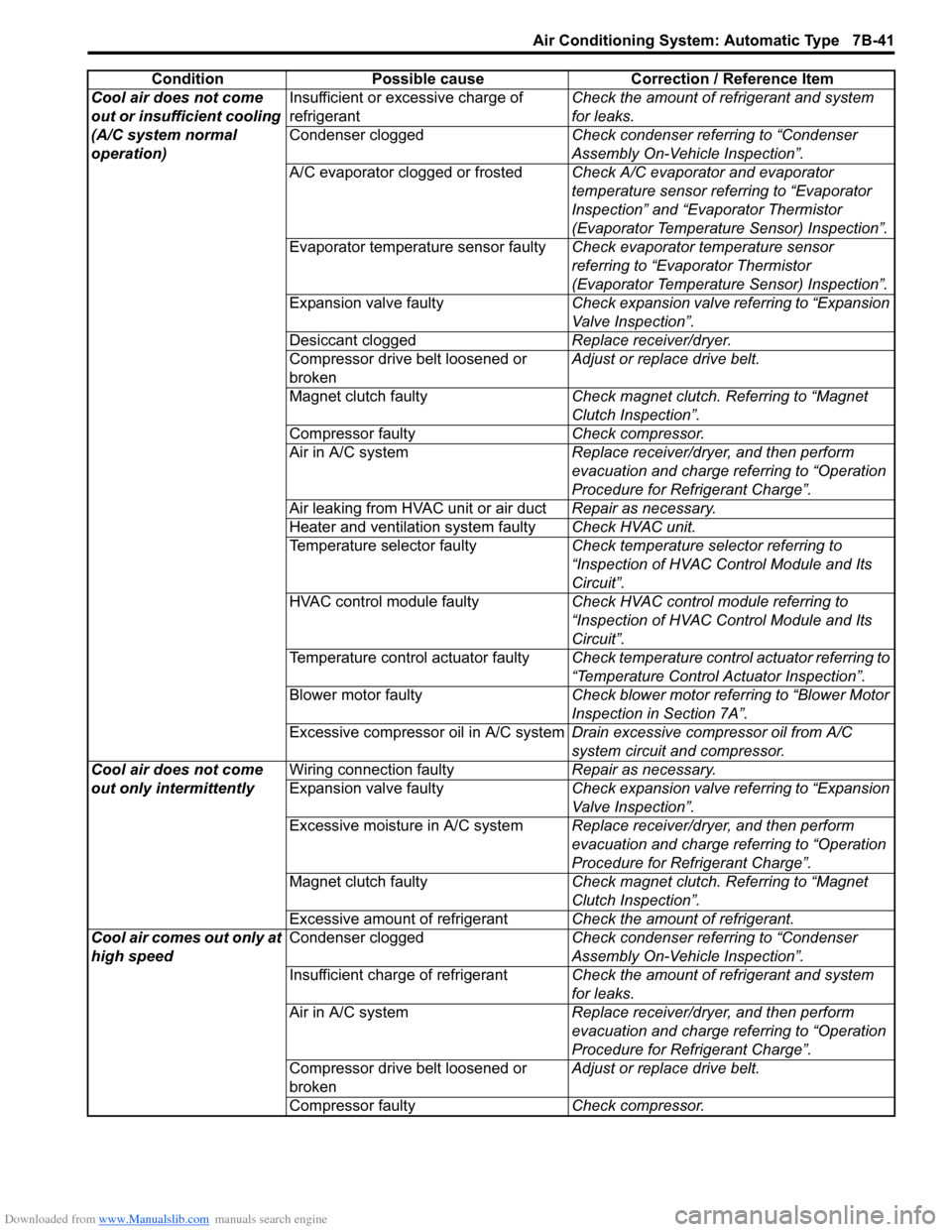

On-Board Diagnostic System DescriptionS7RS0B7221007

NOTE

The diagnostic information as diagnostic

trouble code (DTC) can be known by using

SUZUKI scan tool. For further details, refer to

“DTC Check”.

HVAC control module detect s malfunctions, which may

occur in the following area.

• Outside air temperature sensor

• Inside air temperature sensor

• Evaporator temperature sensor

• Sunload sensor

• ECT sensor

• Temperature control actuator of HVAC unit

• Air flow control actuator of HVAC unit

• A/C refrigerant pressure sensor • HVAC control module

• VSS

• Serial Communication line

• CAN communication line

When HVAC control module detects malfunction, the

“AUTO” indicator lamp (1) flashes to warn and the

diagnostic trouble code (DTC) is stored in the memory of

the module. When diagnosing trouble, the DTC can be

checked according to “DTC Check”.

Schematic and Routing Diagram

Major Components of A/C SystemS7RS0B7222001

Refer to “Major Components of A/C System”.

1

I5RS0A722003-01

Page 989 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-41

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Temperature selector faulty Check temperature selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Temperature control actuator faulty Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Condition Possible cause Correction / Reference Item

Page 990 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-42 Air Conditioning System: Automatic Type

Abnormal Noise Symptom Diagnosis of A/C

System

S7RS0B7224002

Refer to “Abnormal Noise Symptom Diagnosis of A/C

System”.

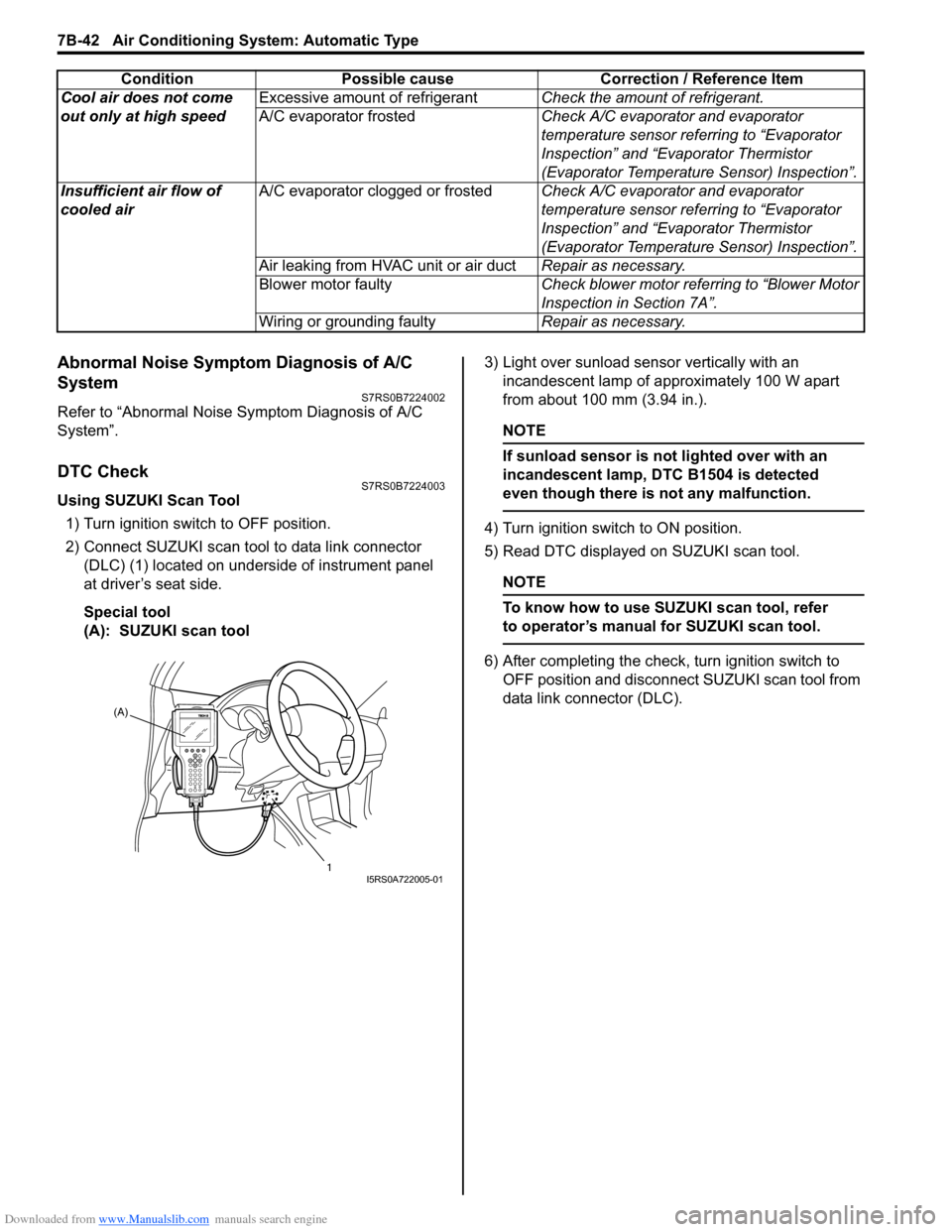

DTC CheckS7RS0B7224003

Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool 3) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

even though there is not any malfunction.

4) Turn ignition switch to ON position.

5) Read DTC displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC).

Cool air does not come

out only at high speed

Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Insufficient air flow of

cooled air A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

(A)

1

I5RS0A722005-01

Page 1005 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-57

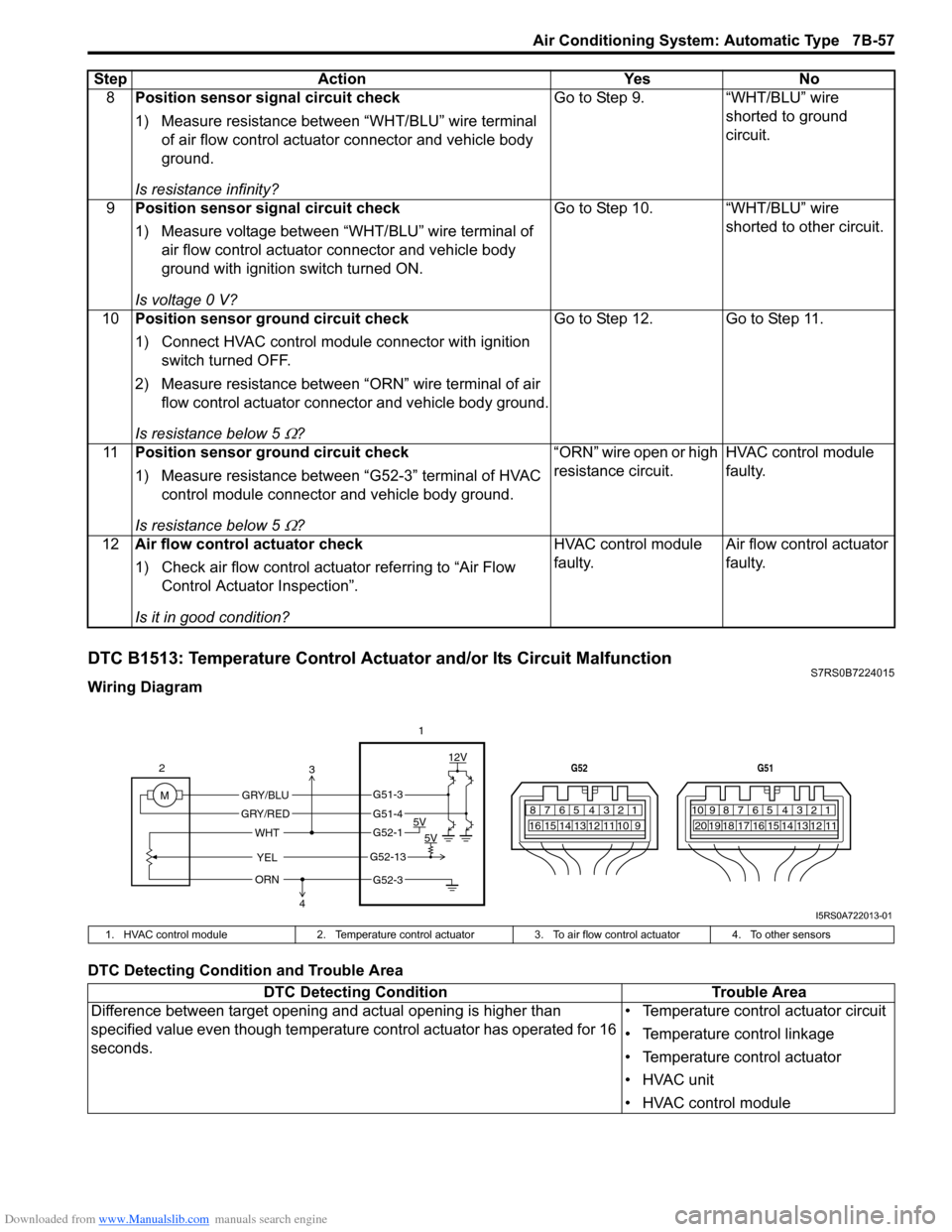

DTC B1513: Temperature Control Actuator and/or Its Circuit MalfunctionS7RS0B7224015

Wiring Diagram

DTC Detecting Condition and Trouble Area8

Position sensor signal circuit check

1) Measure resistance between “WHT/BLU” wire terminal

of air flow control actuator connector and vehicle body

ground.

Is resistance infinity? Go to Step 9. “WHT/BLU” wire

shorted to ground

circuit.

9 Position sensor signal circuit check

1) Measure voltage between “WHT/BLU” wire terminal of

air flow control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 10. “WHT/BLU” wire

shorted to other circuit.

10 Position sensor ground circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure resistance between “ORN” wire terminal of air flow control actuator connector and vehicle body ground.

Is resistance below 5

Ω? Go to Step 12. Go to Step 11.

11 Position sensor ground circuit check

1) Measure resistance between “G52-3” terminal of HVAC

control module connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire open or high

resistance circuit.

HVAC control module

faulty.

12 Air flow control actuator check

1) Check air flow control actuator referring to “Air Flow

Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Air flow control actuator

faulty.

Step Action Yes No

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

M 12V

5V 5V

YEL

WHT

GRY/BLU

GRY/RED

2

1

ORN

G51-3

G51-4

G52-1

G52-13

G52-3

3

4

I5RS0A722013-01

1. HVAC control module 2. Temperature control actuator 3. To air flow control actuator 4. To other sensors

DTC Detecting Condition Trouble Area

Difference between target opening an d actual opening is higher than

specified value even though temperature control actuator has operated for 16

seconds. • Temperature control actuator circuit

• Temperature control linkage

• Temperature control actuator

• HVAC unit

• HVAC control module

Page 1006 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-58 Air Conditioning System: Automatic Type

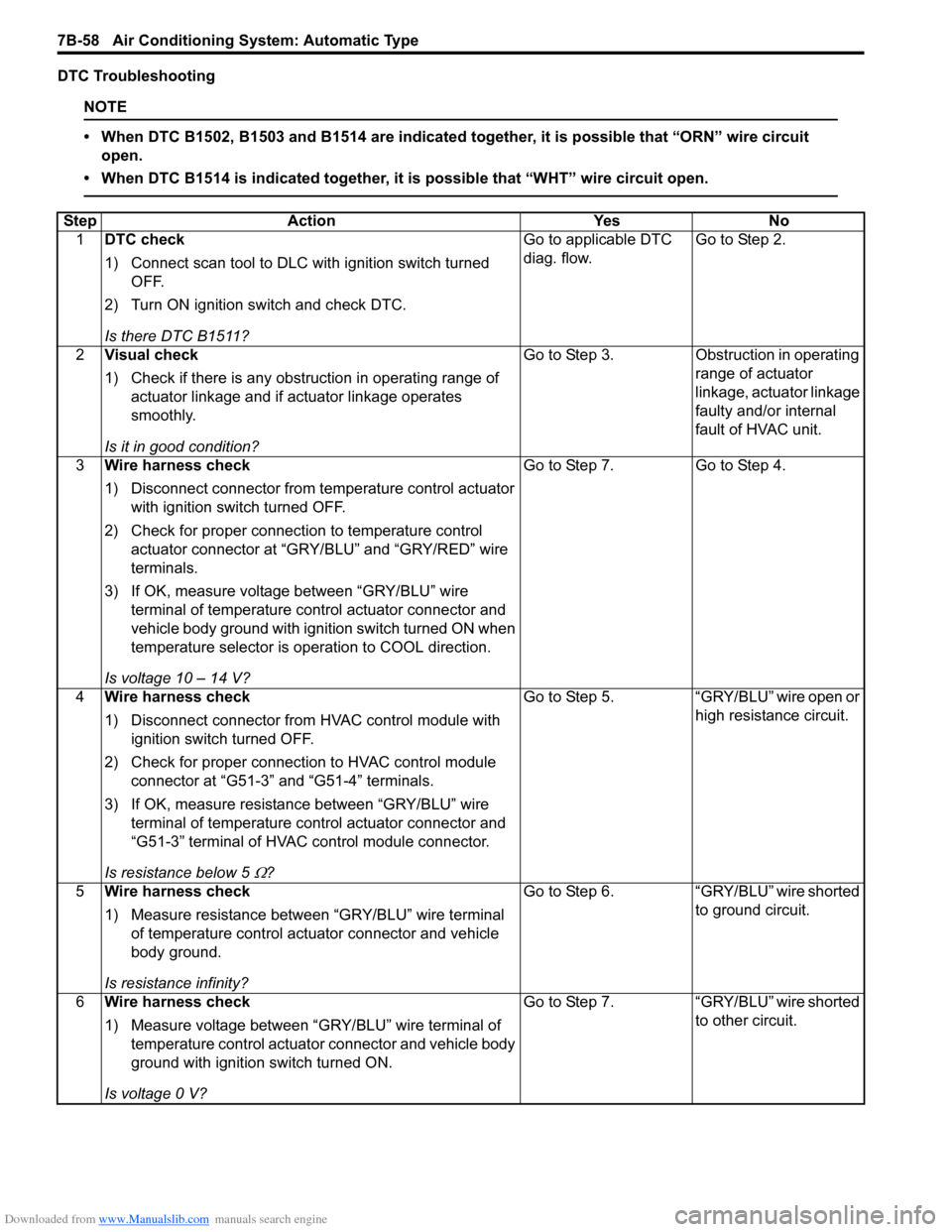

DTC Troubleshooting

NOTE

• When DTC B1502, B1503 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

• When DTC B1514 is indicated together, it is possible that “WHT” wire circuit open.

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC B1511? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Visual check

1) Check if there is any obstruction in operating range of

actuator linkage and if actuator linkage operates

smoothly.

Is it in good condition? Go to Step 3.

Obstruction in operating

range of actuator

linkage, actuator linkage

faulty and/or internal

fault of HVAC unit.

3 Wire harness check

1) Disconnect connector from temperature control actuator

with ignition swit ch turned OFF.

2) Check for proper connection to temperature control actuator connector at “GRY /BLU” and “GRY/RED” wire

terminals.

3) If OK, measure voltage between “GRY/BLU” wire terminal of temperature control actuator connector and

vehicle body ground with ignition switch turned ON when

temperature selector is operation to COOL direction.

Is voltage 10 – 14 V? Go to Step 7.

Go to Step 4.

4 Wire harness check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G51-3” and “G51-4” terminals.

3) If OK, measure resistance between “GRY/BLU” wire terminal of temperature control actuator connector and

“G51-3” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 5. “GRY/BLU” wire open or

high resistance circuit.

5 Wire harness check

1) Measure resistance between “GRY/BLU” wire terminal

of temperature control actuator connector and vehicle

body ground.

Is resistance infinity? Go to Step 6.

“GRY/BLU” wire shorted

to ground circuit.

6 Wire harness check

1) Measure voltage between “GRY/BLU” wire terminal of

temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 7.

“GRY/BLU” wire shorted

to other circuit.

Page 1008 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-60 Air Conditioning System: Automatic Type

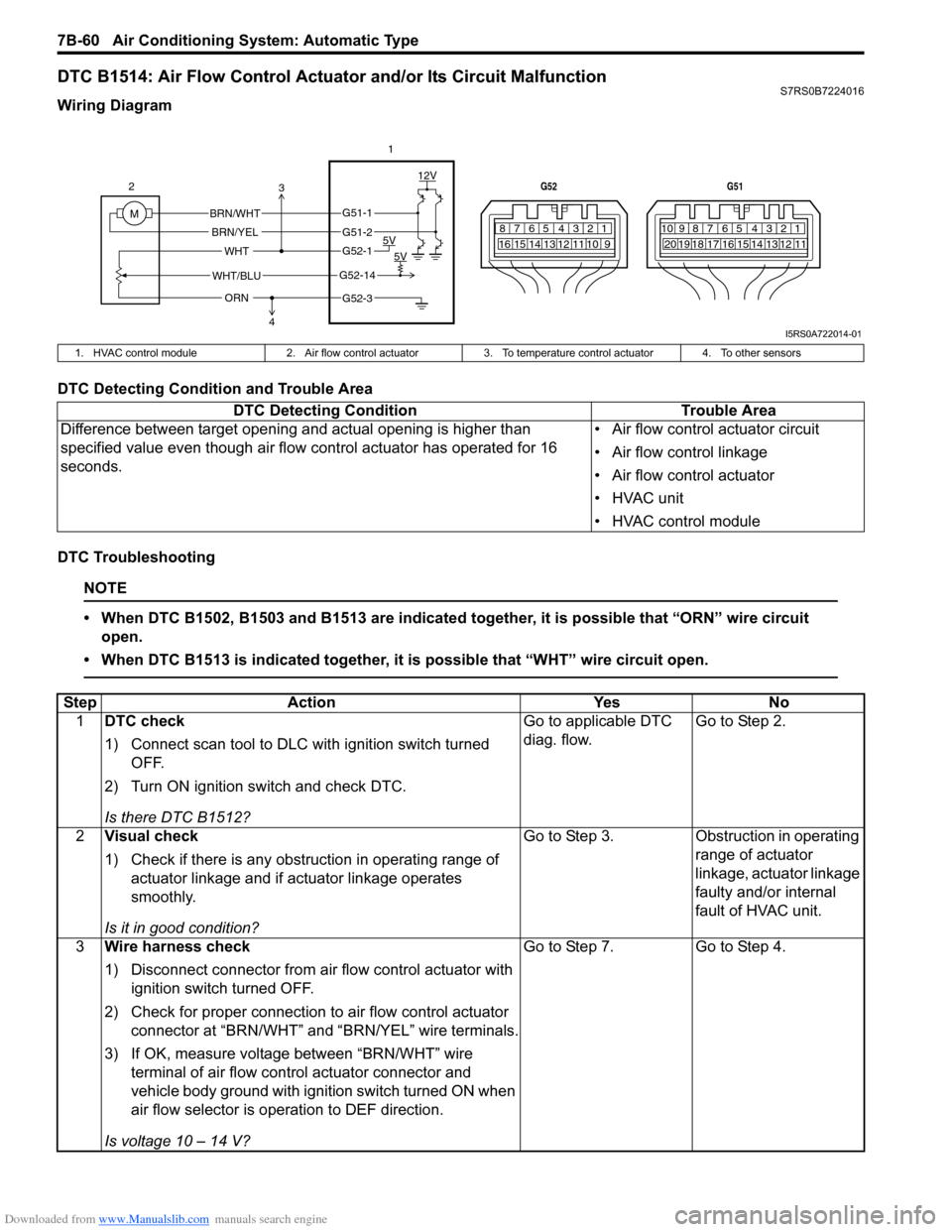

DTC B1514: Air Flow Control Actuator and/or Its Circuit MalfunctionS7RS0B7224016

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

• When DTC B1502, B1503 and B1513 are indicated together, it is possible that “ORN” wire circuit open.

• When DTC B1513 is indicated together, it is possible that “WHT” wire circuit open.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

M 12V

5V 5V

WHT/BLU

WHT

BRN/WHT

BRN/YEL

2

1

ORN

G51-1

G51-2

G52-1

G52-14

G52-3

3

4

I5RS0A722014-01

1. HVAC control module 2. Air flow control actuator3. To temperature control actuator 4. To other sensors

DTC Detecting Condition Trouble Area

Difference between target opening and actual opening is higher than

specified value even though air flow control actuator has operated for 16

seconds. • Air flow control actuator circuit

• Air flow control linkage

• Air flow control actuator

• HVAC unit

• HVAC control module

Step

Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC B1512? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Visual check

1) Check if there is any obstruction in operating range of

actuator linkage and if actuator linkage operates

smoothly.

Is it in good condition? Go to Step 3.

Obstruction in operating

range of actuator

linkage, actuator linkage

faulty and/or internal

fault of HVAC unit.

3 Wire harness check

1) Disconnect connector from air flow control actuator with

ignition switch turned OFF.

2) Check for proper connection to air flow control actuator

connector at “BRN/WHT” and “BRN/YEL” wire terminals.

3) If OK, measure voltage between “BRN/WHT” wire terminal of air flow control actuator connector and

vehicle body ground with ignition switch turned ON when

air flow selector is operation to DEF direction.

Is voltage 10 – 14 V? Go to Step 7.

Go to Step 4.

Page 1020 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-72 Air Conditioning System: Automatic Type

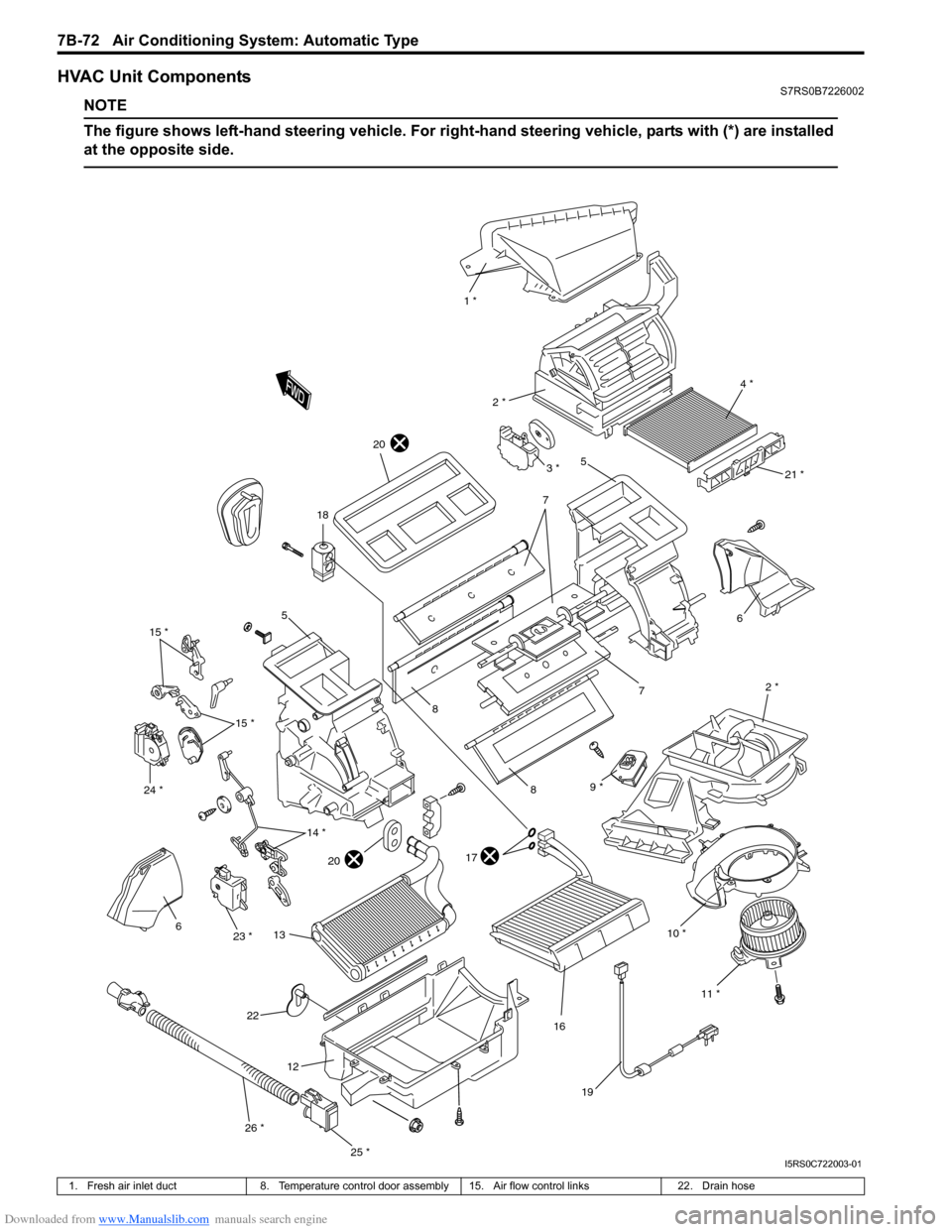

HVAC Unit ComponentsS7RS0B7226002

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

10 * 2 *

6

7

1 *

4 *

2 *

5

7

8

8

17

16

18

19

6

12

11 *

21 *

20

20

22

9 *

13

3 *

5

15 *

14 *

15 *

23 *

24 *

25 *

26 *

I5RS0C722003-01

1. Fresh air inlet duct

8. Temperature control door assembly 15. Air flow control links 22. Drain hose

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

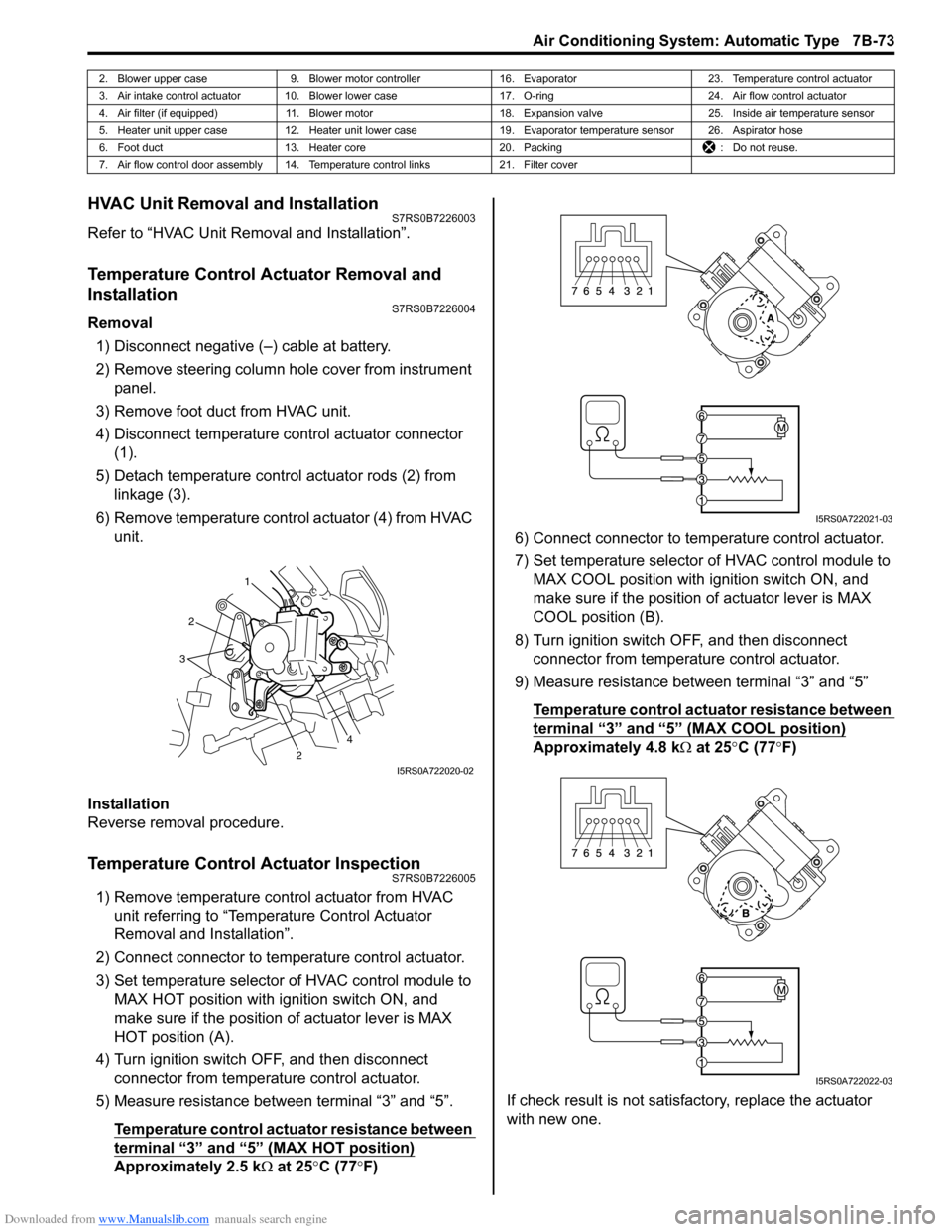

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03