BCM fuse SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 595 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-21

Stability control (ACTIVE, INACTIVE): This indicates

stability control in acti vation / deactivation.

TCS control (brake) ( ACTIVE, INACTIVE): This

indicates brake function of TCS in activation /

deactivation.

TCS control (engine) (ACTIVE, INACTIVE): This

indicates torque control of TCS in activation /

deactivation. ESP®

off state (cont) (ESP ® ON, ESP ® OFF): State

of ESP ® OFF switch.

Steering angle Sen (Neutral, NON newtral): This

indicates steering wheel angle measured by steering

angle sensor is in straight-ahead or not.

Visual InspectionS7RS0B4604059

Check the following parts and systems visually.

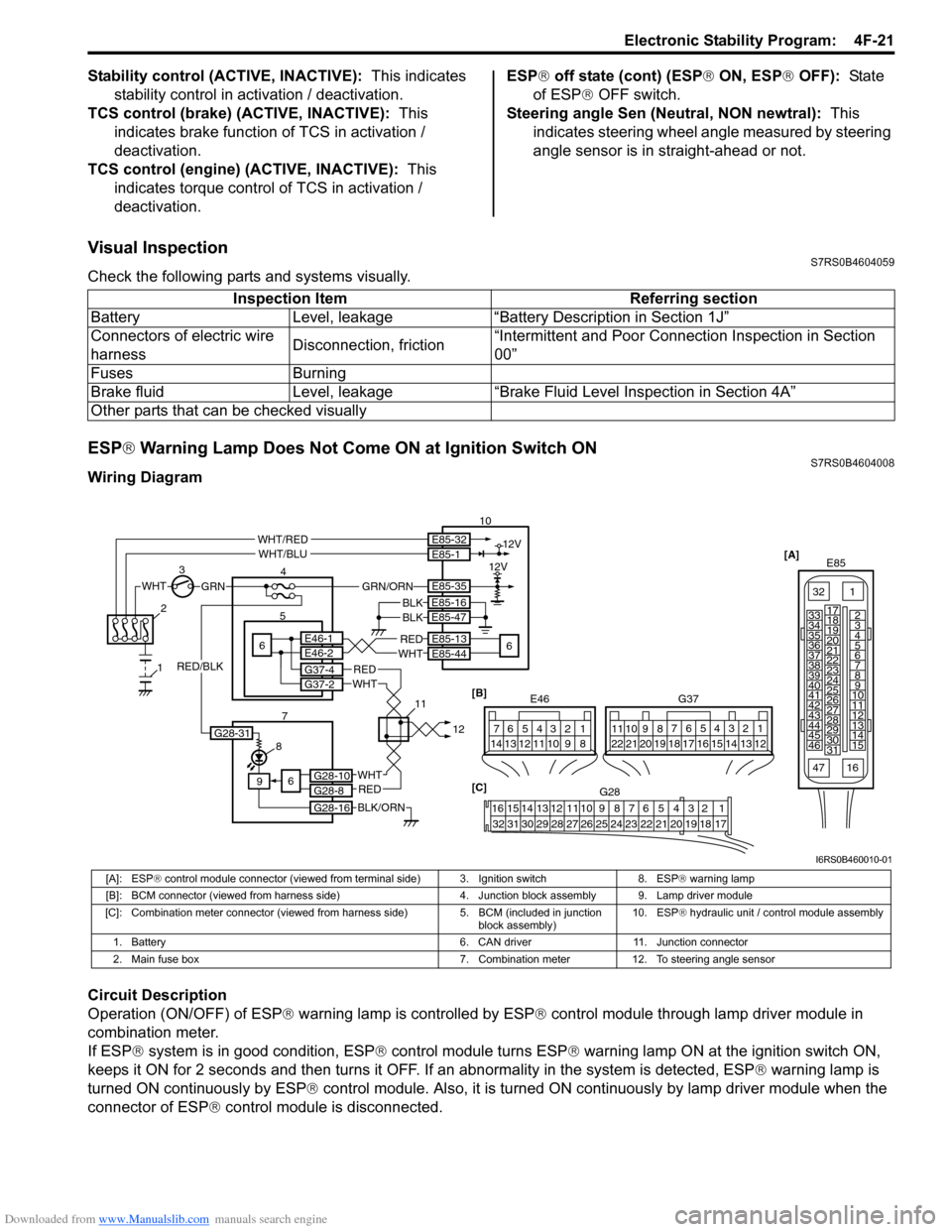

ESP ® Warning Lamp Does Not Come ON at Ignition Switch ONS7RS0B4604008

Wiring Diagram

Circuit Description

Operation (ON/OFF) of ESP ® warning lamp is controlled by ESP ® control module through lamp driver module in

combination meter.

If ESP ® system is in good condition, ESP ® control module turns ESP ® warning lamp ON at the ignition switch ON,

keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ESP ® warning lamp is

turned ON continuously by ESP ® control module. Also, it is turned ON continuously by lamp driver module when the

connector of ESP ® control module is disconnected.Inspection Item Referring section

Battery Level, leakage “Battery Description in Section 1J”

Connectors of electric wire

harness Disconnection, friction“Intermittent and Poor Connec

tion Inspection in Section

00”

Fuses Burning

Brake fluid Level, leakage “Brake Fluid Level Inspection in Section 4A”

Other parts that can be checked visually

[A] E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHTGRN

3

E85-13

E85-44REDWHT6 5E46-1E46-2

4 10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1112[B]

G37

E46124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

G28-31

RED/BLK

I6RS0B460010-01

[A]: ESP ® control module connector (viewed from terminal side) 3. Ignition switch 8. ESP ® warning lamp

[B]: BCM connector (viewed from harness side) 4. Junction block assembly 9. Lamp driver module

[C]: Combination meter connector (viewed from harness side) 5. BCM (included in junction

block assembly) 10. ESP

® hydraulic unit / control module assembly

1. Battery 6. CAN driver 11. Junction connector

2. Main fuse box 7. Combination meter 12. To steering angle sensor

Page 597 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-23

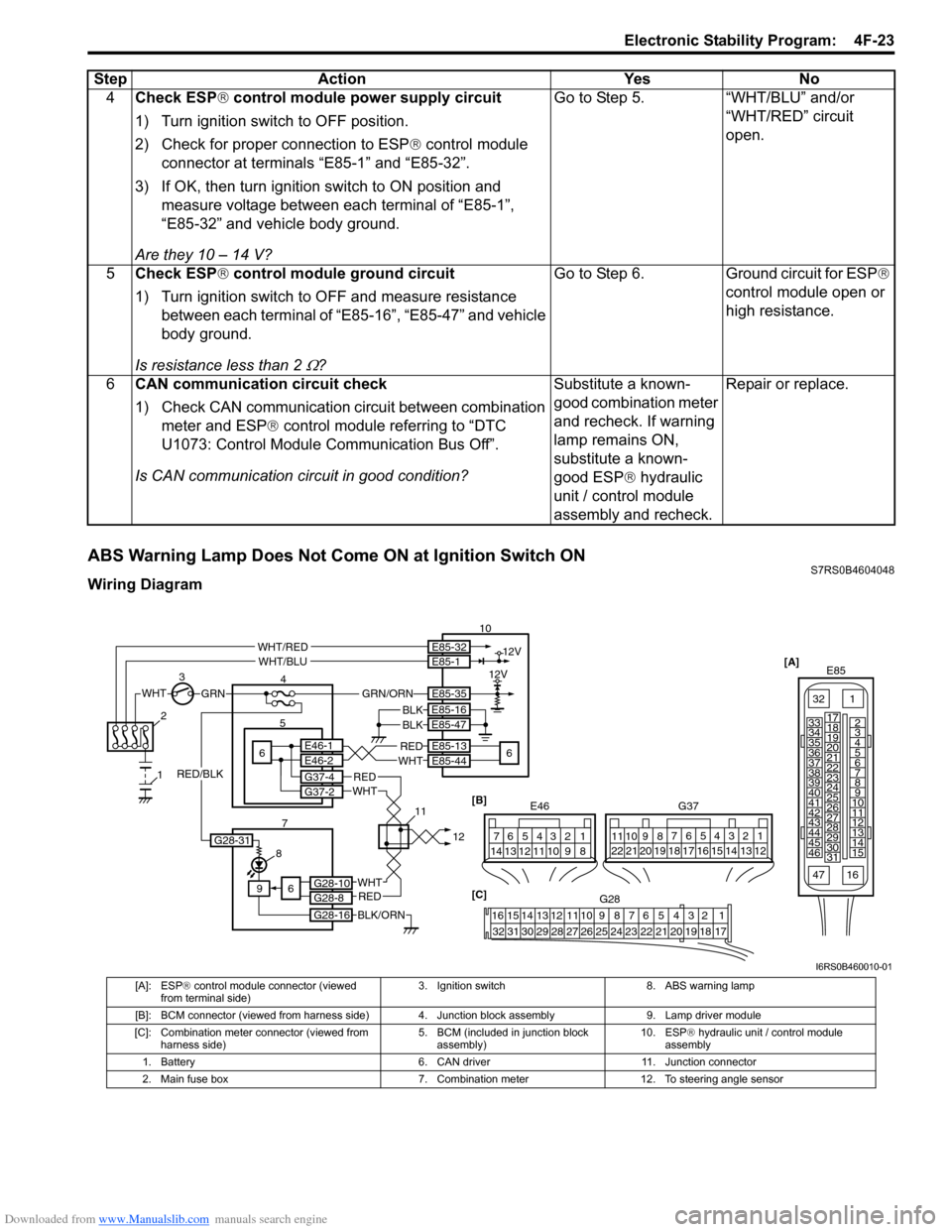

ABS Warning Lamp Does Not Come ON at Ignition Switch ONS7RS0B4604048

Wiring Diagram4

Check ESP ® control module power supply circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to ESP ® control module

connector at terminals “E85-1” and “E85-32”.

3) If OK, then turn ignition switch to ON position and measure voltage between each terminal of “E85-1”,

“E85-32” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5. “WHT/BLU” and/or

“WHT/RED” circuit

open.

5 Check ESP ® control module ground circuit

1) Turn ignition switch to OFF and measure resistance between each terminal of “E85-16”, “E85-47” and vehicle

body ground.

Is resistance less than 2

Ω? Go to Step 6.

Ground circuit for ESP®

control module open or

high resistance.

6 CAN communication circuit check

1) Check CAN communication circuit between combination

meter and ESP ® control module referring to “DTC

U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If warning

lamp remains ON,

substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Repair or replace.

Step

Action YesNo

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHTGRN

3

E85-13

E85-44REDWHT6 5E46-1E46-2

4 10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1112[B]

G37

E46124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

G28-31

RED/BLK

I6RS0B460010-01

[A]: ESP ® control module connector (viewed

from terminal side) 3. Ignition switch 8. ABS warning lamp

[B]: BCM connector (viewed from harness side) 4. Junction block assembly 9. Lamp driver module

[C]: Combination meter connector (viewed from harness side) 5. BCM (included in junction block

assembly) 10. ESP

® hydraulic unit / control module

assembly

1. Battery 6. CAN driver11. Junction connector

2. Main fuse box 7. Combination meter12. To steering angle sensor

Page 598 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-24 Electronic Stability Program:

Circuit Description

Operation (ON/OFF) of ABS warning lamp is controlled by ESP® control module through lamp driver module in

combination meter.

If antilock brake system is in good condition, ESP ® control module turns ABS warning lamp ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning lamp is

turned ON continuously by ESP ® control module. Also, it is turned ON continuously by lamp driver module when the

connector of ESP ® control module is disconnected.

Troubleshooting

Refer to “Troubleshooting” under “ESP ® Warning Lamp Does Not Come ON at Ignition Switch ON”.

ABS Warning Lamp Comes ON SteadyS7RS0B4604049

Wiring Diagram

Refer to “Wiring Diagram” under “ABS Warning Lamp Does Not Come ON at Ignition Switch ON”.

Circuit Description

Refer to “Circuit Description” u nder “ABS Warning Lamp Does Not Co me ON at Ignition Switch ON”.

Troubleshooting

Refer to “Troubleshooting” under “ESP ® Warning Lamp Comes ON Steady”.

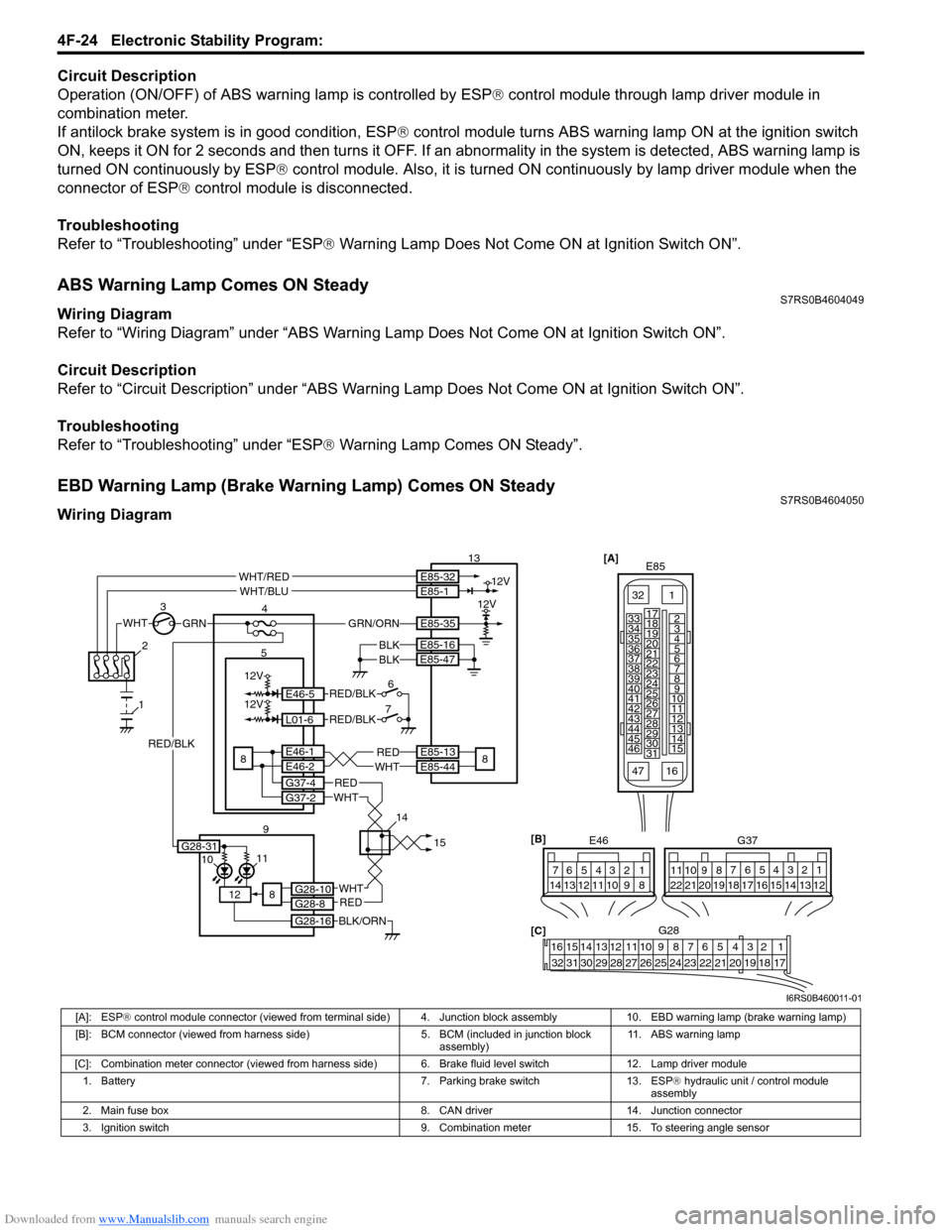

EBD Warning Lamp (Brake Warning Lamp) Comes ON SteadyS7RS0B4604050

Wiring Diagram

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47WHTGRN

3

E85-13

E85-44REDWHT8 5E46-1E46-2

4

13

8

E85-16

E85-47BLKBLK

1110

12

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

8

2

1

9 1415

[B]

G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

12V

12V

6

7E46-5

L01-6

RED/BLK

RED/BLK

G28-31

RED/BLK

I6RS0B460011-01

[A]: ESP ® control module connector (viewed from terminal side) 4. Junction block assembly 10. EBD warning lamp (brake warning lamp)

[B]: BCM connector (viewed from harness side) 5. BCM (included in junction block

assembly) 11. ABS warning lamp

[C]: Combination meter connector (viewed from harness side) 6. Brake fluid level switch 12. Lamp driver module 1. Battery 7. Parking brake switch 13. ESP ® hydraulic unit / control module

assembly

2. Main fuse box 8. CAN driver 14. Junction connector

3. Ignition switch 9. Combination meter 15. To steering angle sensor

Page 600 of 1496

![SUZUKI SWIFT 2006 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

SUZUKI SWIFT 2006 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11](/img/20/7607/w960_7607-599.png)

Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47WHTGRN

3

E85-13REDWHT6 5E46-1E46-2

4

10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

G28-31

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1415 [B]

G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

12V

11

PPL/WHT

PPL/WHT

E85-33

E85-44

12

13

WHTWHT/REDB

G G1

RED/BLK

I6RS0B460012-01

[A]: ESP

® control module connector (viewed

from terminal side) 4. Junction block assembly 10. ESP

® hydraulic unit / control module assembly

[B]: BCM connector (viewed from harness side) 5. BCM (included in junction block

assembly) 11. Data link connector (DLC)

[C]: Combination meter connector (viewed from harness side) 6. CAN driver 12. To SDM

1. Battery 7. Combination meter 13. To ECM and P/S control module

2. Main fuse box 8. ESP ® warning lamp 14. Junction connector

3. Ignition switch 9. Lamp driver module 15. To steering angle sensor

Step Action YesNo

1 Check ESP ® warning lamp

1) Turn ignition switch to ON position.

Does ESP

® warning lamp come ON? Go to Step 2. Go to Step 6.

2 Check fuse

1) Turn ignition switch to OFF position.

Are main fuses for good condition? Go to Step 3. Replace fuse and check

for short.

3 Check ESP ® control module power supply circuit

1) Disconnect ESP ® control module connector.

2) Check for proper connection to ESP ® control module

connector at terminal “E85-35”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminal “E85-35” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” wire circuit

open.

Page 602 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-28 Electronic Stability Program:

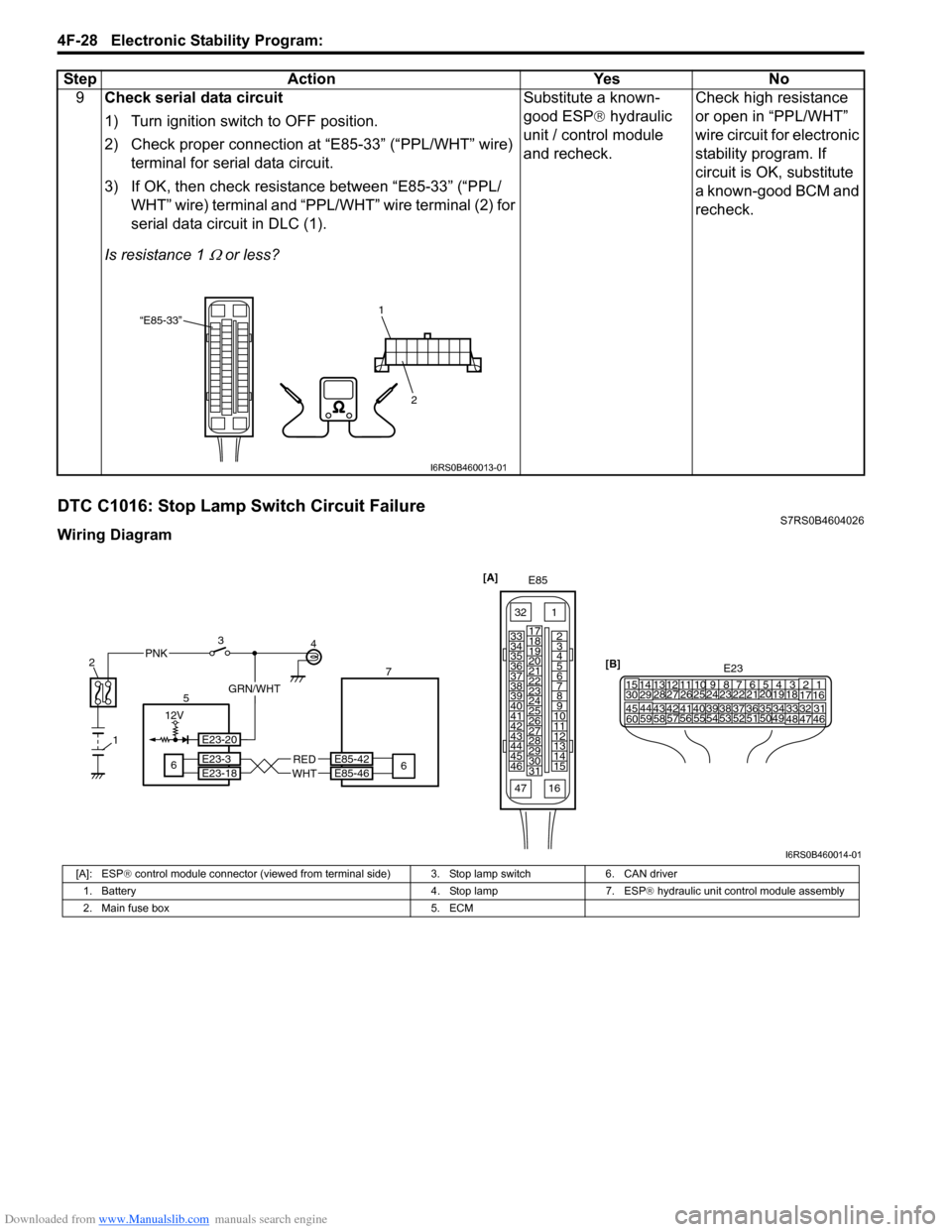

DTC C1016: Stop Lamp Switch Circuit FailureS7RS0B4604026

Wiring Diagram9

Check serial data circuit

1) Turn ignition switch to OFF position.

2) Check proper connection at “E85-33” (“PPL/WHT” wire)

terminal for serial data circuit.

3) If OK, then check resistance between “E85-33” (“PPL/ WHT” wire) terminal and “PPL/WHT” wire terminal (2) for

serial data circuit in DLC (1).

Is resistance 1

Ω or less? Substitute a known-

good ESP

® hydraulic

unit / control module

and recheck. Check high resistance

or open in “PPL/WHT”

wire circuit for electronic

stability program. If

circuit is OK, substitute

a known-good BCM and

recheck.

Step Action Yes No

“E85-33”

2

1

I6RS0B460013-01

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[B]

21

E23 34

1819

5671011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 5826

27

28

15

30

56 4832 31343536374042 39 38

44

45 43 41 33

1213

2382

1

E85-42

E85-46

56RED

WHT

4

6 7

E23-3

E23-18

12V

PNK3

GRN/WHT

E23-20

I6RS0B460014-01

[A]: ESP

® control module connector (viewed from te rminal side) 3. Stop lamp switch 6. CAN driver

1. Battery 4. Stop lamp 7. ESP ® hydraulic unit control module assembly

2. Main fuse box 5. ECM

Page 611 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-37

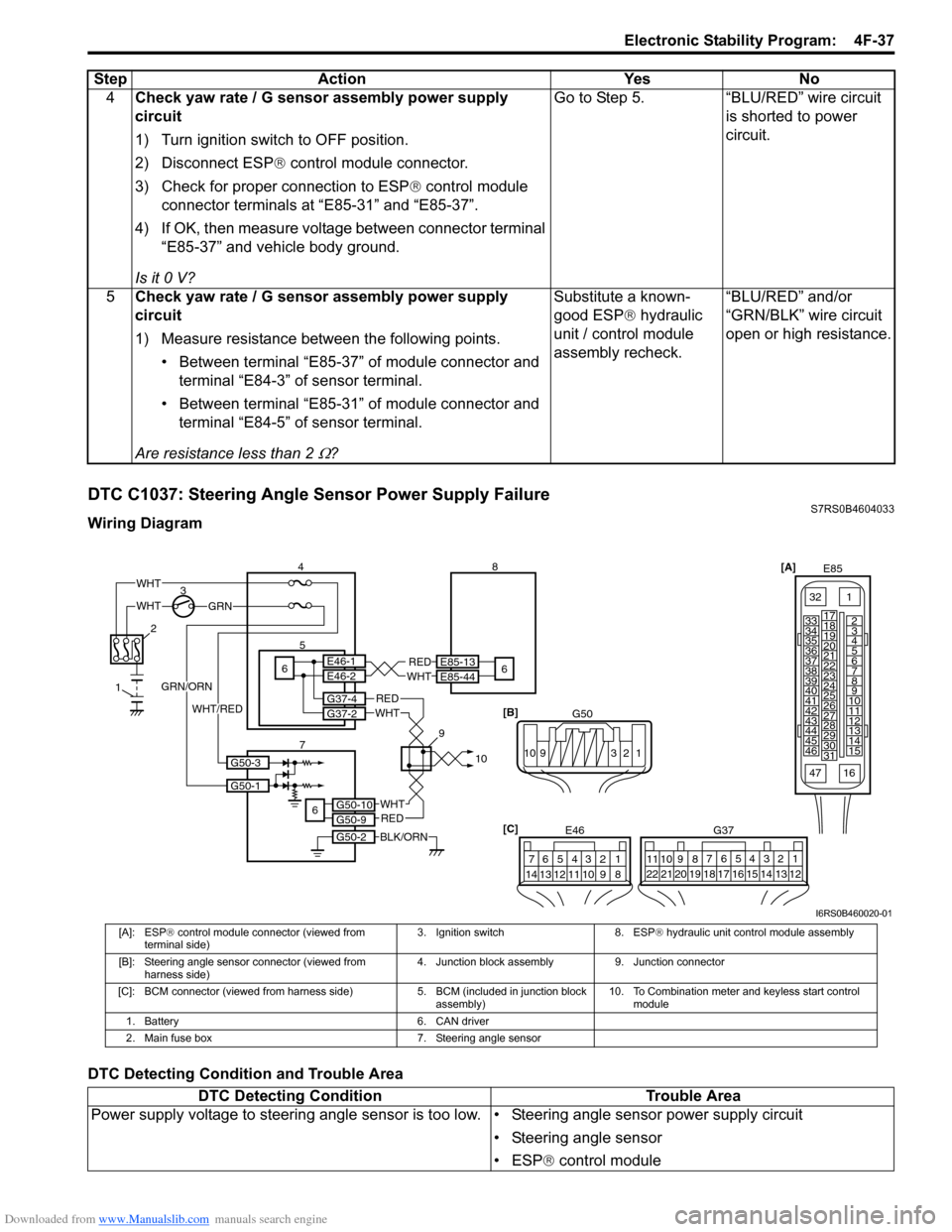

DTC C1037: Steering Angle Sensor Power Supply FailureS7RS0B4604033

Wiring Diagram

DTC Detecting Condition and Trouble Area4

Check yaw rate / G sensor assembly power supply

circuit

1) Turn ignition switch to OFF position.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector terminals at “E85-31” and “E85-37”.

4) If OK, then measure voltage between connector terminal “E85-37” and vehicle body ground.

Is it 0 V? Go to Step 5. “BLU/RED” wire circuit

is shorted to power

circuit.

5 Check yaw rate / G sensor assembly power supply

circuit

1) Measure resistance between the following points.

• Between terminal “E85-37” of module connector and terminal “E84-3” of sensor terminal.

• Between terminal “E85-31” of module connector and terminal “E84-5” of sensor terminal.

Are resistance less than 2

Ω? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly recheck. “BLU/RED” and/or

“GRN/BLK” wire circuit

open or high resistance.

Step

Action YesNo

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[C] G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

WHTGRN

3

E85-13

E85-44REDWHT65E46-1E46-2

4 8

6

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G50-10G50-9

G50-2

6

2

1

7 910

G50-1

G50-3

GRN/ORN

WHT/RED

WHT

[B]

G50

109 321

I6RS0B460020-01

[A]: ESP® control module connector (viewed from

terminal side) 3. Ignition switch 8. ESP

® hydraulic unit control module assembly

[B]: Steering angle sensor connector (viewed from harness side) 4. Junction block assembly 9. Junction connector

[C]: BCM connector (viewed from harnes s side) 5. BCM (included in junction block

assembly) 10. To Combination meter and keyless start control

module

1. Battery 6. CAN driver

2. Main fuse box 7. Steering angle sensor

DTC Detecting Condition Trouble Area

Power supply voltage to steering angle sensor is to o low. • Steering angle sensor power supply circuit

• Steering angle sensor

• ESP® control module

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 654 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-10 Automatic Transmission/Transaxle:

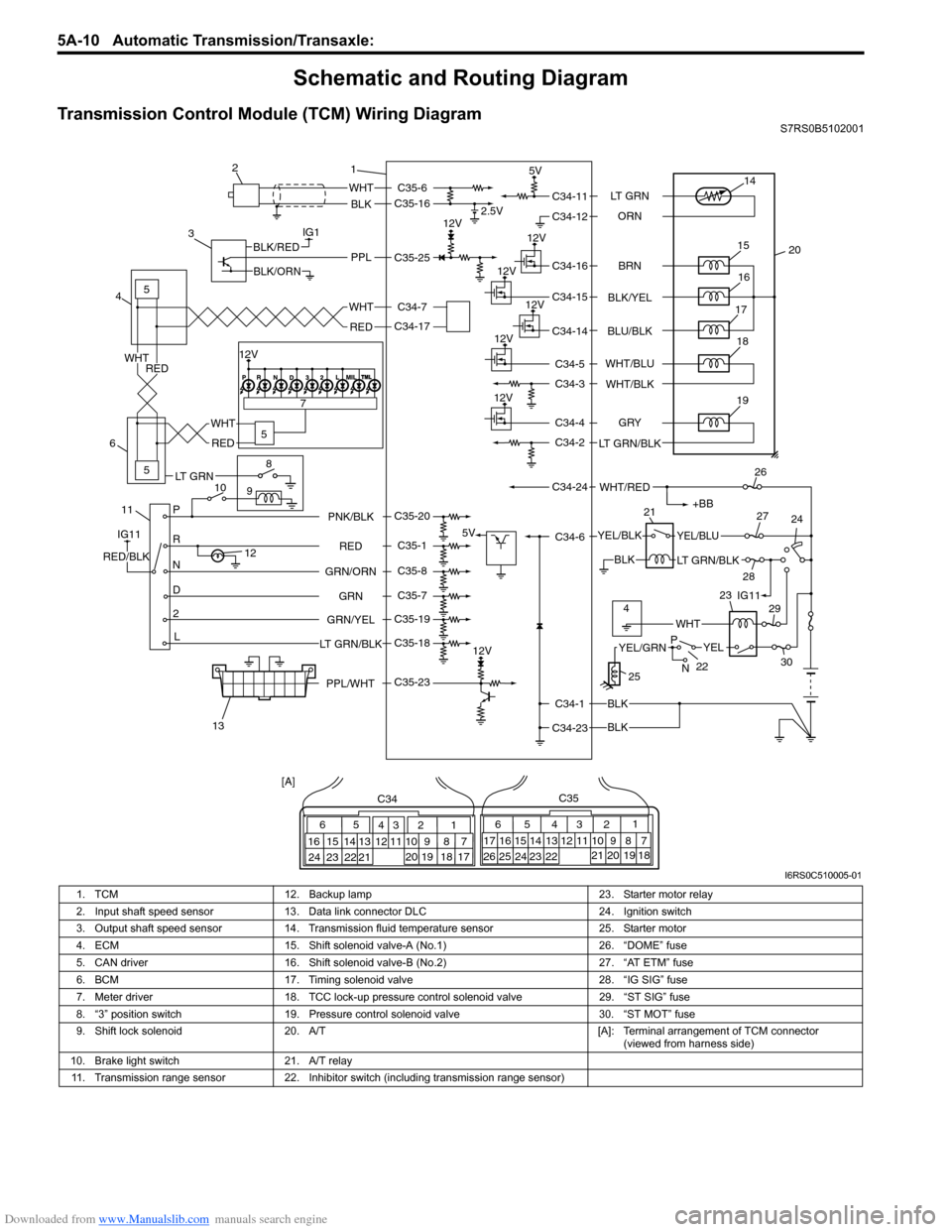

Schematic and Routing Diagram

Transmission Control Module (TCM) Wiring DiagramS7RS0B5102001

IG1

115

5

5

8

9

10 7

P

R

N

D

2

L

12

12V 2.5V

5V

12V

5V

12V

12V

12V

12V

WHT

BLK

BLK

BLK

BLK

PPLBLK/RED

BLK/ORN

IG11

RED/BLK

YEL/BLKYEL/BLU

LT GRN/BLK

+BB

WHT/RED

14

20

15

16

17

19

12V18

1

2

3

4

6

13 21

26

24

27

28 29

30

WHT

WHT

RED

RED

WHT

RED

65

16 15 14 13 12 11 43

24 23 2122 10 9 8 721

1920 18 17

C34

17 16

26 25

15 14

65 3

42

13 12

23 2224 11 10 9

21 20 19 87

18

1

C35

[A]

22

25

YELYEL/GRN

WHT

P

N

BRN

LT GRN

ORN

BLK/YEL

BLU/BLK

GRY

LT GRN/BLK WHT/BLU

WHT/BLK

C34-11

C34-12

C34-16

C34-15

C34-14

C34-4

C34-2

C34-1

C34-23 C34-6

C34-24 C34-5

C34-3

RED

GRN

GRN/ORN PNK/BLK

GRN/YEL

LT GRN/BLKC35-6

C35-16

C35-23 C35-25

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18 C34-17 C34-7

4IG11

12V

23

PPL/WHT

LT GRN

I6RS0C510005-01

1. TCM 12. Backup lamp 23. Starter motor relay

2. Input shaft speed sensor 13. Data link connector DLC 24. Ignition switch

3. Output shaft speed sensor 14. Transmission fluid temperature sensor 25. Starter motor

4. ECM 15. Shift solenoid valve-A (No.1) 26. “DOME” fuse

5. CAN driver 16. Shift solenoid valve-B (No.2) 27. “AT ETM” fuse

6. BCM 17. Timing solenoid valve 28. “IG SIG” fuse

7. Meter driver 18. TCC lock-up pressure control solenoid valve 29. “ST SIG” fuse

8. “3” position switch 19. Pressure control solenoid valve 30. “ST MOT” fuse

9. Shift lock solenoid 20. A/T [A]: Terminal arrangement of TCM connector

(viewed from harness side)

10. Brake light switch 21. A/T relay

11. Transmission range sensor 22. Inhibitor switch (including transmission range sensor)

Page 664 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-20 Automatic Transmission/Transaxle:

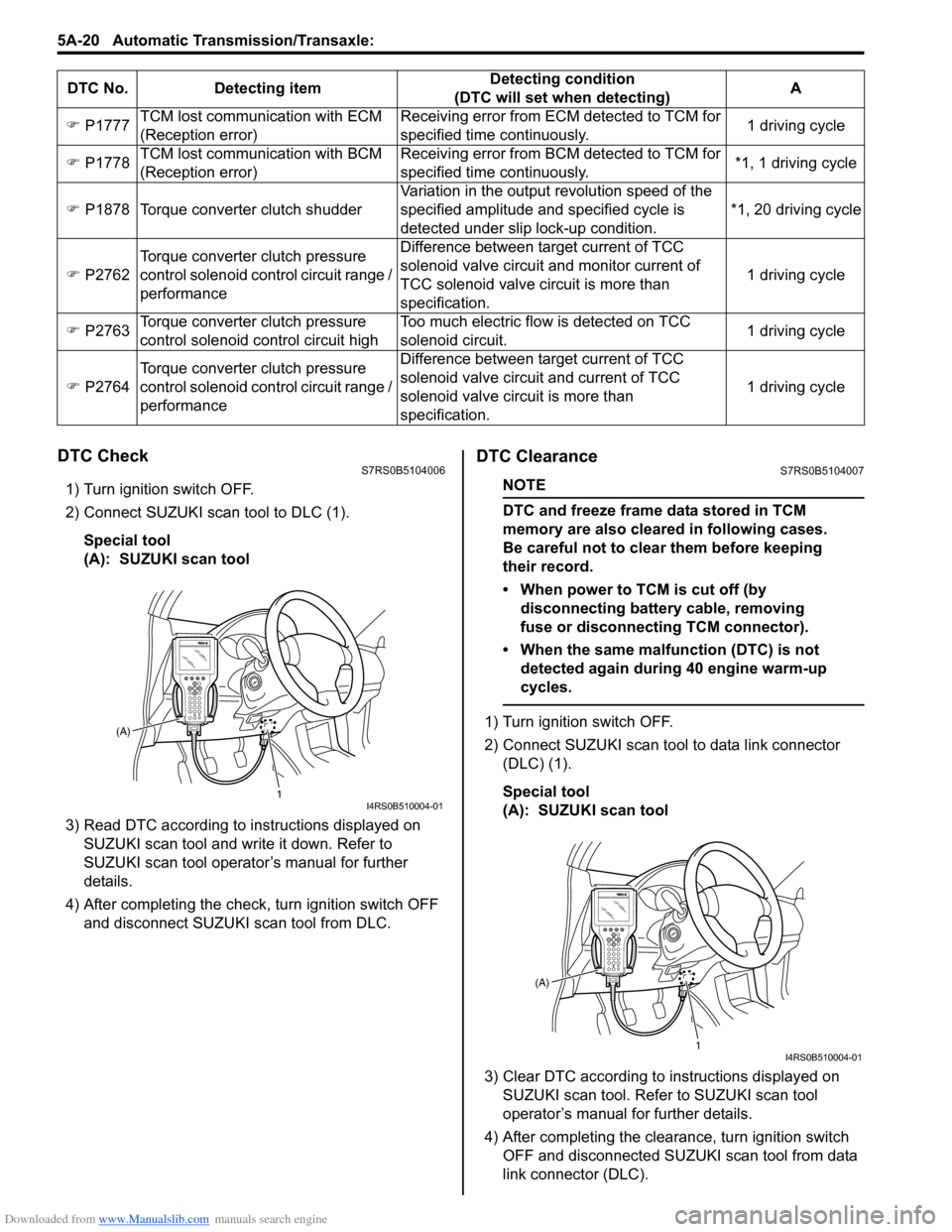

DTC CheckS7RS0B5104006

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to DLC (1).

Special tool

(A): SUZUKI scan tool

3) Read DTC according to instructions displayed on SUZUKI scan tool and wr ite it down. Refer to

SUZUKI scan tool operator’s manual for further

details.

4) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from DLC.

DTC ClearanceS7RS0B5104007

NOTE

DTC and freeze frame data stored in TCM

memory are also cleared in following cases.

Be careful not to clear them before keeping

their record.

• When power to TCM is cut off (by disconnecting battery cable, removing

fuse or disconnecting TCM connector).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles.

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to data link connector (DLC) (1).

Special tool

(A): SUZUKI scan tool

3) Clear DTC according to instructions displayed on SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

4) After completing the clearance, turn ignition switch OFF and disconnected SUZUKI scan tool from data

link connector (DLC).

�)

P1777 TCM lost communication with ECM

(Reception error) Receiving error from ECM detected to TCM for

specified time continuously.

1 driving cycle

�) P1778 TCM lost communication with BCM

(Reception error) Receiving error from BCM detected to TCM for

specified time continuously.

*1, 1 driving cycle

�) P1878 Torque converter clutch shudder Variation in the output revolution speed of the

specified amplitude and specified cycle is

detected under slip lock-up condition. *1, 20 driving cycle

�) P2762 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and monitor current of

TCC solenoid valve ci

rcuit is more than

specification. 1 driving cycle

�) P2763 Torque converter clutch pressure

control solenoid control circuit high Too much electric flow is detected on TCC

solenoid circuit.

1 driving cycle

�) P2764 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and current of TCC

solenoid valve circuit is more than

specification.

1 driving cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting) A

1

(A)I4RS0B510004-01

1

(A)I4RS0B510004-01

Page 886 of 1496

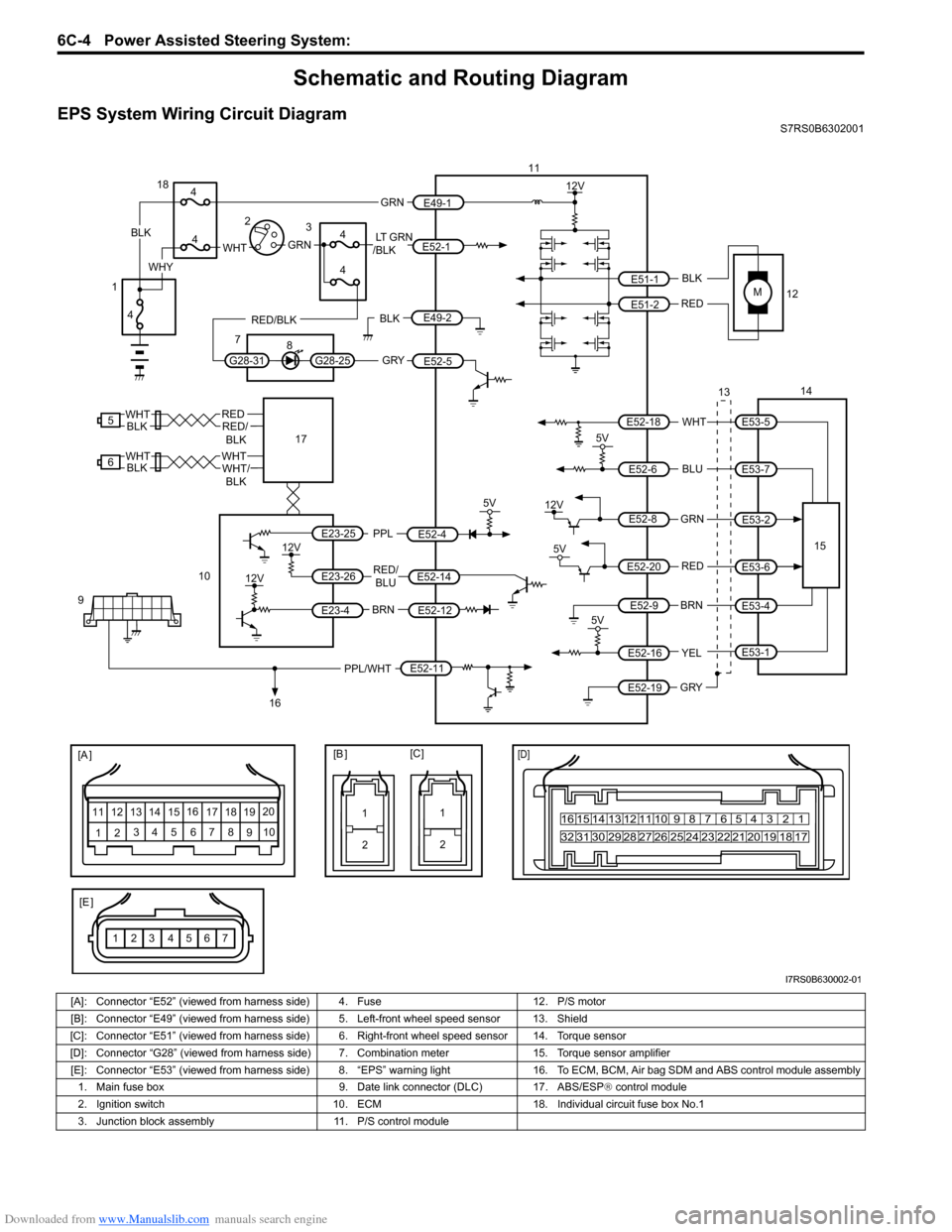

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS7RS0B6302001

M

5V

BRNRED/

BLU

BLK

RED

WHT

BLU

GRN

BRN YEL

E52-11

E52-14E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

PPL/WHT

[A ]

[E ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ][C ]

1210 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[D]

5V

PPL

E52-4

11

12

13 14

15

10

9

16

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

7654321

5

REDRED/

BLKWHT

6WHTWHT/BLKWHTBLK

12V

12V

17BLK

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

18

3

4

4

7 8

4

4

1 2

4

E49-2BLK

I7RS0B630002-01

[A]: Connector “E52” (viewed from harness side) 4. Fuse 12. P/S motor

[B]: Connector “E49” (viewed from harness side ) 5. Left-front wheel speed sensor 13. Shield

[C]: Connector “E51” (viewed from harness side) 6 . Right-front wheel speed sensor 14. Torque sensor

[D]: Connector “G28” (viewed from harness side) 7. Combination meter 15. Torque sensor amplifier

[E]: Connector “E53” (viewed from harness side) 8. “EPS” warning light16. To ECM, BCM, Air bag SDM and ABS control module assembly

1. Main fuse box 9. Date link connector (DLC) 17. ABS/ESP ® control module

2. Ignition switch 10. ECM18. Individual circuit fuse box No.1

3. Junction block assembly 11. P/S control module