Head gasket SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

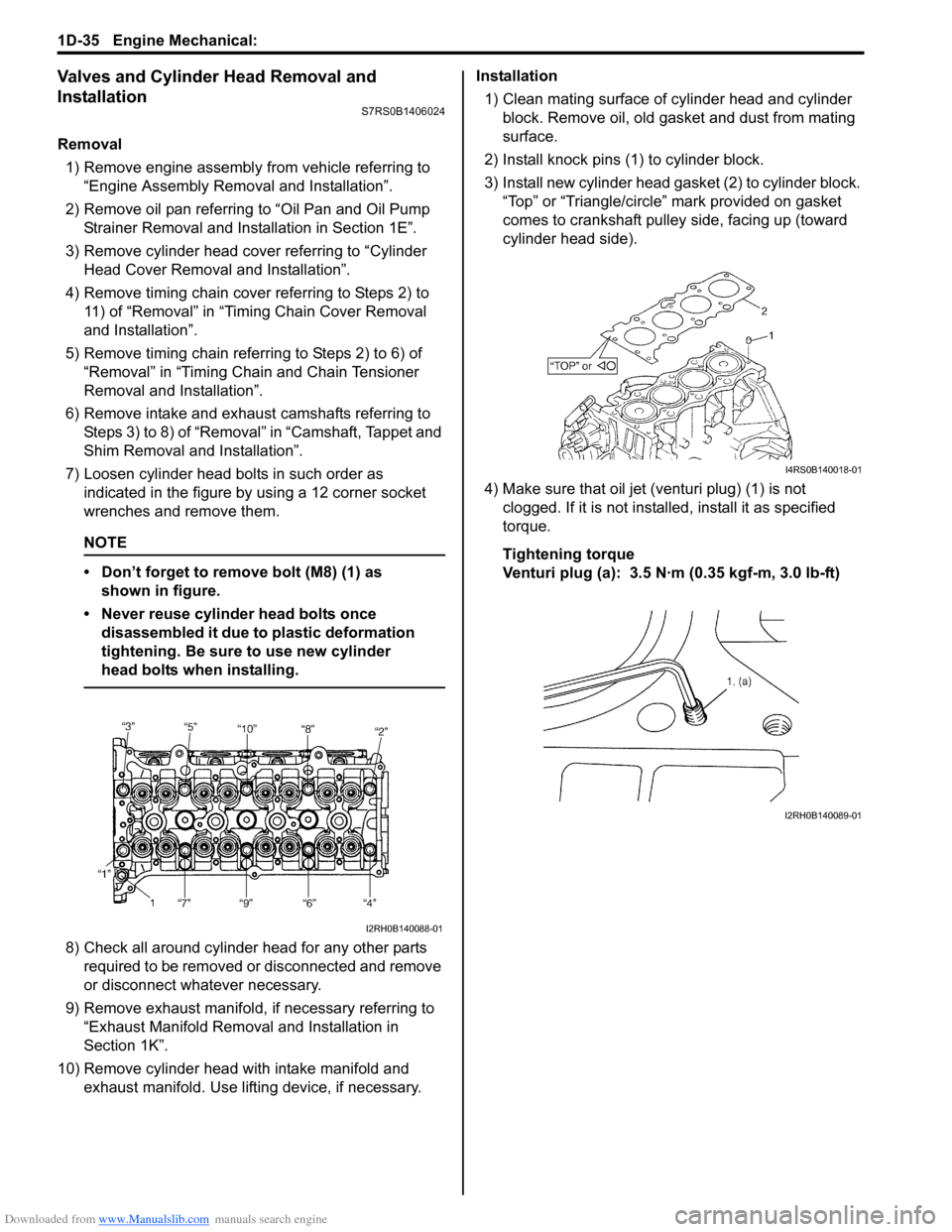

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

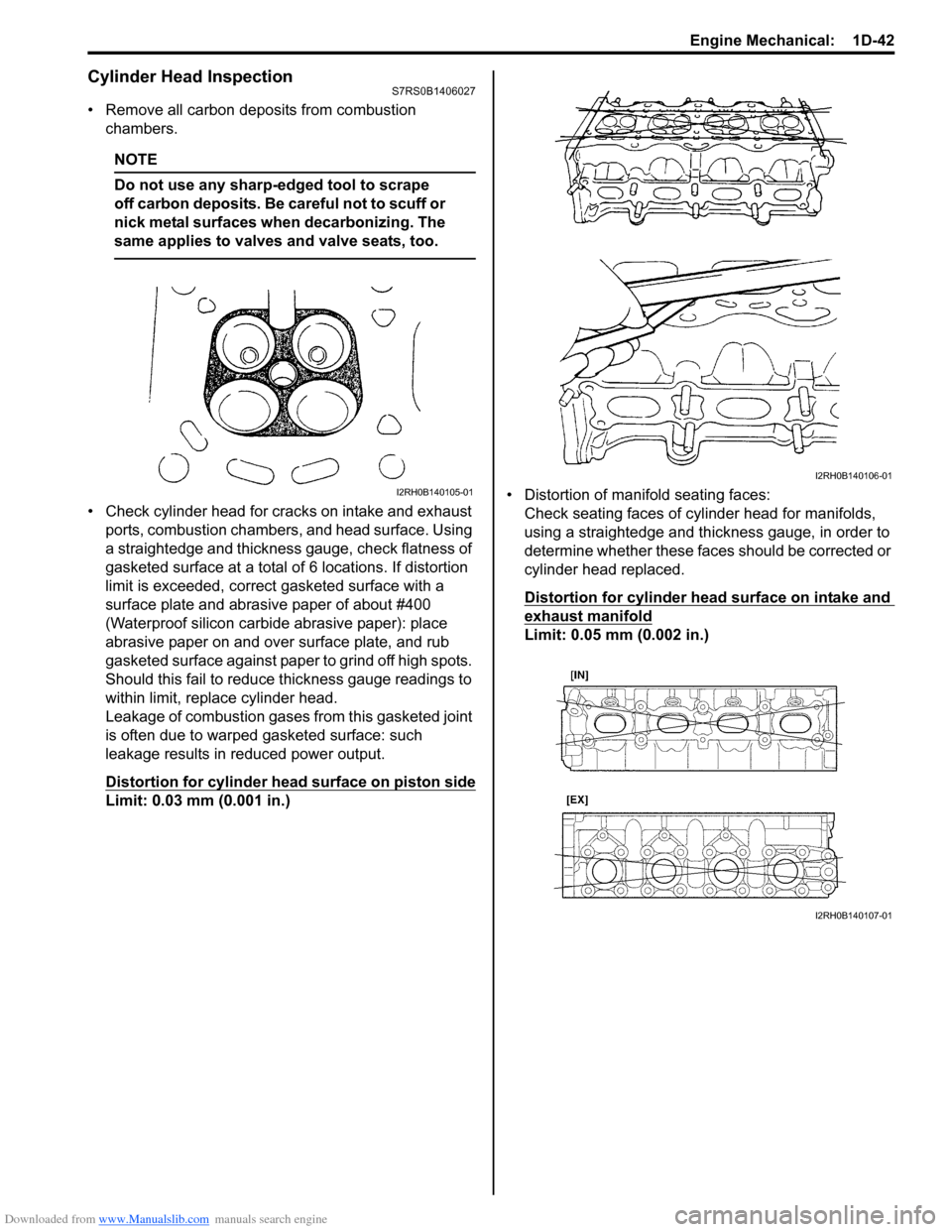

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01

Page 327 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-42

Cylinder Head InspectionS7RS0B1406027

• Remove all carbon deposits from combustion chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.

Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.) • Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 368 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-5 Engine Cooling System:

Repair Instructions

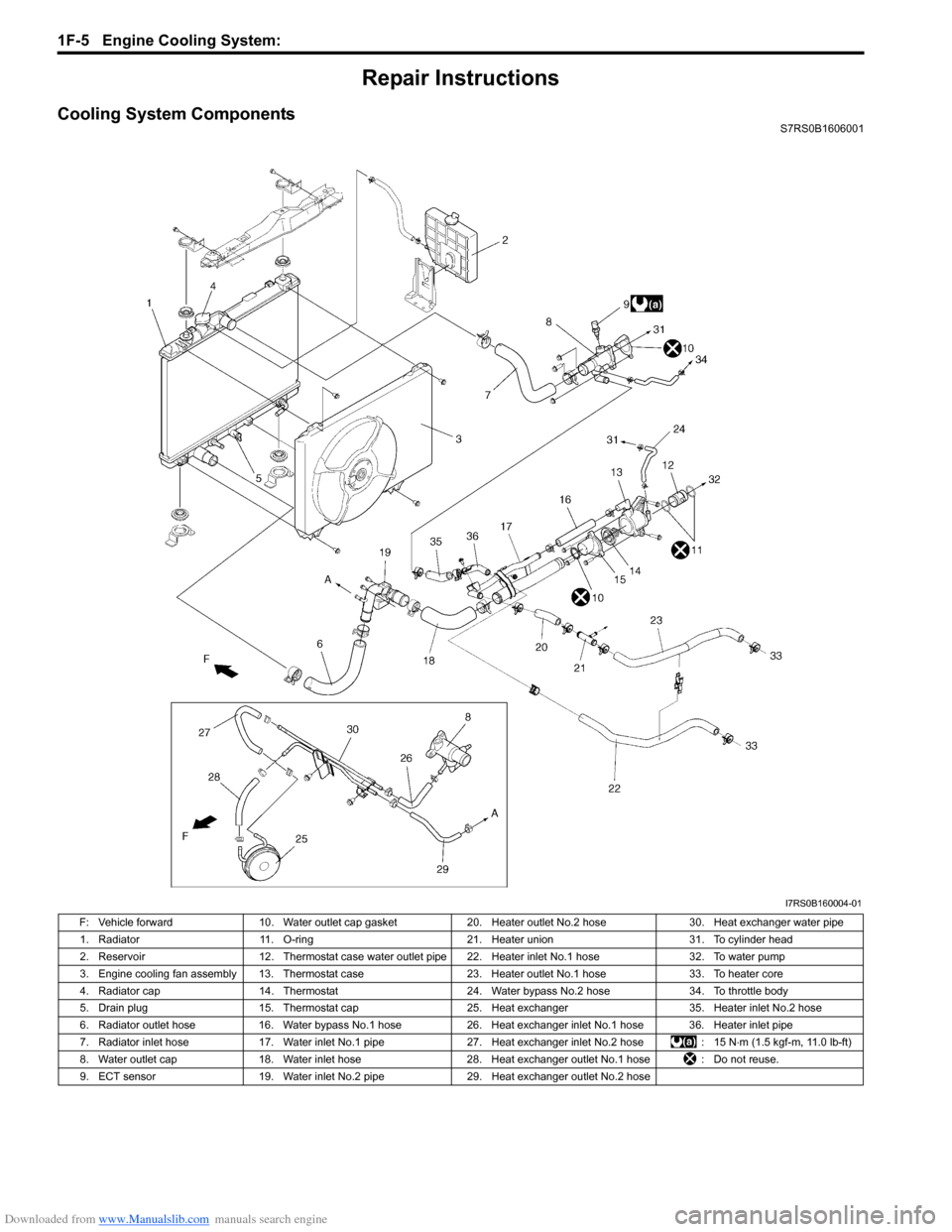

Cooling System ComponentsS7RS0B1606001

I7RS0B160004-01

F: Vehicle forward10. Water outlet cap gasket 20. Heater outlet No.2 hose 30. Heat exchanger water pipe

1. Radiator 11. O-ring 21. Heater union 31. To cylinder head

2. Reservoir 12. Thermostat case water outlet pipe 22. Heater inlet No.1 hose 32. To water pump

3. Engine cooling fan assembly 13. Thermostat case 23. Heater outlet No.1 hose33. To heater core

4. Radiator cap 14. Thermostat 24. Water bypass No.2 hose 34. To throttle body

5. Drain plug 15. Thermostat cap 25. Heat exchanger 35. Heater inlet No.2 hose

6. Radiator outlet hose 16. Water bypass No.1 hose 26.Heat exchanger inlet No.1 hose 36. Heater inlet pipe

7. Radiator inlet hose 17. Water inlet No.1 pipe 27. Heat exchanger inlet No.2 hose : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

8. Water outlet cap 18. Water inlet hose 28. Heat exchanger outlet No.1 hose : Do not reuse.

9. ECT sensor 19. Water inlet No.2 pipe 29. Heat exchanger outlet No.2 hose

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

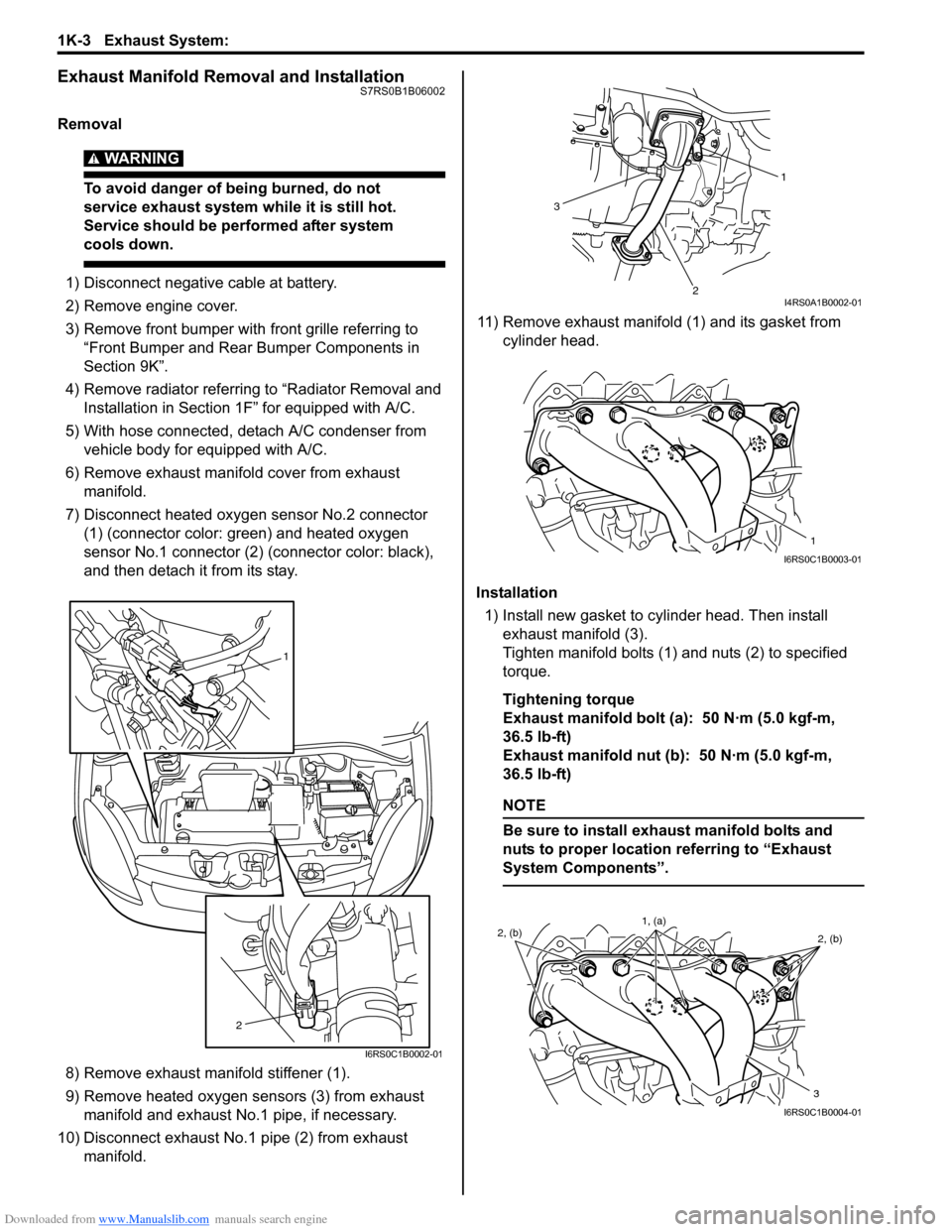

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01