back up light switch SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 822 of 1496

![SUZUKI SWIFT 2006 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

( SUZUKI SWIFT 2006 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

(](/img/20/7607/w960_7607-821.png)

Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

(b)3

9

9

(b)

(d)

I6RS0C520004-03

[A]: Forward

7. Engine left mounting bracket bolt and nuts 14. Clutch operating cylinder bolt

1. Engine 8. Clutch housing lower plate : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

2. Transaxle 9. Engine rear mounting bracket bolts : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

3. Engine rear mounting and bracket 10. Transaxle to engine nut : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Back up light switch connector 11. Ground cable : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

5. Clutch operating cylinder 12. Engine left mounting bracket

6. Transaxle to engine bolt 13. Gear shift & select control cables

Page 823 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

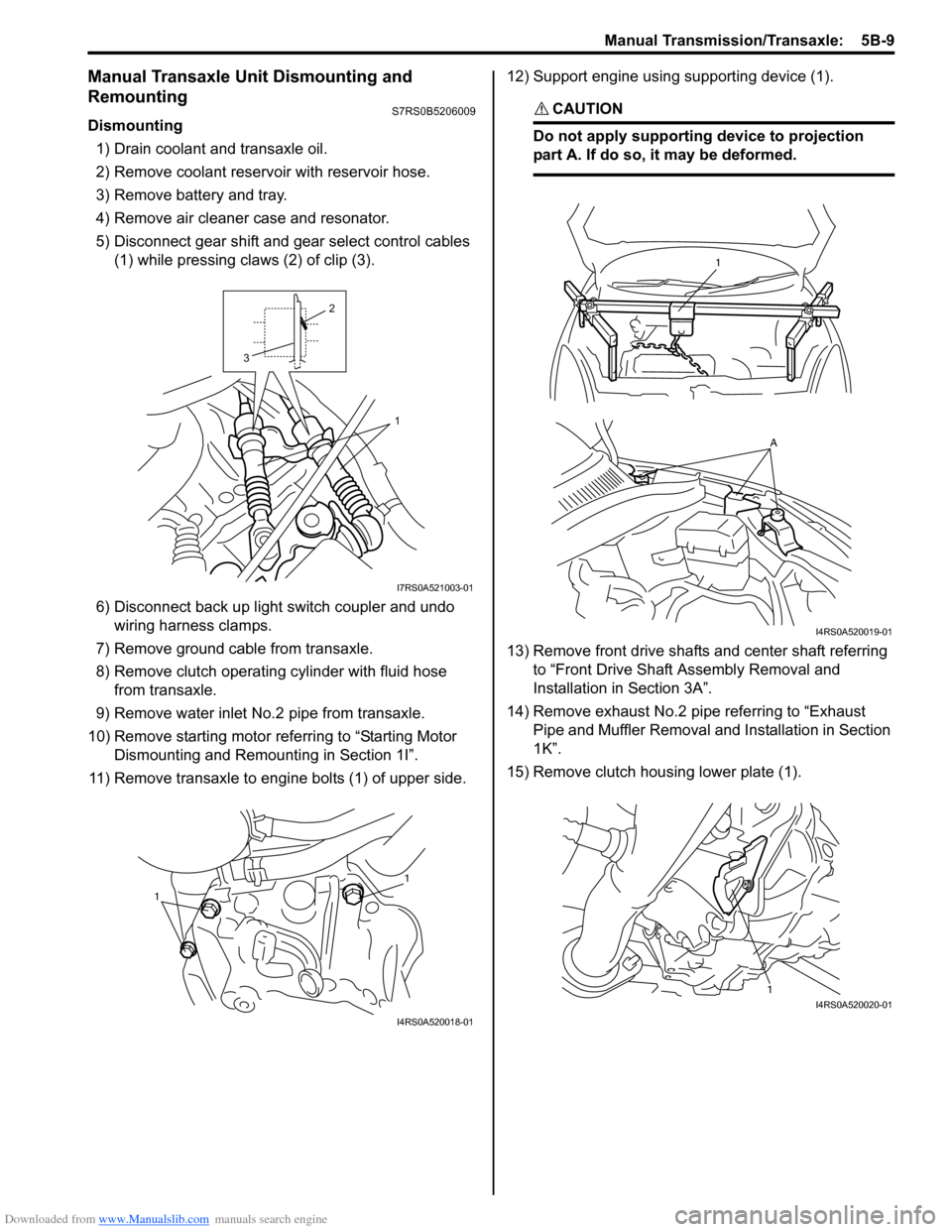

Manual Transaxle Unit Dismounting and

Remounting

S7RS0B5206009

Dismounting1) Drain coolant and transaxle oil.

2) Remove coolant reservoir with reservoir hose.

3) Remove battery and tray.

4) Remove air cleaner case and resonator.

5) Disconnect gear shift and gear select control cables (1) while pressing claws (2) of clip (3).

6) Disconnect back up light switch coupler and undo wiring harness clamps.

7) Remove ground cable from transaxle.

8) Remove clutch operating cylinder with fluid hose from transaxle.

9) Remove water inlet No.2 pipe from transaxle.

10) Remove starting motor re ferring to “Starting Motor

Dismounting and Remounting in Section 1I”.

11) Remove transaxle to engine bolts (1) of upper side. 12) Support engine using supporting device (1).

CAUTION!

Do not apply supporting device to projection

part A. If do so, it may be deformed.

13) Remove front drive shafts and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

14) Remove exhaust No.2 pipe referring to “Exhaust Pipe and Muffler Removal a nd Installation in Section

1K”.

15) Remove clutch housing lower plate (1).

1

2

3

I7RS0A521003-01

1

1

I4RS0A520018-01

1

A

I4RS0A520019-01

1I4RS0A520020-01

Page 827 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-13

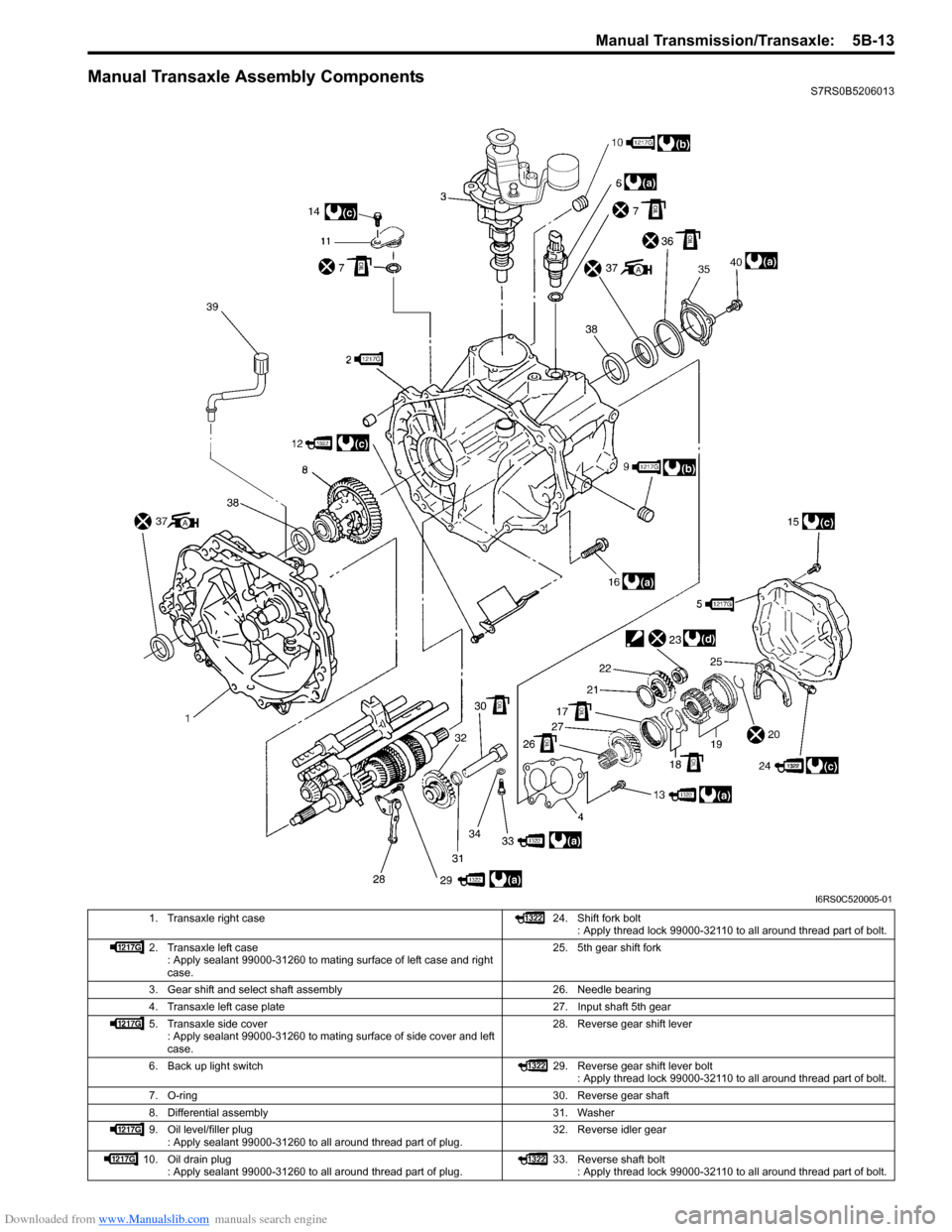

Manual Transaxle Assembly ComponentsS7RS0B5206013

I6RS0C520005-01

1. Transaxle right case 24. Shift fork bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

2. Transaxle left case : Apply sealant 99000-31260 to mating surface of left case and right

case. 25. 5th gear shift fork

3. Gear shift and select shaft assembly 26. Needle bearing

4. Transaxle left case plate 27. Input shaft 5th gear

5. Transaxle side cover : Apply sealant 99000-31260 to mating surface of side cover and left

case. 28. Reverse gear shift lever

6. Back up light switch 29. Reverse gear shift lever bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

7. O-ring 30. Reverse gear shaft

8. Differential assembly 31. Washer

9. Oil level/filler plug : Apply sealant 99000-31260 to all around thread part of plug. 32. Reverse idler gear

10. Oil drain plug : Apply sealant 99000-31260 to all around thread part of plug. 33. Reverse shaft bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

Page 831 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-17

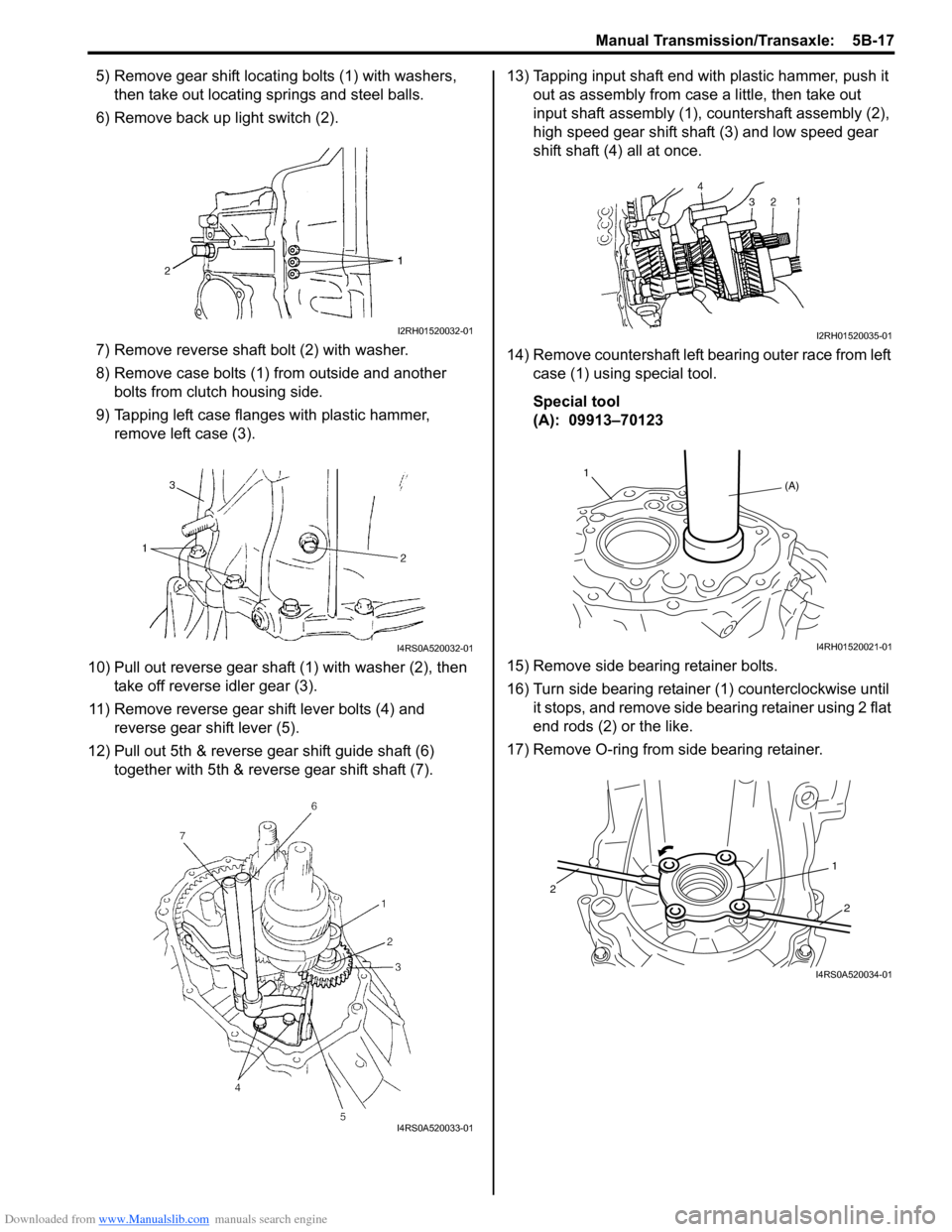

5) Remove gear shift locating bolts (1) with washers,

then take out locating springs and steel balls.

6) Remove back up light switch (2).

7) Remove reverse shaft bolt (2) with washer.

8) Remove case bolts (1) from outside and another bolts from clutch housing side.

9) Tapping left case flanges with plastic hammer, remove left case (3).

10) Pull out reverse gear shaft (1) with washer (2), then take off reverse idler gear (3).

11) Remove reverse gear shift lever bolts (4) and reverse gear shift lever (5).

12) Pull out 5th & reverse gear shift guide shaft (6) together with 5th & reverse gear shift shaft (7). 13) Tapping input shaft end with plastic hammer, push it

out as assembly from case a little, then take out

input shaft assembly (1), countershaft assembly (2),

high speed gear shift shaft (3) and low speed gear

shift shaft (4) all at once.

14) Remove countershaft left bearing outer race from left case (1) using special tool.

Special tool

(A): 09913–70123

15) Remove side bearing retainer bolts.

16) Turn side bearing retainer (1) counterclockwise until it stops, and remove side bearing retainer using 2 flat

end rods (2) or the like.

17) Remove O-ring from side bearing retainer.

I2RH01520032-01

I4RS0A520032-01

I4RS0A520033-01

I2RH01520035-01

(A)

1

I4RH01520021-01

1

2

2

I4RS0A520034-01

Page 836 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-22 Manual Transmission/Transaxle:

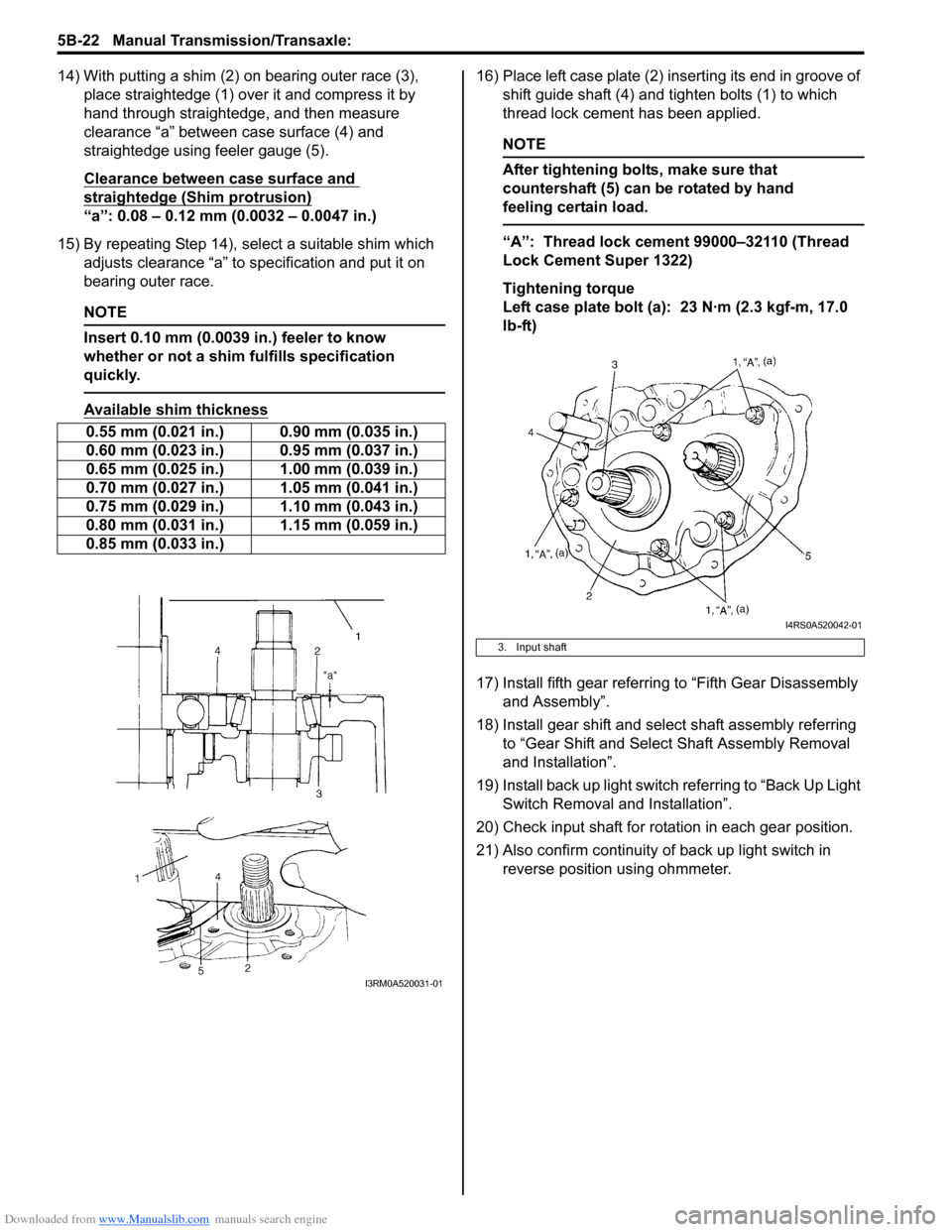

14) With putting a shim (2) on bearing outer race (3), place straightedge (1) over it and compress it by

hand through straightedge, and then measure

clearance “a” between case surface (4) and

straightedge using feeler gauge (5).

Clearance between case surface and

straightedge (Shim protrusion)

“a”: 0.08 – 0.12 mm (0.0032 – 0.0047 in.)

15) By repeating Step 14), select a suitable shim which adjusts clearance “a” to specification and put it on

bearing outer race.

NOTE

Insert 0.10 mm (0.0039 in.) feeler to know

whether or not a shim fulfills specification

quickly.

Available shim thickness

16) Place left case plate (2) inserting its end in groove of shift guide shaft (4) and tighten bolts (1) to which

thread lock cement has been applied.

NOTE

After tightening bolts, make sure that

countershaft (5) can be rotated by hand

feeling certain load.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Left case plate bolt (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

17) Install fifth gear referring to “Fifth Gear Disassembly and Assembly”.

18) Install gear shift and select shaft assembly referring to “Gear Shift and Select Shaft Assembly Removal

and Installation”.

19) Install back up light switch referring to “Back Up Light

Switch Removal and Installation”.

20) Check input shaft for rotation in each gear position.

21) Also confirm continuity of back up light switch in

reverse position using ohmmeter.

0.55 mm (0.021 in.) 0.90 mm (0.035 in.)

0.60 mm (0.023 in.) 0.95 mm (0.037 in.)

0.65 mm (0.025 in.) 1.00 mm (0.039 in.)

0.70 mm (0.027 in.) 1.05 mm (0.041 in.)

0.75 mm (0.029 in.) 1.10 mm (0.043 in.)

0.80 mm (0.031 in.) 1.15 mm (0.059 in.)

0.85 mm (0.033 in.)

I3RM0A520031-01

3. Input shaft

I4RS0A520042-01

Page 849 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-35

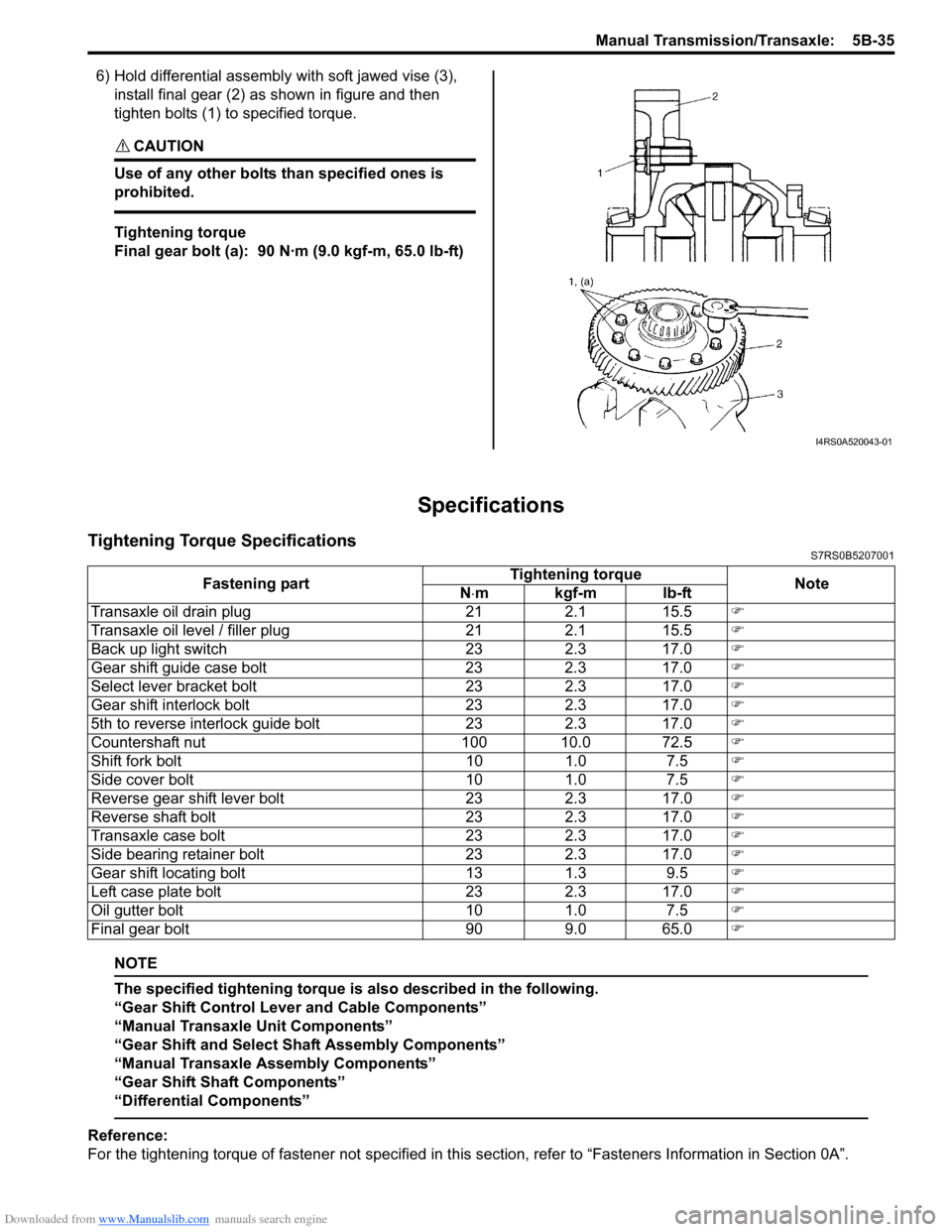

6) Hold differential assembly with soft jawed vise (3),

install final gear (2) as shown in figure and then

tighten bolts (1) to specified torque.

CAUTION!

Use of any other bolts than specified ones is

prohibited.

Tightening torque

Final gear bolt (a): 90 N·m (9.0 kgf-m, 65.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B5207001

NOTE

The specified tightening torque is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Manual Transaxle Unit Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Gear Shift Shaft Components”

“Differential Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A520043-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Transaxle oil drain plug 21 2.1 15.5 �)

Transaxle oil level / filler plug 21 2.1 15.5 �)

Back up light switch 23 2.3 17.0 �)

Gear shift guide case bolt 23 2.3 17.0 �)

Select lever bracket bolt 23 2.3 17.0 �)

Gear shift interlock bolt 23 2.3 17.0 �)

5th to reverse interlock guide bolt 23 2.3 17.0 �)

Countershaft nut 100 10.0 72.5 �)

Shift fork bolt 10 1.0 7.5 �)

Side cover bolt 10 1.0 7.5 �)

Reverse gear shift lever bolt 23 2.3 17.0 �)

Reverse shaft bolt 23 2.3 17.0 �)

Transaxle case bolt 23 2.3 17.0 �)

Side bearing retainer bolt 23 2.3 17.0 �)

Gear shift locating bolt 13 1.3 9.5 �)

Left case plate bolt 23 2.3 17.0 �)

Oil gutter bolt 10 1.0 7.5 �)

Final gear bolt 90 9.0 65.0 �)

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

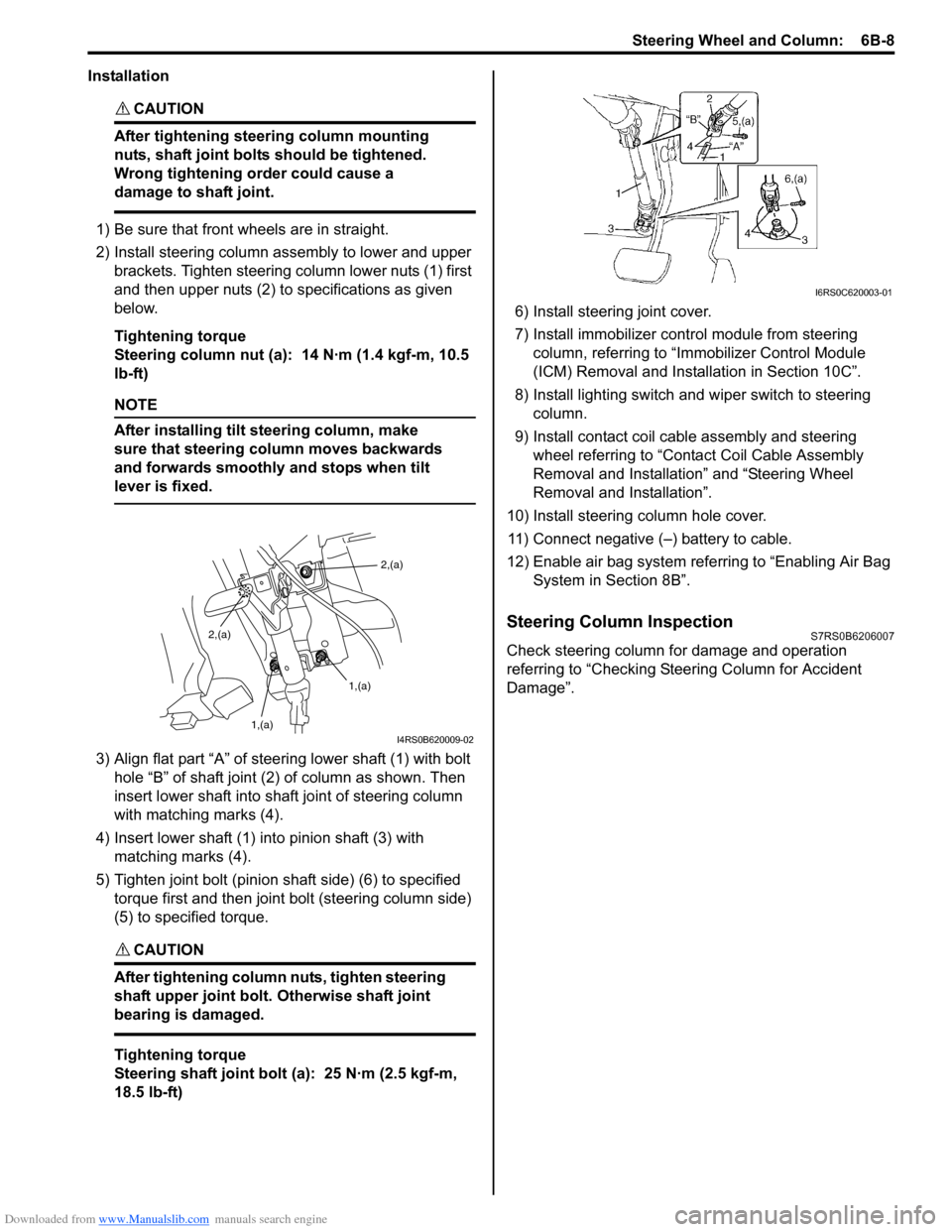

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01

Page 987 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

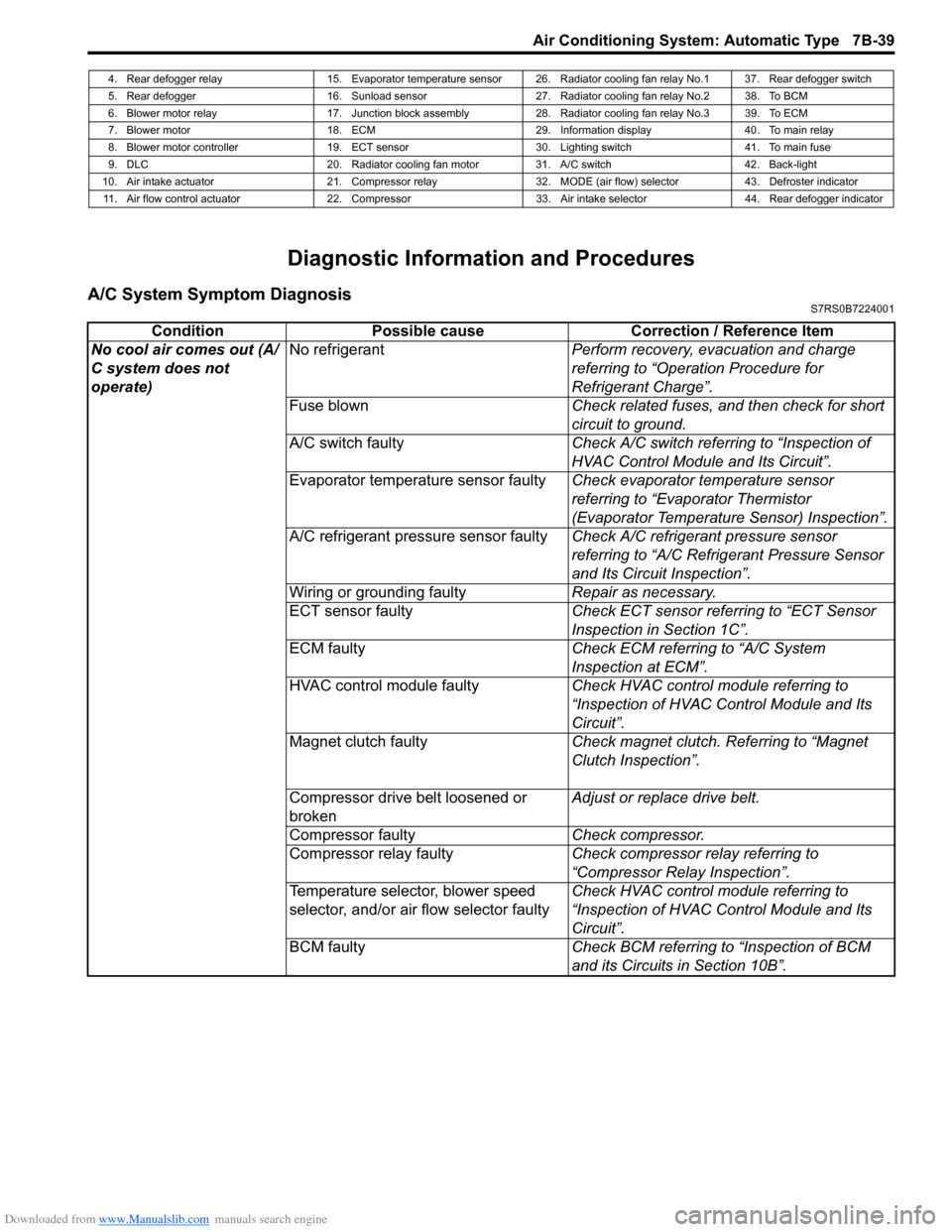

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 992 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-44 Air Conditioning System: Automatic Type

3) Light over sunload sensor vertically with an incandescent lamp approximately 100 W apart from

about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

4) Turn ignition switch to ON position.

5) Erase DTC according to instructions displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the clearance, turn ignition switch to OFF position, and then di sconnect SUZUKI scan

tool from DLC.

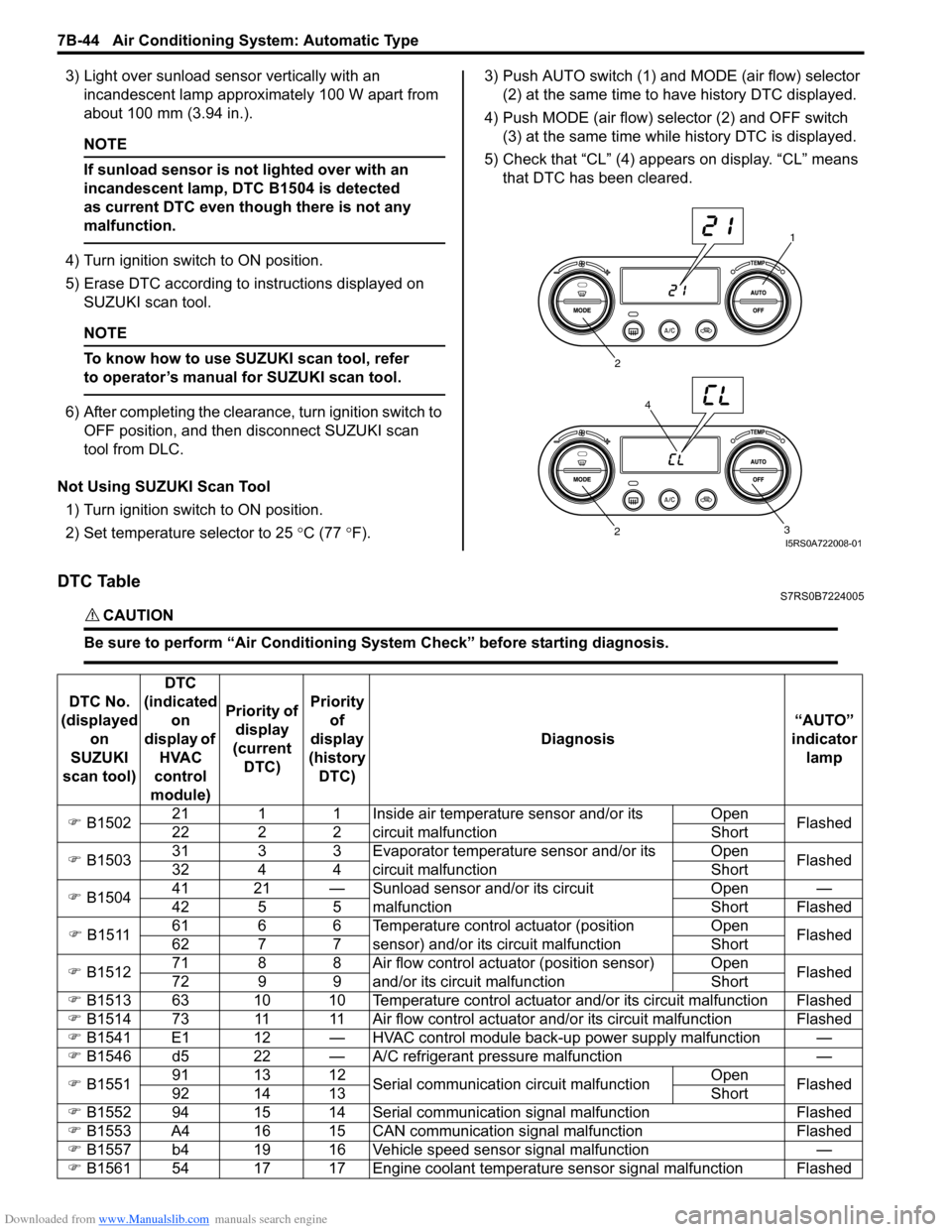

Not Using SUZUKI Scan Tool 1) Turn ignition switch to ON position.

2) Set temperature selector to 25 °C (77 °F). 3) Push AUTO switch (1) and

MODE (air flow) selector

(2) at the same time to have history DTC displayed.

4) Push MODE (air flow) selector (2) and OFF switch (3) at the same time while history DTC is displayed.

5) Check that “CL” (4) appears on display. “CL” means that DTC has been cleared.

DTC TableS7RS0B7224005

CAUTION!

Be sure to perform “Air Conditioning Sy stem Check” before starting diagnosis.

1

2

3

2

4

I5RS0A722008-01

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

�) B1502 21 1 1 Inside air temperature sensor and/or its

circuit malfunction Open

Flashed

22 2 2 Short

�) B1503 31 3 3 Evaporator temperature sensor and/or its

circuit malfunction Open

Flashed

32 4 4 Short

�) B1504 41 21 — Sunload sensor and/or its circuit

malfunction Open —

42 5 5 Short Flashed

�) B1511 61 6 6 Temperature control actuator (position

sensor) and/or its circuit malfunction Open

Flashed

62 7 7 Short

�) B1512 71 8 8 Air flow control actuator (position sensor)

and/or its circuit malfunction Open

Flashed

72 9 9 Short

�) B1513 63 10 10 Temperature control actuator and/or its circuit malfunction Flashed

�) B1514 73 11 11 Air flow control actuator and/or its circuit malfunction Flashed

�) B1541 E1 12 — HVAC control module back-up power supply malfunction —

�) B1546 d5 22 — A/C refrigerant pressure malfunction —

�) B1551 91 13 12

Serial communication circuit malfunction Open

Flashed

92 14 13 Short

�) B1552 94 15 14 Serial communication signal malfunction Flashed

�) B1553 A4 16 15 CAN communication signal malfunction Flashed

�) B1557 b4 19 16 Vehicle speed sensor signal malfunction —

�) B1561 54 17 17 Engine coolant temperature sensor signal malfunction Flashed

Page 1016 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-68 Air Conditioning System: Automatic Type

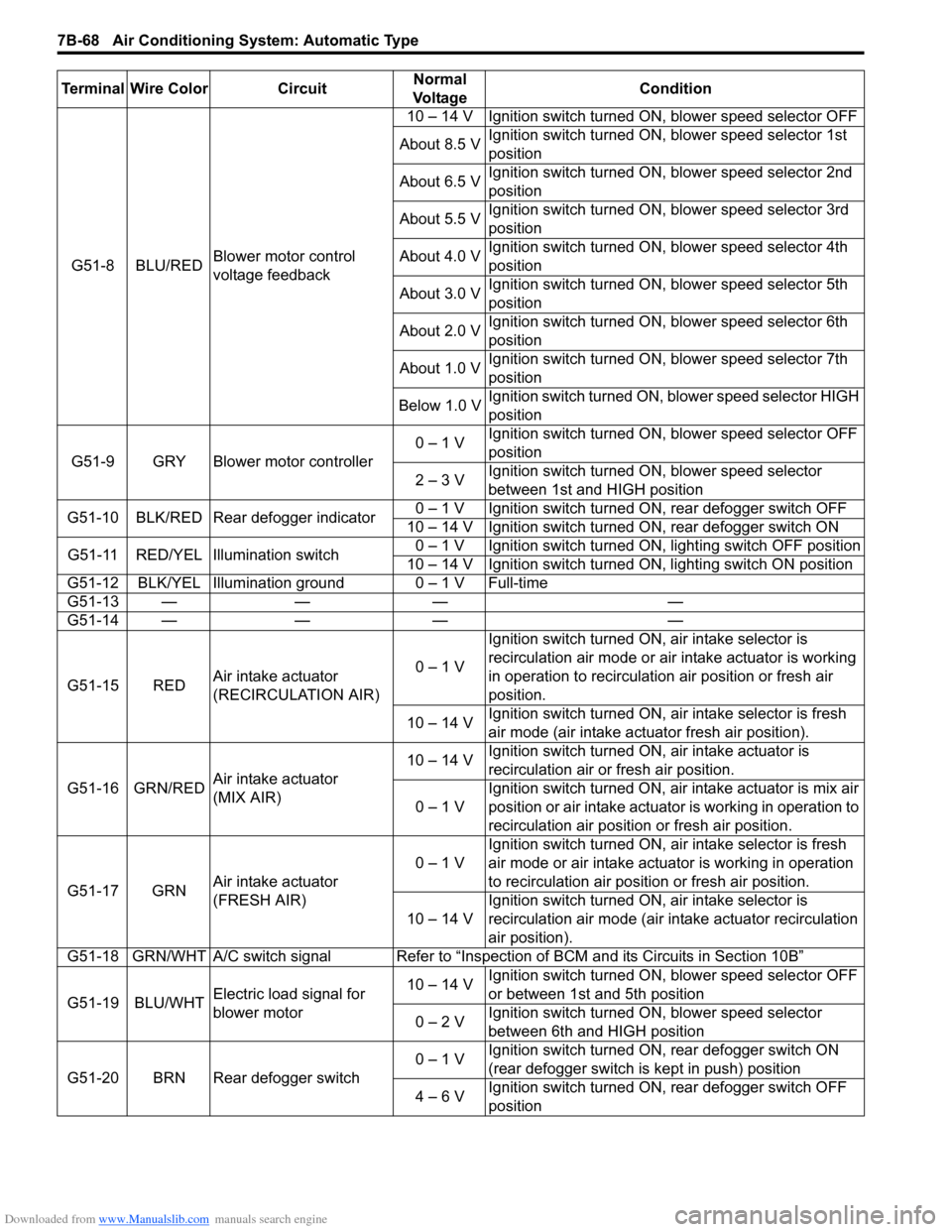

G51-8 BLU/REDBlower motor control

voltage feedback 10 – 14 V Ignition switch turned ON, blower speed selector OFF

About 8.5 V Ignition switch turned ON, blower speed selector 1st

position

About 6.5 V Ignition switch turned ON, blower speed selector 2nd

position

About 5.5 V Ignition switch turned ON, blower speed selector 3rd

position

About 4.0 V Ignition switch turned ON, blower speed selector 4th

position

About 3.0 V Ignition switch turned ON, blower speed selector 5th

position

About 2.0 V Ignition switch turned ON, blower speed selector 6th

position

About 1.0 V Ignition switch turned ON, blower speed selector 7th

position

Below 1.0 V Ignition switch turned ON, blower speed selector HIGH

position

G51-9 GRY Blower motor controller 0 – 1 V

Ignition switch turned ON, blower speed selector OFF

position

2 – 3 V Ignition switch turned ON, blower speed selector

between 1st and HIGH position

G51-10 BLK/RED Rear defogger indicator 0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G51-11 RED/YEL Illumination switch 0 – 1 V Ignition switch turned ON, lighting switch OFF position

10 – 14 V Ignition switch turned ON, lighting switch ON position

G51-12 BLK/YEL Illumination ground 0 – 1 V Full-time

G51-13 — — — —

G51-14 — — — —

G51-15 RED Air intake actuator

(RECIRCULATION AIR) 0 – 1 VIgnition switch turned ON, air intake selector is

recirculation air mode or air intake actuator is working

in operation to recirculation air position or fresh air

position.

10 – 14 V Ignition switch turned ON, ai

r intake selector is fresh

air mode (air intake actuator fresh air position).

G51-16 GRN/RED Air intake actuator

(MIX AIR) 10 – 14 V

Ignition switch turned ON, air intake actuator is

recirculation air or fresh air position.

0 – 1 V Ignition switch turned ON, air intake actuator is mix air

position or air intake actuator is working in operation to

recirculation air position or fresh air position.

G51-17 GRN Air intake actuator

(FRESH AIR) 0 – 1 V

Ignition switch turned ON, ai

r intake selector is fresh

air mode or air intake actuator is working in operation

to recirculation air position or fresh air position.

10 – 14 V Ignition switch turned ON, air intake selector is

recirculation air mode (air intake actuator recirculation

air position).

G51-18 GRN/WHT A/C switch signal Refer to “Inspe ction of BCM and its Circuits in Section 10B”

G51-19 BLU/WHT Electric load signal for

blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector OFF

or between 1st and 5th position

0 – 2 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

G51-20 BRN Rear defogger switch 0 – 1 V

Ignition switch turned ON, rear defogger switch ON

(rear defogger switch is kept in push) position

4 – 6 V Ignition switch turned ON, rear defogger switch OFF

position

Terminal Wire Color Circuit

Normal

Vo l ta g e Condition