coolant specification SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 370 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-7 Engine Cooling System:

Cooling System Flush and RefillS7RS0B1606005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

NOTE

For detail of coolant specification, refer to

“Coolant Description”.

1) Remove radiator cap when engine is cool as follows.a) Turn cap counterclockwise slowly until it reaches a “stop” (Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a hissing sound) then press down on cap and

continue to turn it counterclockwise.

2) With radiator cap removed, run engine until upper radiator hose is hot (this shows that thermostat is

open and coolant is flowing through system).

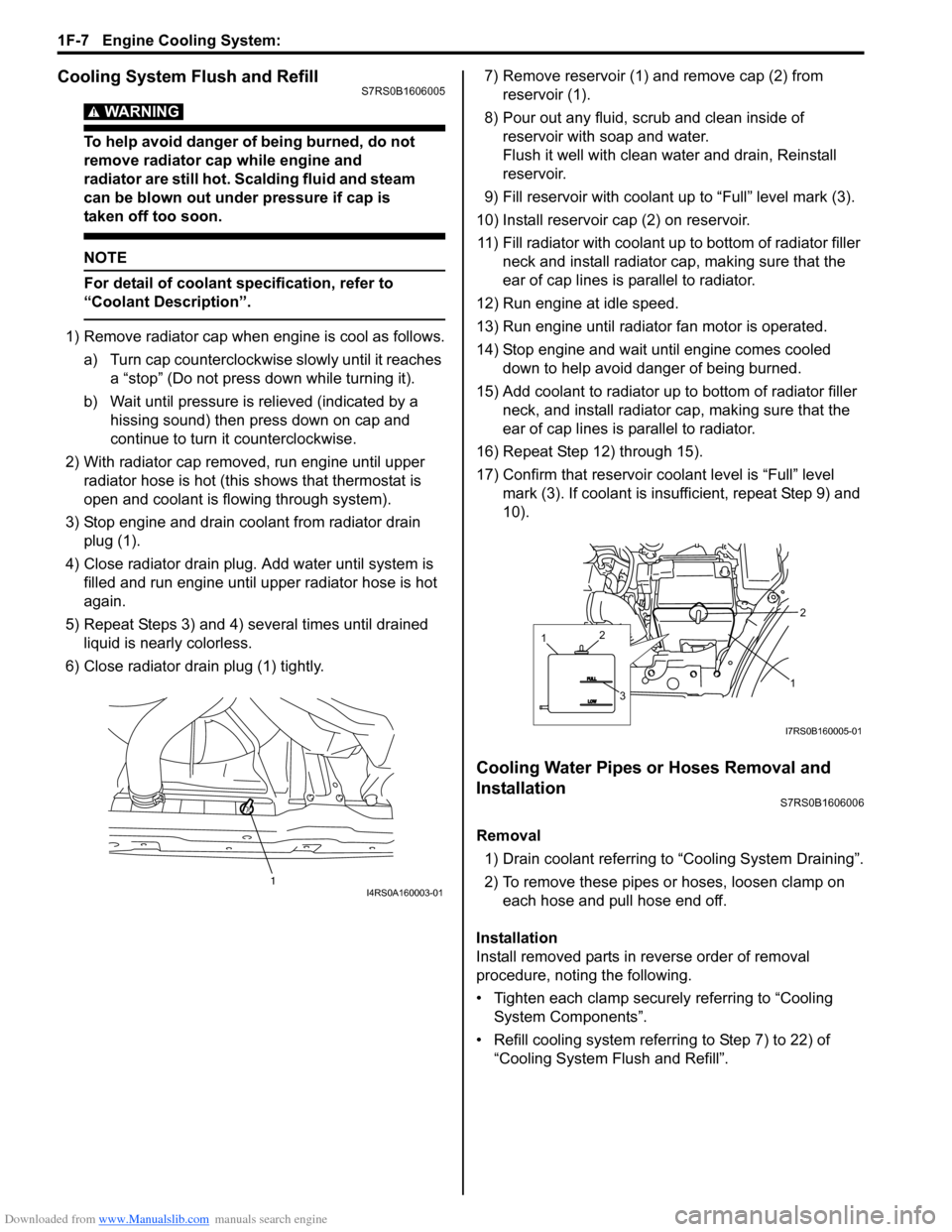

3) Stop engine and drain coolant from radiator drain plug (1).

4) Close radiator drain plug. Add water until system is filled and run engine until up per radiator hose is hot

again.

5) Repeat Steps 3) and 4) several times until drained liquid is nearly colorless.

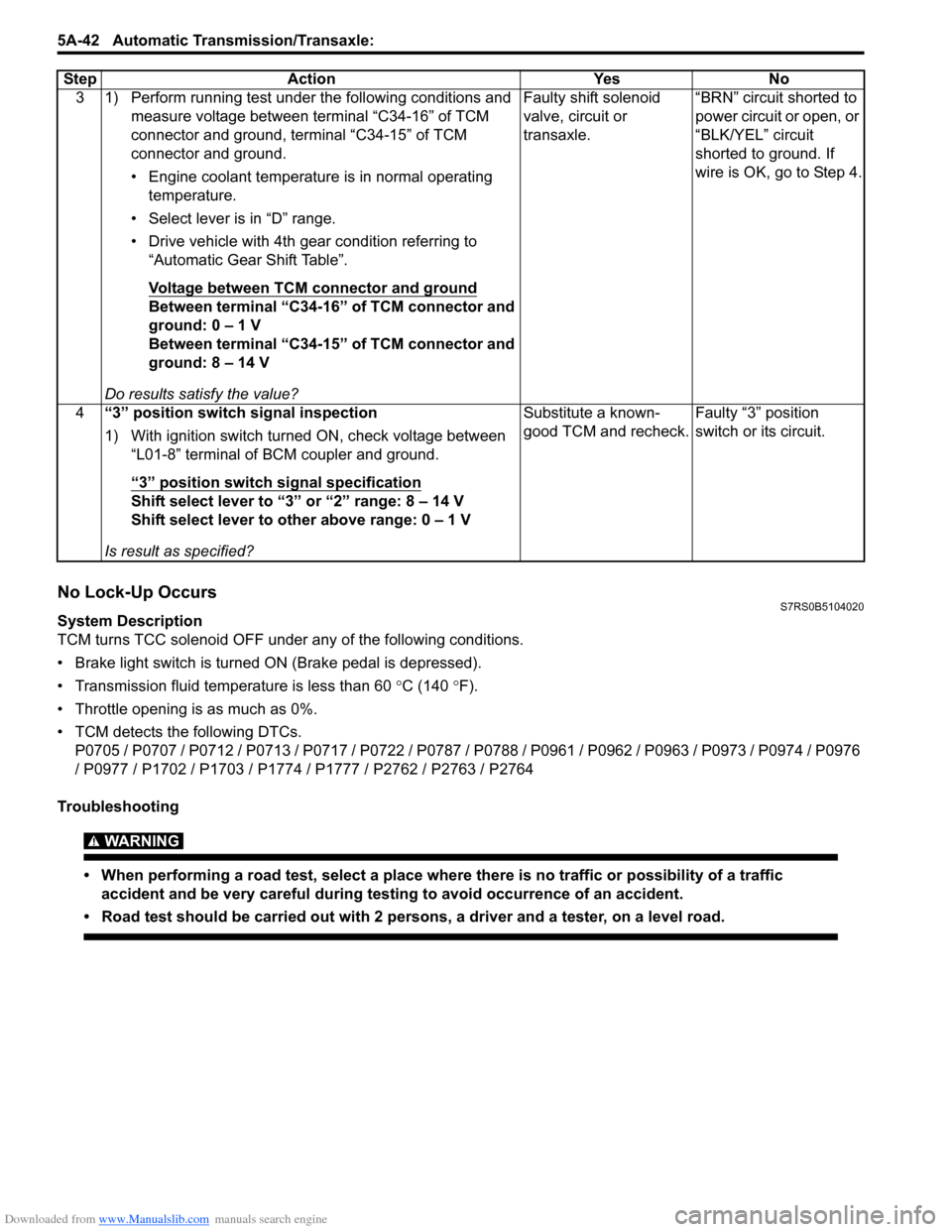

6) Close radiator drain plug (1) tightly. 7) Remove reservoir (1) and remove cap (2) from

reservoir (1).

8) Pour out any fluid, scrub and clean inside of reservoir with soap and water.

Flush it well with clean water and drain, Reinstall

reservoir.

9) Fill reservoir with coolant up to “Full” level mark (3).

10) Install reservoir cap (2) on reservoir. 11) Fill radiator with coolant up to bottom of radiator filler neck and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

12) Run engine at idle speed.

13) Run engine until radiator fan motor is operated.

14) Stop engine and wait until engine comes cooled down to help avoid danger of being burned.

15) Add coolant to radiator up to bottom of radiator filler

neck, and install radiator ca p, making sure that the

ear of cap lines is parallel to radiator.

16) Repeat Step 12) through 15).

17) Confirm that reservoir cool ant level is “Full” level

mark (3). If coolant is insu fficient, repeat Step 9) and

10).

Cooling Water Pipes or Hoses Removal and

Installation

S7RS0B1606006

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) To remove these pipes or hoses, loosen clamp on each hose and pull hose end off.

Installation

Install removed parts in reverse order of removal

procedure, noting the following.

• Tighten each clamp securely referring to “Cooling System Components”.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

1I4RS0A160003-01

1

2

1

3

2

I7RS0B160005-01

Page 686 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-42 Automatic Transmission/Transaxle:

No Lock-Up OccursS7RS0B5104020

System Description

TCM turns TCC solenoid OFF under any of the following conditions.

• Brake light switch is turned ON (Brake pedal is depressed).

• Transmission fluid temperat ure is less than 60 °C (140 °F).

• Throttle opening is as much as 0%.

• TCM detects the following DTCs. P0705 / P0707 / P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976

/ P0977 / P1702 / P1703 / P1774 / P1777 / P2762 / P2763 / P2764

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

3 1) Perform running test under the following conditions and measure voltage between terminal “C34-16” of TCM

connector and ground, terminal “C34-15” of TCM

connector and ground.

• Engine coolant temperature is in normal operating temperature.

• Select lever is in “D” range.

• Drive vehicle with 4th gear condition referring to “Automatic Gear Shift Table”.

Voltage between TCM connector and ground

Between terminal “C34-16” of TCM connector and

ground: 0 – 1 V

Between terminal “C34-15” of TCM connector and

ground: 8 – 14 V

Do results satisfy the value? Faulty shift solenoid

valve, circuit or

transaxle.

“BRN” circuit shorted to

power circuit or open, or

“BLK/YEL” circuit

shorted to ground. If

wire is OK, go to Step 4.

4 “3” position switch signal inspection

1) With ignition switch turned ON, check voltage between

“L01-8” terminal of BCM coupler and ground.

“3” position switch signal specification

Shift select lever to “3” or “2” range: 8 – 14 V

Shift select lever to other above range: 0 – 1 V

Is result as specified? Substitute a known-

good TCM and recheck.

Faulty “3” position

switch or its circuit.

Step Action Yes No

Page 821 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-7

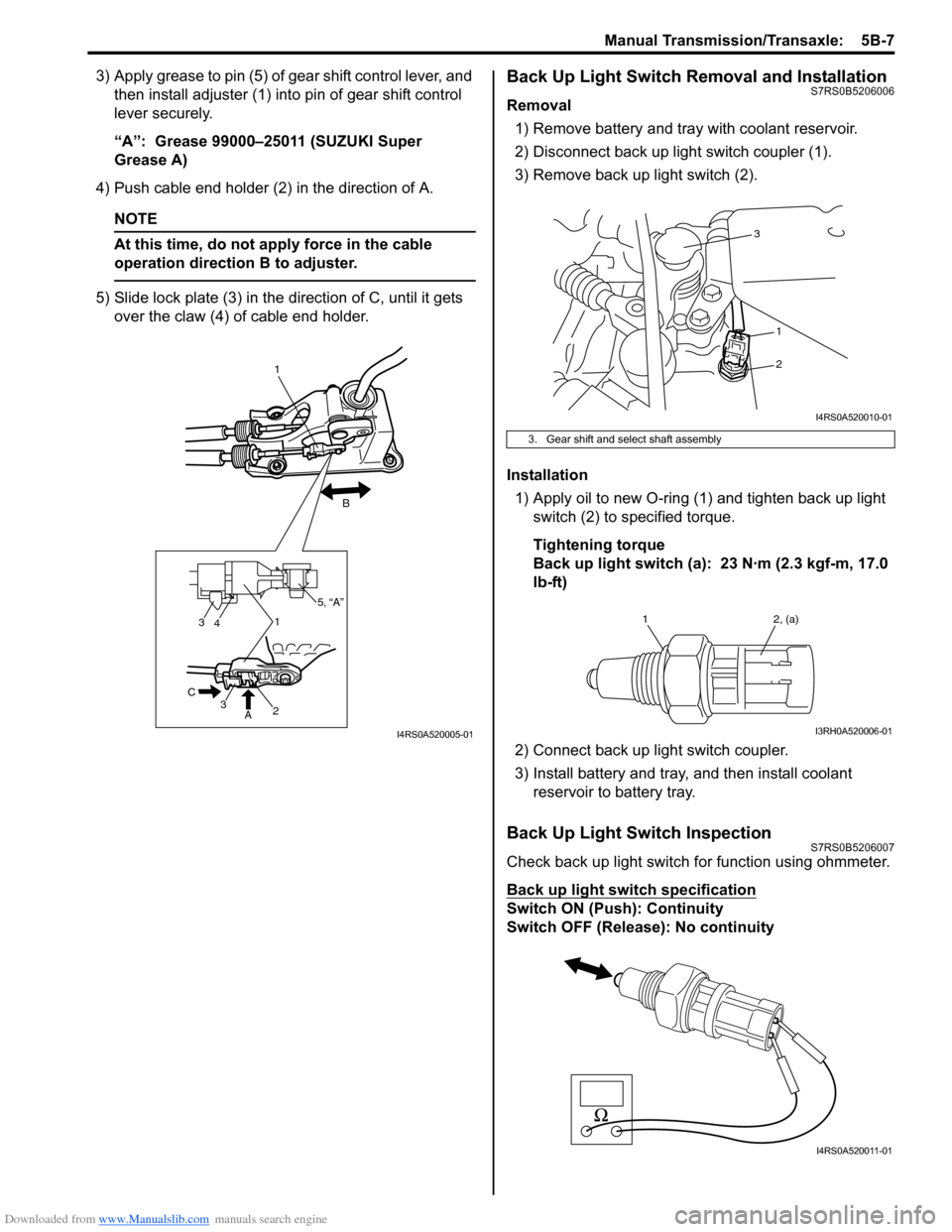

3) Apply grease to pin (5) of gear shift control lever, and then install adjuster (1) into pin of gear shift control

lever securely.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

4) Push cable end holder (2) in the direction of A.

NOTE

At this time, do not a pply force in the cable

operation direction B to adjuster.

5) Slide lock plate (3) in the direction of C, until it gets over the claw (4) of cable end holder.

Back Up Light Switch Removal and InstallationS7RS0B5206006

Removal

1) Remove battery and tray with coolant reservoir.

2) Disconnect back up light switch coupler (1).

3) Remove back up light switch (2).

Installation 1) Apply oil to new O-ring (1) and tighten back up light switch (2) to specified torque.

Tightening torque

Back up light switch (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

2) Connect back up light switch coupler.

3) Install battery and tray, and then install coolant reservoir to battery tray.

Back Up Light Switch InspectionS7RS0B5206007

Check back up light switch for function using ohmmeter.

Back up light switch specification

Switch ON (Push): Continuity

Switch OFF (Release ): No continuity

3

3

41

2

A

C

1

B

5, “A”

I4RS0A520005-01

3. Gear shift and select shaft assembly

3

1

2

I4RS0A520010-01

1 2, (a)

I3RH0A520006-01

I4RS0A520011-01

Page 1302 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-7 Instrumentation / Driver Info. / Horn:

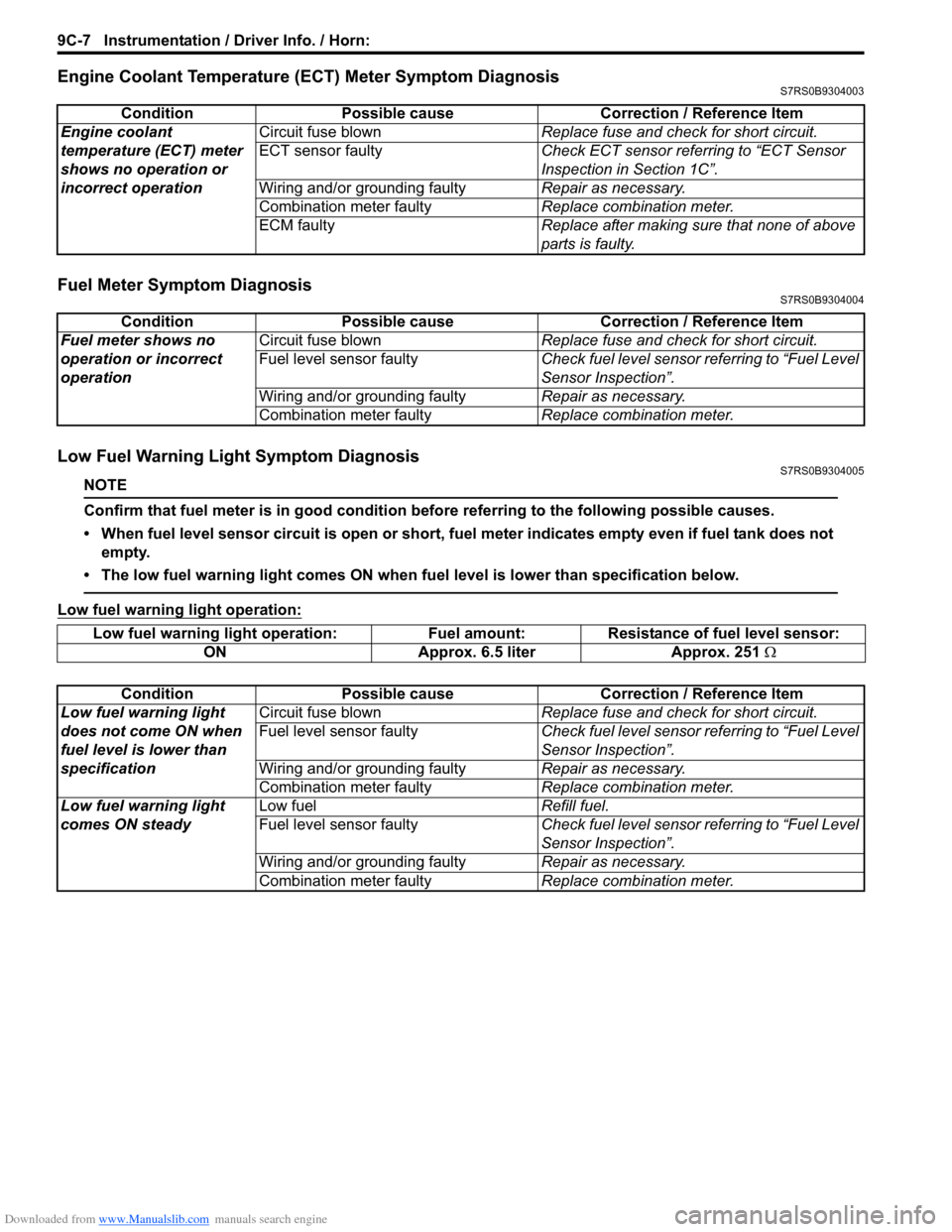

Engine Coolant Temperature (ECT) Meter Symptom DiagnosisS7RS0B9304003

Fuel Meter Symptom DiagnosisS7RS0B9304004

Low Fuel Warning Light Symptom DiagnosisS7RS0B9304005

NOTE

Confirm that fuel meter is in good condition before referring to the following possible causes.

• When fuel level sensor circuit is open or short, fuel meter indicates empty even if fuel tank does not empty.

• The low fuel warning light comes ON when fu el level is lower than specification below.

Low fuel warning light operation:

ConditionPossible cause Correction / Reference Item

Engine coolant

temperature (ECT) meter

shows no operation or

incorrect operation Circuit fuse blown

Replace fuse and check for short circuit.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

ECM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Fuel meter shows no

operation or incorrect

operation Circuit fuse blown

Replace fuse and check for short circuit.

Fuel level sensor faulty Check fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Low fuel warning light operation: Fuel amount: Resistance of fuel level sensor:

ON Approx. 6.5 liter Approx. 251 Ω

Condition Possible cause Correction / Reference Item

Low fuel warning light

does not come ON when

fuel level is lower than

specification Circuit fuse blown

Replace fuse and check for short circuit.

Fuel level sensor faulty Check fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Low fuel warning light

comes ON steady Low fuel

Refill fuel.

Fuel level sensor faulty Check fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Page 1311 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-16

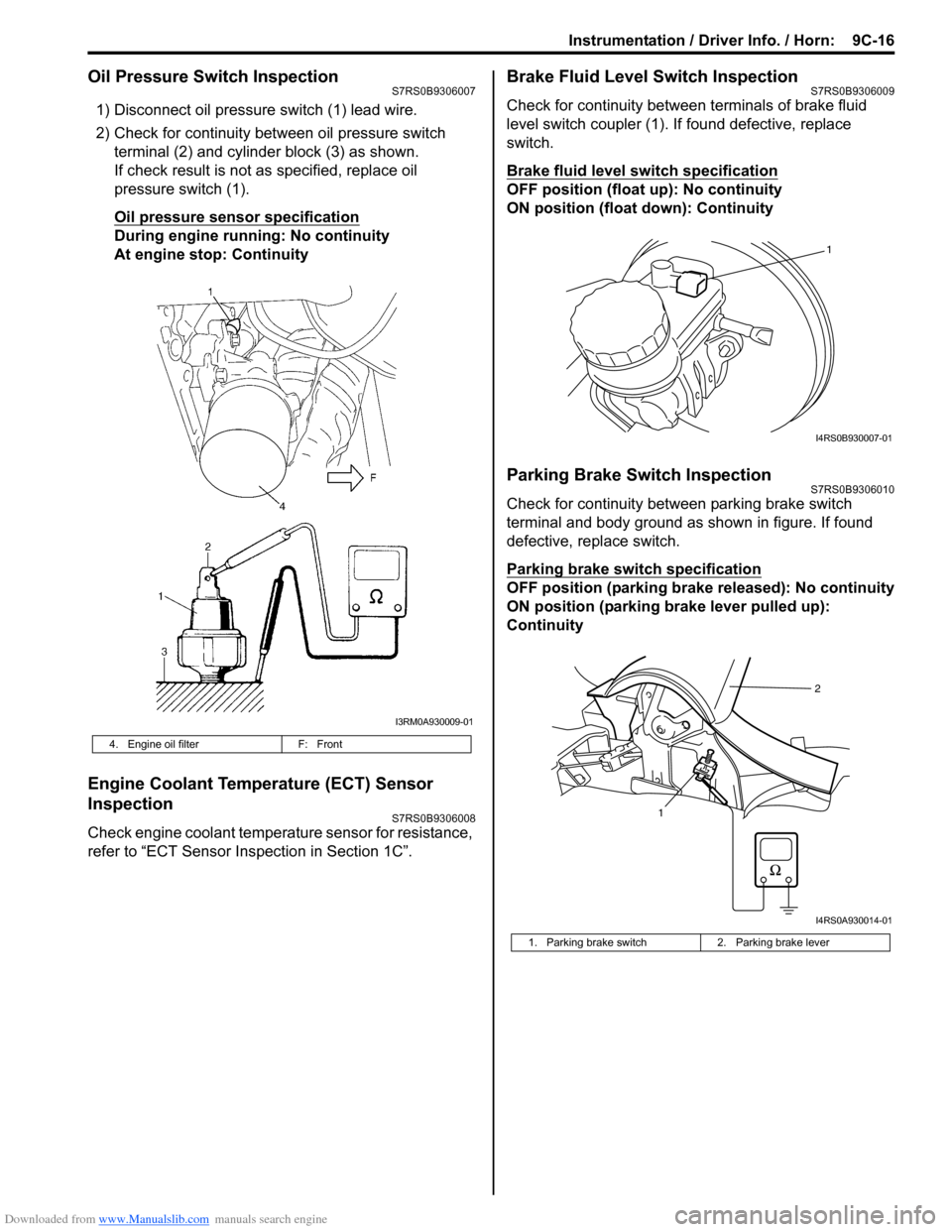

Oil Pressure Switch InspectionS7RS0B9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Engine Coolant Temperature (ECT) Sensor

Inspection

S7RS0B9306008

Check engine coolant temperat ure sensor for resistance,

refer to “ECT Sensor Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS7RS0B9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

Parking Brake Switch InspectionS7RS0B9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

4. Engine oil filter F: Front

I3RM0A930009-01

1. Parking brake switch 2. Parking brake lever

1

I4RS0B930007-01

12

I4RS0A930014-01