maf sensor SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 83 of 1496

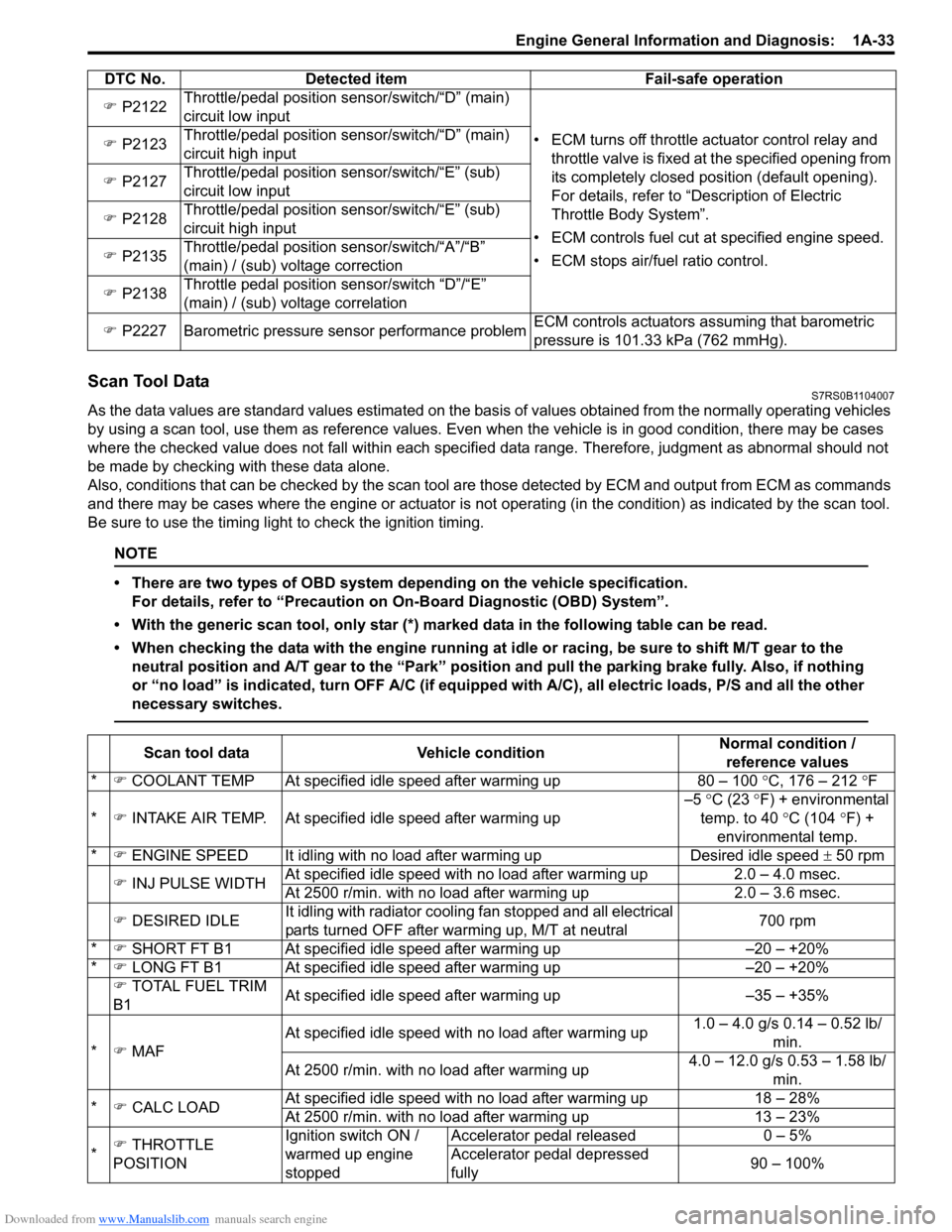

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-33

Scan Tool DataS7RS0B1104007

As the data values are standard values estimated on the basis of values obtained from the normally operating vehicles

by using a scan tool, use them as re ference values. Even when the vehicle is in good condition, there may be cases

where the checked value does not fall within each specified data range. Therefore, judgment as abnormal should not

be made by checking with these data alone.

Also, conditions that can be checked by the scan tool are those detected by ECM and output from ECM as commands

and there may be cases where the engine or actuator is not operating (in the condition) as indicated by the scan tool.

Be sure to use the timing light to check the ignition timing.

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• With the generic scan tool, only star (*) marked data in the following table can be read.

• When checking the data with the engine running at idle or racing, be sure to shift M/T gear to the neutral position and A/T gear to the “Park” position and pull the parking brake fully. Also, if nothing

or “no load” is indicated, turn O FF A/C (if equipped with A/C), all electric loads, P/S and all the other

necessary switches.

�) P2122 Throttle/pedal position sensor/switch/“D” (main)

circuit low input

• ECM turns off throttle actuator control relay and throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2123 Throttle/pedal position sensor/switch/“D” (main)

circuit high input

�) P2127 Throttle/pedal position sensor/switch/“E” (sub)

circuit low input

�) P2128 Throttle/pedal position sensor/switch/“E” (sub)

circuit high input

�) P2135 Throttle/pedal position sensor/switch/“A”/“B”

(main) / (sub) voltage correction

�) P2138 Throttle pedal position sensor/switch “D”/“E”

(main) / (sub) voltage correlation

�) P2227 Barometric pressure sensor performance problem ECM controls actuators assuming that barometric

pressure is 101.33 kPa (762 mmHg).

DTC No. Detected item Fail-safe operation

Scan tool data

Vehicle condition Normal condition /

reference values

* �) COOLANT TEMP At specified idle speed after warming up 80 – 100 °C, 176 – 212 °F

* �) INTAKE AIR TEMP. At specifie d idle speed after warming up –5

°C (23 °F) + environmental

temp. to 40 °C (104 °F) +

environmental temp.

* �) ENGINE SPEED It idling with no load after warming upDesired idle speed ± 50 rpm

�) INJ PULSE WIDTH At specified idle speed with no load after warming up

2.0 – 4.0 msec.

At 2500 r/min. with no load after warming up 2.0 – 3.6 msec.

�) DESIRED IDLE It idling with radiator cooling fan stopped and all electrical

parts turned OFF after warming up, M/T at neutral 700 rpm

* �) SHORT FT B1 At specified idle speed after warming up –20 – +20%

* �) LONG FT B1 At specified idle speed after warming up –20 – +20%

�) TOTAL FUEL TRIM

B1 At specified idle speed after warming up

–35 – +35%

* �) MAF At specified idle speed wit

h no load after warming up 1.0 – 4.0 g/s 0.14 – 0.52 lb/

min.

At 2500 r/min. with no load after warming up 4.0 – 12.0 g/s 0.53 – 1.58 lb/

min.

* �) CALC LOAD At specified idle speed with no load after warming up

18 – 28%

At 2500 r/min. with no load after warming up 13 – 23%

* �)

THROTTLE

POSITION Ignition switch ON /

warmed up engine

stoppedAccelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

Page 85 of 1496

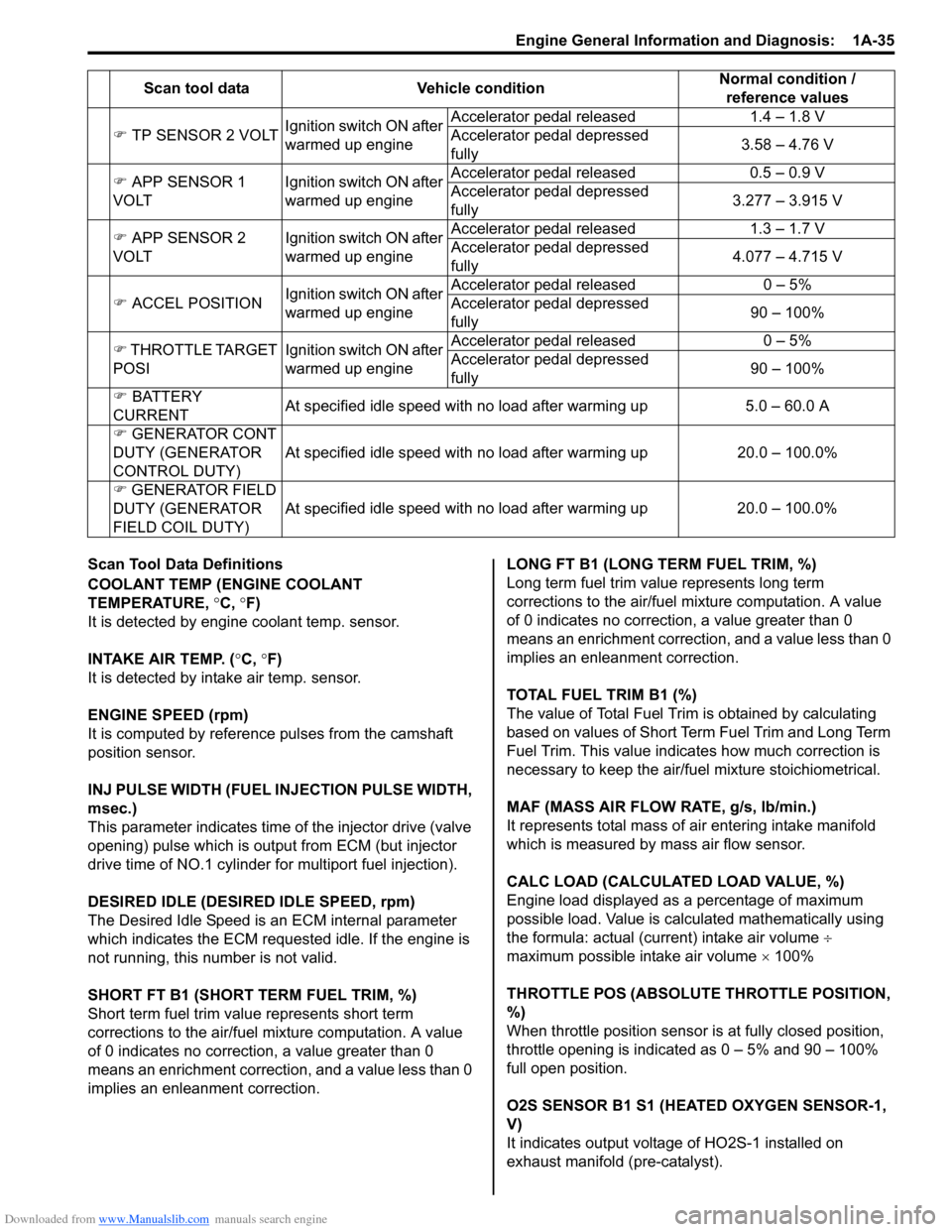

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-35

Scan Tool Data Definitions

COOLANT TEMP (ENGINE COOLANT

TEMPERATURE, °C, °F)

It is detected by engine coolant temp. sensor.

INTAKE AIR TEMP. ( °C, °F)

It is detected by intake air temp. sensor.

ENGINE SPEED (rpm)

It is computed by reference pulses from the camshaft

position sensor.

INJ PULSE WIDTH (FUEL INJECTION PULSE WIDTH,

msec.)

This parameter indicates time of the injector drive (valve

opening) pulse which is output from ECM (but injector

drive time of NO.1 cylinder fo r multiport fuel injection).

DESIRED IDLE (DESIRED IDLE SPEED, rpm)

The Desired Idle Speed is an ECM internal parameter

which indicates the ECM requested idle. If the engine is

not running, this number is not valid.

SHORT FT B1 (SHORT TERM FUEL TRIM, %)

Short term fuel trim valu e represents short term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction. LONG FT B1 (LONG TERM FUEL TRIM, %)

Long term fuel trim value represents long term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction.

TOTAL FUEL TRIM B1 (%)

The value of Total Fuel Trim is obtained by calculating

based on values of Short Term Fuel Trim and Long Term

Fuel Trim. This value indica

tes how much correction is

necessary to keep the air/fuel mixture stoichiometrical.

MAF (MASS AIR FLOW RATE, g/s, lb/min.)

It represents total mass of air entering intake manifold

which is measured by mass air flow sensor.

CALC LOAD (CALCULATED LOAD VALUE, %)

Engine load displayed as a percentage of maximum

possible load. Value is calculated mathematically using

the formula: actual (current) intake air volume ÷

maximum possible intake air volume × 100%

THROTTLE POS (ABSOLUTE THROTTLE POSITION,

%)

When throttle position sensor is at fully closed position,

throttle opening is indicated as 0 – 5% and 90 – 100%

full open position.

O2S SENSOR B1 S1 (HEA TED OXYGEN SENSOR-1,

V)

It indicates output voltage of HO2S-1 installed on

exhaust manifold (pre-catalyst).

�)

TP SENSOR 2 VOLT Ignition switch ON after

warmed up engine Accelerator pedal released

1.4 – 1.8 V

Accelerator pedal depressed

fully 3.58 – 4.76 V

�) APP SENSOR 1

VOLT Ignition switch ON after

warmed up engineAccelerator pedal released

0.5 – 0.9 V

Accelerator pedal depressed

fully 3.277 – 3.915 V

�) APP SENSOR 2

VOLT Ignition switch ON after

warmed up engineAccelerator pedal released

1.3 – 1.7 V

Accelerator pedal depressed

fully 4.077 – 4.715 V

�) ACCEL POSITION Ignition switch ON after

warmed up engine Accelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

�) THROTTLE TARGET

POSI Ignition switch ON after

warmed up engineAccelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

�) BATTERY

CURRENT At specified idle speed with no load after warming up

5.0 – 60.0 A

�) GENERATOR CONT

DUTY (GENERATOR

CONTROL DUTY) At specified idle speed with no load after warming up

20.0 – 100.0%

�) GENERATOR FIELD

DUTY (GENERATOR

FIELD COIL DUTY) At spe

cified idle speed with no load after warming up

20.0 – 100.0%

Scan tool data

Vehicle condition Normal condition /

reference values

Page 91 of 1496

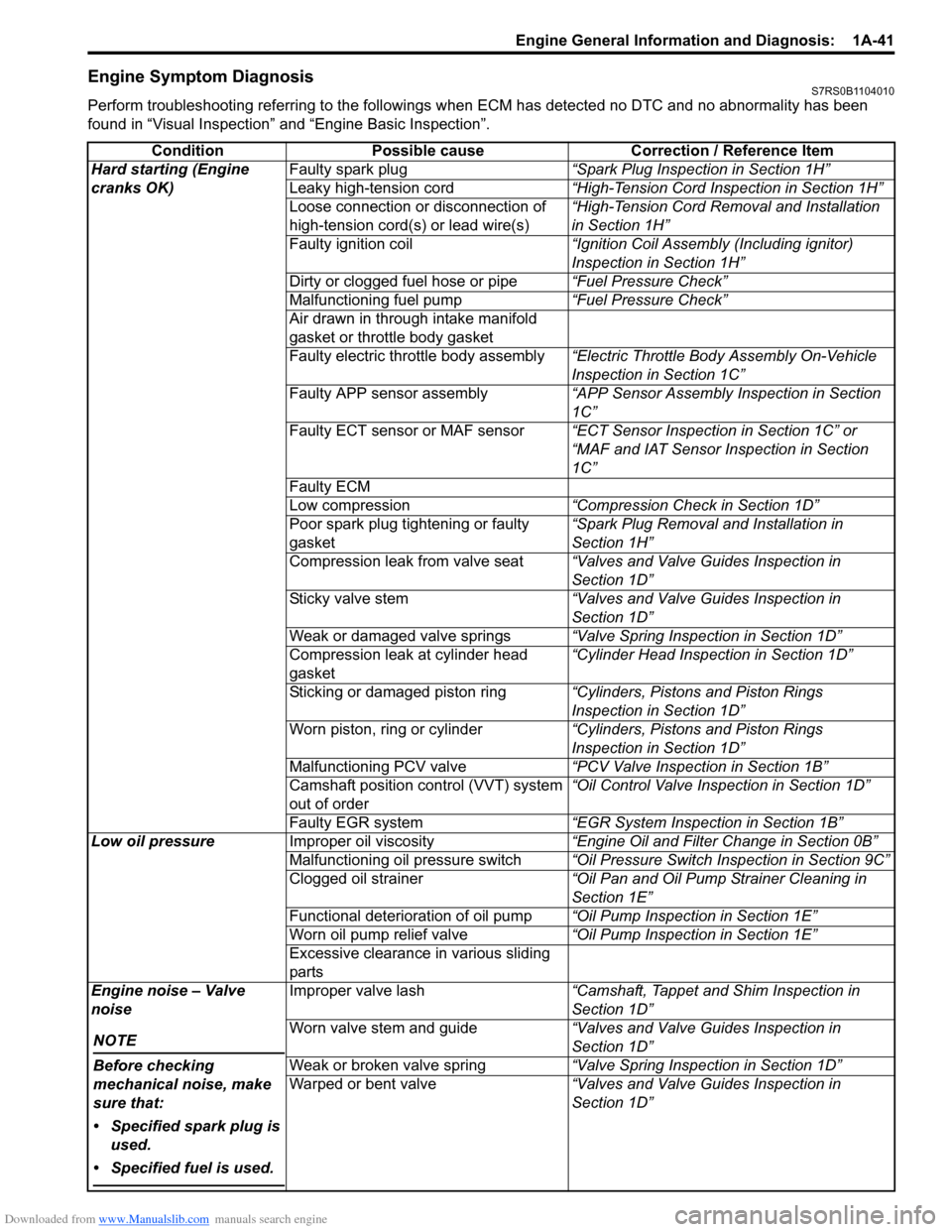

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-41

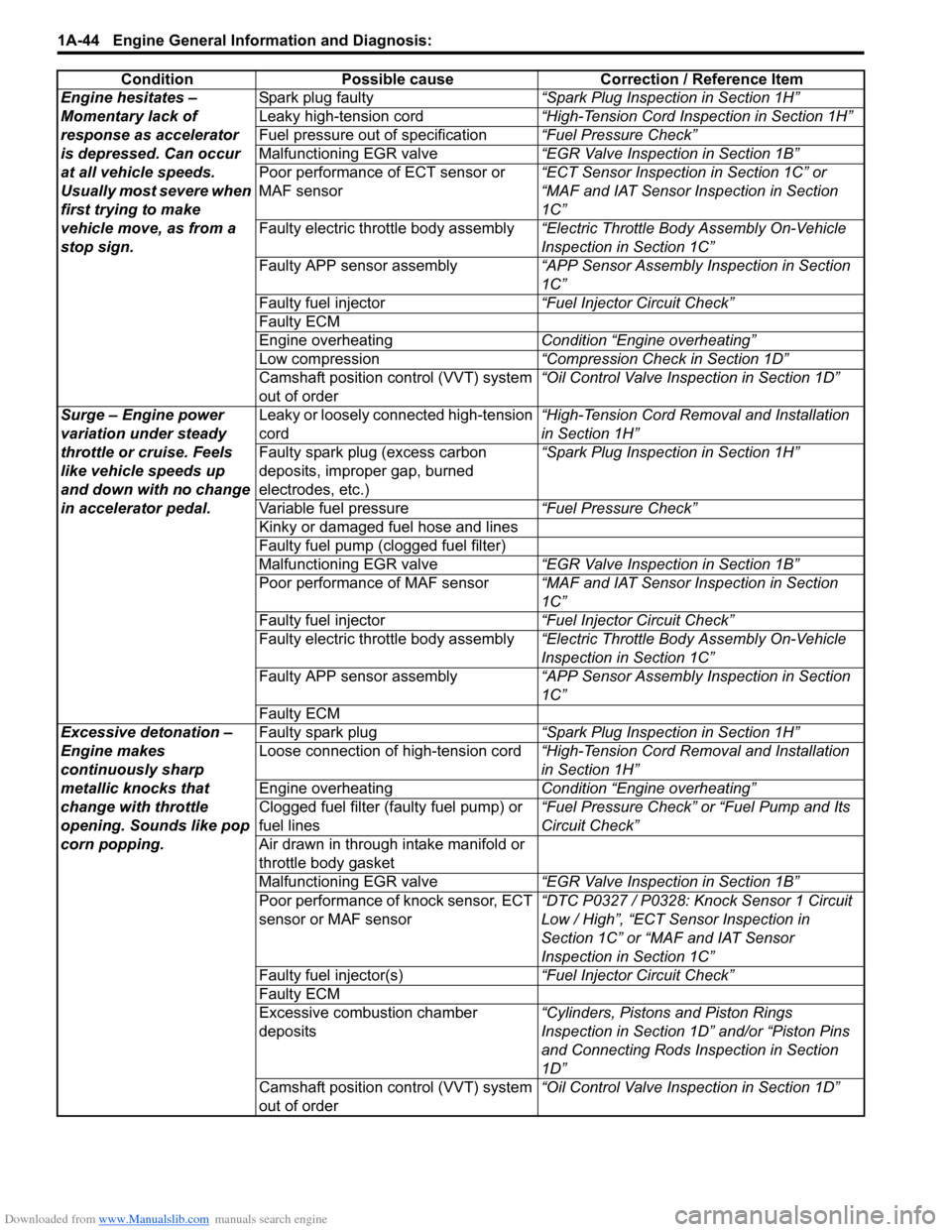

Engine Symptom DiagnosisS7RS0B1104010

Perform troubleshooting referring to the followings when ECM has detected no DTC and no abnormality has been

found in “Visual Inspection” and “Engine Basic Inspection”.

Condition Possible cause Correction / Reference Item

Hard starting (Engine

cranks OK) Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Loose connection or disconnection of

high-tension cord(s) or lead wire(s) “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Dirty or clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pressure Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECT sensor or MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor spark plug tightening or faulty

gasket “Spark Plug Removal and Installation in

Section 1H”

Compression leak from valve seat “Valves and Valve Guides Inspection in

Section 1D”

Sticky valve stem “Valves and Valve Guides Inspection in

Section 1D”

Weak or damaged valve springs “Valve Spring Inspection in Section 1D”

Compression leak at cylinder head

gasket “Cylinder Head Inspection in Section 1D”

Sticking or damaged piston ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston, ring or cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Faulty EGR system “EGR System Inspection in Section 1B”

Low oil pressure Improper oil viscosity “Engine Oil and Filter Change in Section 0B”

Malfunctioning oil pressure switch “Oil Pressure Switch Inspection in Section 9C”

Clogged oil strainer “Oil Pan and Oil Pump Strainer Cleaning in

Section 1E”

Functional deterioration of oil pump “Oil Pump Inspection in Section 1E”

Worn oil pump relief valve “Oil Pump Inspection in Section 1E”

Excessive clearance in various sliding

parts

Engine noise – Valve

noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Improper valve lash “Camshaft, Tappet and Shim Inspection in

Section 1D”

Worn valve stem and guide “Valves and Valve Guides Inspection in

Section 1D”

Weak or broken valve spring “Valve Spring Inspection in Section 1D”

Warped or bent valve “Valves and Valve Guides Inspection in

Section 1D”

Page 93 of 1496

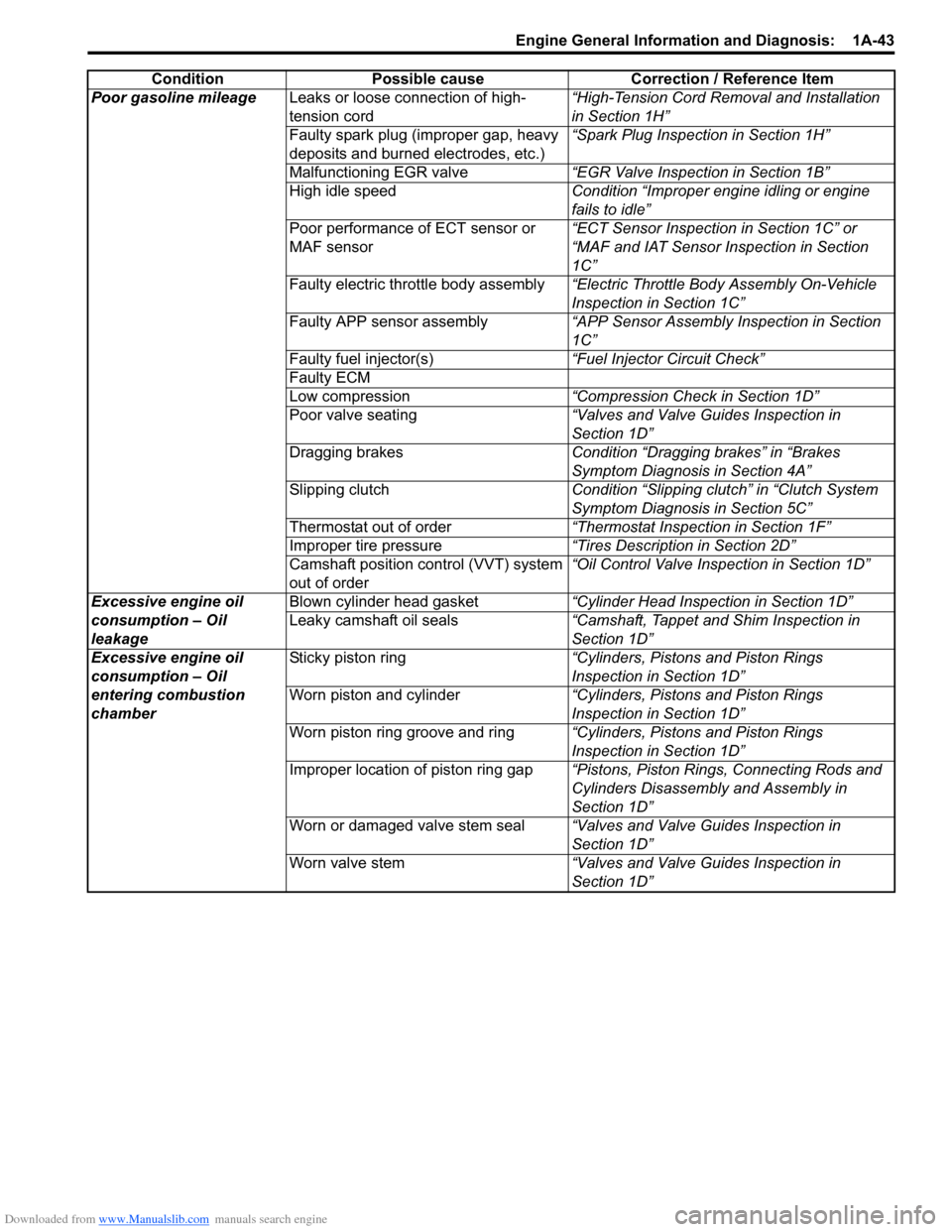

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-43

Poor gasoline mileageLeaks or loose connection of high-

tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.) “Spark Plug Inspection in Section 1H”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

High idle speed Condition “Improper engine idling or engine

fails to idle”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor valve seating “Valves and Valve Guides Inspection in

Section 1D”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Thermostat out of order “Thermostat Inspection in Section 1F”

Improper tire pressure “Tires Description in Section 2D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive engine oil

consumption – Oil

leakage Blown cylinder head gasket

“Cylinder Head Inspection in Section 1D”

Leaky camshaft oil seals “Camshaft, Tappet and Shim Inspection in

Section 1D”

Excessive engine oil

consumption – Oil

entering combustion

chamber Sticky piston ring

“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap “Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal “Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem “Valves and Valve Guides Inspection in

Section 1D”

Condition Possible cause Correction / Reference Item

Page 94 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-44 Engine General Information and Diagnosis:

Engine hesitates –

Momentary lack of

response as accelerator

is depressed. Can occur

at all vehicle speeds.

Usually most severe when

first trying to make

vehicle move, as from a

stop sign.Spark plug faulty

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty ECM

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Surge – Engine power

variation under steady

throttle or cruise. Feels

like vehicle speeds up

and down with no change

in accelerator pedal. Leaky or loosely connected high-tension

cord

“High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (excess carbon

deposits, improper gap, burned

electrodes, etc.) “Spark Plug Inspection in Section 1H”

Variable fuel pressure “Fuel Pressure Check”

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of MAF sensor “MAF and IAT Sensor Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Excessive detonation –

Engine makes

continuously sharp

metallic knocks that

change with throttle

opening. Sounds like pop

corn popping. Faulty spark plug

“Spark Plug Inspection in Section 1H”

Loose connection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Engine overheating Condition “Engine overheating”

Clogged fuel filter (faulty fuel pump) or

fuel lines “Fuel Pressure Check” or “Fuel Pump and Its

Circuit Check”

Air drawn in through intake manifold or

throttle body gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of knock sensor, ECT

sensor or MAF sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”, “ECT Sensor Inspection in

Section 1C” or “MAF and IAT Sensor

Inspection in Section 1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Excessive combustion chamber

deposits “Cylinders, Pistons and Piston Rings

Inspection in Section 1D” and/or “Piston Pins

and Connecting Rods In

spection in Section

1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 95 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-45

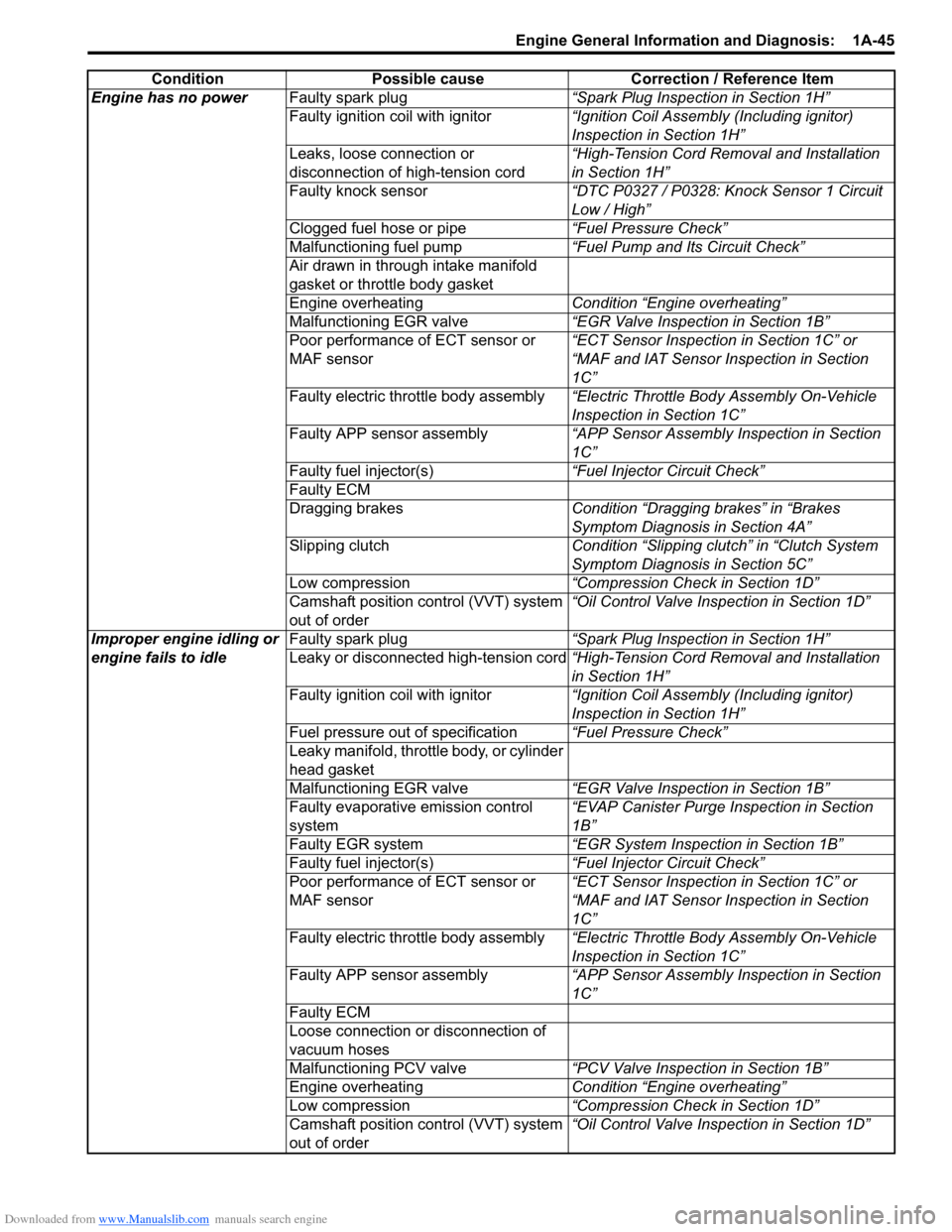

Engine has no powerFaulty spark plug “Spark Plug Inspection in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Leaks, loose connection or

disconnection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty knock sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”

Clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pump and Its Circuit Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Engine overheating Condition “Engine overheating”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Improper engine idling or

engine fails to idle Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Faulty EGR system “EGR System Inspection in Section 1B”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Loose connection or disconnection of

vacuum hoses

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 96 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-46 Engine General Information and Diagnosis:

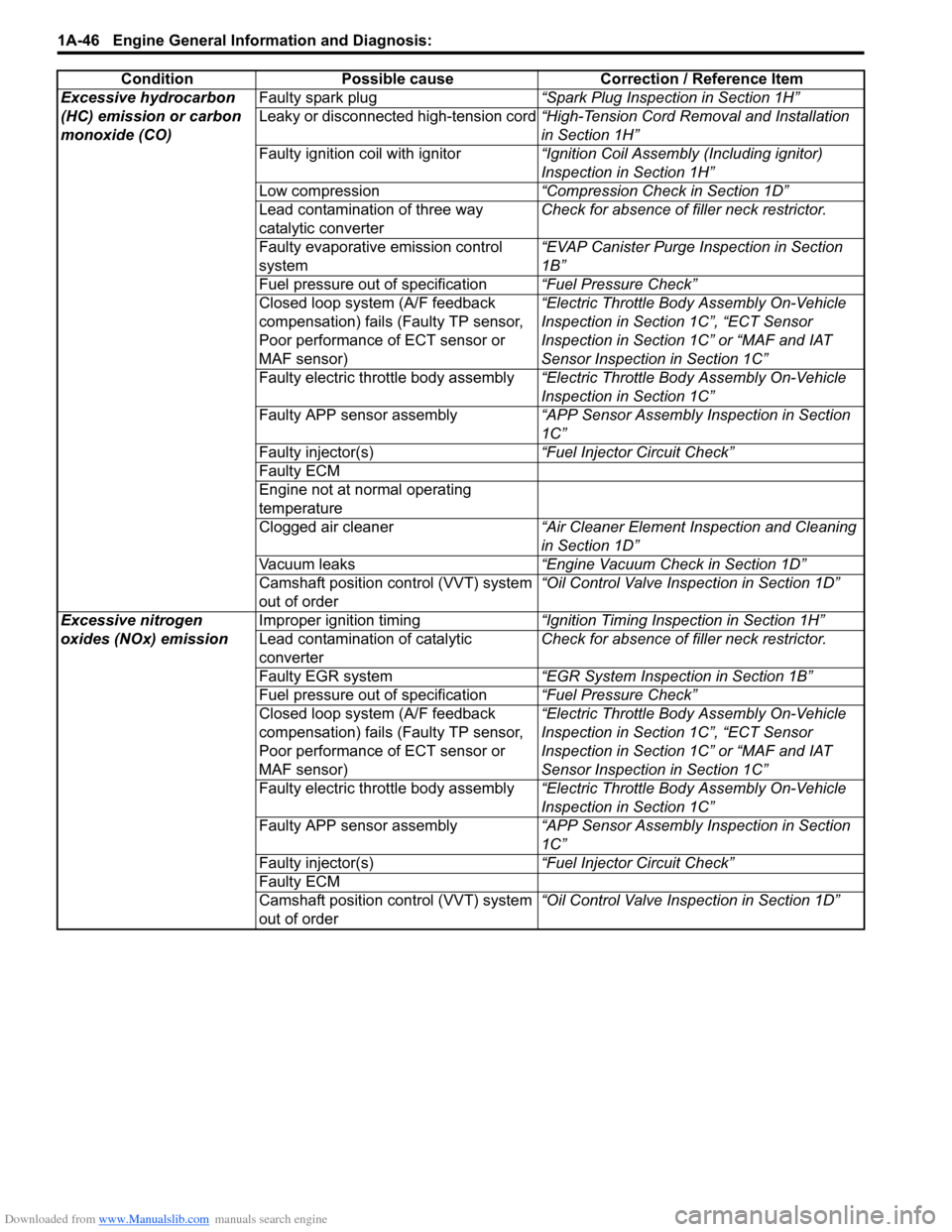

Excessive hydrocarbon

(HC) emission or carbon

monoxide (CO)Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Low compression “Compression Check in Section 1D”

Lead contamination of three way

catalytic converter Check for absence of f

iller neck restrictor.

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Fuel pressure out of specification “Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Faulty TP sensor,

Poor performance of ECT sensor or

MAF sensor) “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”, “ECT Sensor

Inspection in Section 1C” or “MAF and IAT

Sensor Inspection in Section 1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Engine not at normal operating

temperature

Clogged air cleaner “Air Cleaner Element Inspection and Cleaning

in Section 1D”

Vacuum leaks “Engine Vacuum Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive nitrogen

oxides (NOx) emission Improper ignition timing

“Ignition Timing Inspection in Section 1H”

Lead contamination of catalytic

converter Check for absence of f

iller neck restrictor.

Faulty EGR system “EGR System Inspection in Section 1B”

Fuel pressure out of specification “Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Faulty TP sensor,

Poor performance of ECT sensor or

MAF sensor) “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”, “ECT Sensor

Inspection in Section 1C” or “MAF and IAT

Sensor Inspection in Section 1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 108 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-58 Engine General Information and Diagnosis:

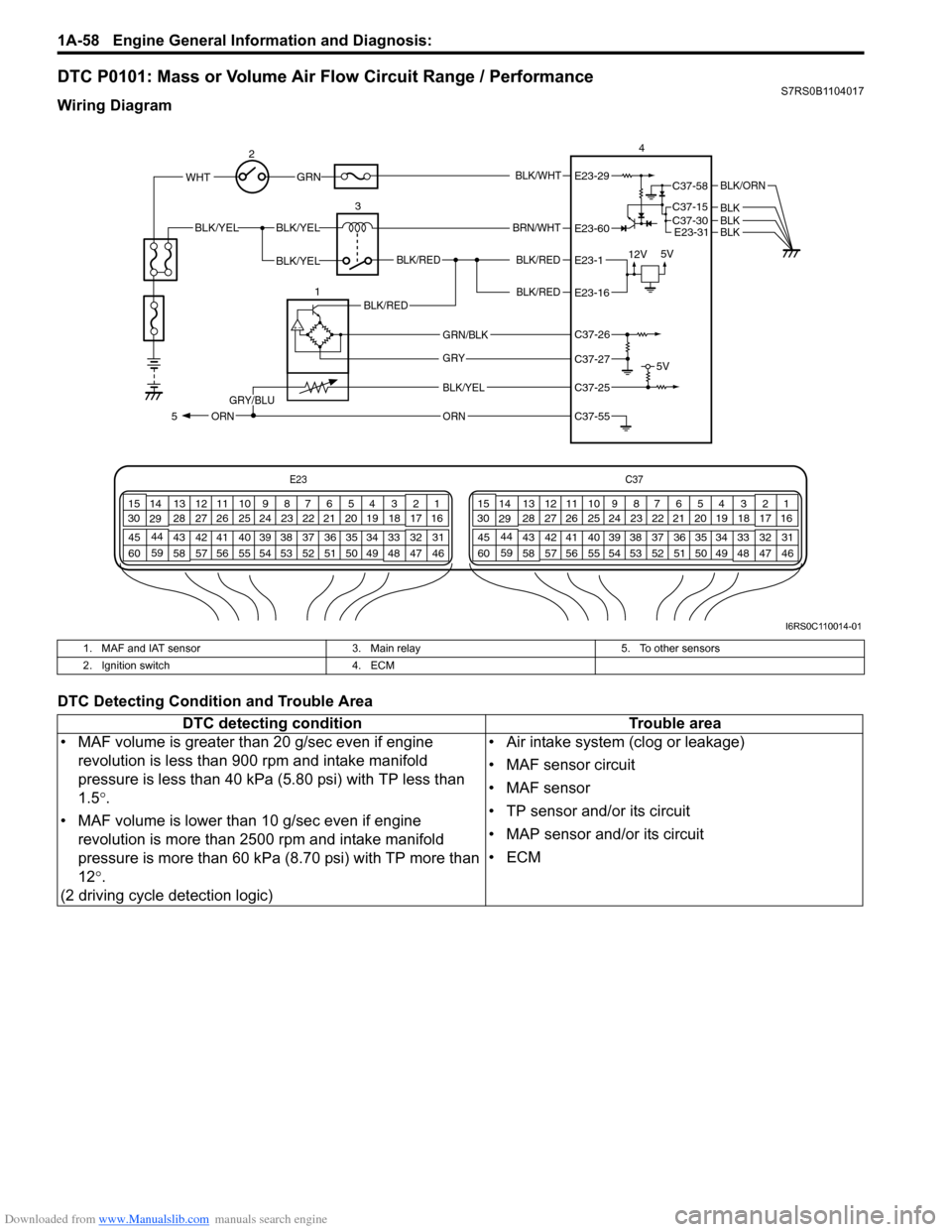

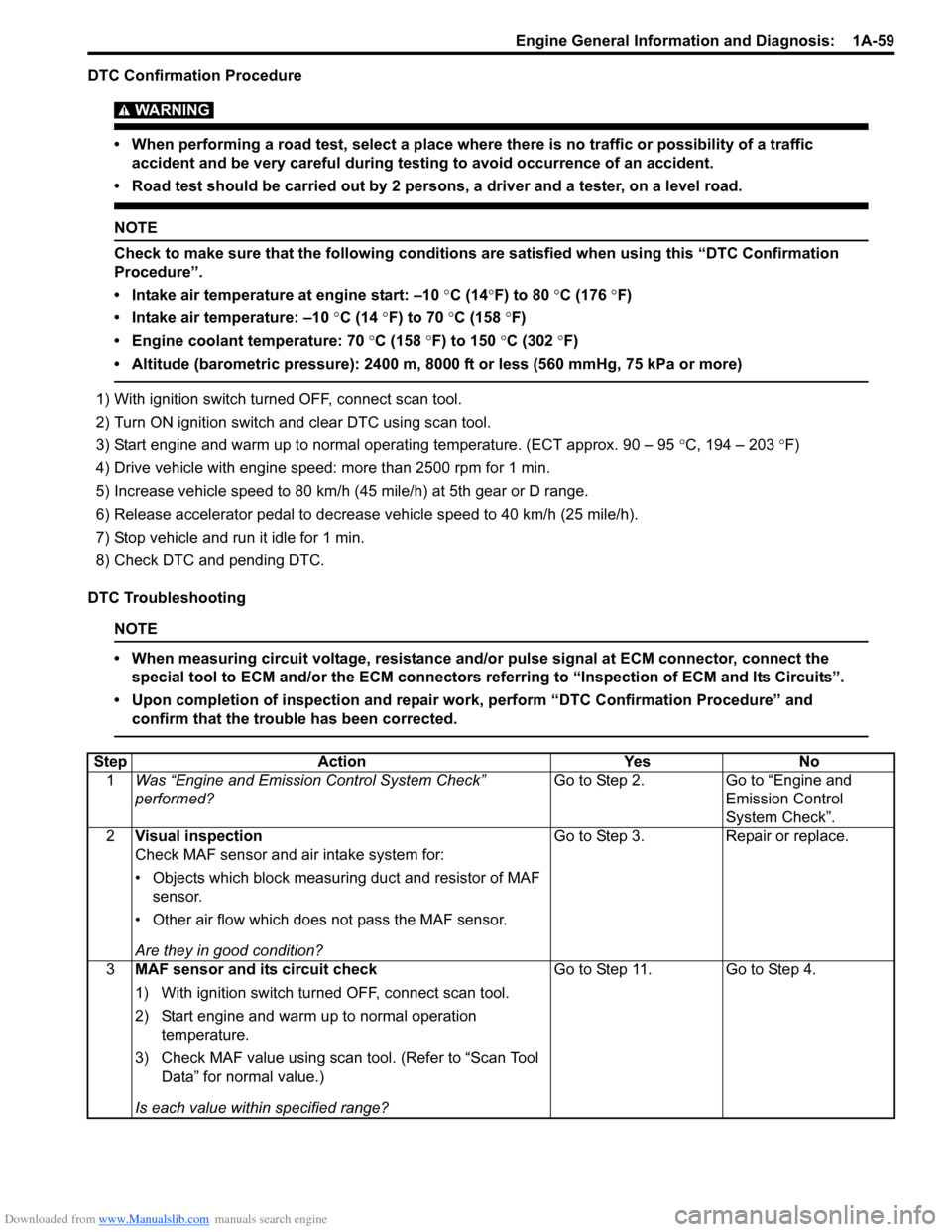

DTC P0101: Mass or Volume Air Flow Circuit Range / PerformanceS7RS0B1104017

Wiring Diagram

DTC Detecting Condition and Trouble Area

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/WHT

BLK/RED

BLK/RED

WHT

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V 5V

5V

2 3 4

E23-29

E23-60

E23-1

E23-16

BLK/ORN

BLKBLK

BLK/RED

BLK/YELGRY/BLU

ORN

1BLK/RED

5

E23-31BLK

ORN

GRY

GRN/BLK

C37-58

C37-15

C37-30

C37-26

C37-27

C37-25

C37-55

I6RS0C110014-01

1. MAF and IAT sensor

3. Main relay5. To other sensors

2. Ignition switch 4. ECM

DTC detecting condition Trouble area

• MAF volume is greater than 20 g/sec even if engine revolution is less than 900 rpm and intake manifold

pressure is less than 40 kPa (5.80 psi) with TP less than

1.5 °.

• MAF volume is lower than 10 g/sec even if engine

revolution is more than 2500 rpm and intake manifold

pressure is more than 60 kPa (8.70 psi) with TP more than

12 °.

(2 driving cycle detection logic) • Air intake system (clog or leakage)

• MAF sensor circuit

•MAF sensor

• TP sensor and/or its circuit

• MAP sensor and/or its circuit

•ECM

Page 109 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-59

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature. (ECT approx. 90 – 95 °C, 194 – 203 °F)

4) Drive vehicle with engine speed: more than 2500 rpm for 1 min.

5) Increase vehicle speed to 80 km/h (45 mile/h) at 5th gear or D range.

6) Release accelerator pedal to decrease vehicle speed to 40 km/h (25 mile/h).

7) Stop vehicle and run it idle for 1 min.

8) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Visual inspection

Check MAF sensor and air intake system for:

• Objects which block measuring duct and resistor of MAF

sensor.

• Other air flow which does not pass the MAF sensor.

Are they in good condition? Go to Step 3.

Repair or replace.

3 MAF sensor and its circuit check

1) With ignition switch turned OFF, connect scan tool.

2) Start engine and warm up to normal operation

temperature.

3) Check MAF value using scan tool. (Refer to “Scan Tool Data” for normal value.)

Is each value within specified range? Go to Step 11. Go to Step 4.

Page 110 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-60 Engine General Information and Diagnosis:

4MAF sensor output voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure voltage between “C37-26” and “C37-27” terminals of ECM connector referring to “MAF and IAT

Sensor On-Vehicle Inspection in Section 1C”.

Is each value within specified range? Poor “C37-26” and/or

“C37-27” terminal

connection.

If OK, substitute a

known-good ECM and

recheck.

Go to Step 5.

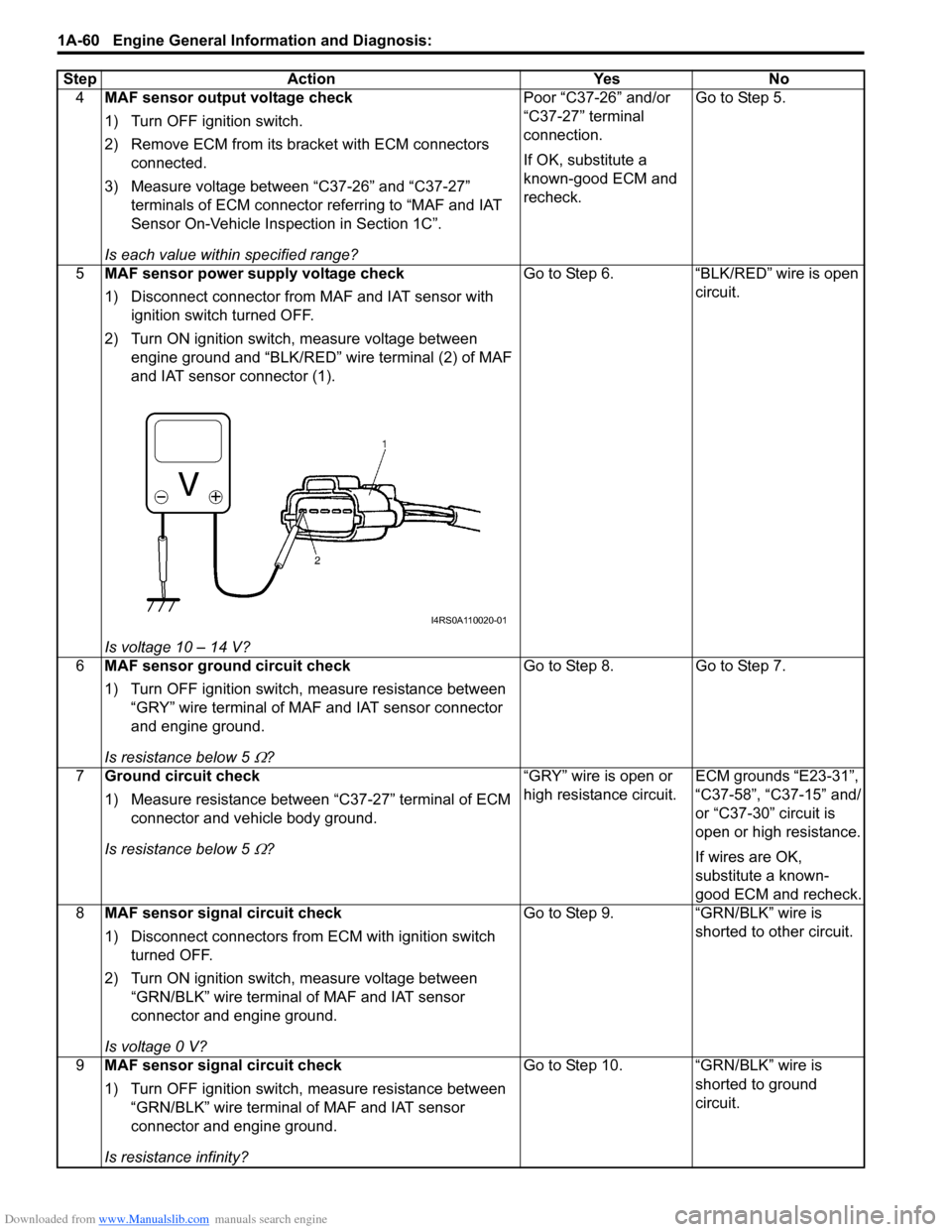

5 MAF sensor power supply voltage check

1) Disconnect connector from MAF and IAT sensor with

ignition switch turned OFF.

2) Turn ON ignition switch, measure voltage between engine ground and “BLK/RED” wire terminal (2) of MAF

and IAT sensor connector (1).

Is voltage 10 – 14 V? Go to Step 6. “BLK/RED” wire is open

circuit.

6 MAF sensor ground circuit check

1) Turn OFF ignition switch, measure resistance between

“GRY” wire terminal of MAF and IAT sensor connector

and engine ground.

Is resistance below 5

Ω? Go to Step 8.

Go to Step 7.

7 Ground circuit check

1) Measure resistance between “C37-27” terminal of ECM

connector and vehicle body ground.

Is resistance below 5

Ω? “GRY” wire is open or

high resistance circuit.

ECM grounds “E23-31”,

“C37-58”, “C37-15” and/

or “C37-30” circuit is

open or high resistance.

If wires are OK,

substitute a known-

good ECM and recheck.

8 MAF sensor signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between “GRN/BLK” wire terminal of MAF and IAT sensor

connector and engine ground.

Is voltage 0 V? Go to Step 9. “GRN/BLK” wire is

shorted to other circuit.

9 MAF sensor signal circuit check

1) Turn OFF ignition switch, measure resistance between

“GRN/BLK” wire terminal of MAF and IAT sensor

connector and engine ground.

Is resistance infinity? Go to Step 10. “GRN/BLK” wire is

shorted to ground

circuit.

Step Action Yes No

I4RS0A110020-01