ron SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 817 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

Diagnostic Information and Procedures

Manual Transaxle Symptom DiagnosisS7RS0B5204001

Repair Instructions

Manual Transaxle Oil ChangeS7RS0B5206001

1) Before changing or inspecting oil, be sure to stop engine and lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil. 5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

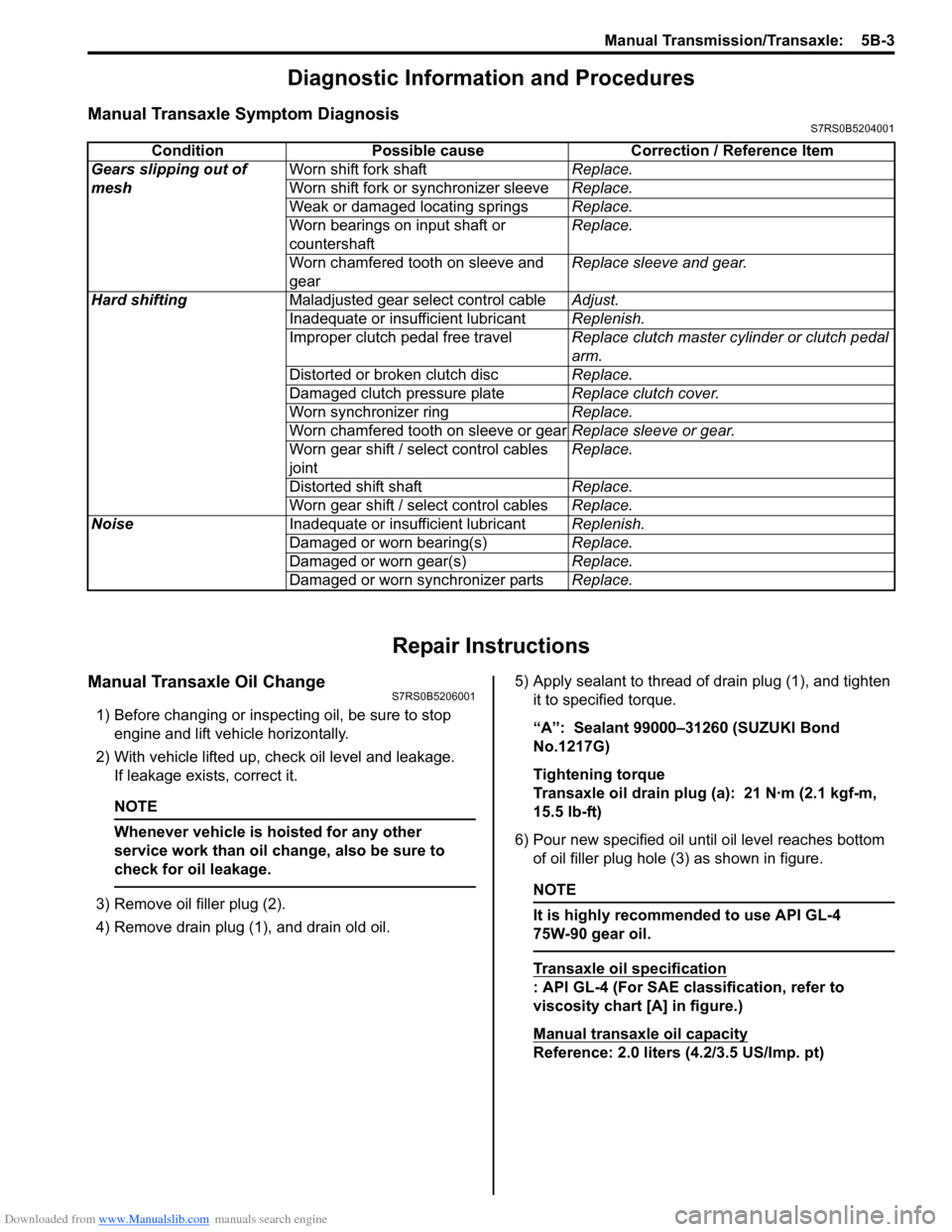

6) Pour new specified oil unt il oil level reaches bottom

of oil filler plug hole (3) as shown in figure.NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.0 liters (4.2/3.5 US/Imp. pt)

Condition Possible cause Correction / Reference Item

Gears slipping out of

mesh Worn shift fork shaft

Replace.

Worn shift fork or synchronizer sleeve Replace.

Weak or damaged locating springs Replace.

Worn bearings on input shaft or

countershaft Replace.

Worn chamfered tooth on sleeve and

gear Replace sleeve and gear.

Hard shifting Maladjusted gear select control cable Adjust.

Inadequate or insufficient lubricant Replenish.

Improper clutch pedal free travel Replace clutch master cylinder or clutch pedal

arm.

Distorted or broken clutch disc Replace.

Damaged clutch pressure plate Replace clutch cover.

Worn synchronizer ring Replace.

Worn chamfered tooth on sleeve or gear Replace sleeve or gear.

Worn gear shift / select control cables

joint Replace.

Distorted shift shaft Replace.

Worn gear shift / select control cables Replace.

Noise Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn synchronizer parts Replace.

Page 818 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-4 Manual Transmission/Transaxle:

7) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil level / filler plug (b): 21 N·m (2.1

kgf-m, 15.5 lb-ft)Differential Side Oil Seal ReplacementS7RS0B5206002

1) Lift up vehicle and drain transaxle oil.

2) Remove front drive shaft and/or center shaft referring to “Front Driv e Shaft Assembly Removal

and Installation in Section 3A”.

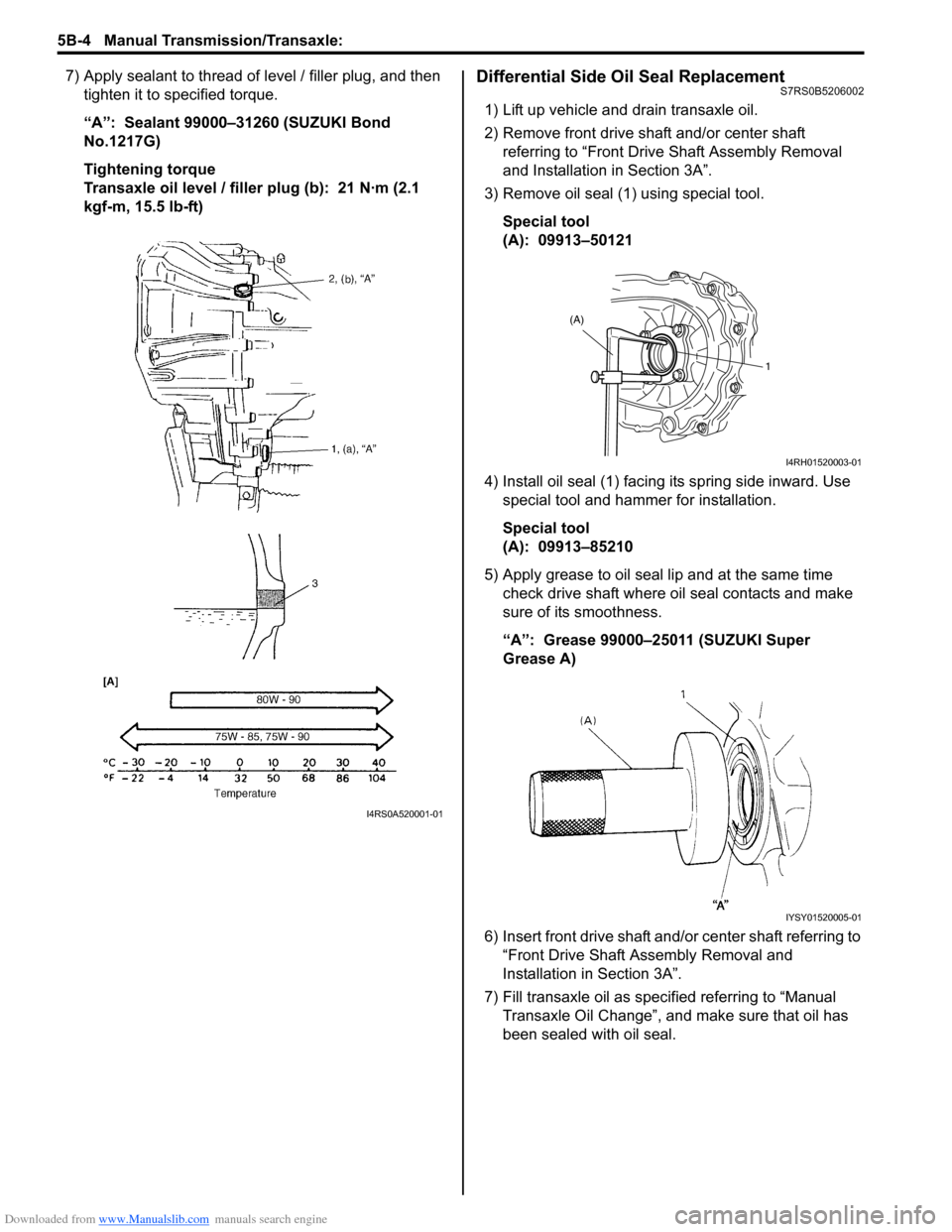

3) Remove oil seal (1) using special tool.

Special tool

(A): 09913–50121

4) Install oil seal (1) facing its spring side inward. Use special tool and hammer for installation.

Special tool

(A): 09913–85210

5) Apply grease to oil seal lip and at the same time check drive shaft where oil seal contacts and make

sure of its smoothness.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

6) Insert front drive shaft and/or center shaft referring to “Front Drive Shaft A ssembly Removal and

Installation in Section 3A”.

7) Fill transaxle oil as specified referring to “Manual Transaxle Oil Change”, and make sure that oil has

been sealed with oil seal.

I4RS0A520001-01

(A)

1

I4RH01520003-01

IYSY01520005-01

Page 823 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

Manual Transaxle Unit Dismounting and

Remounting

S7RS0B5206009

Dismounting1) Drain coolant and transaxle oil.

2) Remove coolant reservoir with reservoir hose.

3) Remove battery and tray.

4) Remove air cleaner case and resonator.

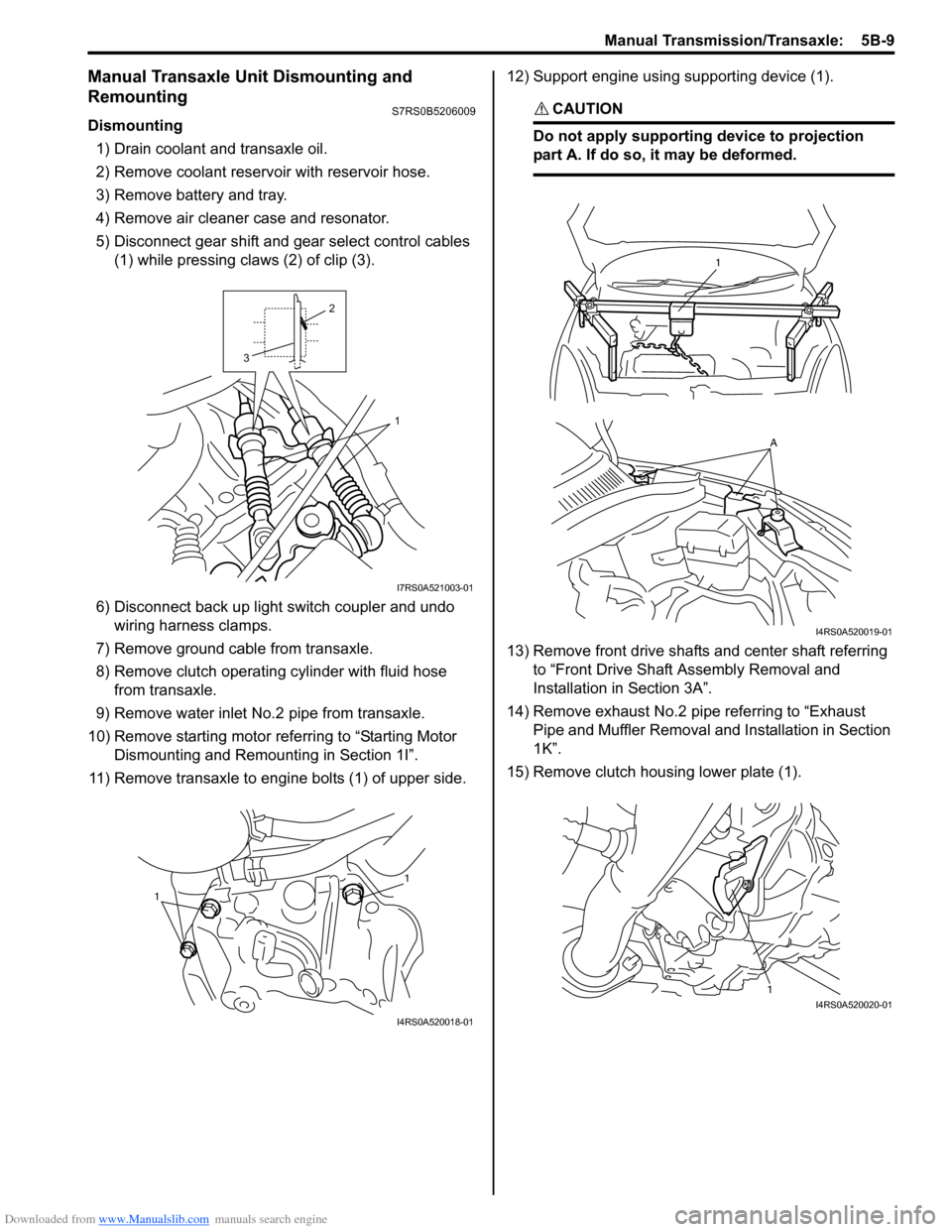

5) Disconnect gear shift and gear select control cables (1) while pressing claws (2) of clip (3).

6) Disconnect back up light switch coupler and undo wiring harness clamps.

7) Remove ground cable from transaxle.

8) Remove clutch operating cylinder with fluid hose from transaxle.

9) Remove water inlet No.2 pipe from transaxle.

10) Remove starting motor re ferring to “Starting Motor

Dismounting and Remounting in Section 1I”.

11) Remove transaxle to engine bolts (1) of upper side. 12) Support engine using supporting device (1).

CAUTION!

Do not apply supporting device to projection

part A. If do so, it may be deformed.

13) Remove front drive shafts and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

14) Remove exhaust No.2 pipe referring to “Exhaust Pipe and Muffler Removal a nd Installation in Section

1K”.

15) Remove clutch housing lower plate (1).

1

2

3

I7RS0A521003-01

1

1

I4RS0A520018-01

1

A

I4RS0A520019-01

1I4RS0A520020-01

Page 828 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-14 Manual Transmission/Transaxle:

Fifth Gear Disassembly and AssemblyS7RS0B5206014

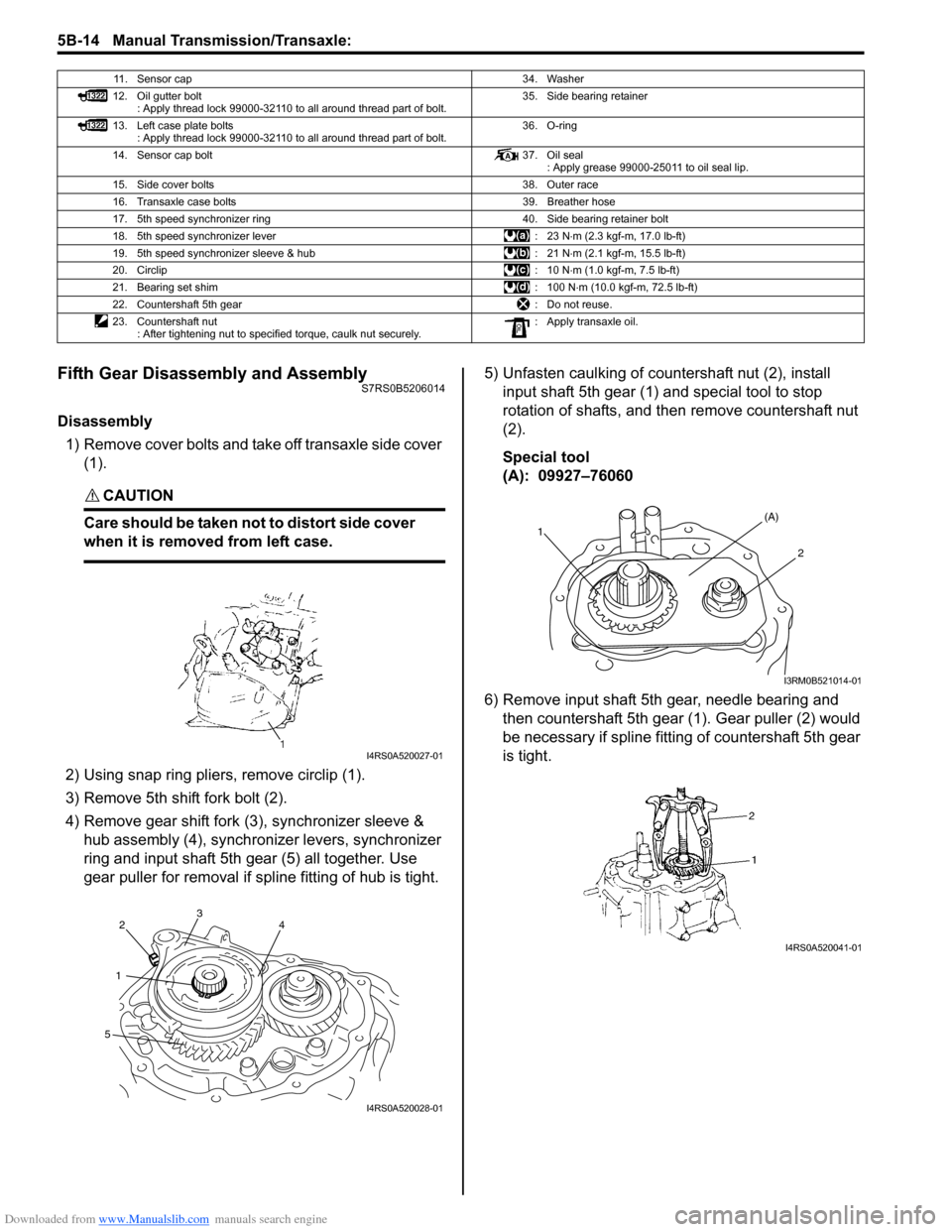

Disassembly1) Remove cover bolts and take off transaxle side cover (1).

CAUTION!

Care should be taken not to distort side cover

when it is removed from left case.

2) Using snap ring pliers, remove circlip (1).

3) Remove 5th shift fork bolt (2).

4) Remove gear shift fork (3), synchronizer sleeve &

hub assembly (4), synchron izer levers, synchronizer

ring and input shaft 5th gear (5) all together. Use

gear puller for removal if spline fitting of hub is tight. 5) Unfasten caulking of countershaft nut (2), install

input shaft 5th gear (1) and special tool to stop

rotation of shafts, and then remove countershaft nut

(2).

Special tool

(A): 09927–76060

6) Remove input shaft 5th gear, needle bearing and then countershaft 5th gear (1). Gear puller (2) would

be necessary if spline fitting of countershaft 5th gear

is tight.

11. Sensor cap 34. Washer

12. Oil gutter bolt : Apply thread lock 99000-32110 to all around thread part of bolt. 35. Side bearing retainer

13. Left case plate bolts : Apply thread lock 99000-32110 to all around thread part of bolt. 36. O-ring

14. Sensor cap bolt 37. Oil seal

: Apply grease 99000-25011 to oil seal lip.

15. Side cover bolts 38. Outer race

16. Transaxle case bolts 39. Breather hose

17. 5th speed synchronizer ring 40. Side bearing retainer bolt

18. 5th speed synchronizer lever : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

19. 5th speed synchronizer sleeve & hub : 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

20. Circlip :10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

21. Bearing set shim : 100 N⋅m (10.0 kgf-m, 72.5 lb-ft)

22. Countershaft 5th gear : Do not reuse.

23. Countershaft nut : After tightening nut to specified torque, caulk nut securely. : Apply transaxle oil.

I4RS0A520027-01

342

1

5

I4RS0A520028-01

1(A)

2

I3RM0B521014-01

I4RS0A520041-01

Page 829 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-15

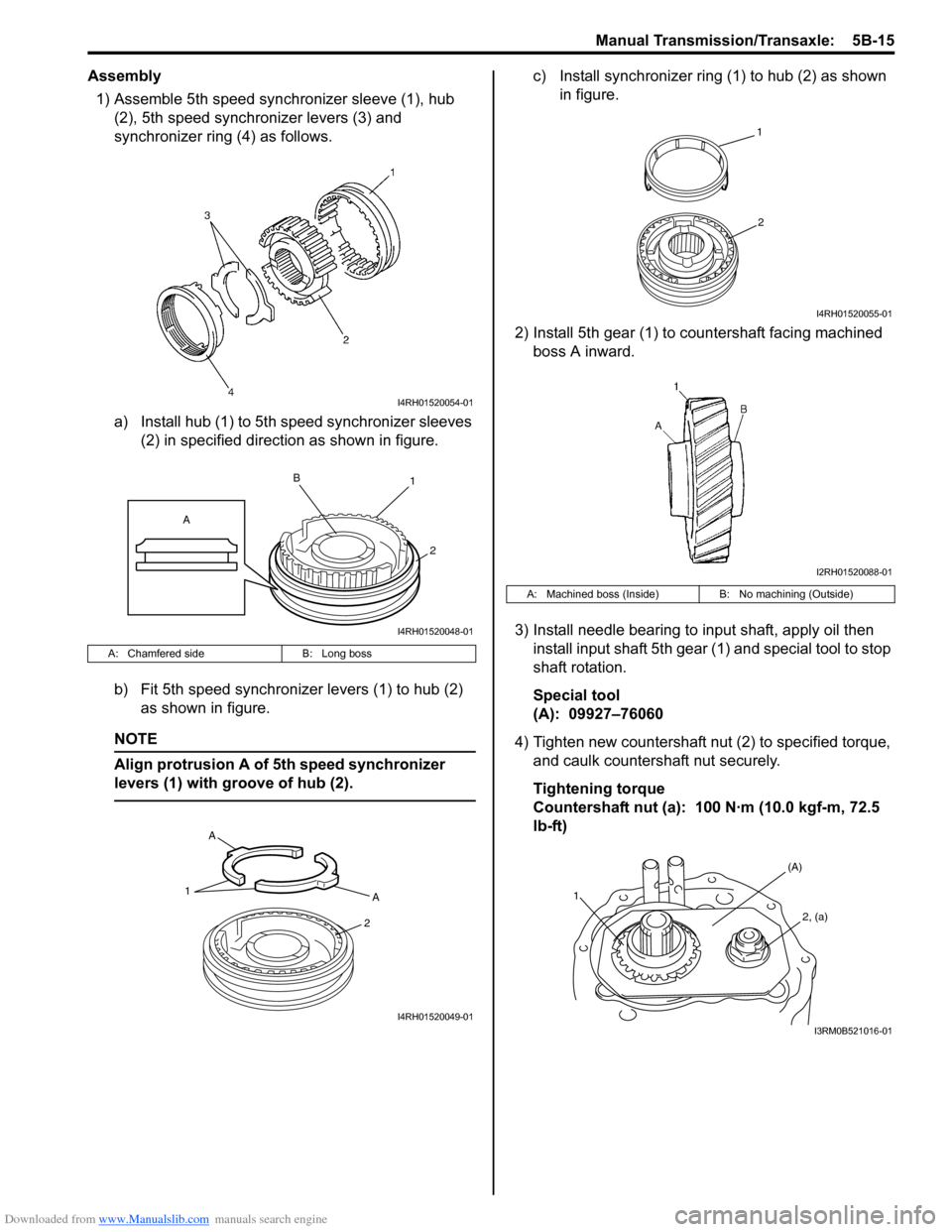

Assembly1) Assemble 5th speed synchronizer sleeve (1), hub (2), 5th speed synchronizer levers (3) and

synchronizer ring (4) as follows.

a) Install hub (1) to 5th speed synchronizer sleeves (2) in specified direction as shown in figure.

b) Fit 5th speed synchronizer levers (1) to hub (2) as shown in figure.

NOTE

Align protrusion A of 5th speed synchronizer

levers (1) with groove of hub (2).

c) Install synchronizer ring (1) to hub (2) as shown in figure.

2) Install 5th gear (1) to countershaft facing machined boss A inward.

3) Install needle bearing to input shaft, apply oil then install input shaft 5th gear (1) and special tool to stop

shaft rotation.

Special tool

(A): 09927–76060

4) Tighten new countershaft nut (2) to specified torque, and caulk countershaft nut securely.

Tightening torque

Countershaft nut (a): 100 N·m (10.0 kgf-m, 72.5

lb-ft)

A: Chamfered side B: Long boss

I4RH01520054-01

1

2

B

A

I4RH01520048-01

1A

2

A

I4RH01520049-01

A: Machined boss (Inside)

B: No machining (Outside)

1

2

I4RH01520055-01

I2RH01520088-01

1

(A)

2, (a)

I3RM0B521016-01

Page 830 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-16 Manual Transmission/Transaxle:

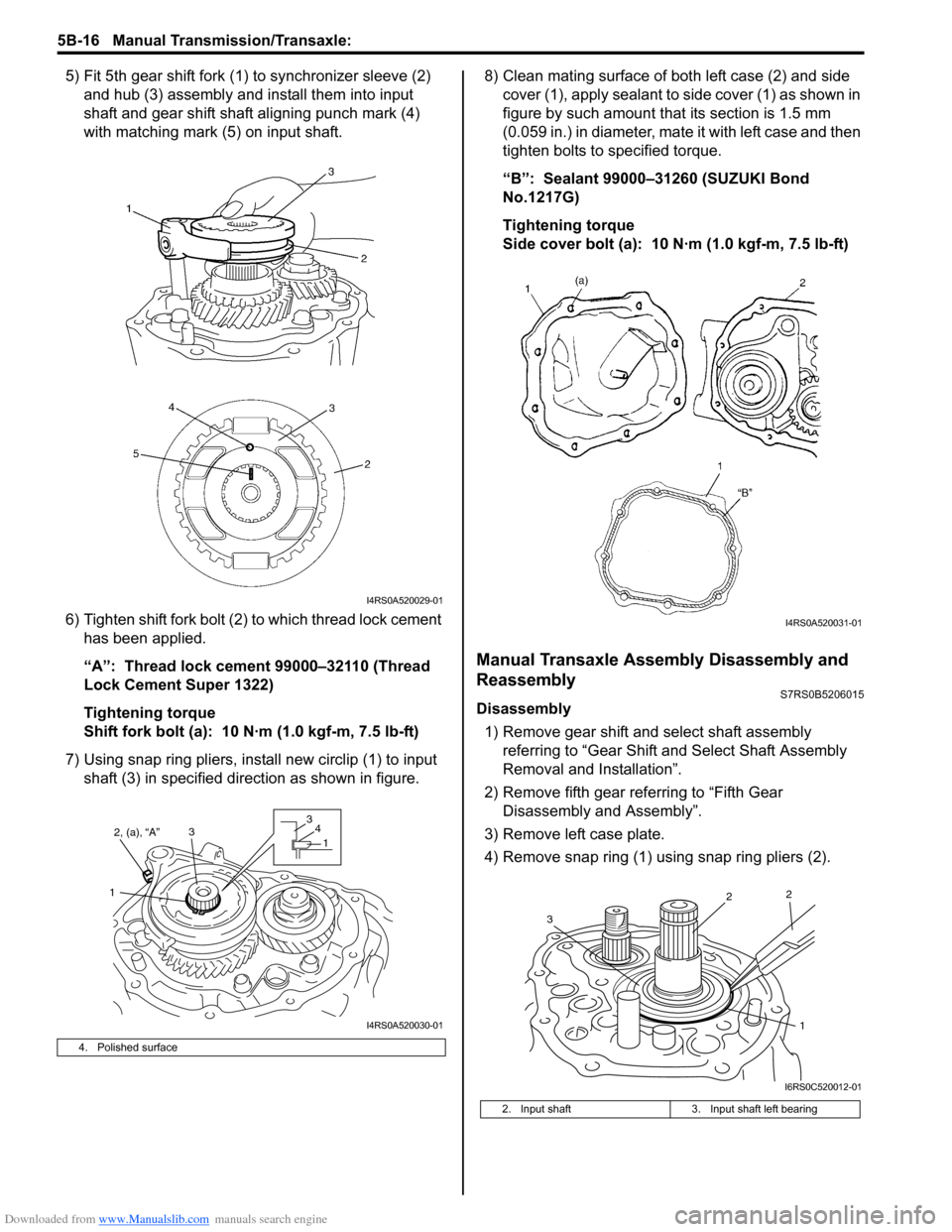

5) Fit 5th gear shift fork (1) to synchronizer sleeve (2) and hub (3) assembly and install them into input

shaft and gear shift shaft aligning punch mark (4)

with matching mark (5) on input shaft.

6) Tighten shift fork bolt (2) to which thread lock cement

has been applied.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Shift fork bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

7) Using snap ring pliers, inst all new circlip (1) to input

shaft (3) in specified direction as shown in figure. 8) Clean mating surface of both left case (2) and side

cover (1), apply sealant to side cover (1) as shown in

figure by such amount t hat its section is 1.5 mm

(0.059 in.) in diameter, mate it with left case and then

tighten bolts to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Side cover bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

Manual Transaxle Assembly Disassembly and

Reassembly

S7RS0B5206015

Disassembly

1) Remove gear shift and select shaft assembly referring to “Gear Shift an d Select Shaft Assembly

Removal and Installation”.

2) Remove fifth gear referring to “Fifth Gear Disassembly and Assembly”.

3) Remove left case plate.

4) Remove snap ring (1) using snap ring pliers (2).

4. Polished surface

I4RS0A520029-01

2, (a), “A”

1 33

4

1

I4RS0A520030-01

2. Input shaft 3. Input shaft left bearing

I4RS0A520031-01

1

2

2

3

I6RS0C520012-01

Page 839 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-25

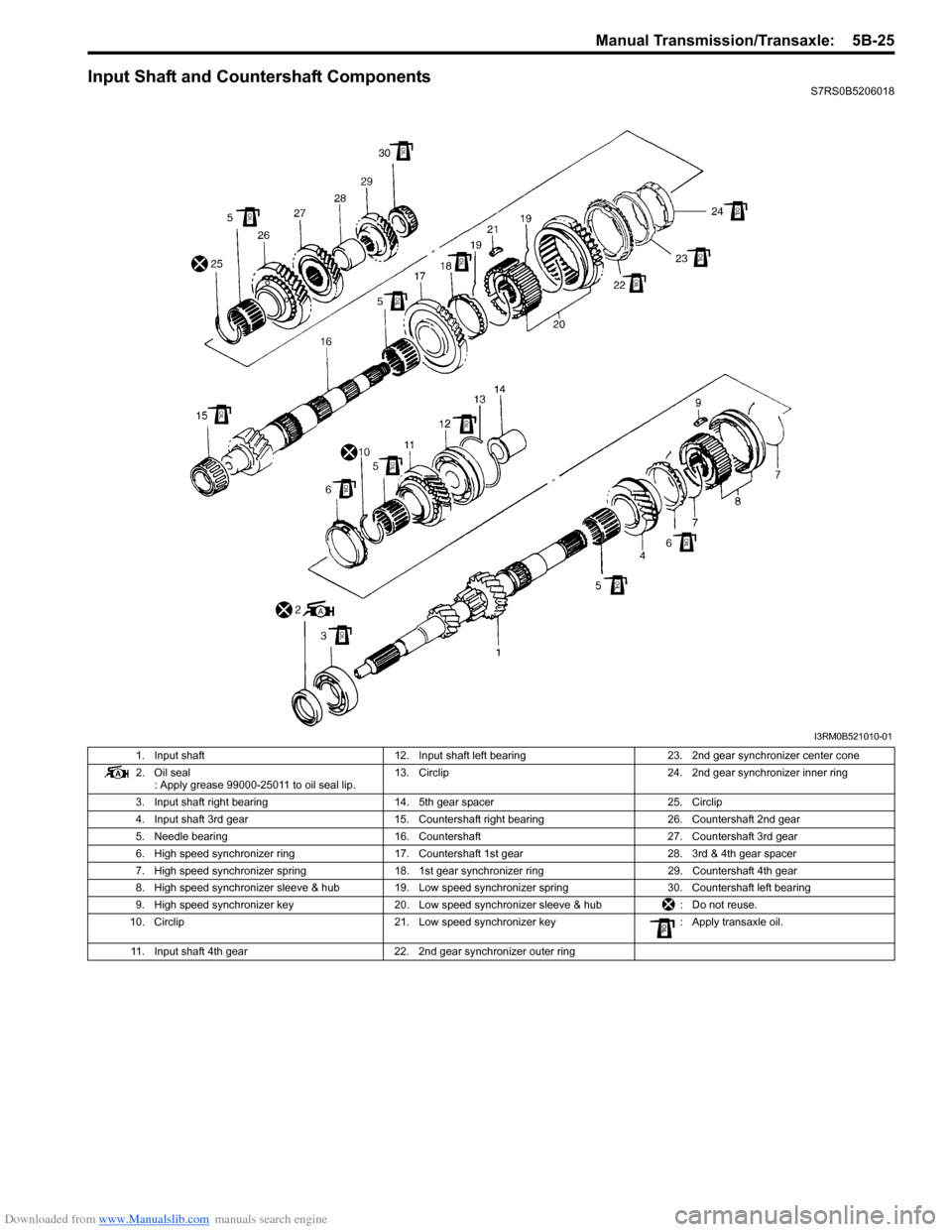

Input Shaft and Countershaft ComponentsS7RS0B5206018

I3RM0B521010-01

1. Input shaft12. Input shaft left bearing 23. 2nd gear synchronizer center cone

2. Oil seal : Apply grease 99000-25011 to oil seal lip. 13. Circlip

24. 2nd gear synchronizer inner ring

3. Input shaft right bearing 14. 5th gear spacer 25. Circlip

4. Input shaft 3rd gear 15. Countershaft right bearing 26. Countershaft 2nd gear

5. Needle bearing 16. Countershaft 27. Countershaft 3rd gear

6. High speed synchronizer ring 17. Countershaft 1st gear 28. 3rd & 4th gear spacer

7. High speed synchronizer spring 18. 1st gear synchronizer ring 29. Countershaft 4th gear

8. High speed synchronizer sleeve & hub 19. Low speed synchronizer spring 30. Countershaft left bearing

9. High speed synchronizer key 20. Low speed synchronizer sleeve & hub : Do not reuse.

10. Circlip 21. Low speed synchronizer key : Apply transaxle oil.

11. Input shaft 4th gear 22. 2nd gear synchronizer outer ring

Page 840 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-26 Manual Transmission/Transaxle:

Input Shaft Assembly Disassembly and

Reassembly

S7RS0B5206019

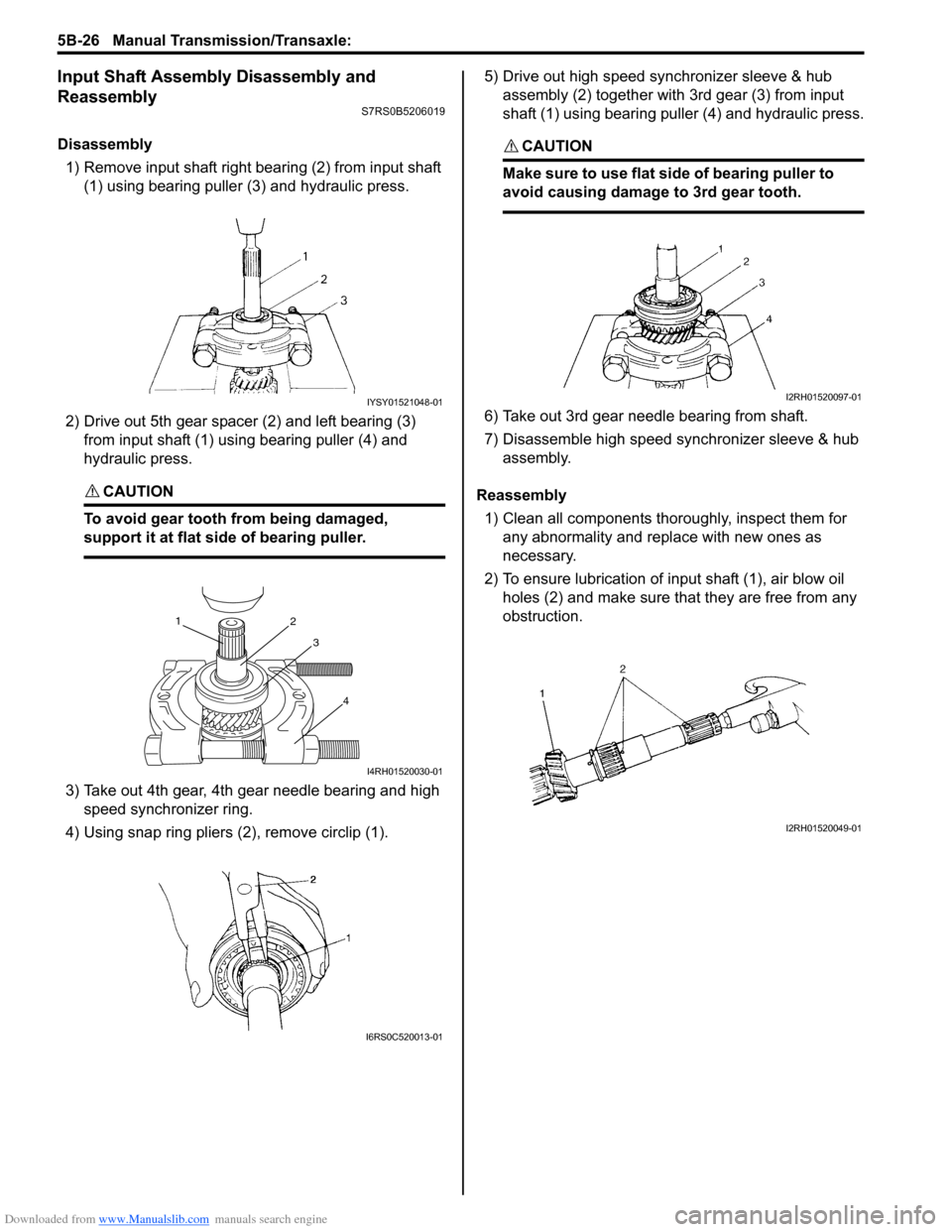

Disassembly1) Remove input shaft right bearing (2) from input shaft (1) using bearing puller (3) and hydraulic press.

2) Drive out 5th gear spacer (2) and left bearing (3) from input shaft (1) using bearing puller (4) and

hydraulic press.

CAUTION!

To avoid gear tooth from being damaged,

support it at flat side of bearing puller.

3) Take out 4th gear, 4th gear needle bearing and high speed synchronizer ring.

4) Using snap ring pliers (2), remove circlip (1). 5) Drive out high speed synchronizer sleeve & hub

assembly (2) together with 3rd gear (3) from input

shaft (1) using bearing puller (4) and hydraulic press.

CAUTION!

Make sure to use flat side of bearing puller to

avoid causing damage to 3rd gear tooth.

6) Take out 3rd gear needle bearing from shaft.

7) Disassemble high speed synchronizer sleeve & hub assembly.

Reassembly 1) Clean all components thoroughly, inspect them for any abnormality and replace with new ones as

necessary.

2) To ensure lubrication of input shaft (1), air blow oil holes (2) and make sure that they are free from any

obstruction.

IYSY01521048-01

1 2

3

4

I4RH01520030-01

I6RS0C520013-01

I2RH01520097-01

I2RH01520049-01

Page 841 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-27

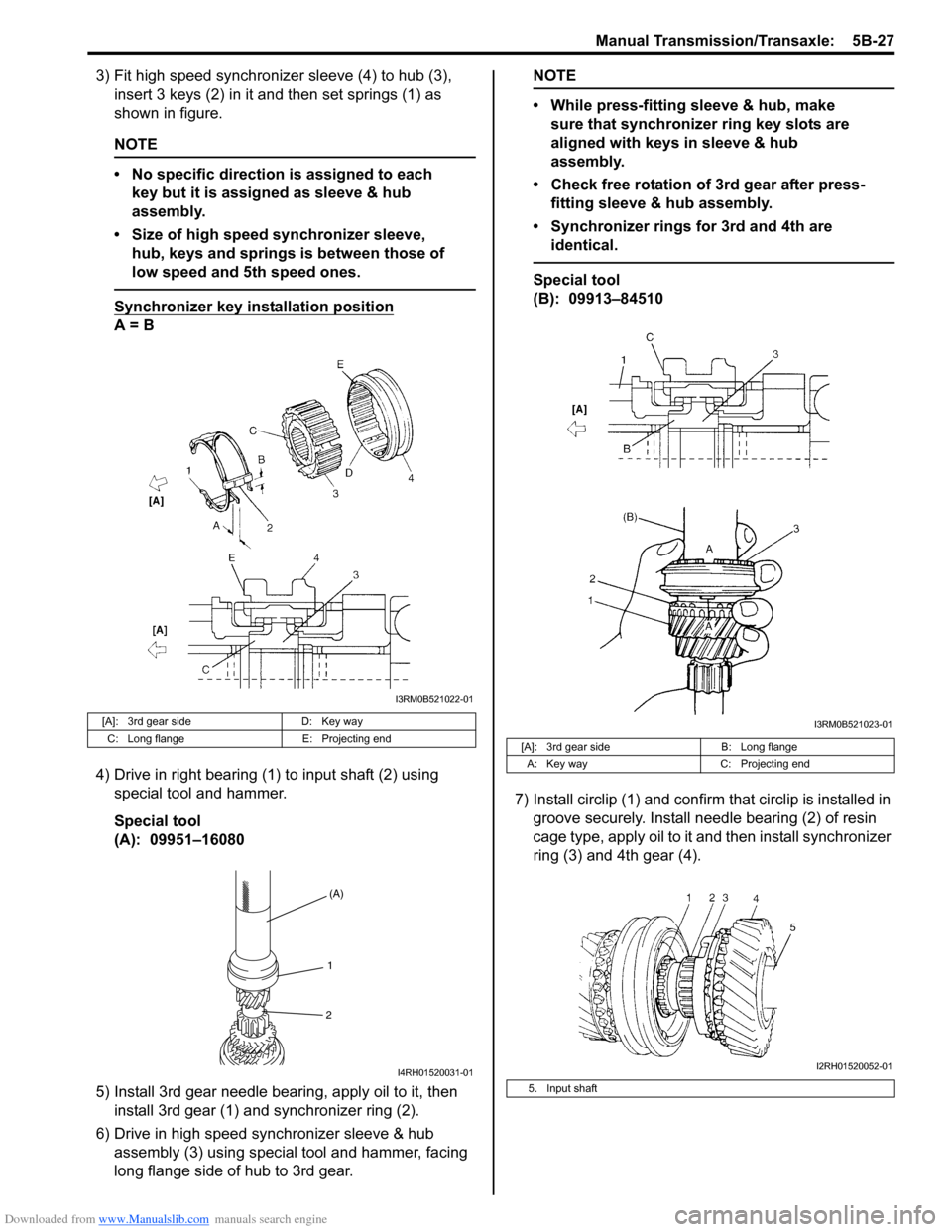

3) Fit high speed synchronizer sleeve (4) to hub (3), insert 3 keys (2) in it and then set springs (1) as

shown in figure.

NOTE

• No specific direction is assigned to each key but it is assigned as sleeve & hub

assembly.

• Size of high speed synchronizer sleeve, hub, keys and springs is between those of

low speed and 5th speed ones.

Synchronizer key in stallation position

A = B

4) Drive in right bearing (1) to input shaft (2) using special tool and hammer.

Special tool

(A): 09951–16080

5) Install 3rd gear needle bearing, apply oil to it, then install 3rd gear (1) and synchronizer ring (2).

6) Drive in high speed synchronizer sleeve & hub assembly (3) using special tool and hammer, facing

long flange side of hub to 3rd gear.

NOTE

• While press-fitting sleeve & hub, make sure that synchronizer ring key slots are

aligned with keys in sleeve & hub

assembly.

• Check free rotation of 3rd gear after press- fitting sleeve & hub assembly.

• Synchronizer rings for 3rd and 4th are identical.

Special tool

(B): 09913–84510

7) Install circlip (1) and confirm that circlip is installed in

groove securely. Install needle bearing (2) of resin

cage type, apply oil to it and then install synchronizer

ring (3) and 4th gear (4).

[A]: 3rd gear side D: Key way

C: Long flange E: Projecting end

I3RM0B521022-01

(A)

1

2

I4RH01520031-01

[A]: 3rd gear side B: Long flange

A: Key way C: Projecting end

5. Input shaft

I3RM0B521023-01

I2RH01520052-01

Page 842 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-28 Manual Transmission/Transaxle:

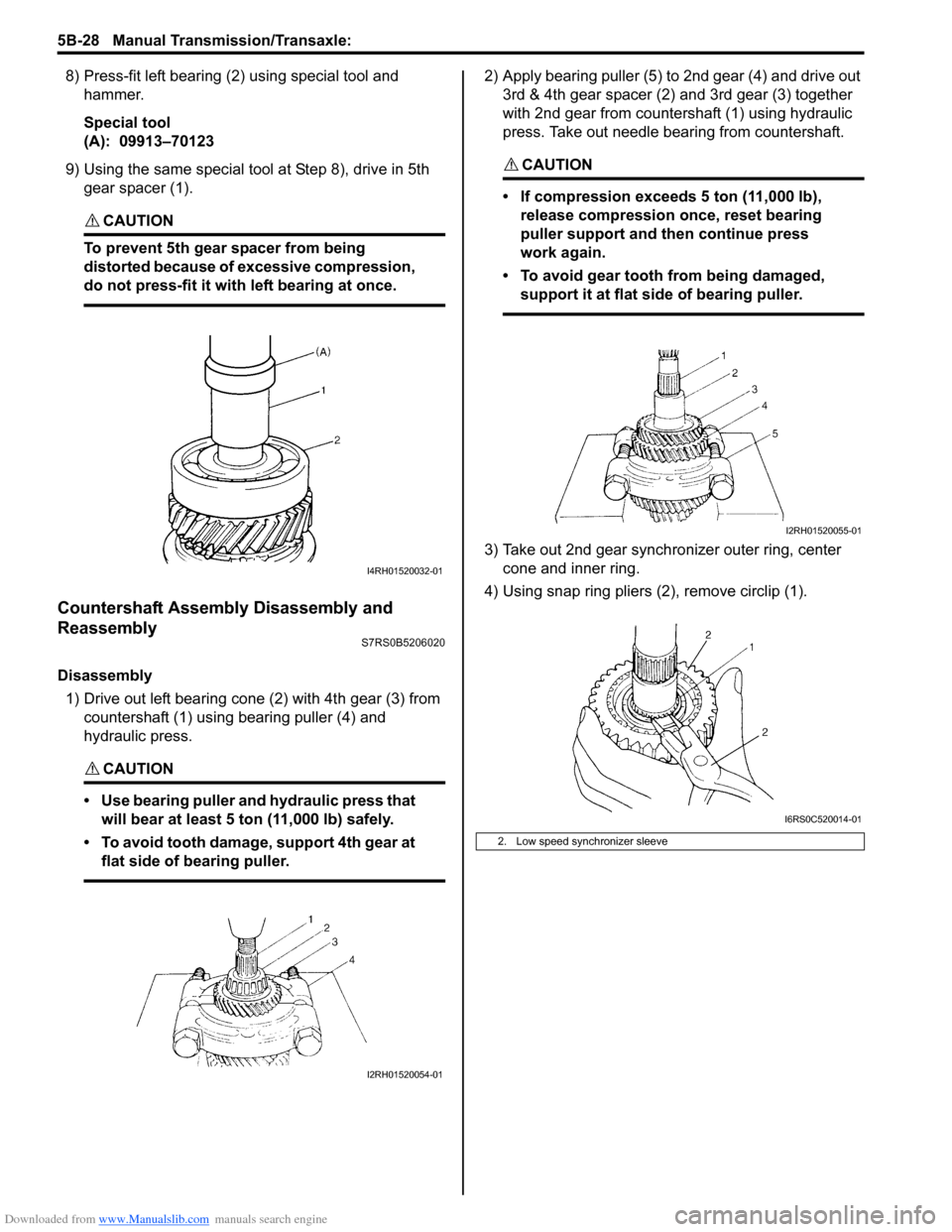

8) Press-fit left bearing (2) using special tool and hammer.

Special tool

(A): 09913–70123

9) Using the same special tool at Step 8), drive in 5th

gear spacer (1).

CAUTION!

To prevent 5th gear spacer from being

distorted because of excessive compression,

do not press-fit it with left bearing at once.

Countershaft Assembly Disassembly and

Reassembly

S7RS0B5206020

Disassembly

1) Drive out left bearing cone (2) with 4th gear (3) from countershaft (1) using bearing puller (4) and

hydraulic press.

CAUTION!

• Use bearing puller and hydraulic press that will bear at least 5 ton (11,000 lb) safely.

• To avoid tooth damage, support 4th gear at flat side of bearing puller.

2) Apply bearing puller (5) to 2nd gear (4) and drive out 3rd & 4th gear spacer (2) and 3rd gear (3) together

with 2nd gear from countershaft (1) using hydraulic

press. Take out needle bearing from countershaft.

CAUTION!

• If compression exceeds 5 ton (11,000 lb), release compression once, reset bearing

puller support and then continue press

work again.

• To avoid gear tooth from being damaged, support it at flat side of bearing puller.

3) Take out 2nd gear synchronizer outer ring, center cone and inner ring.

4) Using snap ring pliers (2), remove circlip (1).

I4RH01520032-01

I2RH01520054-01

2. Low speed synchronizer sleeve

I2RH01520055-01

I6RS0C520014-01