Torque spec SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1316 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-21 Instrumentation / Driver Info. / Horn:

Antenna Amplifier Removal and InstallationS7RS0B9306023

NOTE

Antenna amplifier incorporated with antenna

base.

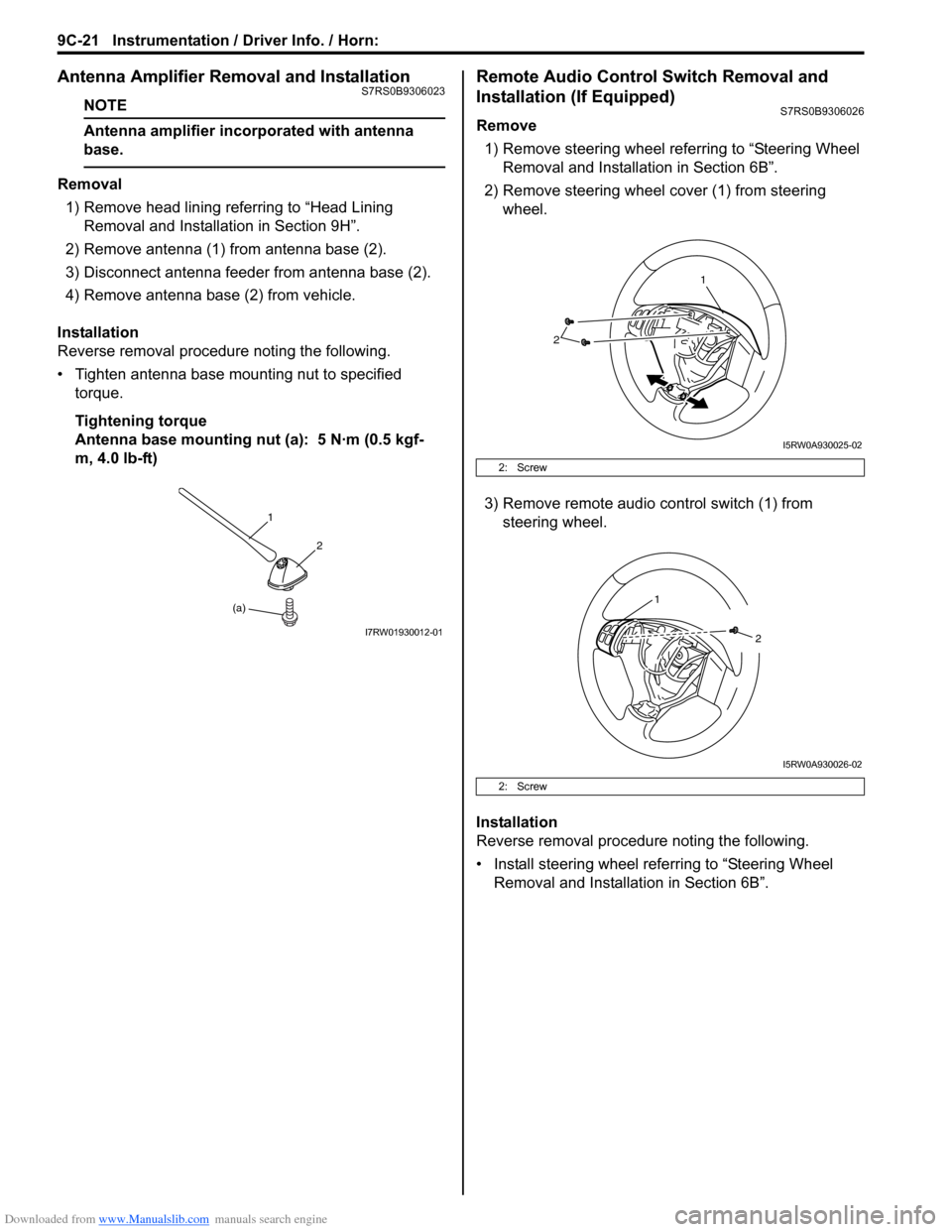

Removal1) Remove head lining referring to “Head Lining Removal and Installa tion in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting nut to specified torque.

Tightening torque

Antenna base mounting nut (a): 5 N·m (0.5 kgf-

m, 4.0 lb-ft)

Remote Audio Control Switch Removal and

Installation (If Equipped)

S7RS0B9306026

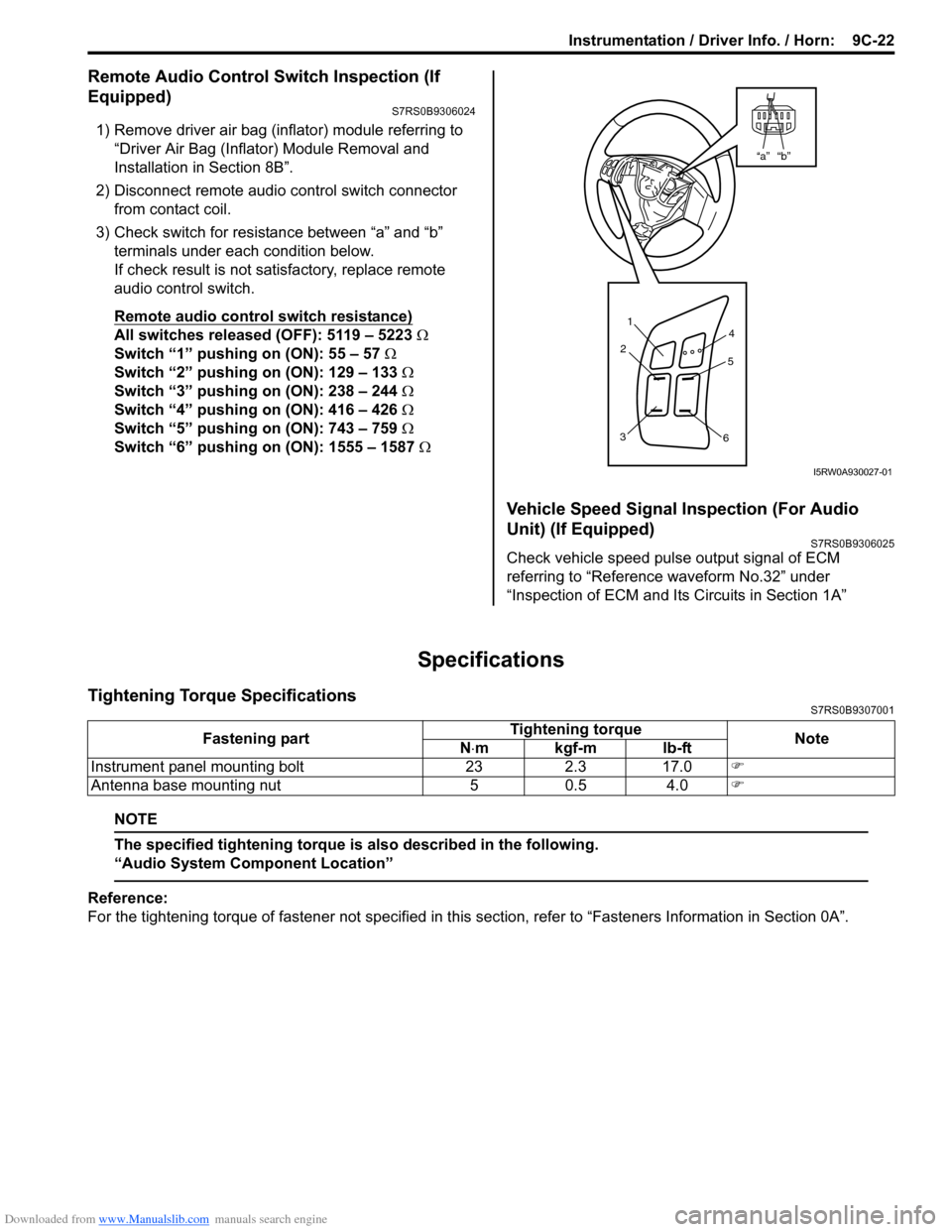

Remove

1) Remove steering wheel re ferring to “Steering Wheel

Removal and Installati on in Section 6B”.

2) Remove steering wheel cover (1) from steering wheel.

3) Remove remote audio control switch (1) from steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel Removal and Installati on in Section 6B”.

(a)1

2

I7RW01930012-01

2: Screw

2: Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

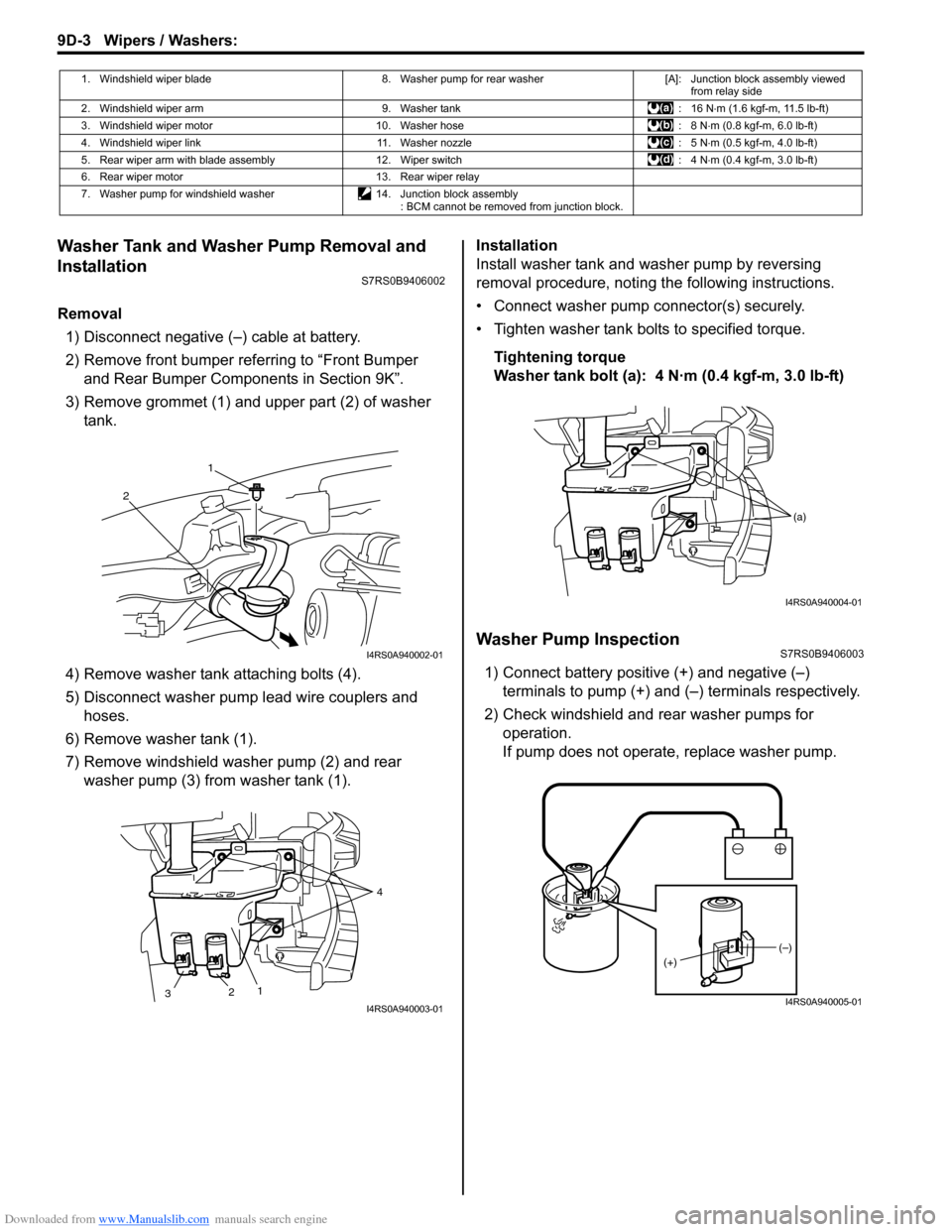

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

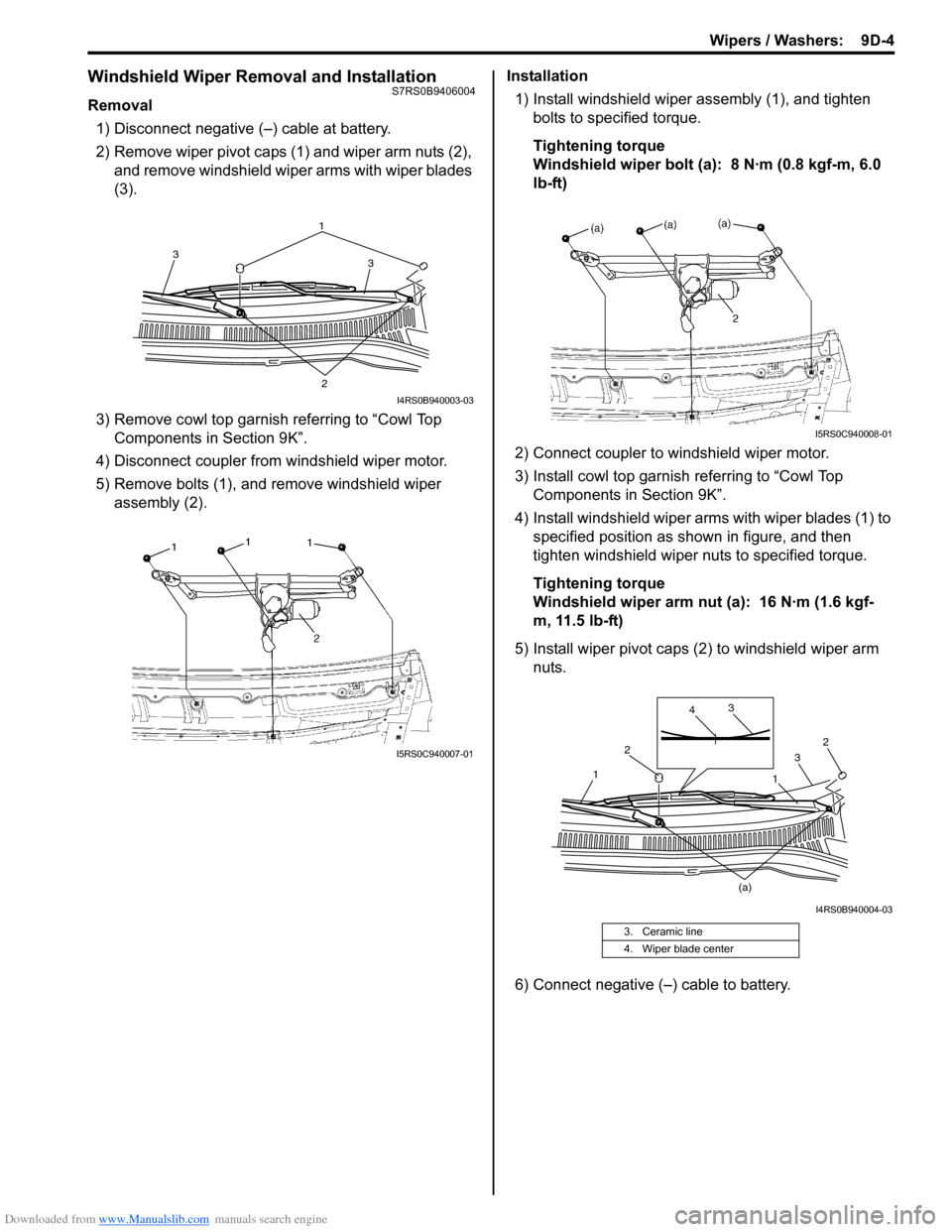

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1321 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-4

Windshield Wiper Removal and InstallationS7RS0B9406004

Removal1) Disconnect negative (–) cable at battery.

2) Remove wiper pivot caps (1) and wiper arm nuts (2), and remove windshield wiper arms with wiper blades

(3).

3) Remove cowl top garnish referring to “Cowl Top Components in Section 9K”.

4) Disconnect coupler from windshield wiper motor.

5) Remove bolts (1), and remove windshield wiper assembly (2). Installation

1) Install windshield wiper assembly (1), and tighten bolts to specified torque.

Tightening torque

Windshield wiper bolt (a): 8 N·m (0.8 kgf-m, 6.0

lb-ft)

2) Connect coupler to windshield wiper motor.

3) Install cowl top garnish referring to “Cowl Top

Components in Section 9K”.

4) Install windshield wiper arms with wiper blades (1) to specified position as shown in figure, and then

tighten windshield wiper nuts to specified torque.

Tightening torque

Windshield wiper arm nut (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

5) Install wiper pivot caps (2 ) to windshield wiper arm

nuts.

6) Connect negative (–) cable to battery.

1 3

3

2

I4RS0B940003-03

I5RS0C940007-01

3. Ceramic line

4. Wiper blade center

I5RS0C940008-01

2

2 3

3

4

1

1

(a)

I4RS0B940004-03

Page 1323 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-6

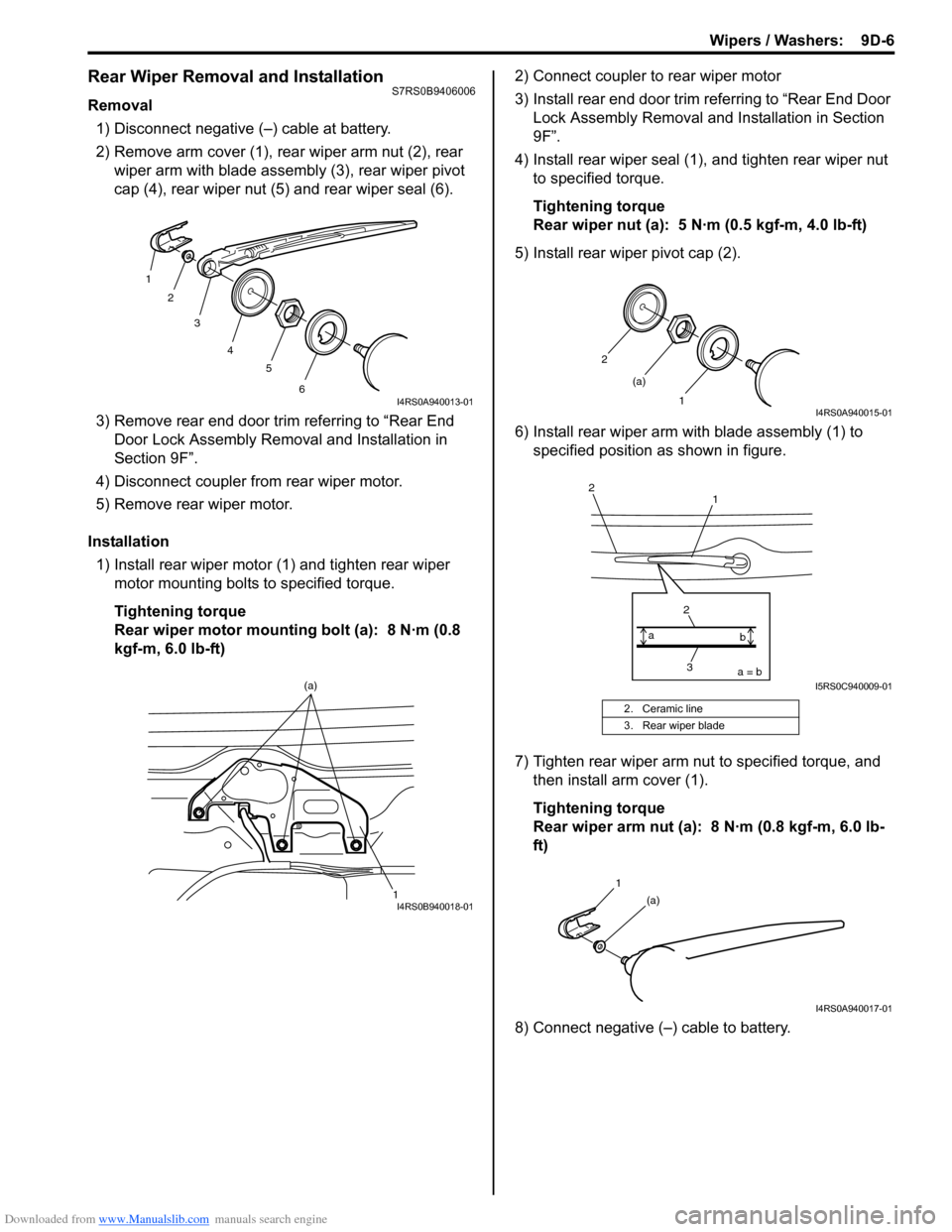

Rear Wiper Removal and InstallationS7RS0B9406006

Removal1) Disconnect negative (–) cable at battery.

2) Remove arm cover (1), rear wiper arm nut (2), rear wiper arm with blade assembly (3), rear wiper pivot

cap (4), rear wiper nut (5) and rear wiper seal (6).

3) Remove rear end door trim referring to “Rear End Door Lock Assembly Remo val and Installation in

Section 9F”.

4) Disconnect coupler from rear wiper motor.

5) Remove rear wiper motor.

Installation 1) Install rear wiper motor (1) and tighten rear wiper motor mounting bolts to specified torque.

Tightening torque

Rear wiper motor mounting bolt (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft) 2) Connect coupler to rear wiper motor

3) Install rear end door trim referring to “Rear End Door

Lock Assembly Removal and Installation in Section

9F”.

4) Install rear wiper seal (1), and tighten rear wiper nut to specified torque.

Tightening torque

Rear wiper nut (a): 5 N·m (0.5 kgf-m, 4.0 lb-ft)

5) Install rear wiper pivot cap (2).

6) Install rear wiper arm with blade assembly (1) to specified position as shown in figure.

7) Tighten rear wiper arm nut to specified torque, and then install arm cover (1).

Tightening torque

Rear wiper arm nut (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

8) Connect negative (–) cable to battery.

1 2

3

4 5

6

I4RS0A940013-01

1

(a)I4RS0B940018-01

2. Ceramic line

3. Rear wiper blade

2

1

(a)

I4RS0A940015-01

1

2

3

2a = b

a

bI5RS0C940009-01

1

(a)

I4RS0A940017-01

Page 1327 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-10

Rear Wiper Relay Removal and InstallationS7RS0B9406012

Removal1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

3) Remove rear wiper relay.

Installation

Reverse removal procedure for installation.

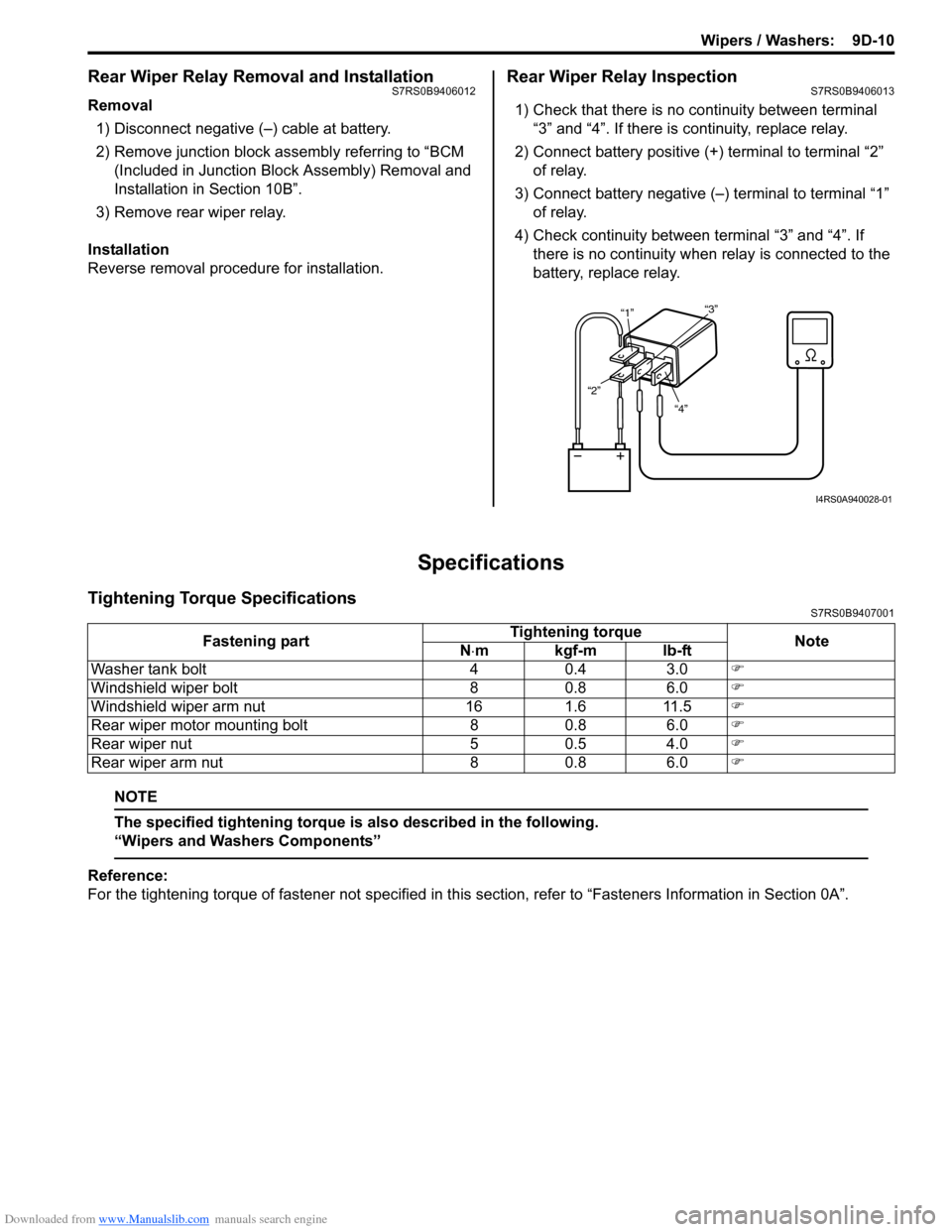

Rear Wiper Relay InspectionS7RS0B9406013

1) Check that there is no continuity between terminal “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

Specifications

Tightening Torque SpecificationsS7RS0B9407001

NOTE

The specified tightening torque is also described in the following.

“Wipers and Washers Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“4”

“2” “1”

“3”

I4RS0A940028-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Washer tank bolt 4 0.4 3.0 �)

Windshield wiper bolt 8 0.8 6.0 �)

Windshield wiper arm nut 16 1.6 11.5 �)

Rear wiper motor mounting bolt 8 0.8 6.0 �)

Rear wiper nut 5 0.5 4.0 �)

Rear wiper arm nut 8 0.8 6.0 �)

Page 1353 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-7

8) Remove key cylinder mounting bolt (1), and then remove key cylinder (2).

9) Disconnect door opening control rod (1) from outside handle.

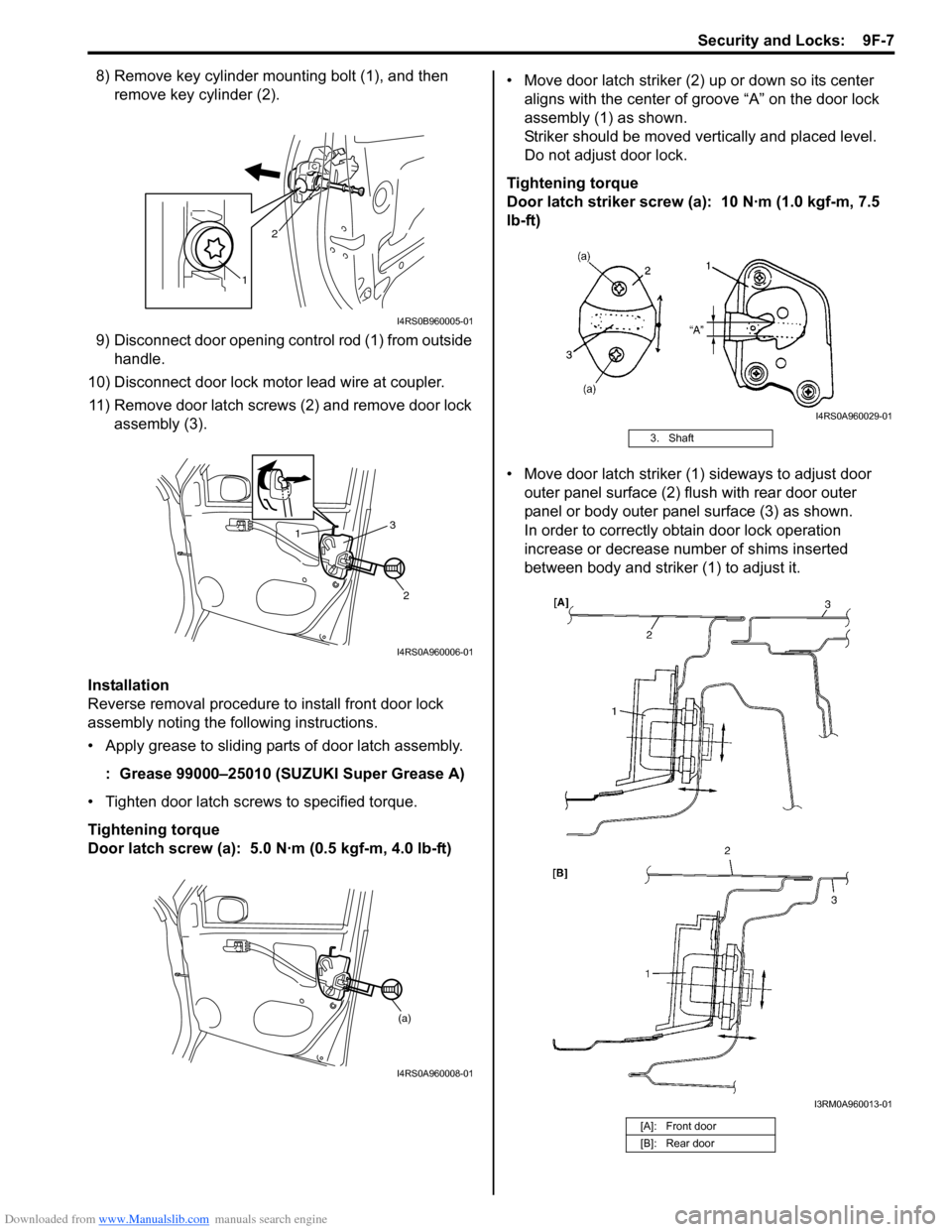

10) Disconnect door lock motor lead wire at coupler. 11) Remove door latch screws (2) and remove door lock assembly (3).

Installation

Reverse removal procedure to install front door lock

assembly noting the following instructions.

• Apply grease to sliding parts of door latch assembly.

: Grease 99000–25010 (SUZUKI Super Grease A)

• Tighten door latch screws to specified torque.

Tightening torque

Door latch screw (a): 5.0 N·m (0.5 kgf-m, 4.0 lb-ft) • Move door latch striker (2) up or down so its center

aligns with the center of groove “A” on the door lock

assembly (1) as shown.

Striker should be moved vertically and placed level.

Do not adjust door lock.

Tightening torque

Door latch striker screw (a): 10 N·m (1.0 kgf-m, 7.5

lb-ft)

• Move door latch striker (1) sideways to adjust door outer panel surface (2) flush with rear door outer

panel or body outer panel surface (3) as shown.

In order to correctly obtain door lock operation

increase or decrease number of shims inserted

between body and striker (1) to adjust it.

1 2

I4RS0B960005-01

1

2

3

I4RS0A960006-01

(a)

I4RS0A960008-01

3. Shaft

[A]: Front door

[B]: Rear door

I4RS0A960029-01

I3RM0A960013-01

Page 1356 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-10 Security and Locks:

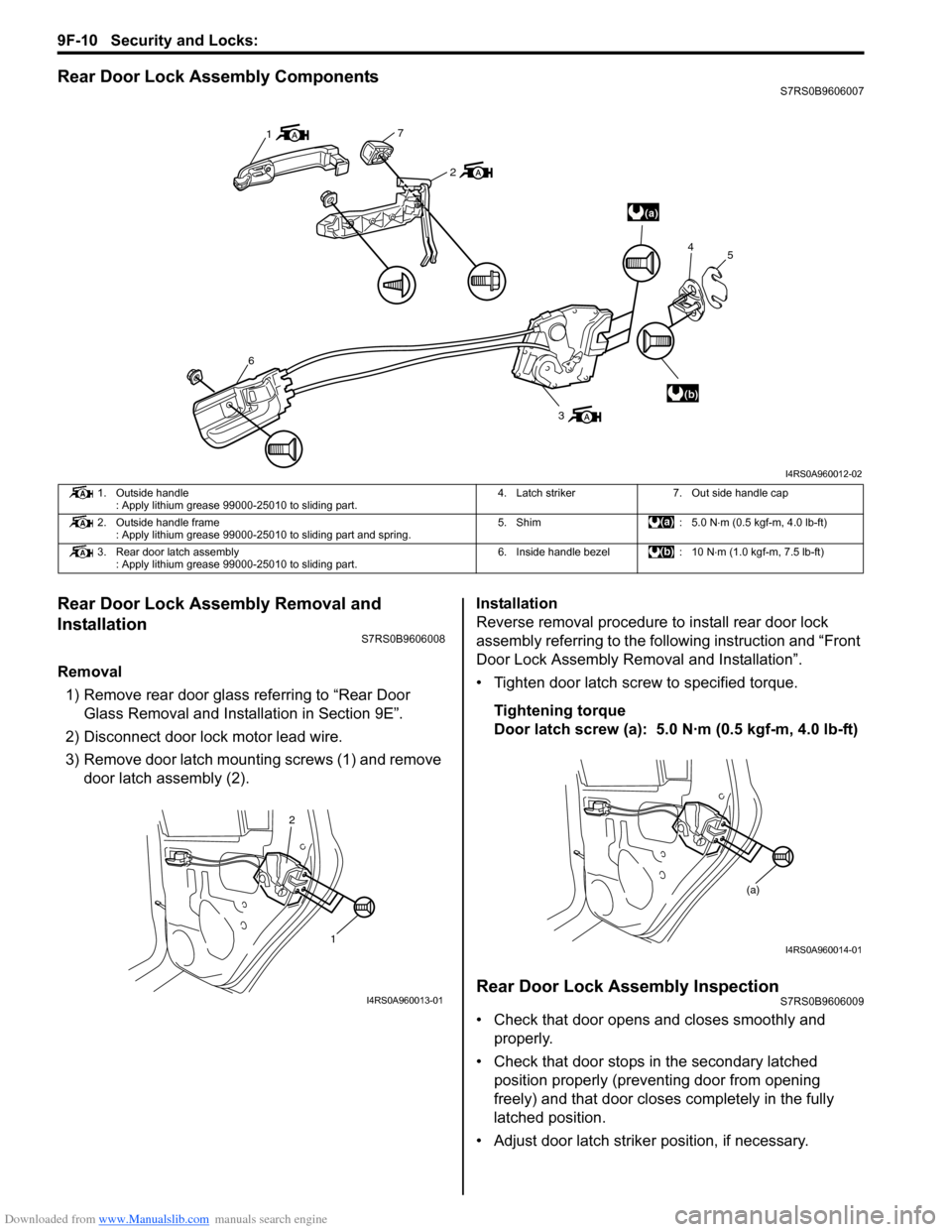

Rear Door Lock Assembly ComponentsS7RS0B9606007

Rear Door Lock Assembly Removal and

Installation

S7RS0B9606008

Removal1) Remove rear door glass referring to “Rear Door Glass Removal and Installation in Section 9E”.

2) Disconnect door lock motor lead wire.

3) Remove door latch mounting screws (1) and remove door latch assembly (2). Installation

Reverse removal procedure to install rear door lock

assembly referring to the following instruction and “Front

Door Lock Assembly Re

moval and Installation”.

• Tighten door latch screw to specified torque.

Tightening torque

Door latch screw (a): 5.0 N·m (0.5 kgf-m, 4.0 lb-ft)

Rear Door Lock Assembly InspectionS7RS0B9606009

• Check that door opens and closes smoothly and properly.

• Check that door stops in the secondary latched position properly (preventing door from opening

freely) and that door closes completely in the fully

latched position.

• Adjust door latch strike r position, if necessary.

(a)

(b)

1

7

2

6

3 4

5

I4RS0A960012-02

1. Outside handle

: Apply lithium grease 99000-25010 to sliding part. 4. Latch striker 7. Out side handle cap

2. Outside handle frame : Apply lithium grease 99000-25010 to sliding part and spring. 5. Shim : 5.0 N

⋅m (0.5 kgf-m, 4.0 lb-ft)

3. Rear door latch assembly : Apply lithium grease 99000-25010 to sliding part. 6. Inside handle bezel : 10 N

⋅m (1.0 kgf-m, 7.5 lb-ft)

1

2

I4RS0A960013-01

(a)

I4RS0A960014-01

Page 1358 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-12 Security and Locks:

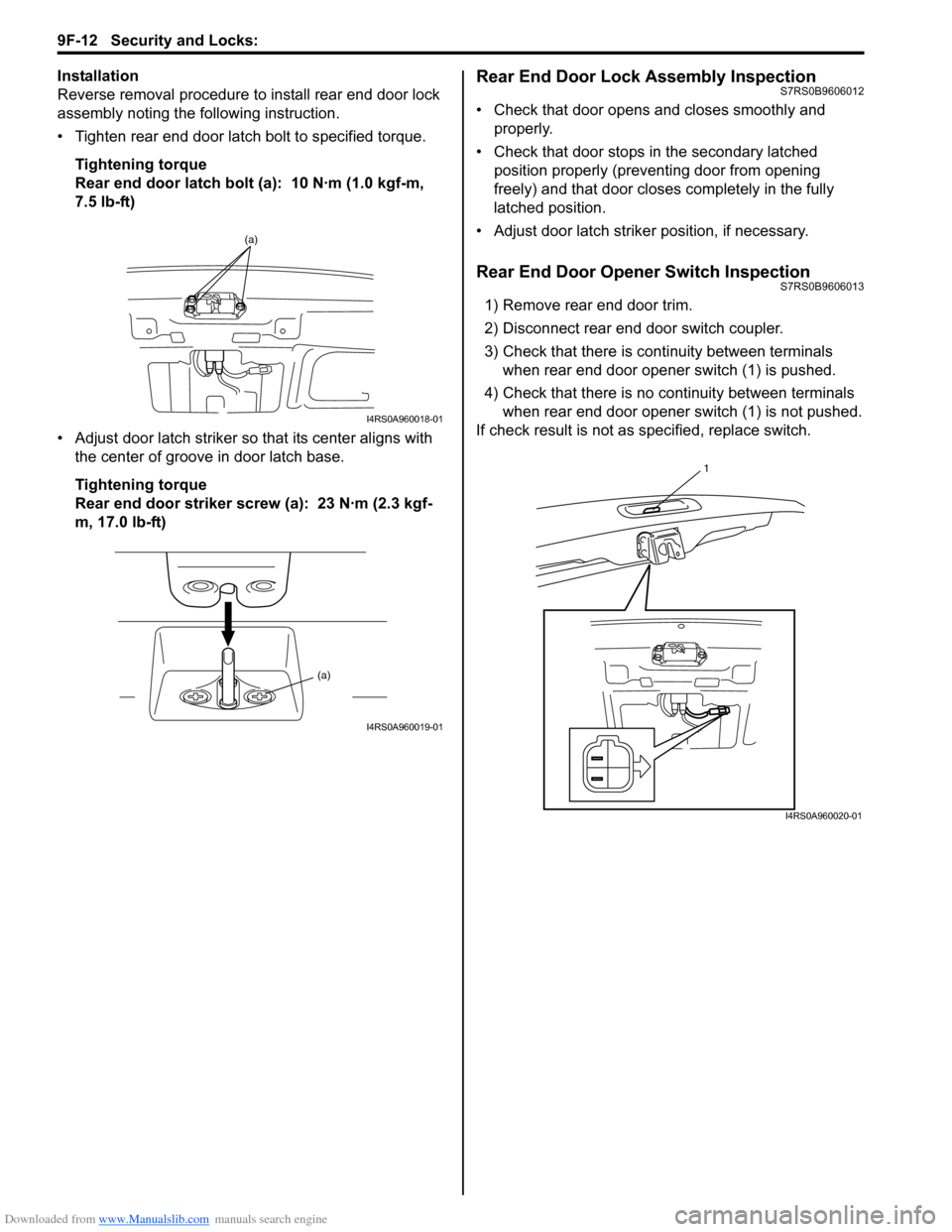

Installation

Reverse removal procedure to install rear end door lock

assembly noting the following instruction.

• Tighten rear end door latch bolt to specified torque.

Tightening torque

Rear end door latch bolt (a): 10 N·m (1.0 kgf-m,

7.5 lb-ft)

• Adjust door latch striker so that its center aligns with the center of groove in door latch base.

Tightening torque

Rear end door striker screw (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)Rear End Door Lock Assembly InspectionS7RS0B9606012

• Check that door opens and closes smoothly and properly.

• Check that door stops in the secondary latched position properly (preventing door from opening

freely) and that door closes completely in the fully

latched position.

• Adjust door latch strike r position, if necessary.

Rear End Door Opener Switch InspectionS7RS0B9606013

1) Remove rear end door trim.

2) Disconnect rear end door switch coupler.

3) Check that there is continuity between terminals

when rear end door opener switch (1) is pushed.

4) Check that there is no continuity between terminals when rear end door opener switch (1) is not pushed.

If check result is not as specified, replace switch.

(a)

I4RS0A960018-01

(a)

I4RS0A960019-01

1

I4RS0A960020-01

Page 1362 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-16 Security and Locks:

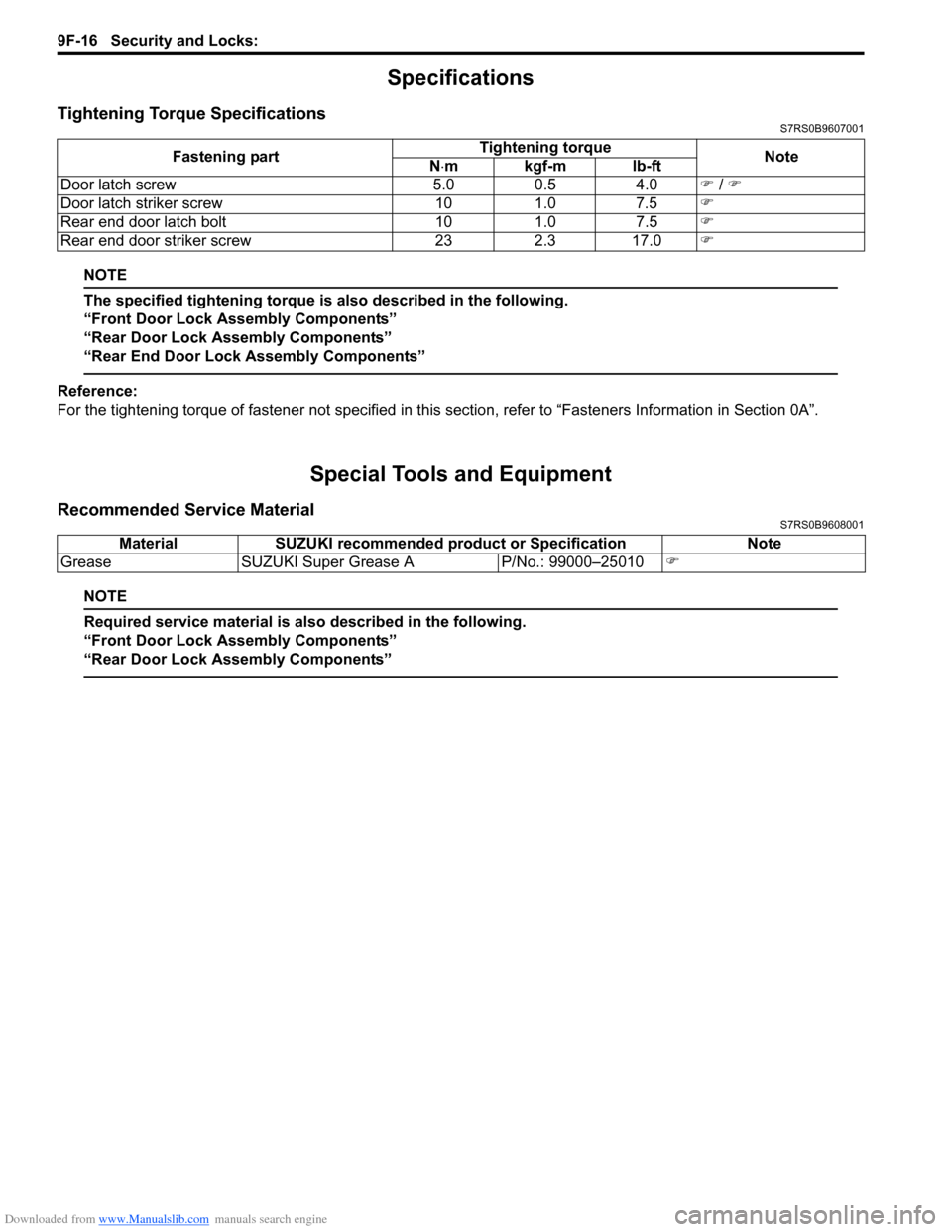

Specifications

Tightening Torque SpecificationsS7RS0B9607001

NOTE

The specified tightening torque is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

“Rear End Door Lock Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9608001

NOTE

Required service material is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Door latch screw 5.0 0.5 4.0 �) / �)

Door latch striker screw 10 1.0 7.5 �)

Rear end door latch bolt 10 1.0 7.5 �)

Rear end door striker screw 23 2.3 17.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25010�)