valve SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 980 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

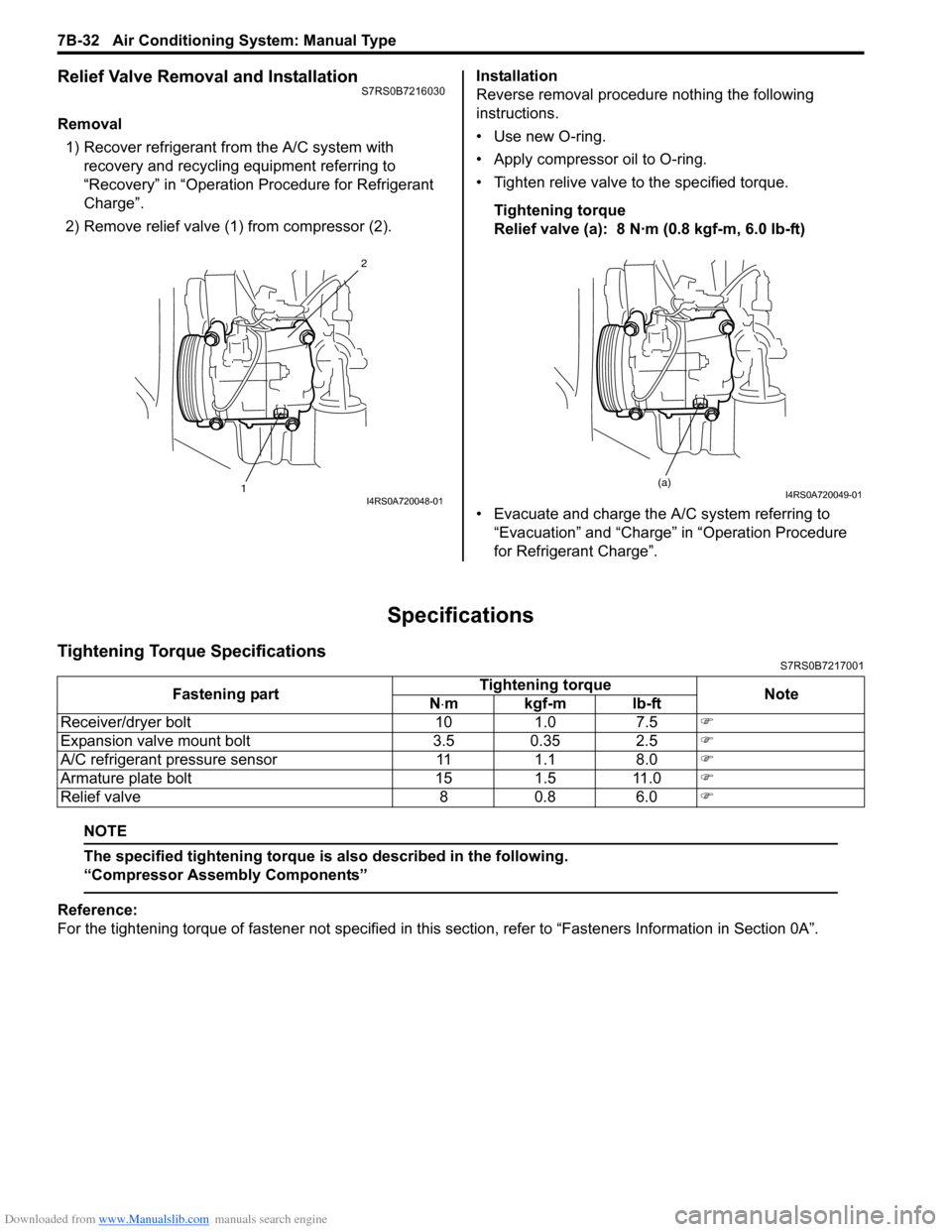

Relief Valve Removal and InstallationS7RS0B7216030

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Remove relief valve (1) from compressor (2). Installation

Reverse removal procedure nothing the following

instructions.

• Use new O-ring.

• Apply compressor oil to O-ring.

• Tighten relive valve to the specified torque.

Tightening torque

Relief valve (a): 8 N·m (0.8 kgf-m, 6.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Specifications

Tightening Torque SpecificationsS7RS0B7217001

NOTE

The specified tightening torque is also described in the following.

“Compressor Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

12I4RS0A720048-01

(a)I4RS0A720049-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Receiver/dryer bolt 10 1.0 7.5 �)

Expansion valve mount bolt 3.5 0.35 2.5 �)

A/C refrigerant pressure sensor 11 1.1 8.0 �)

Armature plate bolt 15 1.5 11.0 �)

Relief valve 8 0.8 6.0 �)

Page 989 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-41

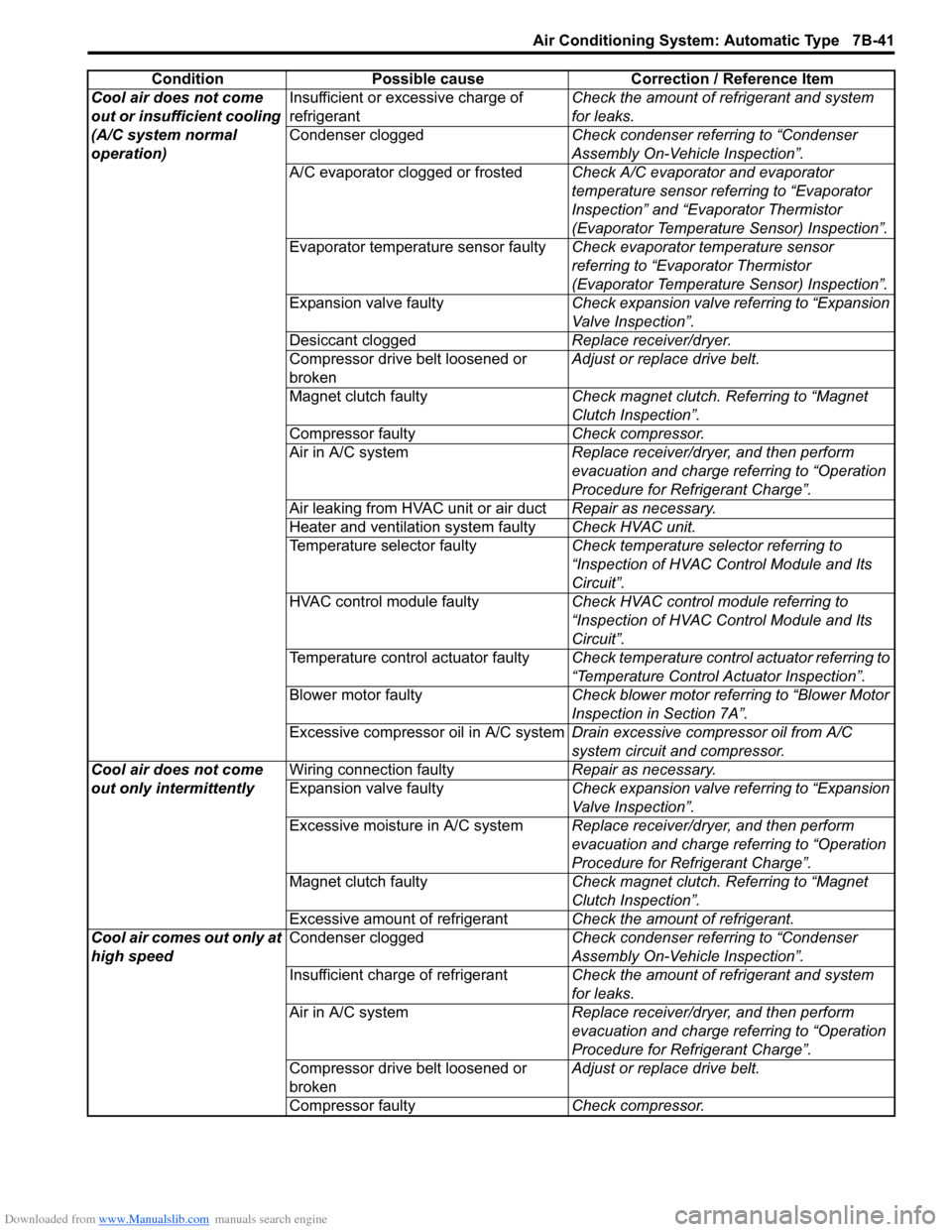

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Temperature selector faulty Check temperature selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Temperature control actuator faulty Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Condition Possible cause Correction / Reference Item

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

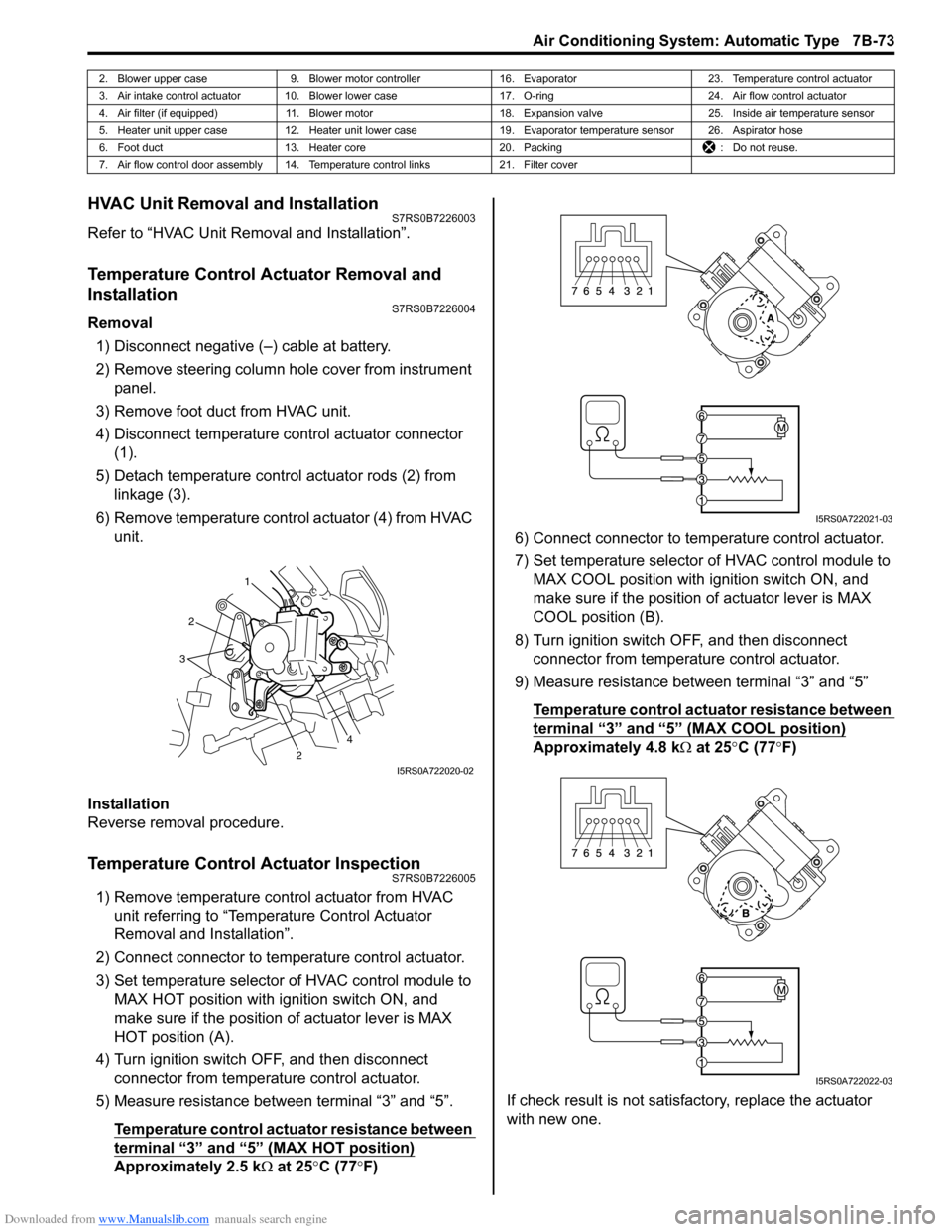

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

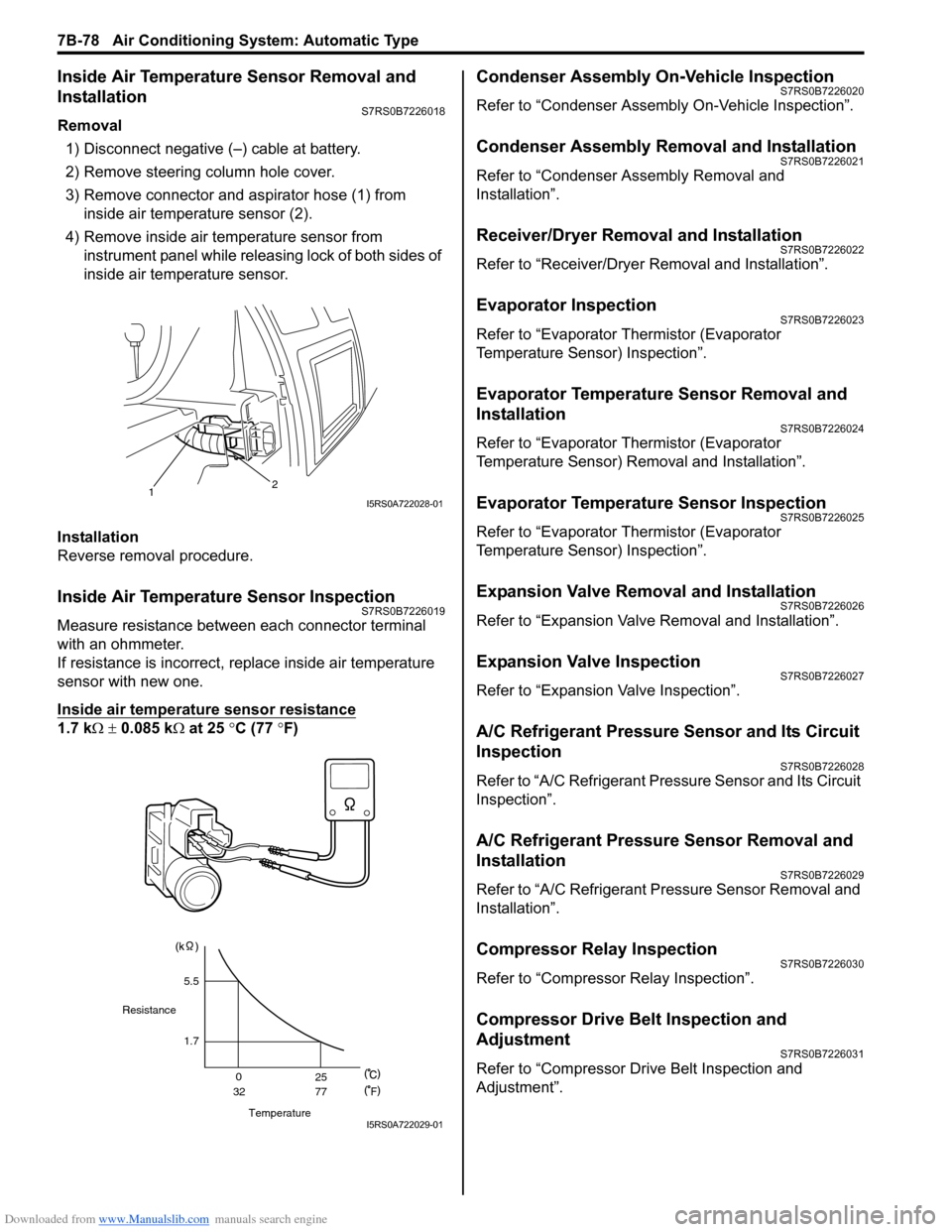

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1027 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-79

Compressor Drive Belt Removal and

Installation

S7RS0B7226032

Refer to “Compressor Drive Belt Removal and

Installation”.

Compressor Assembly Removal and

Installation

S7RS0B7226033

Refer to “Compressor Assembly Removal and

Installation”.

Compressor Assembly ComponentsS7RS0B7226034

Refer to “Compressor Assembly Components”.

Magnet Clutch Removal and InstallationS7RS0B7226035

Refer to “Magnet Clutch Removal and Installation”.

Magnet Clutch InspectionS7RS0B7226036

Refer to “Magnet Clutch Inspection”.

Relief Valve InspectionS7RS0B7226039

Refer to “Relief Valve Inspection”.

Special Tools and Equipment

Special ToolS7RS0B7228001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 1172 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-1 Wiring Systems:

Body, Cab and Accessories

Wiring Systems

Precautions

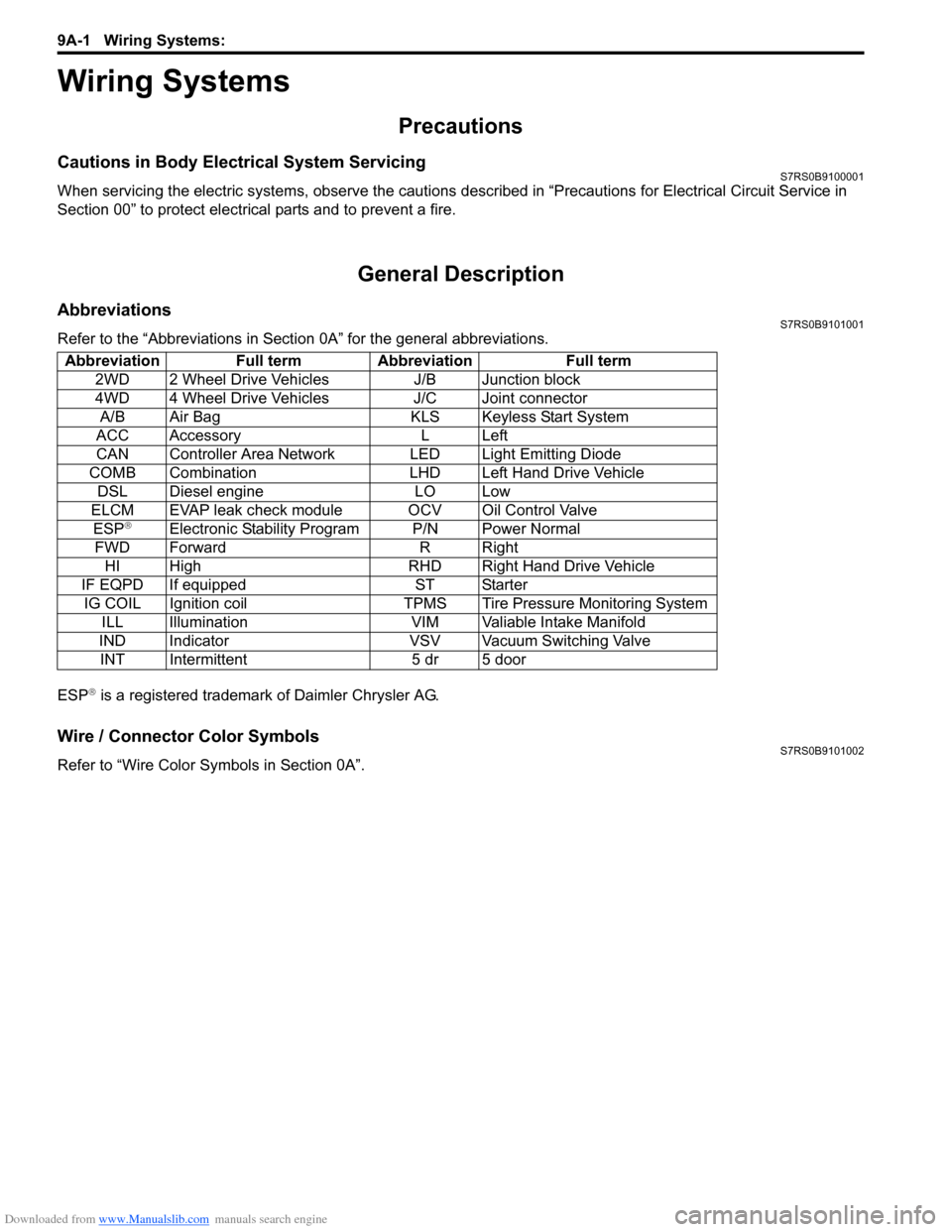

Cautions in Body Electrical System ServicingS7RS0B9100001

When servicing the electric systems, observe the cautions described in “Precautions for Electrical Circuit Service in

Section 00” to protect electrical parts and to prevent a fire.

General Description

AbbreviationsS7RS0B9101001

Refer to the “Abbreviations in Sect ion 0A” for the general abbreviations.

ESP

® is a registered trademark of Daimler Chrysler AG.

Wire / Connector Color SymbolsS7RS0B9101002

Refer to “Wire Color Sy mbols in Section 0A”.

Abbreviation Full term Abbreviation Full term

2WD 2 Wheel Drive Vehicles J/B Junction block

4WD 4 Wheel Drive Vehicles J/C Joint connectorA/B Air Bag KLS Keyless Start System

ACC Accessory L Left

CAN Controller Area Network LED Light Emitting Diode

COMB Combination LHD Left Hand Drive Vehicle DSL Diesel engine LO Low

ELCM EVAP leak check module OCV Oil Control Valve ESP

®Electronic Stability Program P/N Power Normal

FWD Forward R Right HI High RHD Right Hand Drive Vehicle

IF EQPD If equipped ST Starter IG COIL Ignition coil TPMS Tire Pressure Monitoring System ILL Illumination VIM Valiable Intake Manifold

IND Indicator VSV Vacuum Switching Valve INT Intermittent 5 dr 5 door

Page 1182 of 1496

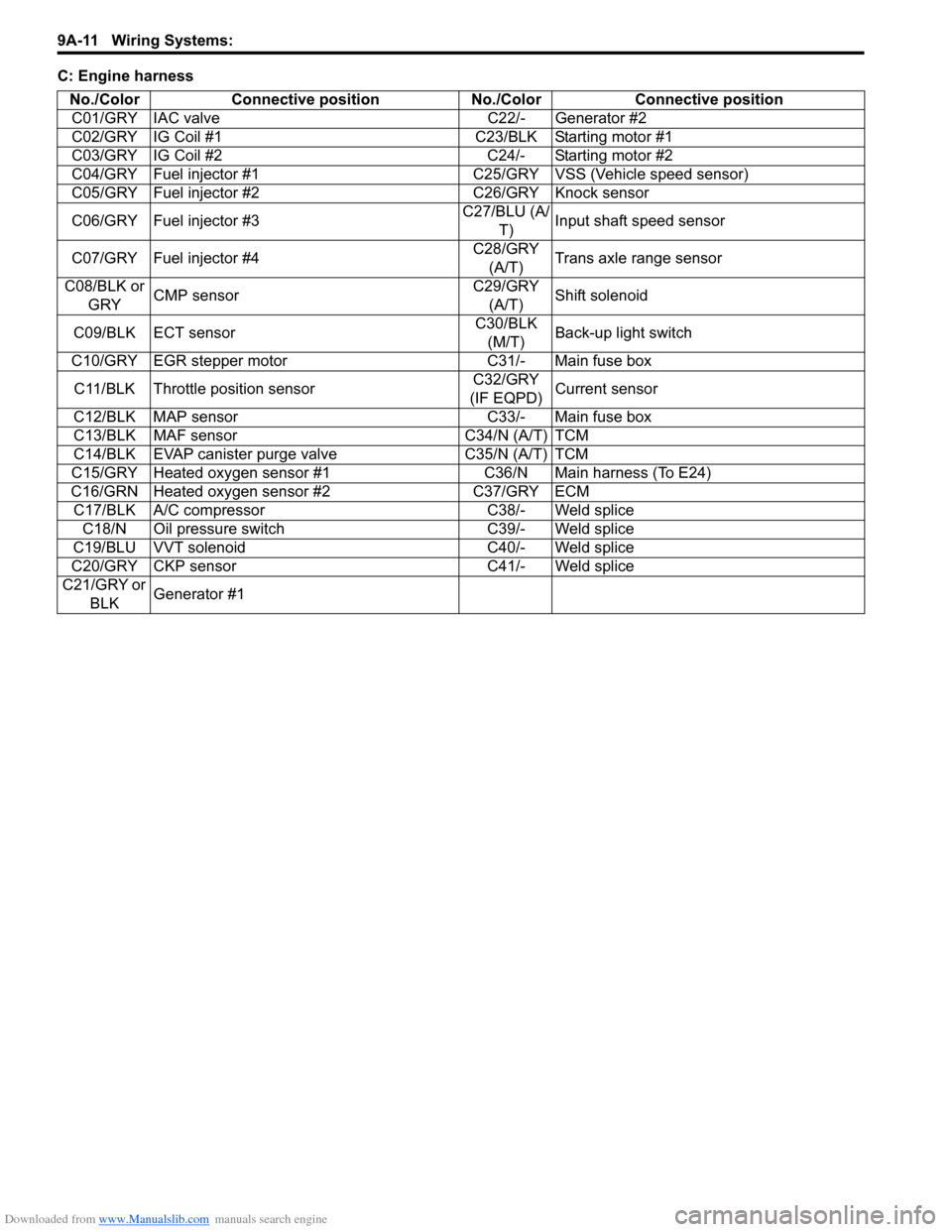

Downloaded from www.Manualslib.com manuals search engine 9A-11 Wiring Systems:

C: Engine harnessNo./Color Connective position No./Color Connective positionC01/GRY IAC valve C22/- Generator #2

C02/GRY IG Coil #1 C23/BLK Starting motor #1

C03/GRY IG Coil #2 C24/- Starting motor #2

C04/GRY Fuel injector #1 C25/GR Y VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK or GRY CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C11/BLK Throttle position sensor C32/GRY

(IF EQPD) Current sensor

C12/BLK MAP sensor C33/- Main fuse box

C13/BLK MAF sensor C34/N (A/T) TCM

C14/BLK EVAP canister purge valve C35/N (A/T) TCM

C15/GRY Heated oxygen sensor #1 C36/N Main harness (To E24)

C16/GRN Heated oxygen sensor #2 C37/GRY ECM C17/BLK A/C compressor C38/- Weld splice C18/N Oil pressure switch C39/- Weld splice

C19/BLU VVT solenoid C40/- Weld splice

C20/GRY CKP sensor C41/- Weld splice

C21/GRY or BLK Generator #1

Page 1184 of 1496

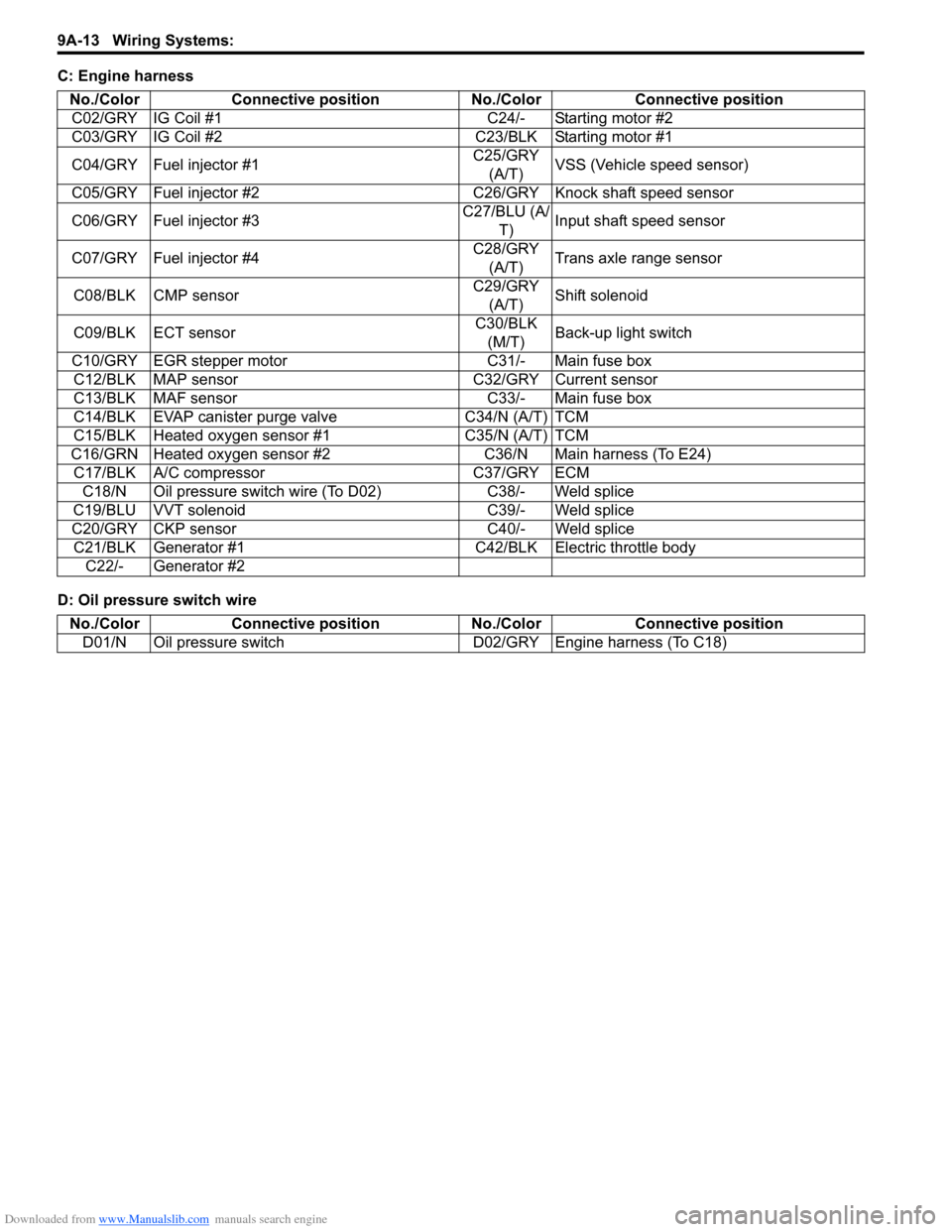

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

C: Engine harness

D: Oil pressure switch wireNo./Color Connective position No./Color Connective position

C02/GRY IG Coil #1 C24/- Starting motor #2

C03/GRY IG Coil #2 C23/BLK Starting motor #1

C04/GRY Fuel injector #1 C25/GRY

(A/T) VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock shaft speed sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C12/BLK MAP sensor C32/GRY Current sensor

C13/BLK MAF sensor C33/- Main fuse box

C14/BLK EVAP canister purge valve C34/N (A/T) TCM

C15/BLK Heated oxygen sensor #1 C35/N (A/T) TCM

C16/GRN Heated oxygen sensor #2 C36/N Main harness (To E24) C17/BLK A/C compressor C37/GRY ECM C18/N Oil pressure switch wire (To D02) C38/- Weld splice

C19/BLU VVT solenoid C39/- Weld splice

C20/GRY CKP sensor C40/- Weld splice C21/BLK Generator #1 C42/BLK Electric throttle body C22/- Generator #2

No./Color Connective position No./ColorConnective position

D01/N Oil pressure switch D02/GRY Engine harness (To C18)

Page 1222 of 1496

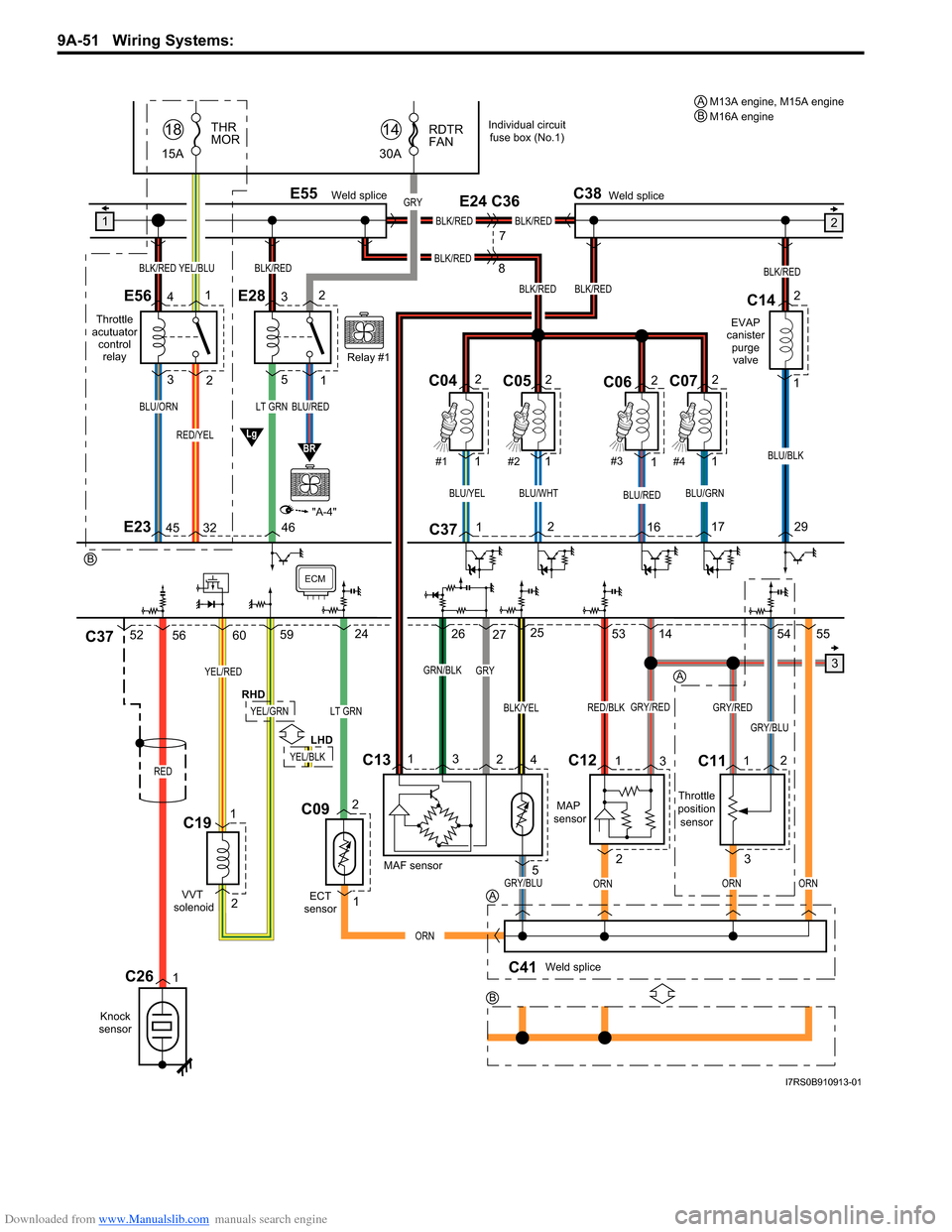

Downloaded from www.Manualslib.com manuals search engine 9A-51 Wiring Systems:

Throttle

acutuator controlrelay

4532

BLK/REDYEL/BLU

1

243E562

135E28

15A THR

MOR

18

M13A engine, M15A engine

M16A engine

A

B

A

A

B

B

2C09

LT GRN

1

C12

C13

C11

E23

C37

C37

Knock

sensor

C19

ECM

C042

1C052

1C062

1C072

1

#2

#1 #3

#4

BLU/REDBLU/WHTBLU/YELBLU/GRN

BLK/RED

BLU/BLK

EVAP

canister purgevalve

C14

ECT

sensor

ORN

MAF sensor

MAP

sensorThrottle

position sensor

Weld spliceC41

ORNORNORN

LT GRNBLU/REDBLU/ORN

RED/YEL

GRY

"A-4"

Lg

30A RDTR

FAN

14

Relay #1

BR

46

1

2

1

29

17

16

2

1

2425

26 27

4

3

2

1

5

1

2 3

1

32

2

3

54 55

RED/BLKGRY/REDGRY/RED

GRY/BLU

53 14

E24 C36

8

7

C26

RED

1

56

VVT

solenoid

1

2

60 59

BLK/RED

E55Weld spliceC38Weld splice

BLK/REDBLK/RED

BLK/REDBLK/RED

BLK/RED

GRN/BLKGRY

BLK/YEL

GRY/BLU

52

YEL/RED

Individual circuit

fuse box (No.1)

YEL/GRN

YEL/BLK

RHD

LHD

I7RS0B910913-01

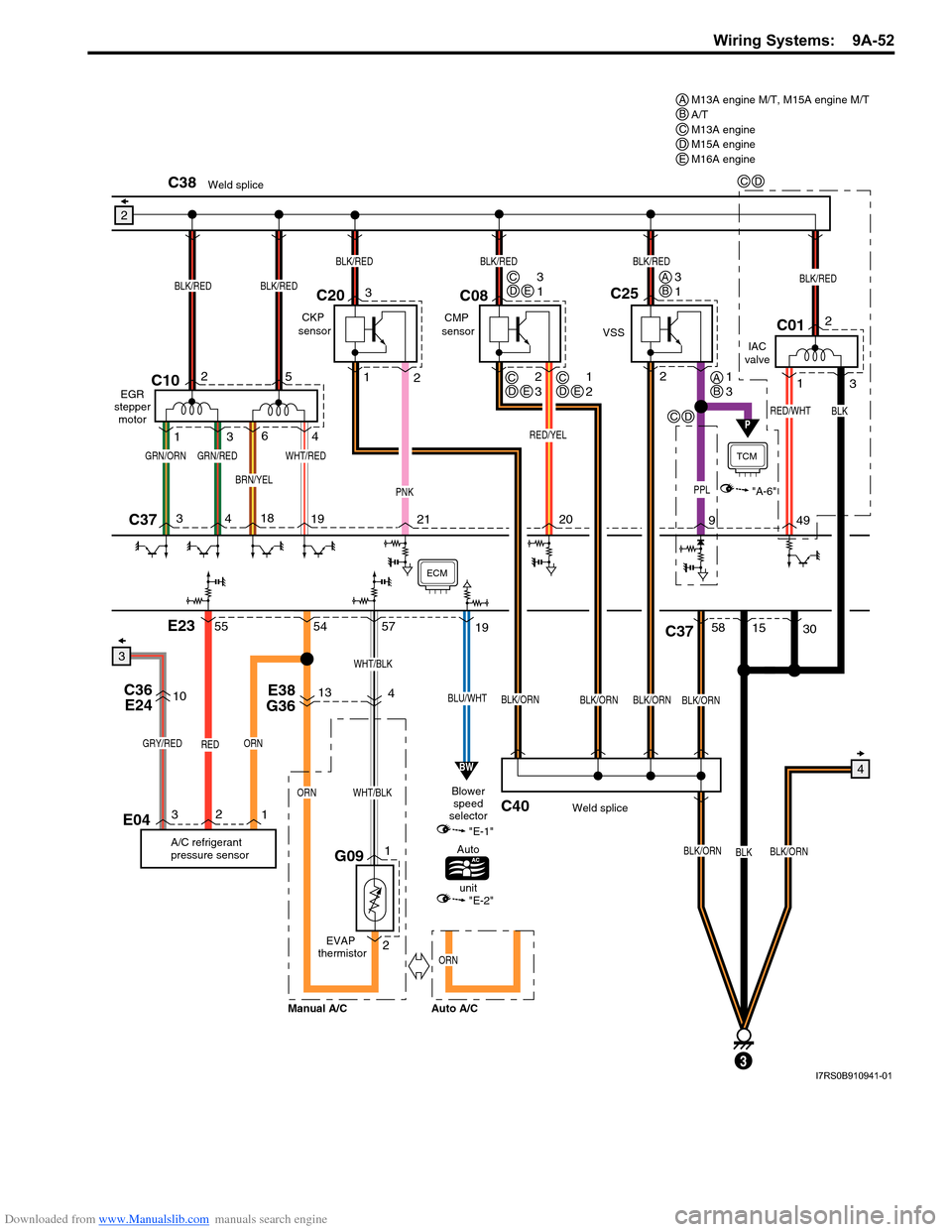

Page 1223 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-52

"E-1"

"E-2"

EGR

stepper motor

PPL

P

"A-6"

AB

AB

CD

CD

ECM

2

3

REDORNGRY/RED

EVAP

thermistor

1

2G09

13

ORN

ORN

E38

G36

BW

Blower

speed

selector

Auto

unit

A/C refrigerant

pressure sensor

E04

C10

BRN/YEL

WHT/REDGRN/RED

6

4312

5

CKP

sensor CMP

sensor VSS

TCM

C37

BLK

3

155830

C25

21

3CDE12CDE23 3

1

CDE31

1 2

3

C08

C20

C37

18 19

4320

219

PNK

RED/YEL

E2354

55

C36

E2410

1

2

3

19

4

RED/WHT

49

BLK/RED

BLK

C012

1 3

IAC

valve

BLU/WHT

GRN/ORN

WHT/BLK

57

4

WHT/BLK

BLK/RED

BLK/ORNBLK/ORNBLK/ORNBLK/ORN

C40Weld splice

BLK/ORNBLK/ORN

C38Weld splice

BLK/REDBLK/RED

BLK/REDBLK/RED

M13A engine M/T, M15A engine M/T

A/T

M13A engine

M15A engine

M16A engine

ABCDE

Manual A/C

Auto A/C

I7RS0B910941-01