wheel nuts SUZUKI SWIFT 2006 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 519 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-3

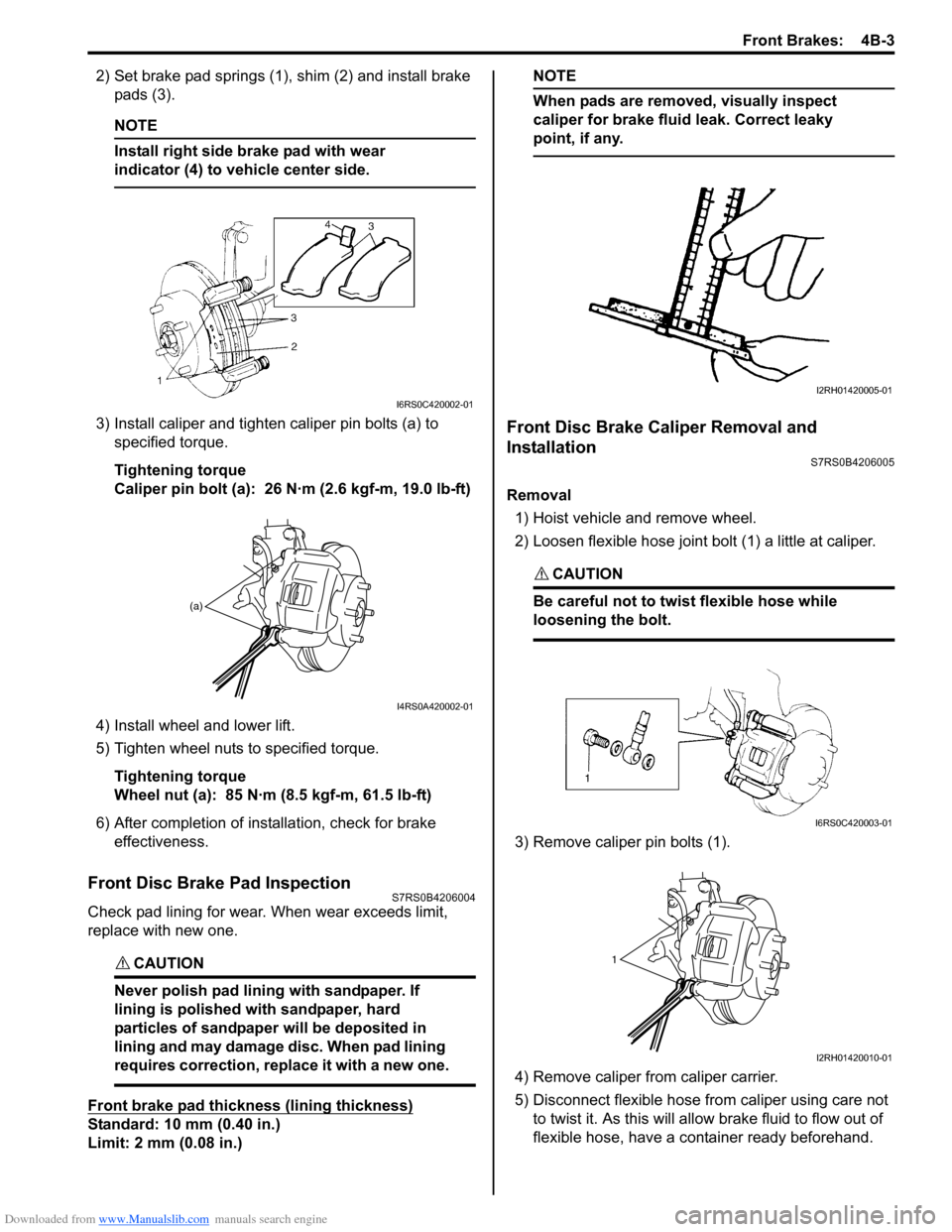

2) Set brake pad springs (1), shim (2) and install brake pads (3).

NOTE

Install right side brake pad with wear

indicator (4) to vehicle center side.

3) Install caliper and tighten caliper pin bolts (a) to specified torque.

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

4) Install wheel and lower lift.

5) Tighten wheel nuts to specified torque. Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completion of installation, check for brake effectiveness.

Front Disc Brake Pad InspectionS7RS0B4206004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Front brake pad thickness (lining thickness)

Standard: 10 mm (0.40 in.)

Limit: 2 mm (0.08 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

Front Disc Brake Caliper Removal and

Installation

S7RS0B4206005

Removal

1) Hoist vehicle and remove wheel.

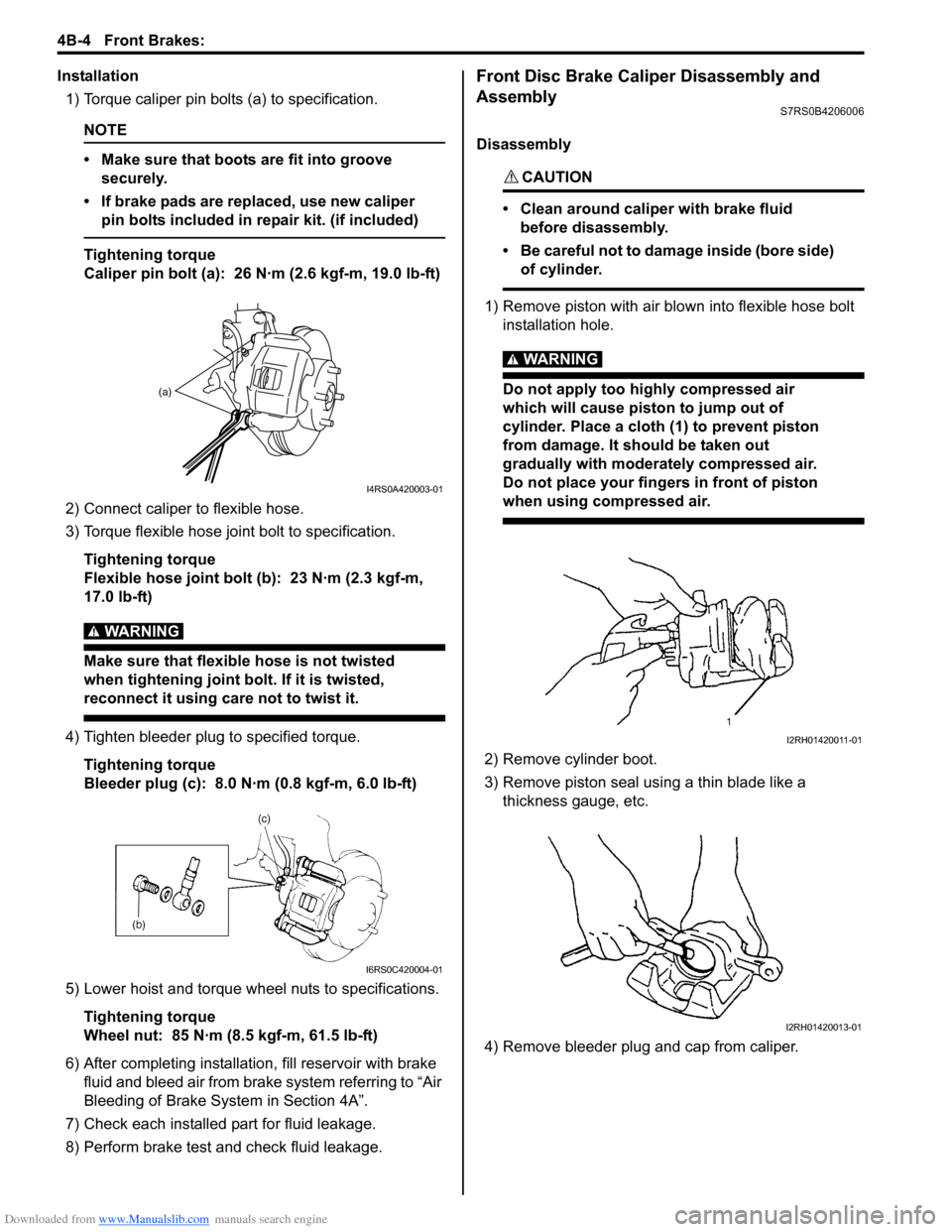

2) Loosen flexible hose joint bolt (1) a little at caliper.

CAUTION!

Be careful not to twist flexible hose while

loosening the bolt.

3) Remove caliper pin bolts (1).

4) Remove caliper fr om caliper carrier.

5) Disconnect flexible hose fr om caliper using care not

to twist it. As this will allow brake fluid to flow out of

flexible hose, have a container ready beforehand.

I6RS0C420002-01

(a)

I4RS0A420002-01

I2RH01420005-01

I6RS0C420003-01

1

I2RH01420010-01

Page 520 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-4 Front Brakes:

Installation1) Torque caliper pin bolts (a) to specification.

NOTE

• Make sure that boots are fit into groove securely.

• If brake pads are replaced, use new caliper pin bolts included in repair kit. (if included)

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

2) Connect caliper to flexible hose.

3) Torque flexible hose jo int bolt to specification.

Tightening torque

Flexible hose joint bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

4) Tighten bleeder plug to specified torque. Tightening torque

Bleeder plug (c): 8.0 N·m (0.8 kgf-m, 6.0 lb-ft)

5) Lower hoist and torque wheel nuts to specifications. Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completing installation, fill reservoir with brake

fluid and bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) Perform brake test and check fluid leakage.

Front Disc Brake Caliper Disassembly and

Assembly

S7RS0B4206006

Disassembly

CAUTION!

• Clean around caliper with brake fluid before disassembly.

• Be careful not to damage inside (bore side) of cylinder.

1) Remove piston with air blown into flexible hose bolt installation hole.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth (1) to prevent piston

from damage. It should be taken out

gradually with moderately compressed air.

Do not place your fingers in front of piston

when using compressed air.

2) Remove cylinder boot.

3) Remove piston seal using a thin blade like a thickness gauge, etc.

4) Remove bleeder plug and cap from caliper.

(a)

I4RS0A420003-01

I6RS0C420004-01

I2RH01420011-01

I2RH01420013-01

Page 523 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Brakes: 4B-7

Installation1) Install disc to wheel hub.

2) Install caliper assemb ly to steering knuckle.

3) Torque caliper carrier bolts to specification.

Tightening torque

Caliper carrier bolt (a): 85 N·m (8.5 kgf-m, 61.5

lb-ft)

4) Torque front wheel nuts to specification. Tightening torque

Wheel nut (b): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

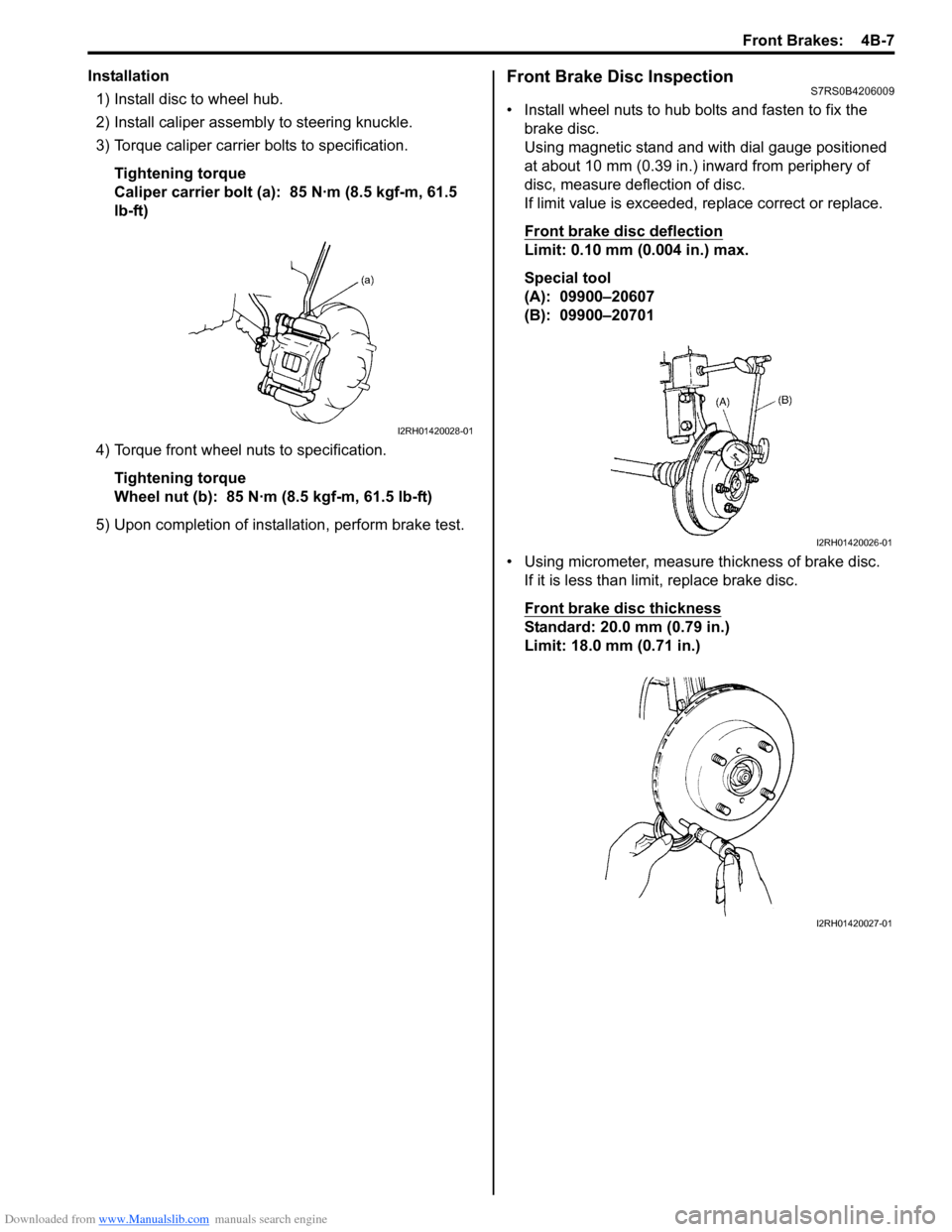

5) Upon completion of installation, perform brake test.Front Brake Disc InspectionS7RS0B4206009

• Install wheel nuts to hub bolts and fasten to fix the brake disc.

Using magnetic stand and with dial gauge positioned

at about 10 mm (0.39 in.) inward from periphery of

disc, measure deflection of disc.

If limit value is exceeded, replace correct or replace.

Front brake disc deflection

Limit: 0.10 mm (0.004 in.) max.

Special tool

(A): 09900–20607

(B): 09900–20701

• Using micrometer, measure thickness of brake disc. If it is less than limit, replace brake disc.

Front brake disc thickness

Standard: 20.0 mm (0.79 in.)

Limit: 18.0 mm (0.71 in.)

I2RH01420028-01

I2RH01420026-01

I2RH01420027-01

Page 527 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-3

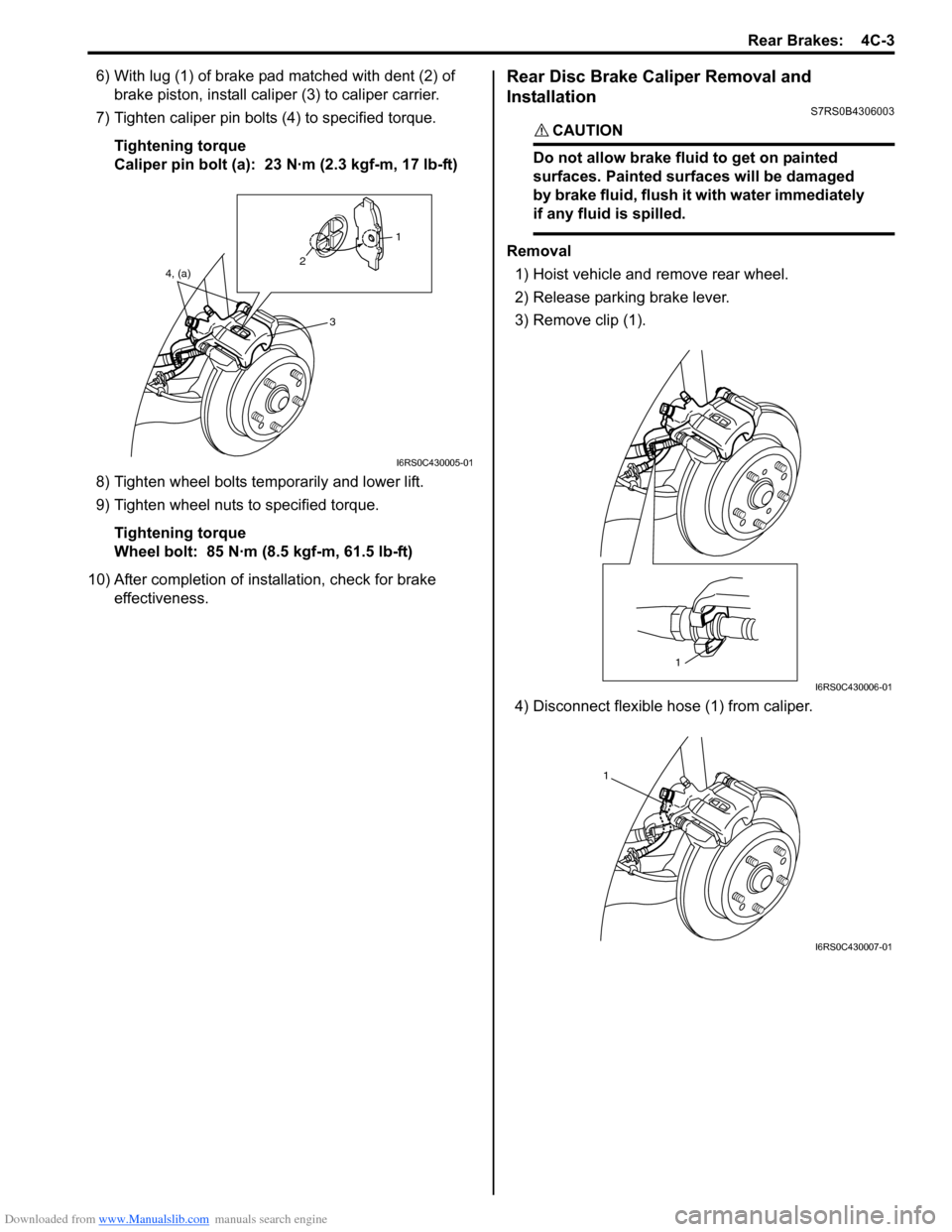

6) With lug (1) of brake pad matched with dent (2) of brake piston, install caliper (3) to caliper carrier.

7) Tighten caliper pin bolts (4) to specified torque.

Tightening torque

Caliper pin bolt (a): 23 N·m (2.3 kgf-m, 17 lb-ft)

8) Tighten wheel bolts temporarily and lower lift.

9) Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

10) After completion of installation, check for brake effectiveness.Rear Disc Brake Caliper Removal and

Installation

S7RS0B4306003

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Hoist vehicle and remove rear wheel.

2) Release parking brake lever.

3) Remove clip (1).

4) Disconnect flexible hose (1) from caliper.

4, (a) 21

3

I6RS0C430005-01

1

I6RS0C430006-01

1

I6RS0C430007-01

Page 529 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-5

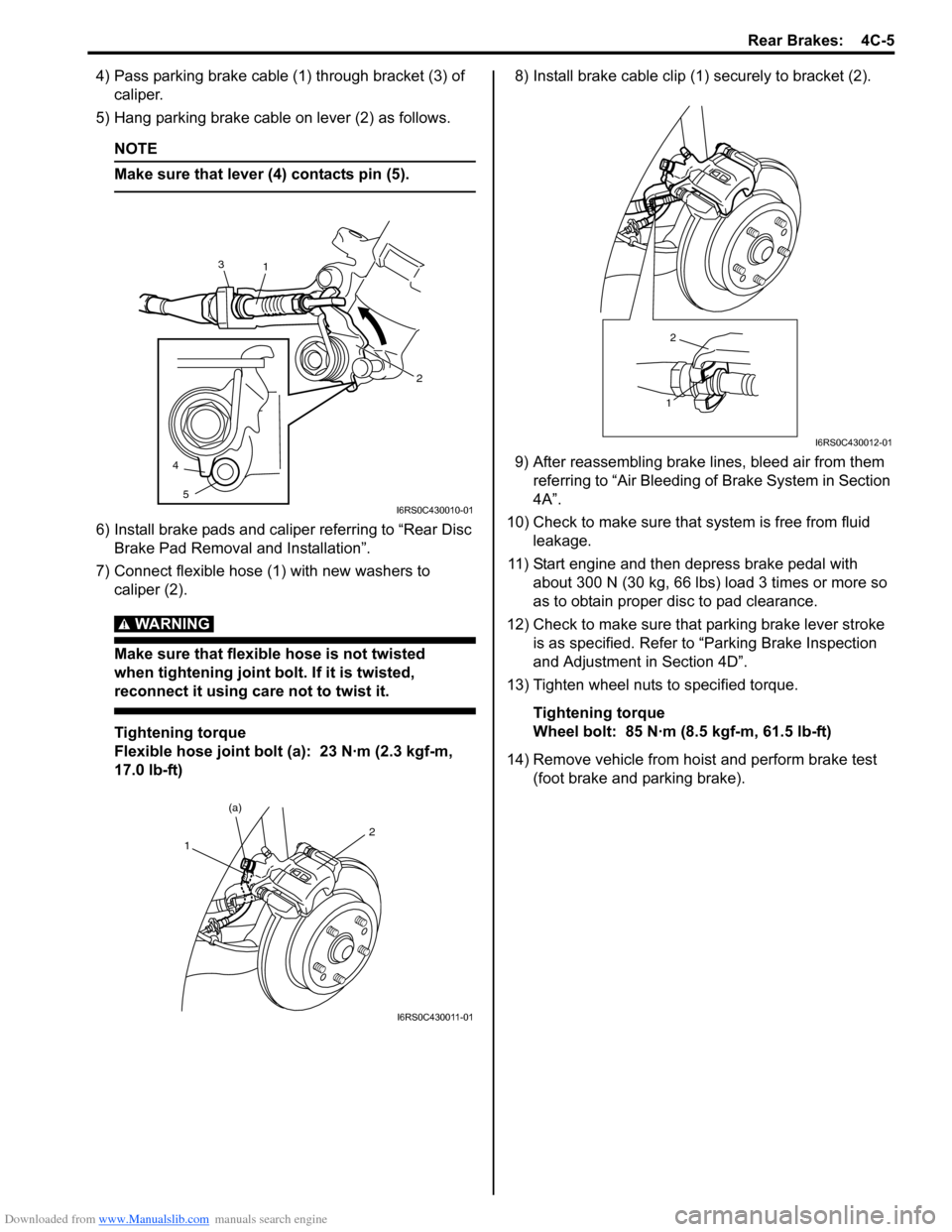

4) Pass parking brake cable (1) through bracket (3) of caliper.

5) Hang parking brake cable on lever (2) as follows.

NOTE

Make sure that lever (4) contacts pin (5).

6) Install brake pads and caliper referring to “Rear Disc Brake Pad Removal and Installation”.

7) Connect flexible hose (1) with new washers to caliper (2).

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

Tightening torque

Flexible hose joint bolt (a): 23 N·m (2.3 kgf-m,

17.0 lb-ft) 8) Install brake cable clip (1) securely to bracket (2).

9) After reassembling brake lines, bleed air from them

referring to “Air Bleeding of Brake System in Section

4A”.

10) Check to make sure that system is free from fluid

leakage.

11) Start engine and then depress brake pedal with about 300 N (30 kg, 66 lbs) load 3 times or more so

as to obtain proper disc to pad clearance.

12) Check to make sure that parking brake lever stroke is as specified. Refer to “Parking Brake Inspection

and Adjustment in Section 4D”.

13) Tighten wheel nuts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Remove vehicle from hoist and perform brake test (foot brake and parking brake).

1

23

45

I6RS0C430010-01

1 (a)2

I6RS0C430011-01

1

2

I6RS0C430012-01

Page 533 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-9

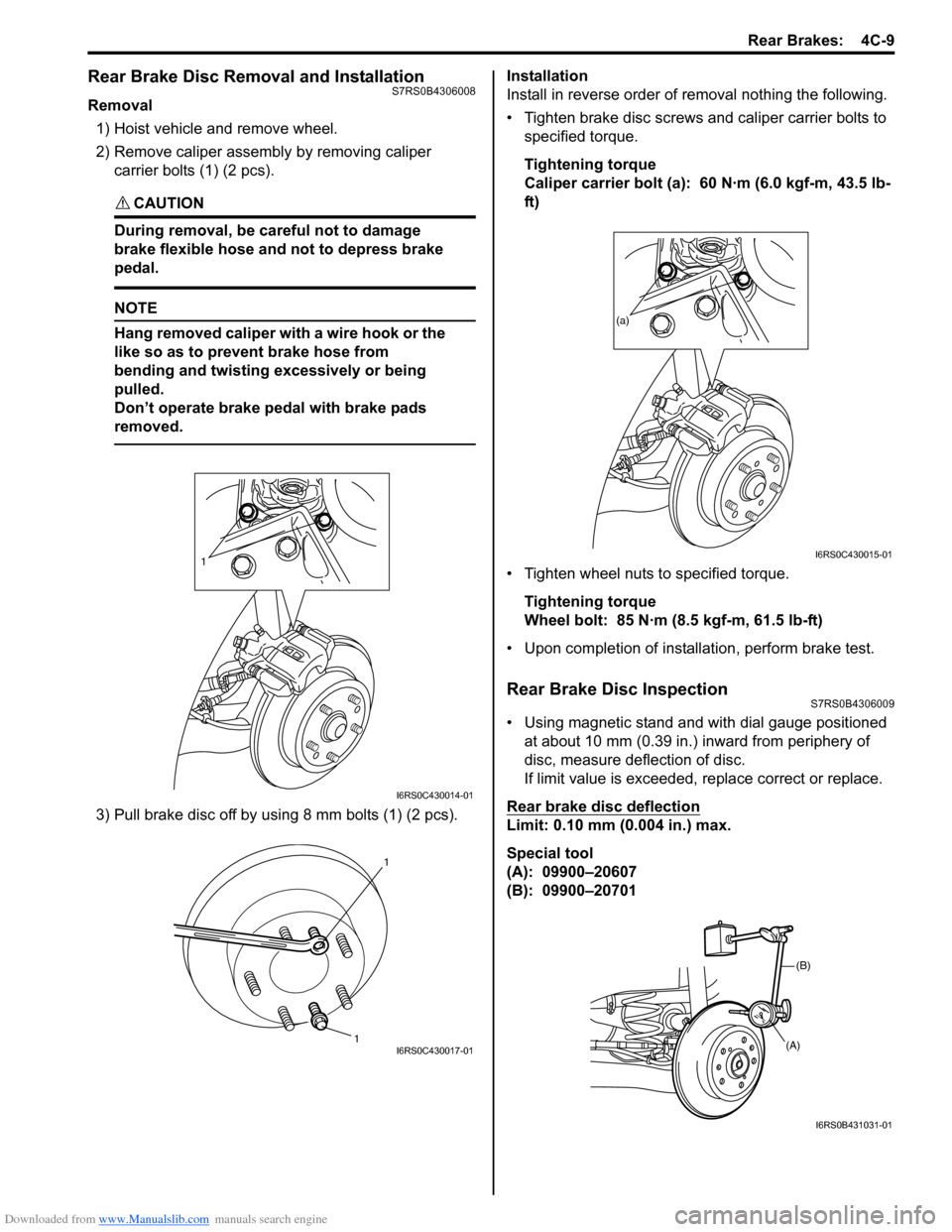

Rear Brake Disc Removal and InstallationS7RS0B4306008

Removal1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper

carrier bolts (1) (2 pcs).

CAUTION!

During removal, be ca reful not to damage

brake flexible hose and not to depress brake

pedal.

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs). Installation

Install in reverse order of removal nothing the following.

• Tighten brake disc screws and caliper carrier bolts to

specified torque.

Tightening torque

Caliper carrier bolt (a): 60 N·m (6.0 kgf-m, 43.5 lb-

ft)

• Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Upon completion of installation, perform brake test.

Rear Brake Disc InspectionS7RS0B4306009

• Using magnetic stand and with dial gauge positioned at about 10 mm (0.39 in.) inward from periphery of

disc, measure deflection of disc.

If limit value is exceeded, replace correct or replace.

Rear brake disc deflection

Limit: 0.10 mm (0.004 in.) max.

Special tool

(A): 09900–20607

(B): 09900–20701

1

I6RS0C430014-01

1 1I6RS0C430017-01

(a)

I6RS0C430015-01

(B)

(A)

I6RS0B431031-01

Page 538 of 1496

Downloaded from www.Manualslib.com manuals search engine 4D-3 Parking Brake:

6) Release parking brake lever and then make sure that there is no drag in rear wheel.

If there is, repeats go to step 2).

7) Make sure that the number of notch is between 4 and 9 when operating parking brake lever.

8) If the number of notch is not between 4 and 9, replace parking brake cable and/or inspect rear

brake caliper.

Parking brake stroke

When lever is pulled up at 200 N (20kg, 44lbs) : 4

to 9 notches

Parking Brake Cable Removal and InstallationS7RS0B4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 5) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer (parking brake lever) and clamps.

4) Disconnect parking brake cable from lever referring to “Rear Disc Brake Caliper Removal and Installation

in Section 4C”.

5) Remove parking brake cable and parking cable bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake Cable Construction”.

• Tighten bolts and nuts to specified torque referring to “Parking Brake Cable Construction”.

Tightening torque

Parking brake lever bolt: 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Parking cable clamp bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Parking cable bracket bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Adjust parking brake cable. Refer to “Parking Brake Inspection and Adjustment”.

• Check brake disc for dragging and brake system for proper performance. Brake test should be performed.

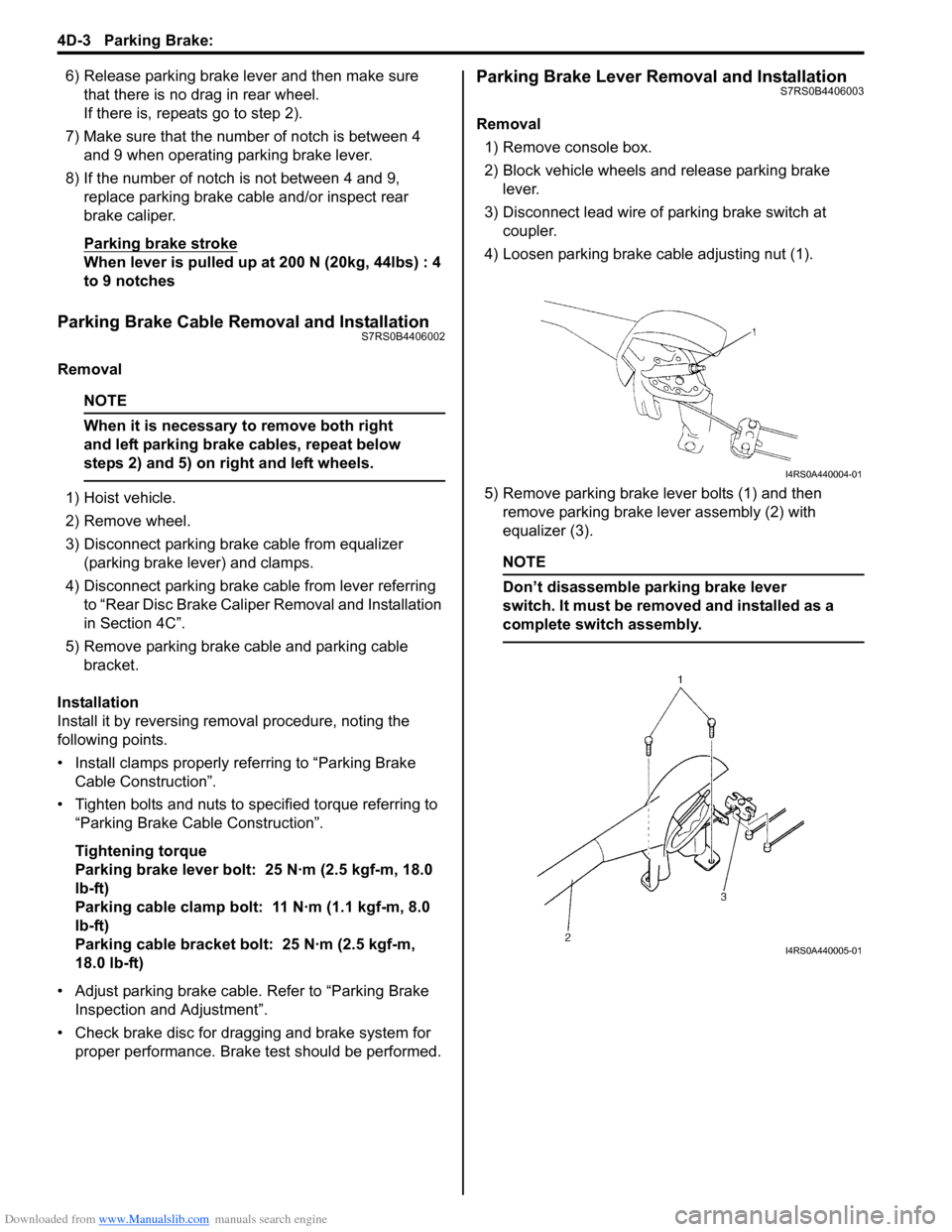

Parking Brake Lever Removal and InstallationS7RS0B4406003

Removal

1) Remove console box.

2) Block vehicle wheels and release parking brake lever.

3) Disconnect lead wire of parking brake switch at coupler.

4) Loosen parking brake cable adjusting nut (1).

5) Remove parking brake lever bolts (1) and then remove parking brake lever assembly (2) with

equalizer (3).

NOTE

Don’t disassemble parking brake lever

switch. It must be removed and installed as a

complete switch assembly.

I4RS0A440004-01

I4RS0A440005-01

Page 872 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-1 Steering Wheel and Column:

Steeri ng

Steering Wheel and Column

Precautions

Service Precautions of Steering Wheel and

Column

S7RS0B6200001

For service precautions, refer to “Precautions on Service

and Diagnosis of Air Bag System in Section 8B”.

Service and Diagnosis

For diagnosis and servicing, refer to “Precautions on

Service and Diagnosis of Air Bag System in Section 8B”.

Disabling Air Bag System

For disabling air bag system, refer to “Disabling Air Bag

System in Section 8B”. Enabling Air Bag System

For enabling air bag system, refer to “Enabling Air Bag

System in Section 8B”.

Handling and Storage

For handling and storage, refer to “Precautions on

Handling and Storage of Air Bag System Components in

Section 8B”.

Disposal

For disposal, refer to “Prec

autions on Disposal of Air

Bag and Seat Belt Pretensioner in Section 8B”.

General Description

Steering Wheel and Column ConstructionS7RS0B6201001

This double tube type steering column has the following three important features in addition to the steering function:

• The column is energy absorbing, desig ned to compress in a front-end collision.

• The ignition switch and lock are mounted conveniently on this column.

• With the column mounted lock, the ignition and steering op erations can be locked to inhibit theft of the vehicle.

To insure the energy absorbing action, it is important th at only the specified screws, bolts and nuts be used as

designated, and that they are tightened to the specified torque. When the column assembly is removed from the

vehicle, special care must be taken in handling it. Use of a steering wheel puller or a sharp blow on the end of the

steering shaft, leaning on the assembly, or dropping the a ssembly could shear the plastic shear pins which maintain

column length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is mounted

to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the restraint of the

driver’s and passenger’s seat belts by deploying the air b ags. The air bag (inflator) module should be handled with

care to prevent accidental deployment. When servicing, be sure to observe “Precautions on Service and Diagnosis of

Air Bag System in Section 8B”.

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

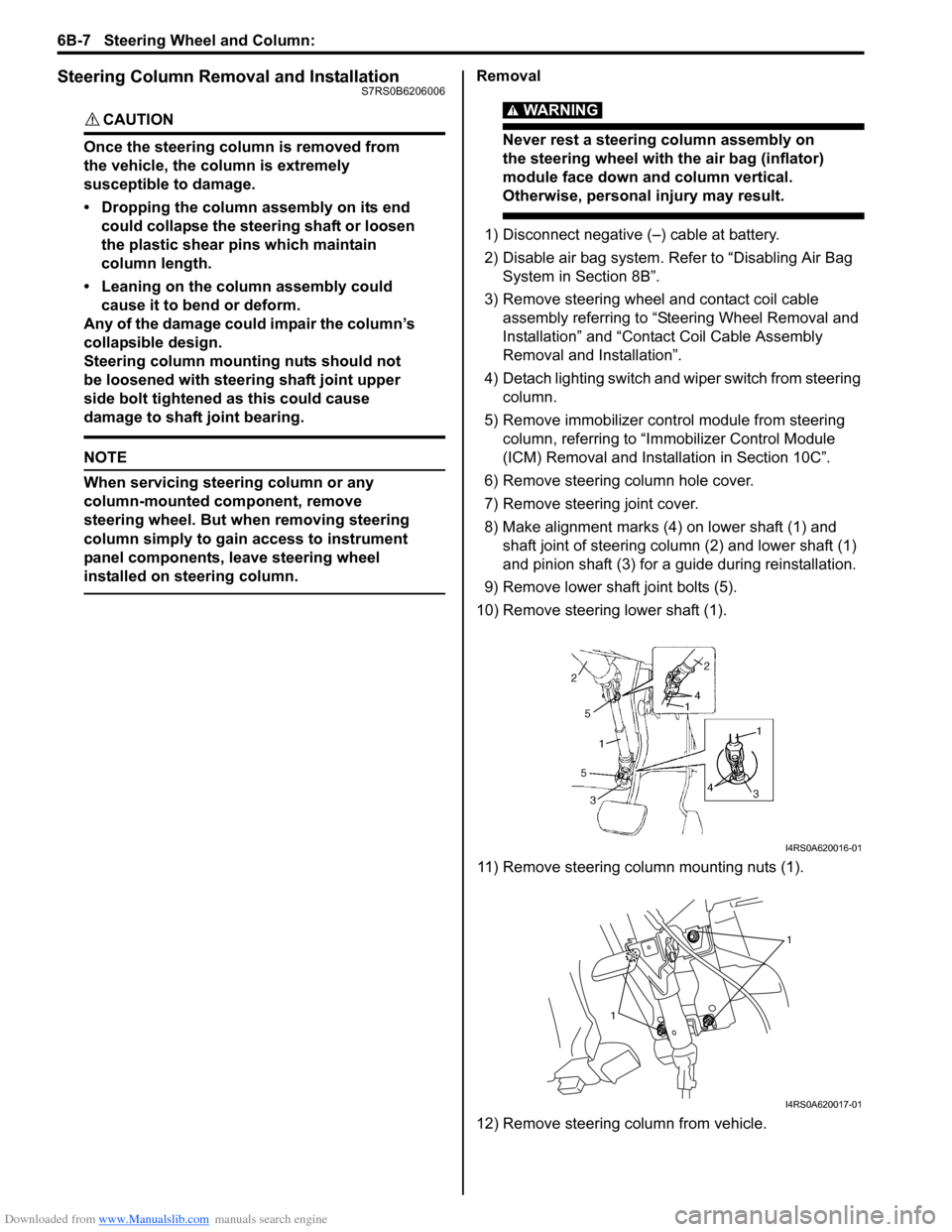

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

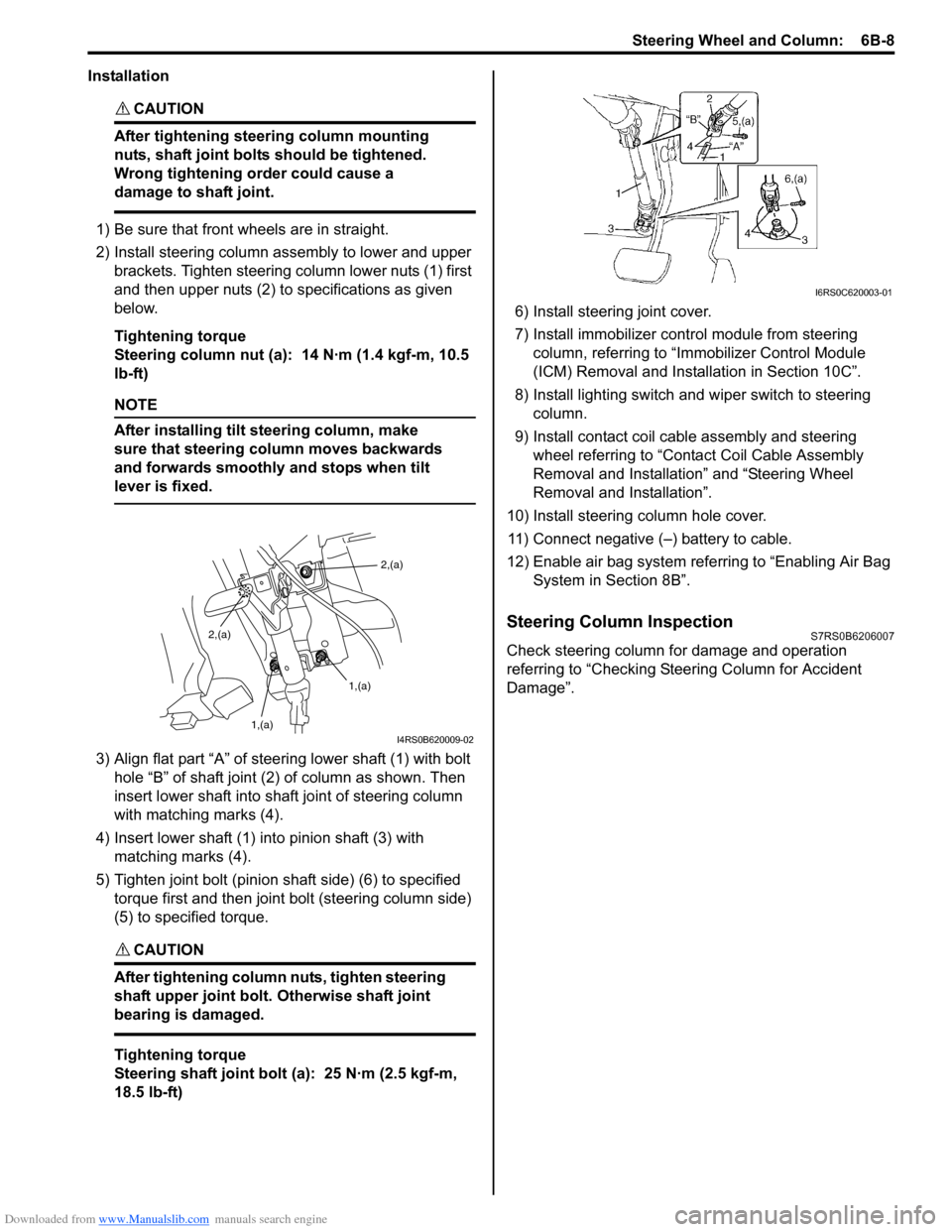

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01