System check SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 854 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-2 Clutch:

Diagnostic Information and Procedures

Clutch System Symptom DiagnosisS7RS0B5304001

Repair Instructions

Clutch Pedal InspectionS7RS0B5306001

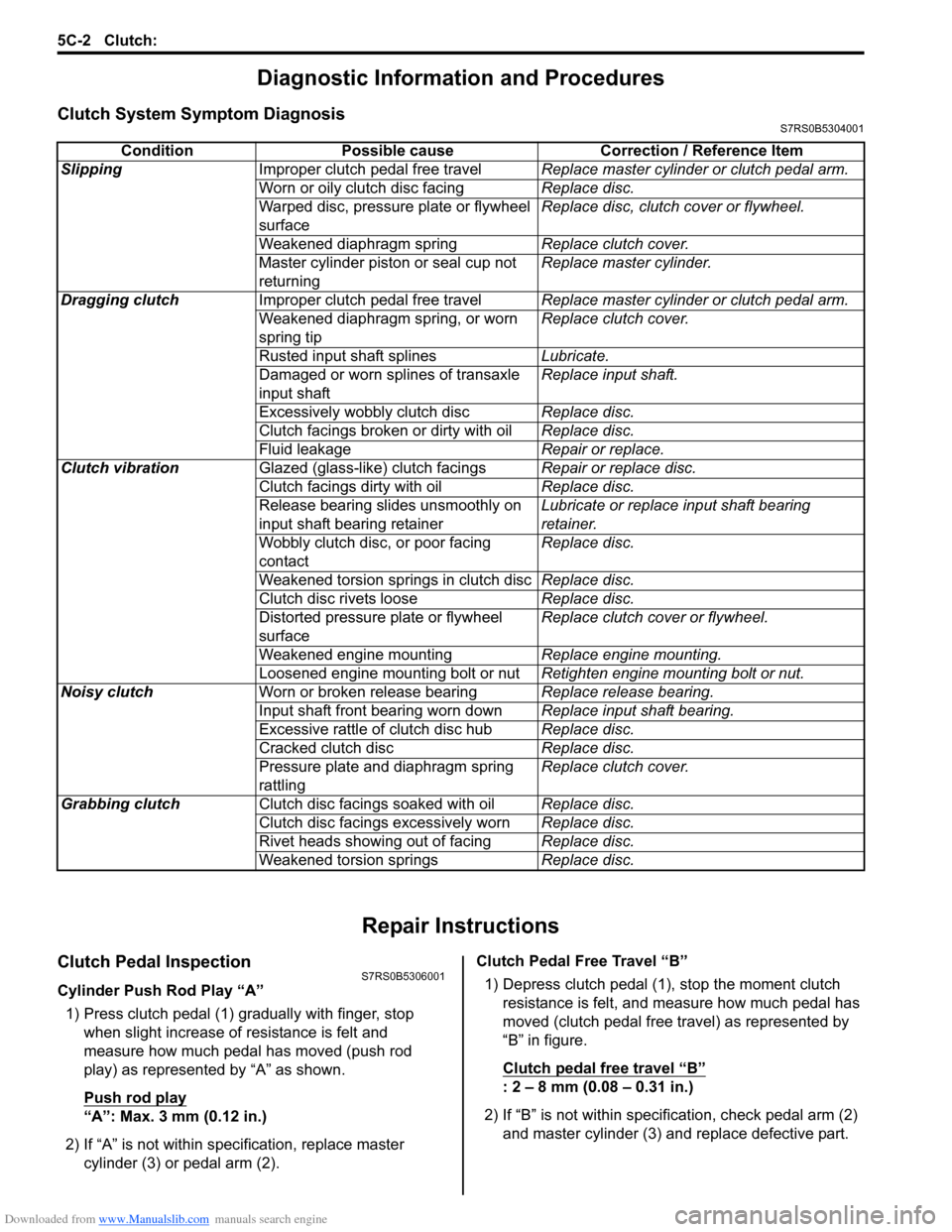

Cylinder Push Rod Play “A”1) Press clutch pedal (1) gradually with finger, stop when slight increase of resistance is felt and

measure how much pedal has moved (push rod

play) as represented by “A” as shown.

Push rod play

“A”: Max. 3 mm (0.12 in.)

2) If “A” is not within specification, replace master cylinder (3) or pedal arm (2). Clutch Pedal Free Travel “B”

1) Depress clutch pedal (1), stop the moment clutch resistance is felt, and measure how much pedal has

moved (clutch pedal free travel) as represented by

“B” in figure.

Clutch pedal free travel

“B”

: 2 – 8 mm (0.08 – 0.31 in.)

2) If “B” is not within specification, check pedal arm (2) and master cylinder (3) and replace defective part.

Condition Possible cause Correction / Reference Item

Slipping Improper clutch pedal free travel Replace master cylinder or clutch pedal arm.

Worn or oily clutch disc facing Replace disc.

Warped disc, pressure plate or flywheel

surface Replace disc, clutch cover or flywheel.

Weakened diaphragm spring Replace clutch cover.

Master cylinder piston or seal cup not

returning Replace master cylinder.

Dragging clutch Improper clutch pedal free travel Replace master cylinder or clutch pedal arm.

Weakened diaphragm spring, or worn

spring tip Replace clutch cover.

Rusted input shaft splines Lubricate.

Damaged or worn splines of transaxle

input shaft Replace input shaft.

Excessively wobbly clutch disc Replace disc.

Clutch facings broken or dirty with oil Replace disc.

Fluid leakage Repair or replace.

Clutch vibration Glazed (glass-like) clutch facings Repair or replace disc.

Clutch facings dirty with oil Replace disc.

Release bearing slides unsmoothly on

input shaft bearing retainer Lubricate or replace input shaft bearing

retainer.

Wobbly clutch disc, or poor facing

contact Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose Replace disc.

Distorted pressure plate or flywheel

surface Replace clutch cover or flywheel.

Weakened engine mounting Replace engine mounting.

Loosened engine mounting bolt or nut Retighten engine mounting bolt or nut.

Noisy clutch Worn or broken release bearing Replace release bearing.

Input shaft front bearing worn down Replace input shaft bearing.

Excessive rattle of clutch disc hub Replace disc.

Cracked clutch disc Replace disc.

Pressure plate and diaphragm spring

rattling Replace clutch cover.

Grabbing clutch Clutch disc facings soaked with oil Replace disc.

Clutch disc facings excessively worn Replace disc.

Rivet heads showing out of facing Replace disc.

Weakened torsion springs Replace disc.

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

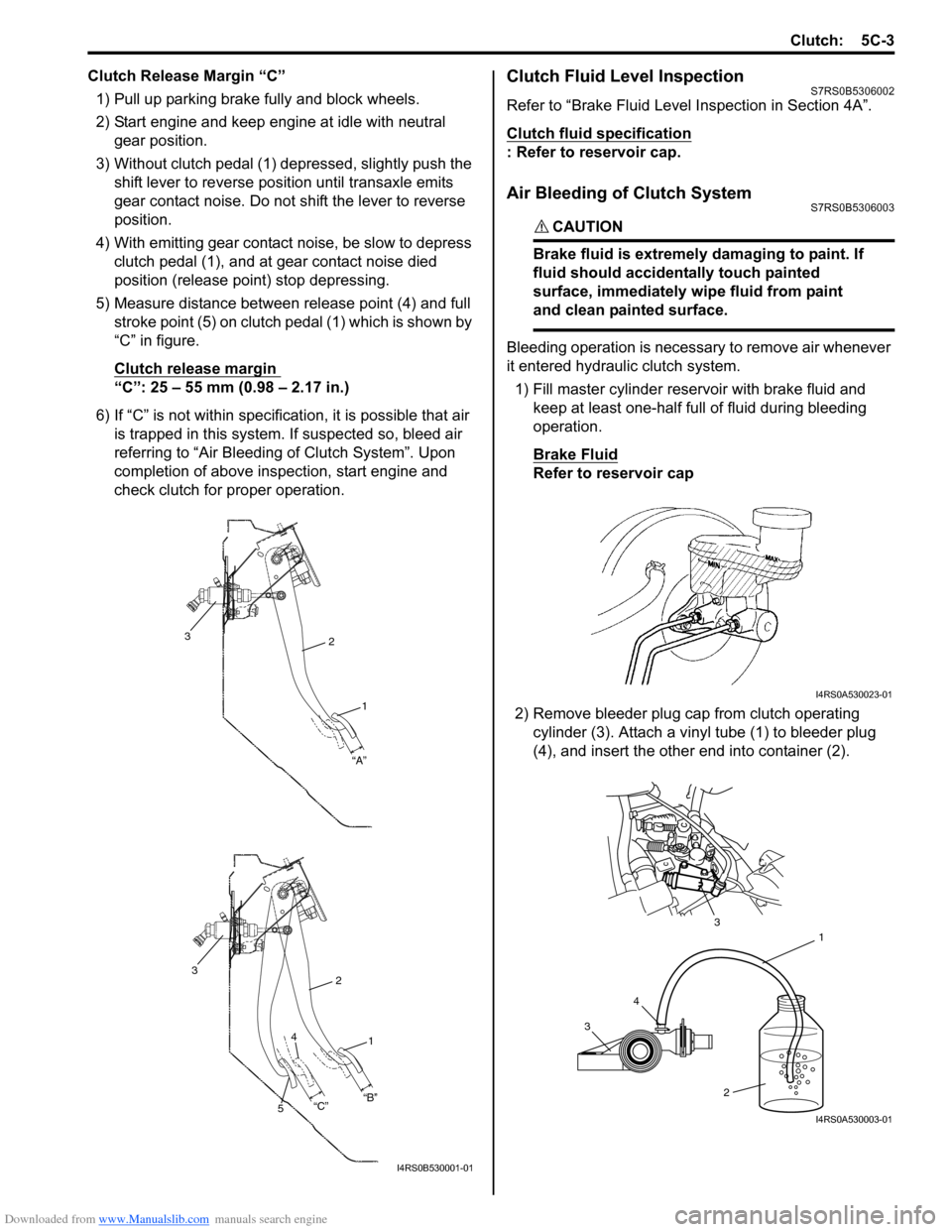

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 858 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-6 Clutch:

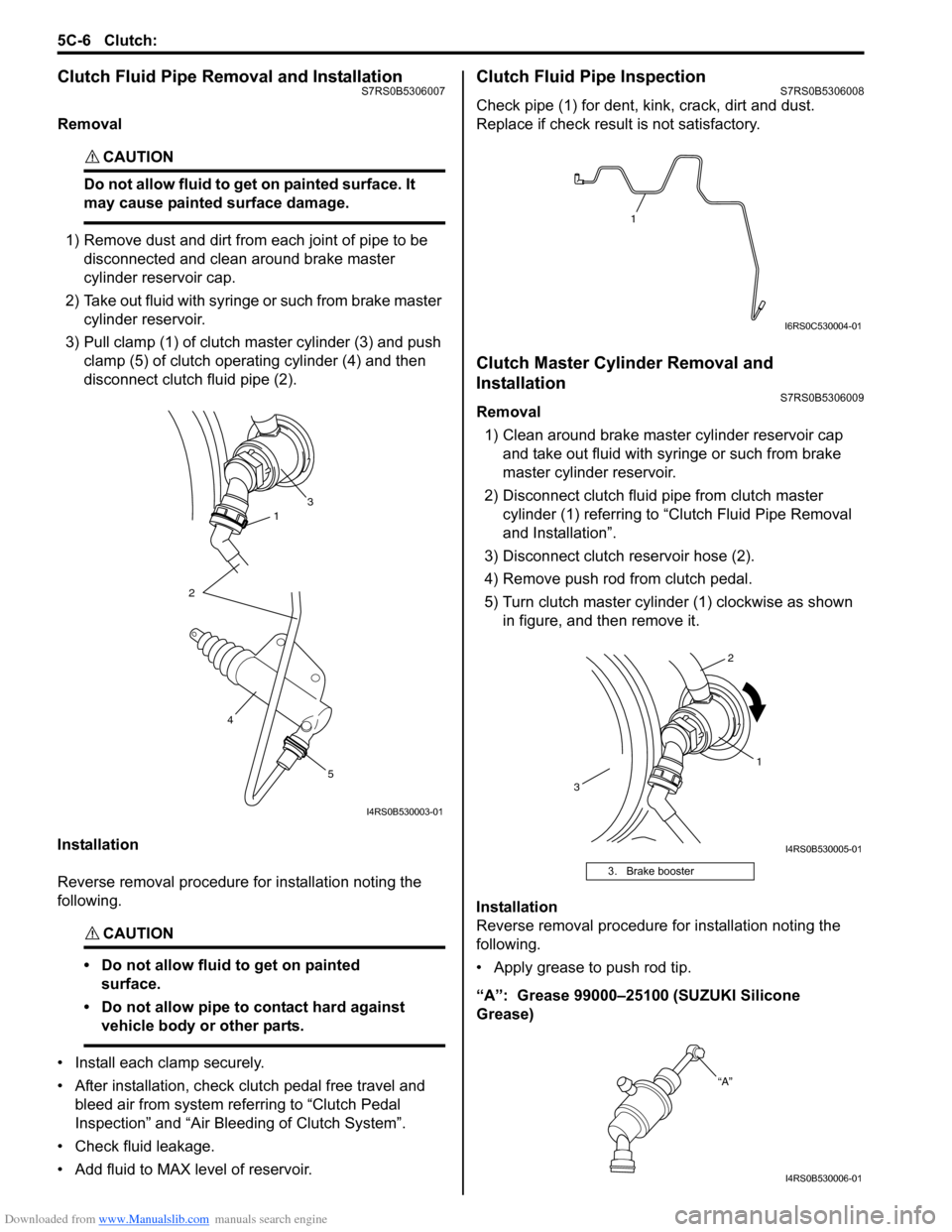

Clutch Fluid Pipe Removal and InstallationS7RS0B5306007

Removal

CAUTION!

Do not allow fluid to get on painted surface. It

may cause painted surface damage.

1) Remove dust and dirt from each joint of pipe to be disconnected and clean around brake master

cylinder reservoir cap.

2) Take out fluid with syringe or such from brake master cylinder reservoir.

3) Pull clamp (1) of clutch master cylinder (3) and push clamp (5) of clutch operating cylinder (4) and then

disconnect clutch fluid pipe (2).

Installation

Reverse removal procedure for installation noting the

following.

CAUTION!

• Do not allow fluid to get on painted surface.

• Do not allow pipe to contact hard against vehicle body or other parts.

• Install each clamp securely.

• After installation, check clutch pedal free travel and bleed air from system referring to “Clutch Pedal

Inspection” and “Air Blee ding of Clutch System”.

• Check fluid leakage.

• Add fluid to MAX level of reservoir.

Clutch Fluid Pipe InspectionS7RS0B5306008

Check pipe (1) for dent, kink, crack, dirt and dust.

Replace if check result is not satisfactory.

Clutch Master Cylinder Removal and

Installation

S7RS0B5306009

Removal 1) Clean around brake master cylinder reservoir cap and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe from clutch master cylinder (1) referring to “C lutch Fluid Pipe Removal

and Installation”.

3) Disconnect clutch reservoir hose (2).

4) Remove push rod from clutch pedal.

5) Turn clutch master cylinder (1) clockwise as shown in figure, and then remove it.

Installation

Reverse removal procedure for installation noting the

following.

• Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

31

2

5

4

I4RS0B530003-01

3. Brake booster

1

I6RS0C530004-01

1

2

3

I4RS0B530005-01

“A”

I4RS0B530006-01

Page 863 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-11

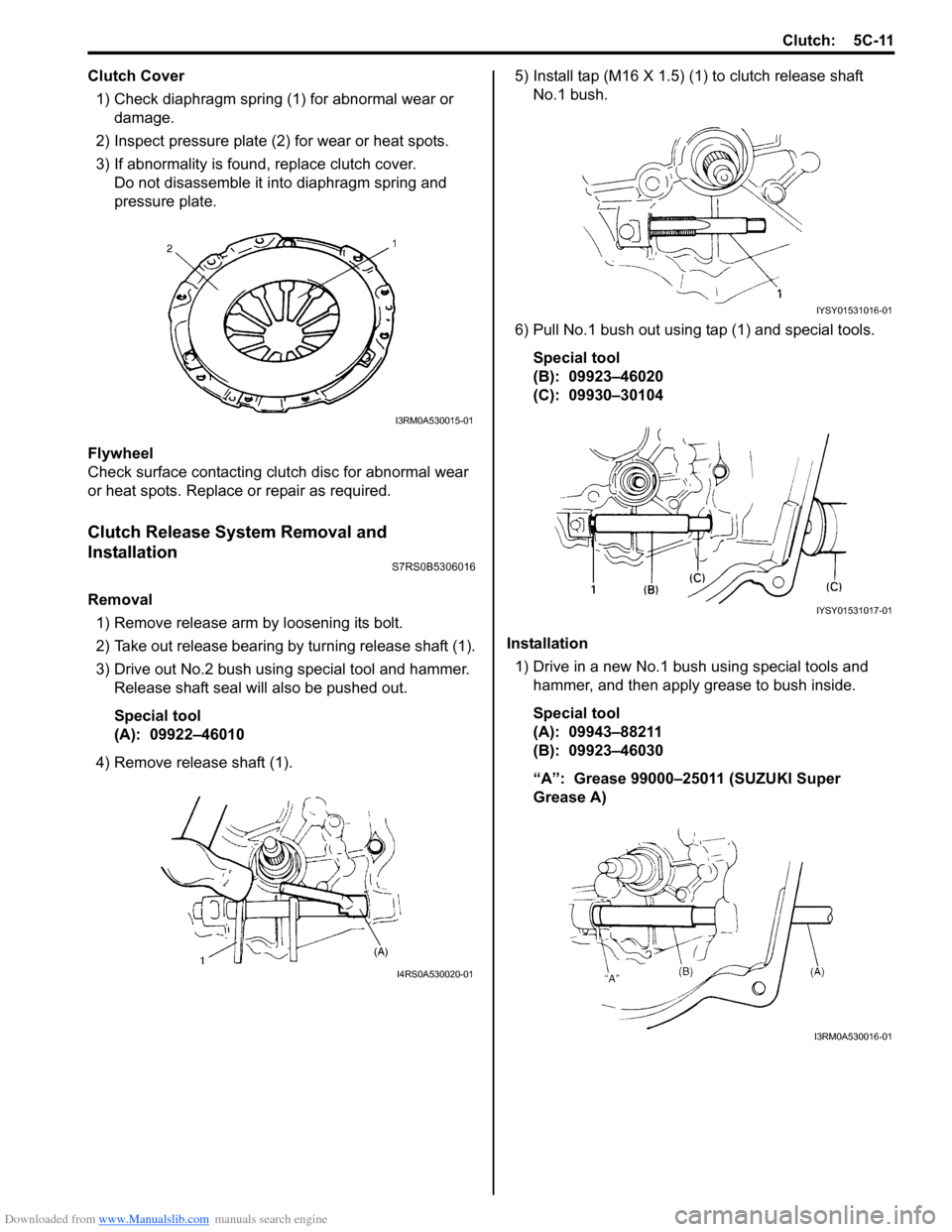

Clutch Cover1) Check diaphragm spring (1) for abnormal wear or damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace clutch cover. Do not disassemble it into diaphragm spring and

pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear

or heat spots. Replace or repair as required.

Clutch Release System Removal and

Installation

S7RS0B5306016

Removal 1) Remove release arm by loosening its bolt.

2) Take out release bearing by turning release shaft (1).

3) Drive out No.2 bush usin g special tool and hammer.

Release shaft seal will also be pushed out.

Special tool

(A): 09922–46010

4) Remove release shaft (1). 5) Install tap (M16 X 1.5) (1) to clutch release shaft

No.1 bush.

6) Pull No.1 bush out using tap (1) and special tools. Special tool

(B): 09923–46020

(C): 09930–30104

Installation 1) Drive in a new No.1 bush using special tools and

hammer, and then apply grease to bush inside.

Special tool

(A): 09943–88211

(B): 09923–46030

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

I3RM0A530015-01

I4RS0A530020-01

IYSY01531016-01

IYSY01531017-01

I3RM0A530016-01

Page 865 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-13

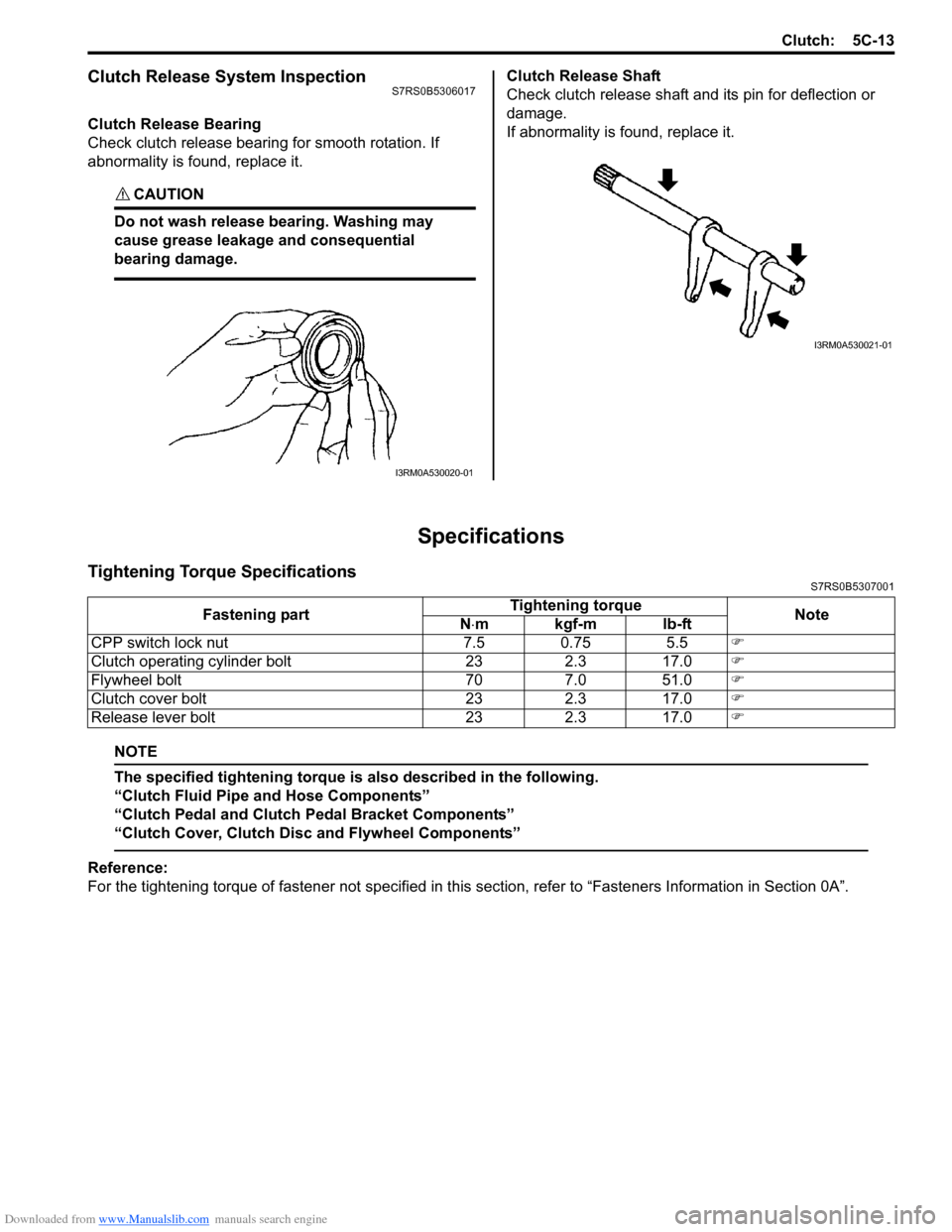

Clutch Release System InspectionS7RS0B5306017

Clutch Release Bearing

Check clutch release bearing for smooth rotation. If

abnormality is found, replace it.

CAUTION!

Do not wash release bearing. Washing may

cause grease leakage and consequential

bearing damage.

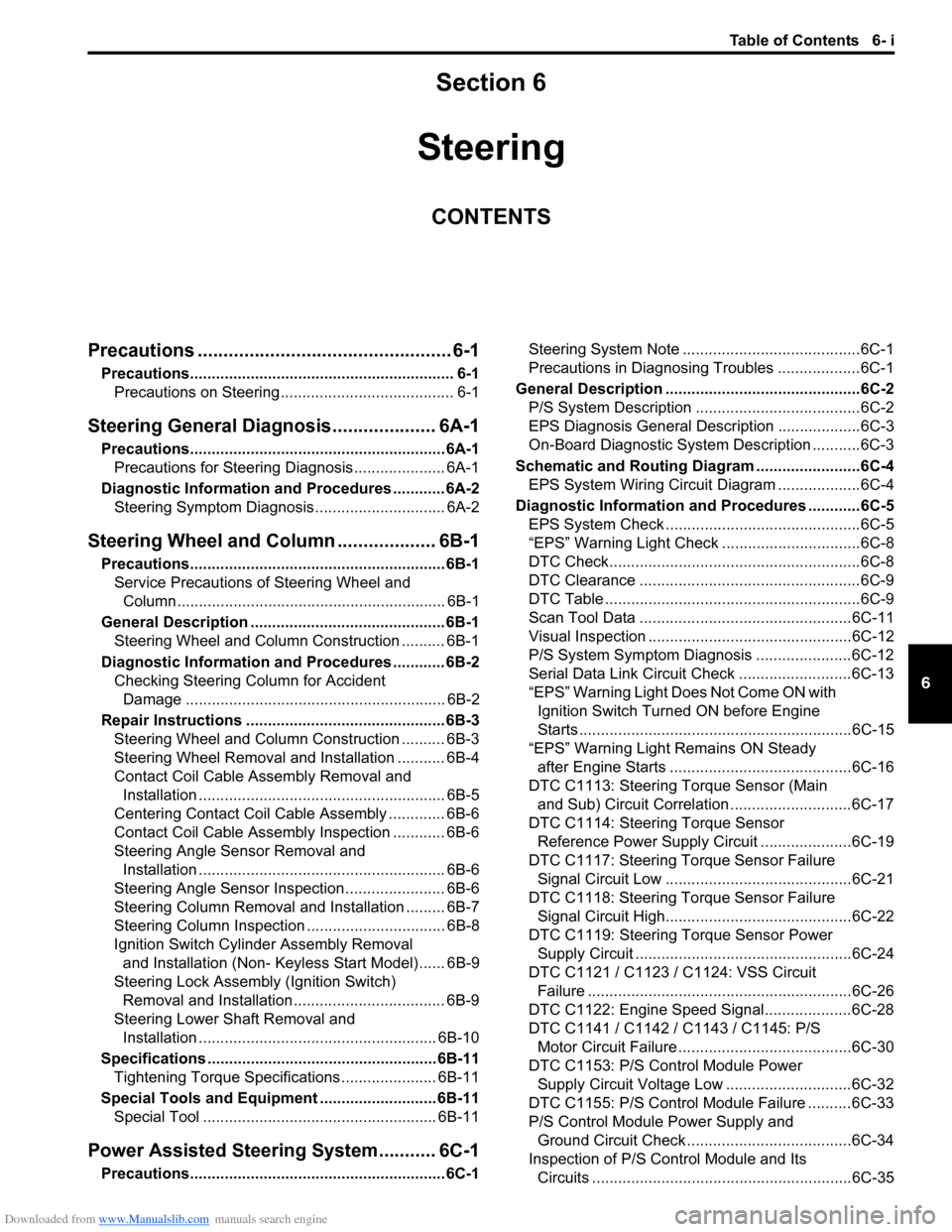

Clutch Release Shaft

Check clutch release shaft and its pin for deflection or

damage.

If abnormality is found, replace it.

Specifications

Tightening Torque SpecificationsS7RS0B5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Fluid Pipe and Hose Components”

“Clutch Pedal and Clutch Pedal Bracket Components”

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I3RM0A530020-01

I3RM0A530021-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

CPP switch lock nut 7.5 0.75 5.5 �)

Clutch operating cylinder bolt 23 2.3 17.0 �)

Flywheel bolt 70 7.0 51.0 �)

Clutch cover bolt 23 2.3 17.0 �)

Release lever bolt 23 2.3 17.0 �)

Page 867 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35

Page 871 of 1496

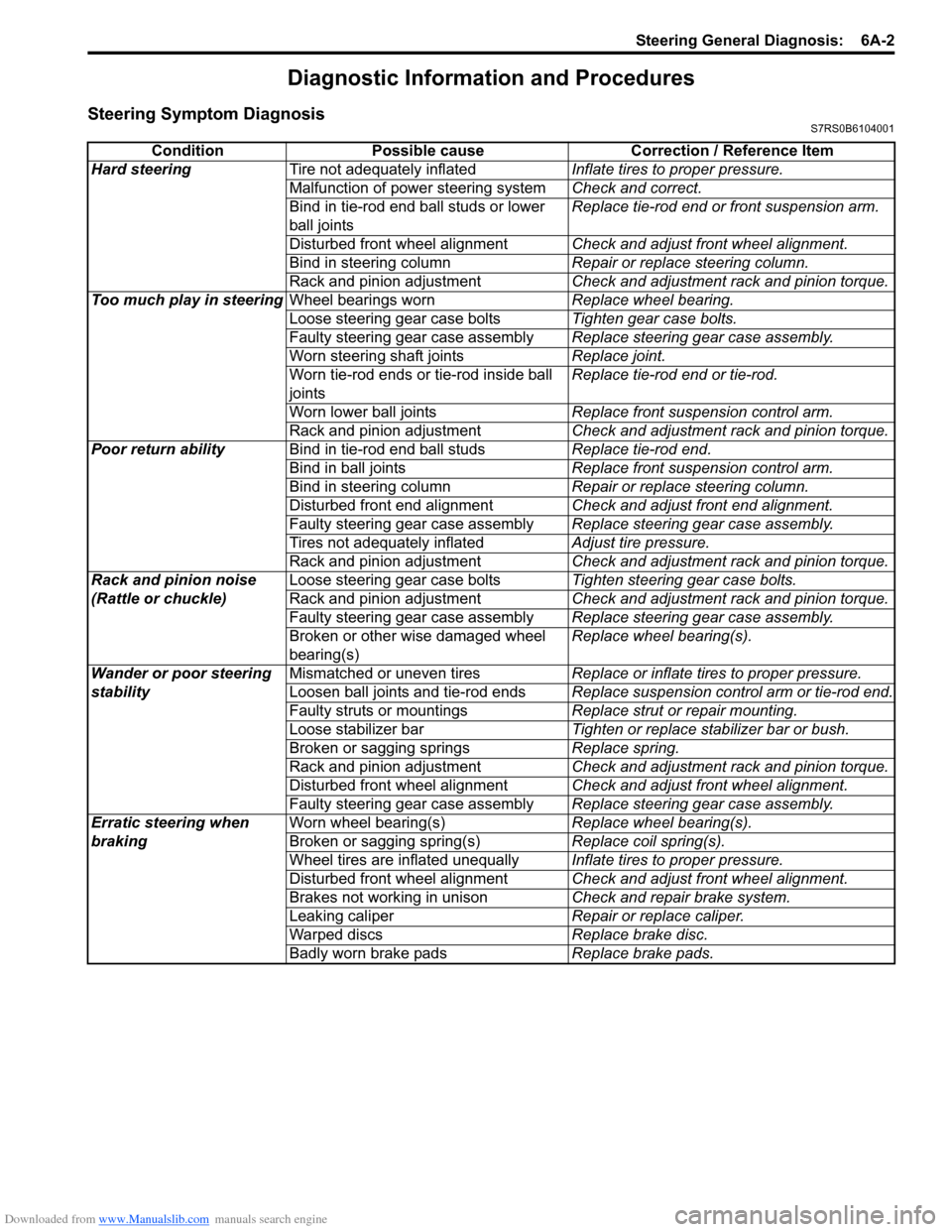

Downloaded from www.Manualslib.com manuals search engine Steering General Diagnosis: 6A-2

Diagnostic Information and Procedures

Steering Symptom DiagnosisS7RS0B6104001

ConditionPossible cause Correction / Reference Item

Hard steering Tire not adequately inflated Inflate tires to proper pressure.

Malfunction of power steering system Check and correct.

Bind in tie-rod end ball studs or lower

ball joints Replace tie-rod end or front suspension arm.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Bind in steering column Repair or replace steering column.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Too much play in steering Wheel bearings worn Replace wheel bearing.

Loose steering gear case bolts Tighten gear case bolts.

Faulty steering gear case assembly Replace steering gear case assembly.

Worn steering shaft joints Replace joint.

Worn tie-rod ends or tie-rod inside ball

joints Replace tie-rod end or tie-rod.

Worn lower ball joints Replace front suspension control arm.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Poor return ability Bind in tie-rod end ball studs Replace tie-rod end.

Bind in ball joints Replace front suspension control arm.

Bind in steering column Repair or replace steering column.

Disturbed front end alignment Check and adjust front end alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Tires not adequately inflated Adjust tire pressure.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Rack and pinion noise

(Rattle or chuckle) Loose steering gear case bolts

Tighten steering gear case bolts.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Faulty steering gear case assembly Replace steering gear case assembly.

Broken or other wise damaged wheel

bearing(s) Replace wheel bearing(s).

Wander or poor steering

stability Mismatched or uneven tires

Replace or inflate tires to proper pressure.

Loosen ball joints and tie-rod ends Replace suspension control arm or tie-rod end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Erratic steering when

braking Worn wheel bearing(s)

Replace wheel bearing(s).

Broken or sagging spring(s) Replace coil spring(s).

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Brakes not working in unison Check and repair brake system.

Leaking caliper Repair or replace caliper.

Warped discs Replace brake disc.

Badly worn brake pads Replace brake pads.

Page 875 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-4

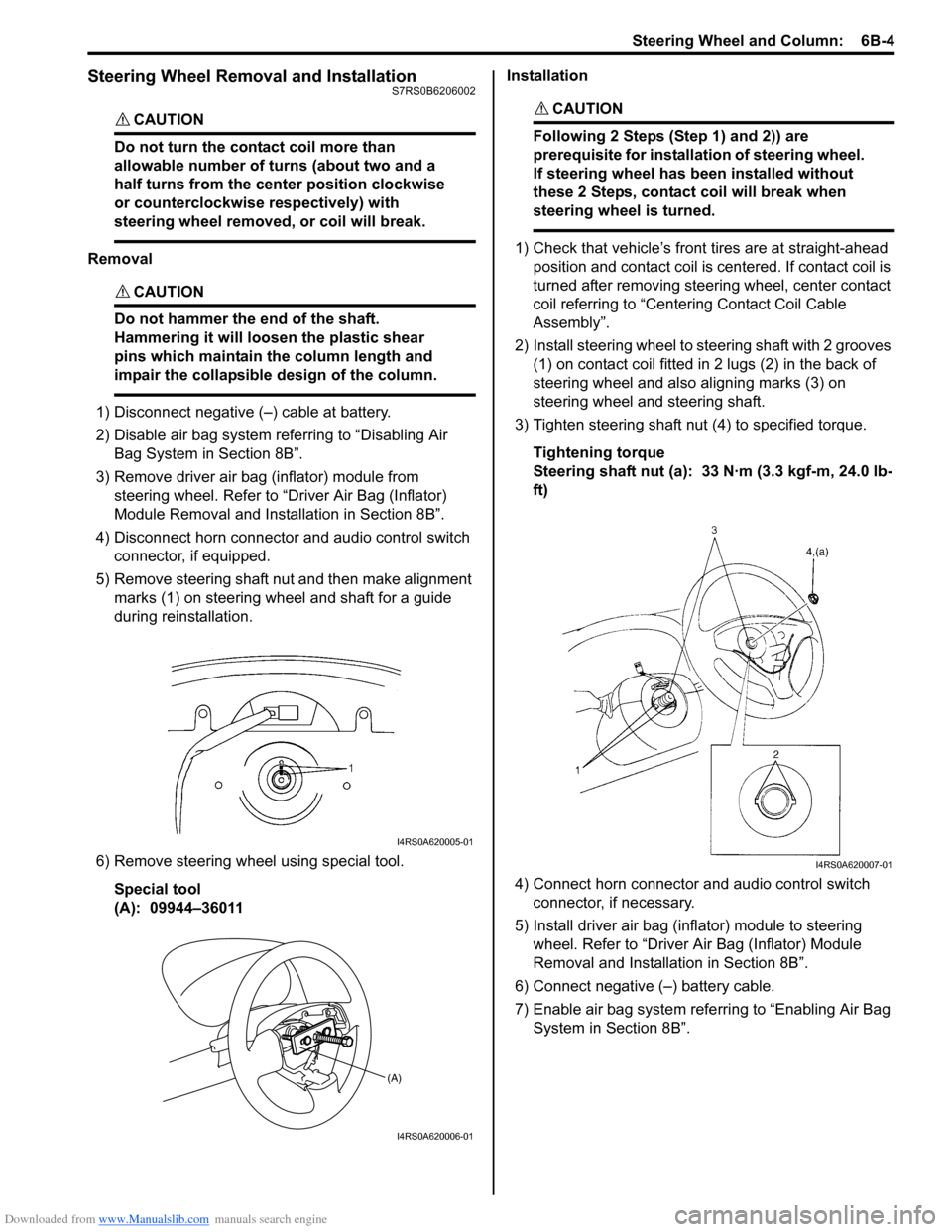

Steering Wheel Removal and InstallationS7RS0B6206002

CAUTION!

Do not turn the contact coil more than

allowable number of turns (about two and a

half turns from the center position clockwise

or counterclockwise respectively) with

steering wheel removed, or coil will break.

Removal

CAUTION!

Do not hammer the end of the shaft.

Hammering it will loosen the plastic shear

pins which maintain the column length and

impair the collapsible design of the column.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove driver air bag (inflator) module from steering wheel. Refer to “Driver Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Disconnect horn connector and audio control switch connector, if equipped.

5) Remove steering shaft nut and then make alignment marks (1) on steering wheel and shaft for a guide

during reinstallation.

6) Remove steering wheel using special tool. Special tool

(A): 09944–36011 Installation

CAUTION!

Following 2 Steps (Step 1) and 2)) are

prerequisite for installation of steering wheel.

If steering wheel has

been installed without

these 2 Steps, contact coil will break when

steering wheel is turned.

1) Check that vehicle’s front tires are at straight-ahead position and contact coil is centered. If contact coil is

turned after removing steering wheel, center contact

coil referring to “Centering Contact Coil Cable

Assembly”.

2) Install steering wheel to steering shaft with 2 grooves (1) on contact coil fitted in 2 lugs (2) in the back of

steering wheel and also aligning marks (3) on

steering wheel and steering shaft.

3) Tighten steering shaft nut (4) to specified torque.

Tightening torque

Steering shaft nut (a): 33 N·m (3.3 kgf-m, 24.0 lb-

ft)

4) Connect horn connector and audio control switch connector, if necessary.

5) Install driver air bag (inflator) module to steering wheel. Refer to “Driver Air Bag (Inflator) Module

Removal and Installati on in Section 8B”.

6) Connect negative (–) battery cable.

7) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

I4RS0A620005-01

(A)

I4RS0A620006-01

I4RS0A620007-01

Page 876 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-5 Steering Wheel and Column:

Contact Coil Cable Assembly Removal and

Installation

S7RS0B6206003

CAUTION!

Do not turn contact coil more than allowable

number of turns (about two and a half turns

from the center position clockwise or

counterclockwise respectively), or coil will

break.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering wheel from steering column referring to “Steering Wheel Removal and

Installation”.

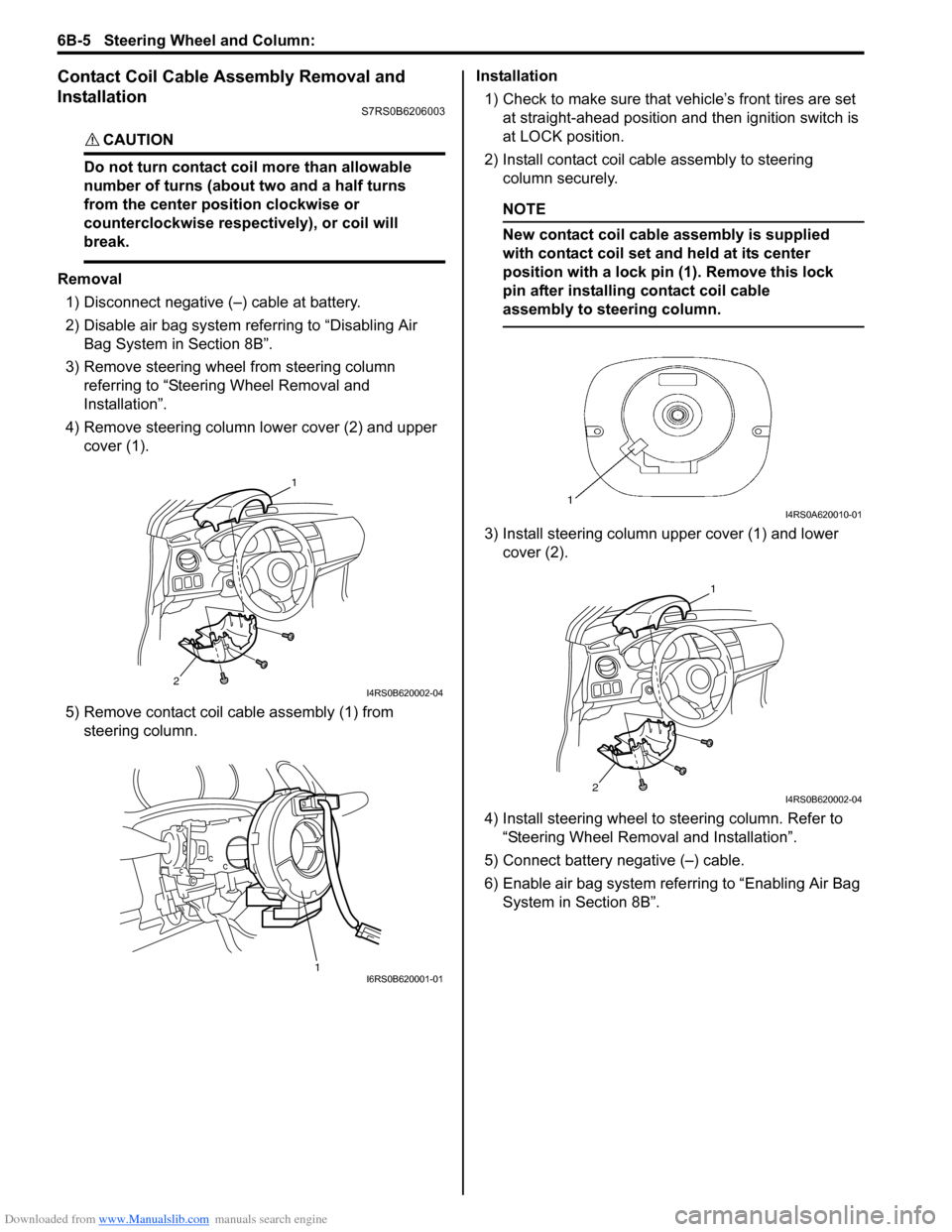

4) Remove steering column lower cover (2) and upper cover (1).

5) Remove contact coil cable assembly (1) from steering column. Installation

1) Check to make sure that vehicle’s front tires are set

at straight-ahead position and then ignition switch is

at LOCK position.

2) Install contact coil cable assembly to steering column securely.

NOTE

New contact coil cable assembly is supplied

with contact coil set and held at its center

position with a lock pin (1). Remove this lock

pin after installing contact coil cable

assembly to steering column.

3) Install steering column upper cover (1) and lower cover (2).

4) Install steering wheel to steering column. Refer to

“Steering Wheel Removal and Installation”.

5) Connect battery negative (–) cable.

6) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

2

1

I4RS0B620002-04

1I6RS0B620001-01

I4RS0A620010-01

2

1

I4RS0B620002-04

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

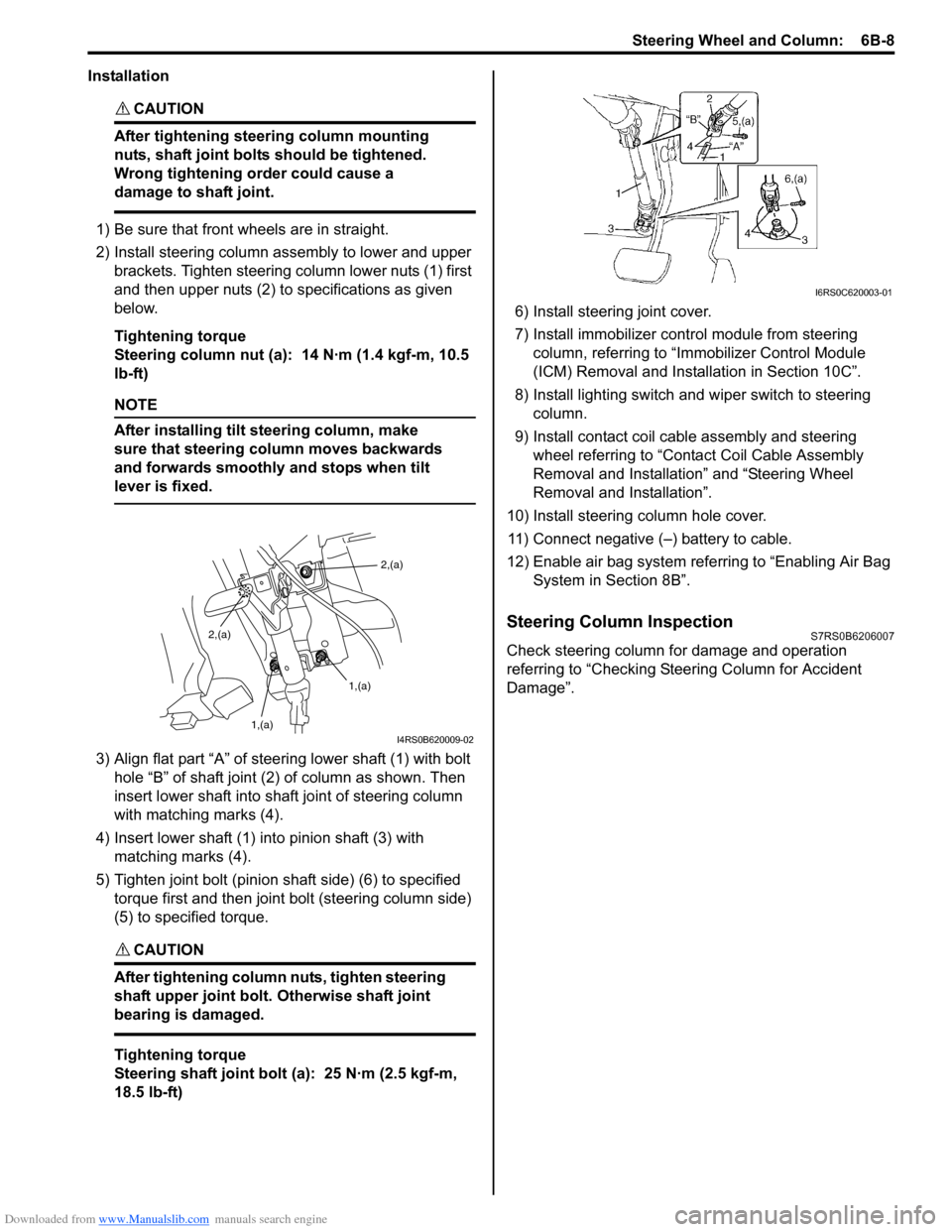

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01