Body SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1311 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-16

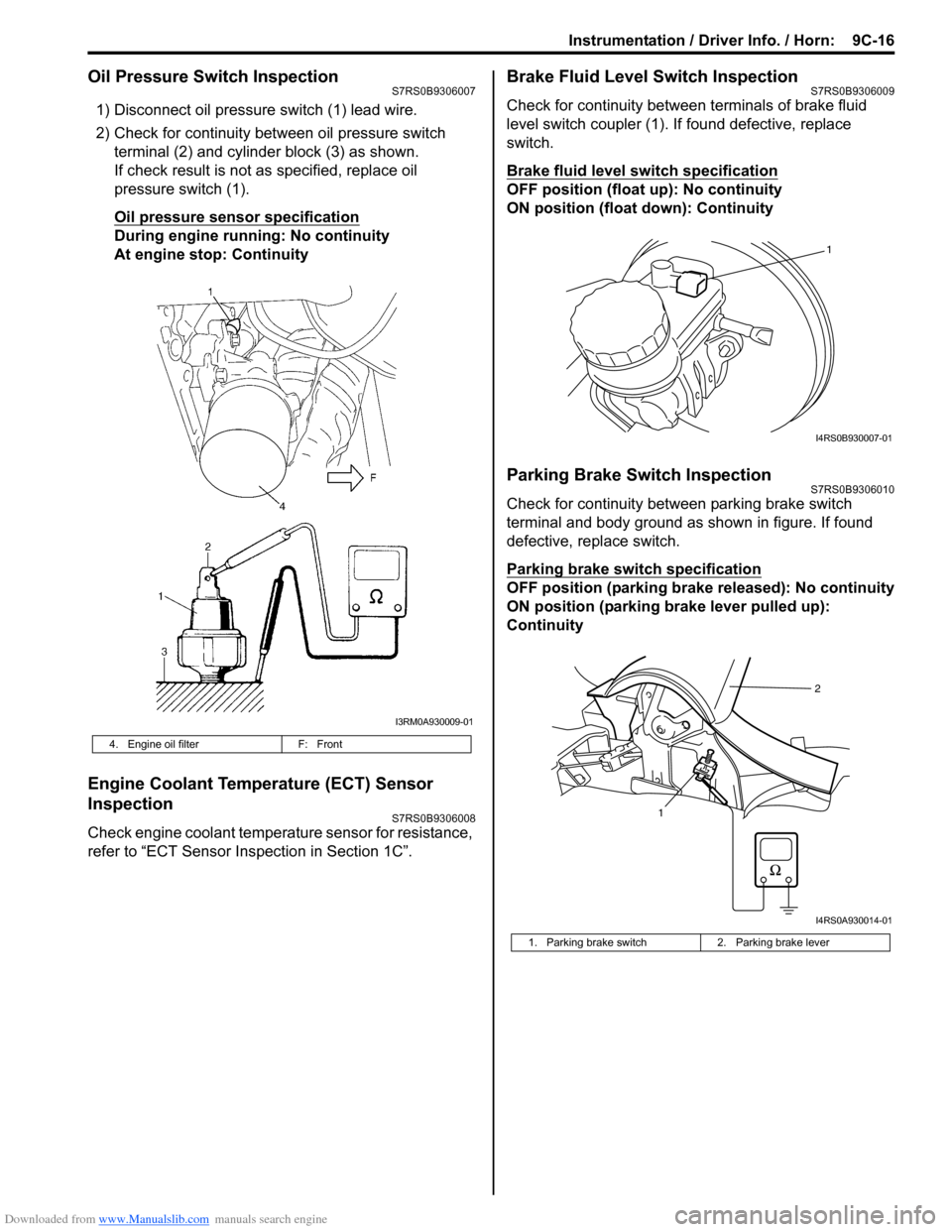

Oil Pressure Switch InspectionS7RS0B9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Engine Coolant Temperature (ECT) Sensor

Inspection

S7RS0B9306008

Check engine coolant temperat ure sensor for resistance,

refer to “ECT Sensor Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS7RS0B9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

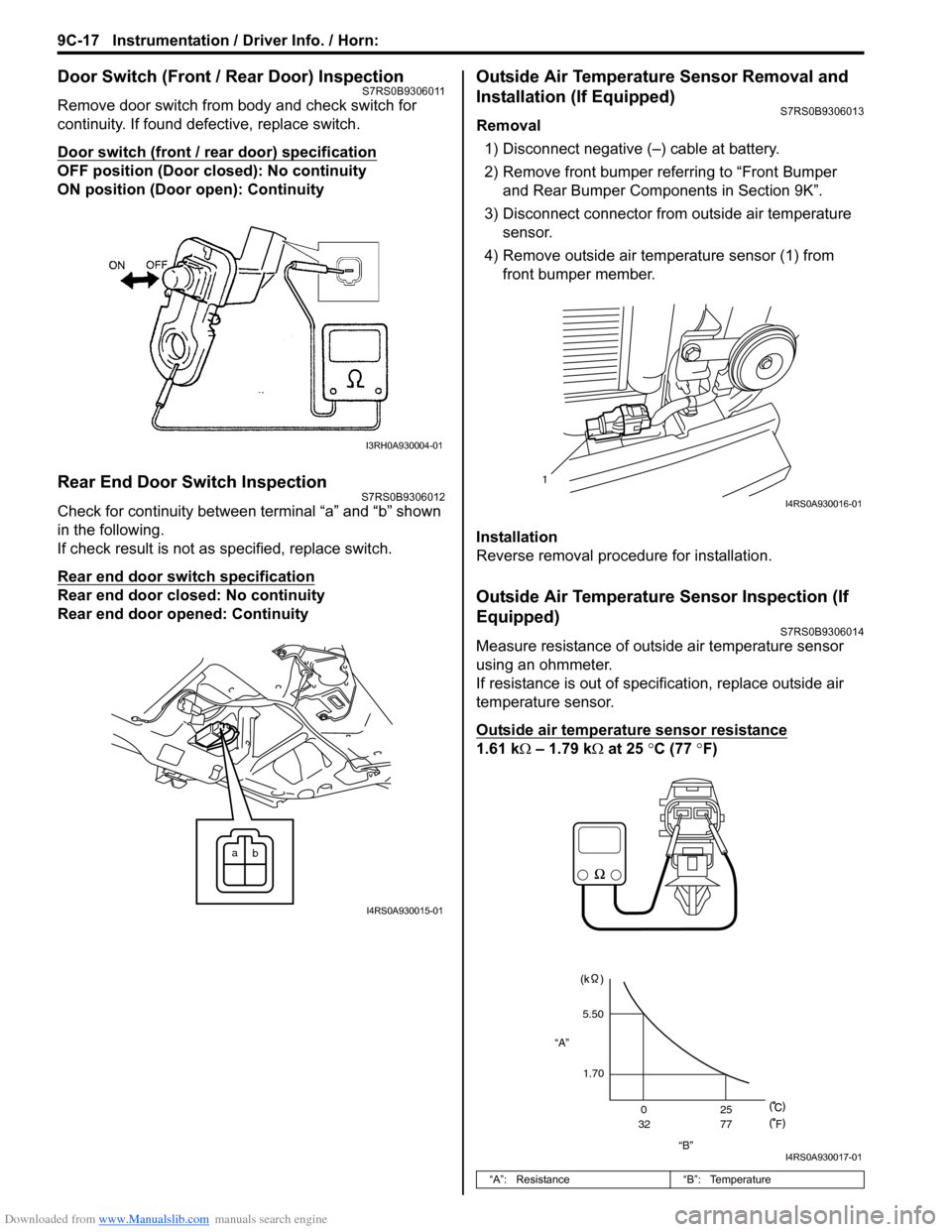

Parking Brake Switch InspectionS7RS0B9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

4. Engine oil filter F: Front

I3RM0A930009-01

1. Parking brake switch 2. Parking brake lever

1

I4RS0B930007-01

12

I4RS0A930014-01

Page 1312 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-17 Instrumentation / Driver Info. / Horn:

Door Switch (Front / Rear Door) InspectionS7RS0B9306011

Remove door switch from body and check switch for

continuity. If found defective, replace switch.

Door switch (front / rear door) specification

OFF position (Door closed): No continuity

ON position (Door open): Continuity

Rear End Door Switch InspectionS7RS0B9306012

Check for continuity between terminal “a” and “b” shown

in the following.

If check result is not as specified, replace switch.

Rear end door switch specification

Rear end door closed: No continuity

Rear end door opened: Continuity

Outside Air Temperature Sensor Removal and

Installation (If Equipped)

S7RS0B9306013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect connector from outside air temperature sensor.

4) Remove outside air temperature sensor (1) from front bumper member.

Installation

Reverse removal procedure for installation.

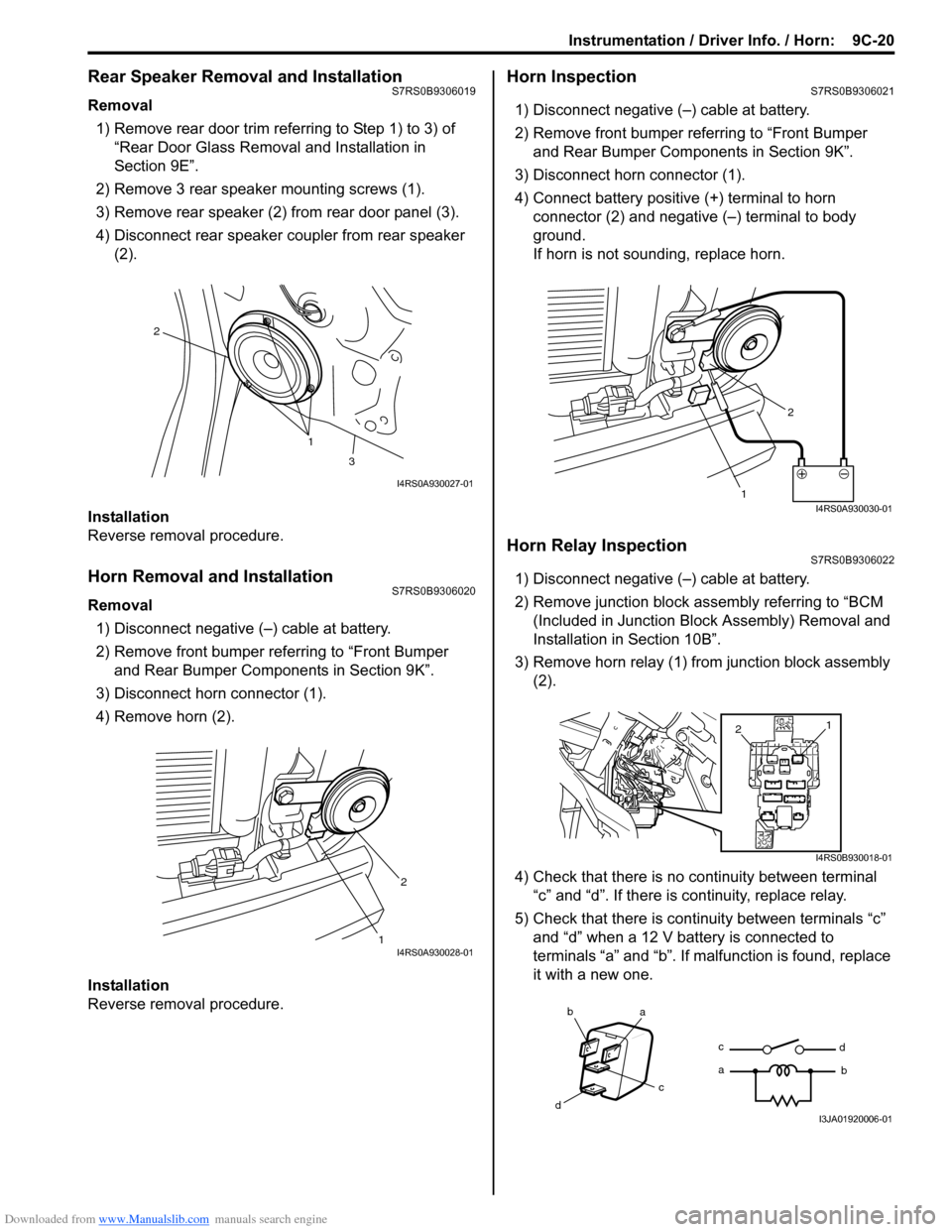

Outside Air Temperature Sensor Inspection (If

Equipped)

S7RS0B9306014

Measure resistance of outside air temperature sensor

using an ohmmeter.

If resistance is out of specif ication, replace outside air

temperature sensor.

Outside air temperature sensor resistance

1.61 kΩ – 1.79 k Ω at 25 °C (77 °F)

I3RH0A930004-01

a

b

I4RS0A930015-01

“A”: Resistance “B”: Temperature

1

I4RS0A930016-01

“B”

“A”

5.50

1.70 0

32 25

77

F

I4RS0A930017-01

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

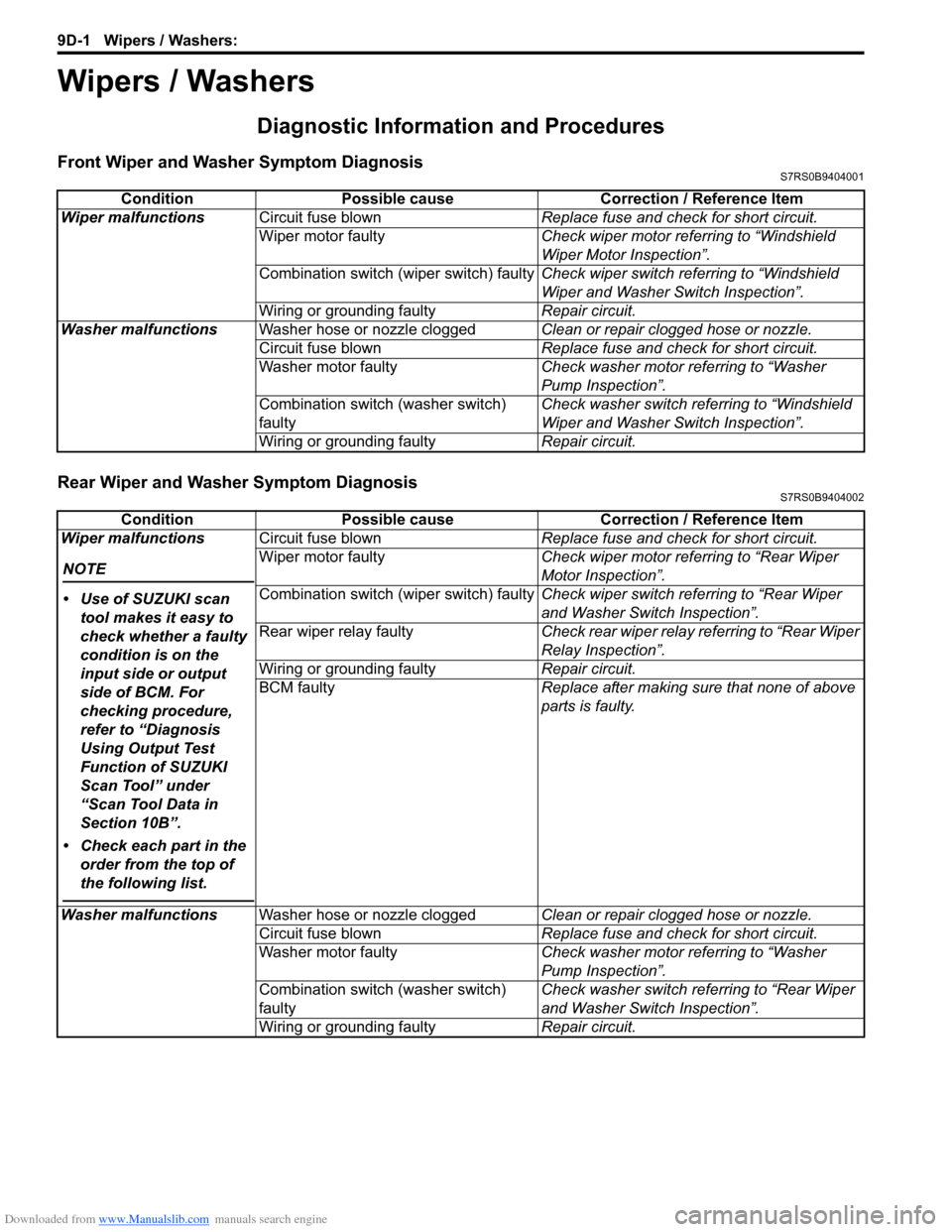

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1328 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

General Description

Rear End Door Window Defogger System DescriptionS7RS0B9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

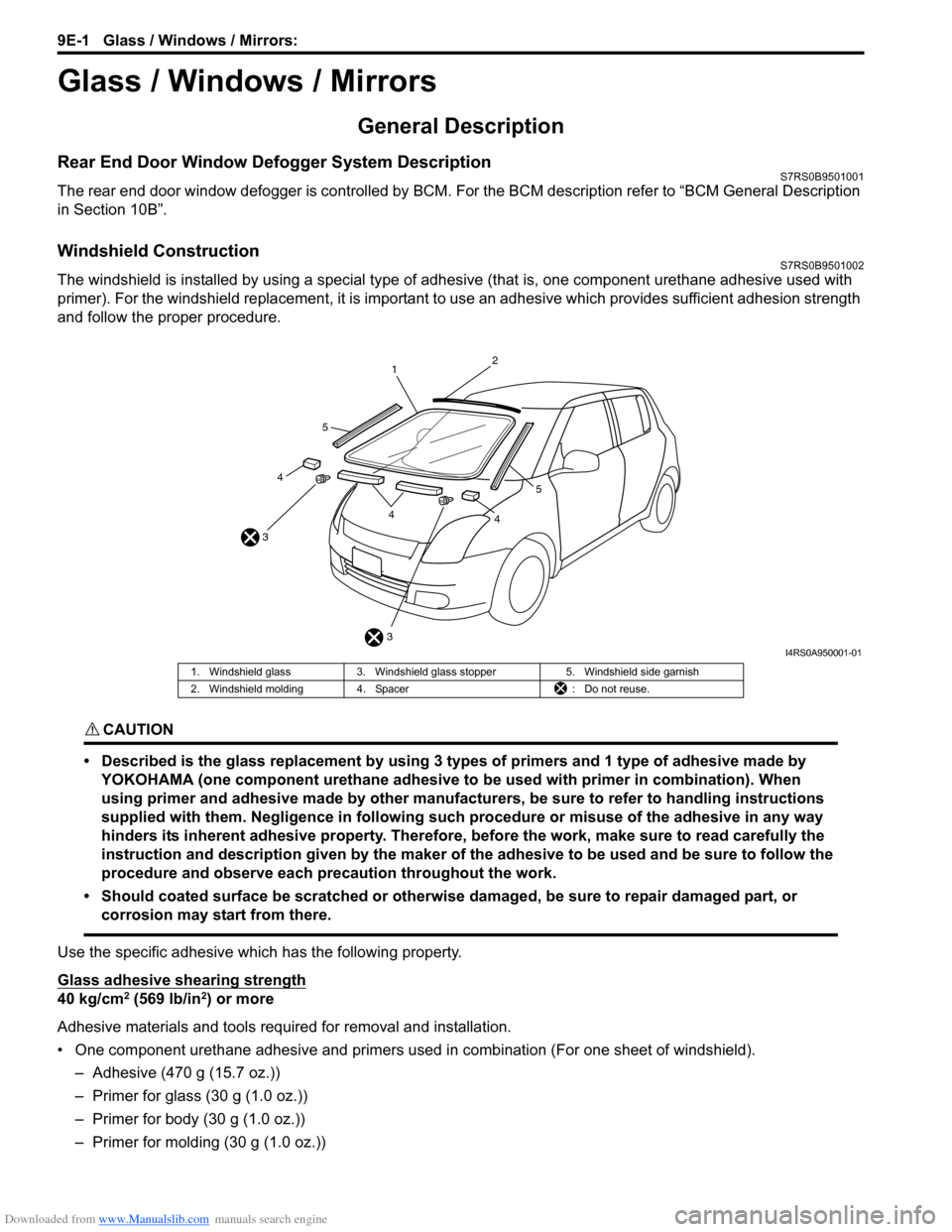

Windshield ConstructionS7RS0B9501002

The windshield is installed by using a special type of adhesive (that is, one component urethane adhesive used with

primer). For the windshield replacement, it is important to use an adhesive which provides sufficient adhesion strength

and follow the proper procedure.

CAUTION!

• Described is the glass replacement by using 3 types of primers and 1 type of adhesive made by YOKOHAMA (one component urethane adhesive to be used with primer in combination). When

using primer and adhesive made by other manufacturers, be sure to refer to handling instructions

supplied with them. Negligence in following such procedure or misuse of the adhesive in any way

hinders its inherent adhesive property. Therefore, before the work, make sure to read carefully the

instruction and description given by the maker of the adhesive to be used and be sure to follow the

procedure and observe each precaution throughout the work.

• Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or corrosion may start from there.

Use the specific adhesive which has the following property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or more

Adhesive materials and tools required for removal and installation.

• One component urethane adhesive and primers used in combination (For one sheet of windshield). – Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

3

3 1

2

44

4

5

5

I4RS0A950001-01

1. Windshield glass

3. Windshield glass stopper 5. Windshield side garnish

2. Windshield molding 4. Spacer : Do not reuse.

Page 1331 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-4

Repair Instructions

Windshield Removal and InstallationS7RS0B9506001

Removal1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Remove windshield side garnish.

4) Using tape, cover body surface around glass to prevent any damage.

5) Remove rear view mirror , sun visor and front pillar

trims (right & left).

6) If necessary, remove instrument panel. Refer to “Instrument Panel Removal and Installation in

Section 9C”.

7) If necessary, remove he ad lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

8) Remove (or cut) windshield molding.

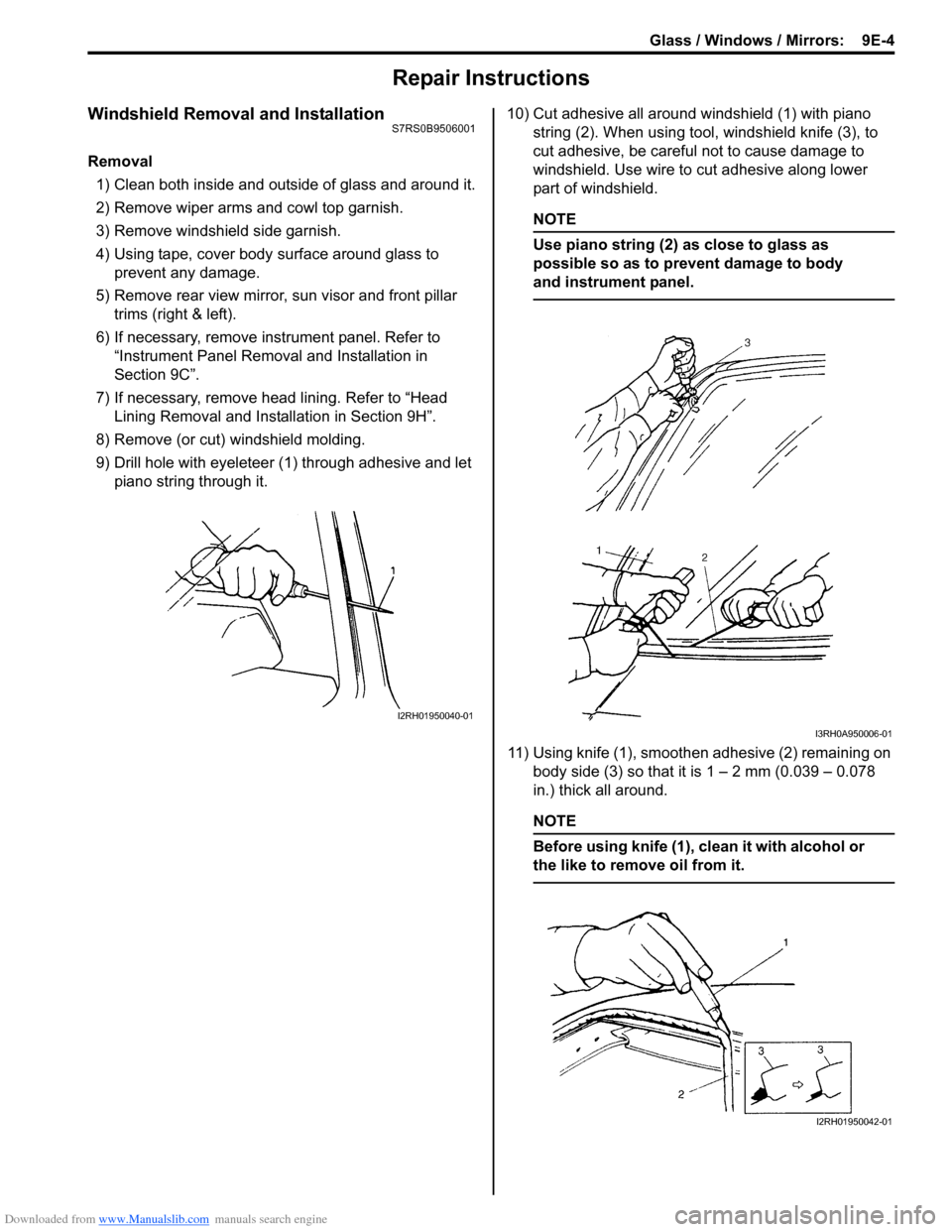

9) Drill hole with eyeleteer (1 ) through adhesive and let

piano string through it. 10) Cut adhesive all around windshield (1) with piano

string (2). When using tool, windshield knife (3), to

cut adhesive, be careful not to cause damage to

windshield. Use wire to cut adhesive along lower

part of windshield.

NOTE

Use piano string (2) as close to glass as

possible so as to prevent damage to body

and instrument panel.

11) Using knife (1), smoothen adhesive (2) remaining on body side (3) so that it is 1 – 2 mm (0.039 – 0.078

in.) thick all around.

NOTE

Before using knife (1), clean it with alcohol or

the like to remove oil from it.

I2RH01950040-01

I3RH0A950006-01

I2RH01950042-01

Page 1332 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-5 Glass / Windows / Mirrors:

12) When reusing windshield, remove the adhesive (1) from it, using care not to damage primer coated

surface (2).

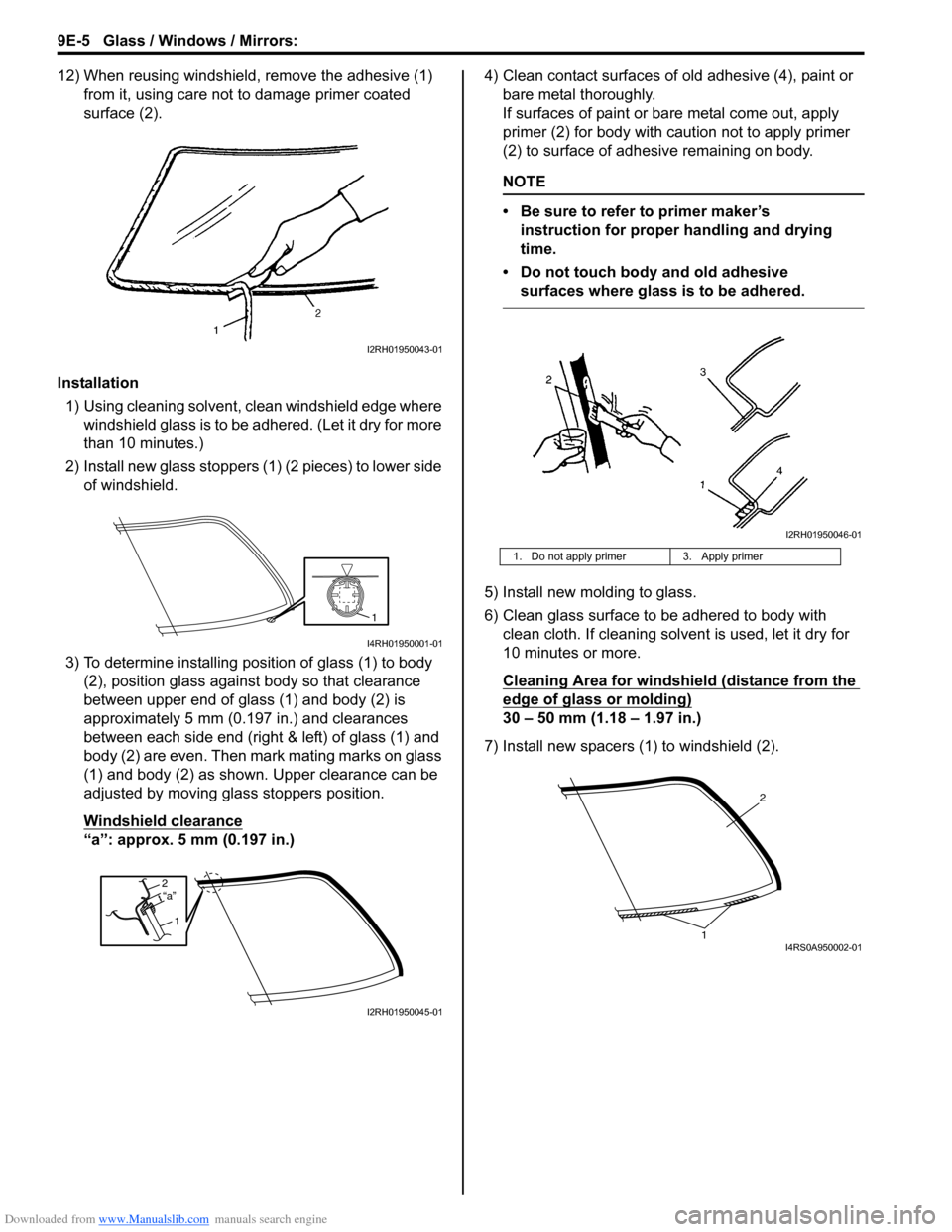

Installation 1) Using cleaning solvent, clean windshield edge where windshield glass is to be adhered. (Let it dry for more

than 10 minutes.)

2) Install new glass stoppers (1) (2 pieces) to lower side of windshield.

3) To determine installing position of glass (1) to body (2), position glass against body so that clearance

between upper end of glass (1) and body (2) is

approximately 5 mm (0.197 in.) and clearances

between each side end (right & left) of glass (1) and

body (2) are even. Then mark mating marks on glass

(1) and body (2) as shown. Upper clearance can be

adjusted by moving glass stoppers position.

Windshield clearance

“a”: approx. 5 mm (0.197 in.) 4) Clean contact surfaces of old adhesive (4), paint or

bare metal thoroughly.

If surfaces of paint or ba re metal come out, apply

primer (2) for body with caution not to apply primer

(2) to surface of adhesive remaining on body.

NOTE

• Be sure to refer to primer maker’s instruction for proper handling and drying

time.

• Do not touch body and old adhesive surfaces where glass is to be adhered.

5) Install new molding to glass.

6) Clean glass surface to be adhered to body with clean cloth. If cleaning solvent is used, let it dry for

10 minutes or more.

Cleaning Area for windshie ld (distance from the

edge of glass or molding)

30 – 50 mm (1.18 – 1.97 in.)

7) Install new spacers (1) to windshield (2).

I2RH01950043-01

1

I4RH01950001-01

2

1“a”

I2RH01950045-01

1. Do not apply primer 3. Apply primer

I2RH01950046-01

2

1I4RS0A950002-01

Page 1333 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-6

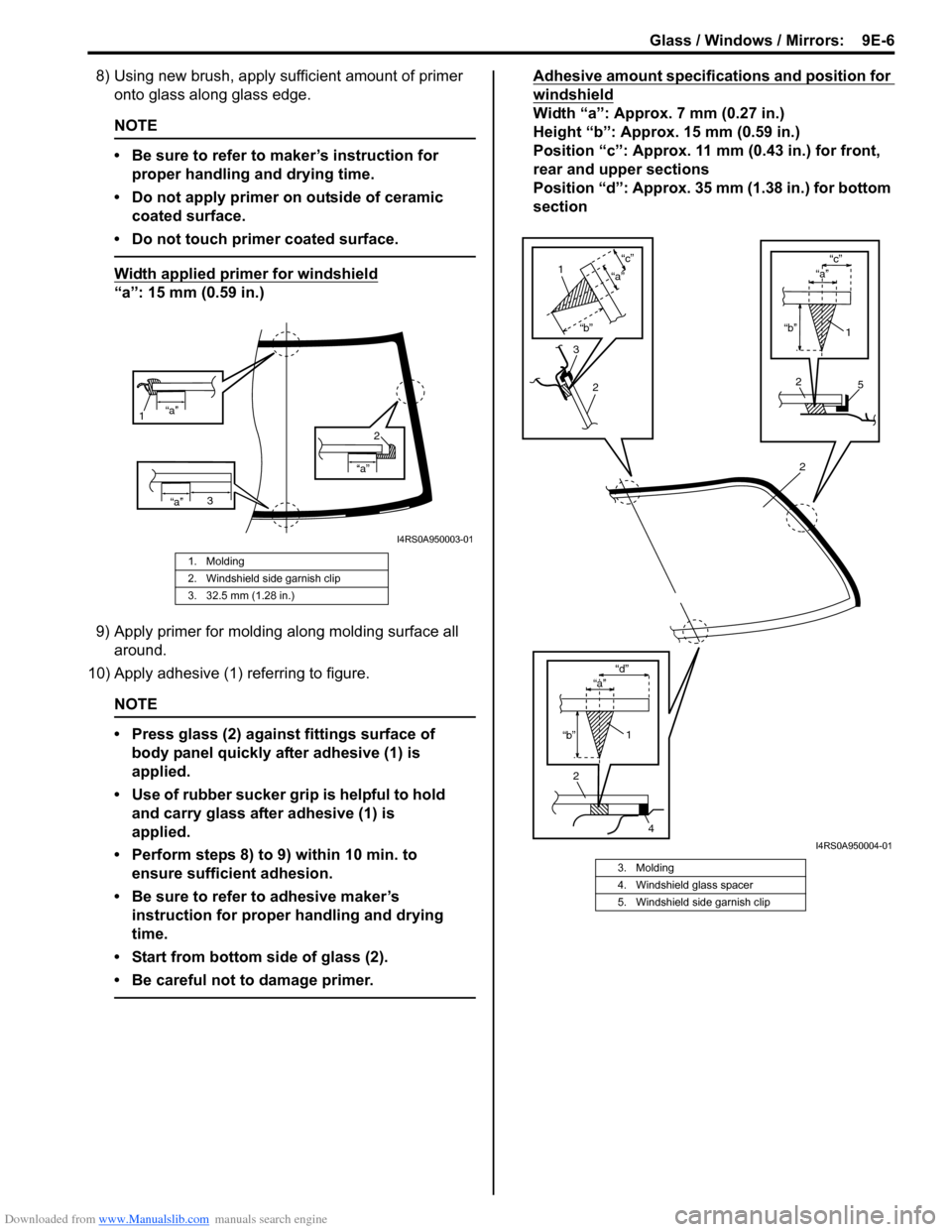

8) Using new brush, apply sufficient amount of primer onto glass along glass edge.

NOTE

• Be sure to refer to maker’s instruction for

proper handling and drying time.

• Do not apply primer on outside of ceramic coated surface.

• Do not touch primer coated surface.

Width applied primer for windshield

“a”: 15 mm (0.59 in.)

9) Apply primer for molding along molding surface all around.

10) Apply adhesive (1) referring to figure.

NOTE

• Press glass (2) against fittings surface of body panel quickly after adhesive (1) is

applied.

• Use of rubber sucker gr ip is helpful to hold

and carry glass after adhesive (1) is

applied.

• Perform steps 8) to 9) within 10 min. to ensure sufficient adhesion.

• Be sure to refer to adhesive maker’s instruction for proper handling and drying

time.

• Start from bottom side of glass (2).

• Be careful not to damage primer.

Adhesive amount specifications and position for

windshield

Width “a”: Approx. 7 mm (0.27 in.)

Height “b”: Approx. 15 mm (0.59 in.)

Position “c”: Approx. 11 mm (0.43 in.) for front,

rear and upper sections

Position “d”: Approx. 35 mm (1.38 in.) for bottom

section

1. Molding

2. Windshield side garnish clip

3. 32.5 mm (1.28 in.)

“a”

1

“a”

“a”

2

3

I4RS0A950003-01

3. Molding

4. Windshield glass spacer

5. Windshield side garnish clip

2

2

4

1

“b” “d”

“b”

“c”

2

1

“a”

3

2

1

“b”

“c”

5

“a”

“a”

I4RS0A950004-01

Page 1334 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-7 Glass / Windows / Mirrors:

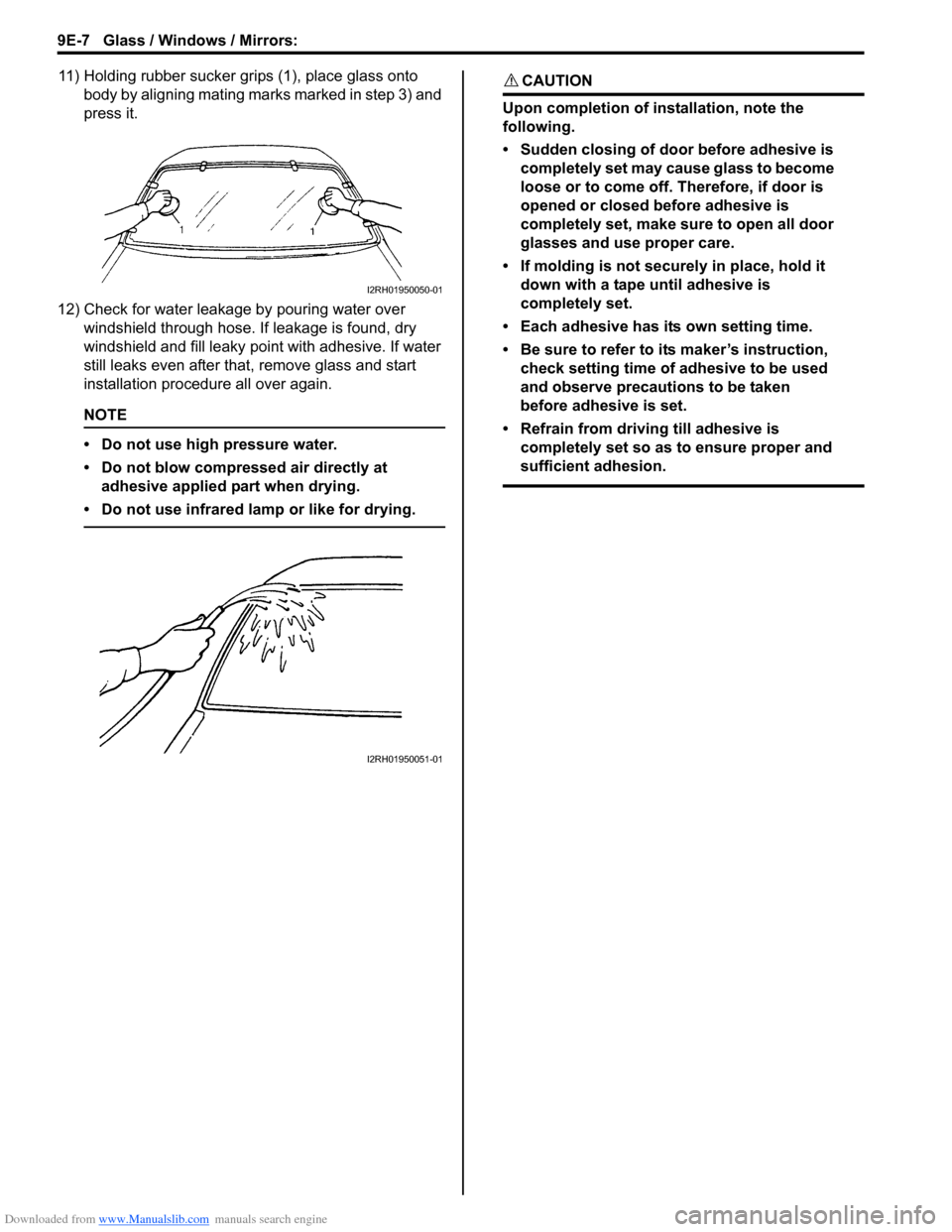

11) Holding rubber sucker grips (1), place glass onto body by aligning mating marks marked in step 3) and

press it.

12) Check for water leakage by pouring water over windshield through hose. If leakage is found, dry

windshield and fill leaky po int with adhesive. If water

still leaks even after that , remove glass and start

installation procedure all over again.

NOTE

• Do not use high pressure water.

• Do not blow compressed air directly at adhesive applied part when drying.

• Do not use infrared lamp or like for drying.

CAUTION!

Upon completion of installation, note the

following.

• Sudden closing of door before adhesive is completely set may cause glass to become

loose or to come off. Therefore, if door is

opened or closed before adhesive is

completely set, make sure to open all door

glasses and use proper care.

• If molding is not securely in place, hold it down with a tape until adhesive is

completely set.

• Each adhesive has its own setting time.

• Be sure to refer to its maker’s instruction, check setting time of adhesive to be used

and observe precautions to be taken

before adhesive is set.

• Refrain from driving till adhesive is completely set so as to ensure proper and

sufficient adhesion.

I2RH01950050-01

I2RH01950051-01

Page 1340 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-13 Glass / Windows / Mirrors:

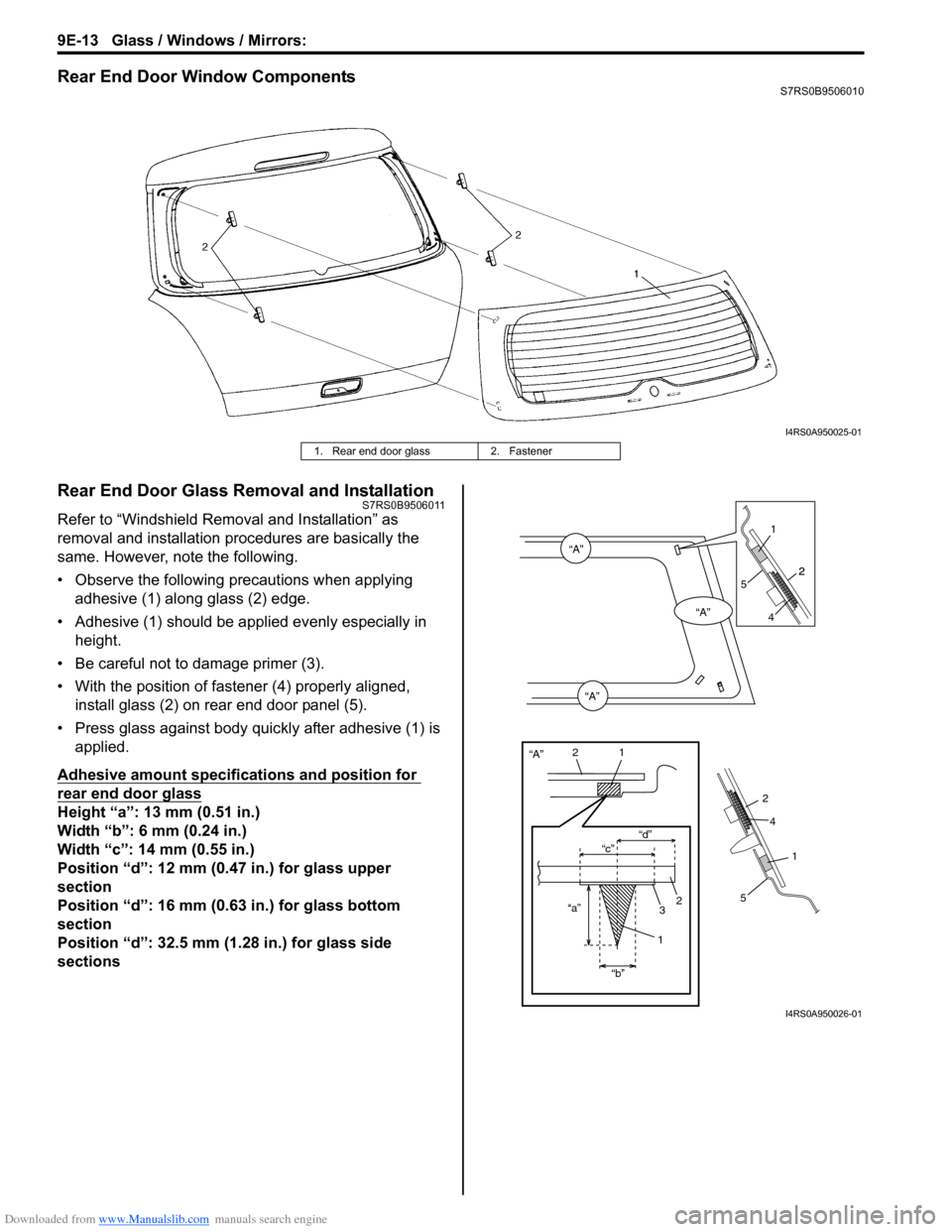

Rear End Door Window ComponentsS7RS0B9506010

Rear End Door Glass Removal and InstallationS7RS0B9506011

Refer to “Windshield Removal and Installation” as

removal and installation procedures are basically the

same. However, note the following.

• Observe the following precautions when applying adhesive (1) along glass (2) edge.

• Adhesive (1) should be app lied evenly especially in

height.

• Be careful not to damage primer (3).

• With the position of fastener (4) properly aligned, install glass (2) on rear end door panel (5).

• Press glass against body quickly after adhesive (1) is applied.

Adhesive amount specifications and position for

rear end door glass

Height “a”: 13 mm (0.51 in.)

Width “b”: 6 mm (0.24 in.)

Width “c”: 14 mm (0.55 in.)

Position “d”: 12 mm (0.47 in.) for glass upper

section

Position “d”: 16 mm (0.63 in.) for glass bottom

section

Position “d”: 32.5 mm (1.28 in.) for glass side

sections

I4RS0A950025-01

1. Rear end door glass 2. Fastener

“A”

“A”

“A”

“A”

“c”“d”

“a” “b”

21

2

3

1

2

1

1

2

5

2

4

4

5

I4RS0A950026-01