lock SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1290 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-8 Lighting Systems:

Headlight Switch (in Lighting Switch) Removal

and Installation

S7RS0B9206004

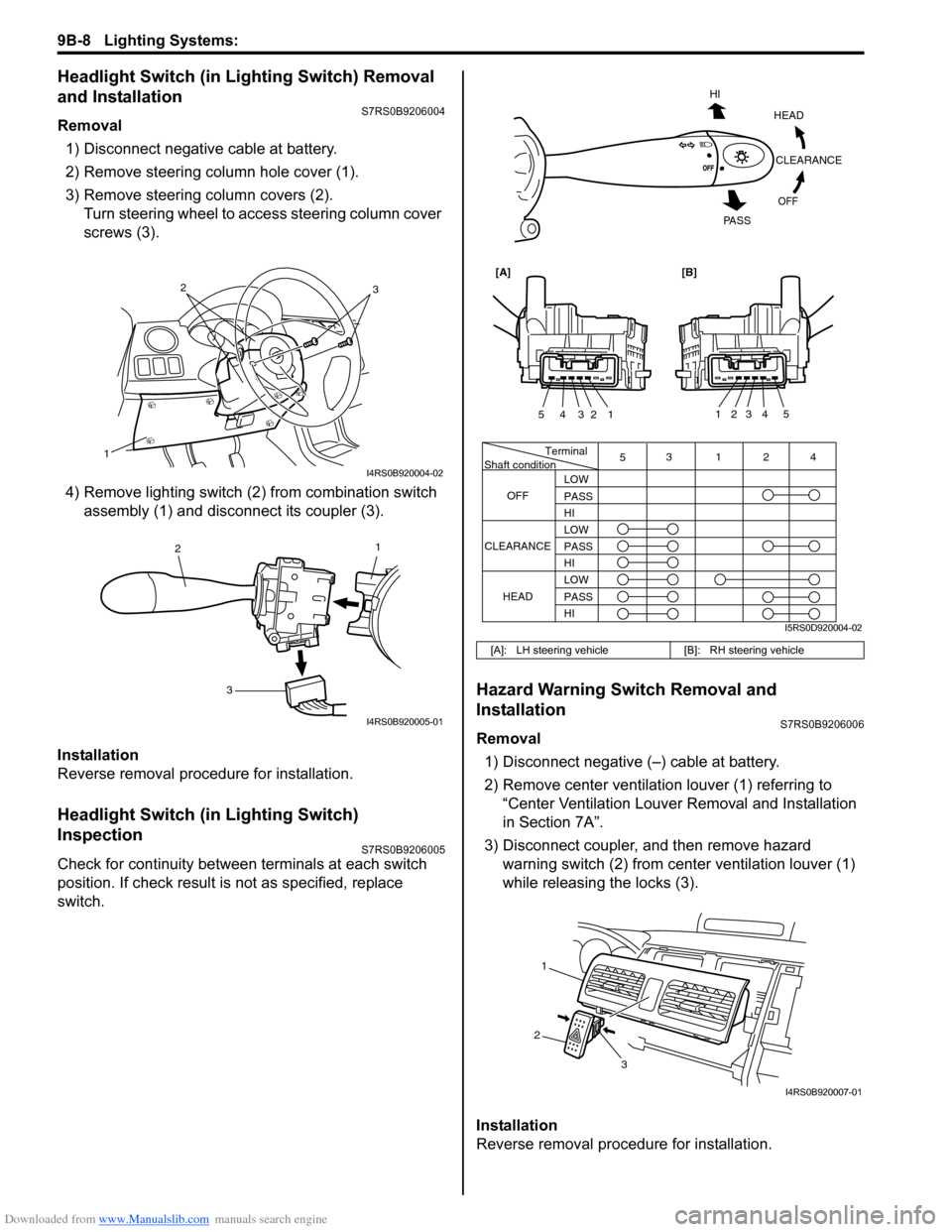

Removal1) Disconnect negative cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to acce ss steering column cover

screws (3).

4) Remove lighting switch (2 ) from combination switch

assembly (1) and disconnect its coupler (3).

Installation

Reverse removal procedure for installation.

Headlight Switch (in Lighting Switch)

Inspection

S7RS0B9206005

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Hazard Warning Switch Removal and

Installation

S7RS0B9206006

Removal 1) Disconnect negative (–) cable at battery.

2) Remove center ventilation louver (1) referring to

“Center Ventilation Louver Removal and Installation

in Section 7A”.

3) Disconnect coupler, and then remove hazard warning switch (2) from center ventilation louver (1)

while releasing the locks (3).

Installation

Reverse removal procedure for installation.

1

32

I4RS0B920004-02

1

2

3

I4RS0B920005-01

[A]: LH steering vehicle [B]: RH steering vehicle

Terminal

Shaft condition

OFF 5

3124

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

CLEARANCE

HEAD

HEADCLEARANCE

OFF

HI

PA S S

54321

54321

[A][B]

I5RS0D920004-02

1

2 3

I4RS0B920007-01

Page 1291 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-9

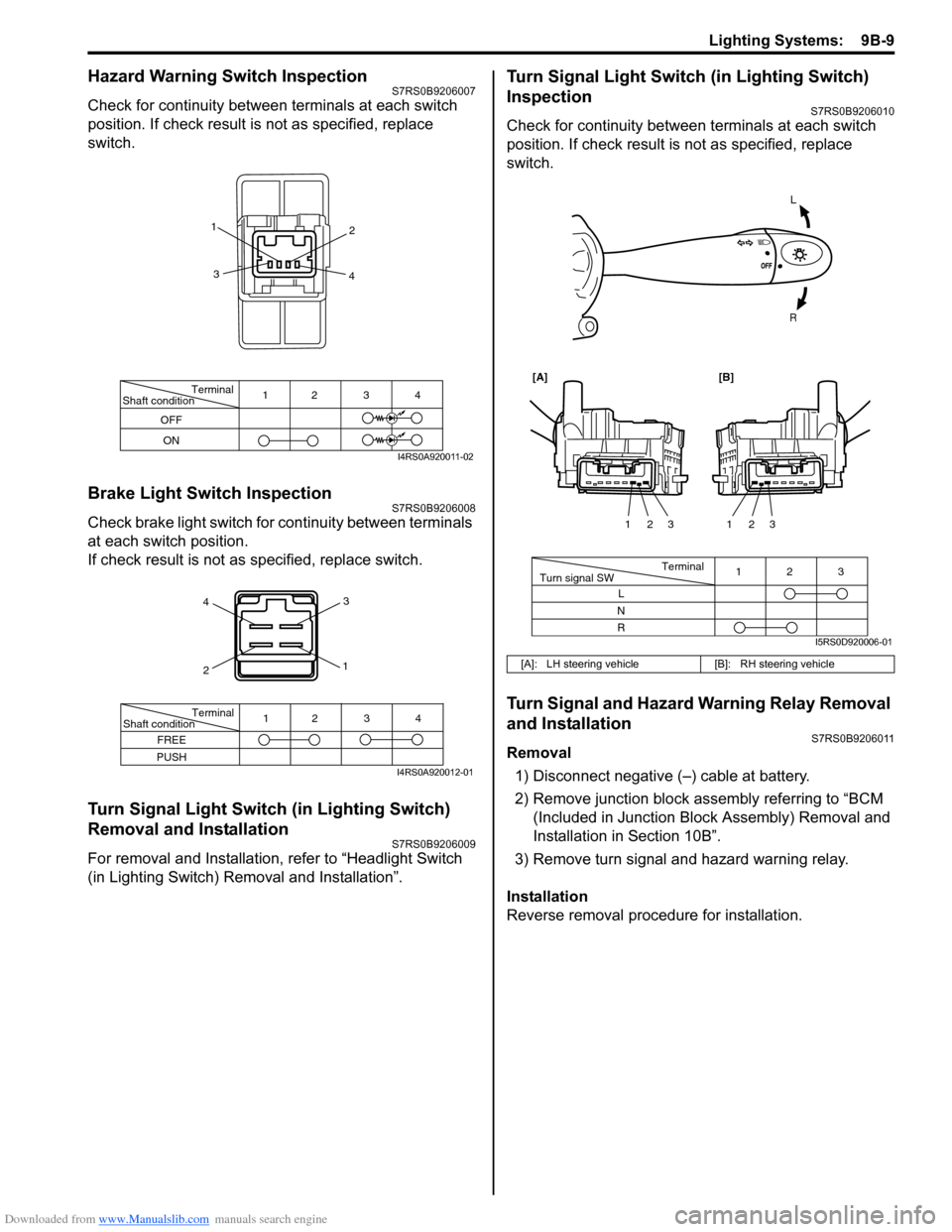

Hazard Warning Switch InspectionS7RS0B9206007

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Brake Light Switch InspectionS7RS0B9206008

Check brake light switch for continuity between terminals

at each switch position.

If check result is not as specified, replace switch.

Turn Signal Light Switch (in Lighting Switch)

Removal and Installation

S7RS0B9206009

For removal and Installation, refer to “Headlight Switch

(in Lighting Switch) Removal and Installation”.

Turn Signal Light Switch (in Lighting Switch)

Inspection

S7RS0B9206010

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Turn Signal and Hazard Warning Relay Removal

and Installation

S7RS0B9206011

Removal

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove turn signal and hazard warning relay.

Installation

Reverse removal procedure for installation.

Terminal

Shaft condition

OFF

ON 12 3 4

1

2

3 4

I4RS0A920011-02

4

2 3

1

Terminal

Shaft condition

FREE

PUSH 12 3 4

I4RS0A920012-01

[A]: LH steering vehicle

[B]: RH steering vehicle

L

R

Terminal

Turn signal SW 3

12

L

N

R 123

123

[A][B]

I5RS0D920006-01

Page 1292 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-10 Lighting Systems:

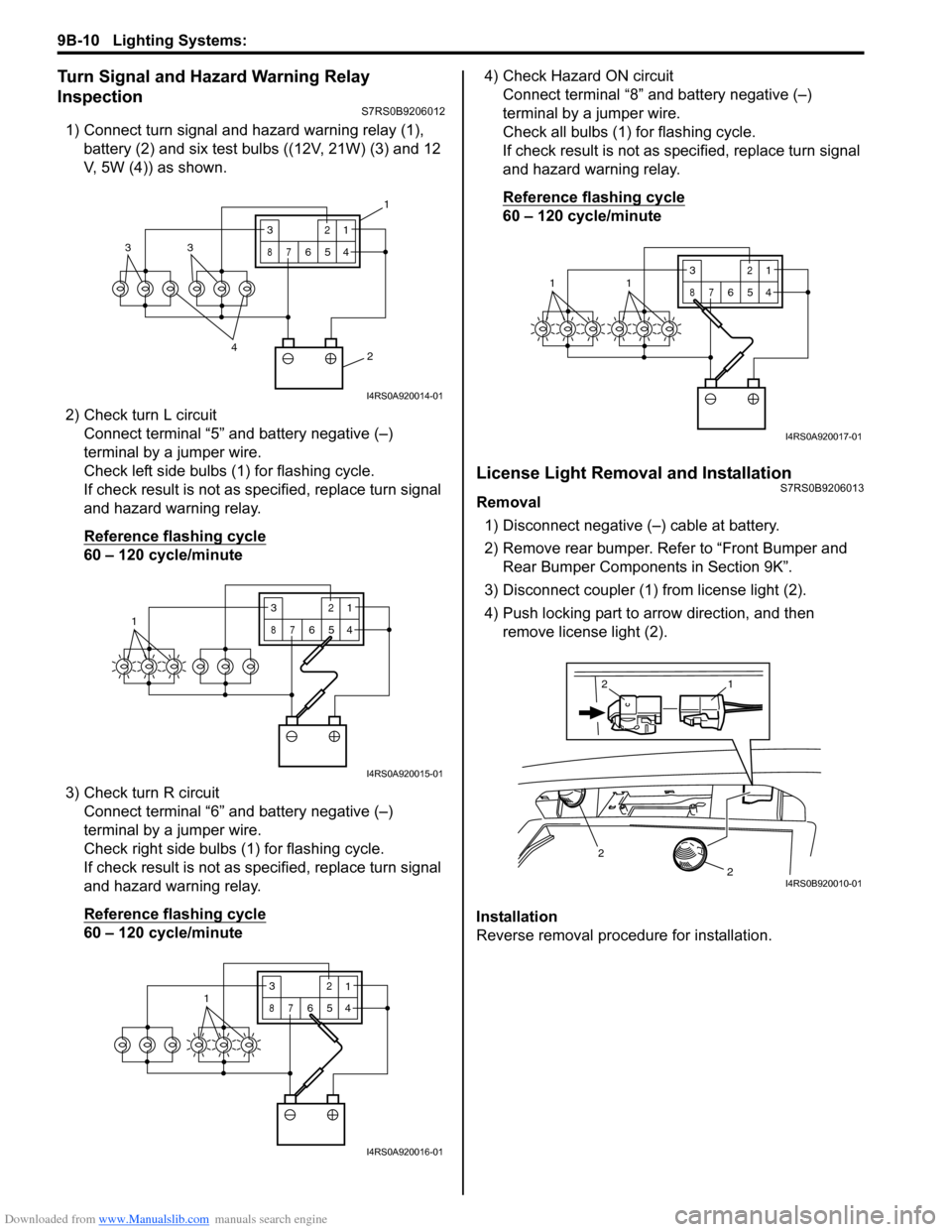

Turn Signal and Hazard Warning Relay

Inspection

S7RS0B9206012

1) Connect turn signal and hazard warning relay (1), battery (2) and six test bulbs ((12V, 21W) (3) and 12

V, 5W (4)) as shown.

2) Check turn L circuit Connect terminal “5” and battery negative (–)

terminal by a jumper wire.

Check left side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

3) Check turn R circuit Connect terminal “6” and battery negative (–)

terminal by a jumper wire.

Check right side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute 4) Check Hazard ON circuit

Connect terminal “8” and battery negative (–)

terminal by a jumper wire.

Check all bulbs (1) for flashing cycle.

If check result is not as sp ecified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

License Light Removal and InstallationS7RS0B9206013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear bumper. Refe r to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Disconnect coupler (1) from license light (2).

4) Push locking part to arrow direction, and then remove license light (2).

Installation

Reverse removal procedure for installation.

2

4

33

3

87

12

654

1

I4RS0A920014-01

13

87

12

654

I4RS0A920015-01

3

87

12

6541

I4RS0A920016-01

3

87

12

6

5411

I4RS0A920017-01

2

2

1

2

I4RS0B920010-01

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

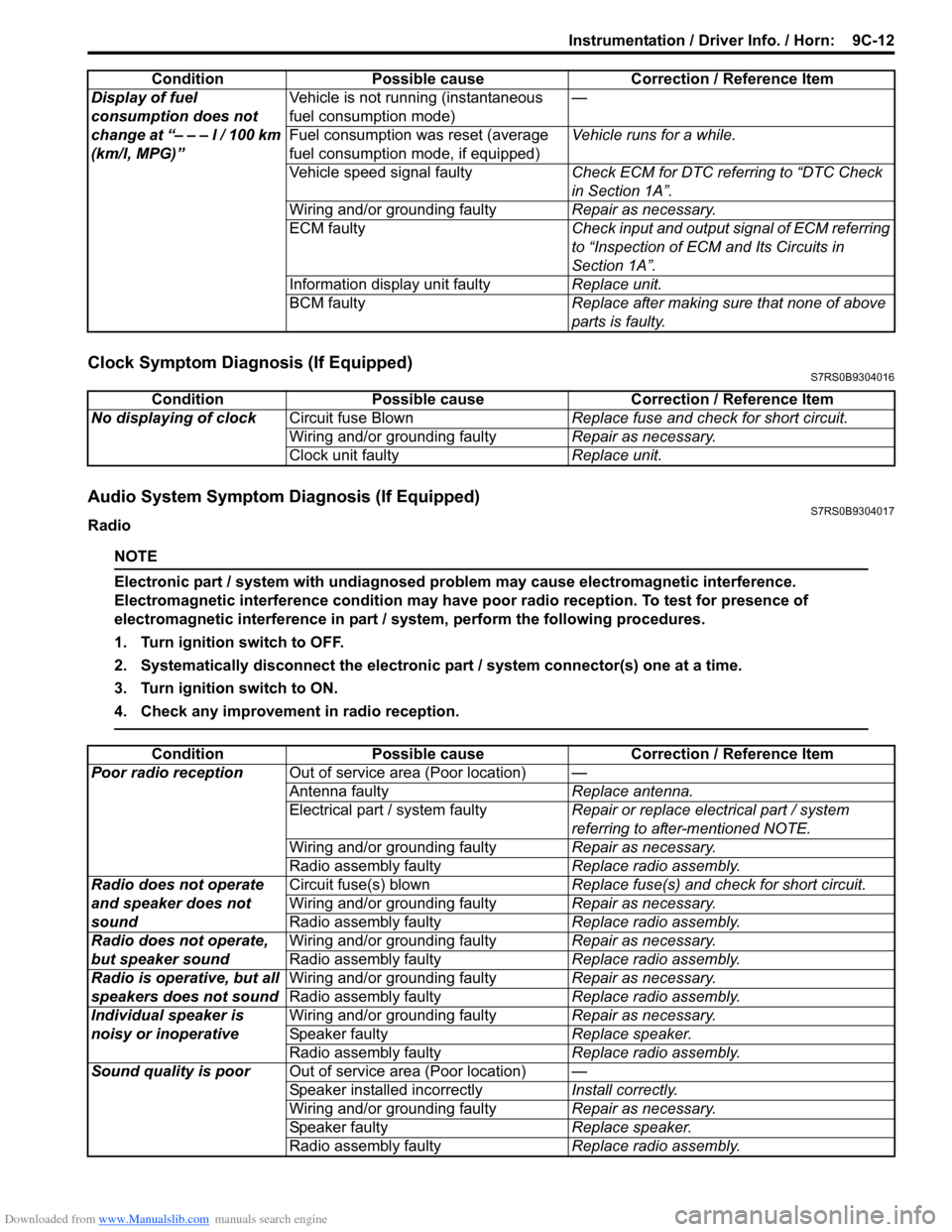

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Page 1309 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-14

Navigation Symptom Diagnosis (If Equipped)S7RS0B9304019

Repair Instructions

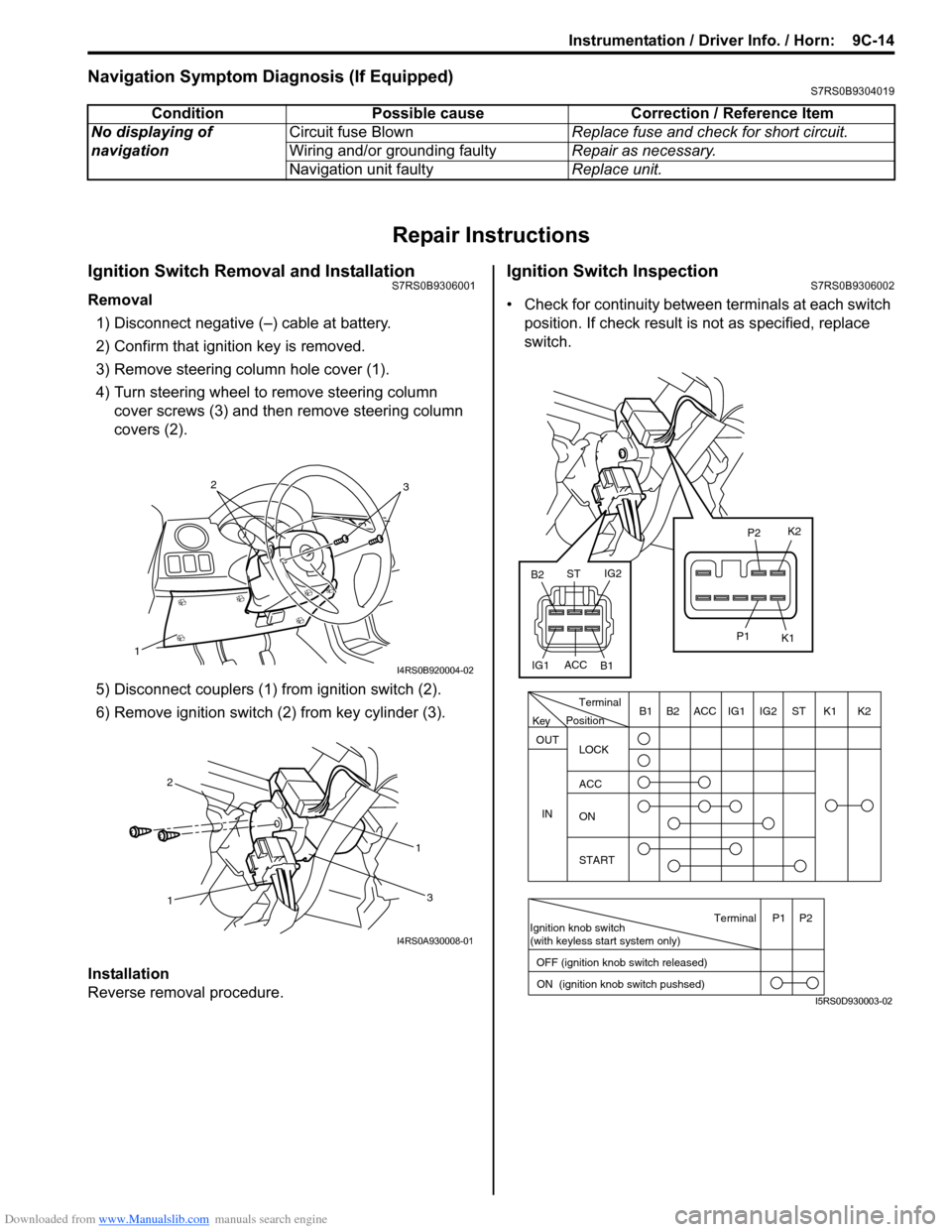

Ignition Switch Removal and InstallationS7RS0B9306001

Removal

1) Disconnect negative (–) cable at battery.

2) Confirm that ignition key is removed.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3) and then remove steering column

covers (2).

5) Disconnect couplers (1) from ignition switch (2).

6) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure.

Ignition Switch InspectionS7RS0B9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Condition Possible cause Correction / Reference Item

No displaying of

navigation Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Navigation unit faulty Replace unit.

1

32

I4RS0B920004-02

1 1

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START

OUT

INK2K1ST

IG2

IG1

ACC

B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1 IG2

ST

B2

B1 K2

K1

P2

P1

Terminal

OFF (ignition knob switch released) ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02

Page 1311 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-16

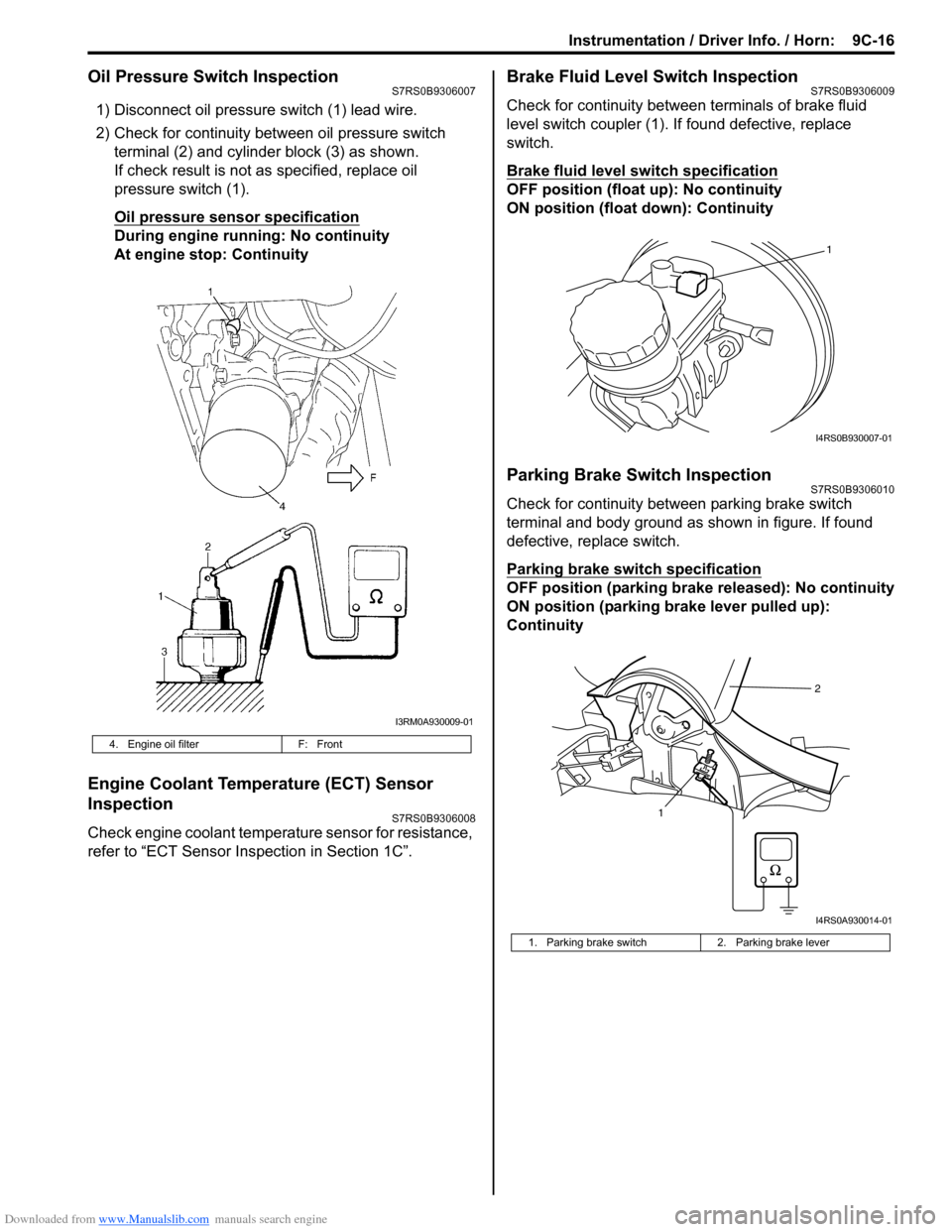

Oil Pressure Switch InspectionS7RS0B9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Engine Coolant Temperature (ECT) Sensor

Inspection

S7RS0B9306008

Check engine coolant temperat ure sensor for resistance,

refer to “ECT Sensor Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS7RS0B9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

Parking Brake Switch InspectionS7RS0B9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

4. Engine oil filter F: Front

I3RM0A930009-01

1. Parking brake switch 2. Parking brake lever

1

I4RS0B930007-01

12

I4RS0A930014-01

Page 1314 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-19 Instrumentation / Driver Info. / Horn:

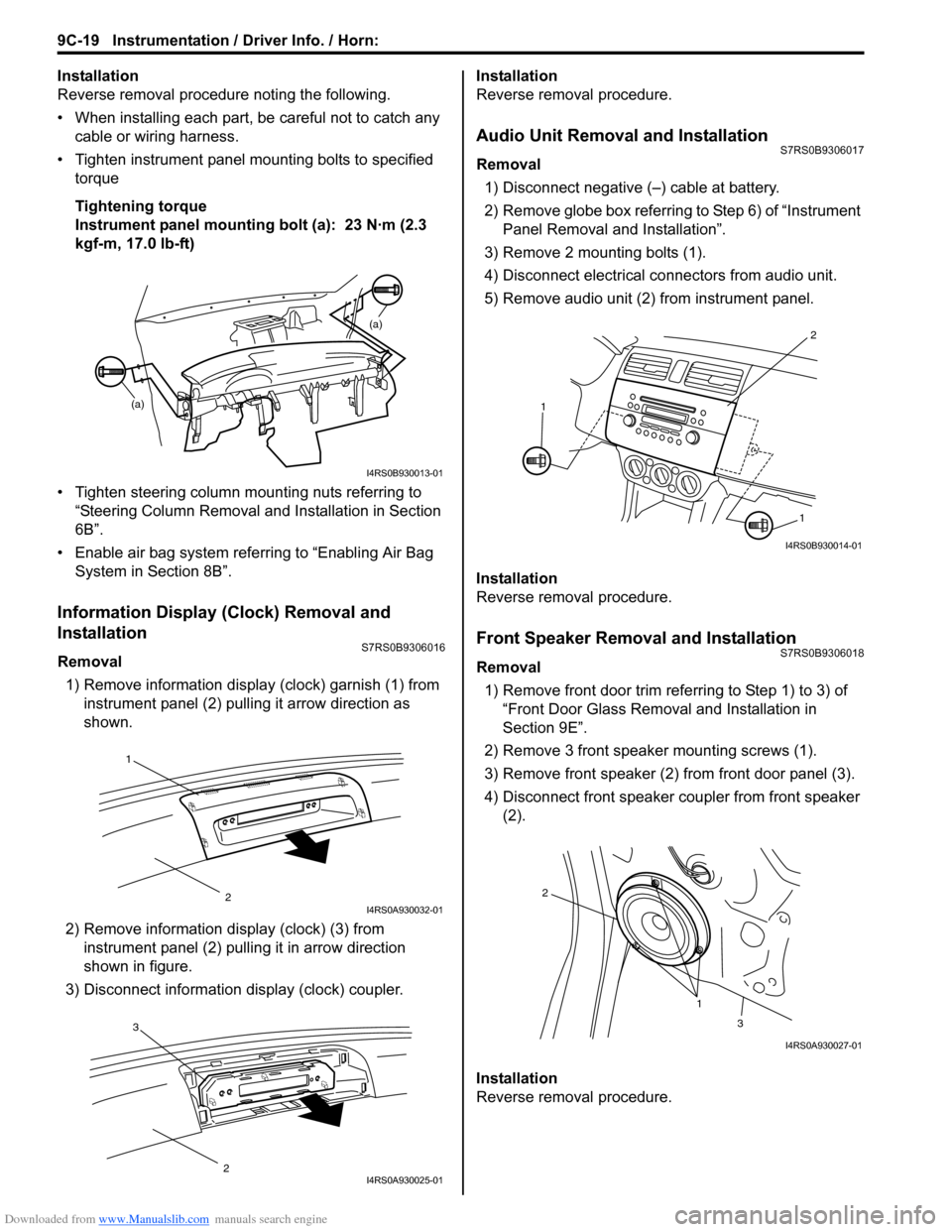

Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten instrument panel mounting bolts to specified

torque

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Tighten steering column mounting nuts referring to “Steering Column Removal an d Installation in Section

6B”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Information Display (Clock) Removal and

Installation

S7RS0B9306016

Removal

1) Remove information display (clock) garnish (1) from instrument panel (2) pulling it arrow direction as

shown.

2) Remove information di splay (clock) (3) from

instrument panel (2) pulli ng it in arrow direction

shown in figure.

3) Disconnect information display (clock) coupler. Installation

Reverse removal procedure.

Audio Unit Removal and InstallationS7RS0B9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove globe box referring to Step 6) of “Instrument Panel Removal and Installation”.

3) Remove 2 mounting bolts (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and InstallationS7RS0B9306018

Removal 1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Remo val and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker (2).

Installation

Reverse removal procedure.

(a) (a)

I4RS0B930013-01

1

2I4RS0A930032-01

3

2I4RS0A930025-01

2

1

1

I4RS0B930014-01

1

2

3

I4RS0A930027-01

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

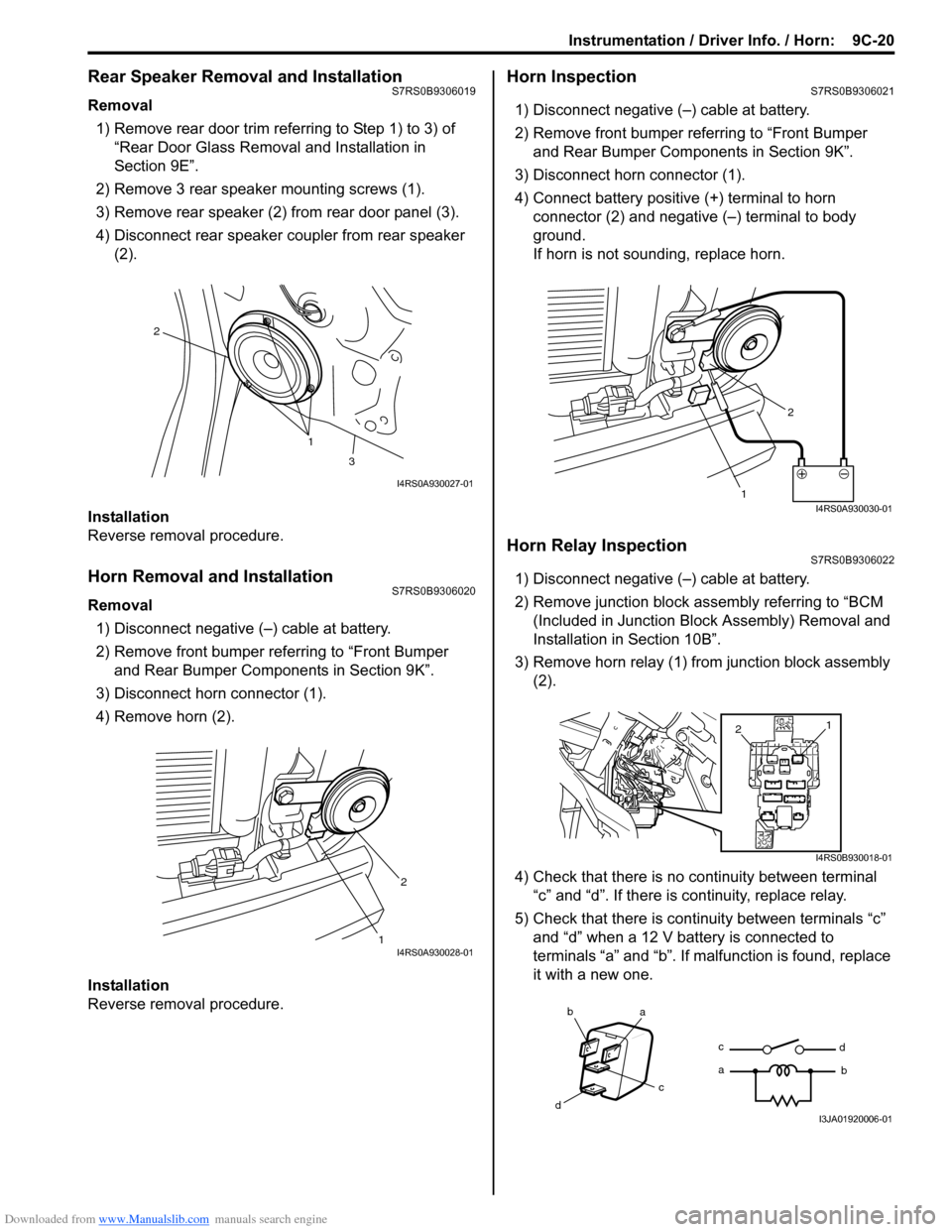

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

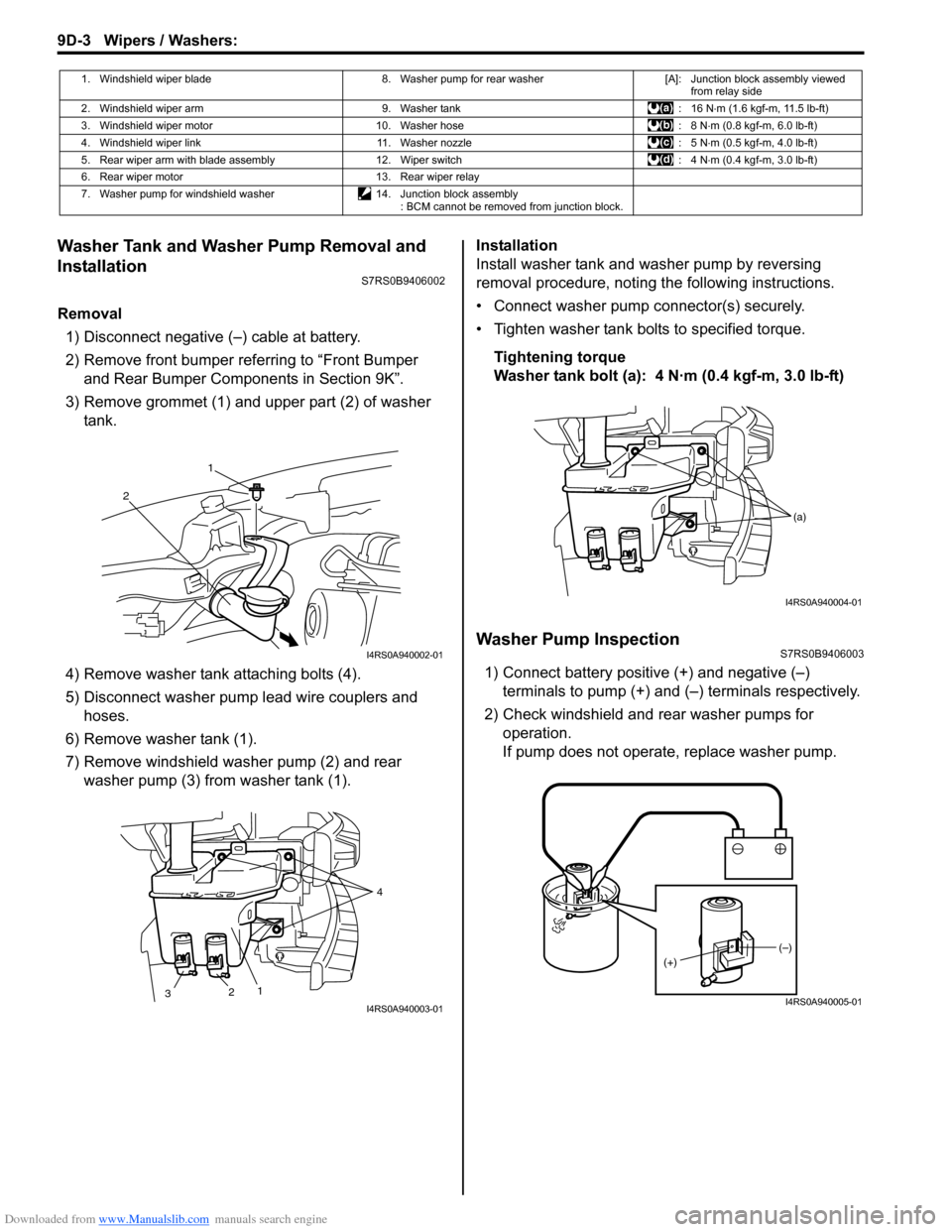

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1323 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-6

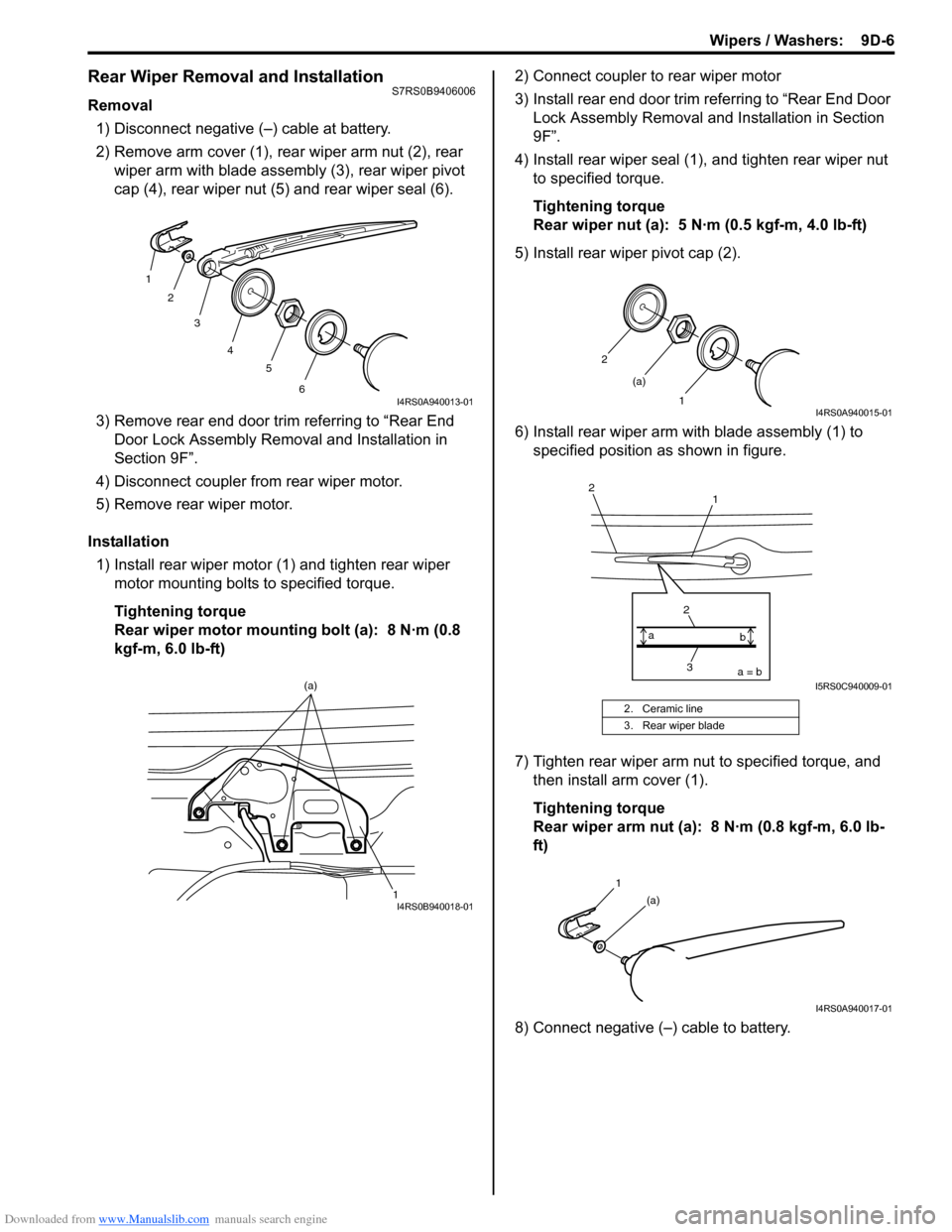

Rear Wiper Removal and InstallationS7RS0B9406006

Removal1) Disconnect negative (–) cable at battery.

2) Remove arm cover (1), rear wiper arm nut (2), rear wiper arm with blade assembly (3), rear wiper pivot

cap (4), rear wiper nut (5) and rear wiper seal (6).

3) Remove rear end door trim referring to “Rear End Door Lock Assembly Remo val and Installation in

Section 9F”.

4) Disconnect coupler from rear wiper motor.

5) Remove rear wiper motor.

Installation 1) Install rear wiper motor (1) and tighten rear wiper motor mounting bolts to specified torque.

Tightening torque

Rear wiper motor mounting bolt (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft) 2) Connect coupler to rear wiper motor

3) Install rear end door trim referring to “Rear End Door

Lock Assembly Removal and Installation in Section

9F”.

4) Install rear wiper seal (1), and tighten rear wiper nut to specified torque.

Tightening torque

Rear wiper nut (a): 5 N·m (0.5 kgf-m, 4.0 lb-ft)

5) Install rear wiper pivot cap (2).

6) Install rear wiper arm with blade assembly (1) to specified position as shown in figure.

7) Tighten rear wiper arm nut to specified torque, and then install arm cover (1).

Tightening torque

Rear wiper arm nut (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

8) Connect negative (–) cable to battery.

1 2

3

4 5

6

I4RS0A940013-01

1

(a)I4RS0B940018-01

2. Ceramic line

3. Rear wiper blade

2

1

(a)

I4RS0A940015-01

1

2

3

2a = b

a

bI5RS0C940009-01

1

(a)

I4RS0A940017-01