throttle actuator SUZUKI SWIFT 2006 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 244 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-194 Engine General Information and Diagnosis:

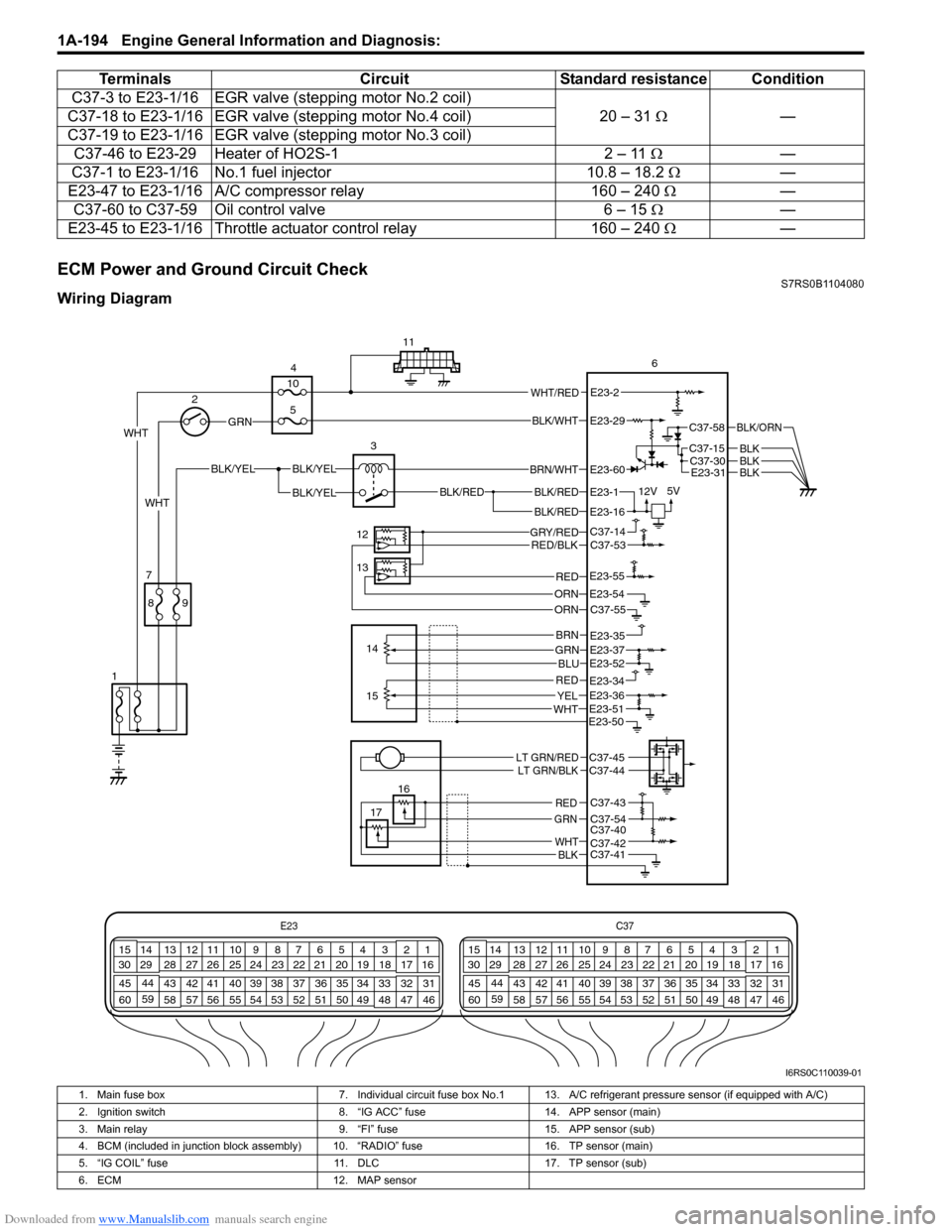

ECM Power and Ground Circuit CheckS7RS0B1104080

Wiring DiagramC37-3 to E23-1/16 EGR valve

(stepping motor No.2 coil)

20 – 31 Ω —

C37-18 to E23-1/16 EGR valv e (stepping motor No.4 coil)

C37-19 to E23-1/16 EGR valv e (stepping motor No.3 coil)

C37-46 to E23-29 Heater of HO2S-1 2 – 11 Ω—

C37-1 to E23-1/16 No.1 fuel injector 10.8 – 18.2 Ω —

E23-47 to E23-1/16 A/C compressor relay 160 – 240 Ω —

C37-60 to C37-59 Oil control valve 6 – 15 Ω —

E23-45 to E23-1/16 Throttle actuator control relay 160 – 240 Ω —

Terminals

CircuitStandard resistance Condition

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/RED

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V

5VE23-1

E23-60

E23-16

WHT 2

4

11

6

3

12

13 14

7

1

16

17

89

15

10

5

WHT/REDE23-2

C37-58

C37-15C37-30

BLK/ORN

BLKBLKE23-31BLK

WHT

GRY/REDRED/BLK

ORN

C37-14C37-53

C37-55E23-54

REDE23-55

GRNBRN

BLU

REDYELWHT

E23-35E23-37E23-52

E23-51

E23-34E23-36

E23-50

LT GRN/REDLT GRN/BLKC37-45C37-44

C37-43

C37-54C37-40C37-42C37-41

RED

GRN

WHTBLK

ORN

BLK/WHTE23-29

I6RS0C110039-01

1. Main fuse box 7. Individual circuit fuse box No.1 13. A/C refrigerant pressure sensor (if equipped with A/C)

2. Ignition switch 8. “IG ACC” fuse14. APP sensor (main)

3. Main relay 9. “FI” fuse15. APP sensor (sub)

4. BCM (included in junction block assembly) 10. “RADIO” fuse 16. TP sensor (main)

5. “IG COIL” fuse 11. DLC17. TP sensor (sub)

6. ECM 12. MAP sensor

Page 274 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-2 Engine Electrical Devices:

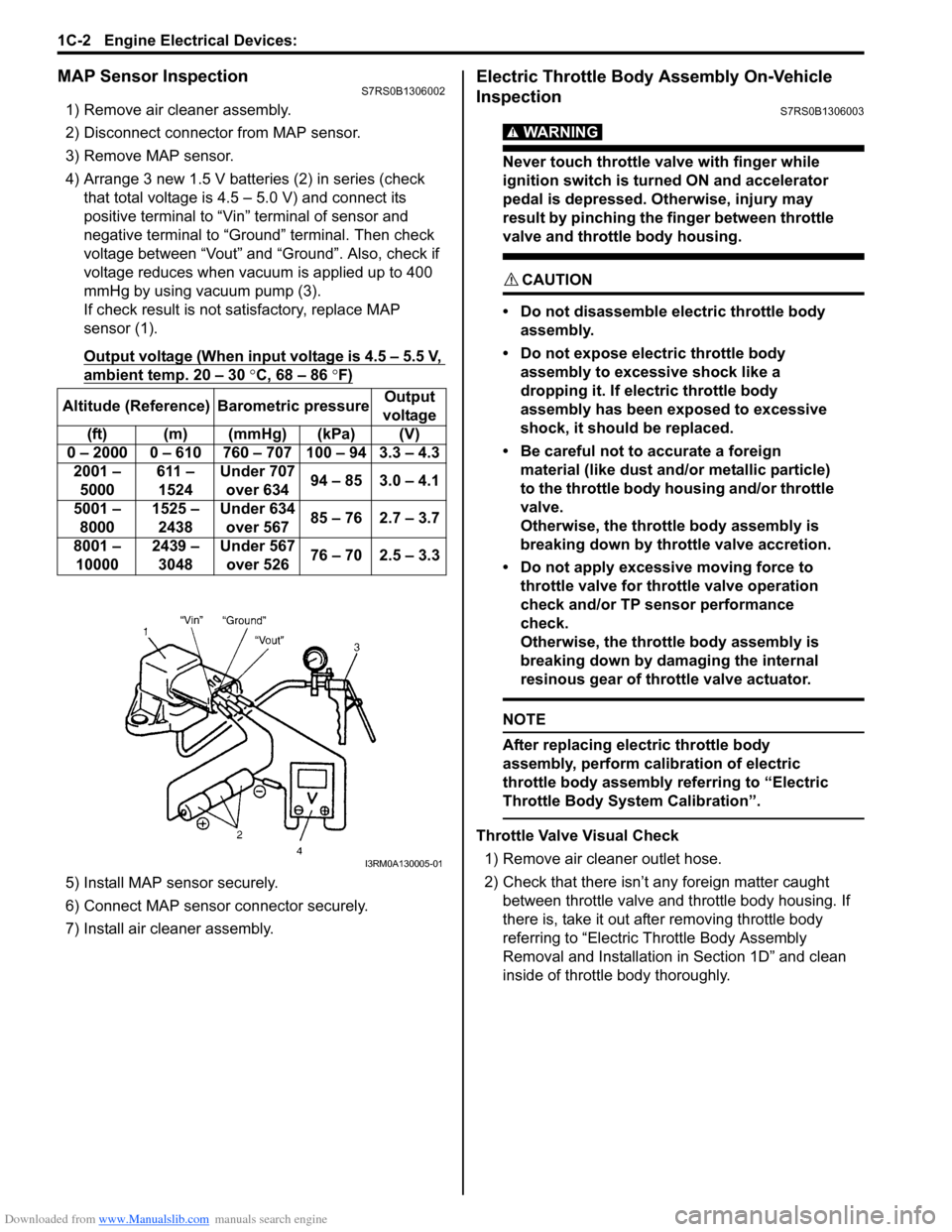

MAP Sensor InspectionS7RS0B1306002

1) Remove air cleaner assembly.

2) Disconnect connector from MAP sensor.

3) Remove MAP sensor.

4) Arrange 3 new 1.5 V batteries (2) in series (check that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin ” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30 °C, 68 – 86 °F)

5) Install MAP sensor securely.

6) Connect MAP sensor connector securely.

7) Install air cleaner assembly.

Electric Throttle Body Assembly On-Vehicle

Inspection

S7RS0B1306003

WARNING!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION!

• Do not disassemble electric throttle body assembly.

• Do not expose electric throttle body assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accurate a foreign material (like dust and/ or metallic particle)

to the throttle body housing and/or throttle

valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to throttle valve for thro ttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

NOTE

After replacing electric throttle body

assembly, perform calibration of electric

throttle body assembly referring to “Electric

Throttle Body System Calibration”.

Throttle Valve Visual Check

1) Remove air cleaner outlet hose.

2) Check that there isn’t any foreign matter caught between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Th rottle Body Assembly

Removal and Installation in Section 1D” and clean

inside of throttle body thoroughly.

Altitude (Reference) Barometric pressure

Output

voltage

(ft) (m) (mmHg) (kPa) (V)

0 – 2000 0 – 610 760 – 707 100 – 94 3.3 – 4.3 2001 – 5000 611 –

1524 Under 707

over 634 94 – 85 3.0 – 4.1

5001 – 8000 1525 –

2438 Under 634

over 567 85 – 76 2.7 – 3.7

8001 – 10000 2439 –

3048 Under 567

over 526 76 – 70 2.5 – 3.3

I3RM0A130005-01

Page 275 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-3

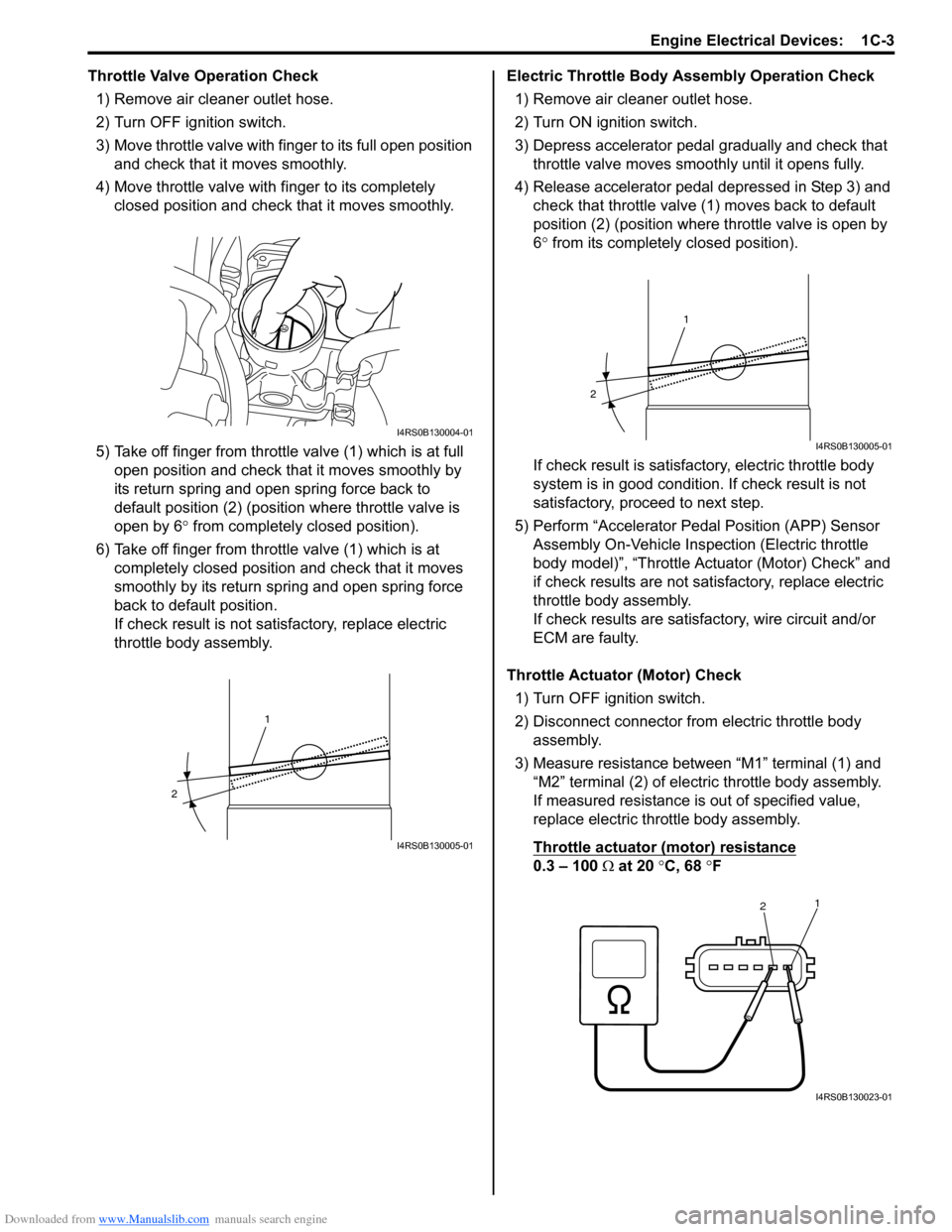

Throttle Valve Operation Check1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position and check that it moves smoothly.

4) Move throttle valve with fi nger to its completely

closed position and check that it moves smoothly.

5) Take off finger from throttle valve (1) which is at full open position and check that it moves smoothly by

its return spring and open spring force back to

default position (2) (positio n where throttle valve is

open by 6 ° from completely closed position).

6) Take off finger from throttle valve (1) which is at completely closed position and check that it moves

smoothly by its return spring and open spring force

back to default position.

If check result is not satisfactory, replace electric

throttle body assembly. Electric Throttle Body

Assembly Operation Check

1) Remove air cleaner outlet hose.

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that throttle valve moves smoo thly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and check that throttle valve (1) moves back to default

position (2) (position where throttle valve is open by

6° from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition. If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pe dal Position (APP) Sensor

Assembly On-Vehicle Inspection (Electric throttle

body model)”, “Throttle Actuator (Motor) Check” and

if check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check 1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body assembly.

3) Measure resistance between “M1” terminal (1) and “M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100 Ω at 20 °C, 68 °F

I4RS0B130004-01

1

2

I4RS0B130005-01

1

2

I4RS0B130005-01

2 1

I4RS0B130023-01

Page 667 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-23

Scan Tool DataS7RS0B5104009

As the data values given in the following table are standard values estimated on the basis of values obtained from the

normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good

condition, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, condition in the following table that can be checked by the scan tool are those detected by TCM and output from

TCM as commands and there may be cases where the auto matic transaxle or actuator is not operating (in the

condition) as indicated by the scan tool.

NOTE

The following scan tool data related to automatic transaxle can be checked only by communicating

with TCM.

�) P1777 TCM lost communication with ECM

(Reception error) • Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed to be 0%.

• Engine revolution is assumed to be 0 RPM.

• After 15 minutes pass from detecting malfunction, engine coolant temperature is assumed to be 90 °C (194 °F).

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Upshifting to 4th gear is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P1778 TCM lost communication with BCM

(Reception error) “3” position switch is assumed to be OFF.

�) P1878 Torque converter clutch shudder Slip contro lled lock-up function is inhibited to operate.

�) P2762 Torque converter clutch pressure control

solenoid control circuit range /

performance • Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when transmission fluid

temperature is 150 °C (302 ° F) or more.

• Gear position is fixed in 1st gear when vehicle speed is 10 km/h (6 mile/h) or less.

�) P2763 Torque converter clutch pressure control

solenoid control circuit high • Lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when A/T fluid

temperature is more than 150 °C (302 °F).

• Vehicle speed is slower than 10 km/h (6 mile/h), gear position is fixed in 1st gear for prevention of engine stall.

�) P2764 Torque converter clutch pressure control

solenoid control circuit low • Lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when A/T fluid

temperature is more than 150 °C (302 °F).

DTC No. Trouble area Fail-safe operation

Scan tool data

Vehicle condition Normal condition / reference

values

�) GEAR POSITION Ignition switch ON Select lever is in “P” position

P or N

Select lever is in “R” position R

Select lever is in “N” position P or N

Select lever is in “D” position 1

Select lever is in “3” position 1

Select lever is in “2” position 1

Select lever is in “L” position 1

Page 963 of 1496

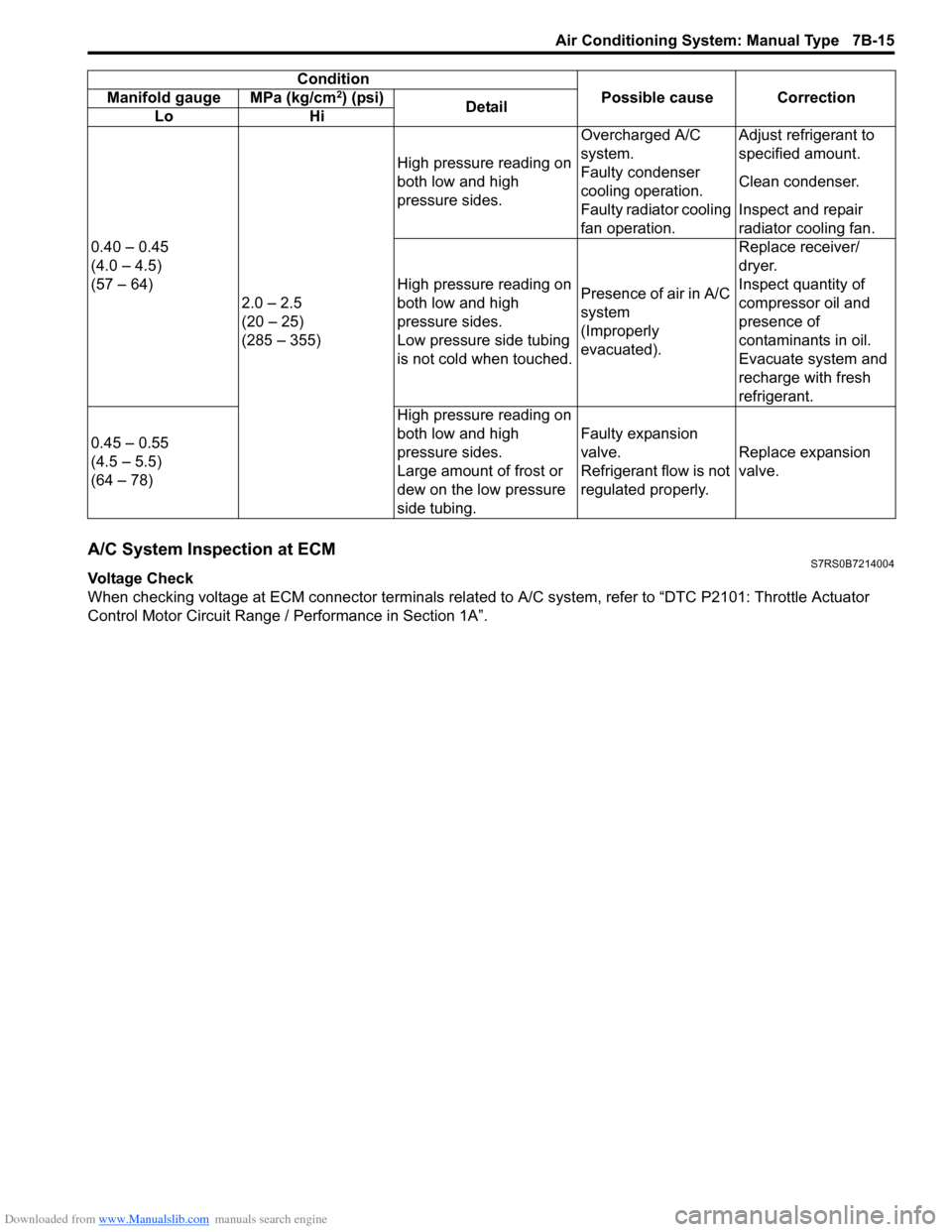

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

A/C System Inspection at ECMS7RS0B7214004

Voltage Check

When checking voltage at ECM connector terminals related to A/C system, refer to “DTC P2101: Throttle Actuator

Control Motor Circuit Range / Performance in Section 1A”.

0.40 – 0.45

(4.0 – 4.5)

(57 – 64)

2.0 – 2.5

(20 – 25)

(285 – 355) High pressure reading on

both low and high

pressure sides.

Overcharged A/C

system.

Adjust refrigerant to

specified amount.

Faulty condenser

cooling operation. Clean condenser.

Faulty radiator cooling

fan operation. Inspect and repair

radiator cooling fan.

High pressure reading on

both low and high

pressure sides.

Low pressure side tubing

is not cold when touched. Presence of air in A/C

system

(Improperly

evacuated).Replace receiver/

dryer.

Inspect quantity of

compressor oil and

presence of

contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78) High pressure reading on

both low and high

pressure sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion

valve.

Refrigerant flow is not

regulated properly.

Replace expansion

valve.

Condition

Possible cause Correction

Manifold gauge MPa (kg/cm

2) (psi)

Detail

Lo Hi

Page 1185 of 1496

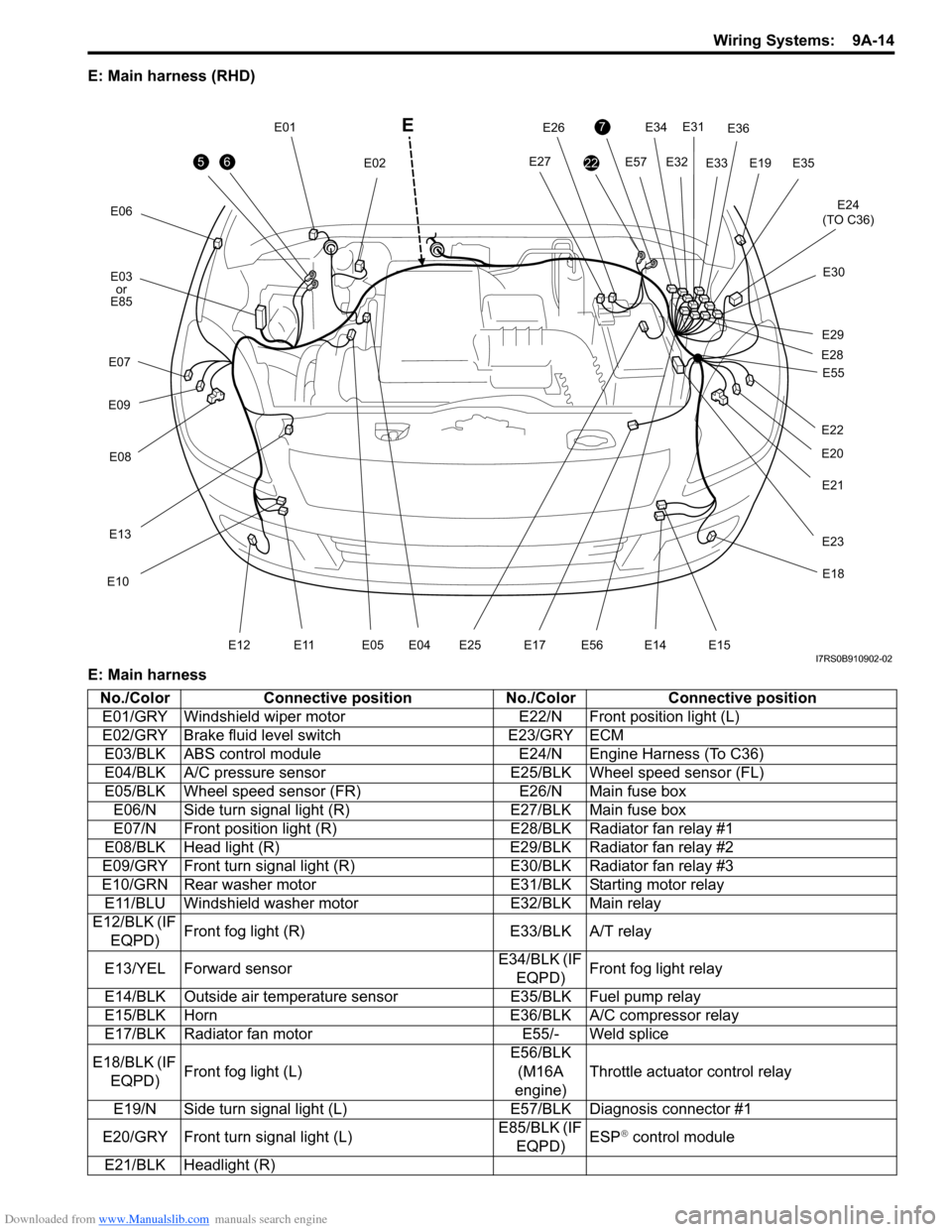

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-14

E: Main harness (RHD)

E: Main harness

56

E06E12

E03or

E85

E07

E09

E08

E13

E10

E11E05 E04

E01 E02

E19

7

22

E34E31

E32

E57

E24

(TO C36)

E33

E36

E35

E30

E29

E28

E20

E21

E22

E27

E26

E23

E25E17E56

E18

E14 E15

E55

E

I7RS0B910902-02

No./Color

Connective position No./ColorConnective position

E01/GRY Windshield wiper motor E22/N Front position light (L)

E02/GRY Brake fluid level switch E23/GRY ECM

E03/BLK ABS control module E24/N Engine Harness (To C36)

E04/BLK A/C pressure sensor E25/BLK Wheel speed sensor (FL)

E05/BLK Wheel speed sensor (FR) E26/N Main fuse box

E06/N Side turn signal light (R) E27/BLK Main fuse box

E07/N Front position light (R) E28/BLK Radiator fan relay #1

E08/BLK Head light (R) E29/BLK Radiator fan relay #2

E09/GRY Front turn signal light (R) E30/BLK Radiator fan relay #3

E10/GRN Rear washer motor E31/BLK Starting motor relay

E11/BLU Windshield washer motor E32/BLK Main relay

E12/BLK (IF EQPD) Front fog light (R)

E33/BLK A/T relay

E13/YEL Forward sensor E34/BLK (IF

EQPD) Front fog light relay

E14/BLK Outside air temperature sensor E35/BLK Fuel pump relay

E15/BLK Horn E36/BLK A/C compressor relay

E17/BLK Radiator fan motor E55/- Weld splice

E18/BLK (IF EQPD) Front fog light (L) E56/BLK

(M16A

engine) Throttle actuator control relay

E19/N Side turn signal light (L) E57/BLK Diagnosis connector #1

E20/GRY Front turn signal light (L) E85/BLK (IF

EQPD) ESP

® control module

E21/BLK Headlight (R)

Page 1205 of 1496

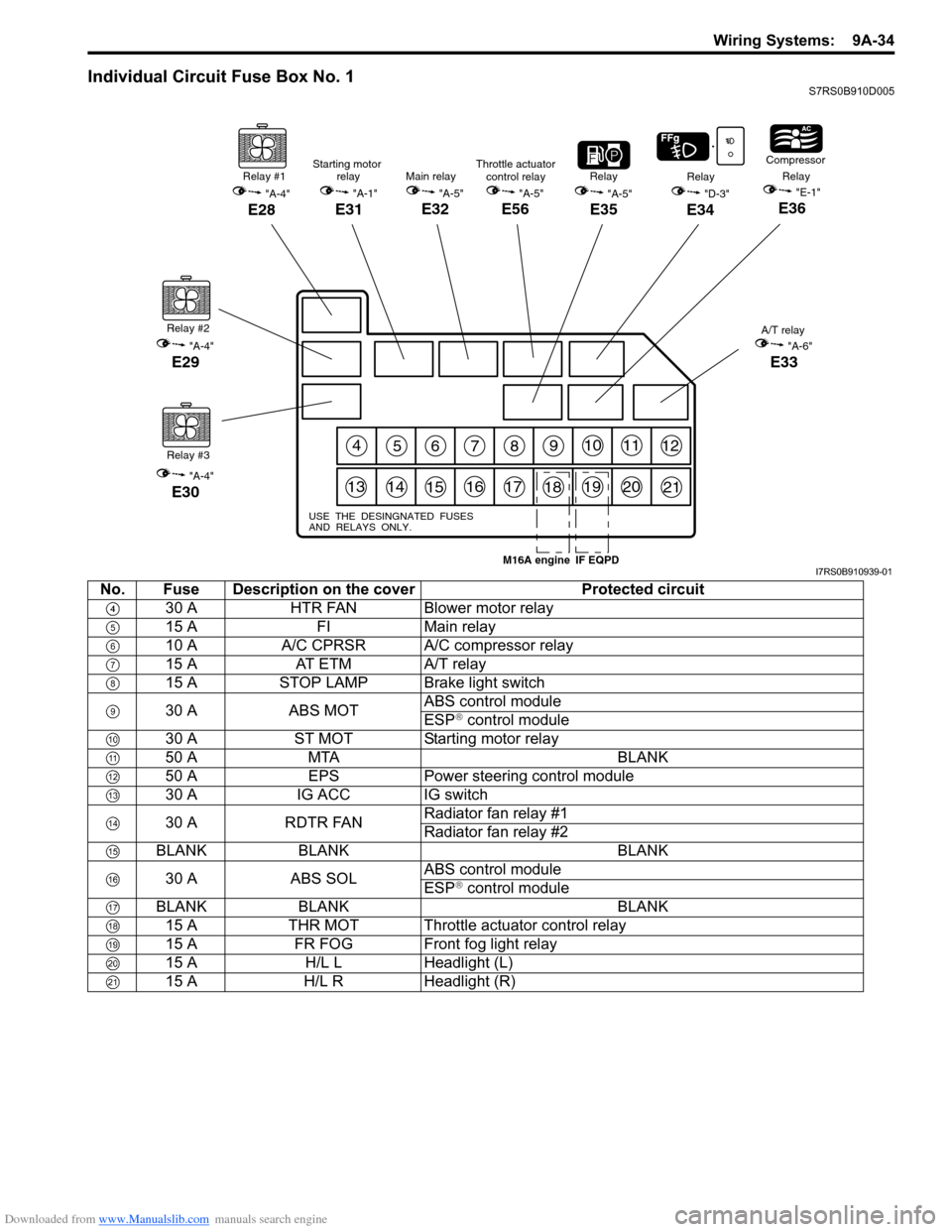

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-34

Individual Circuit Fuse Box No. 1S7RS0B910D005

456789101112

131415161718192021

USE THE DESINGNATED FUSES

AND RELAYS ONLY.

Relay #1

"A-4"

E28

Relay #2

"A-4"

E29

Relay #3

"A-4"

E30

"A-5"

E35

RelayRelay

"D-3"

E34

Compressor

Relay"E-1"

E36

A/T relay

"A-6"

E33

Main relay

"A-5"

E32

Starting motor relay

"A-1"

E31

Throttle actuatorcontrol relay

"A-5"

E56

IF EQPDM16A engineI7RS0B910939-01

No. Fuse Description on the cover Protected circuit

30 A HTR FAN Blower motor relay

15 A FIMain relay

10 A A/C CPRSR A/C compressor relay

15 A AT ETM A/T relay

15 A STOP LAMP Brake light switch

30 A ABS MOT ABS control module

ESP

® control module

30 A ST MOT Starting motor relay

50 A MTA BLANK

50 A EPS Power steering control module

30 A IG ACC IG switch

30 A RDTR FAN Radiator fan relay #1

Radiator fan relay #2

BLANK BLANK BLANK

30 A ABS SOL ABS control module

ESP

® control module

BLANK BLANK BLANK 15 A THR MOT Throttle actuator control relay

15 A FR FOG Front fog light relay

15 A H/L L Headlight (L)

15 A H/L R Headlight (R)

Page 1225 of 1496

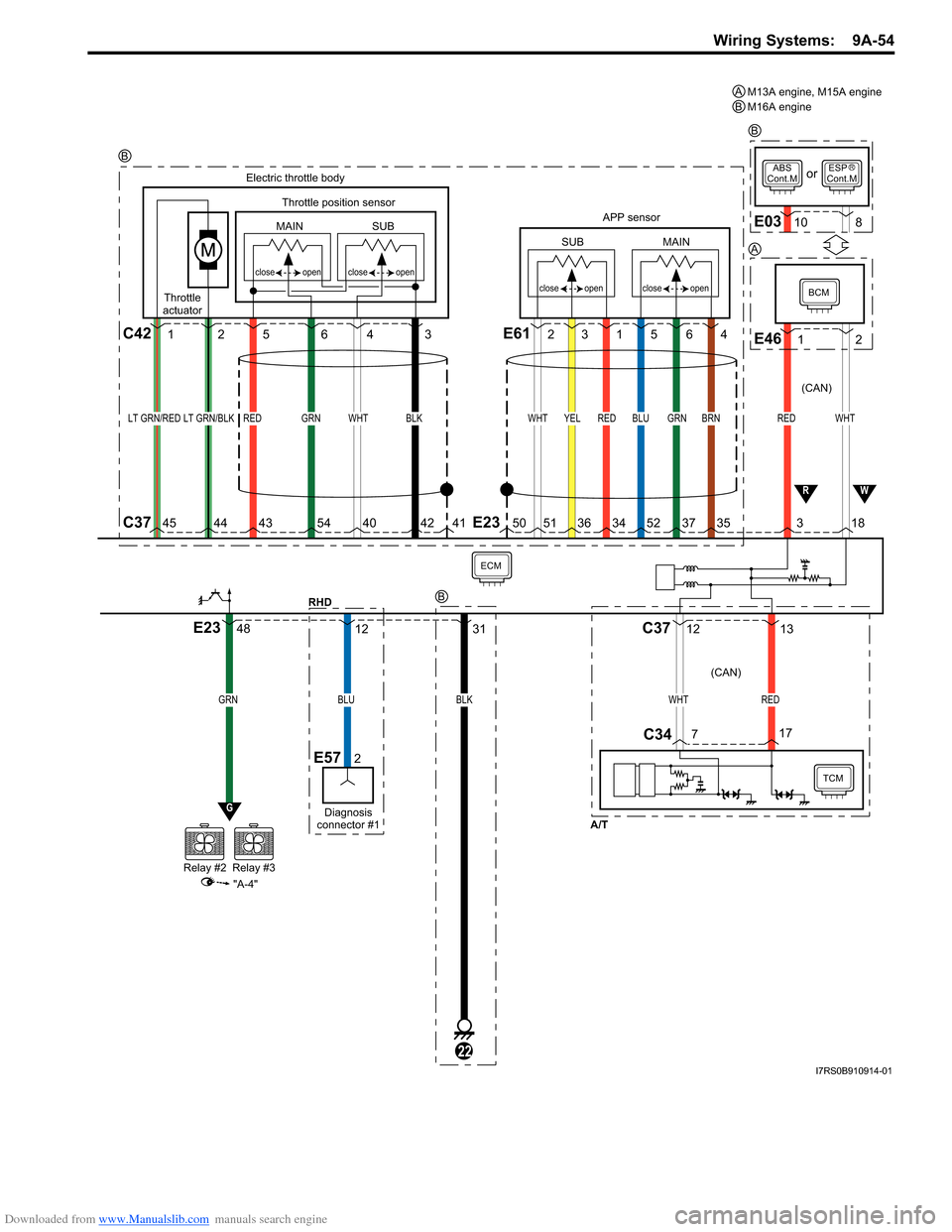

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-54

BLU

12

Diagnosis

connector #1

E572

ECM

GRN

Relay #2Relay #3

G

"A-4"

E2348

RHD

WHT

BCM

APP sensor

Electric throttle body

Throttle position sensor

SUB

open

close

open

close

open

close

open

close

MAIN

SUB

MAIN

Throttle

actuator

REDBRNGRNBLUREDYELWHTBLKWHTGRNREDLT GRN/REDLT GRN/BLK

E46

3 18

TCM

WHTRED

7 17

C37

C34

1 2

ABS

Cont.MESP

Cont.M

E0310 8

or

E612

3C421 256431564

12 13

RW

5041424054434445513634523735E23

C37

A/T

BLK

31

22

(CAN) (CAN)

M13A engine, M15A engine

M16A engine

AB

B

RB

B

A

I7RS0B910914-01