Axle SUZUKI SWIFT 2006 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 478 of 1496

Downloaded from www.Manualslib.com manuals search engine 3-1 Precautions:

Driveline / Axle

Precautions

Precautions

Precautions for Driveline / AxleS7RS0B3000001

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Page 479 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-1

Driveline / Axle

Drive Shaft / Axle

General Description

Front Drive Shaft ConstructionS7RS0B3101001

A constant velocity ball joint is used on the wheel side of both right and left side drive shaft assemblies. For A/T

vehicle, a tripod type constant velocity joint is used on the differential side and center shaft side. For M/T vehicle, a

double offset type constant velocity joint (DOJ) is used on the differential side and center shaft side. The drive shaft

can slide through the tripod joint or the double offset joint (DOJ) in the extension/contraction direction.

Component Location

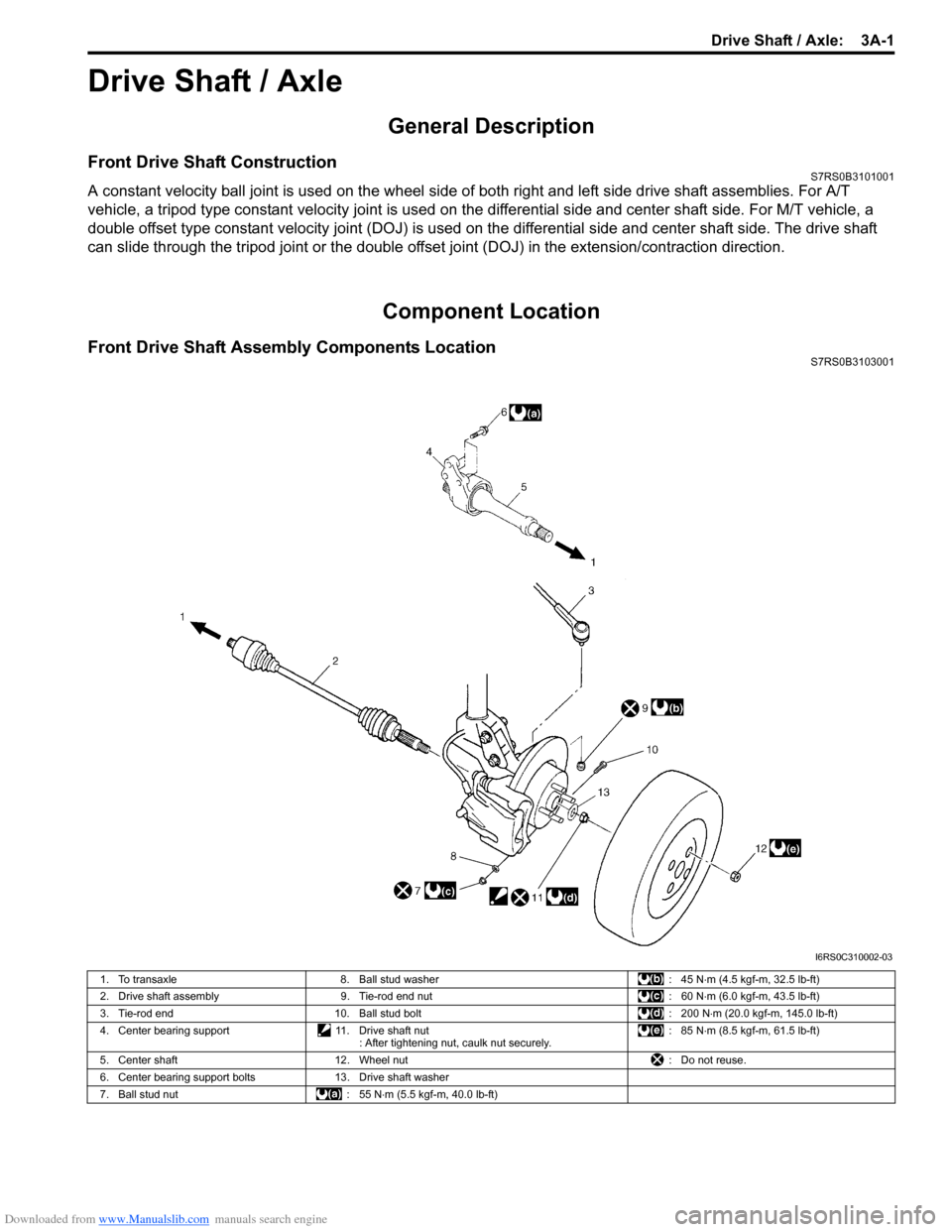

Front Drive Shaft Assembly Components LocationS7RS0B3103001

I6RS0C310002-03

1. To transaxle 8. Ball stud washer : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

2. Drive shaft assembly 9. Tie-rod end nut : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Tie-rod end 10. Ball stud bolt : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

4. Center bearing support 11. Drive shaft nut

: After tightening nut, caulk nut securely. : 85 N

⋅m (8.5 kgf-m, 61.5 lb-ft)

5. Center shaft 12. Wheel nut : Do not reuse.

6. Center bearing support bolts 13. Drive shaft washer

7. Ball stud nut : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

Page 480 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-2 Drive Shaft / Axle:

Diagnostic Information and Procedures

Front Drive Shaft Symptom DiagnosisS7RS0B3104001

ConditionPossible cause Correction / Reference Item

Abnormal noise Worn or breakage of the drive shaft joint Replace.

Worn or breakage of the center bearing Replace.

Page 481 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-3

Repair Instructions

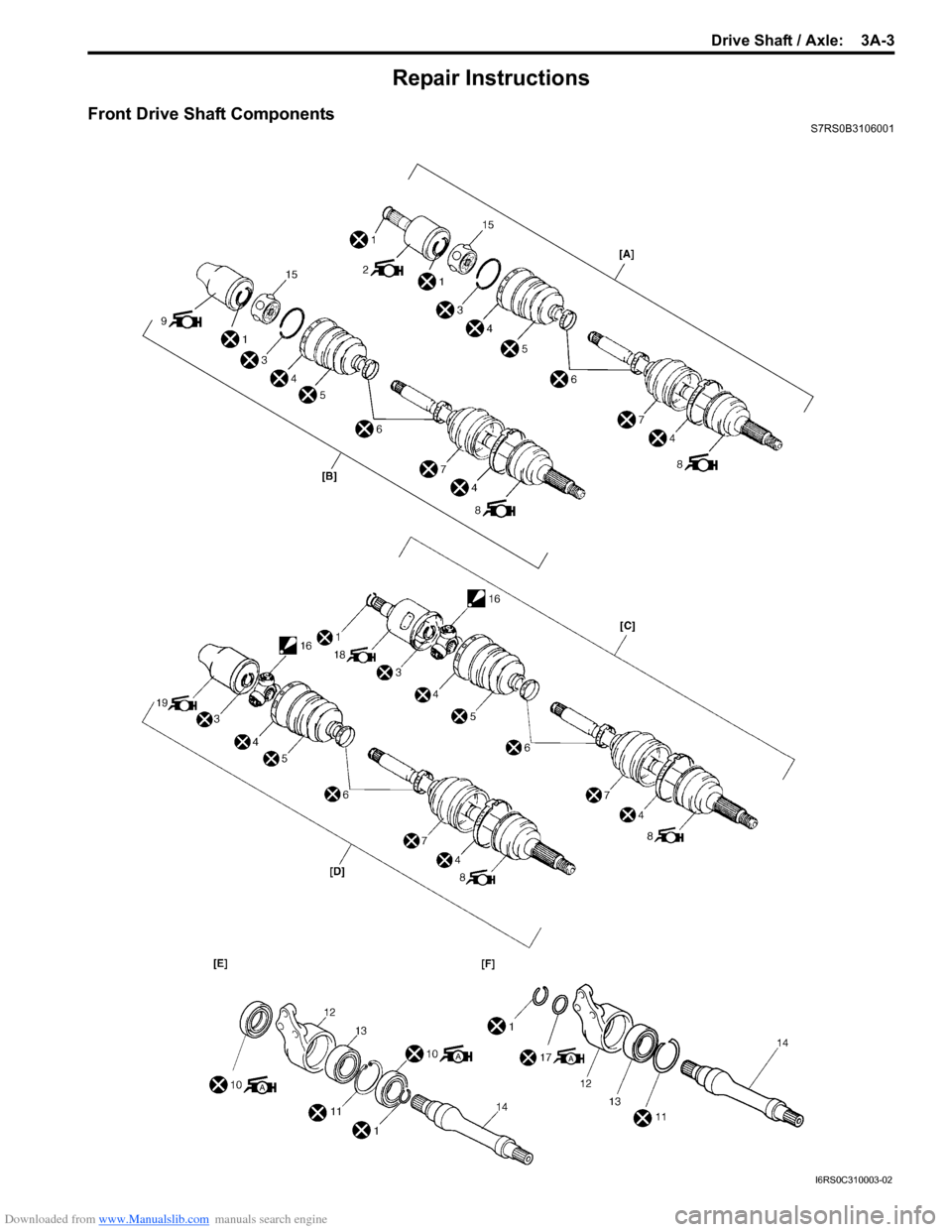

Front Drive Shaft ComponentsS7RS0B3106001

I6RS0C310003-02

Page 482 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-4 Drive Shaft / Axle:

Front Drive Shaft Assembly On-Vehicle

Inspection

S7RS0B3106002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for smooth rotation.

If any abnormality is found, replace.

Front Drive Shaft Assembly Removal and

Installation

S7RS0B3106003

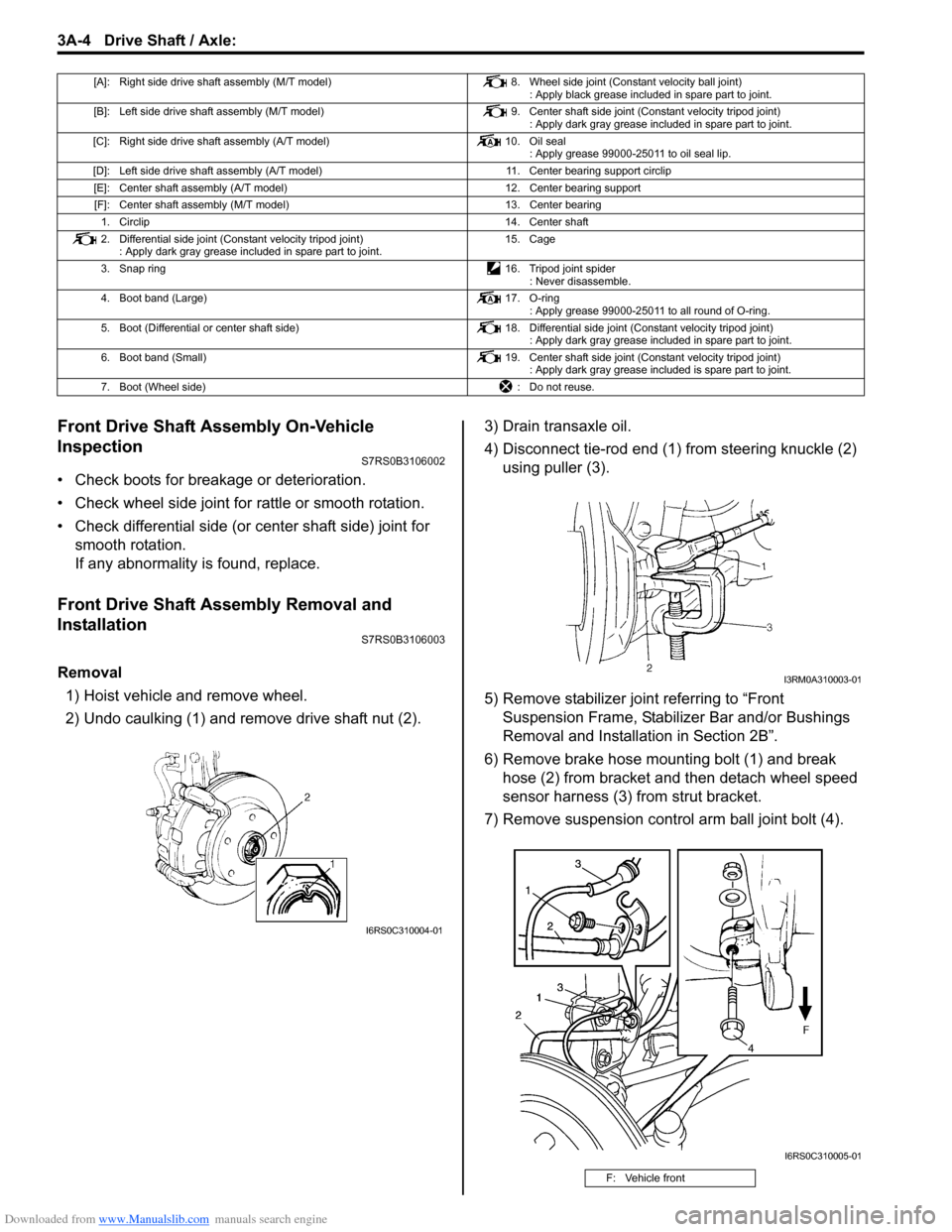

Removal

1) Hoist vehicle and remove wheel.

2) Undo caulking (1) and remove drive shaft nut (2). 3) Drain transaxle oil.

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).

5) Remove stabilizer join t referring to “Front

Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

6) Remove brake hose mounting bolt (1) and break hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

7) Remove suspension contro l arm ball joint bolt (4).

[A]: Right side drive shaft assembly (M/T model) 8. Wheel side joint (Constant velocity ball joint)

: Apply black grease included in spare part to joint.

[B]: Left side drive shaft assembly (M/T model) 9. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

[C]: Right side drive shaft assembly (A/T model) 10. Oil seal

: Apply grease 99000-25011 to oil seal lip.

[D]: Left side drive shaft assembly (A/T model) 11. Center bearing support circlip

[E]: Center shaft assembly (A/T model) 12. Center bearing support

[F]: Center shaft assembly (M/T model) 13. Center bearing

1. Circlip 14. Center shaft

2. Differential side joint (Constant velocity tripod joint) : Apply dark gray grease included in spare part to joint. 15. Cage

3. Snap ring 16. Tripod joint spider

: Never disassemble.

4. Boot band (Large) 17. O-ring

: Apply grease 99000-25011 to all round of O-ring.

5. Boot (Differential or center shaft side) 18. Differential side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

6. Boot band (Small) 19. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included is spare part to joint.

7. Boot (Wheel side) : Do not reuse.

I6RS0C310004-01

F: Vehicle front

I3RM0A310003-01

I6RS0C310005-01

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

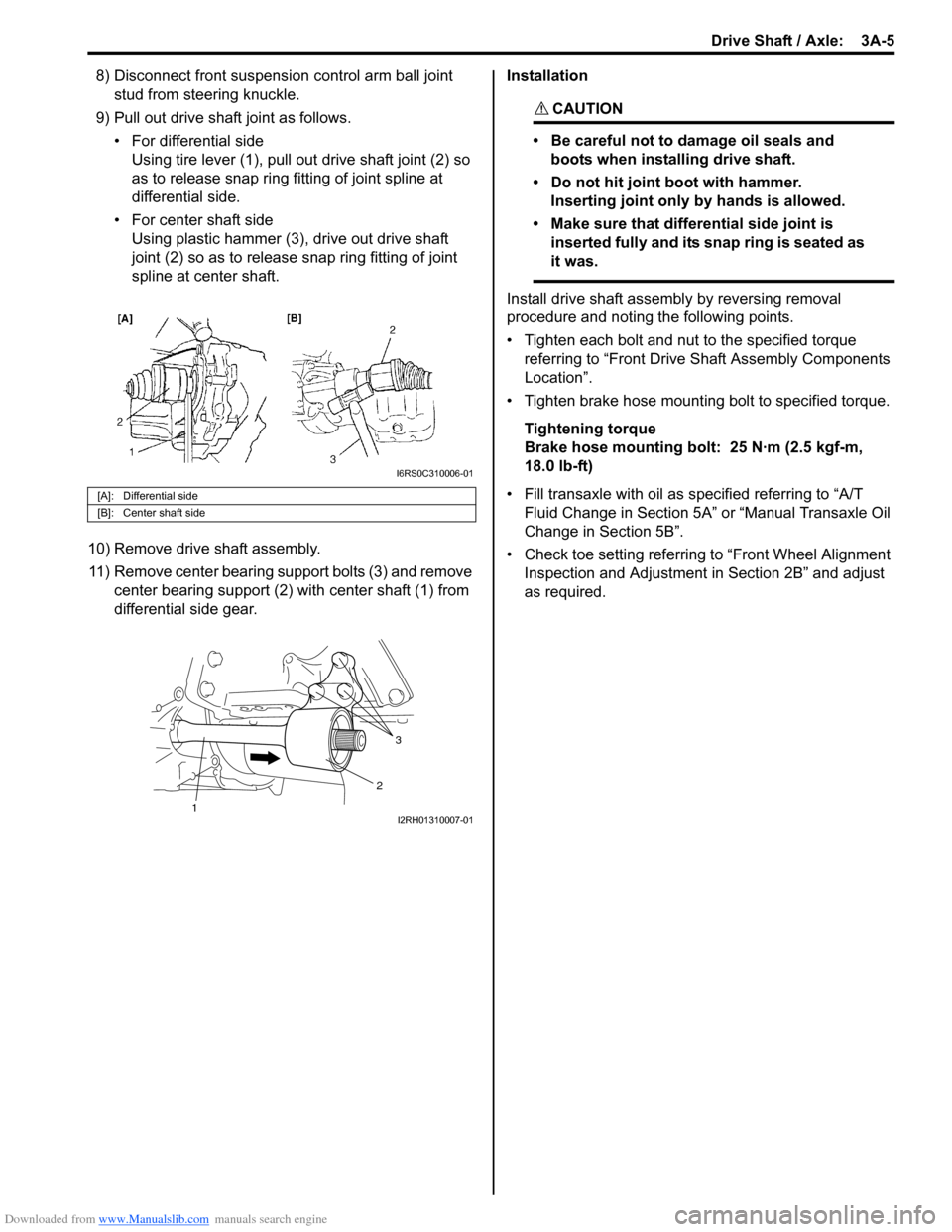

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

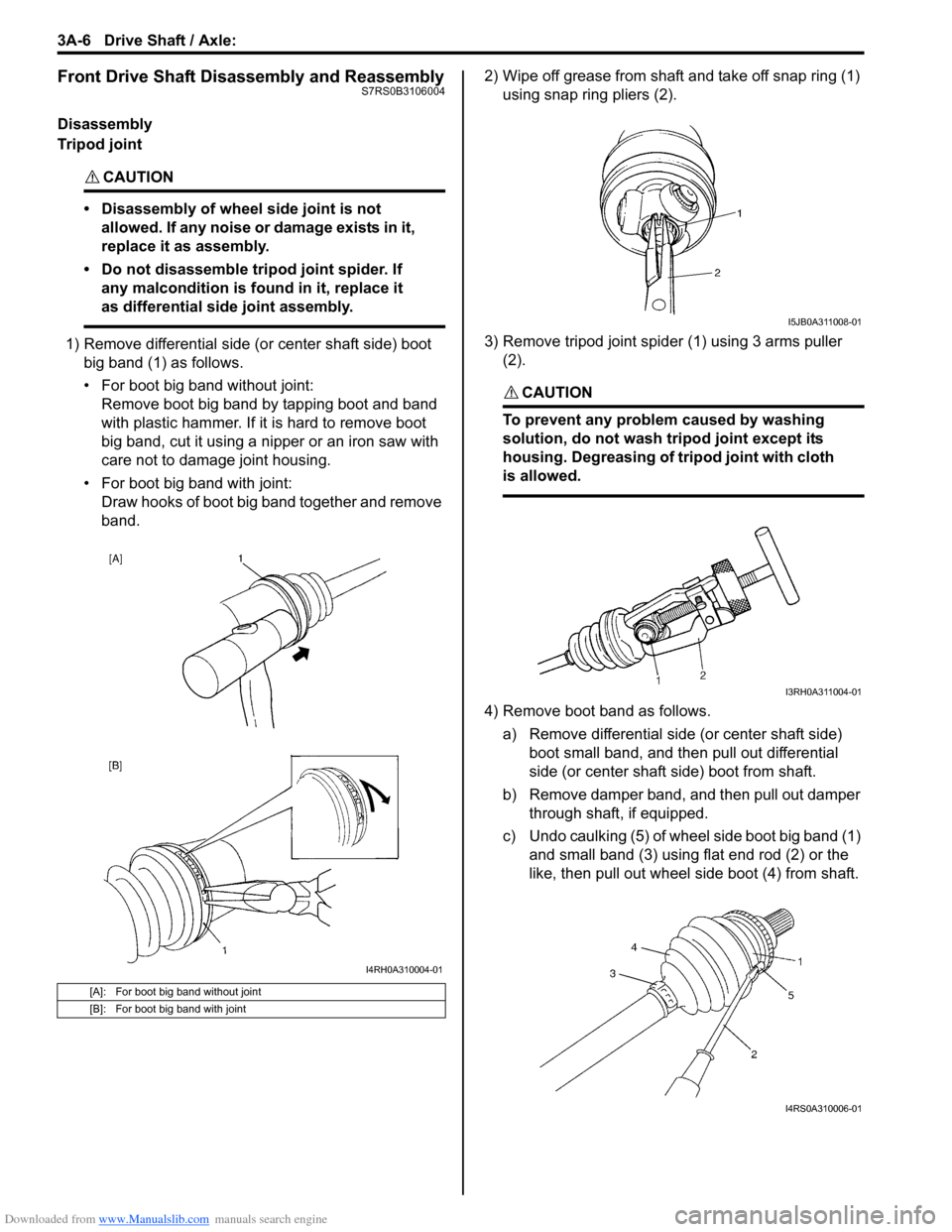

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 484 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-6 Drive Shaft / Axle:

Front Drive Shaft Disassembly and ReassemblyS7RS0B3106004

Disassembly

Tripod joint

CAUTION!

• Disassembly of wheel side joint is not allowed. If any noise or damage exists in it,

replace it as assembly.

• Do not disassemble tripod joint spider. If any malcondition is found in it, replace it

as differential side joint assembly.

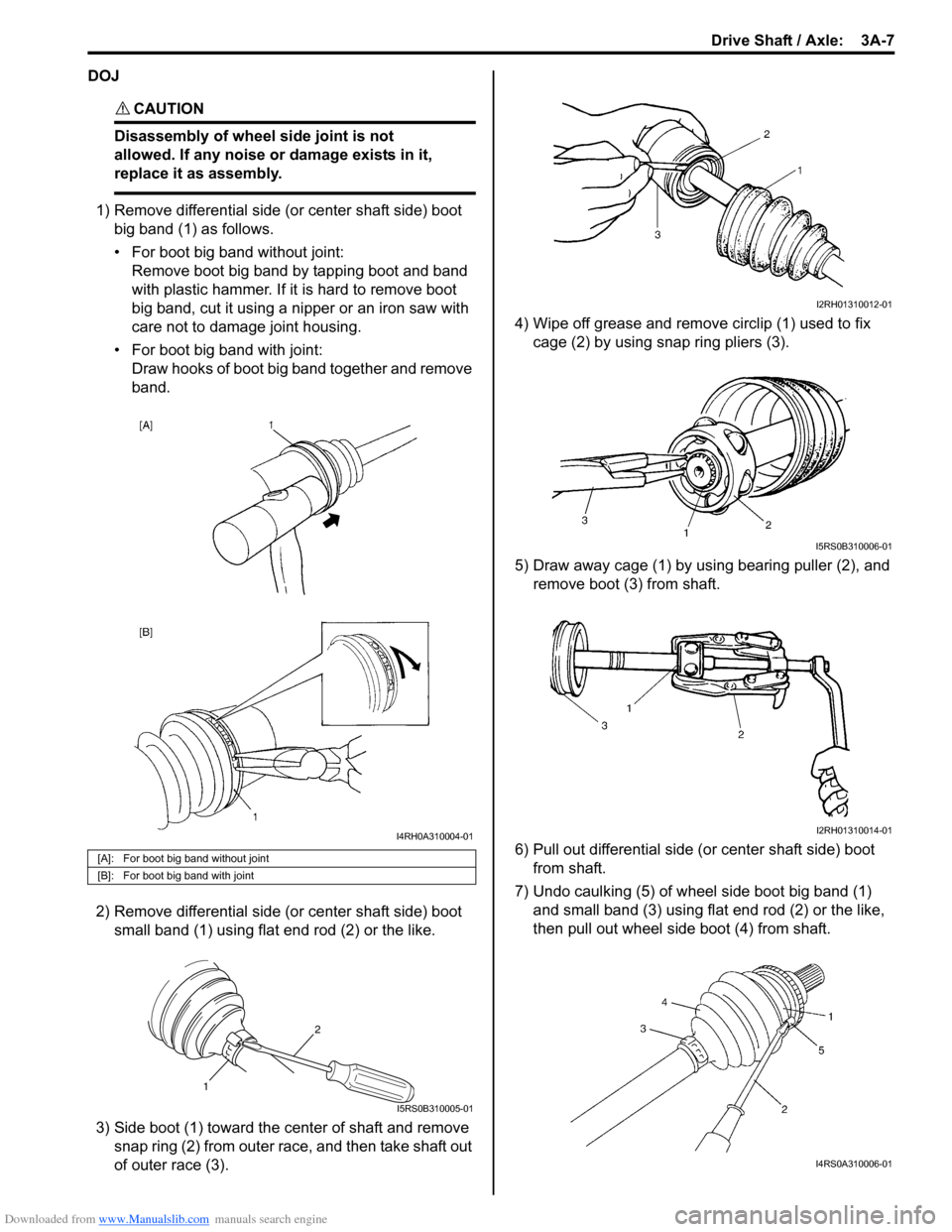

1) Remove differential side (or center shaft side) boot

big band (1) as follows.

• For boot big band without joint:Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint: Draw hooks of boot big band together and remove

band. 2) Wipe off grease from shaft and take off snap ring (1)

using snap ring pliers (2).

3) Remove tripod joint spid er (1) using 3 arms puller

(2).

CAUTION!

To prevent any problem caused by washing

solution, do not wash tripod joint except its

housing. Degreasing of tr ipod joint with cloth

is allowed.

4) Remove boot band as follows.

a) Remove differential side (or center shaft side) boot small band, and then pull out differential

side (or center shaft side) boot from shaft.

b) Remove damper band, and then pull out damper through shaft, if equipped.

c) Undo caulking (5) of wheel side boot big band (1) and small band (3) using flat end rod (2) or the

like, then pull out wheel side boot (4) from shaft.

[A]: For boot big band without joint

[B]: For boot big band with joint

I4RH0A310004-01

I5JB0A311008-01

I3RH0A311004-01

I4RS0A310006-01

Page 485 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-7

DOJ

CAUTION!

Disassembly of wheel side joint is not

allowed. If any noise or damage exists in it,

replace it as assembly.

1) Remove differential side (or center shaft side) boot big band (1) as follows.

• For boot big band without joint:Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint: Draw hooks of boot big band together and remove

band.

2) Remove differential side (or center shaft side) boot small band (1) using flat end rod (2) or the like.

3) Side boot (1) toward the center of shaft and remove snap ring (2) from outer race, and then take shaft out

of outer race (3). 4) Wipe off grease and remove circlip (1) used to fix

cage (2) by using snap ring pliers (3).

5) Draw away cage (1) by using bearing puller (2), and remove boot (3) from shaft.

6) Pull out differential side (or center shaft side) boot from shaft.

7) Undo caulking (5) of wheel side boot big band (1) and small band (3) using flat end rod (2) or the like,

then pull out wheel side boot (4) from shaft.

[A]: For boot big band without joint

[B]: For boot big band with joint

I4RH0A310004-01

2

1

I5RS0B310005-01

I2RH01310012-01

I5RS0B310006-01

I2RH01310014-01

I4RS0A310006-01

Page 486 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-8 Drive Shaft / Axle:

Reassembly

Tripod joint

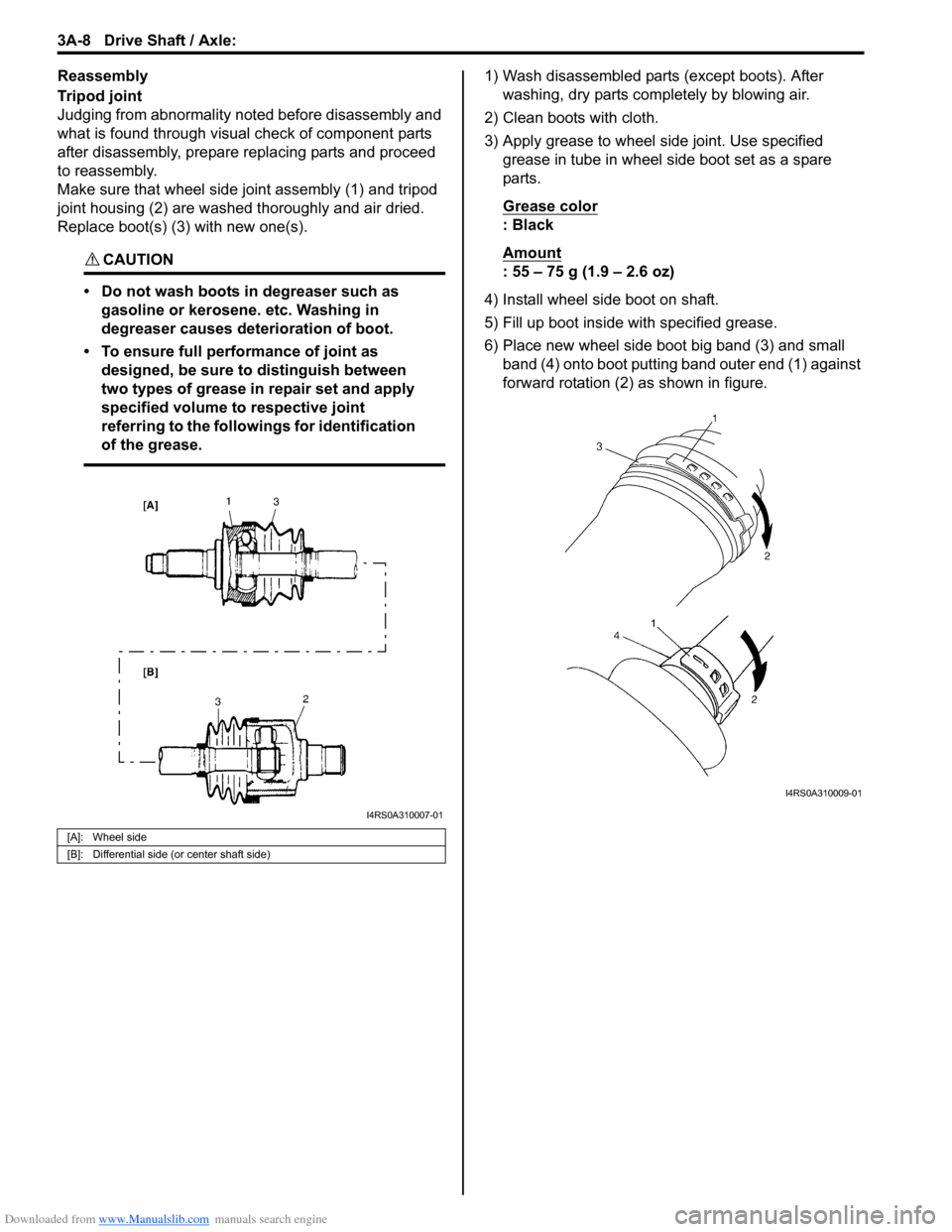

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly (1) and tripod

joint housing (2) are washed thoroughly and air dried.

Replace boot(s) (3) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts comp letely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside with specified grease.

6) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure.

[A]: Wheel side

[B]: Differential side (or center shaft side)

I4RS0A310007-01

I4RS0A310009-01

Page 487 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-9

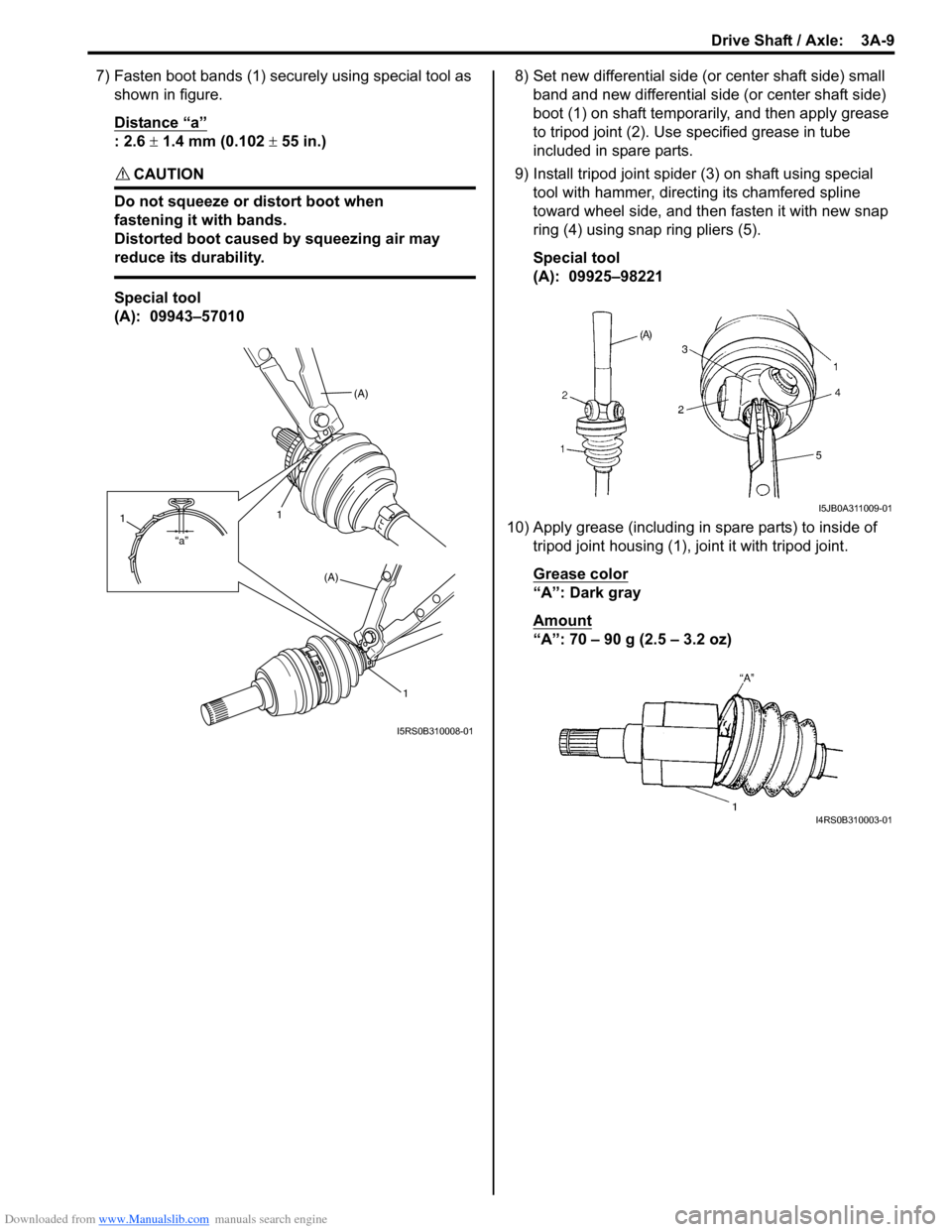

7) Fasten boot bands (1) securely using special tool as

shown in figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 55 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010 8) Set new differential side (or center shaft side) small

band and new differential side (or center shaft side)

boot (1) on shaft temporarily, and then apply grease

to tripod joint (2). Use specified grease in tube

included in spare parts.

9) Install tripod joint spider (3) on shaft using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (4) using snap ring pliers (5).

Special tool

(A): 09925–98221

10) Apply grease (including in spare parts) to inside of tripod joint housing (1), jo int it with tripod joint.

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz)

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

I5JB0A311009-01

I4RS0B310003-01