belt SUZUKI SWIFT 2006 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 987 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 989 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-41

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Temperature selector faulty Check temperature selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Temperature control actuator faulty Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Condition Possible cause Correction / Reference Item

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

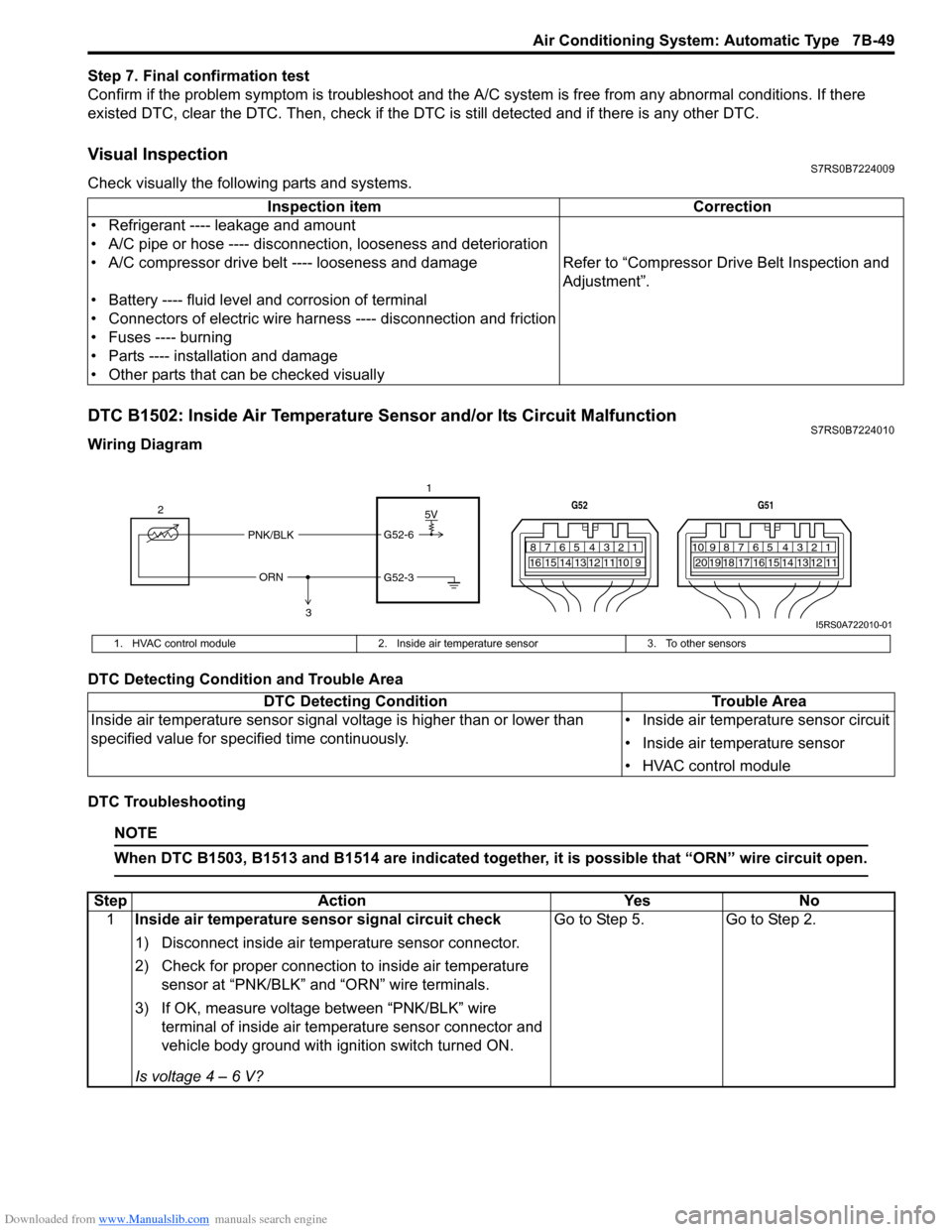

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

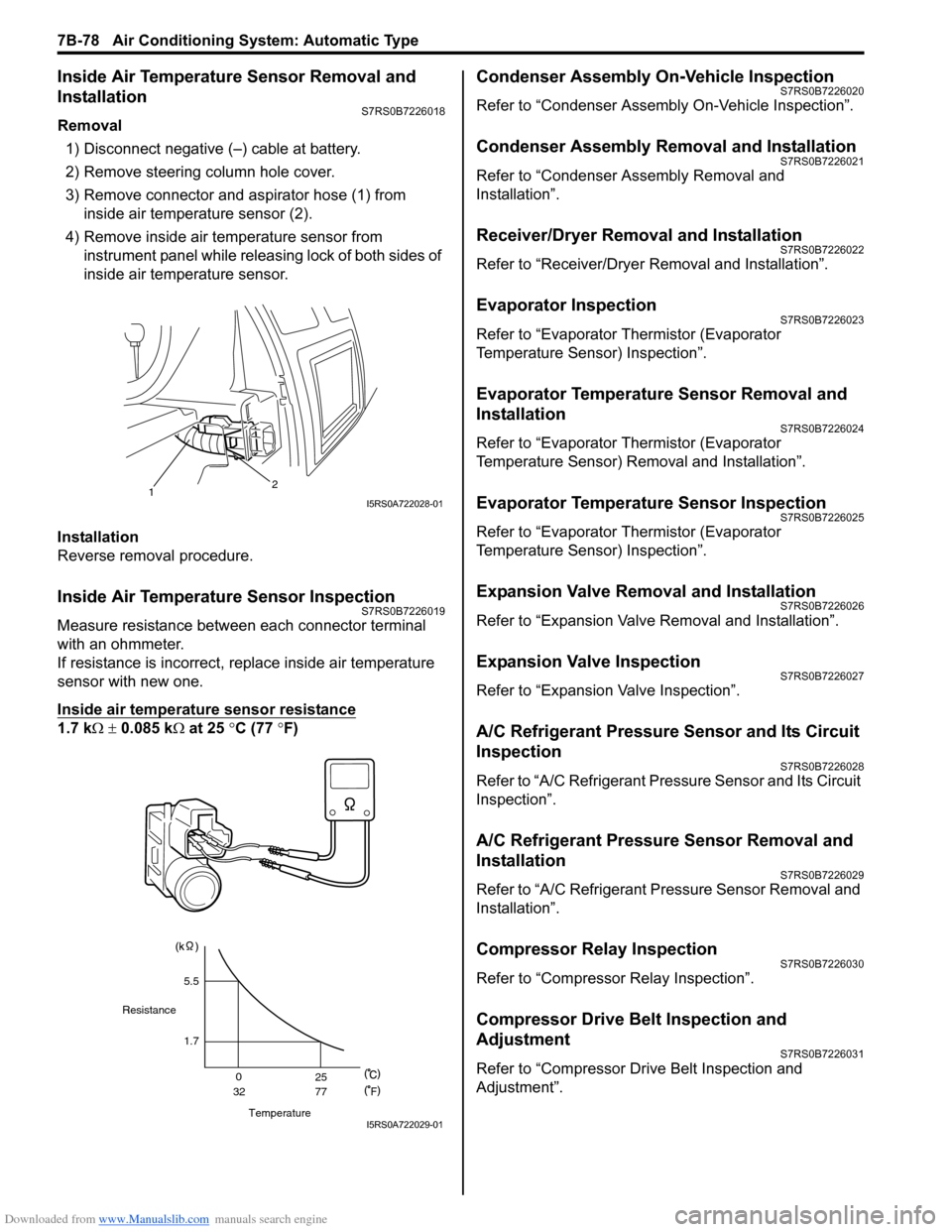

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1027 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-79

Compressor Drive Belt Removal and

Installation

S7RS0B7226032

Refer to “Compressor Drive Belt Removal and

Installation”.

Compressor Assembly Removal and

Installation

S7RS0B7226033

Refer to “Compressor Assembly Removal and

Installation”.

Compressor Assembly ComponentsS7RS0B7226034

Refer to “Compressor Assembly Components”.

Magnet Clutch Removal and InstallationS7RS0B7226035

Refer to “Magnet Clutch Removal and Installation”.

Magnet Clutch InspectionS7RS0B7226036

Refer to “Magnet Clutch Inspection”.

Relief Valve InspectionS7RS0B7226039

Refer to “Relief Valve Inspection”.

Special Tools and Equipment

Special ToolS7RS0B7228001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 1029 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts .......... ............................... ........ 8A-1

Precautions........................................................... 8A-1

Precautions on Service a nd Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-1 Seat Belt Construction ........................................ 8A-1

Diagnostic Information and Procedures ............ 8A-2 Repair and Inspection Required after Accident ............................................................ 8A-2

Repair Instructions .............................................. 8A-3 Front Seat Belt Components ............................... 8A-3

Front Seat Belt Removal and Installation ............ 8A-4

Front Seat Belt Inspection ................................... 8A-4

Rear Seat Belt Components ............................... 8A-6

Rear Seat Belt Removal and Installation ............ 8A-7

Rear Seat Belt Inspection ................................... 8A-7

Specifications ....................................................... 8A-7

Tightening Torque Specifications ........................ 8A-7

Air Bag System ............... ......................... 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air Bag System Components . ................................ 8B-2

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5 Air Bag System Construction .............................. 8B-5

Air Bag System Input / Output Table .................. 8B-6

Schematic and Routing Diagram ........................ 8B-7 Air Bag System Wiring Circuit Diagram .............. 8B-7

Component Locatio n ........................................... 8B-9

Air Bag System Components, Wiring and Connectors Location ......................................... 8B-9

Diagnostic Information and Procedures .......... 8B-10 Air Bag Diagnostic System Check .................... 8B-10

Air Bag Diagnostic System Check Flow ............ 8B-10

DTC Table ......................................................... 8B-11

DTC Check ....................................................... 8B-12 DTC Clearance ................................................. 8B-12

Scan Tool Data ................................................. 8B-13

“AIR BAG” Warning Right Comes ON Steady .. 8B-13

“AIR BAG” Warning Right Does Not Come

ON ................................................................... 8B-15

“AIR BAG” Warning Right Flashes .................... 8B-16

DTC B1013: SDM fault...................................... 8B-17

DTC B1014: “AIR BAG” Warning Right Circuit Failure ............................................................. 8B-17

DTC B1016: Power Source Voltage High ......... 8B-18

DTC B1017: Power Source Voltage Low .......... 8B-20

DTC B1021: Front Air Bag Module Deployed ... 8B-22

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) Deployed...................................... 8B-22

DTC B1026: Pretensioner Activated ................. 8B-23

DTC B1027: Reusable Number Exceeded ....... 8B-24

DTC B1031: Driver Air Bag Initiator Circuit

Resistance High .............................................. 8B-24

DTC B1032: Driver Air Bag Initiator Circuit

Resistance Low ............................................... 8B-29

DTC B1033: Driver Air Bag Initiator Circuit

Short to Ground............................................... 8B-34

DTC B1034: Driver Air Bag Initiator Circuit

Short to Power Circuit .... ................................. 8B-39

DTC B1041: Passenger Air Bag Initiator Circuit Resistance High ................................... 8B-44

DTC B1042: Passenger Air Bag Initiator Circuit Resistance Low.................................... 8B-47

DTC B1043: Passenger Air Bag Initiator Circuit Short to Ground ................................... 8B-50

DTC B1044: Passenger Air Bag Initiator Circuit Short to Power Circ uit .......................... 8B-53

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance

High ................................................................. 8B-56

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circu it Resistance Low .. 8B-58

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to Ground .. 8B-60

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power

Circuit .............................................................. 8B-62

DTC B1061 / B1065: Driver / Passenger Side- Air Bag Initiator Circuit Resistance High ......... 8B-64

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127

Page 1031 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 8-1

Restraint

Precautions

Precautions

Precautions on RestraintS7RS0B8000001

Air Bag System Service Warning

Refer to “Air Bag System Service Warning in Section 00”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Precautions on Service and Diagnosis of Seat Belt

Refer to “Precautions on Service and Diagnosis of Seat Belt in Section 8A”.

Precautions on Service and Diagnosis of Air Bag System

Refer to “Precautions on Service and Diagnosis of Air Bag System in Section 8B”.

Precautions on Handling and Storage of Air Bag Components

Refer to “Precautions on Handling and Storage of Air Bag System Components in Section 8B”.

Precautions on Disposal of Air Bag and Seat Belt Pretensioner

Refer to “Precautions on Disposal of Air Bag and Seat Belt Pretensioner in Section 8B”.

Page 1032 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat

Belt

S7RS0B8100001

WARNING!

If replacing seat belt is necessary, replace

buckle and seat belt assembly together as a

set. This is for the reason of ensuring locking

of tongue plate with buckle. If these parts are

replaced individually, such a locking

condition may become unreliable. For this

reason, SUZUKI will supply only the spare

buckle and seat belt assembly in a set part.

Before servicing or replacing seat belts, refer to the

following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions. • Keep sharp edges and damaging objects away from

belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading

and then to specified torque.

• Do not attempt any repair s on retractor mechanisms

or retractor covers. Replace defective assemblies with

new replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

General Description

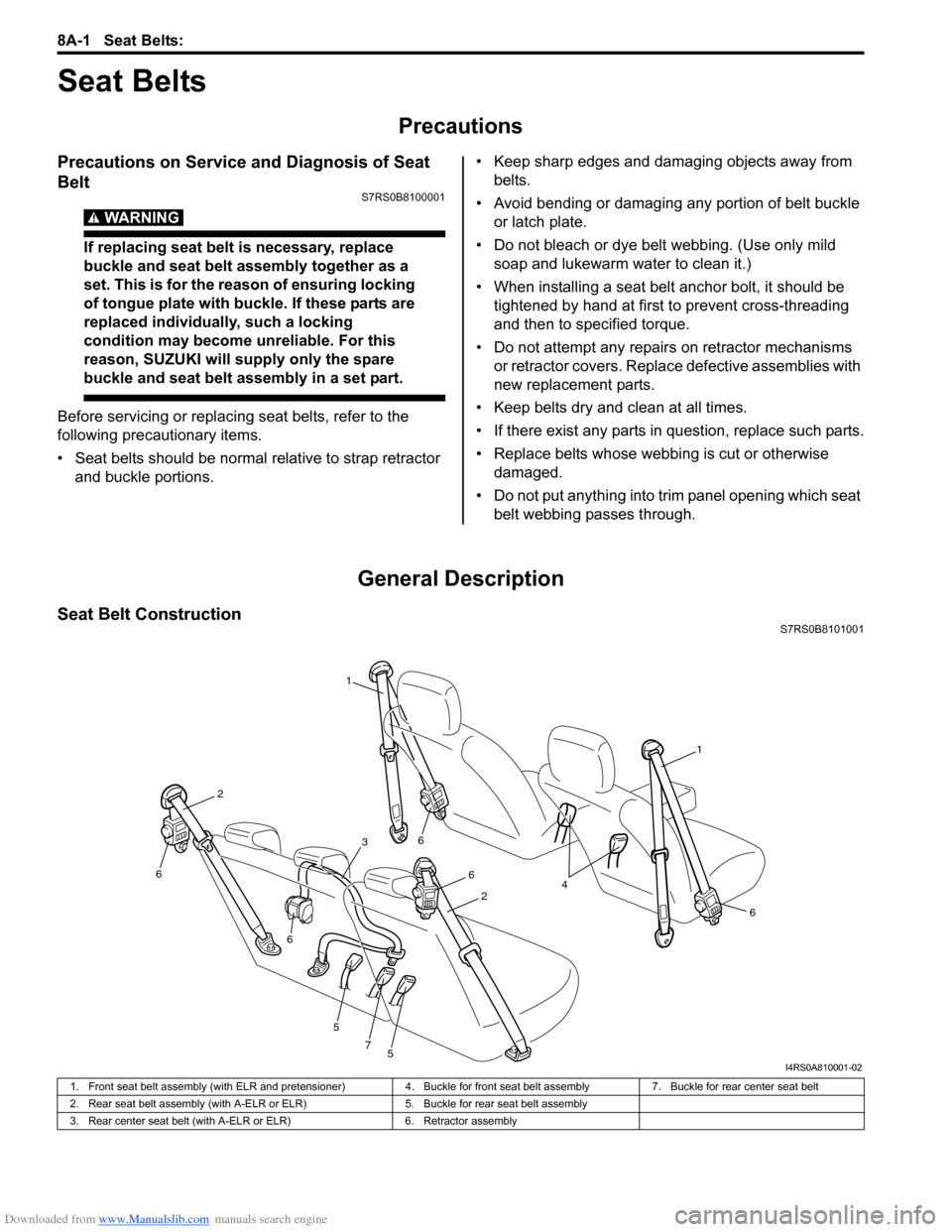

Seat Belt ConstructionS7RS0B8101001

1

1

6

6

6

5

5

7

6

6

2

2

3

4

I4RS0A810001-02

1. Front seat belt assembly (with ELR and pretensioner) 4. Buckle for front seat belt assembly7. Buckle for rear center seat belt

2. Rear seat belt assembly (with A-ELR or ELR) 5. Buckle for rear seat belt assembly

3. Rear center seat belt (with A-ELR or ELR) 6. Retractor assembly

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.