700 SUZUKI SWIFT 2006 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1277 of 1496

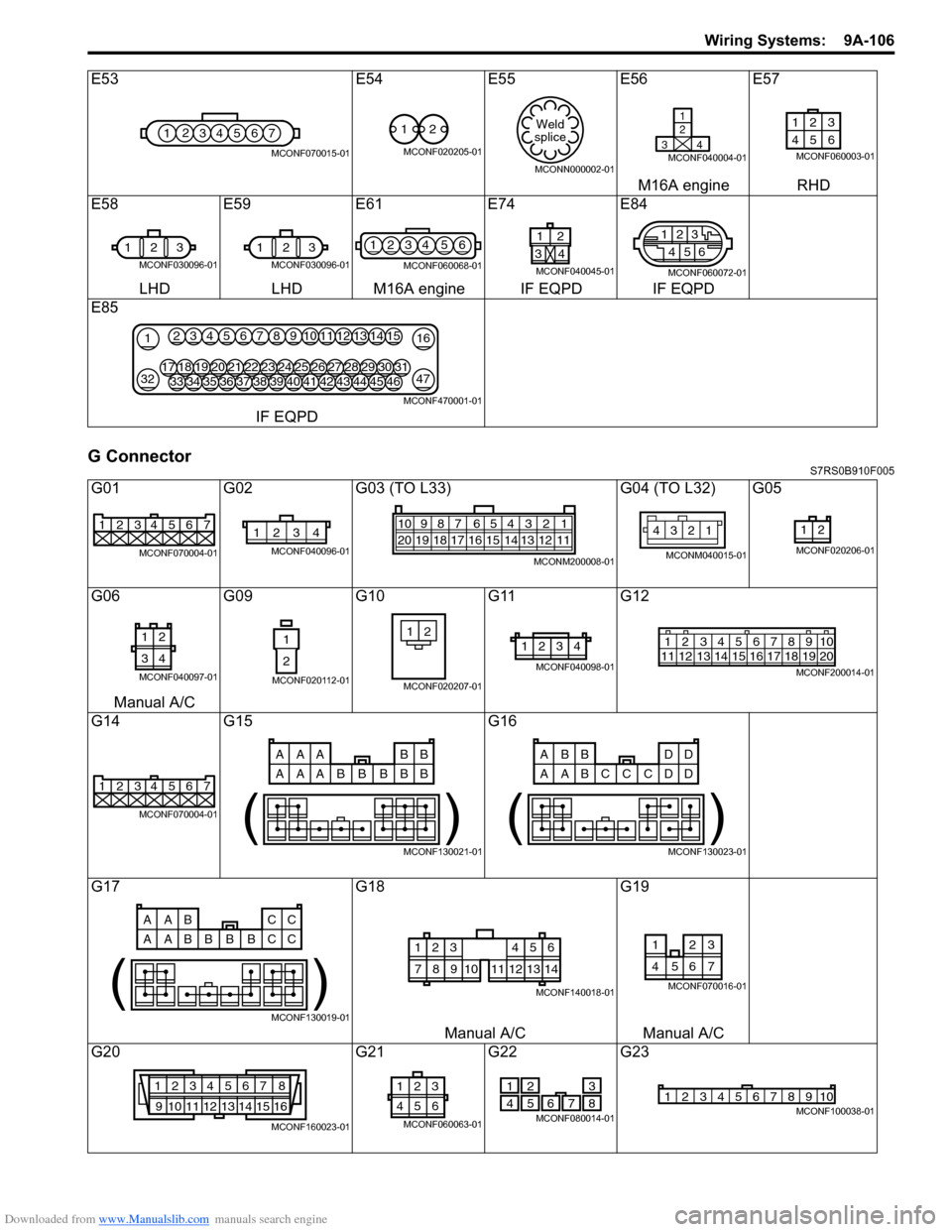

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-106

G ConnectorS7RS0B910F005

E53E54E55 E56E57

M16A engine RHD

E58 E59E61E74 E84

LHD LHD M16A engine IF EQPD IF EQPD

E85

IF EQPD

G01 G02G03 (TO L33) G04 (TO L32) G05

G06 G09G10G11G12

Manual A/C

G14 G15 G16

G17 G18G19

Manual A/C Manual A/C

G20 G21G22G23

1234567

MCONF070015-01

12

MCONF020205-01

Weld

splice

MCONN000002-01

1

2

34

MCONF040004-01

123

46 5

MCONF060003-01

1 23

MCONF030096-01

123

MCONF030096-01

1234 56

MCONF060068-01

1

34

2

MCONF040045-01

2

5

46

13

MCONF060072-01

21

3247

163451213141567891011

3334353643444546373839404142181719202128293031222324252627

MCONF470001-01

1234567

MCONF070004-01

1234

MCONF040096-01

54 32 167910

20 19 18 17 16 15 14 13 12 118

MCONM200008-01

12

34

MCONM040015-01

12

MCONF020206-01

12

34

MCONF040097-01

1

2

MCONF020112-01

21

MCONF020207-01

1234

MCONF040098-01

125678911 12 13 14 15 16 17 18 1910

2034

MCONF200014-01

1234567

MCONF070004-01

AAA BB

AAA B

BB

BB

( )

MCONF130021-01

ABB DD

AAB D

CC

CD

( )

MCONF130023-01

AAB CC

AAB C

BB

BC

( )

MCONF130019-01

123

78910

456

11121314

MCONF140018-01

3

7654

21

MCONF070016-01

1234567 8

9 10111213141516

MCONF160023-01

3

21

654

MCONF060063-01

2

51

47 6

8

3

MCONF080014-01

12345678910MCONF100038-01

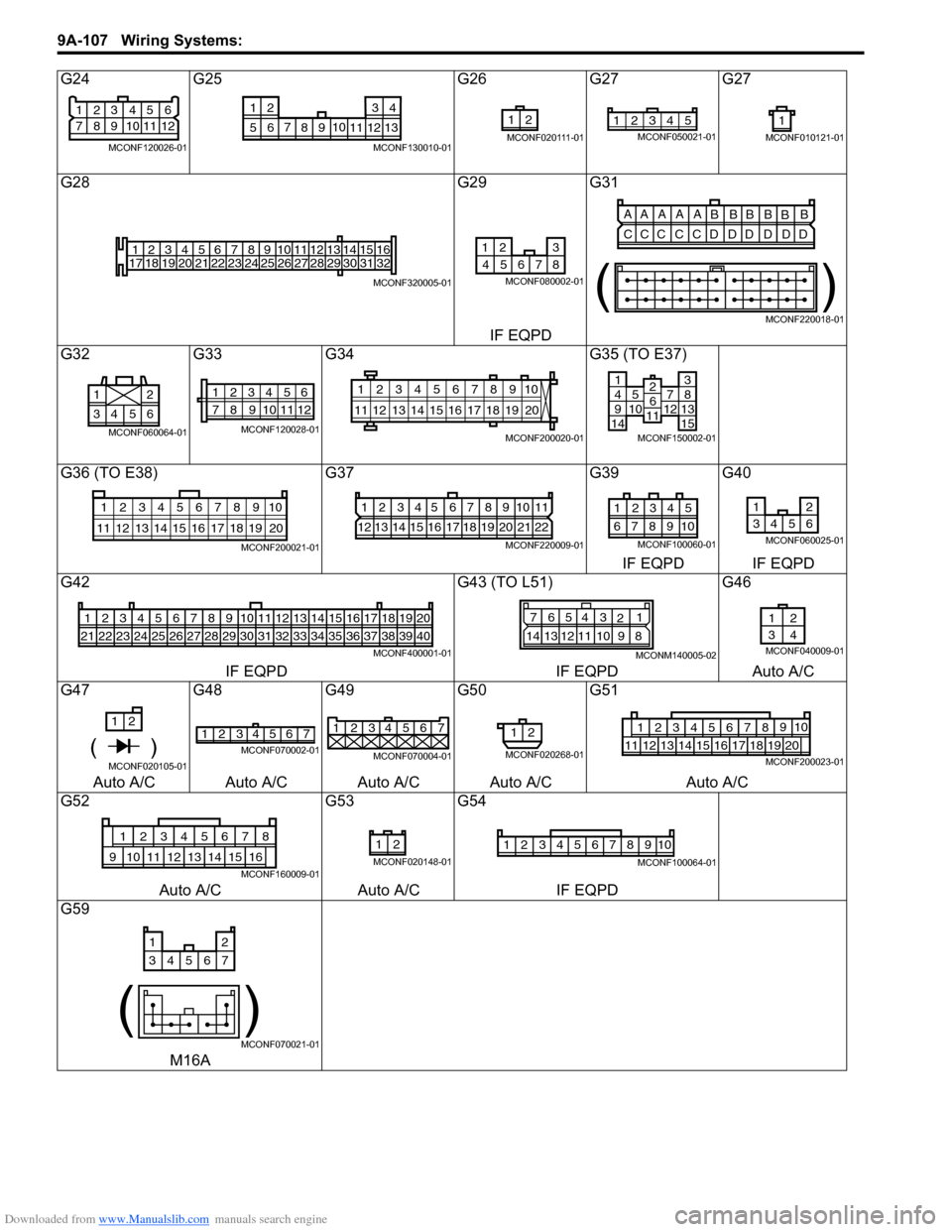

Page 1278 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-107 Wiring Systems:

G24G25 G26G27 G27

G28 G29G31

IF EQPD

G32 G33G34 G35 (TO E37)

G36 (TO E38) G37G39G40

IF EQPD IF EQPD

G42 G43 (TO L51)G46

IF EQPD IF EQPDAuto A/C

G47 G48G49G50G51

Auto A/C Auto A/C Auto A/C Auto A/C Auto A/C

G52 G53G54

Auto A/C Auto A/CIF EQPD

G59

M16A

21

83

9 4

10 5

11 6

12

7

MCONF120026-01

710

56 12 34

8 9 11 12 13

MCONF130010-01

21

MCONF020111-01

12345MCONF050021-011

MCONF010121-01

1

17 2

18 3

19 4

20 5

21 6

22 7

23 8

24 9

25 10

26 11

27 12

28 13

29 14

30 15

31 16

32

MCONF320005-01

12 3

8

467 5

MCONF080002-01

AA A A A

BBBB

BB

CCC C CD DD D DD

()

MCONF220018-01

6543 21

MCONF060064-01

12345

78 11 6

12

910

MCONF120028-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200020-01

14951071214

381315

2611

MCONF150002-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200021-01

1234567891011

12 13 14 15 16 17 18 19 20 21 22

MCONF220009-01

54321

109876

MCONF100060-01

12

3456

MCONF060025-01

123456

212223242526

7

27

8

28

9

29

10

30

11

31

12

32

13

33

14

34

15

35

16

36

17

37

18

38

19

39

20

40

MCONF400001-01

7 654 3

21

14 13 12 11 10 9 8

MCONM140005-02

12

34

MCONF040009-01

1 2

( )MCONF020105-01

2

14 3657MCONF070002-01

1234567

MCONF070004-01

12

MCONF020268-01

12349105678

11121718192013141516MCONF200023-01

12345678

910151611121314

MCONF160009-01

21

MCONF020148-01

12345678910

MCONF100064-01

12

34567

()

MCONF070021-01

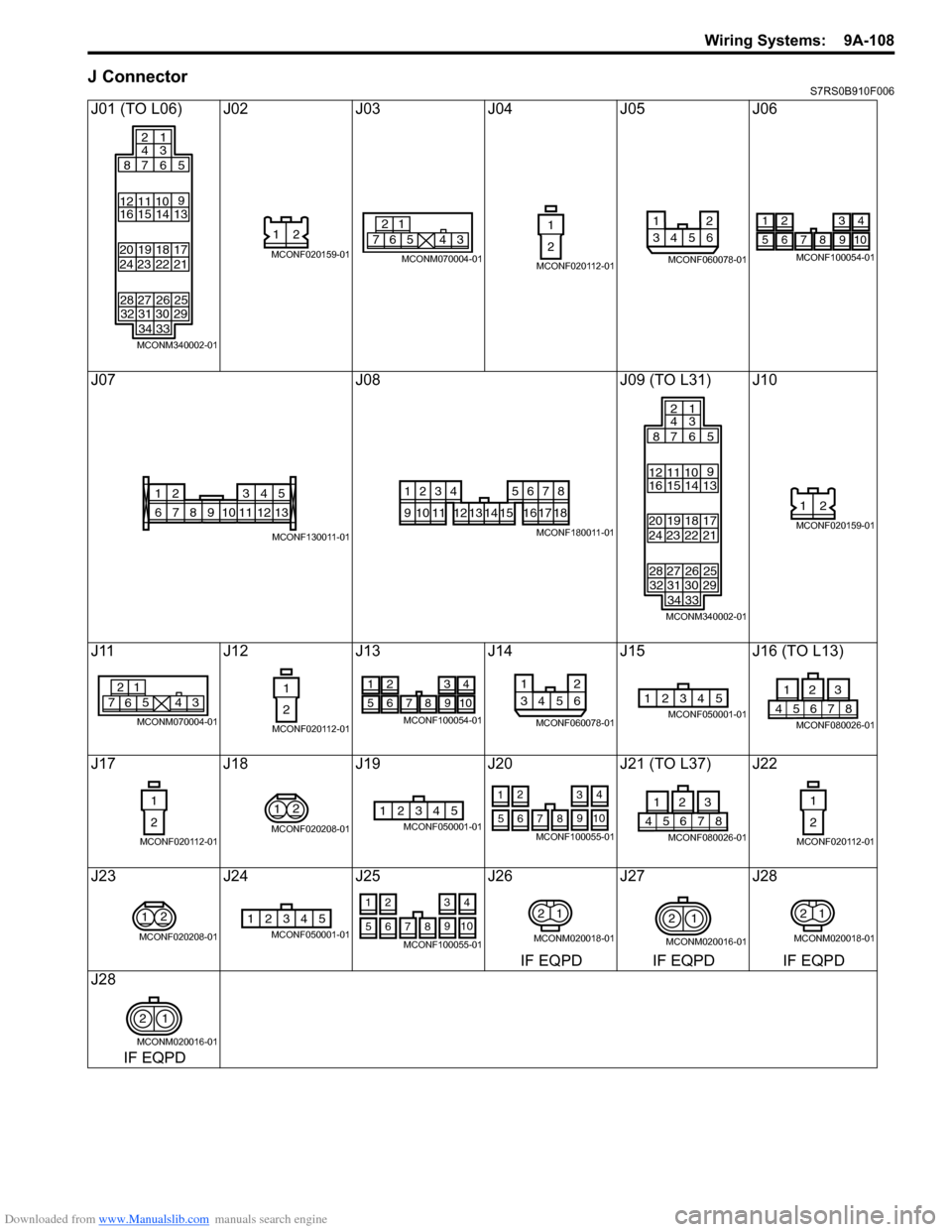

Page 1279 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-108

J ConnectorS7RS0B910F006

J01 (TO L06) J02J03J04J05J06

J07 J08J09 (TO L31) J10

J11 J12J13J14 J15 J16 (TO L13)

J17 J18J19 J20 J21 (TO L37) J22

J23 J24J25 J26 J27 J28

IF EQPD IF EQPD IF EQPD

J28

IF EQPD

313234 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-016

21

7543

MCONM070004-01

1

2

MCONF020112-01

12

3456

MCONF060078-01

1234

5678910

MCONF100054-01

135

68910111324

712

MCONF130011-01

1234

91011

5678

12131415161718

MCONF180011-01

3132 34 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-01

6

21

7543

MCONM070004-01

1

2

MCONF020112-01

1234

5678910

MCONF100054-01

12

3456

MCONF060078-01

12345MCONF050001-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-01

12

MCONM020018-01

2

1

MCONM020016-01

12

MCONM020018-01

21

MCONM020016-01

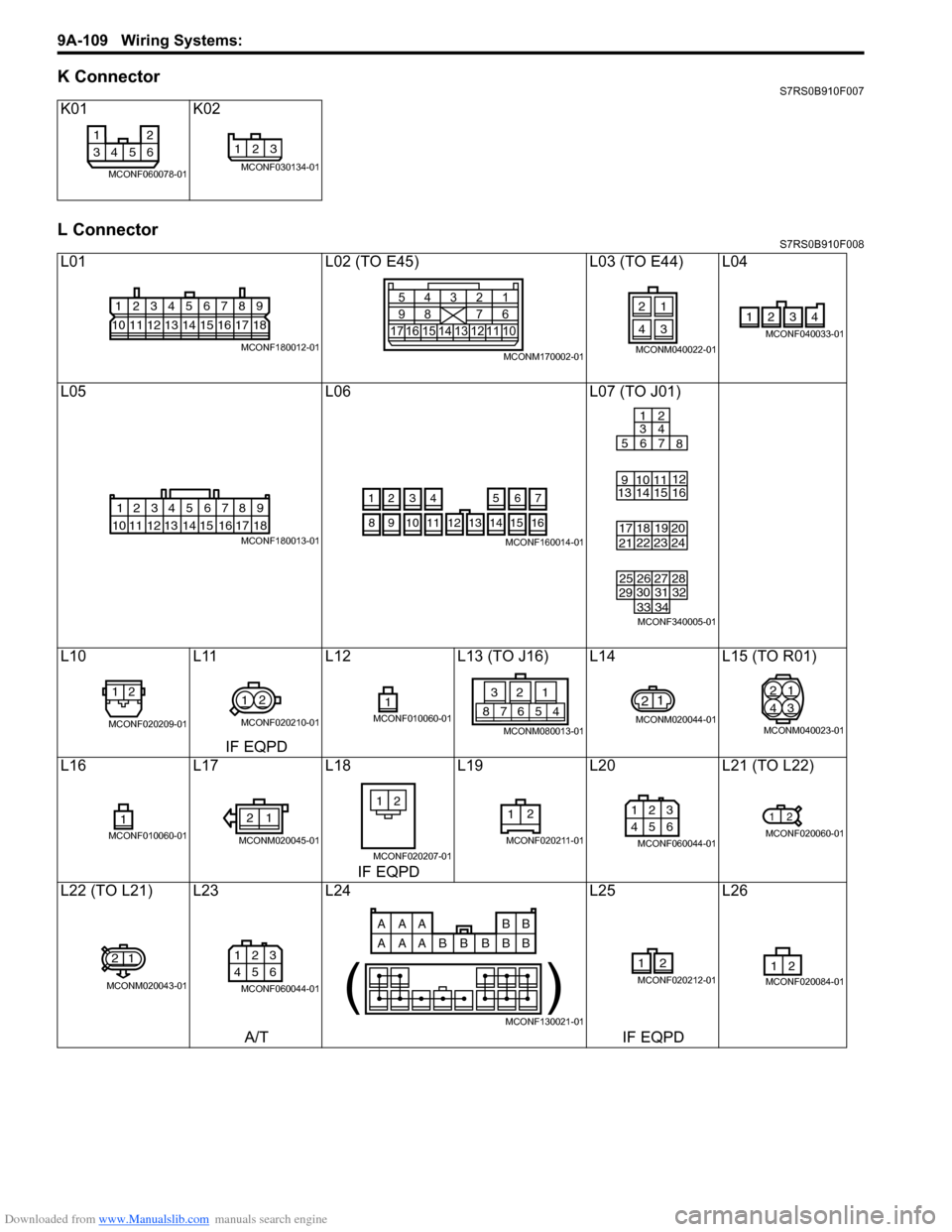

Page 1280 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-109 Wiring Systems:

K ConnectorS7RS0B910F007

L ConnectorS7RS0B910F008

K01K02

L01 L02 (TO E45)L03 (TO E44) L04

L05 L06L07 (TO J01)

L10 L11L12L13 (TO J16) L14 L15 (TO R01)

IF EQPD

L16 L17L18L19L20 L21 (TO L22)

IF EQPD

L22 (TO L21) L23 L24L25L26

A/T IF EQPD

12

3456

MCONF060078-01

123

MCONF030134-01

123456789

101112131415161718

MCONF180012-01175

9161312 11 101514

4

832

71

6

MCONM170002-01

21

43

MCONM040022-01

2341

MCONF040033-01

123456789

15 16 17 18

1110 12 13 14

MCONF180013-01

4

3

56

1214

11

10 15

721

13

16

98

MCONF160014-01

31 32

3433

30

29

24

28

23

27

22

26

21

25

13 2019

14

91011

15

18 16

17 7

1

3

2

4

56 8

12

MCONF340005-01

12

MCONF020209-01

1 2

MCONF020210-01

1MCONF010060-0145678

213

MCONM080013-01

21

MCONM020044-01

2

4 1

3

MCONM040023-01

1MCONF010060-01

12

MCONM020045-01

21

MCONF020207-01

12

MCONF020211-01

1 23

456

MCONF060044-01

12

MCONF020060-01

21

MCONM020043-01

1 23

456

MCONF060044-01

AAA BB

AAA B

BB

BB

( )

MCONF130021-01

12

MCONF020212-0121MCONF020084-01

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

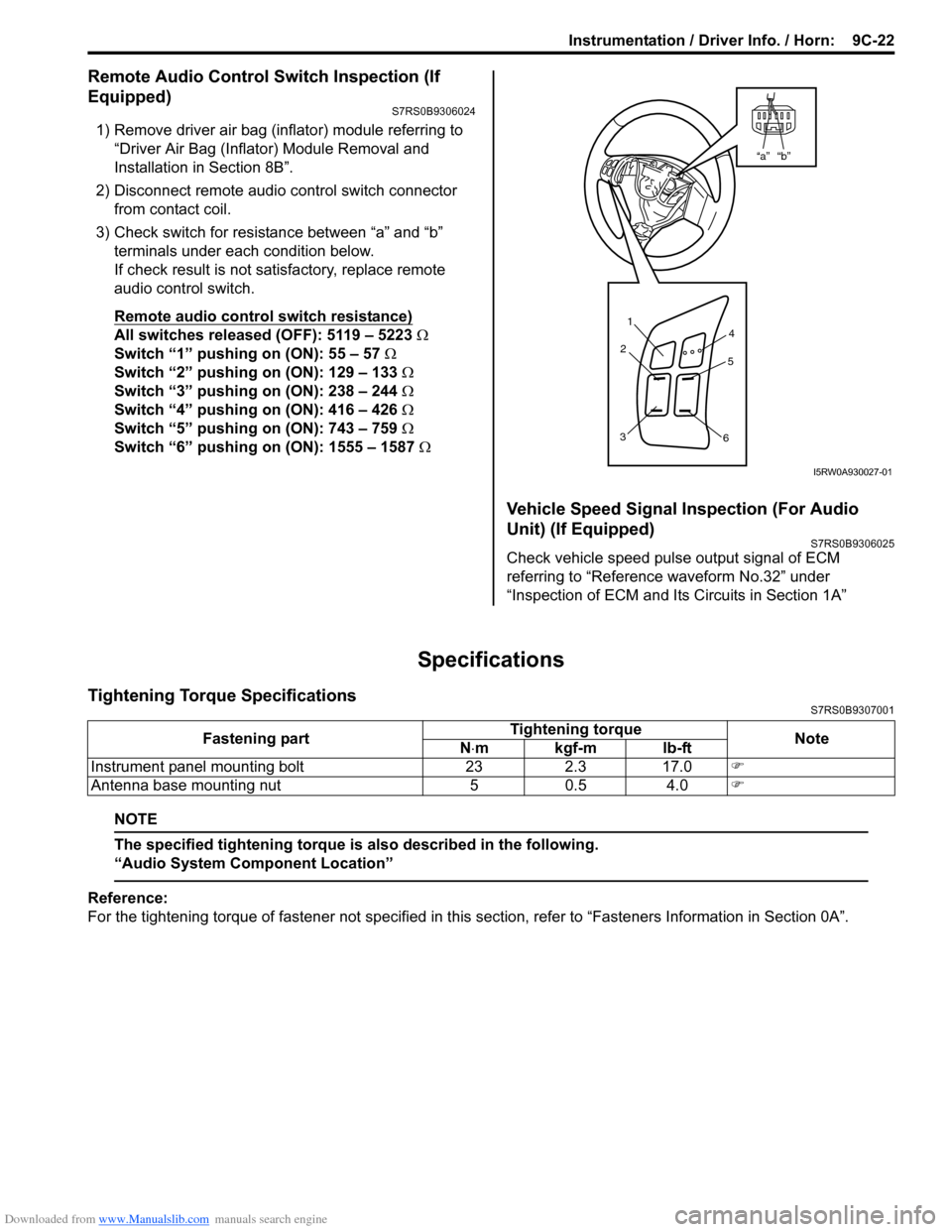

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1327 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-10

Rear Wiper Relay Removal and InstallationS7RS0B9406012

Removal1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

3) Remove rear wiper relay.

Installation

Reverse removal procedure for installation.

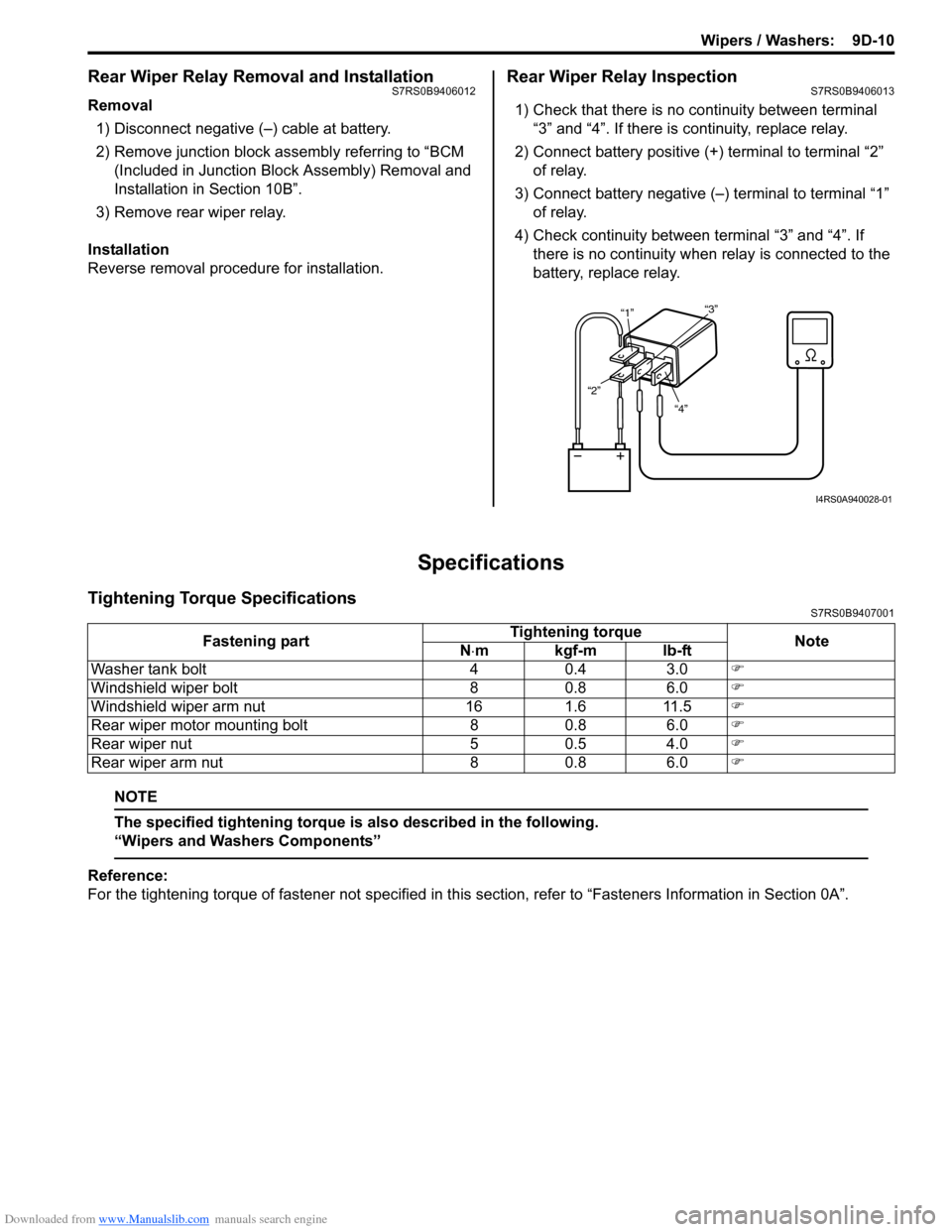

Rear Wiper Relay InspectionS7RS0B9406013

1) Check that there is no continuity between terminal “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

Specifications

Tightening Torque SpecificationsS7RS0B9407001

NOTE

The specified tightening torque is also described in the following.

“Wipers and Washers Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“4”

“2” “1”

“3”

I4RS0A940028-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Washer tank bolt 4 0.4 3.0 �)

Windshield wiper bolt 8 0.8 6.0 �)

Windshield wiper arm nut 16 1.6 11.5 �)

Rear wiper motor mounting bolt 8 0.8 6.0 �)

Rear wiper nut 5 0.5 4.0 �)

Rear wiper arm nut 8 0.8 6.0 �)

Page 1362 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-16 Security and Locks:

Specifications

Tightening Torque SpecificationsS7RS0B9607001

NOTE

The specified tightening torque is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

“Rear End Door Lock Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9608001

NOTE

Required service material is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Door latch screw 5.0 0.5 4.0 �) / �)

Door latch striker screw 10 1.0 7.5 �)

Rear end door latch bolt 10 1.0 7.5 �)

Rear end door striker screw 23 2.3 17.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25010�)

Page 1363 of 1496

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-1

Body, Cab and Accessories

Seats

Repair Instructions

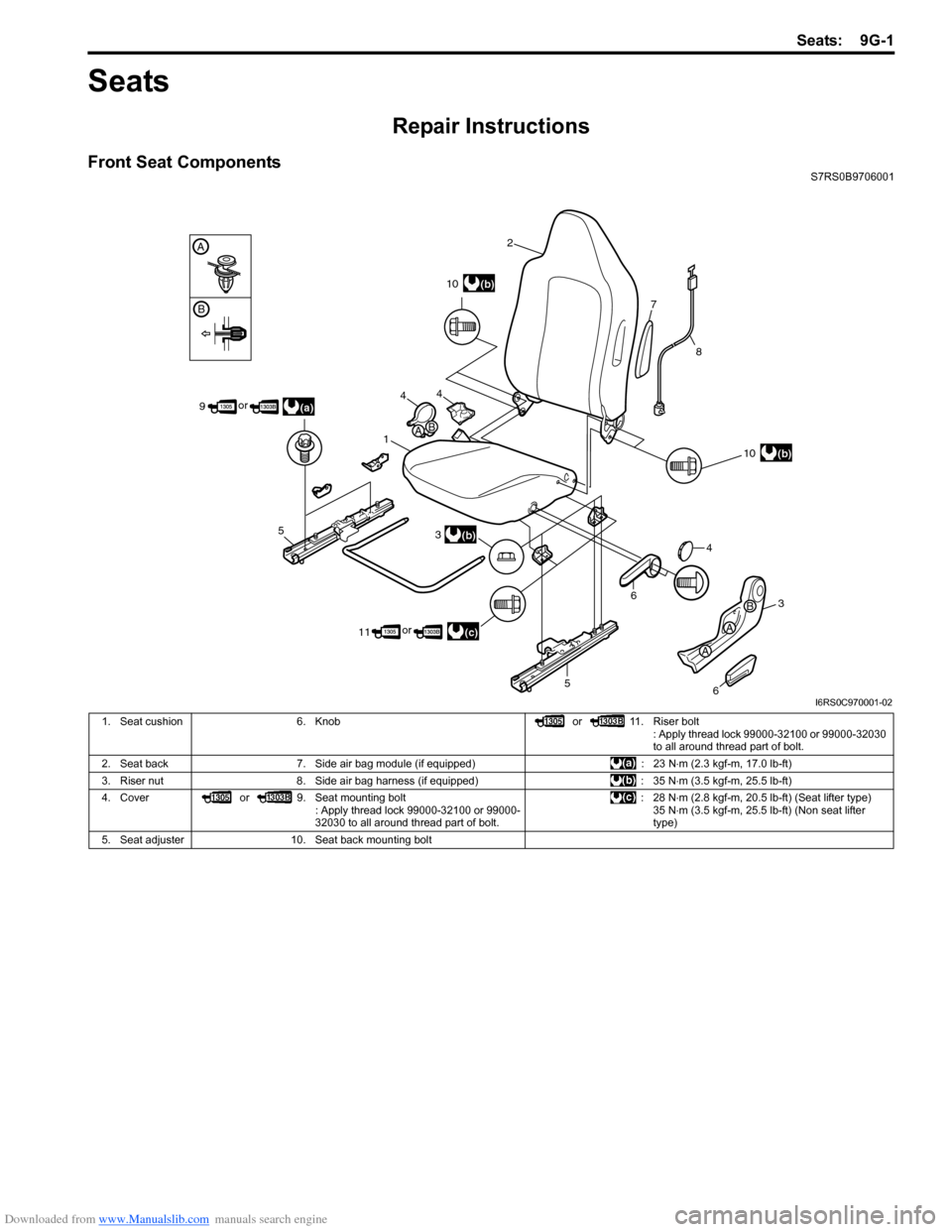

Front Seat ComponentsS7RS0B9706001

2

4

1 3

11

6

3

4

6

7

8

(b)

(b)

10

5

(a)

or

94

5

(c)

(b)

10

or

A

A

B

AB

B

A

I6RS0C970001-02

1. Seat cushion 6. Knob or 11. Riser bolt

: Apply thread lock 99000-32100 or 99000-32030

to all around thread part of bolt.

2. Seat back 7. Side air bag module (if equipped) : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Riser nut 8. Side air bag harness (if equipped) : 35 N⋅m (3.5 kgf-m, 25.5 lb-ft)

4. Cover or 9. Seat mounting bolt

: Apply thread lock 99000-32100 or 99000-

32030 to all around thread part of bolt. :28 N

⋅m (2.8 kgf-m, 20.5 lb-ft) (Seat lifter type)

35 N ⋅m (3.5 kgf-m, 25.5 lb-ft) (Non seat lifter

type)

5. Seat adjuster 10. Seat back mounting bolt

Page 1364 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-2 Seats:

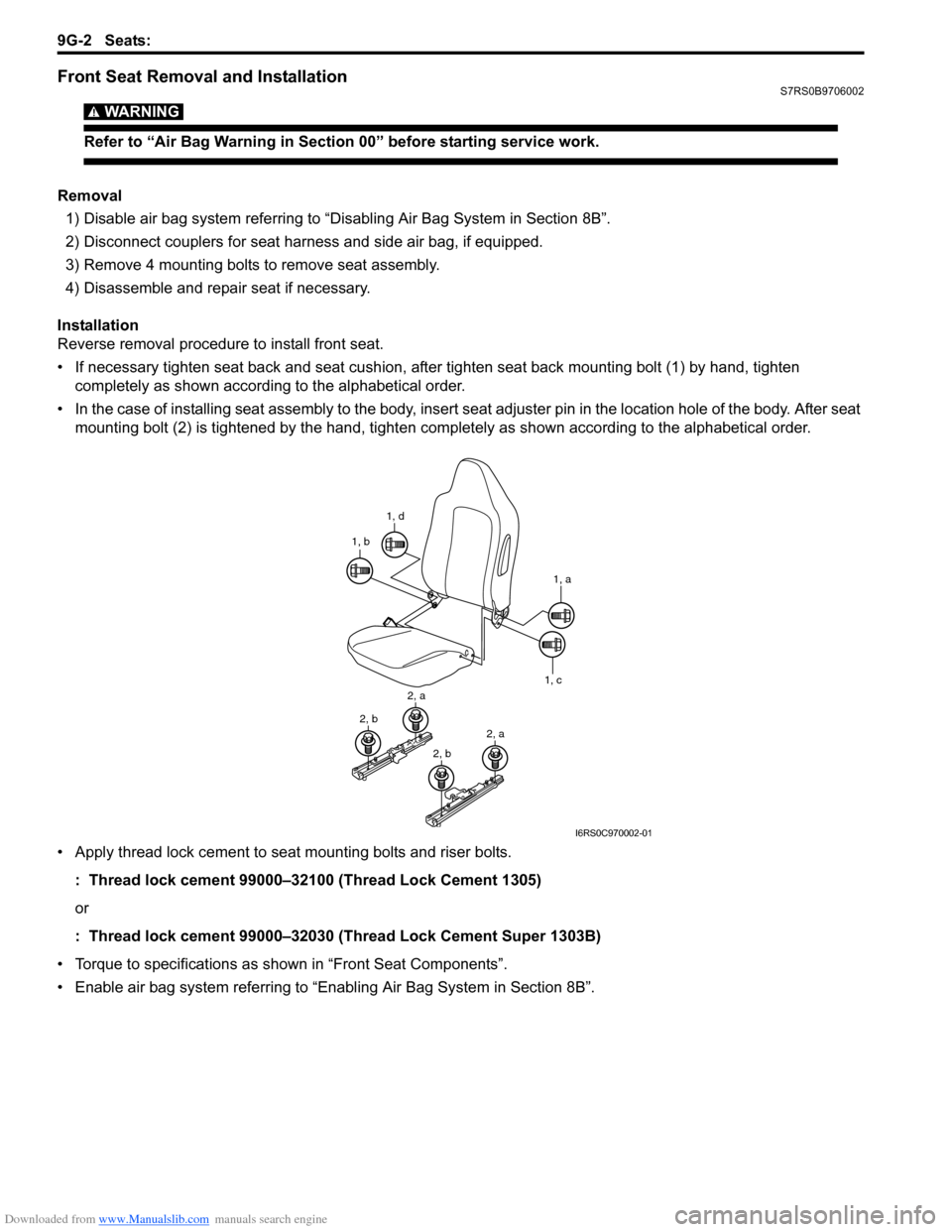

Front Seat Removal and InstallationS7RS0B9706002

WARNING!

Refer to “Air Bag Warning in Section 00” before starting service work.

Removal1) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

2) Disconnect couplers for seat harness and side air bag, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat if necessary.

Installation

Reverse removal procedure to install front seat.

• If necessary tighten seat back and seat cushion, after tighten seat back mounting bolt (1) by hand, tighten completely as shown according to the alphabetical order.

• In the case of installing seat assembly to the body, insert se at adjuster pin in the location hole of the body. After seat

mounting bolt (2) is tightened by t he hand, tighten completely as shown according to the alphabetical order.

• Apply thread lock cement to seat mounting bolts and riser bolts. : Thread lock cement 99000–32100 (Thread Lock Cement 1305)

or

: Thread lock cement 99000–32030 (Thread Lock Cement Super 1303B)

• Torque to specifications as shown in “Front Seat Components”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

1, d

1, b

1, a

1, c

2, a

2, b2, a

2, b

I6RS0C970002-01

Page 1365 of 1496

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-3

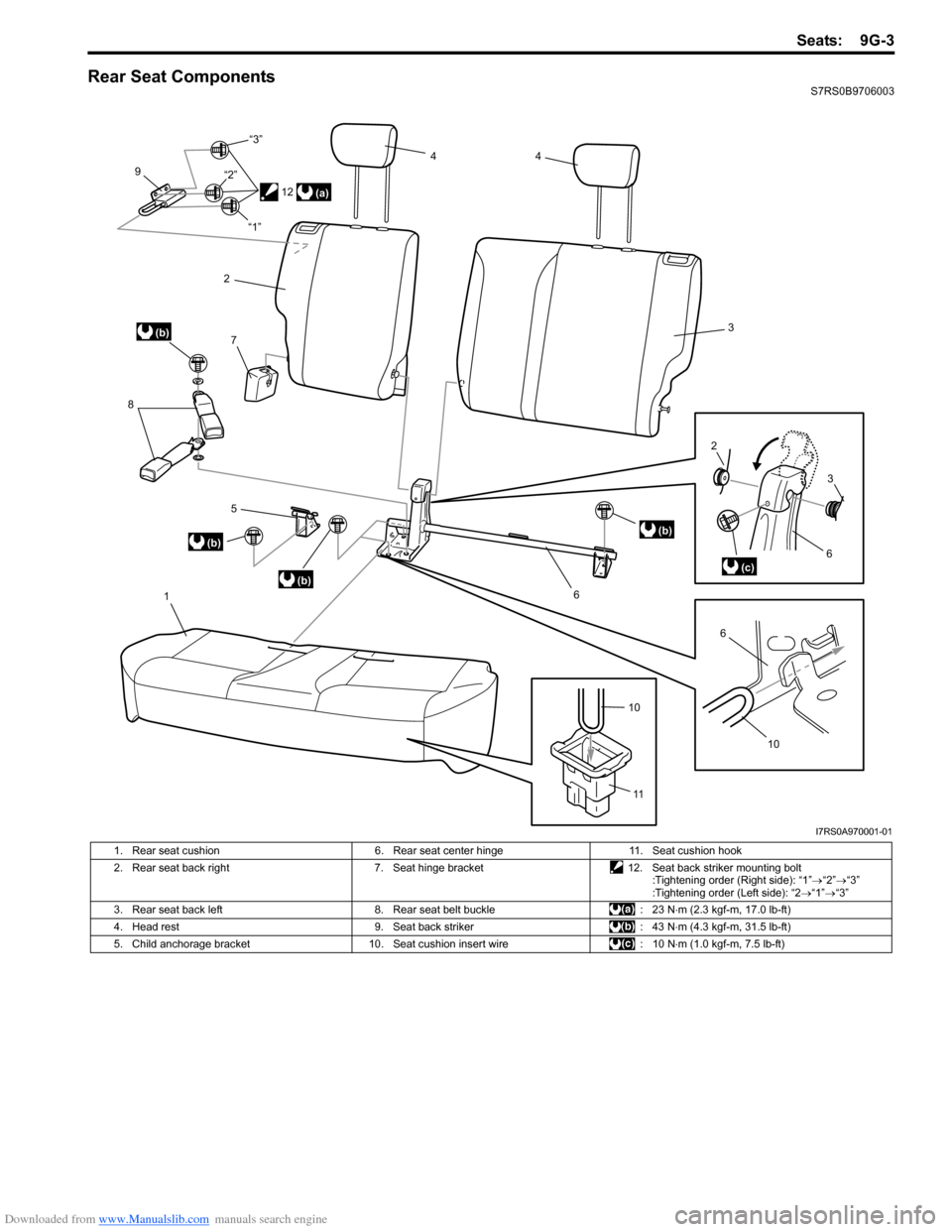

Rear Seat ComponentsS7RS0B9706003

1

5

(b)

(b)

(b)

8

7

9

2

4

4

3

(b)

6

6(c)

2

3

10

6

(a)

10

11

12

“1”

“2”

“3”

I7RS0A970001-01

1. Rear seat cushion

6. Rear seat center hinge11. Seat cushion hook

2. Rear seat back right 7. Seat hinge bracket12. Seat back striker mounting bolt

:Tightening order (Right side): “1” →“2” →“3”

:Tightening order (Left side): “2 →“1” →“3”

3. Rear seat back left 8. Rear seat belt buckle : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Head rest 9. Seat back striker : 43 N⋅m (4.3 kgf-m, 31.5 lb-ft)

5. Child anchorage bracket 10. Seat cushion insert wire : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)