tel SUZUKI SWIFT 2006 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 802 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-158 Automatic Transmission/Transaxle:

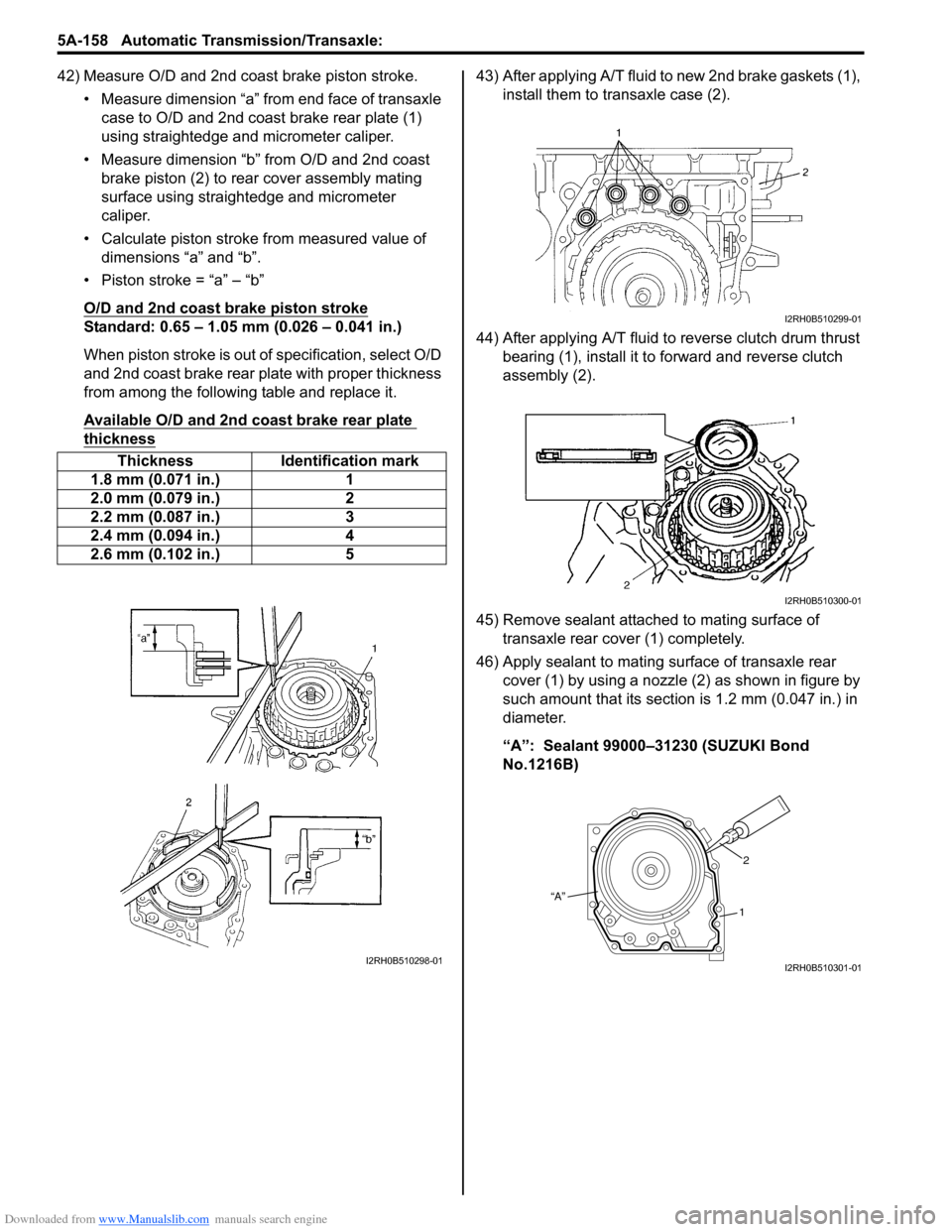

42) Measure O/D and 2nd coast brake piston stroke.• Measure dimension “a” from end face of transaxle case to O/D and 2nd coast brake rear plate (1)

using straightedge and micrometer caliper.

• Measure dimension “b” from O/D and 2nd coast brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.)

When piston stroke is out of specification, select O/D

and 2nd coast brake rear plate with proper thickness

from among the following table and replace it.

Available O/D and 2nd coast brake rear plate

thickness

43) After applying A/T fluid to new 2nd brake gaskets (1), install them to transaxle case (2).

44) After applying A/T fluid to reverse clutch drum thrust bearing (1), install it to forward and reverse clutch

assembly (2).

45) Remove sealant attached to mating surface of transaxle rear cover (1) completely.

46) Apply sealant to mating surface of transaxle rear cover (1) by using a nozzle (2) as shown in figure by

such amount that its section is 1.2 mm (0.047 in.) in

diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Thickness Identification mark

1.8 mm (0.071 in.) 1

2.0 mm (0.079 in.) 2

2.2 mm (0.087 in.) 3

2.4 mm (0.094 in.) 4

2.6 mm (0.102 in.) 5

I2RH0B510298-01

I2RH0B510299-01

I2RH0B510300-01

“A” 2

1

I2RH0B510301-01

Page 844 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-30 Manual Transmission/Transaxle:

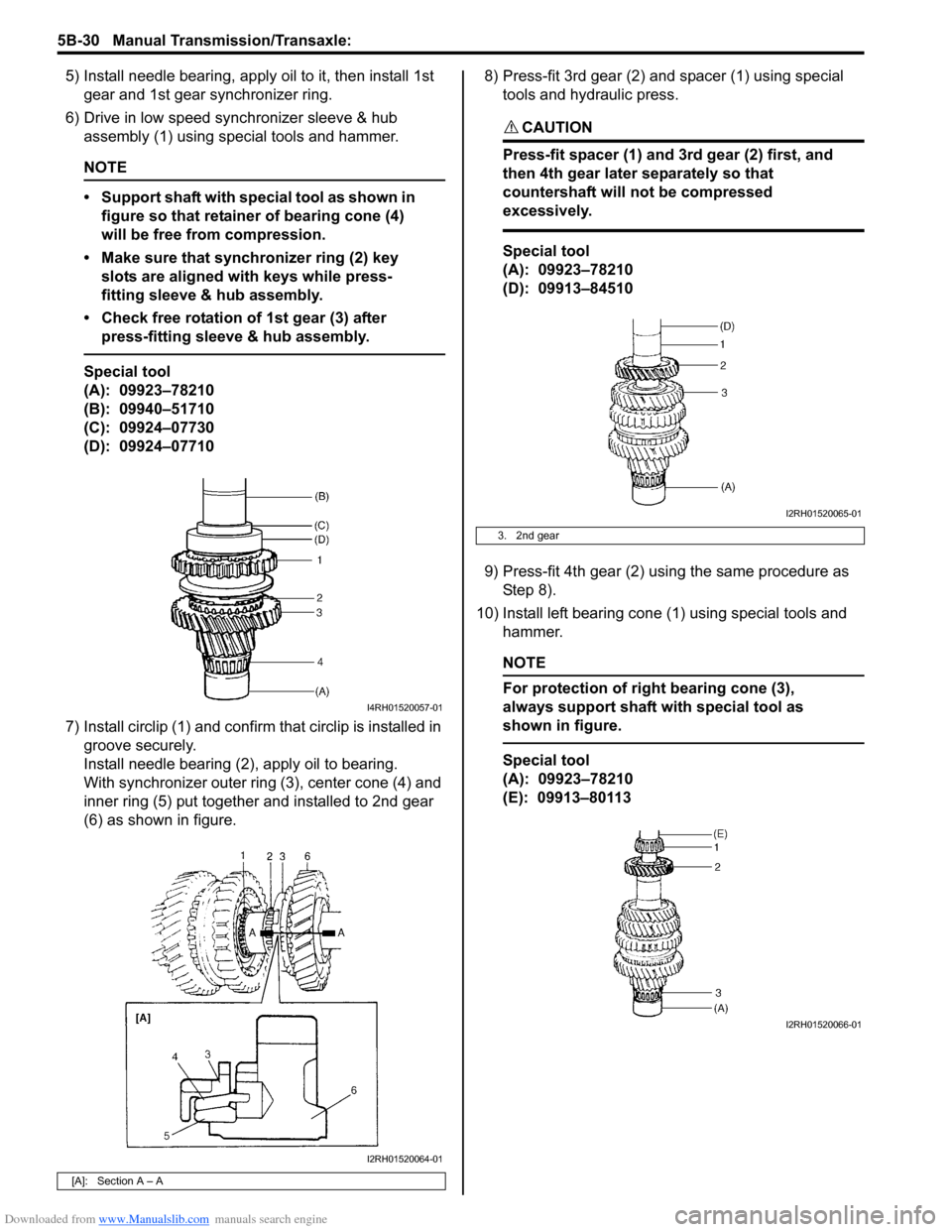

5) Install needle bearing, apply oil to it, then install 1st gear and 1st gear synchronizer ring.

6) Drive in low speed synchronizer sleeve & hub assembly (1) using special tools and hammer.

NOTE

• Support shaft with special tool as shown in figure so that retainer of bearing cone (4)

will be free from compression.

• Make sure that synchronizer ring (2) key slots are aligned with keys while press-

fitting sleeve & hub assembly.

• Check free rotation of 1st gear (3) after press-fitting sleeve & hub assembly.

Special tool

(A): 09923–78210

(B): 09940–51710

(C): 09924–07730

(D): 09924–07710

7) Install circlip (1) and confirm that circlip is installed in groove securely.

Install needle bearing (2), apply oil to bearing.

With synchronizer outer ring (3), center cone (4) and

inner ring (5) put together and installed to 2nd gear

(6) as shown in figure. 8) Press-fit 3rd gear (2) and spacer (1) using special

tools and hydraulic press.

CAUTION!

Press-fit spacer (1) and 3rd gear (2) first, and

then 4th gear later separately so that

countershaft will not be compressed

excessively.

Special tool

(A): 09923–78210

(D): 09913–84510

9) Press-fit 4th gear (2) using the same procedure as Step 8).

10) Install left bearing cone (1) using special tools and hammer.

NOTE

For protection of right bearing cone (3),

always support shaft with special tool as

shown in figure.

Special tool

(A): 09923–78210

(E): 09913–80113

[A]: Section A – A

I4RH01520057-01

I2RH01520064-01

3. 2nd gear

I2RH01520065-01

I2RH01520066-01

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

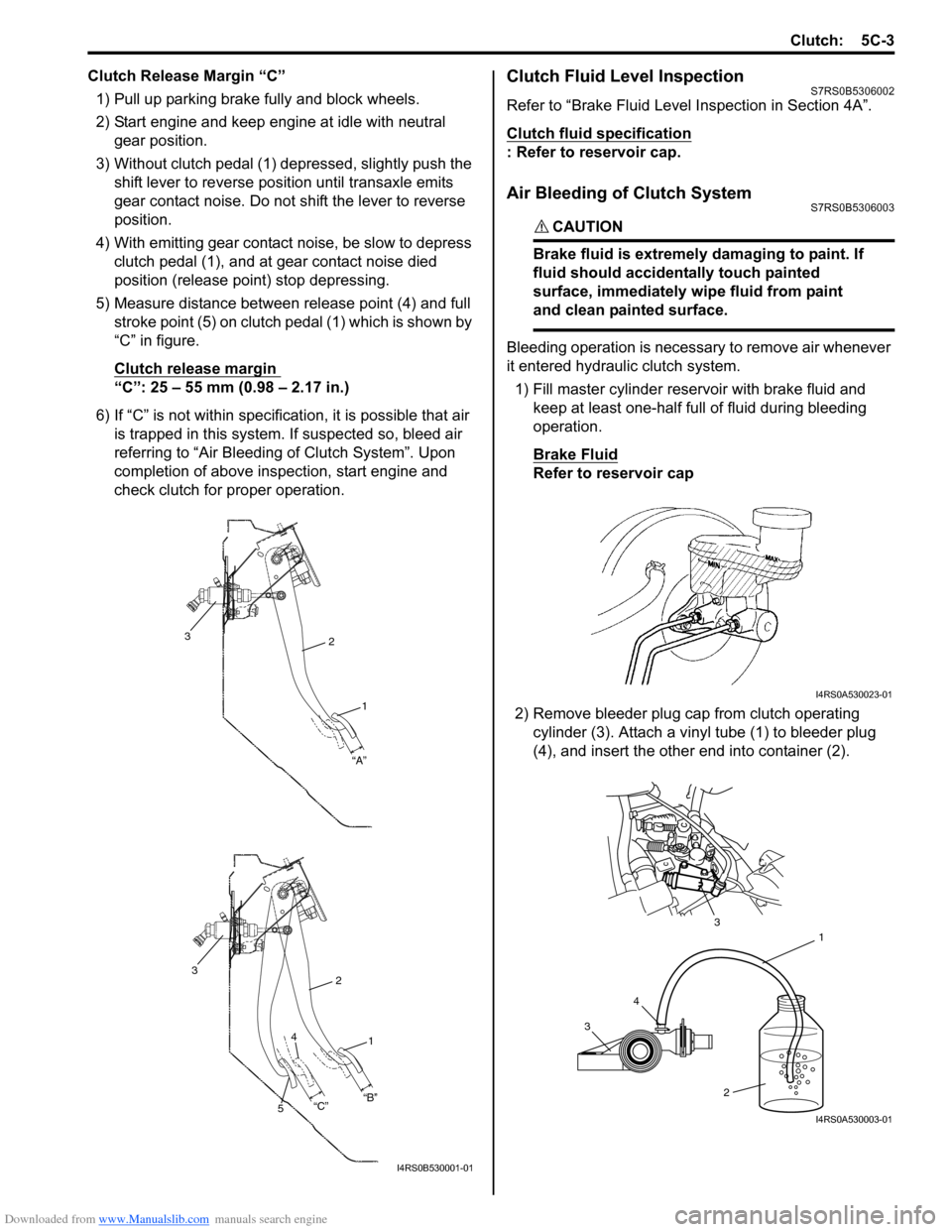

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 871 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering General Diagnosis: 6A-2

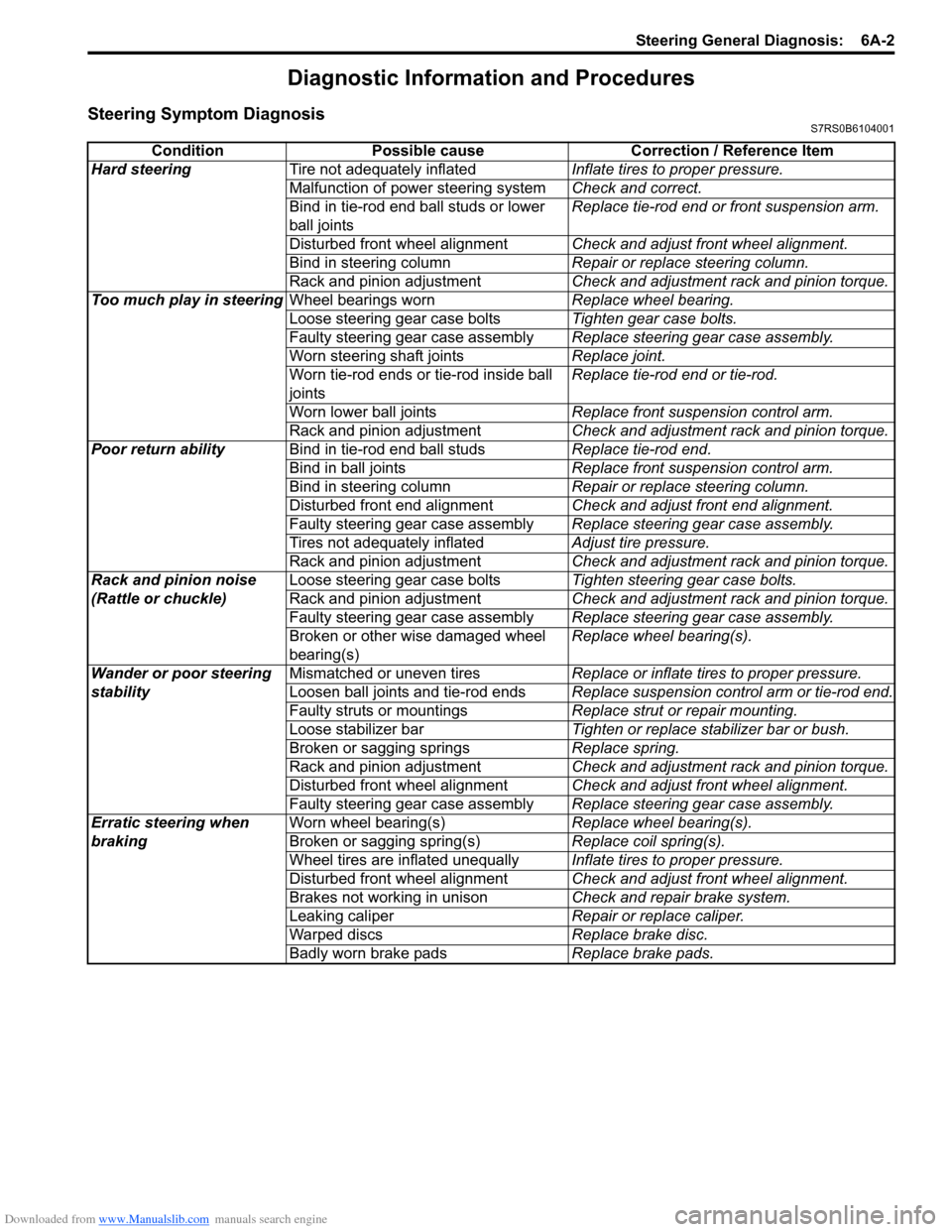

Diagnostic Information and Procedures

Steering Symptom DiagnosisS7RS0B6104001

ConditionPossible cause Correction / Reference Item

Hard steering Tire not adequately inflated Inflate tires to proper pressure.

Malfunction of power steering system Check and correct.

Bind in tie-rod end ball studs or lower

ball joints Replace tie-rod end or front suspension arm.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Bind in steering column Repair or replace steering column.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Too much play in steering Wheel bearings worn Replace wheel bearing.

Loose steering gear case bolts Tighten gear case bolts.

Faulty steering gear case assembly Replace steering gear case assembly.

Worn steering shaft joints Replace joint.

Worn tie-rod ends or tie-rod inside ball

joints Replace tie-rod end or tie-rod.

Worn lower ball joints Replace front suspension control arm.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Poor return ability Bind in tie-rod end ball studs Replace tie-rod end.

Bind in ball joints Replace front suspension control arm.

Bind in steering column Repair or replace steering column.

Disturbed front end alignment Check and adjust front end alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Tires not adequately inflated Adjust tire pressure.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Rack and pinion noise

(Rattle or chuckle) Loose steering gear case bolts

Tighten steering gear case bolts.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Faulty steering gear case assembly Replace steering gear case assembly.

Broken or other wise damaged wheel

bearing(s) Replace wheel bearing(s).

Wander or poor steering

stability Mismatched or uneven tires

Replace or inflate tires to proper pressure.

Loosen ball joints and tie-rod ends Replace suspension control arm or tie-rod end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Erratic steering when

braking Worn wheel bearing(s)

Replace wheel bearing(s).

Broken or sagging spring(s) Replace coil spring(s).

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Brakes not working in unison Check and repair brake system.

Leaking caliper Repair or replace caliper.

Warped discs Replace brake disc.

Badly worn brake pads Replace brake pads.

Page 941 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-5

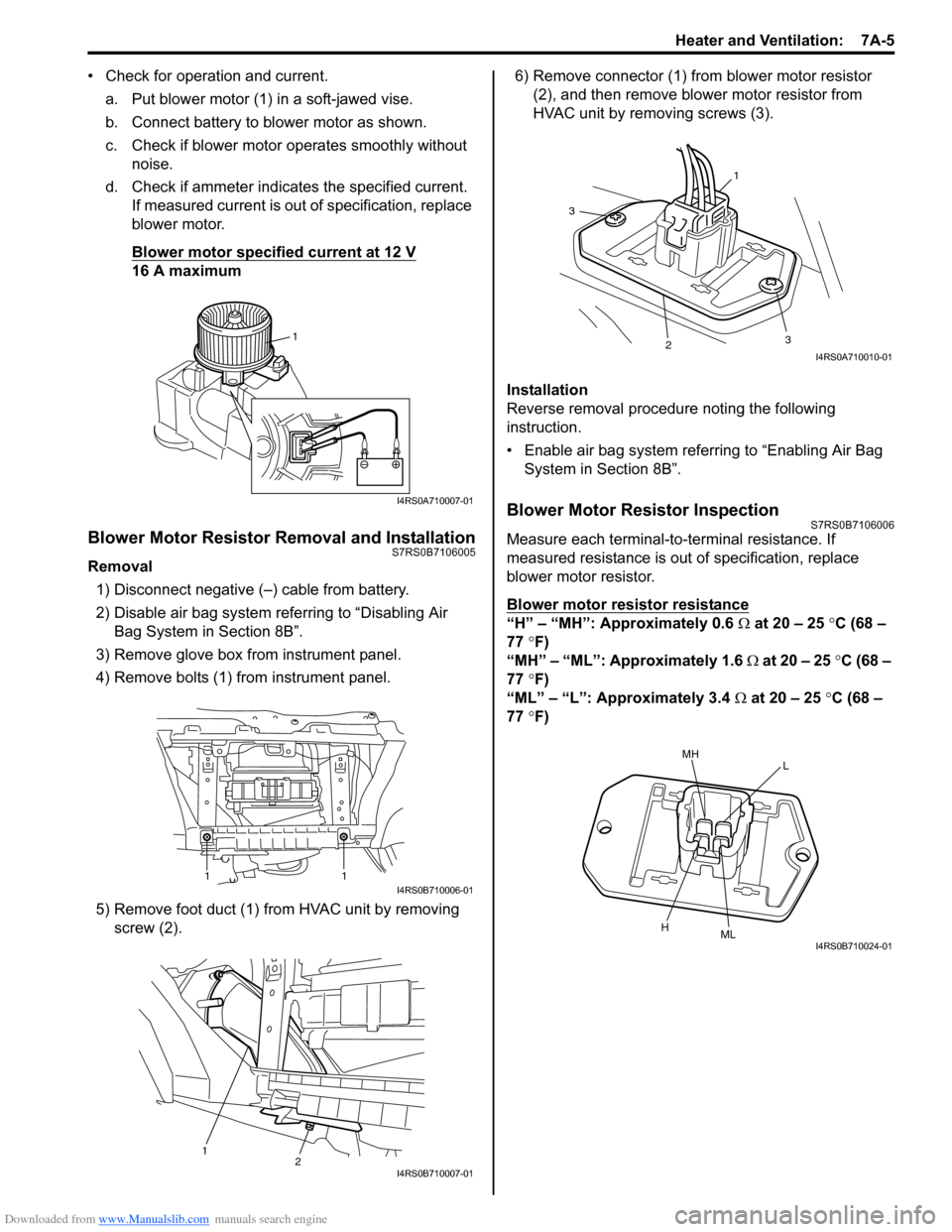

• Check for operation and current.a. Put blower motor (1) in a soft-jawed vise.

b. Connect battery to blower motor as shown.

c. Check if blower motor operates smoothly without noise.

d. Check if ammeter indicates the specified current. If measured current is out of specification, replace

blower motor.

Blower motor specified current at 12 V

16 A maximum

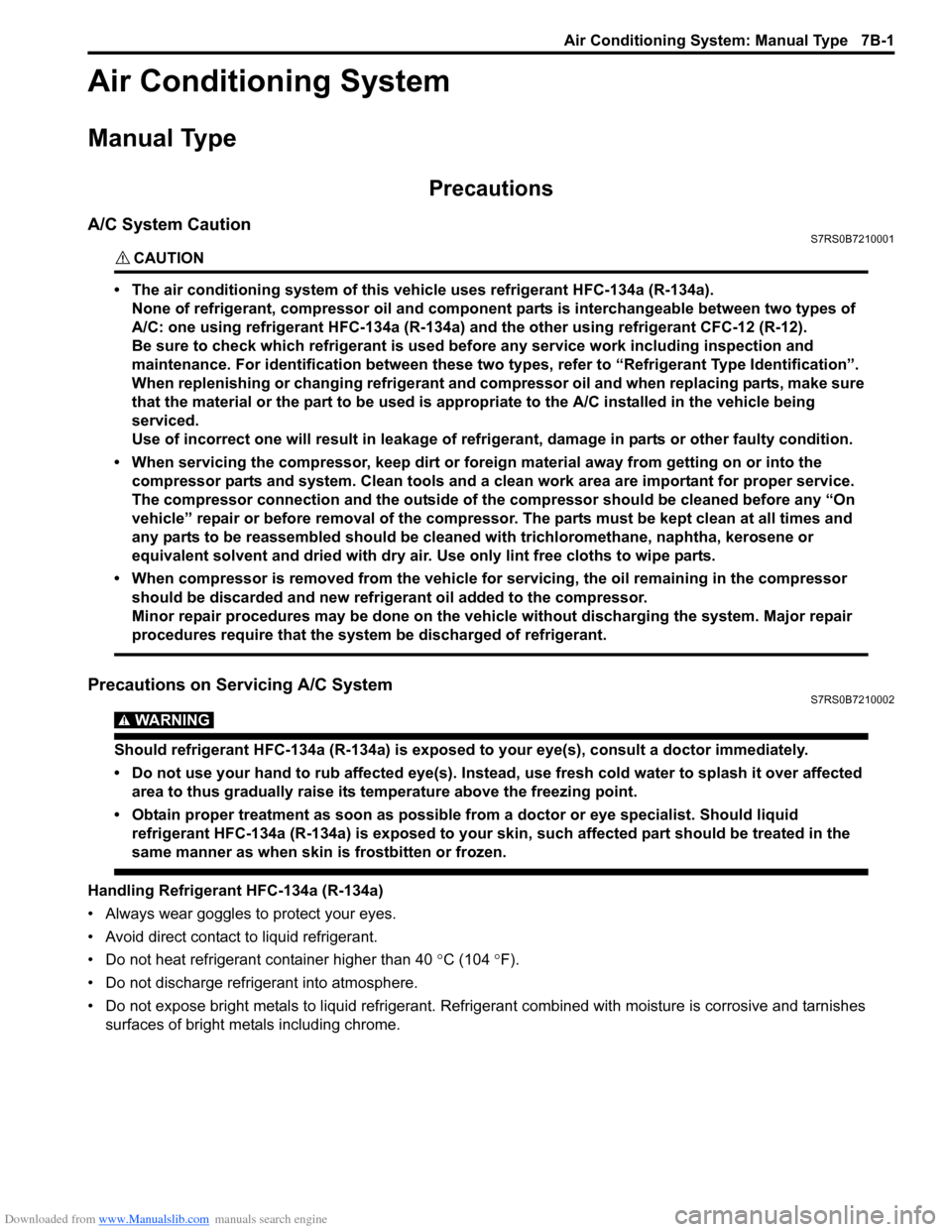

Blower Motor Resistor Removal and InstallationS7RS0B7106005

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove bolts (1) from instrument panel.

5) Remove foot duct (1) from HVAC unit by removing screw (2). 6) Remove connector (1) from blower motor resistor

(2), and then remove blower motor resistor from

HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor Resistor InspectionS7RS0B7106006

Measure each terminal-to-terminal resistance. If

measured resistance is out of specification, replace

blower motor resistor.

Blower motor resistor resistance

“H” – “MH”: Approximately 0.6 Ω at 20 – 25 °C (68 –

77 °F)

“MH” – “ML”: Approximately 1.6 Ω at 20 – 25 °C (68 –

77 °F)

“ML” – “L”: Approximately 3.4 Ω at 20 – 25 °C (68 –

77 °F)

1

I4RS0A710007-01

11I4RS0B710006-01

12I4RS0B710007-01

1

3

23

I4RS0A710010-01

MHL

HMLI4RS0B710024-01

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

Page 950 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

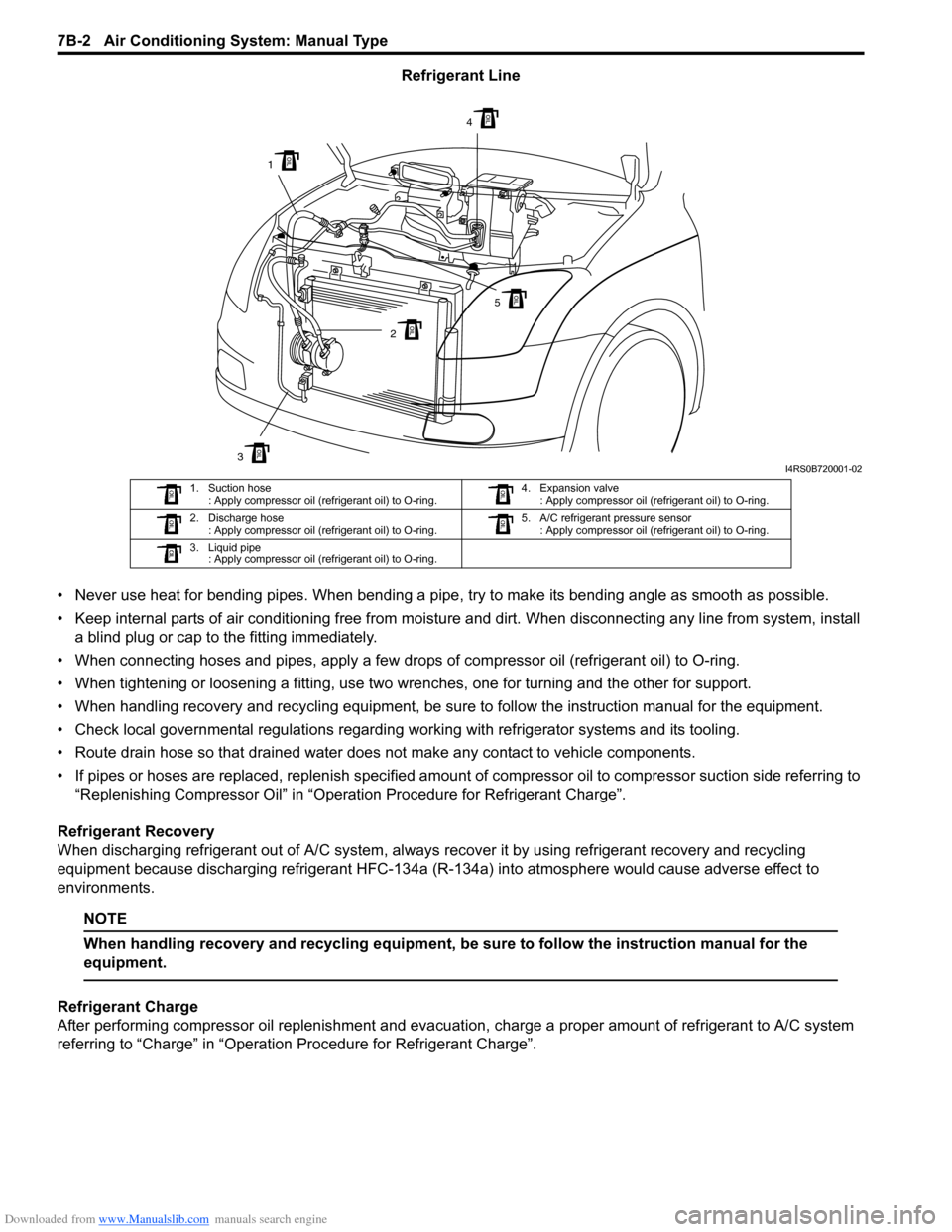

Refrigerant Line

• Never use heat for bending pipes. When bending a pipe , try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moistu re and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compre ssor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling equipment, be sure to follow the instruction manual for the

equipment.

Refrigerant Charge

After performing compressor oil replenishment and evacuat ion, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

3

1

2

4

5

I4RS0B720001-02

1. Suction hose : Apply compressor oil (refrigerant oil) to O-ring. 4. Expansion valve

: Apply compressor oil (refrigerant oil) to O-ring.

2. Discharge hose : Apply compressor oil (refrigerant oil) to O-ring. 5. A/C refrigerant pressure sensor

: Apply compressor oil (refrigerant oil) to O-ring.

3. Liquid pipe : Apply compressor oil (refrigerant oil) to O-ring.

Page 957 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

Abnormal Noise Symptom Diagnosis of A/C SystemS7RS0B7214002

Abnormal Noise from Compressor

Abnormal Noise from Magnetic Clutch

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft PulleyInsufficient airflow of

cooled air

A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutions Inadequate clearance in scroll area

Replace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolution Loose or faulty compressor drive belt

Adjust drive belt tension or replace drive belt.

Loose compressor mounting bolts Retighten mounting bolts.

A loud rattle is heard at

low engine rpm Loose compressor clutch plate bolt

Retighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operation Worn or damaged bearings

Replace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operation Faulty magnet clutch clearance

(excessive clearance)

Adjust magnet clutch clearance.

Worn magnet clutch friction surface Replace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surface Replace compressor body assembly.

Condition

Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartment Faulty tubing clamps

Reposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in re frigerant pressure Attach a silencer to tubing, or modify its

position and length.

Condition

Possible cause Correction / Reference Item

Considerable vibration in

condenser assembly Resonance from condenser assembly

bracket and body Firmly insert a silenc

er between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

acceleration Loosen crankshaft pulley bolt

Retighten bolt.

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

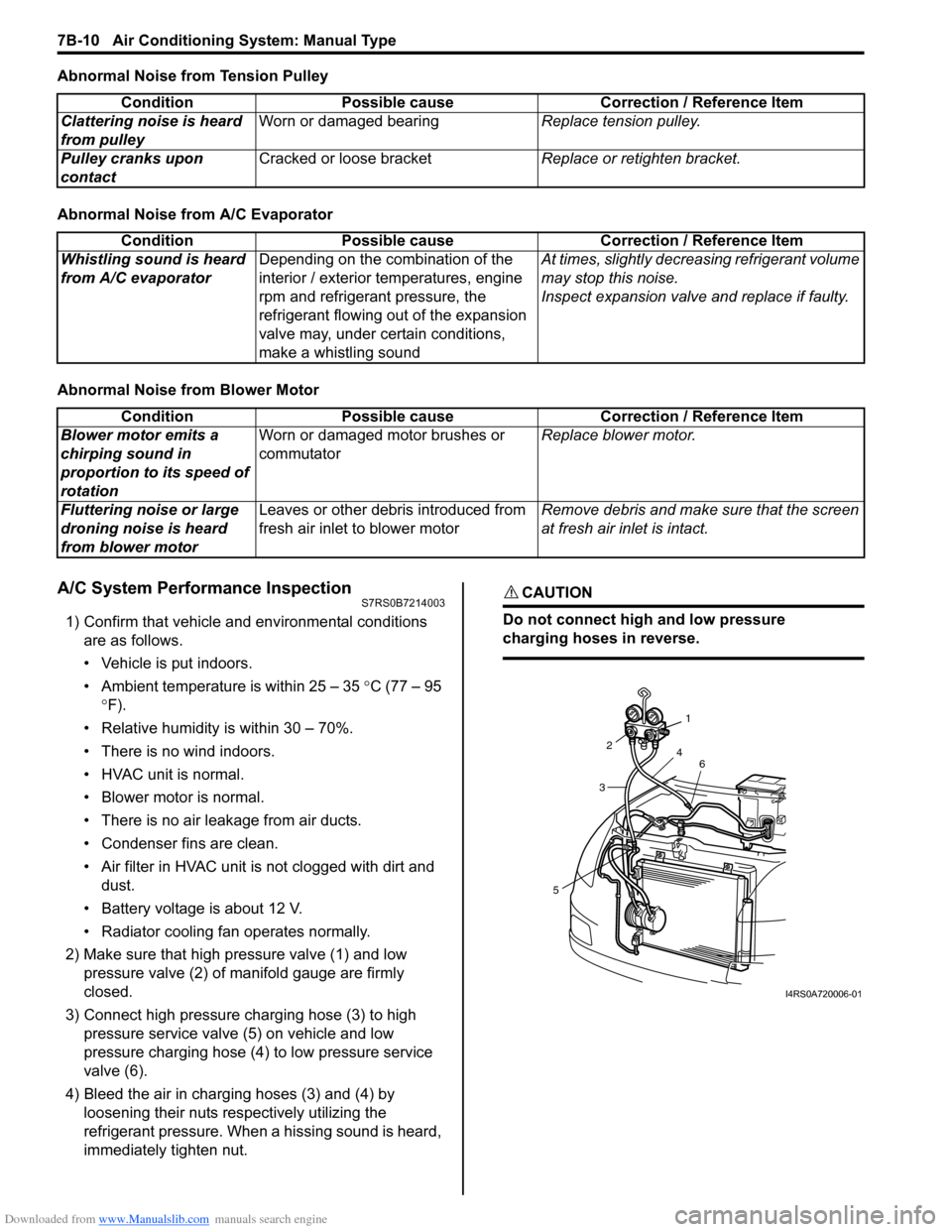

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 961 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-13

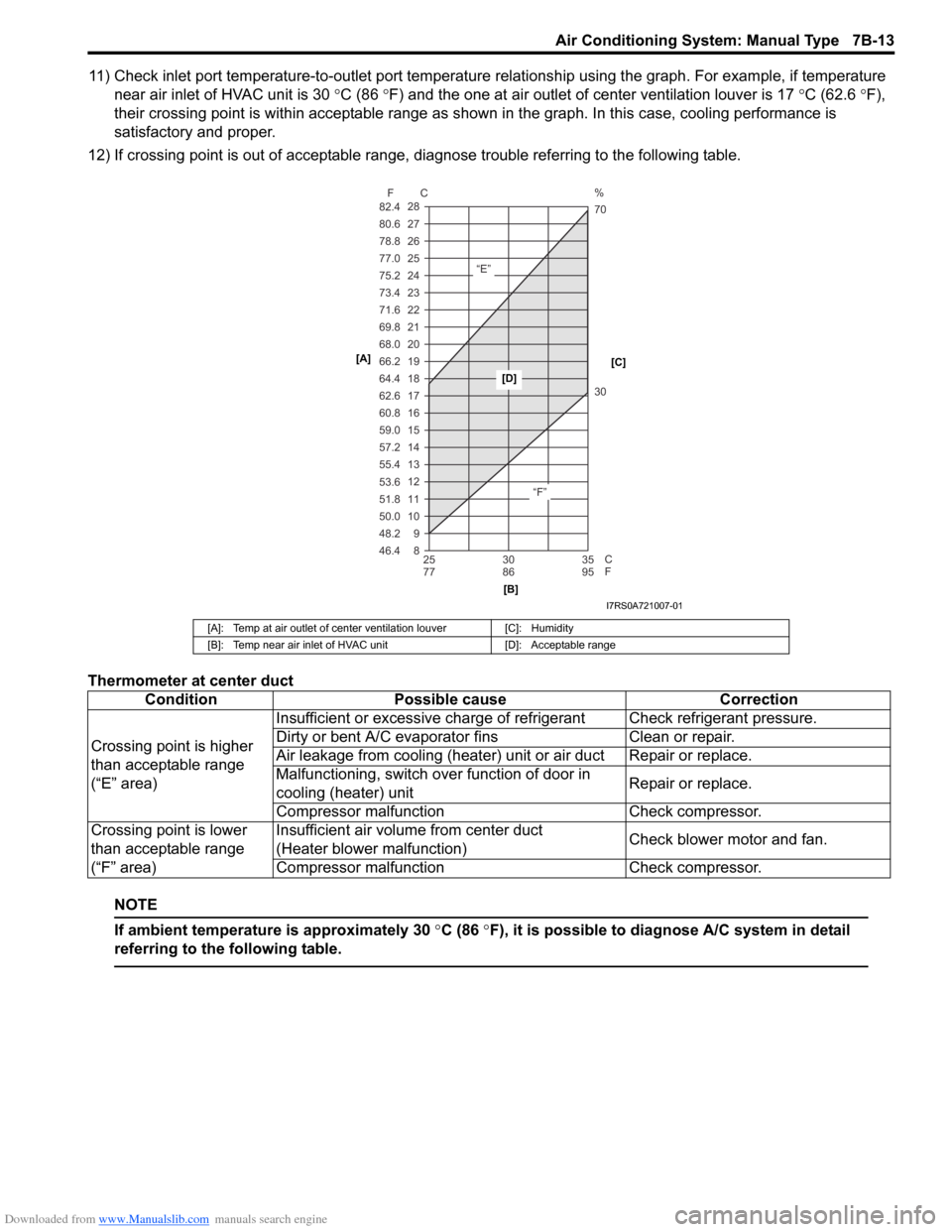

11) Check inlet port temperature-to-outlet port temperature relationship using the graph. For example, if temperature

near air inlet of HVAC unit is 30 °C (86 °F) and the one at air outlet of center ventilation louver is 17 °C (62.6 °F),

their crossing point is within acceptable range as shown in the graph. In this case, cooling performance is

satisfactory and proper.

12) If crossing point is out of acceptable range, diagnose trouble referring to the following table.

Thermometer at center duct

NOTE

If ambient temperature is approximately 30 °C (86 °F), it is possible to diagnose A/C system in detail

referring to the following table.

[A]: Temp at air outlet of center ventilation louver [C]: Humidity

[B]: Temp near air inlet of HVAC unit [D]: Acceptable range

ConditionPossible cause Correction

Crossing point is higher

than acceptable range

(“E” area) Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins

Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of door in

cooling (heater) unit Repair or replace.

Compressor malfunct ion Check compressor.

Crossing point is lower

than acceptable range

(“F” area) Insufficient air volume from center duct

(Heater blower malfunction)

Check blower motor and fan.

Compressor malfunct ion Check compressor.

8 9

10 11 12 13 14

15 16 17 18 19

20

21

22

23

24

25 26

27

28

46.4 48.2 50.0 51.8 53.6 55.4 57.2 59.0 60.8 62.6 64.4

66.2 68.0

69.8

71.6

73.4

75.2

77.0

78.8 80.6

82.4

25 30 35

77 86 95

F C

C

F

“E”

“F”30 70 %

[A]

[B][C]

[D]

I7RS0A721007-01