torque SUZUKI SWIFT 2006 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 363 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-11

Specifications

Tightening Torque SpecificationsS7RS0B1507001

NOTE

The specified tightening torque is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1508001

NOTE

Required service material is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Special ToolS7RS0B1508002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Oil pressure switch 13 1.3 9.5 �)

Heat exchanger stand bolt 22 2.2 16.0 �)

Oil pump strainer bolt 11 1.1 8.0 �)

Oil pump strainer bracket bolt 11 1.1 8.0 �)

Oil pan bolt (M6) 11 1.1 8.0 �)

Oil pan bolt (M10) 55 5.5 40.0 �)

Oil pan nut 11 1.1 8.0 �)

Oil pan drain plug 35 3.5 25.5 �)

Transaxle stiffener bolt 55 5.5 40.0 �)

Oil pump rotor plate bolt 11 1.1 8.0 �)

MaterialSUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

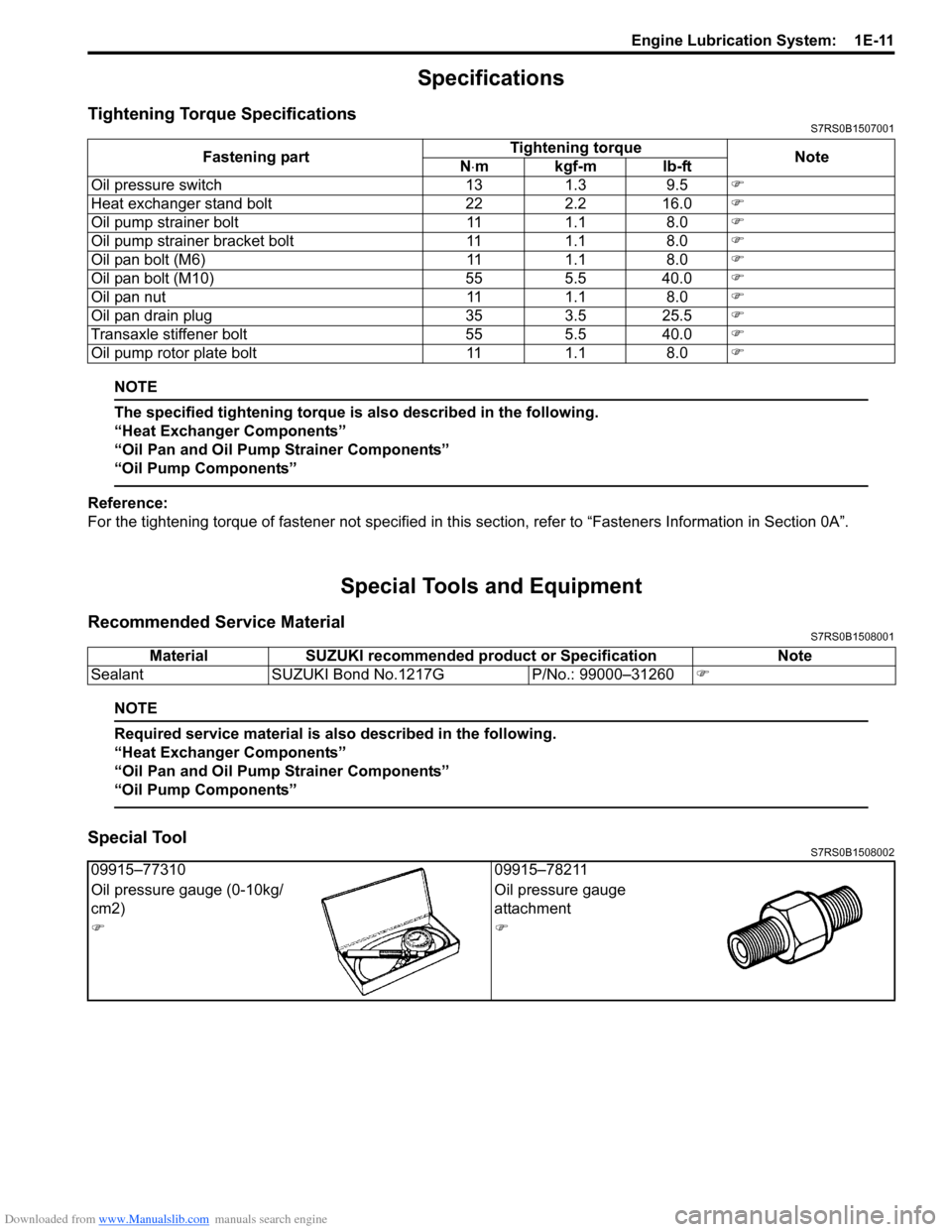

09915–77310 09915–78211

Oil pressure gauge (0-10kg/

cm2) Oil pressure gauge

attachment

�)�)

Page 374 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Water Pump Removal and InstallationS7RS0B1606014

Removal1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

4) Remove water pump assembly (1).

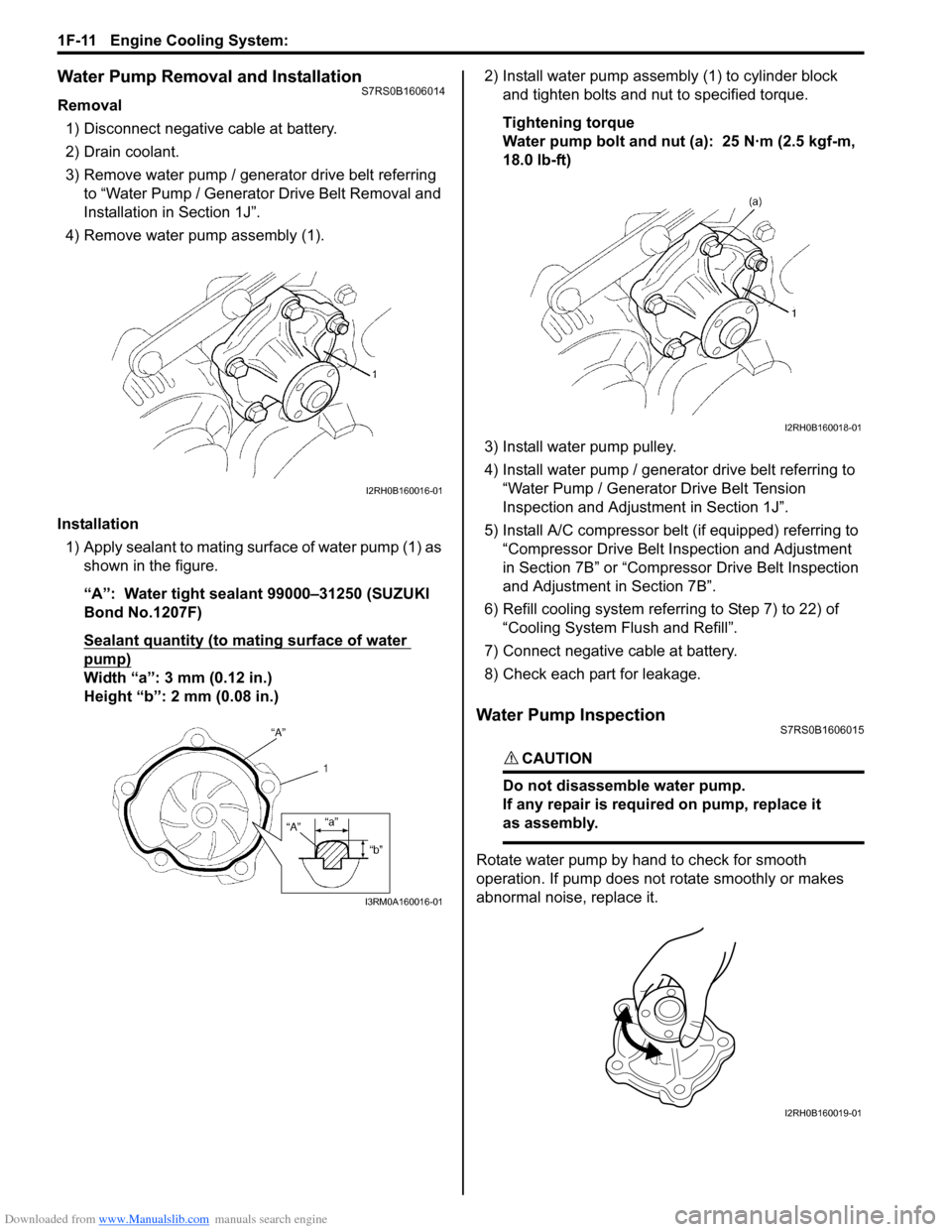

Installation 1) Apply sealant to mating surface of water pump (1) as shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.) 2) Install water pump assemb

ly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

5) Install A/C compressor belt (if equipped) referring to “Compressor Drive Belt Inspection and Adjustment

in Section 7B” or “Compressor Drive Belt Inspection

and Adjustment in Section 7B”.

6) Refill cooling system referri ng to Step 7) to 22) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

Water Pump InspectionS7RS0B1606015

CAUTION!

Do not disassemble water pump.

If any repair is requir ed on pump, replace it

as assembly.

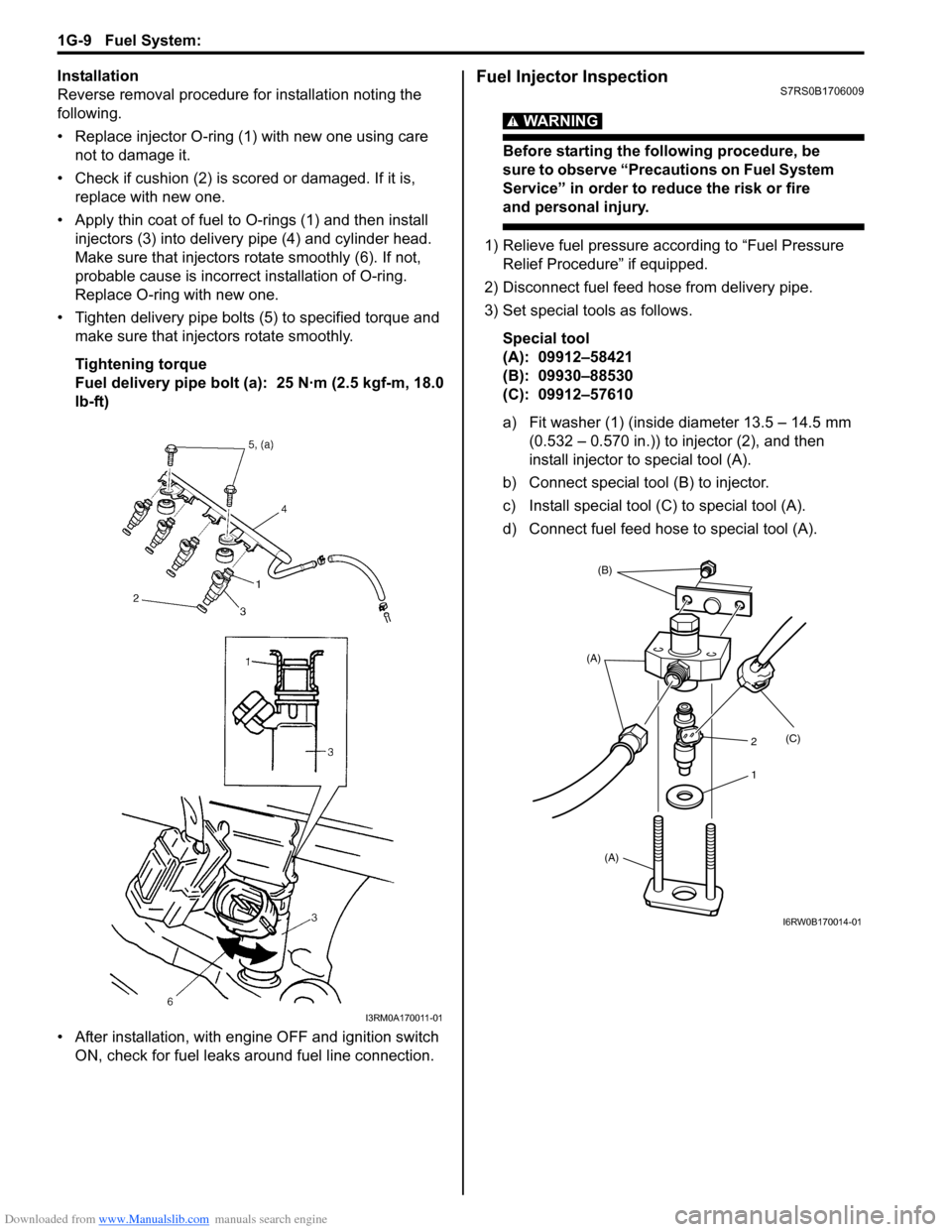

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

I2RH0B160019-01

Page 375 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-12

Specifications

Tightening Torque SpecificationsS7RS0B1607001

NOTE

The specified tightening torque is also described in the following.

“Cooling System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1608001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Water pump bolt and nut 25 2.5 18.0 �)

MaterialSUZUKI recommended product or Specification Note

Water tight sealant SUZUKI Bond No.1207F P/No.: 99000–31250�)

Page 384 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-9 Fuel System:

Installation

Reverse removal procedure for installation noting the

following.

• Replace injector O-ring (1) with new one using care not to damage it.

• Check if cushion (2) is scor ed or damaged. If it is,

replace with new one.

• Apply thin coat of fuel to O-rings (1) and then install injectors (3) into delivery pipe (4) and cylinder head.

Make sure that injectors rota te smoothly (6). If not,

probable cause is incorrect installation of O-ring.

Replace O-ring with new one.

• Tighten delivery pipe bolts (5) to specified torque and make sure that inject ors rotate smoothly.

Tightening torque

Fuel delivery pipe bolt (a): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

• After installation, with engine OFF and ignition switch ON, check for fuel leaks around fuel line connection.Fuel Injector InspectionS7RS0B1706009

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

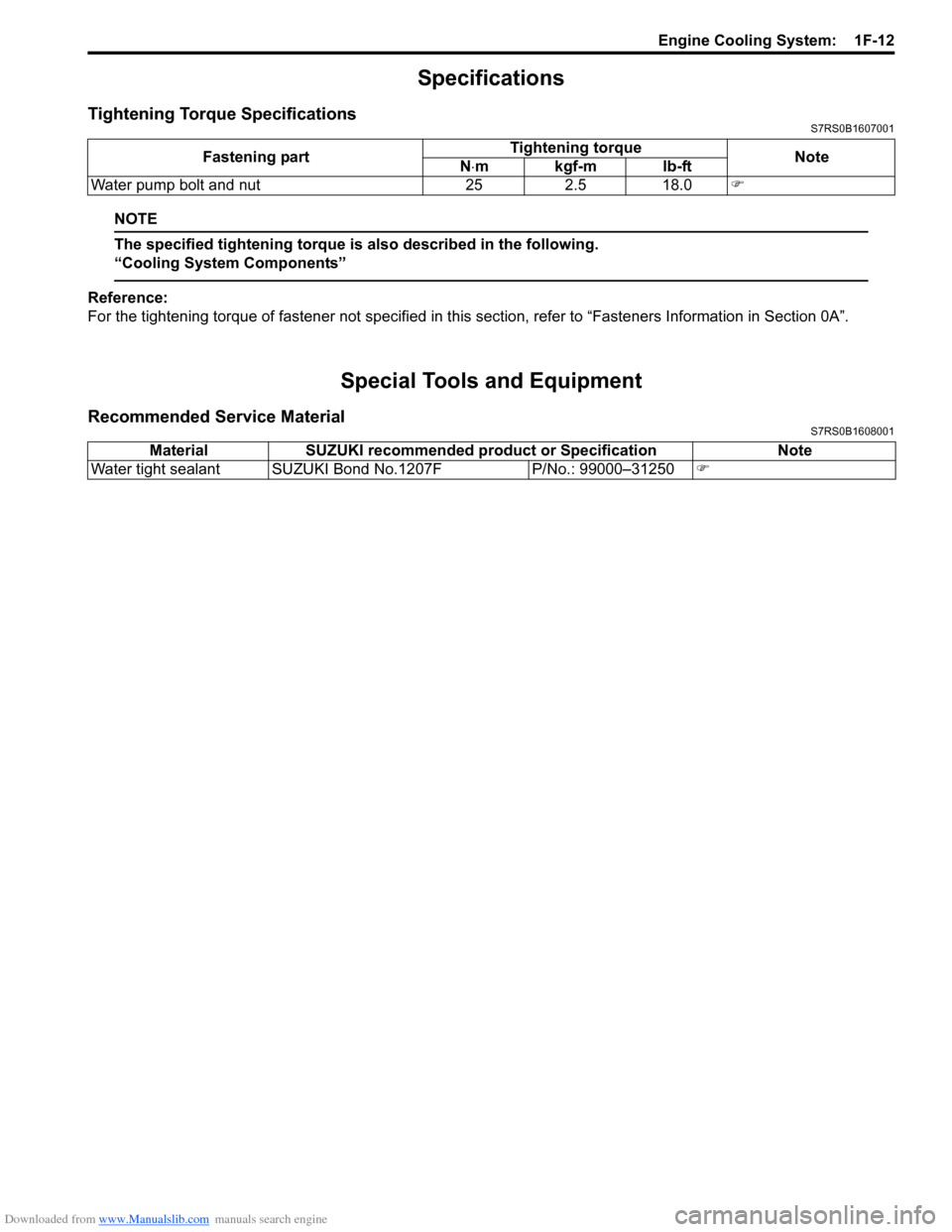

1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure” if equipped.

2) Disconnect fuel feed hose from delivery pipe.

3) Set special tools as follows.

Special tool

(A): 09912–58421

(B): 09930–88530

(C): 09912–57610

a) Fit washer (1) (inside diameter 13.5 – 14.5 mm (0.532 – 0.570 in.)) to injector (2), and then

install injector to special tool (A).

b) Connect special tool (B) to injector.

c) Install special tool (C) to special tool (A).

d) Connect fuel feed hose to special tool (A).

I3RM0A170011-01

(B)

(A)

(A) (C)

2

1

I6RW0B170014-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

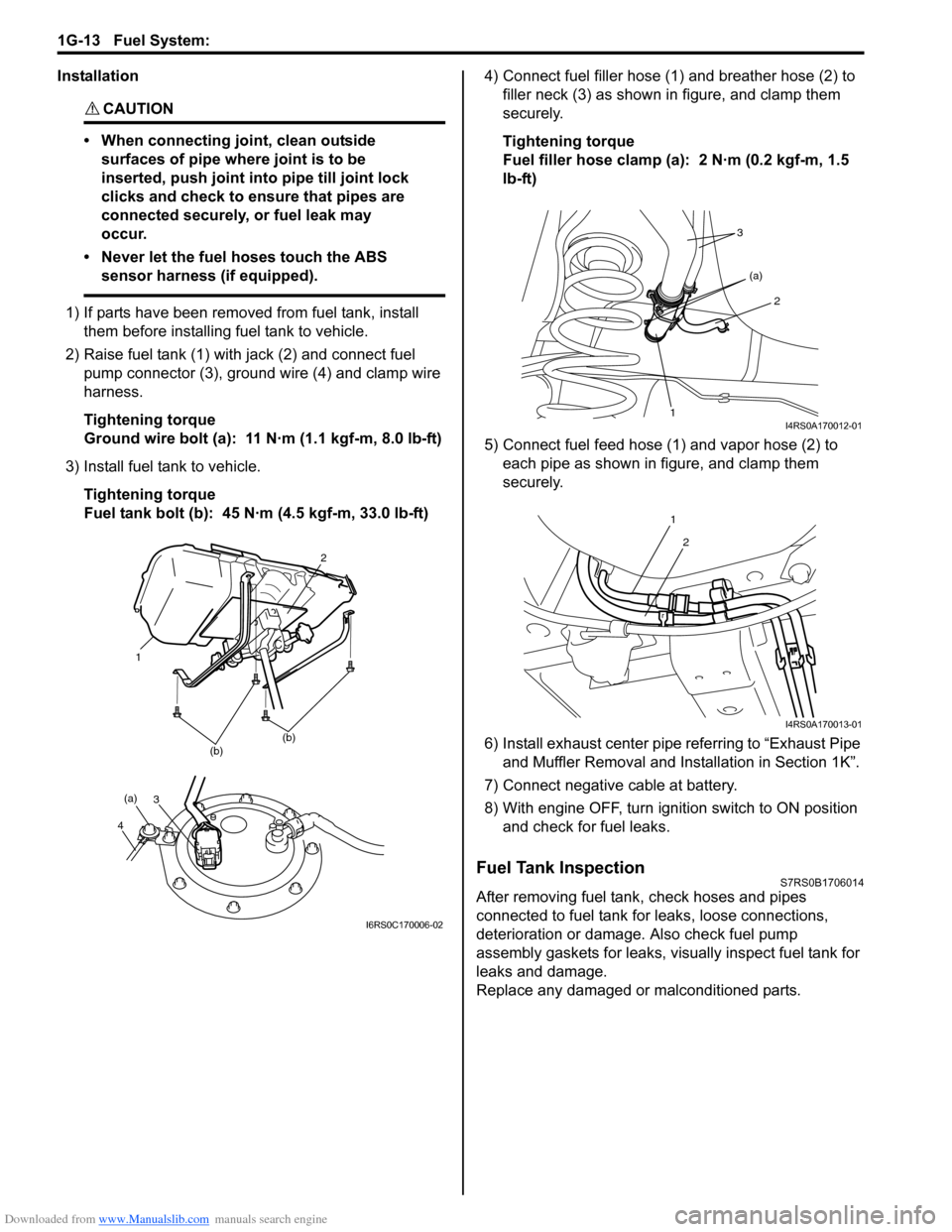

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

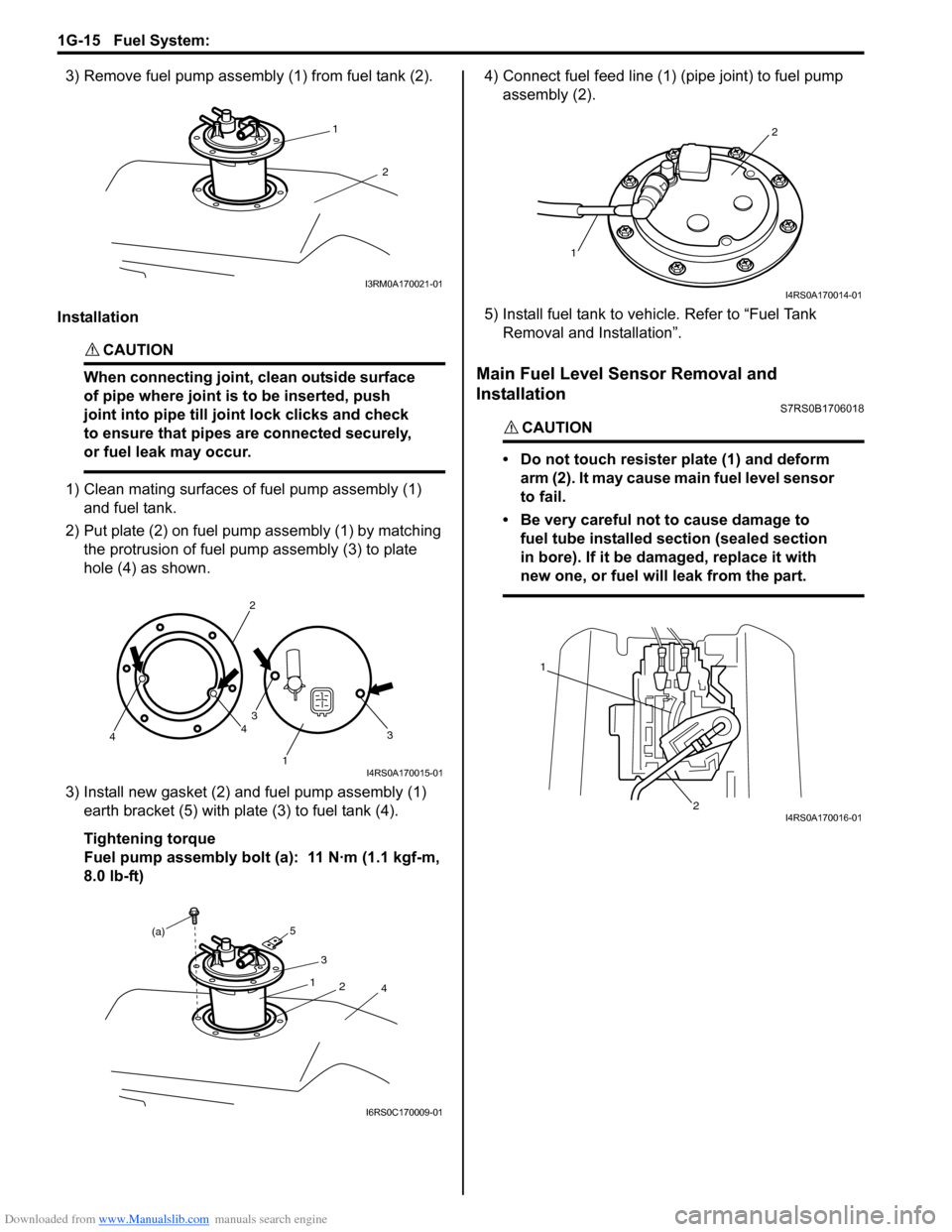

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 391 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

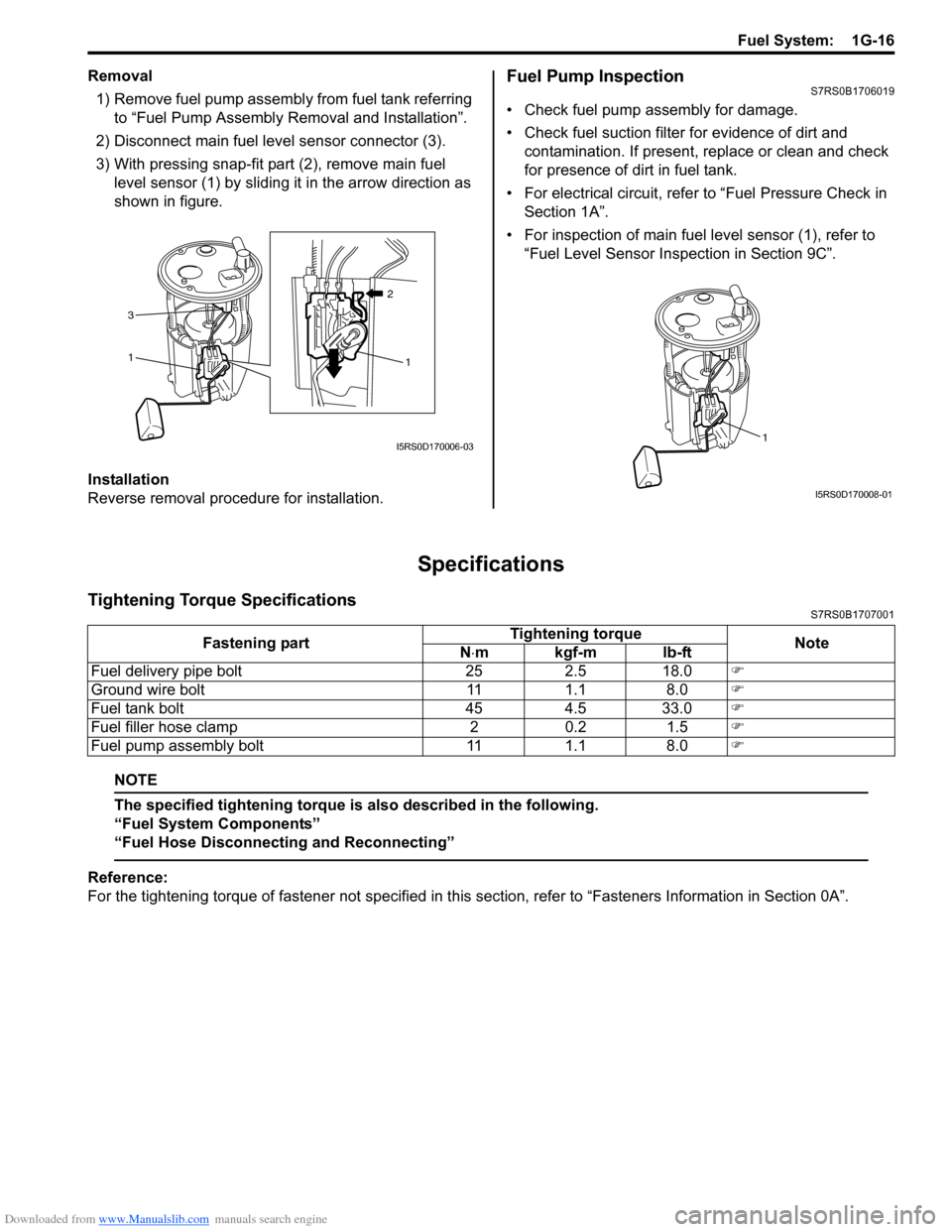

Removal1) Remove fuel pump assembly from fuel tank referring to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.Fuel Pump InspectionS7RS0B1706019

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and contamination. If present, replace or clean and check

for presence of dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in Section 1A”.

• For inspection of main fuel level sensor (1), refer to “Fuel Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS7RS0B1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

21

3

I5RS0D170006-031

I5RS0D170008-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0 �)

Ground wire bolt 11 1.1 8.0 �)

Fuel tank bolt 45 4.5 33.0 �)

Fuel filler hose clamp 2 0.2 1.5 �)

Fuel pump assembly bolt 11 1.1 8.0 �)

Page 399 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-7

High-Tension Cord InspectionS7RS0B1806002

Measure resistance of high-tension cord (1) by using

ohmmeter.

If resistance exceeds specification, replace high-tension

cord(s).

High-tension cord resistance

No.1 cylinder high-tension cord resistance: 1.4 – 4.0

k Ω

No.3 cylinder high-tension cord resistance: 0.6 – 2.0

k Ω

Spark Plug Removal and InstallationS7RS0B1806003

Removal

1) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

2) Pull out high-tension cords by gripping their caps and then remove ignition coil assemblies referring to

“Ignition Coil Assembly (Inc luding ignitor) Removal

and Installation”.

3) Remove spark plugs.

Installation 1) Install spark plugs and tighten them to specified torque.

Tightening torque

Spark plug: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Install ignition coil assemblies referring to “Ignition Coil Assembly (Including ignitor) Removal and

Installation”.

3) Install high-tension cords securely by gripping their caps.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

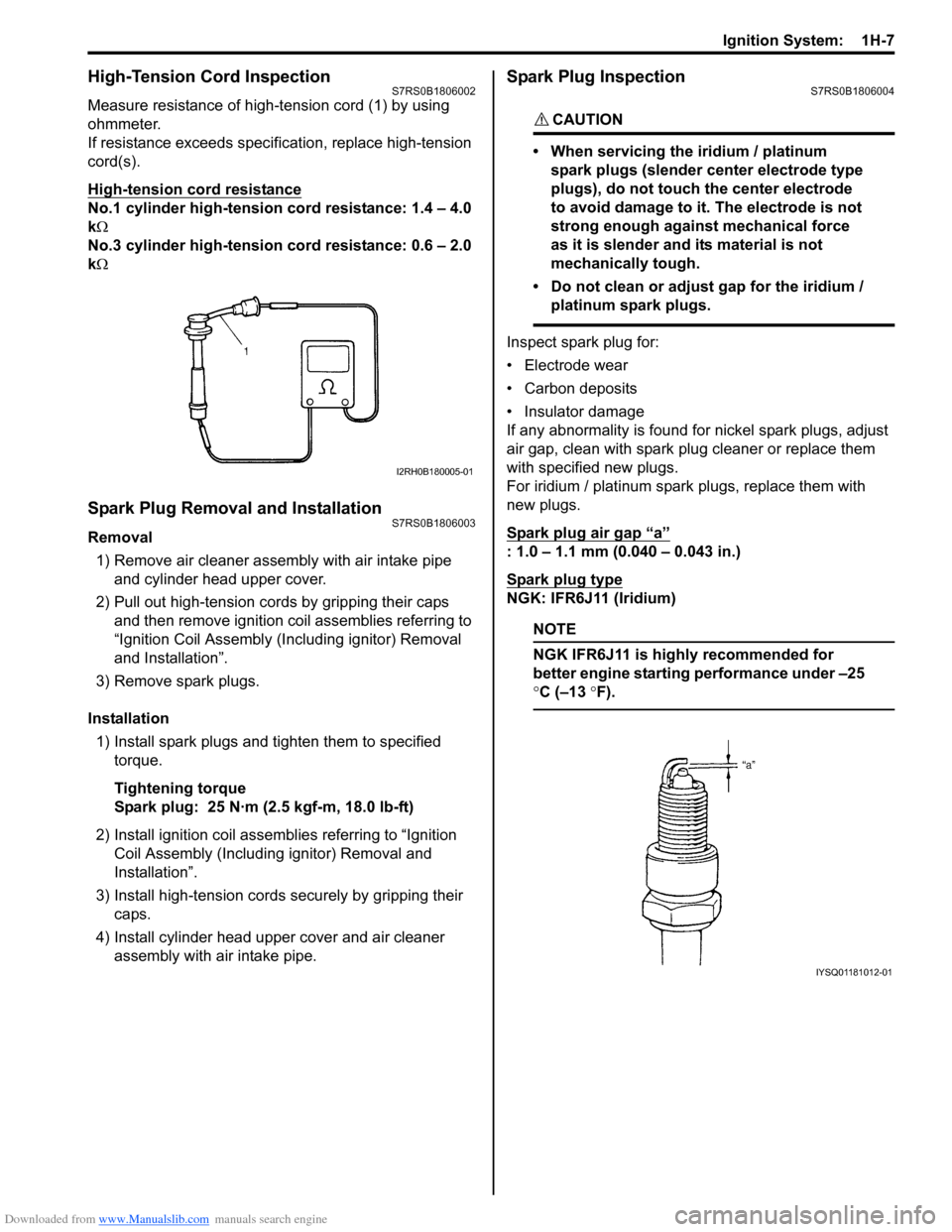

Spark Plug InspectionS7RS0B1806004

CAUTION!

• When servicing the iridium / platinum

spark plugs (slender center electrode type

plugs), do not touch the center electrode

to avoid damage to it. The electrode is not

strong enough against mechanical force

as it is slender and its material is not

mechanically tough.

• Do not clean or adjust gap for the iridium / platinum spark plugs.

Inspect spark plug for:

• Electrode wear

• Carbon deposits

• Insulator damage

If any abnormality is found for nickel spark plugs, adjust

air gap, clean with spark plug cleaner or replace them

with specified new plugs.

For iridium / platinum spark plugs, replace them with

new plugs.

Spark plug air gap

“a”

: 1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK: IFR6J11 (Iridium)

NOTE

NGK IFR6J11 is highly recommended for

better engine starting performance under –25

°C (–13 °F).

I2RH0B180005-01

IYSQ01181012-01

Page 400 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-8 Ignition System:

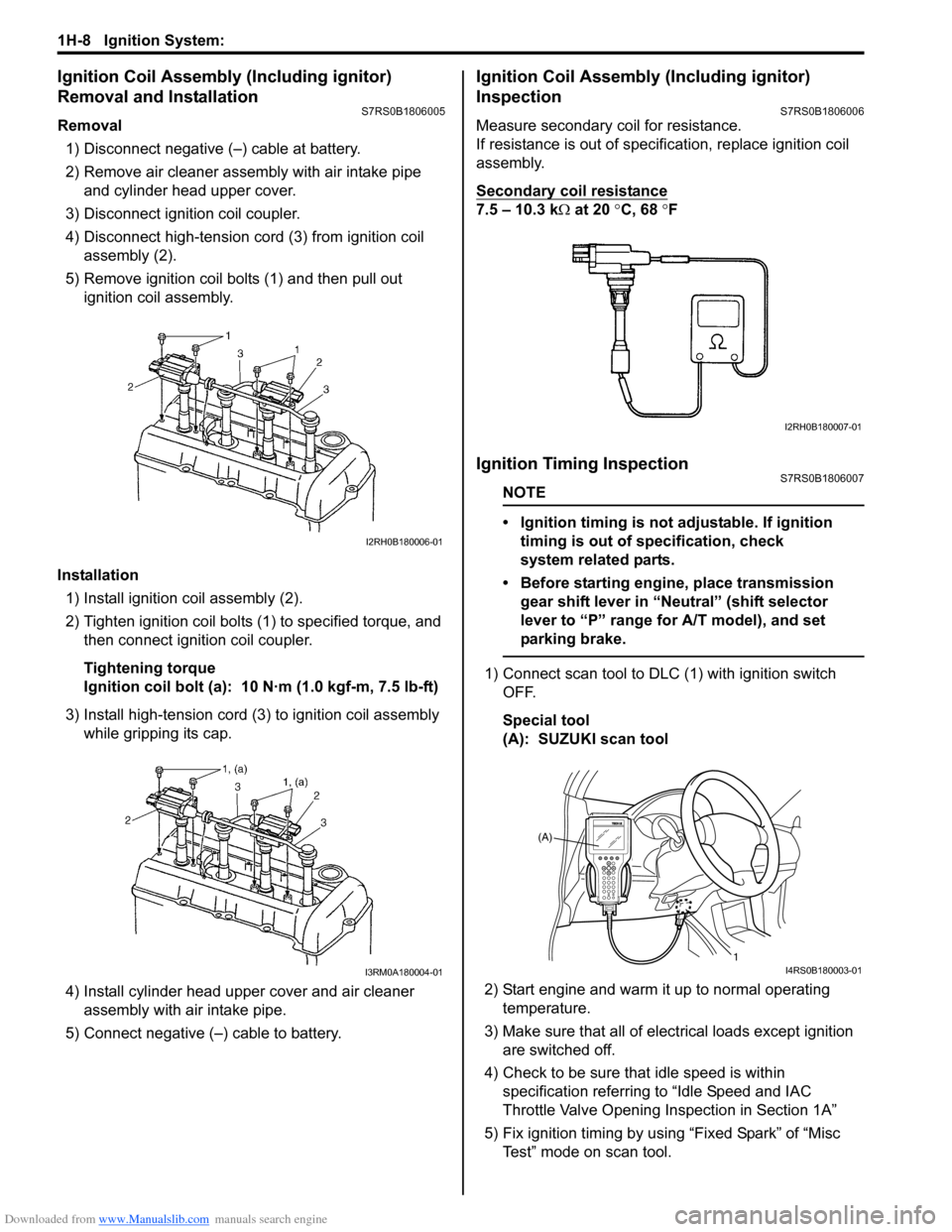

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S7RS0B1806005

Removal1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly (2).

5) Remove ignition coil bolts (1) and then pull out ignition coil assembly.

Installation 1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and then connect igni tion coil coupler.

Tightening torque

Ignition coil bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly while gripping its cap.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

5) Connect negative (–) cable to battery.

Ignition Coil Assembly (Including ignitor)

Inspection

S7RS0B1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.5 – 10.3 k Ω at 20 °C, 68 ° F

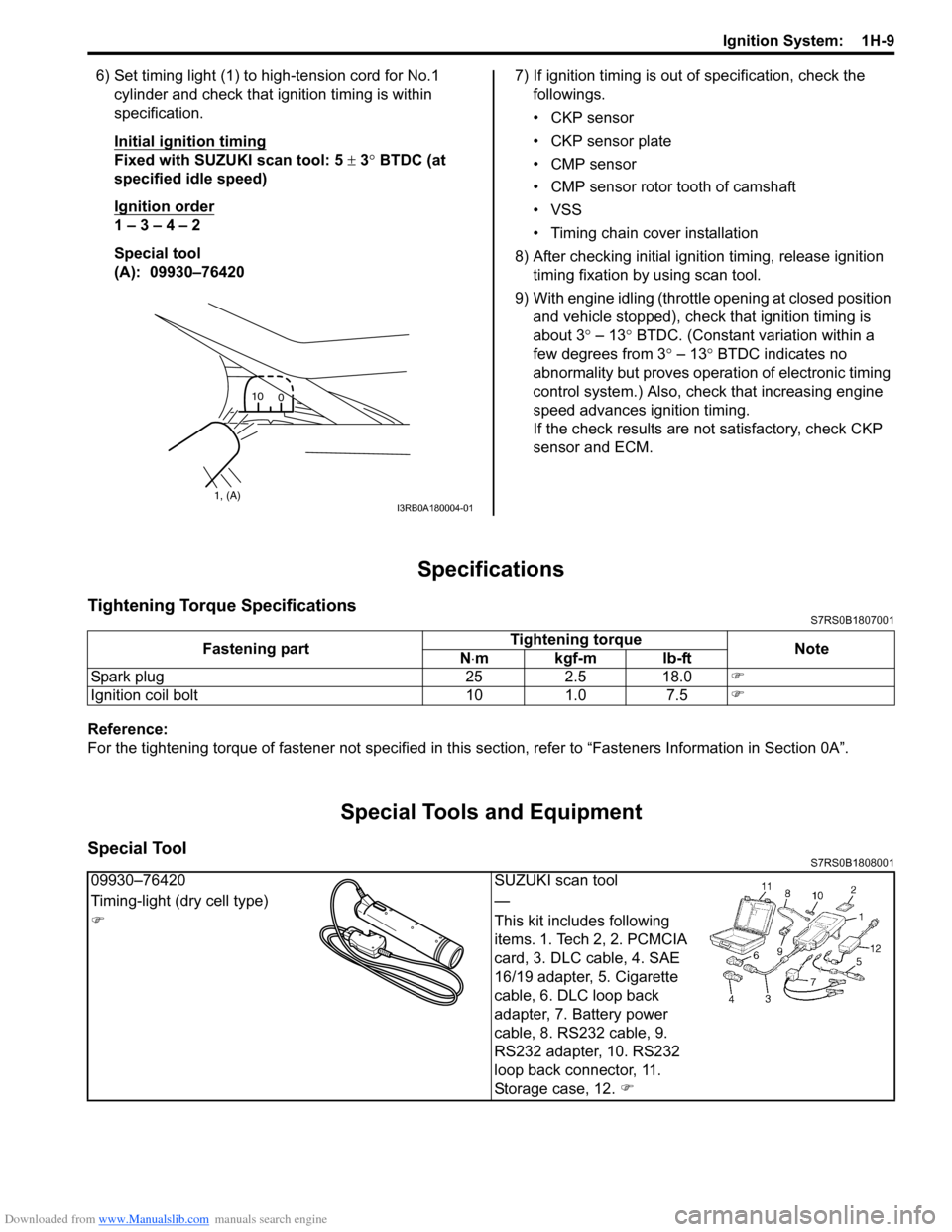

Ignition Timing InspectionS7RS0B1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating temperature.

3) Make sure that all of electrical loads except ignition are switched off.

4) Check to be sure that idle speed is within specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”

5) Fix ignition timing by using “Fixed Spark” of “Misc Test” mode on scan tool.

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A)

1

I4RS0B180003-01

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)