air SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1364 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-2 Seats:

Front Seat Removal and InstallationS7RS0B9706002

WARNING!

Refer to “Air Bag Warning in Section 00” before starting service work.

Removal1) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

2) Disconnect couplers for seat harness and side air bag, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat if necessary.

Installation

Reverse removal procedure to install front seat.

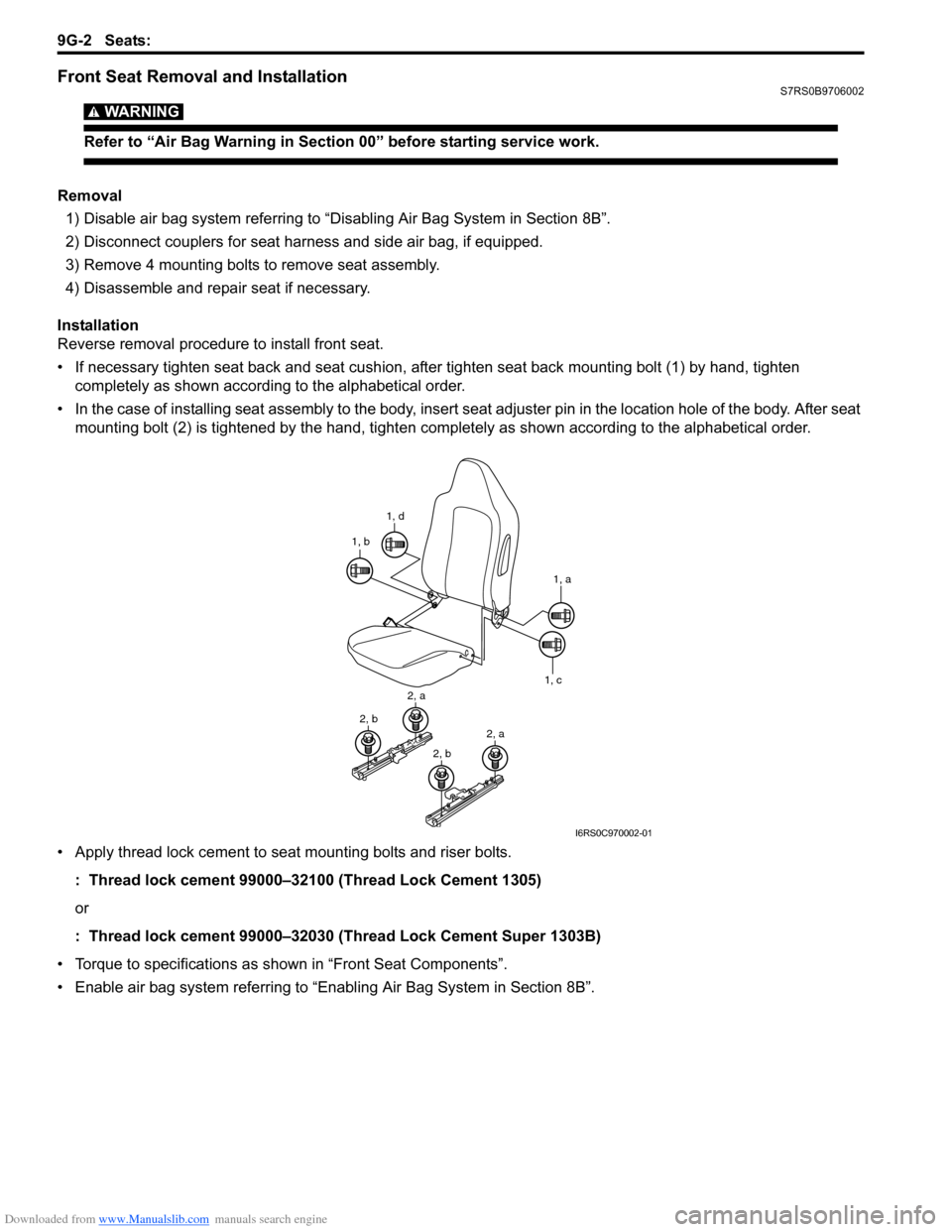

• If necessary tighten seat back and seat cushion, after tighten seat back mounting bolt (1) by hand, tighten completely as shown according to the alphabetical order.

• In the case of installing seat assembly to the body, insert se at adjuster pin in the location hole of the body. After seat

mounting bolt (2) is tightened by t he hand, tighten completely as shown according to the alphabetical order.

• Apply thread lock cement to seat mounting bolts and riser bolts. : Thread lock cement 99000–32100 (Thread Lock Cement 1305)

or

: Thread lock cement 99000–32030 (Thread Lock Cement Super 1303B)

• Torque to specifications as shown in “Front Seat Components”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

1, d

1, b

1, a

1, c

2, a

2, b2, a

2, b

I6RS0C970002-01

Page 1366 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-4 Seats:

Rear Seat Removal and InstallationS7RS0B9706004

Removal1) Fold rear seat back forward.

2) Remove seat mounting bolts and nuts to remove seat assembly.

3) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install rear seat.

• Tighten seat back striker mounting bolts according to “Rear Seat Components”.

• Torque to specifications in “Rear Seat Components”.

• When installing seat cushion, align seat cushion hook with center hinge bracket.

Specifications

Tightening Torque SpecificationsS7RS0B9707001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Components”

“Rear Seat Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9708001

NOTE

Required service material is also described in the following.

“Front Seat Components”

Material SUZUKI recommended product or Specification Note

Thread lock cement Thread Lock Cement Super 1303B P/No.: 99000–32030 �)

Thread Lock Cement 1305 P/No.: 99000–32100 �)

Page 1367 of 1496

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-1

Body, Cab and Accessories

Interior Trim

Repair Instructions

Floor Carpet Removal and InstallationS7RS0B9806001

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal1) Remove front seats and rear seats referring to “Front Seat Removal and Installa tion in Section 9G” and

“Rear Seat Removal and Installation in Section 9G”.

2) Remove seat belt lower anchor bolt.

3) Remove dash side trims, fr ont side sill scuffs, center

pillar inner lower trims, qu arter inner front trims and

rear side sill scuffs.

4) Remove console box.

5) Remove floor carpet.

Installation

Reverse removal sequence to install floor carpet, noting

the following instruction.

• For tightening torque of rear seat mounting bolt, refer to “Rear Seat Components in Section 9G”.

• For tightening torque of front seat mounting bolt, refer to “Front Seat Components in Section 9G”.

Head Lining Removal and InstallationS7RS0B9806002

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

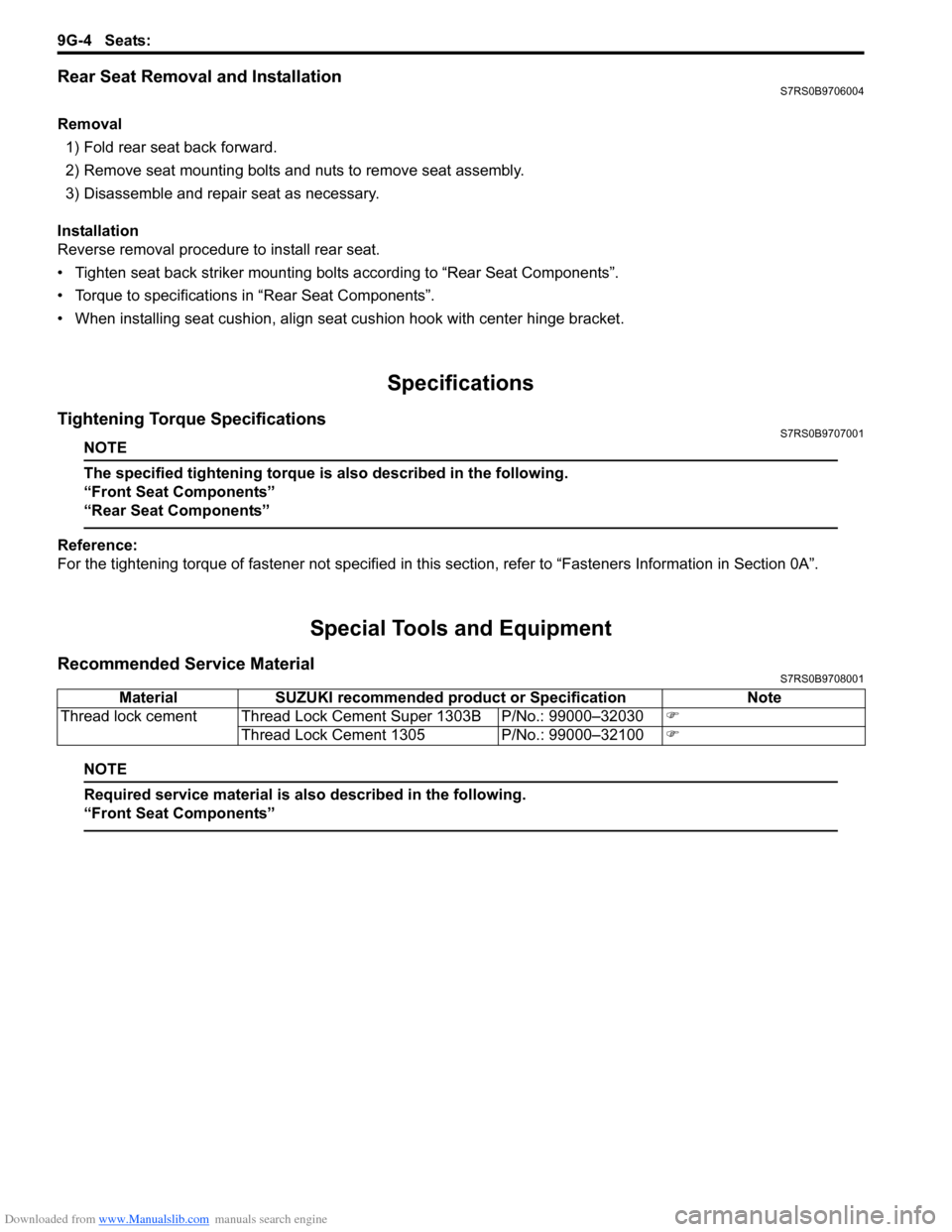

1) Remove sun visor (1), room mirror (2), dome light (3), assistant grip (4) and head lining clips (5). 2) Remove front pillar trim (1

), front side sill scuff (2)

and dash side trim (3).

3) Remove front seat belt u pper anchor (1), center pillar

inner trim (2), center pillar inner upper trim (3) and

rear side sill scuff (4).

4) Remove tail end member trim (1).

I6RS0C980001-02

[A]: With curtain air bag 4. Forward

[B]: Without curtain air bag

“A”“A”

“A”

2

4

1

3

“A”

“A”

1

[B]

[A]

“B”“B”

“C”“C”

I6RS0C980002-01

“A”

“B”

“A”

“B”

1

3

2

4

I4RS0A980002-01

“A”

“A”

“A”

“A”“A”1

I4RS0A980003-01

Page 1370 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-1 Hood / Fenders / Doors:

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

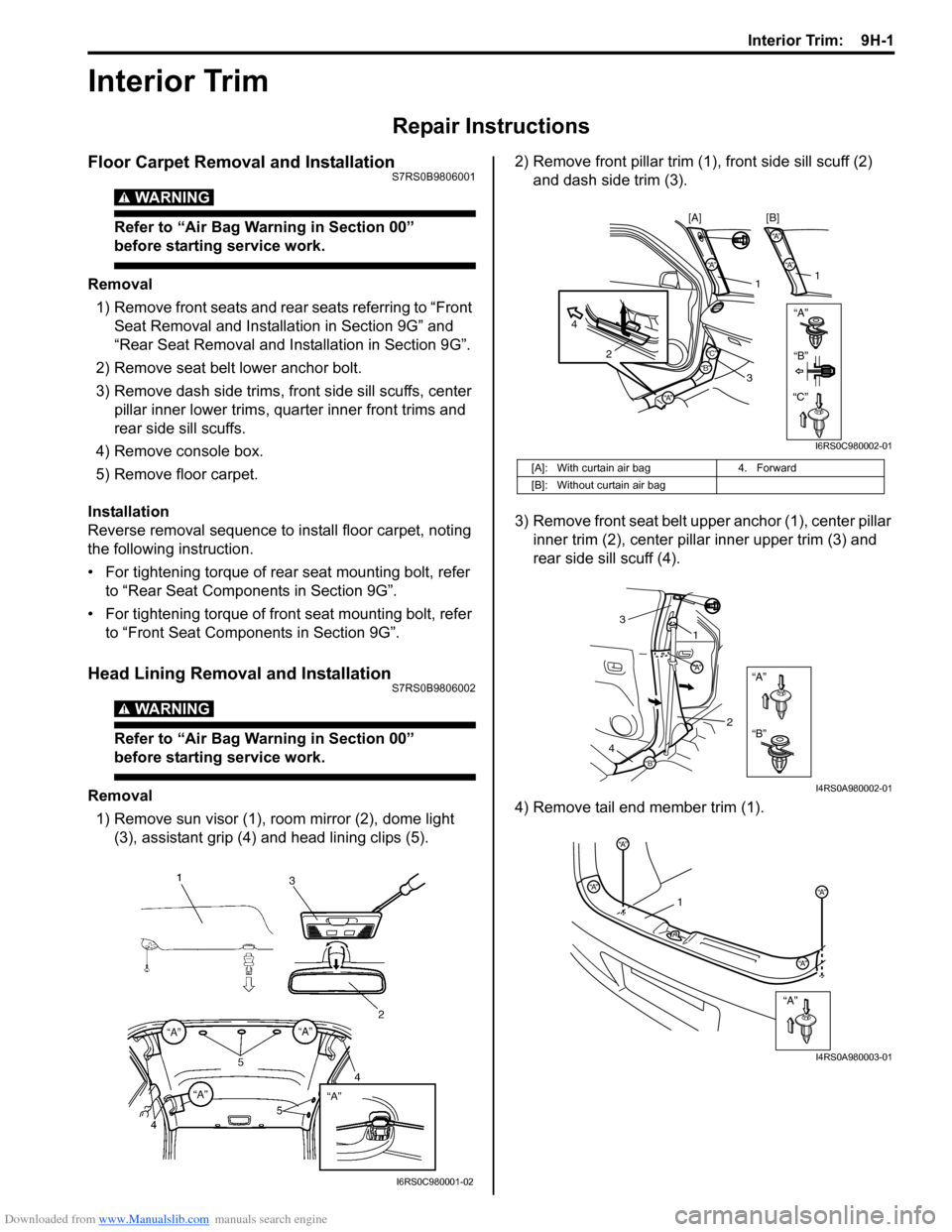

Hood Removal and InstallationS7RS0B9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge. Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to “Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS7RS0B9A06002

Inspection

• Check that hood opens and closes smoothly and properly. Lubricate if necessary.

• Check that hood stops in the secondary latched position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.

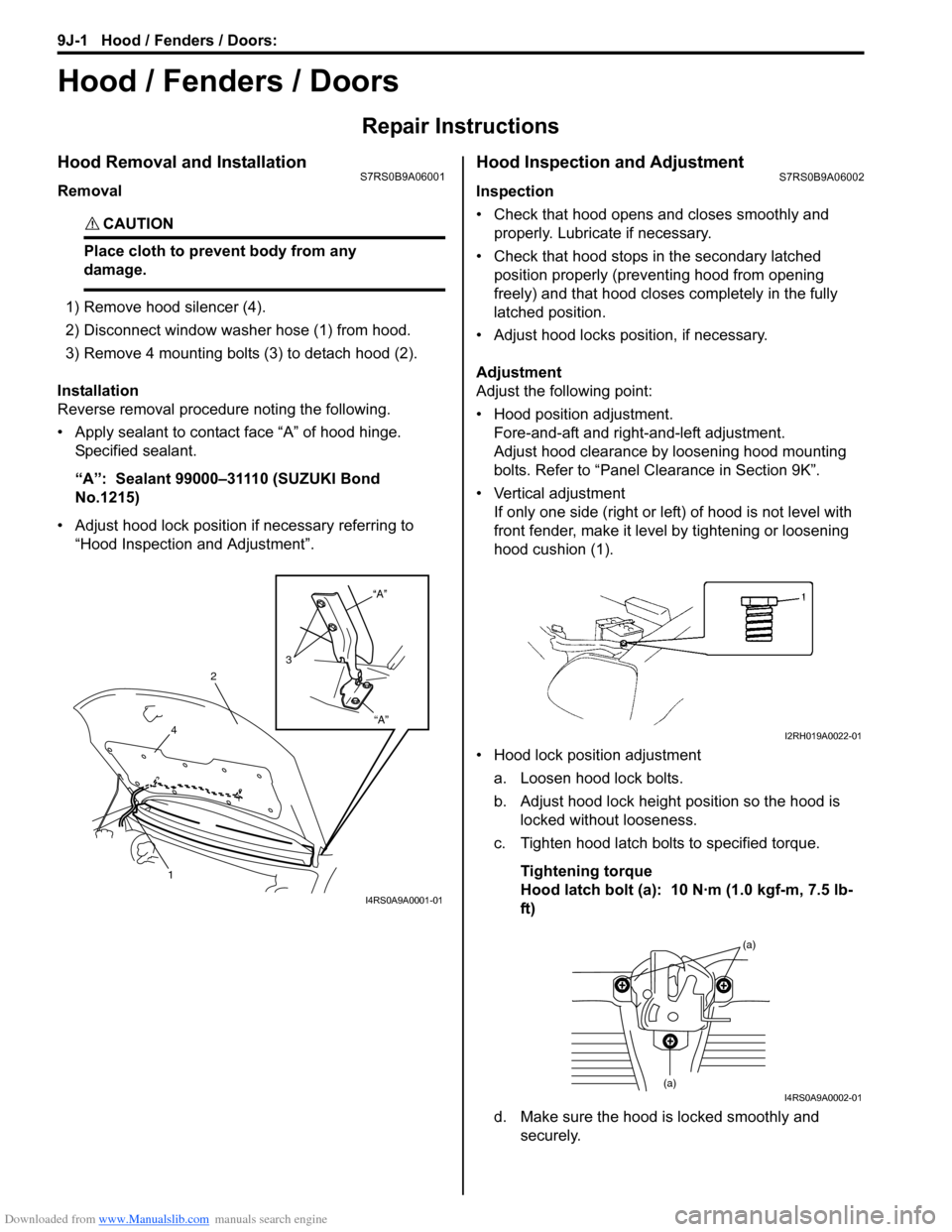

Adjustment

Adjust the following point:

• Hood position adjustment. Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and securely.

“A”

“A”

3

2

4

1

I4RS0A9A0001-01

I2RH019A0022-01

(a)

(a)I4RS0A9A0002-01

Page 1378 of 1496

Downloaded from www.Manualslib.com manuals search engine 9K-1 Body Structure:

Body, Cab and Accessories

Body Structure

Repair Instructions

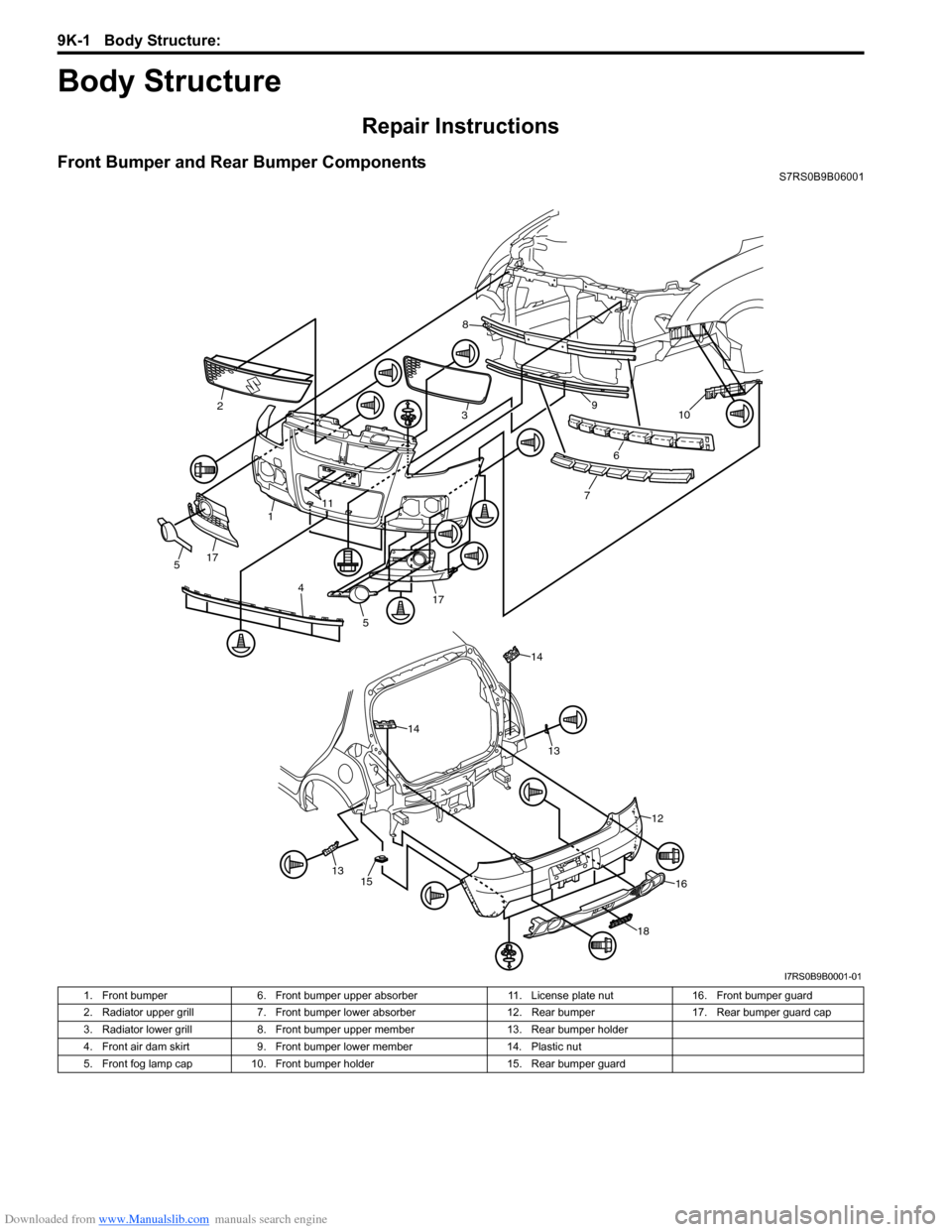

Front Bumper and Rear Bumper ComponentsS7RS0B9B06001

10

6

79

8

32

1

5

4 1117

175

1315

14

12

16

18

14

13

I7RS0B9B0001-01

1. Front bumper

6. Front bumper upper absorber 11. License plate nut16. Front bumper guard

2. Radiator upper grill 7. Front bumper lower absorber 12. Rear bumper17. Rear bumper guard cap

3. Radiator lower grill 8. Front bumper upper member 13. Rear bumper holder

4. Front air dam skirt 9. Front bumper lower member 14. Plastic nut

5. Front fog lamp cap 10. Front bumper holder 15. Rear bumper guard

Page 1382 of 1496

Downloaded from www.Manualslib.com manuals search engine 9K-5 Body Structure:

Side Body

Hole to hole distance

Hole to hole distance

I4RS0A9B0005-02

a (a’). Jig hole (φ 8 mm) e (e’). Rear door lower hinge installation rear hole i (i’). Jig hole ( φ 10 mm)

b (b’). Front door upper hinge installation upper hole f (f’). Rear door upper hinge installation upper hole j (j’). Rear door switc h installation hole (large hole)

c (c’). Front door lower hinge installation lower hole g (g’). Jig hole ( φ 10 mm) k (k’). Rear side sill scuff installation hole

d (d’). Bleeding hole h (h’). Curtain air bag clip installation hole

a-d: 1055 mm (41.54 in.) c-e: 1021 mm (40.20 in.) f-j: 835 mm (32.87 in.) a-f: 747 mm (29.41 in.) c-f: 1123 mm (44.21 in.) h-i: 601 mm (23.66 in.)

a-g: 378 mm (14.88 in.) d-g: 1129 mm (44.45 in.) h-j: 817 mm (32.17 in.)

b-c: 383 mm (15.08 in.) e-f: 354 mm (13.94 in.) h-k: 1097 mm (43.19 in.)

b-e: 1085 mm (42.72 in.) e-j: 946 mm (37.24 in.) i-k: 1153 mm (45.39 in.) b-f: 1061 mm (41.77 in.) f-i: 926 mm (36.46 in.)

a-a’: 1039 mm (40.91 in.) e-e’: 1474 mm (58.03 in.) i-i’: 1009 mm (39.72 in.)

b-b’: 1461 mm (57.52 in.) f-f’: 1468 mm (57.80 in.) j-j’: 1327 mm (52.24 in.) c-c’: 1489 mm (58.62 in.) g-g’: 1018 mm (40.08 in.) k-k’: 1472 mm (57.95 in.)

d-d’: 1472 mm (57.95 in.) h-h’: 1022 mm (40.24 in.)

Page 1388 of 1496

Downloaded from www.Manualslib.com manuals search engine 9L-1 Paint / Coatings:

Body, Cab and Accessories

Paint / Coatings

General Description

Anti-Corrosion Treatment ConstructionS7RS0B9C01001

WARNING!

Standard shop practices, particularly eye protection, should be followed during the performance of the

following operations to avoid personal injury.

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials ar e called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as described

blow.

• Steel sheets are treated with cathodic electro primer which is excellent in corrosion resistance.

• Rust proof wax coatings are applied to door and side sill insides where mois ture is liable to stay.

• Vinyl coating is applied to body underside and wheel housing inside.

• Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to prevent water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation which

does disturb the rust proof treatment will cause corrosion to th at area. Therefore, it is the essential function of any

repair operation to correctly recoat t he related surfaces of the relevant area.

All the metal panels are coated with metal conditioners an d primer coating during vehicle production. Following the

repair and/or replacement parts installation, every access ible bare metal surface should be cleaned and coated with

rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the spec ific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anti corrosion barrier. The sealer is applied to the door and hood hem areas

and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching joints of a new

replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible characteristics

and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conf ormance with the place and purpose of a

specific use. Observe the ma nufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques specified

for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides) where it

is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof wax, it may be the

penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body drain

holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body components.

5) Apply anti corrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).

Page 1389 of 1496

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-2

Plastic Parts FinishingS7RS0B9C01002

Paintable plastic parts are ABS plastic parts.

Painting

Rigid or hand ABS plastic needs no primer coating.

General acrylic lacquers can be painted properly over hard ABS plastic in terms of adherence.

1) Use cleaning solvent for paint finish to wash each part.

2) Apply conventional acrylic color lacquer to part surface.

3) Follow lacquer directions for required drying time. (Proper drying temperature range is 60 – 70 °C (140 – 158 ° F)).

Reference

Plastic parts employ not only ABS (Acrylonitrile Butadiene Styrene) plastic but also polypro pylene, vinyl, or the like

plastic. Burning test method to iden tify ABS plastic is described below.

1) Use a sharp blade to cut off a plastic sliver from the part at its hidden backside.

2) Hold sliver with pincer s and set it on fire.

3) Carefully observe condition of the burning plastic.

4) ABS plastic must raise readily dist inguishable back smoke while burning with its residue suspended in air

temporarily.

5) Polypropylene must raise no readily distinguishable smoke while burning.

Page 1398 of 1496

![SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0 SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0](/img/20/7607/w960_7607-1397.png)

Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.09 in.)

I6RS0C9D0001-01

[A]: Roof side weather-strip installation position

3. Roof molding clip (Push-in type)

: Install roof molding clip to specified position on body with epoxy adhesive applied.

1. Roof molding 4. Windshield side garnish

2. Roof side weather-strip

Page 1401 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 10- i

10

Section 10

CONTENTS

Control Systems

Precautions ............................................... 10-1

Precautions........................................................... 10-1

Precautions for Control Systems......................... 10-1

Body Electrical Contro l System ........... 10B-1

Precautions......................................................... 10B-1

Precautions in Diagnosing Trouble ................... 10B-1

General Description ........................................... 10B-1 BCM General Description ................................. 10B-1

CAN Communication System Description......... 10B-2

Theft Deterrent Light ......................................... 10B-3

Security Alarm Description (If Equipped) .......... 10B-3

Schematic and Routing Diagram ...................... 10B-4 Body Electrical Control System Wiring Circuit Diagram .......................................................... 10B-4

Connector Layout Diagram of BCM and Junction Block Assembly ................................ 10B-7

Component Locatio n ......................................... 10B-8

BCM and Related System Component Location .......................................................... 10B-8

Diagnostic Information an d Procedures .......... 10B-9

BCM Self-Diagnosis Function ........................... 10B-9

Body Electrical Control System Check............ 10B-10

Scan Tool Data ............................................... 10B-12

DTC Table ....................................................... 10B-14

DTC Check ..................................................... 10B-14

DTC Clearance ............................................... 10B-15

BCM Power Circuit and Ground Circuit Check 10B-16

DTC B1133 (DTC No. 1133): Battery Voltage Too High ....................................................... 10B-17

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient

Temp.) Sensor Circuit Ma lfunction ................ 10B-18

DTC B1150 (No. 1150): Air Bag Communication Circuit Malfunction .............. 10B-19

DTC B1157 (No. 1157): Air Bag Deployment Signal Input ................................................... 10B-20

DTC B1170 (No. 1170 ): EEPROM Access

Error .............................................................. 10B-21

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control

Module .......................................................... 10B-21

DTC U1073 (No. 1073): Control Module Communication Bus Off ................................ 10B-24 DTC U1100 (No. 1100): Lost Communication

with ECM ....................................................... 10B-25

DTC U1101 (No. 1101): Lost Communication with TCM ....................................................... 10B-27

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control Module ................ 10B-29

Inspection of BCM and its Circuits .................. 10B-31

Repair Instructions ........... ...............................10B-39

BCM (Included in Junction Block Assembly) Removal and Installation ............................... 10B-39

Outside Air Temperature Sensor Removal and Installation .............................................. 10B-39

Outside Air Temperature Sensor Inspection ... 10B-39

Security Alarm Mode Selection Procedure (If Equipped) ...................................................... 10B-39

Special Tools and Equipmen t .........................10B-40

Special Tool .................................................... 10B-40

Immobilizer Control Syst em ................. 10C-1

Precautions.........................................................10C-1

Precautions in Diagnosing Troubles .................10C-1

Precaution in Replacing ECM ...........................10C-1

Precautions in Handli ng Immobilizer Control

System ............................................................10C-1

General Description ...........................................10C-2 Immobilizer Control System Introduction ..........10C-2

Immobilizer Control System Components Location...........................................................10C-3

On-Board Diagnostic System Description (Self-diagnosis Function) ................................10C-3

Schematic and Routing Diag ram ......................10C-4

Immobilizer Control System Wiring Circuit Diagram...........................................................10C-4

Diagnostic Information an d Procedures ..........10C-5

Immobilizer Control System Check ...................10C-5

Diagnostic Trouble Code (DTC) Check.............10C-5

Diagnostic Trouble Code (DTC) Clearance ......10C-6

Diagnostic Trouble Code (DTC) Table ..............10C-6

Scan Tool Data .................................................10C-7

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine Stop ..10C-7

Immobilizer Indicator Lamp Remains ON after Engine Starts...................................................10C-8

DTC P1614: Transponder Re sponse Error .......10C-9