Inspection of BCM SUZUKI SWIFT 2006 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1402 of 1496

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

DTC P1615: ID Code Does Not Registered (Vehicle equipped with keyless start system

only) ................................................................10C-9

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system

only) ..............................................................10C-10

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control

Module) (Vehicle equipped with keyless

start system only) ..........................................10C-11

DTC P1621: Immobilizer Communication Line Error ......................................................10C-12

DTC P1622: EEPROM Reading / Writing Error ..............................................................10C-13

DTC P1623: Unregistered Transponder .........10C-13

DTC P1625: Immobilizer An tenna Error..........10C-14

DTC P1636: Immobilizer Information Registration Failure .......................................10C-14

DTC P1638: Immobilizer Information Mismatched ...................................................10C-15

Inspection of Immobilizer Control Module (ICM) and Its Circuit ....... ...............................10C-16

Repair Instructions ........... ...............................10C-18

Immobilizer Control Mo dule (ICM) Removal

and Installation ..............................................10C-18

Registration of the Ignition Key .......................10C-18

Procedure after ECM Replacement ................10C-18

Special Tools and Equipmen t .........................10C-19

Special Tool ....................................................10C-19

Keyless Start System ....... ......................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7 Keyless Start System El ectric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8 Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagn osis Introduction ... 10E-8 Keyless Start System Chec

k ............................. 10E-8

Customer Questionnaire (E xample) .................. 10E-9

Key Indicator Lamp Check .............................. 10E-10

DTC Check...................................................... 10E-10

DTC Table ....................................................... 10E-11

DTC Clearance ............................................... 10E-12

Keyless Start System Symp tom Diagnosis ..... 10E-12

Keyless Start System Operation Inspection .... 10E-13

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC Check ............................................................ 10E-18

Key Indicator Lamp Circuit Check (Key indicator lamp doesn’t light when ignition

knob switch is pushed.) ................................. 10E-20

Keyless Start Control Module Power and Ground Circuit Check .................................... 10E-22

DTC No. 11: Communi cation Error with

Steering Lock Unit ......................................... 10E-23

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-24

DTC No. 21 / No. 22: Internal Error of Keyless Start Control Module (EEPROM reading

error) / (EEPROM writing error) ............ ........ 10E-24

DTC No. 31: Lost Commun ication with BCM .. 10E-25

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-27

DTC No. 51 / No. 52 / No. 53: Driver Side / Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-28

Repair Instructions ............ .............................. 10E-30

Antennas and Request Switches Removal and Installation .............................................. 10E-30

Front Door (Driver and Passenger Side), Rear End Door Request Switch Inspection............ 10E-31

Steering Lock Unit Removal and Installation .. 10E-31

Steering Lock Unit Inspection ......................... 10E-31

Front Door Lock Switch In spection ................. 10E-31

Keyless Start Control Module Removal and Installation ..................................................... 10E-32

Remote Controller Inspection.......................... 10E-32

Replacement of Remote Controller Battery .... 10E-32

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-33

Page 1404 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-1 Body Electrical Control System:

Control Systems

Body Electrical Control System

Precautions

Precautions in Diagnosing TroubleS7RS0BA200001

• Diagnostic information stored in BCM memory can be cleared as well as checked by using SUZUKI scan tool.

Before using scan tool, read its Operator ’s (Instruction) Manual carefully to have good understanding as to what

functions are available and how to use it.

• Be sure to read “Precautions for Electrical Circuit Serv ice in Section 00” before inspection and observe what is

written there.

• Communication of ECM, TCM (if equipped), ABS/ESP ® control module, steering angle sensor (ESP ® model),

keyless start control module (if equipped), combinatio n meter and BCM is established by CAN (Controller Area

Network). For detail of CAN communication for BCM, refer to “CAN Communication System Description”.

Therefore, handle CAN communication line with care referr ing to “Precaution for CAN Communication System in

Section 00”.

General Description

BCM General DescriptionS7RS0BA201001

The Body electrical Control Module (BCM) is incorporated in junction block assembly. Do not attempt removal of BCM

from junction block assembly as it may cause contact failure.

The BCM incorporates relays and controllers which are used for the following systems and controls them.

• Power door lock

• Keyless entry (if equipped)

• Door lock function of keyle ss start system (if equipped)

• Rear wiper

• Combination meter

• Interior light

• Warning buzzer

• Rear end door window defogger and door mirror heater (if equipped)

• Rear end door opener

• Theft deterrent light

Also, the BCM has a function to cause the interior light and open door warning lamp in the combination meter to turn

off when any door is left open for longer than 15 minutes to reduce wasteful battery consumption.

In addition, it is possible to check operation of actuator whic h is controlled by BCM by using the output test function of

SUZUKI scan tool to operate actuator simulatively.

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

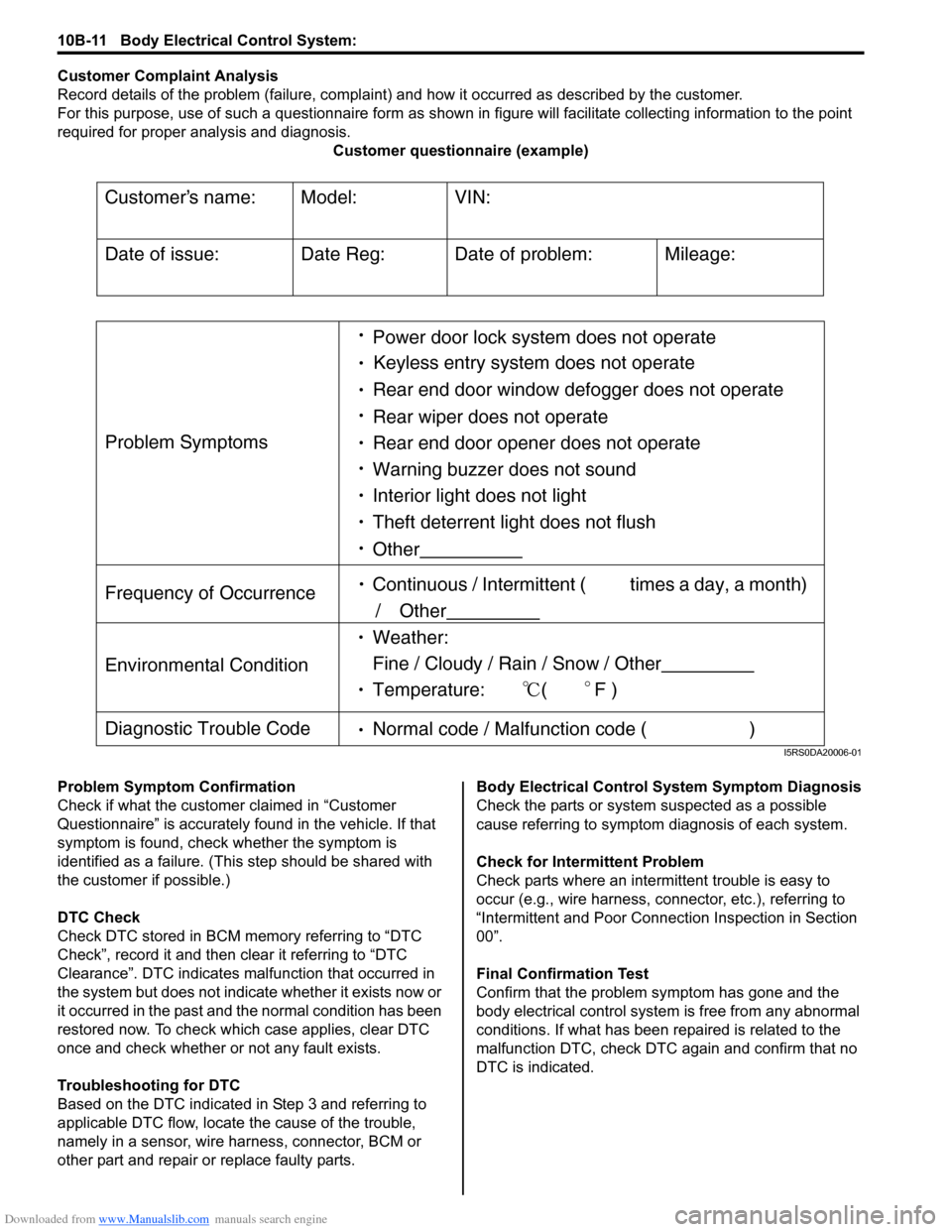

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1421 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-18

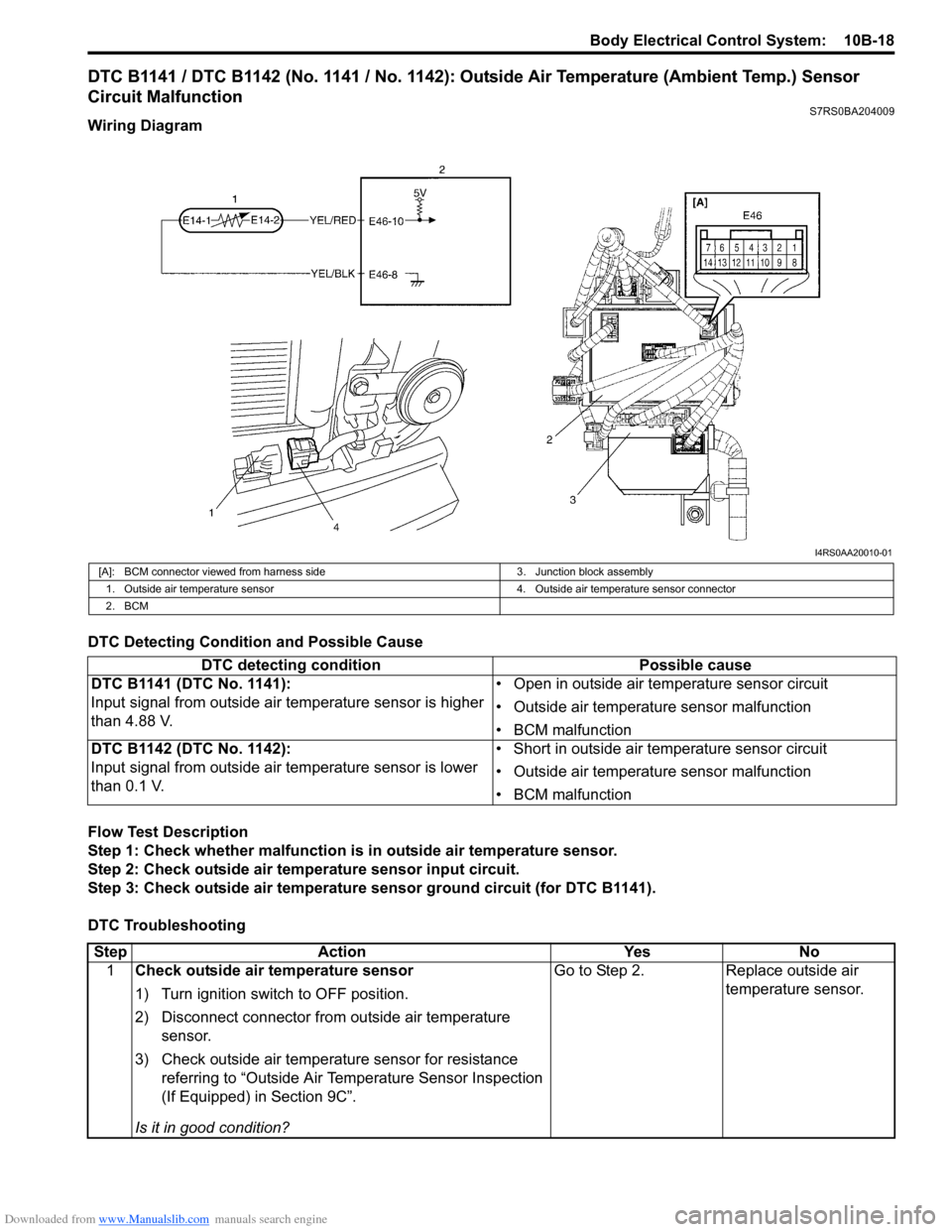

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient Temp.) Sensor

Circuit Malfunction

S7RS0BA204009

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check whether malfunction is in outside air temperature sensor.

Step 2: Check outside air temperature sensor input circuit.

Step 3: Check outside air temperature sensor ground circuit (for DTC B1141).

DTC Troubleshooting

I4RS0AA20010-01

[A]: BCM connector viewed from harness side 3. Junction block assembly

1. Outside air temperature sensor 4. Outside air temperature sensor connector

2. BCM

DTC detecting condition Possible cause

DTC B1141 (DTC No. 1141):

Input signal from outside air temperature sensor is higher

than 4.88 V. • Open in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

DTC B1142 (DTC No. 1142):

Input signal from outside air temperature sensor is lower

than 0.1 V. • Short in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

Step

Action YesNo

1 Check outside air temperature sensor

1) Turn ignition switch to OFF position.

2) Disconnect connector from outside air temperature

sensor.

3) Check outside air temperature sensor for resistance referring to “Outside Air Temperature Sensor Inspection

(If Equipped) in Section 9C”.

Is it in good condition? Go to Step 2.

Replace outside air

temperature sensor.

Page 1426 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

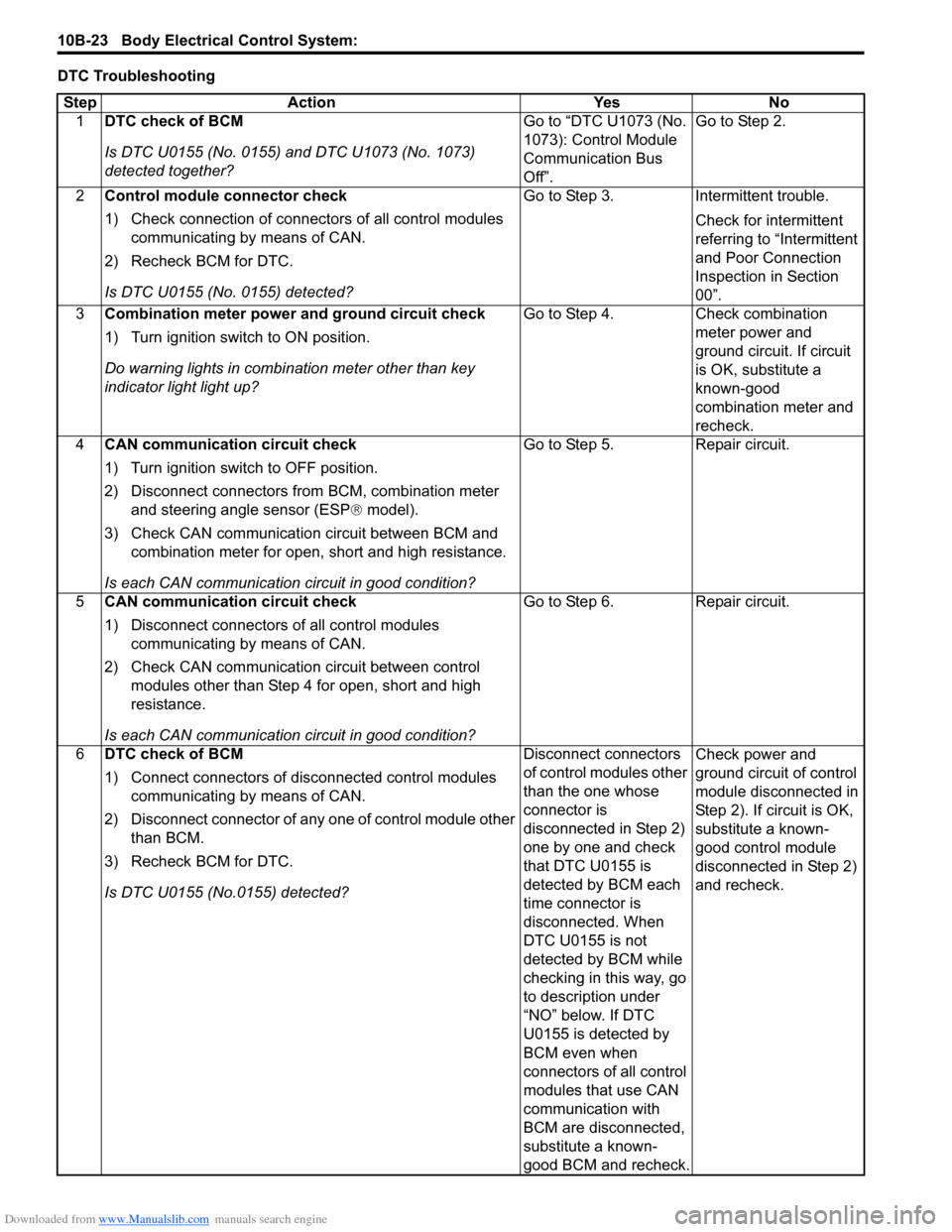

DTC TroubleshootingStep Action YesNo

1 DTC check of BCM

Is DTC U0155 (No. 0155) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U0155 (No. 0155) detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator light light up? Go to Step 4.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, combination meter

and steering angle sensor (ESP ® model).

3) Check CAN communication circuit between BCM and combination meter for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U0155 (No.0155) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U0155 is

detected by BCM each

time connector is

disconnected. When

DTC U0155 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U0155 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Page 1427 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-24

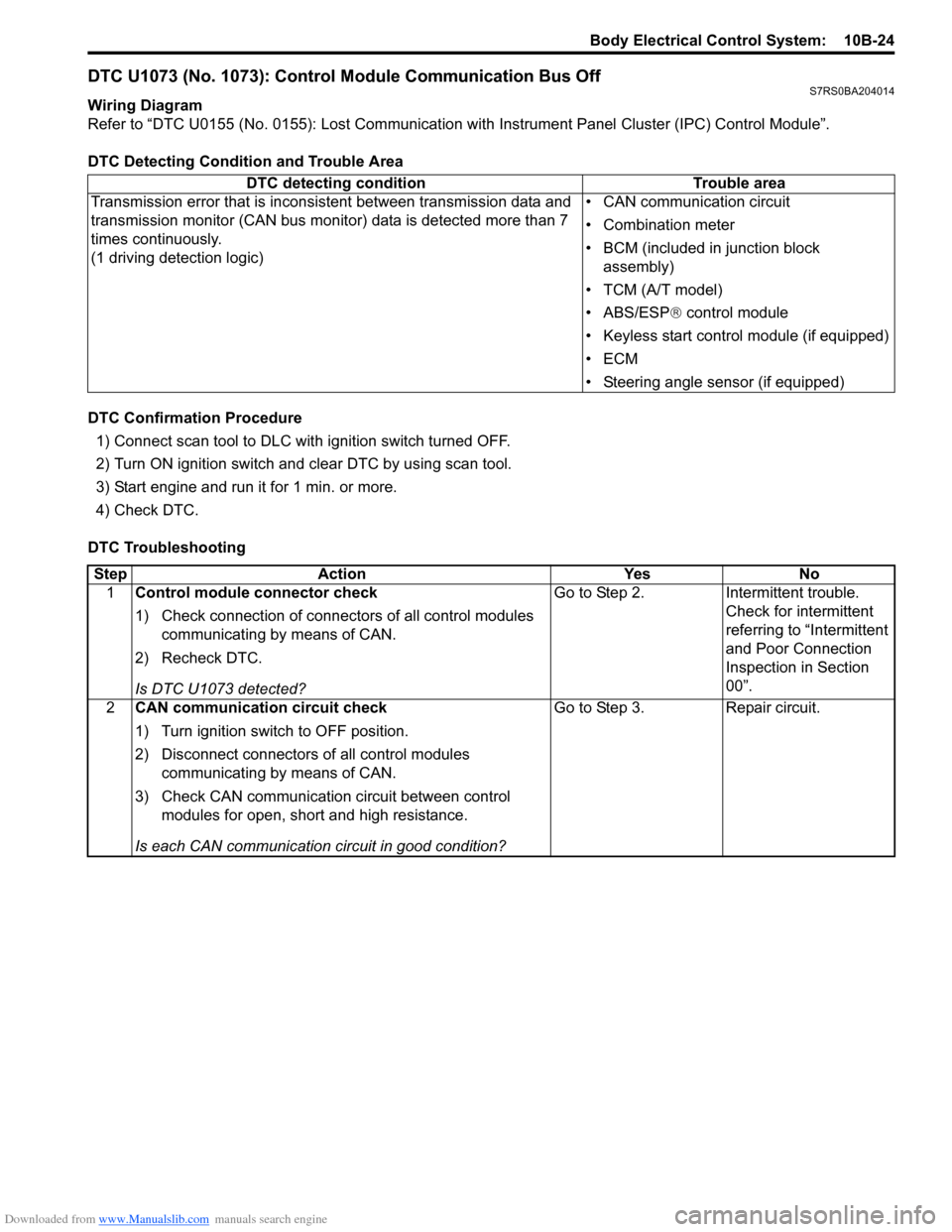

DTC U1073 (No. 1073): Control Module Communication Bus OffS7RS0BA204014

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Transmission error that is inconsistent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously.

(1 driving detection logic) • CAN communication circuit

• Combination meter

• BCM (included in junction block

assembly)

• TCM (A/T model)

• ABS/ESP ® control module

• Keyless start control module (if equipped)

•ECM

• Steering angle sensor (if equipped)

Step Action YesNo

1 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 detected? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 3.

Repair circuit.

Page 1429 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-26

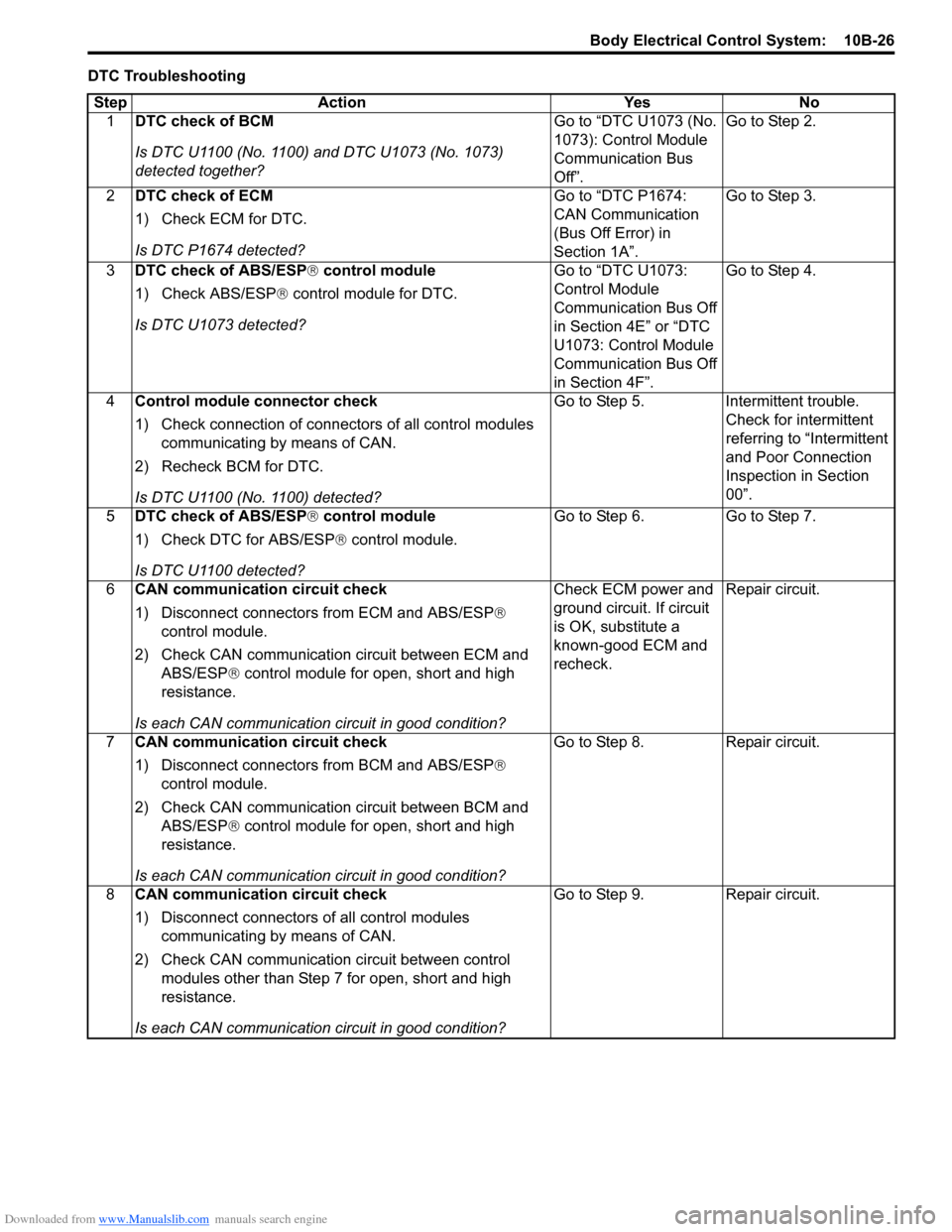

DTC TroubleshootingStep Action Yes No 1 DTC check of BCM

Is DTC U1100 (No. 1100) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 DTC check of ECM

1) Check ECM for DTC.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 3.

3 DTC check of ABS/ESP ® control module

1) Check ABS/ESP ® control module for DTC.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus Off

in Section 4E” or “DTC

U1073: Control Module

Communication Bus Off

in Section 4F”.Go to Step 4.

4 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1100 (No. 1100) detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 DTC check of ABS/ESP ® control module

1) Check DTC for ABS/ESP ® control module.

Is DTC U1100 detected? Go to Step 6. Go to Step 7.

6 CAN communication circuit check

1) Disconnect connector s from ECM and ABS/ESP ®

control module.

2) Check CAN communication circuit between ECM and ABS/ESP ® control module for open, short and high

resistance.

Is each CAN communication circuit in good condition? Check ECM power and

ground circuit. If circuit

is OK, substitute a

known-good ECM and

recheck.

Repair circuit.

7 CAN communication circuit check

1) Disconnect connector s from BCM and ABS/ESP ®

control module.

2) Check CAN communication circuit between BCM and ABS/ESP ® control module for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 8. Repair circuit.

8 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 7 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 9. Repair circuit.

Page 1431 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-28

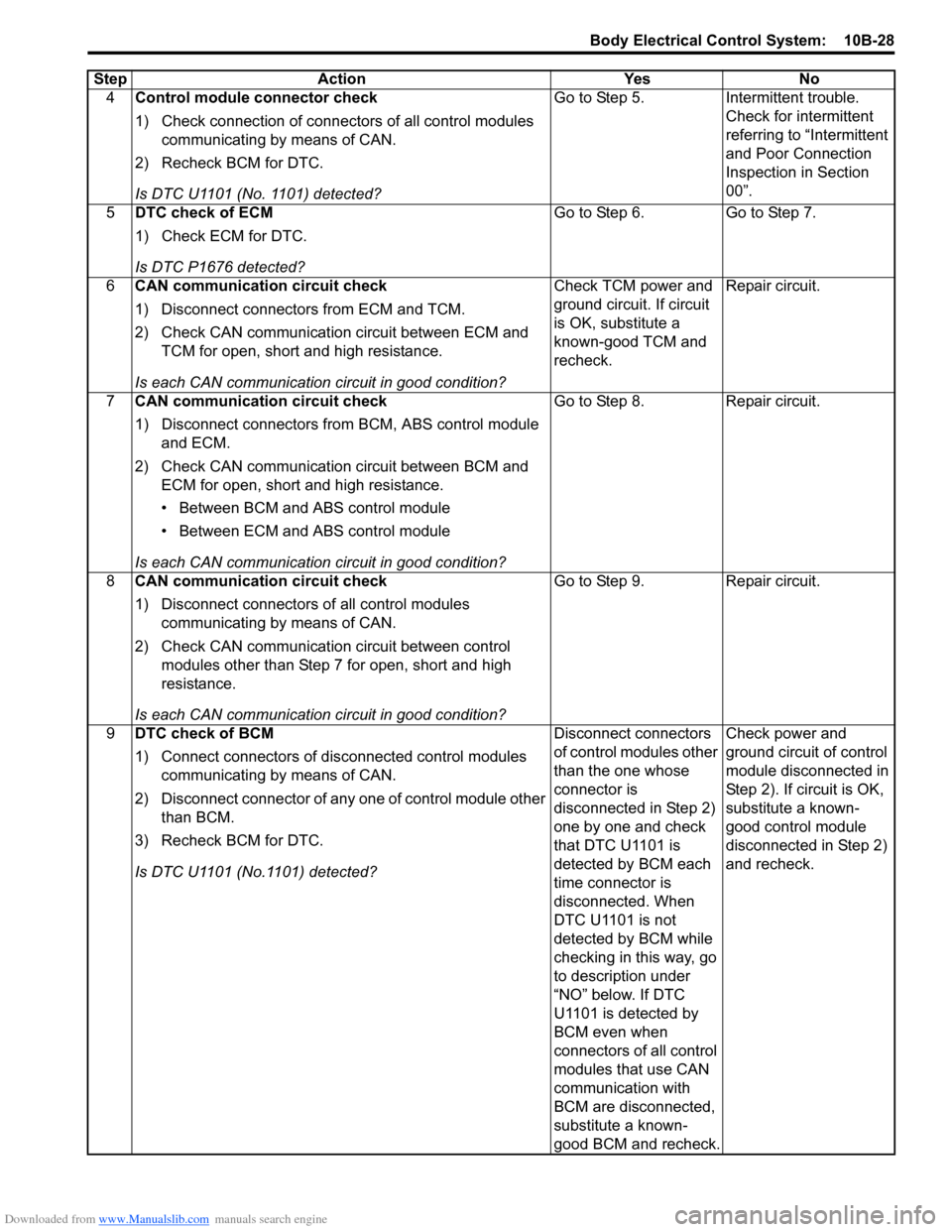

4Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1101 (No. 1101) detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 DTC check of ECM

1) Check ECM for DTC.

Is DTC P1676 detected? Go to Step 6. Go to Step 7.

6 CAN communication circuit check

1) Disconnect connectors from ECM and TCM.

2) Check CAN communication circuit between ECM and

TCM for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

7 CAN communication circuit check

1) Disconnect connectors from BCM, ABS control module

and ECM.

2) Check CAN communication circuit between BCM and ECM for open, short and high resistance.

• Between BCM and ABS control module

• Between ECM and ABS control module

Is each CAN communication circuit in good condition? Go to Step 8. Repair circuit.

8 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 7 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 9. Repair circuit.

9 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U1101 (No.1101) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U1101 is

detected by BCM each

time connector is

disconnected. When

DTC U1101 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U1101 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Step Action Yes No

Page 1432 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-29 Body Electrical Control System:

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control ModuleS7RS0BA204017

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

BCM can not receive data sent by CAN from keyless start control module for

longer than specified time continuously. • CAN communication circuit

• Combination meter

• Keyless start control module

• BCM (included in junction block

assembly)

Step Action YesNo

1 DTC check of BCM

Is DTC U1144 (No. 1144) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 DTC check of keyless start control module

1) Check keyless start co ntrol module for DTC.

Is DTC No. 33 detected? Go to “DTC No. 33:

Control Module

Communication Bus Off

in Section 10E”.Go to Step 3.

3 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1144 (No. 1144) detected? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 CAN communication circuit check

1) Disconnect connectors from BCM, combination meter

and keyless start control module.

2) Check CAN communication circuit for open, short and high resistance.

• Between BCM and combination meter

• Between combination meter and keyless start control module

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

Page 1434 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-31 Body Electrical Control System:

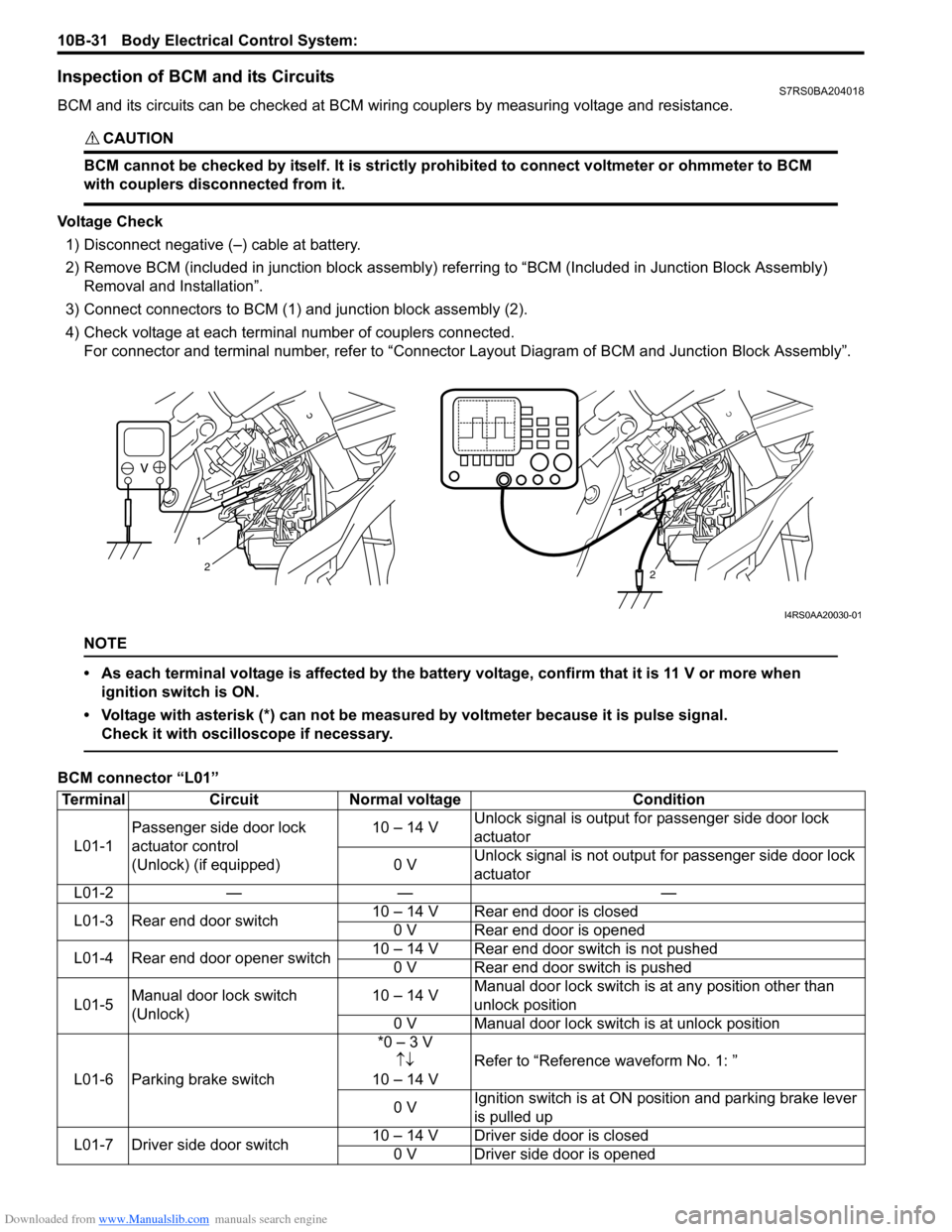

Inspection of BCM and its CircuitsS7RS0BA204018

BCM and its circuits can be checked at BCM wiring couplers by measuring voltage and resistance.

CAUTION!

BCM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to BCM

with couplers disconnected from it.

Voltage Check1) Disconnect negative (–) cable at battery.

2) Remove BCM (included in junction block assembly) refe rring to “BCM (Included in Junction Block Assembly)

Removal and Installation”.

3) Connect connectors to BCM (1) and junction block assembly (2).

4) Check voltage at each terminal number of couplers connected. For connector and terminal number, refer to “Connector Layout Diagram of BCM and Junction Block Assembly”.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is ON.

• Voltage with asterisk (*) can not be measured by voltmeter because it is pulse signal. Check it with oscilloscope if necessary.

BCM connector “L01”

1

2

1

2

I4RS0AA20030-01

Terminal CircuitNormal voltage Condition

L01-1 Passenger side door lock

actuator control

(Unlock) (if equipped) 10 – 14 V

Unlock signal is output fo

r passenger side door lock

actuator

0 V Unlock signal is not output for passenger side door lock

actuator

L01-2 — — —

L01-3 Rear end door switch 10 – 14 V Rear end door is closed

0 V Rear end door is opened

L01-4 Rear end door opener switch 10 – 14 V Rear end door switch is not pushed

0 V Rear end door switch is pushed

L01-5 Manual door lock switch

(Unlock) 10 – 14 V

Manual door lock switch is at any position other than

unlock position

0 V Manual door lock switch is at unlock position

L01-6 Parking brake switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON po

sition and parking brake lever

is pulled up

L01-7 Driver side door switch 10 – 14 V Driver side door is closed

0 V Driver side door is opened