Gear SUZUKI SWIFT 2006 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 767 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-123

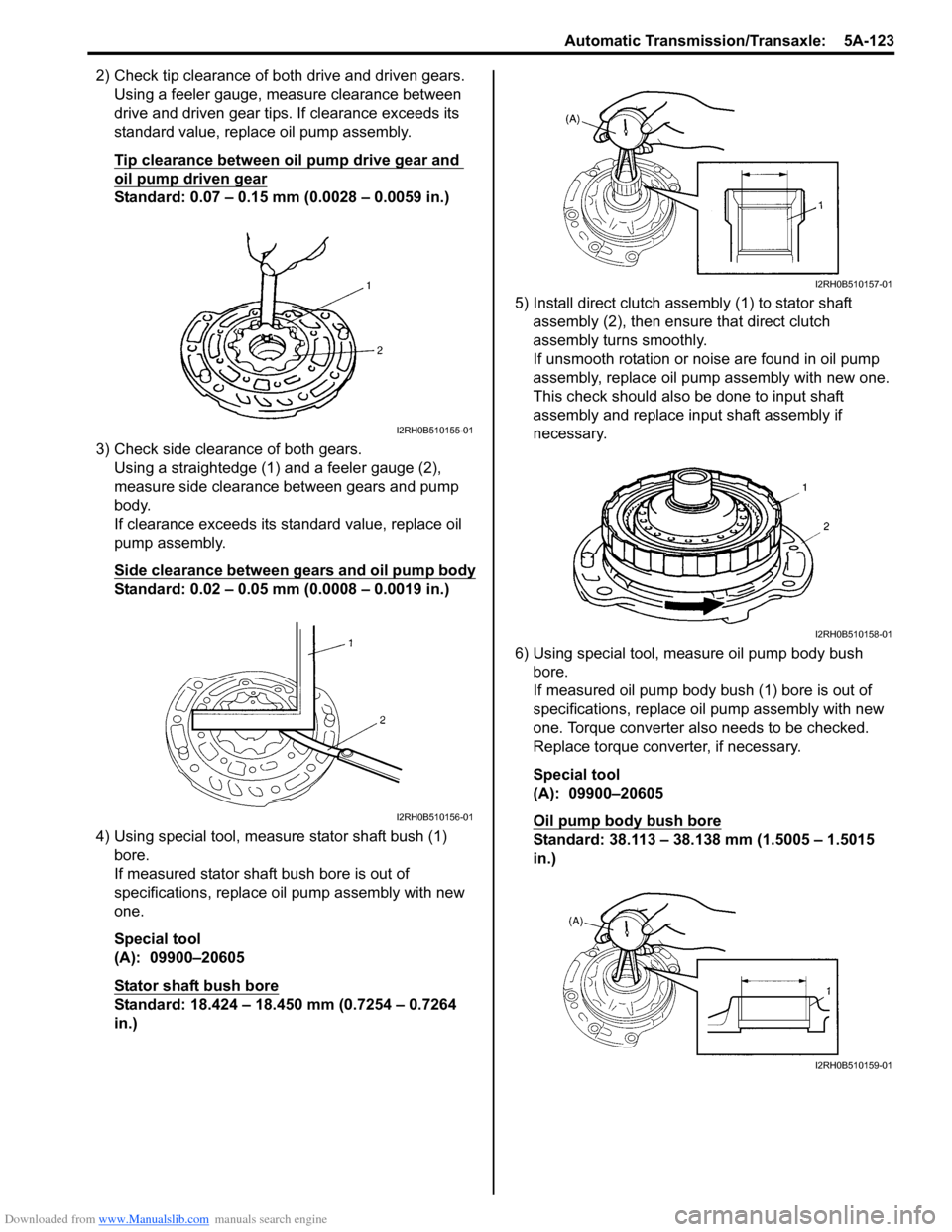

2) Check tip clearance of both drive and driven gears.Using a feeler gauge, m easure clearance between

drive and driven gear tips. If clearance exceeds its

standard value, replace oil pump assembly.

Tip clearance between oil pump drive gear and

oil pump driven gear

Standard: 0.07 – 0.15 mm (0.0028 – 0.0059 in.)

3) Check side clearance of both gears. Using a straightedge (1) and a feeler gauge (2),

measure side clearance between gears and pump

body.

If clearance exceeds its standard value, replace oil

pump assembly.

Side clearance between gears and oil pump body

Standard: 0.02 – 0.05 mm (0.0008 – 0.0019 in.)

4) Using special tool, measure stator shaft bush (1) bore.

If measured stator shaft bush bore is out of

specifications, replace oil pump assembly with new

one.

Special tool

(A): 09900–20605

Stator shaft bush bore

Standard: 18.424 – 18.450 mm (0.7254 – 0.7264

in.) 5) Install direct clutch asse

mbly (1) to stator shaft

assembly (2), then ensure that direct clutch

assembly turns smoothly.

If unsmooth rotation or noise are found in oil pump

assembly, replace oil pump assembly with new one.

This check should also be done to input shaft

assembly and replace input shaft assembly if

necessary.

6) Using special tool, measure oil pump body bush bore.

If measured oil pump body bush (1) bore is out of

specifications, replace o il pump assembly with new

one. Torque converter also needs to be checked.

Replace torque converter, if necessary.

Special tool

(A): 09900–20605

Oil pump body bush bore

Standard: 38.113 – 38.138 mm (1.5005 – 1.5015

in.)

I2RH0B510155-01

I2RH0B510156-01

I2RH0B510157-01

I2RH0B510158-01

I2RH0B510159-01

Page 782 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-138 Automatic Transmission/Transaxle:

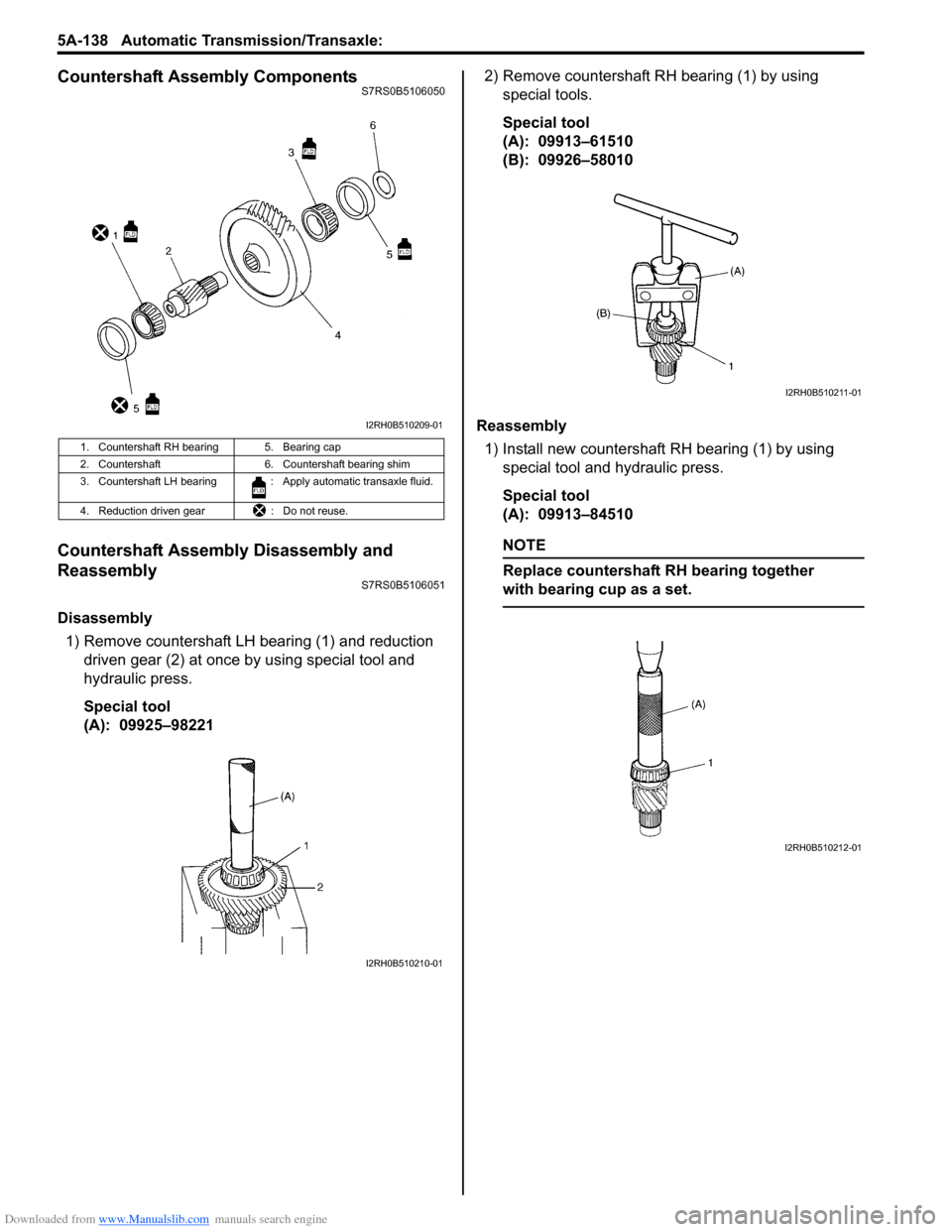

Countershaft Assembly ComponentsS7RS0B5106050

Countershaft Assembly Disassembly and

Reassembly

S7RS0B5106051

Disassembly1) Remove countershaft LH bearing (1) and reduction driven gear (2) at once by using special tool and

hydraulic press.

Special tool

(A): 09925–98221 2) Remove countershaft RH bearing (1) by using

special tools.

Special tool

(A): 09913–61510

(B): 09926–58010

Reassembly 1) Install new countershaft RH bearing (1) by using special tool and hydraulic press.

Special tool

(A): 09913–84510

NOTE

Replace countershaft RH bearing together

with bearing cup as a set.

1. Countershaft RH bearing 5. Bearing cap

2. Countershaft 6. Countershaft bearing shim

3. Countershaft LH bearing : Apply automatic transaxle fluid.

4. Reduction driven gear : Do not reuse.

I2RH0B510209-01

I2RH0B510210-01

I2RH0B510211-01

I2RH0B510212-01

Page 783 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-139

2) Install reduction driven gear (1) with special tools and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210 3) Install countershaft LH bearing (1) with special tools

and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210

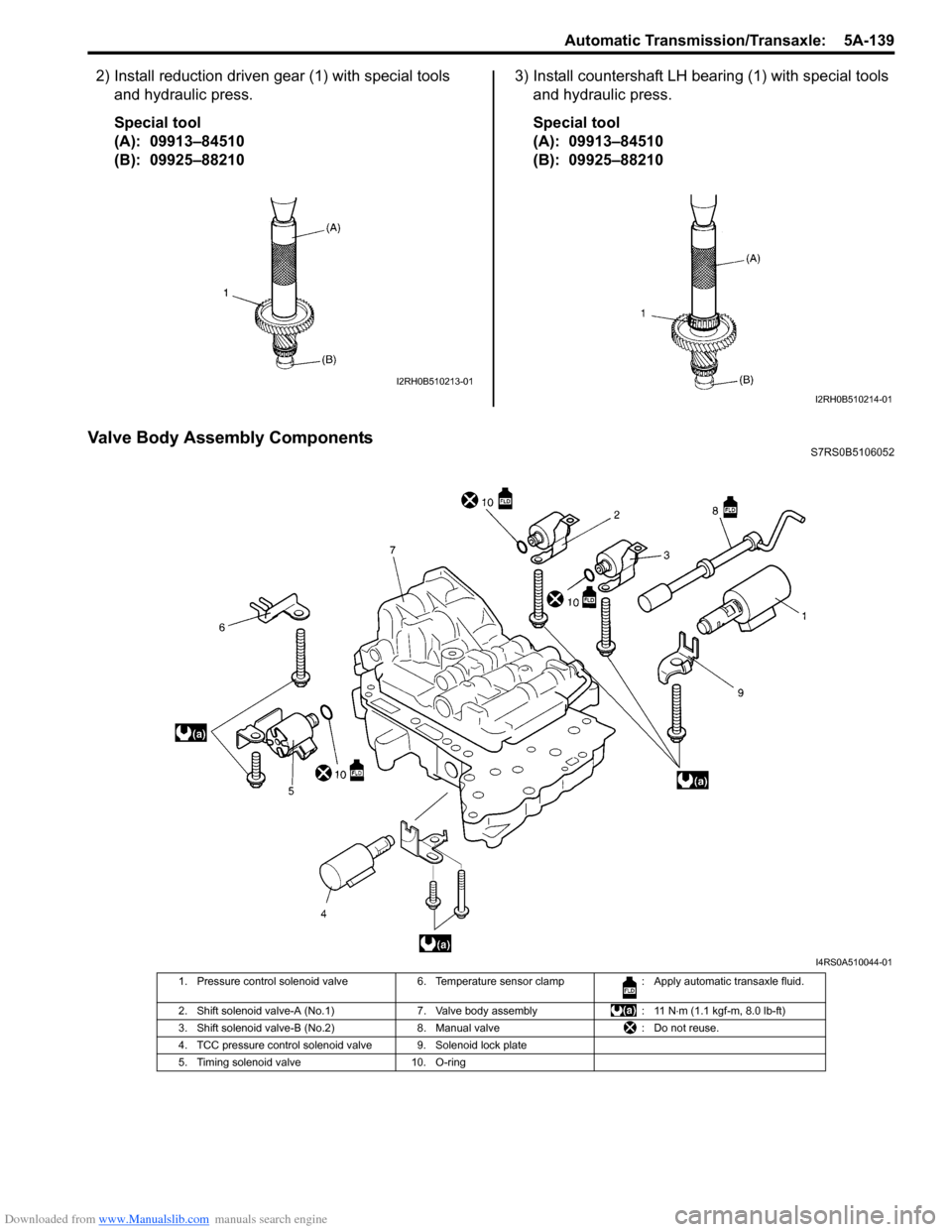

Valve Body Assembly ComponentsS7RS0B5106052

I2RH0B510213-01

I2RH0B510214-01

I4RS0A510044-01

1. Pressure control solenoid valve 6. Temperature sensor clamp : Apply automatic transaxle fluid.

2. Shift solenoid valve-A (No.1) 7. Valve body assembly: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

3. Shift solenoid valve-B (No.2) 8. Manual valve: Do not reuse.

4. TCC pressure control solenoid valve 9. Solenoid lock plate

5. Timing solenoid valve 10. O-ring

Page 785 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-141

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Shift solenoid valve-A and -B are identical

• After applying A/T fluid to new O-rings, fit them to solenoid valves, then insta ll solenoid valves to valve

body.

• Tighten solenoid valve bolts to specified torque

Tightening torque

Solenoid valve bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Solenoid valve bolt specification

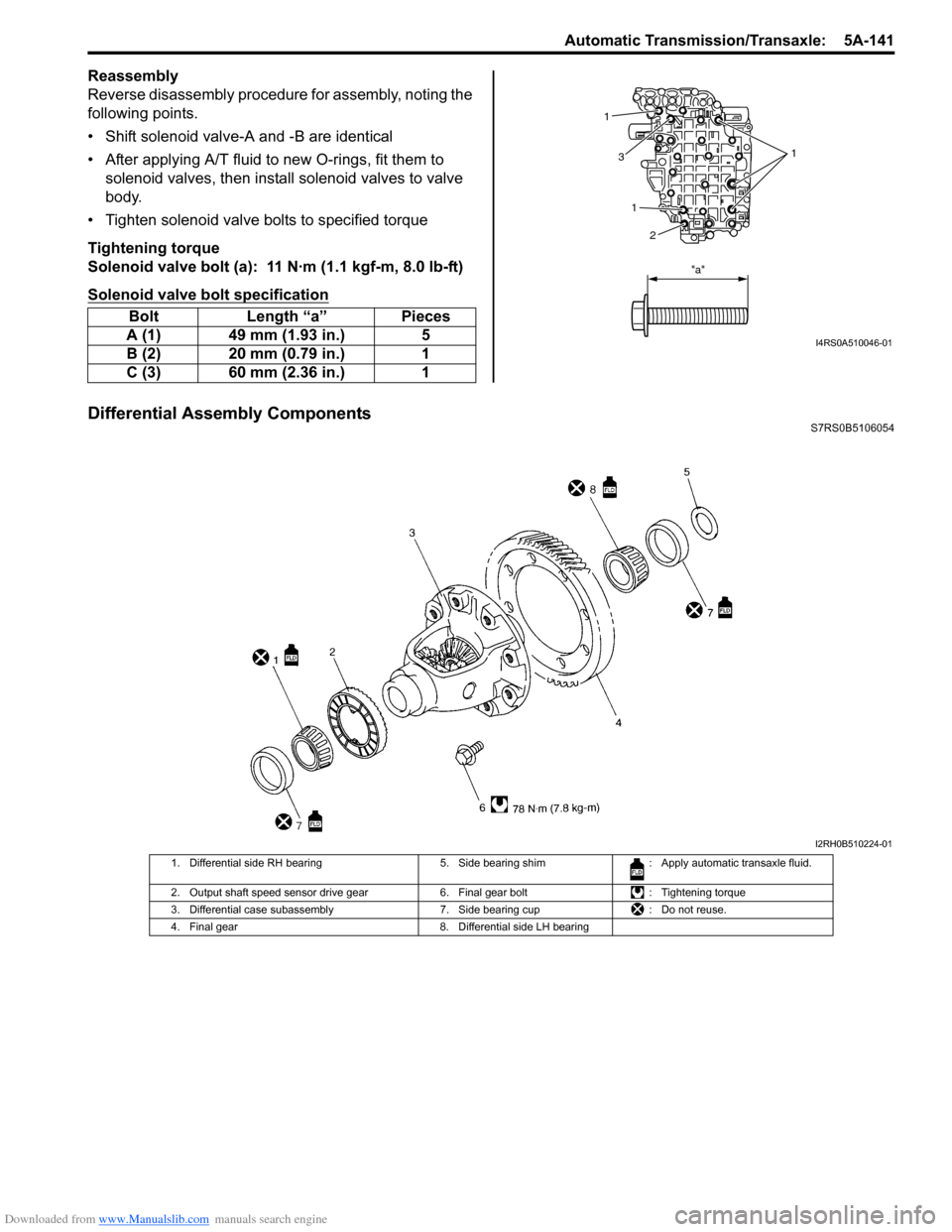

Differential Assembly ComponentsS7RS0B5106054

Bolt Length “a” Pieces

A (1) 49 mm (1.93 in.) 5

B (2) 20 mm (0.79 in.) 1

C (3) 60 mm (2.36 in.) 1

1

1

1

3

2

"a"

I4RS0A510046-01

I2RH0B510224-01

1. Differential side RH bearing 5. Side bearing shim: Apply automatic transaxle fluid.

2. Output shaft speed sensor drive gear 6. Final gear bolt: Tightening torque

3. Differential case subassembly 7. Side bearing cup: Do not reuse.

4. Final gear 8. Differential side LH bearing

Page 786 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-142 Automatic Transmission/Transaxle:

Differential Assembly Disassembly and

Reassembly

S7RS0B5106055

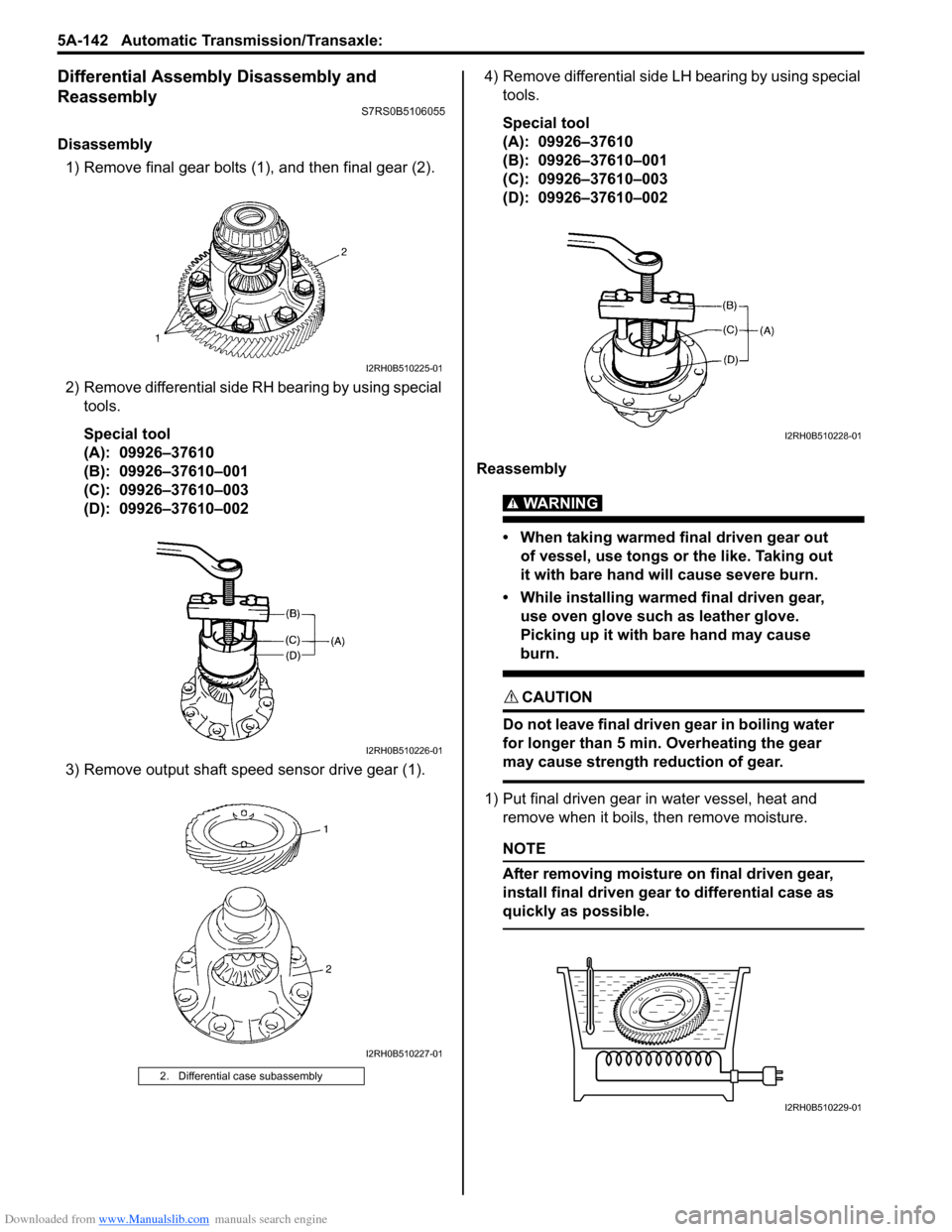

Disassembly1) Remove final gear bolts (1), and then final gear (2).

2) Remove differential side RH bearing by using special tools.

Special tool

(A): 09926–37610

(B): 09926–37610–001

(C): 09926–37610–003

(D): 09926–37610–002

3) Remove output shaft speed sensor drive gear (1). 4) Remove differential side LH bearing by using special

tools.

Special tool

(A): 09926–37610

(B): 09926–37610–001

(C): 09926–37610–003

(D): 09926–37610–002

Reassembly

WARNING!

• When taking warmed final driven gear out of vessel, use tongs or the like. Taking out

it with bare hand will cause severe burn.

• While installing warme d final driven gear,

use oven glove such as leather glove.

Picking up it with bare hand may cause

burn.

CAUTION!

Do not leave final driven gear in boiling water

for longer than 5 min. Overheating the gear

may cause strength reduction of gear.

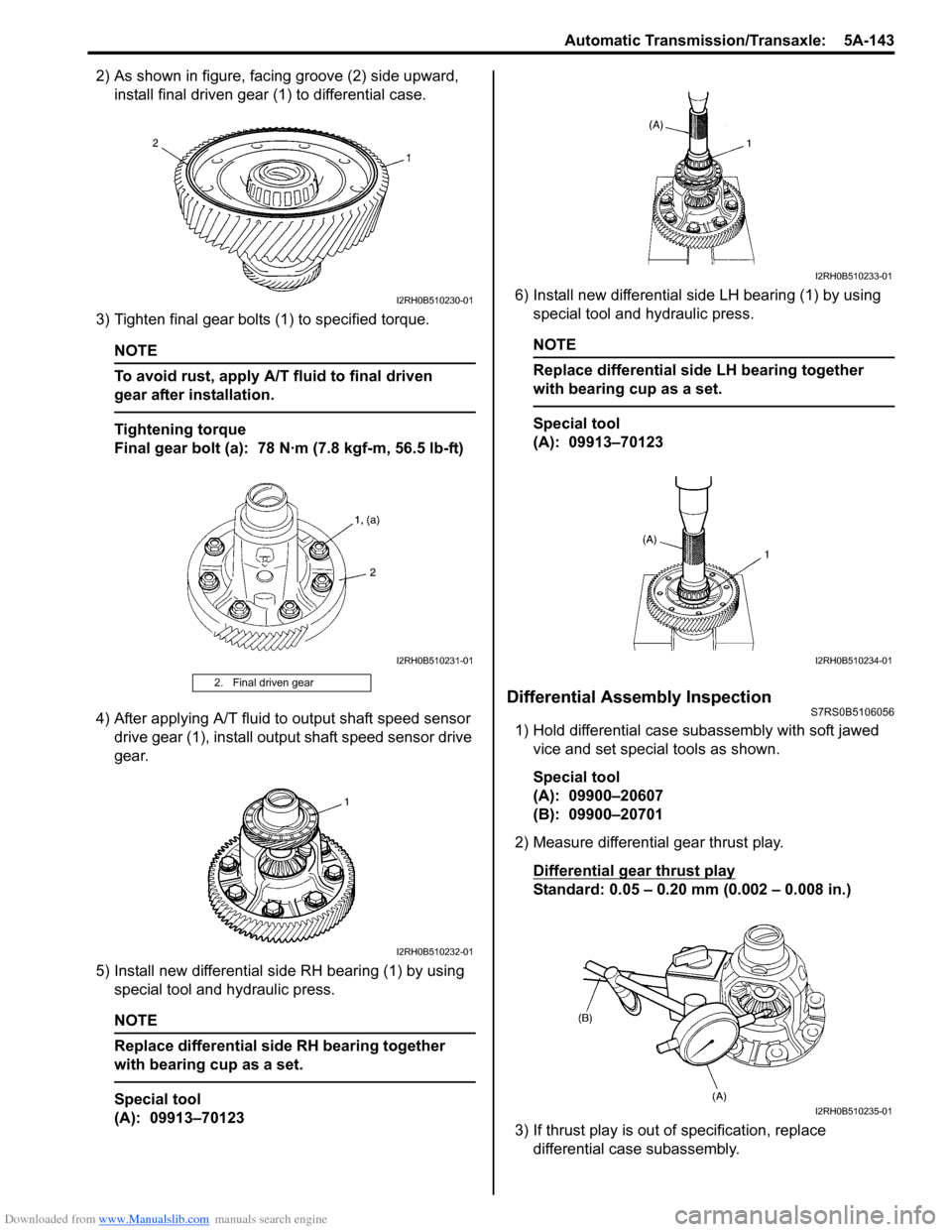

1) Put final driven gear in water vessel, heat and remove when it boils, then remove moisture.

NOTE

After removing moisture on final driven gear,

install final driven gear to differential case as

quickly as possible.

2. Differential case subassembly

I2RH0B510225-01

I2RH0B510226-01

I2RH0B510227-01

I2RH0B510228-01

I2RH0B510229-01

Page 787 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-143

2) As shown in figure, facing groove (2) side upward, install final driven gear (1) to differential case.

3) Tighten final gear bolts (1) to specified torque.

NOTE

To avoid rust, apply A/T fluid to final driven

gear after installation.

Tightening torque

Final gear bolt (a): 78 N·m (7.8 kgf-m, 56.5 lb-ft)

4) After applying A/T fluid to output shaft speed sensor drive gear (1), install output shaft speed sensor drive

gear.

5) Install new differential side RH bearing (1) by using special tool and hydraulic press.

NOTE

Replace differential side RH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123 6) Install new differential side LH bearing (1) by using

special tool and hydraulic press.

NOTE

Replace differential side LH bearing together

with bearing cup as a set.

Special tool

(A): 09913–70123

Differential Assembly InspectionS7RS0B5106056

1) Hold differential case subassembly with soft jawed

vice and set special tools as shown.

Special tool

(A): 09900–20607

(B): 09900–20701

2) Measure differential gear thrust play.

Differential gear thrust play

Standard: 0.05 – 0.20 mm (0.002 – 0.008 in.)

3) If thrust play is out of specification, replace differential case subassembly.

2. Final driven gear

I2RH0B510230-01

I2RH0B510231-01

I2RH0B510232-01

I2RH0B510233-01

I2RH0B510234-01

I2RH0B510235-01

Page 792 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-148 Automatic Transmission/Transaxle:

One-way clutch No.1 assembly1) Install one-way clutch No.1 assembly (2) to rear planetary sun gear subassembly (1).

2) Securing rear planetary sun gear subassembly, ensure that one-way clutch No.1 assembly rotates

only in one direction.

If the one-way clutch rotates in both directions or it

does not rotate in either direction, replace it with new

one.

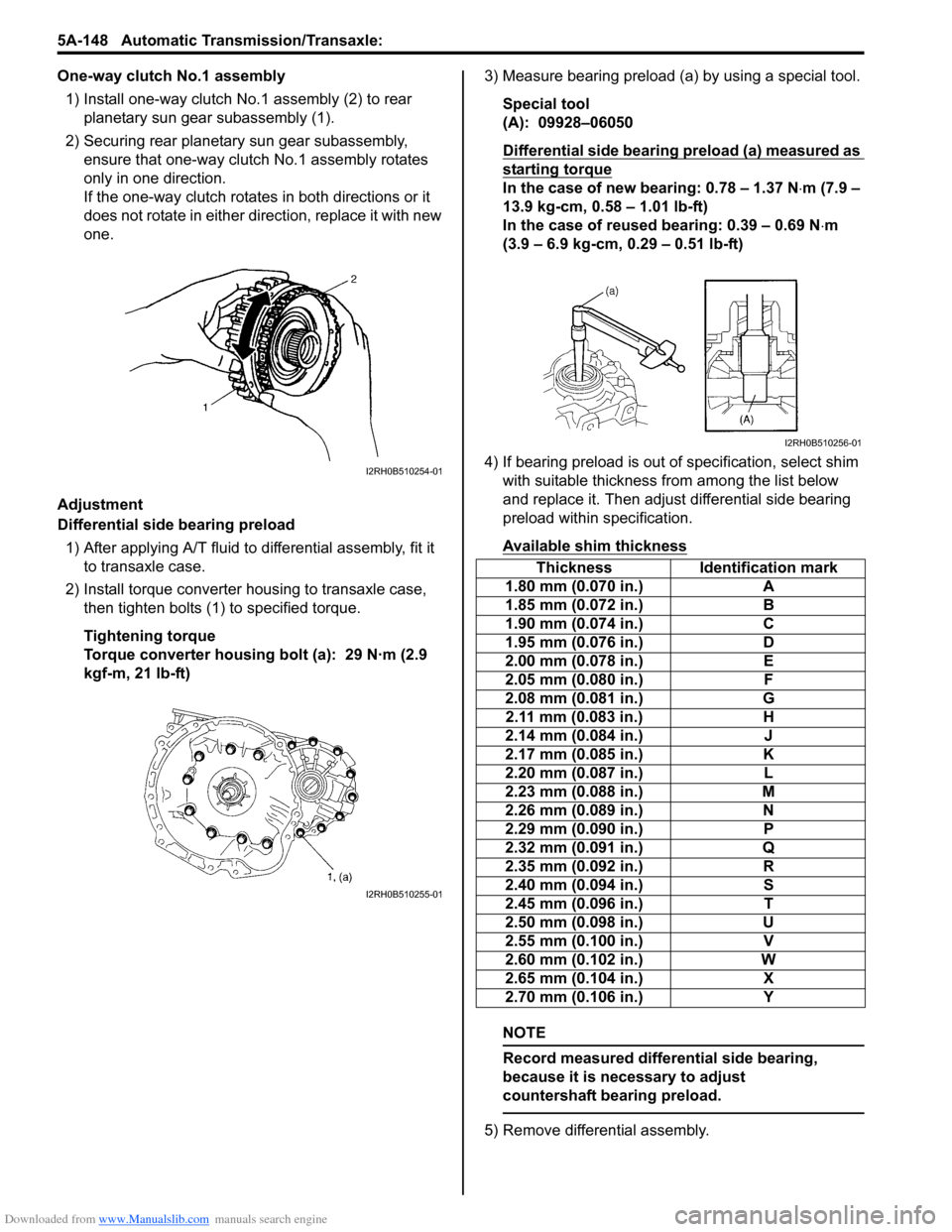

Adjustment

Differential side bearing preload 1) After applying A/T fluid to differential assembly, fit it to transaxle case.

2) Install torque converter housing to transaxle case, then tighten bolts (1) to specified torque.

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft) 3) Measure bearing preload (a) by using a special tool.

Special tool

(A): 09928–06050

Differential side bearing preload (a) measured as

starting torque

In the case of new bearing: 0.78 – 1.37 N ⋅m (7.9 –

13.9 kg-cm, 0.58 – 1.01 lb-ft)

In the case of reused bearing: 0.39 – 0.69 N ⋅m

(3.9 – 6.9 kg-cm, 0.29 – 0.51 lb-ft)

4) If bearing preload is out of specification, select shim with suitable thickness from among the list below

and replace it. Then adjust differential side bearing

preload within specification.

Available shim thickness

NOTE

Record measured differential side bearing,

because it is necessary to adjust

countershaft bearing preload.

5) Remove differential assembly.

I2RH0B510254-01

I2RH0B510255-01

Thickness Identification mark

1.80 mm (0.070 in.) A

1.85 mm (0.072 in.) B

1.90 mm (0.074 in.) C

1.95 mm (0.076 in.) D

2.00 mm (0.078 in.) E

2.05 mm (0.080 in.) F

2.08 mm (0.081 in.) G

2.11 mm (0.083 in.) H

2.14 mm (0.084 in.) J

2.17 mm (0.085 in.) K

2.20 mm (0.087 in.) L

2.23 mm (0.088 in.) M

2.26 mm (0.089 in.) N

2.29 mm (0.090 in.) P

2.32 mm (0.091 in.) Q

2.35 mm (0.092 in.) R

2.40 mm (0.094 in.) S

2.45 mm (0.096 in.) T

2.50 mm (0.098 in.) U

2.55 mm (0.100 in.) V

2.60 mm (0.102 in.) W

2.65 mm (0.104 in.) X

2.70 mm (0.106 in.) Y

I2RH0B510256-01

Page 796 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-152 Automatic Transmission/Transaxle:

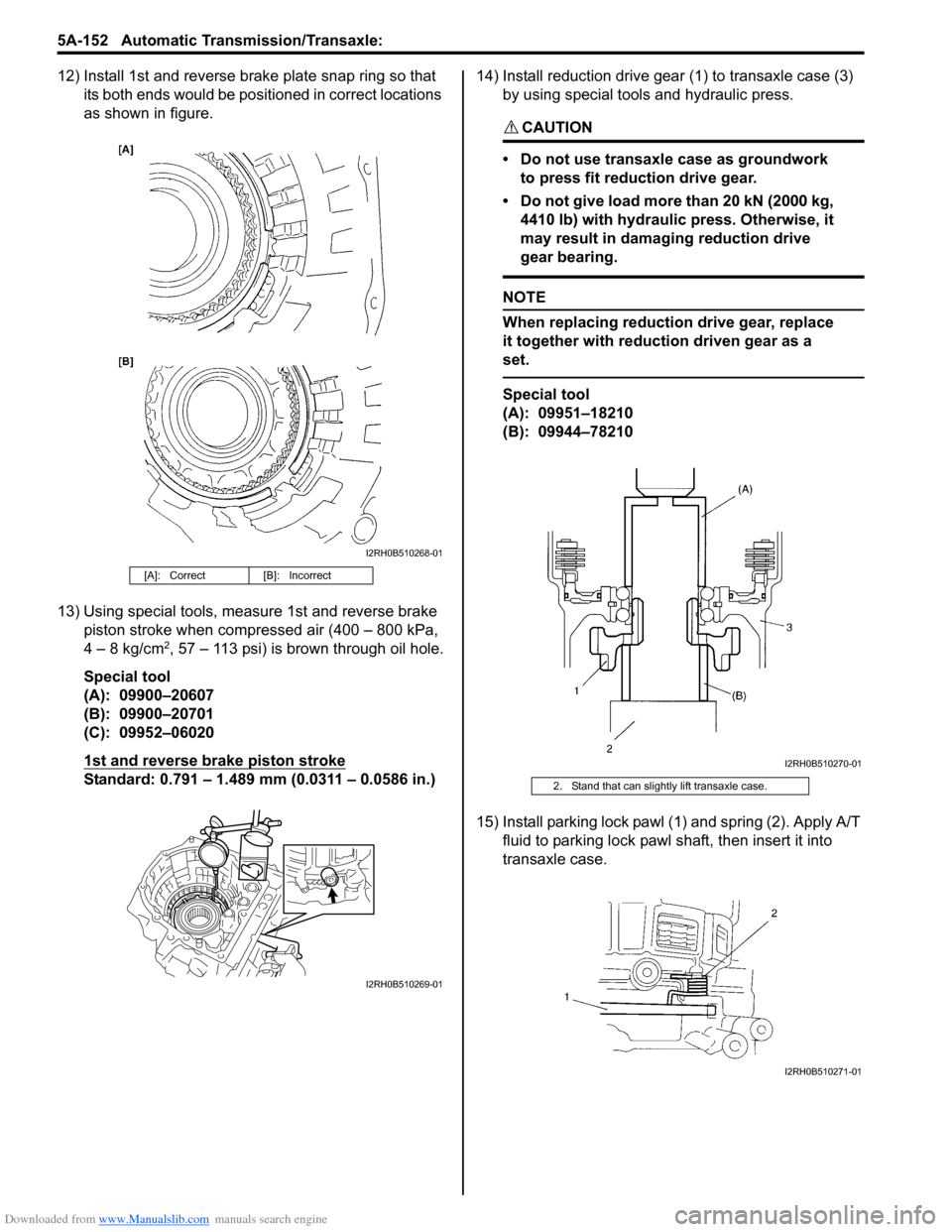

12) Install 1st and reverse brake plate snap ring so that its both ends would be positioned in correct locations

as shown in figure.

13) Using special tools, meas ure 1st and reverse brake

piston stroke when compressed air (400 – 800 kPa,

4 – 8 kg/cm

2, 57 – 113 psi) is brown through oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.791 – 1.489 mm (0.0311 – 0.0586 in.) 14) Install reduction drive gear (1) to transaxle case (3)

by using special tools and hydraulic press.

CAUTION!

• Do not use transaxle case as groundwork to press fit reduction drive gear.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

NOTE

When replacing reduction drive gear, replace

it together with reduction driven gear as a

set.

Special tool

(A): 09951–18210

(B): 09944–78210

15) Install parking lock pawl (1) and spring (2). Apply A/T fluid to parking lock pawl sh aft, then insert it into

transaxle case.

[A]: Correct [B]: Incorrect

I2RH0B510268-01

I2RH0B510269-01

2. Stand that can slightly lift transaxle case.

I2RH0B510270-01

I2RH0B510271-01

Page 797 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-153

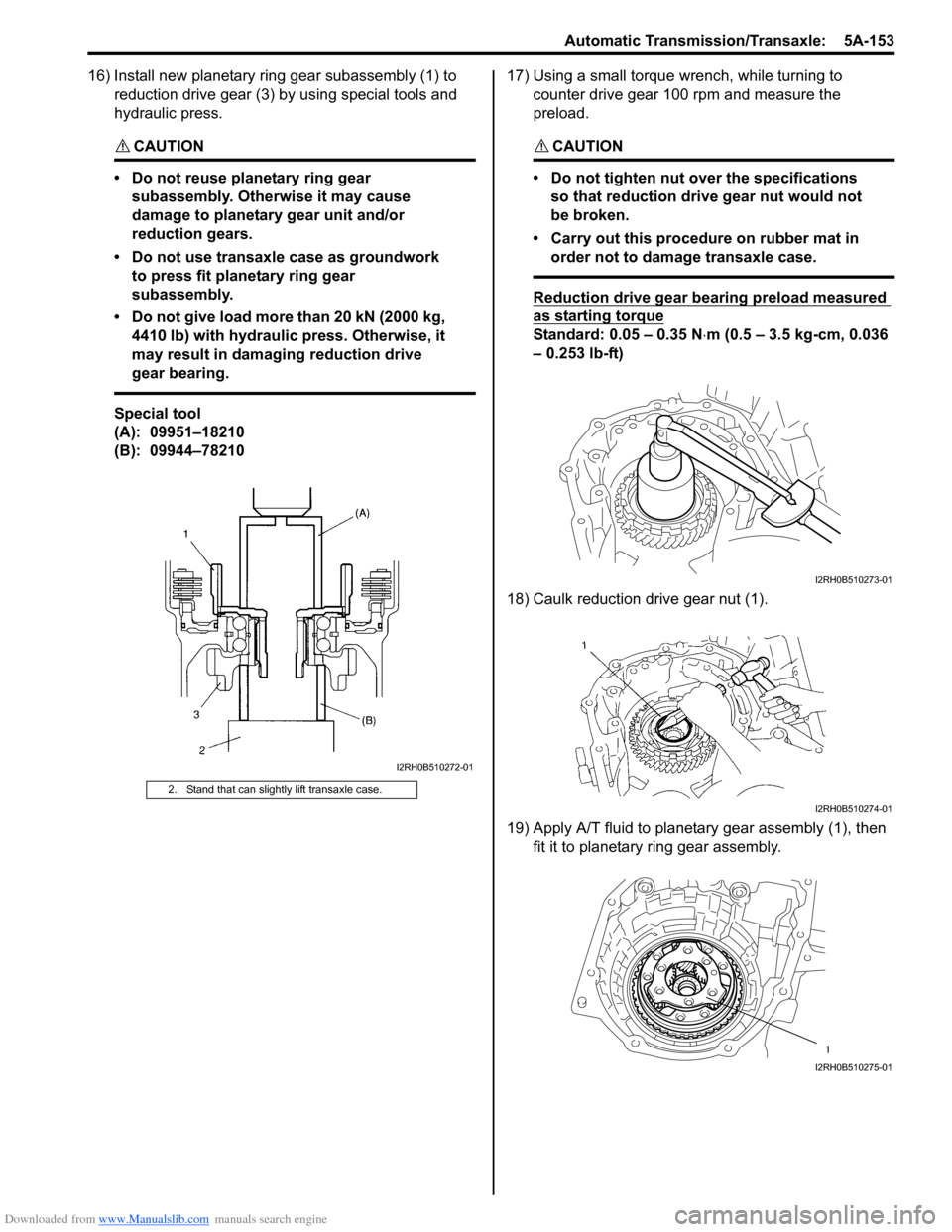

16) Install new planetary ring gear subassembly (1) to reduction drive gear (3) by using special tools and

hydraulic press.

CAUTION!

• Do not reuse planetary ring gear subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

• Do not use transaxle case as groundwork to press fit planetary ring gear

subassembly.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

Special tool

(A): 09951–18210

(B): 09944–78210 17) Using a small torque

wrench, while turning to

counter drive gear 100 rpm and measure the

preload.

CAUTION!

• Do not tighten nut over the specifications so that reduction drive gear nut would not

be broken.

• Carry out this procedure on rubber mat in order not to damage transaxle case.

Reduction drive gear bearing preload measured

as starting torque

Standard: 0.05 – 0.35 N ⋅m (0.5 – 3.5 kg-cm, 0.036

– 0.253 lb-ft)

18) Caulk reduction drive gear nut (1).

19) Apply A/T fluid to planetary gear assembly (1), then fit it to planetary ring gear assembly.

2. Stand that can slightly lift transaxle case.

I2RH0B510272-01

I2RH0B510273-01

I2RH0B510274-01

1

I2RH0B510275-01

Page 798 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-154 Automatic Transmission/Transaxle:

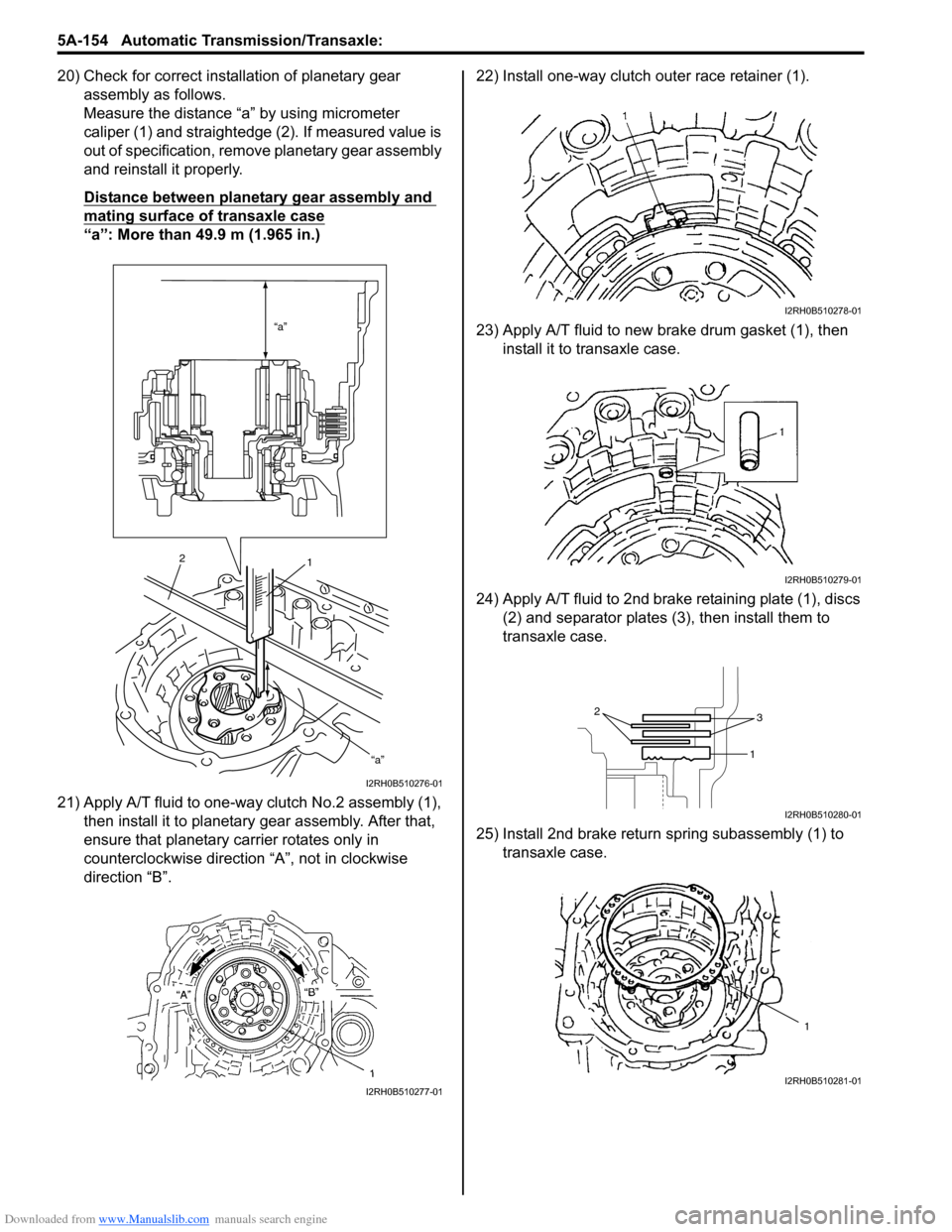

20) Check for correct installation of planetary gear assembly as follows.

Measure the distance “a” by using micrometer

caliper (1) and straightedge (2). If measured value is

out of specification, remove planetary gear assembly

and reinstall it properly.

Distance between planetary gear assembly and

mating surface of transaxle case

“a”: More than 49.9 m (1.965 in.)

21) Apply A/T fluid to one-way clutch No.2 assembly (1), then install it to planetar y gear assembly. After that,

ensure that planetary carrier rotates only in

counterclockwise direction “A”, not in clockwise

direction “B”. 22) Install one-way clutch outer race retainer (1).

23) Apply A/T fluid to new brake drum gasket (1), then

install it to transaxle case.

24) Apply A/T fluid to 2nd brak e retaining plate (1), discs

(2) and separator plates (3), then install them to

transaxle case.

25) Install 2nd brake return spring subassembly (1) to transaxle case.

“a”

“a”

2 1

I2RH0B510276-01

I2RH0B510277-01

I2RH0B510278-01

I2RH0B510279-01

2

3

1

I2RH0B510280-01

1

I2RH0B510281-01