Torque spec SUZUKI SWIFT 2006 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 453 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

Specifications

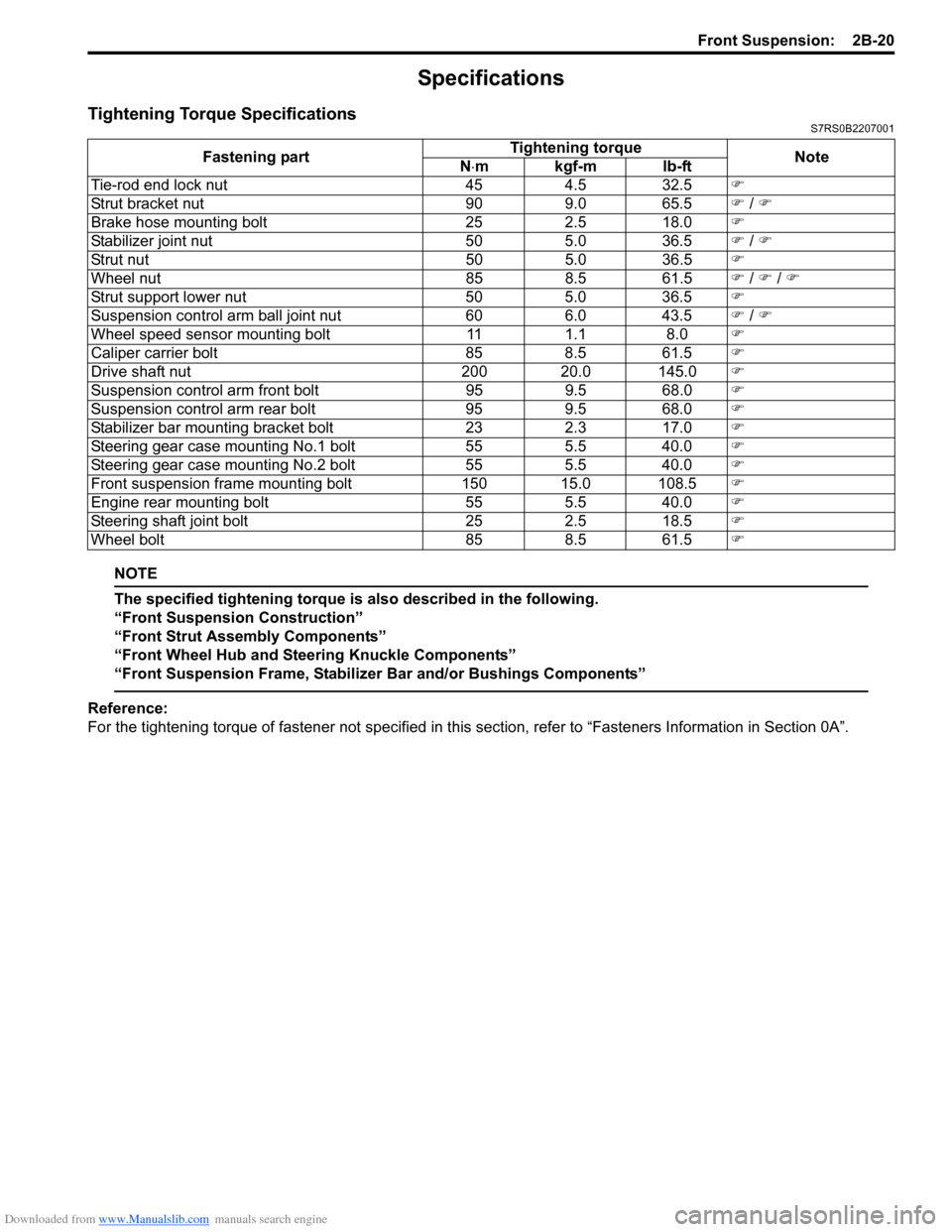

Tightening Torque SpecificationsS7RS0B2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushings Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end lock nut 454.5 32.5 �)

Strut bracket nut 909.0 65.5 �) / �)

Brake hose mounting bolt 252.5 18.0 �)

Stabilizer joint nut 505.0 36.5 �) / �)

Strut nut 505.0 36.5 �)

Wheel nut 858.5 61.5 �) / �) / �)

Strut support lower nut 505.0 36.5 �)

Suspension control arm ball joint nut 606.0 43.5 �) / �)

Wheel speed sensor mounting bolt 111.1 8.0 �)

Caliper carrier bolt 858.5 61.5 �)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm front bolt 959.5 68.0 �)

Suspension control arm rear bolt 959.5 68.0 �)

Stabilizer bar mounting bracket bolt 232.3 17.0 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Front suspension frame mounting bolt 150 15.0 108.5�)

Engine rear mounting bolt 555.5 40.0 �)

Steering shaft joint bolt 252.5 18.5 �)

Wheel bolt 858.5 61.5 �)

Page 457 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-3

2) Remove floor jack (2) from rear axle.

3) Install rear wheels and tighten wheel nuts specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

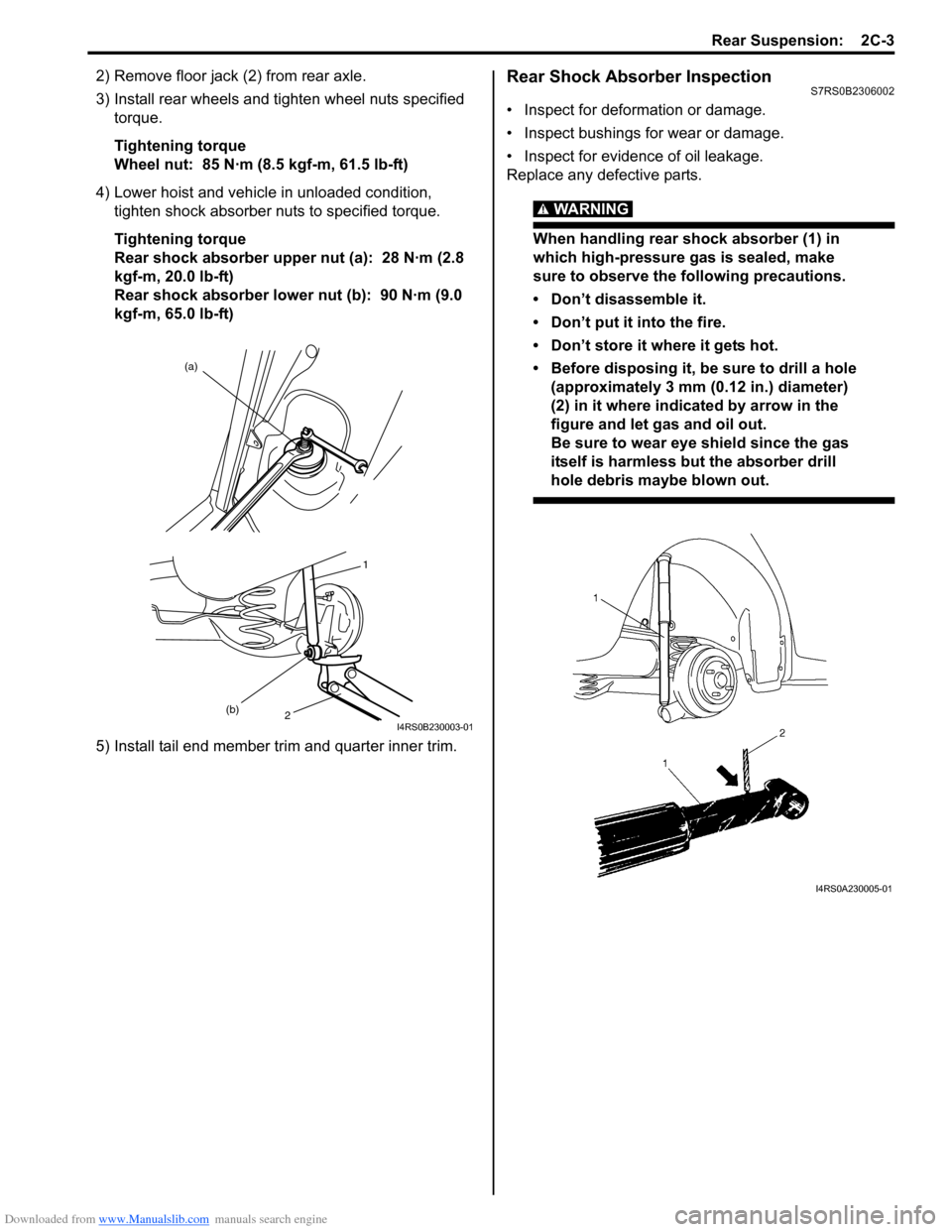

4) Lower hoist and vehicle in unloaded condition, tighten shock absorber nuts to specified torque.

Tightening torque

Rear shock absorber upper nut (a): 28 N·m (2.8

kgf-m, 20.0 lb-ft)

Rear shock absorber lower nut (b): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

5) Install tail end member trim and quarter inner trim.Rear Shock Absorber InspectionS7RS0B2306002

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective parts.

WARNING!

When handling rear shock absorber (1) in

which high-pressure gas is sealed, make

sure to observe the following precautions.

• Don’t disassemble it.

• Don’t put it into the fire.

• Don’t store it where it gets hot.

• Before disposing it, be sure to drill a hole (approximately 3 mm (0.12 in.) diameter)

(2) in it where indicated by arrow in the

figure and let gas and oil out.

Be sure to wear eye shield since the gas

itself is harmless but the absorber drill

hole debris maybe blown out.

(a)

1

(b) 2

I4RS0B230003-01

I4RS0A230005-01

Page 459 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-5

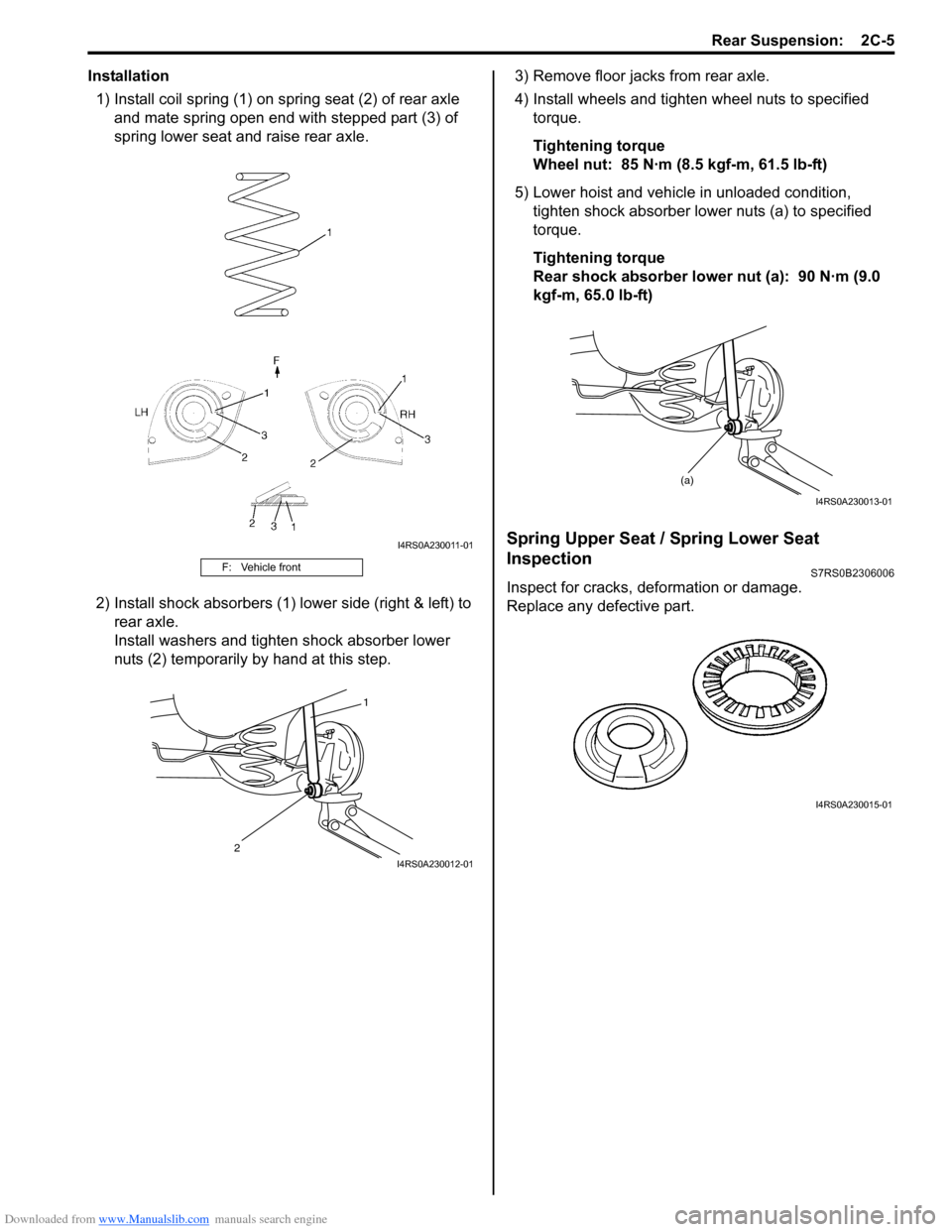

Installation1) Install coil spring (1) on spring seat (2) of rear axle and mate spring open end with stepped part (3) of

spring lower seat and raise rear axle.

2) Install shock absorbers (1) lower side (right & left) to rear axle.

Install washers and tighten shock absorber lower

nuts (2) temporarily by hand at this step. 3) Remove floor jacks from rear axle.

4) Install wheels and tighten wheel nuts to specified

torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

5) Lower hoist and vehicle in unloaded condition, tighten shock absorber lower nuts (a) to specified

torque.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Spring Upper Seat / Spring Lower Seat

Inspection

S7RS0B2306006

Inspect for cracks, deformation or damage.

Replace any defective part.

F: Vehicle front

I4RS0A230011-01

1

2

I4RS0A230012-01

(a)

I4RS0A230013-01

I4RS0A230015-01

Page 462 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-8 Rear Suspension:

3) Install coil springs (right & left) on spring seats of rear

axle referring to “Spring Upper Seat and Lower Seat

Removal and Installation” and “Rear Coil Spring

Removal and Installation”.

4) Install shock absorbers lower side (right & left) and washers referring to “Rear Shock Absorber Removal

and Installation”.

5) Install brake dust covers, spindles and wheel speed sensors (right and left) referring to “Spindle Removal

and Installation”.

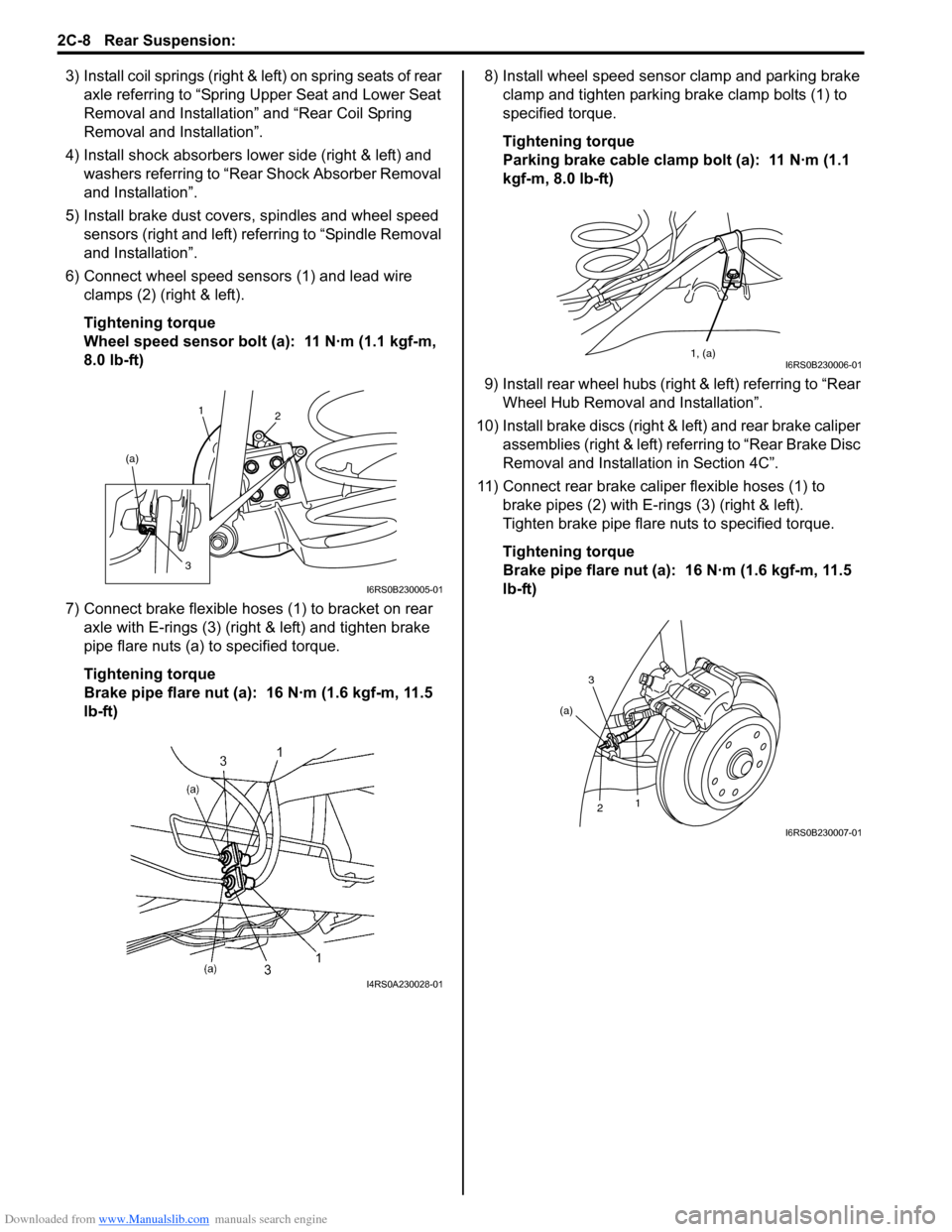

6) Connect wheel speed sensors (1) and lead wire clamps (2) (right & left).

Tightening torque

Wheel speed sensor bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Connect brake flexible hoses (1) to bracket on rear axle with E-rings (3) (right & left) and tighten brake

pipe flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft) 8) Install wheel speed sensor clamp and parking brake

clamp and tighten parking brake clamp bolts (1) to

specified torque.

Tightening torque

Parking brake cable clamp bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

9) Install rear wheel hubs (right & left) referring to “Rear Wheel Hub Removal and Installation”.

10) Install brake discs (right & left) and rear brake caliper assemblies (right & left) referring to “Rear Brake Disc

Removal and Installati on in Section 4C”.

11) Connect rear brake caliper flexible hoses (1) to brake pipes (2) with E-rings (3) (right & left).

Tighten brake pipe flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

1 2

(a)

3

I6RS0B230005-01

I4RS0A230028-01

1, (a)I6RS0B230006-01

3

2 1

(a)

I6RS0B230007-01

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

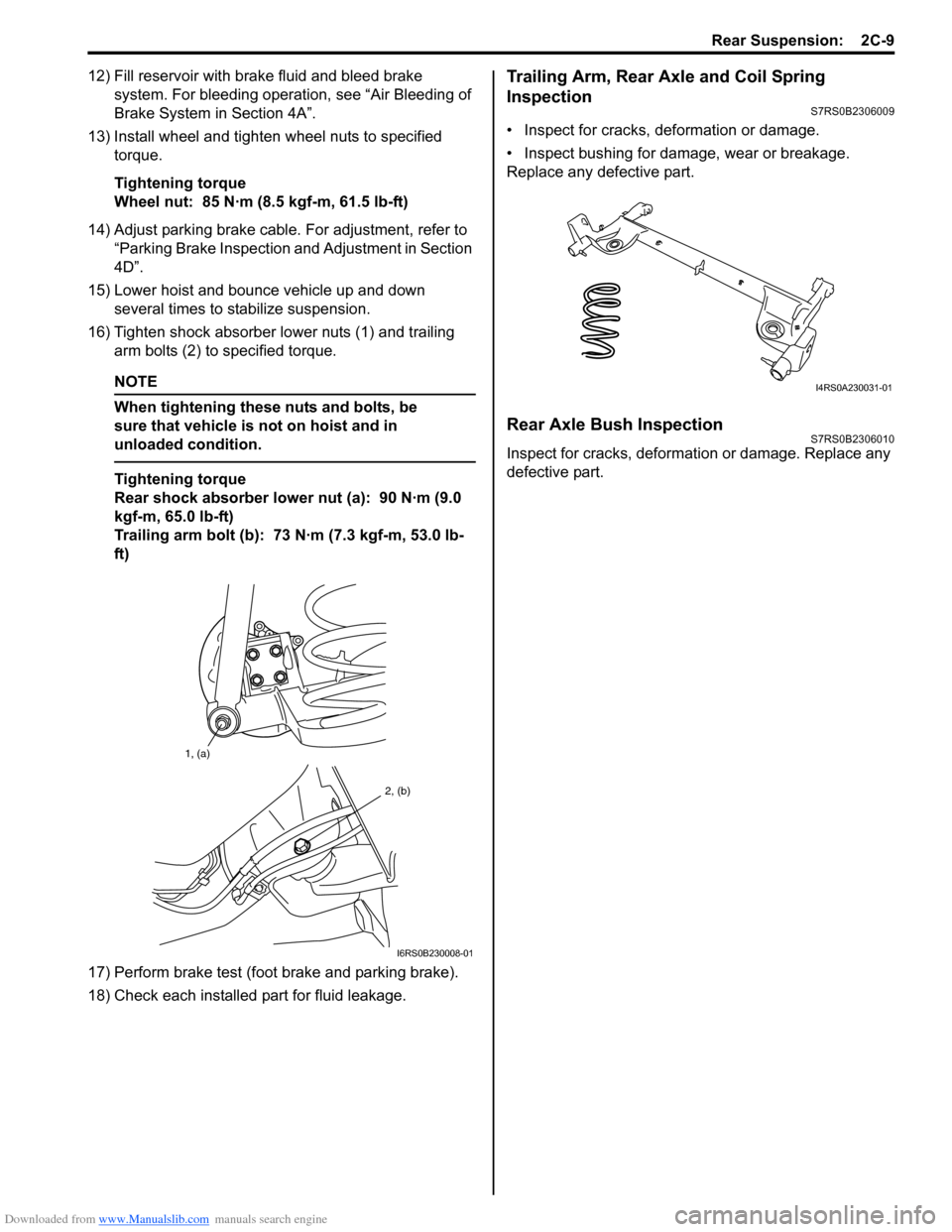

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

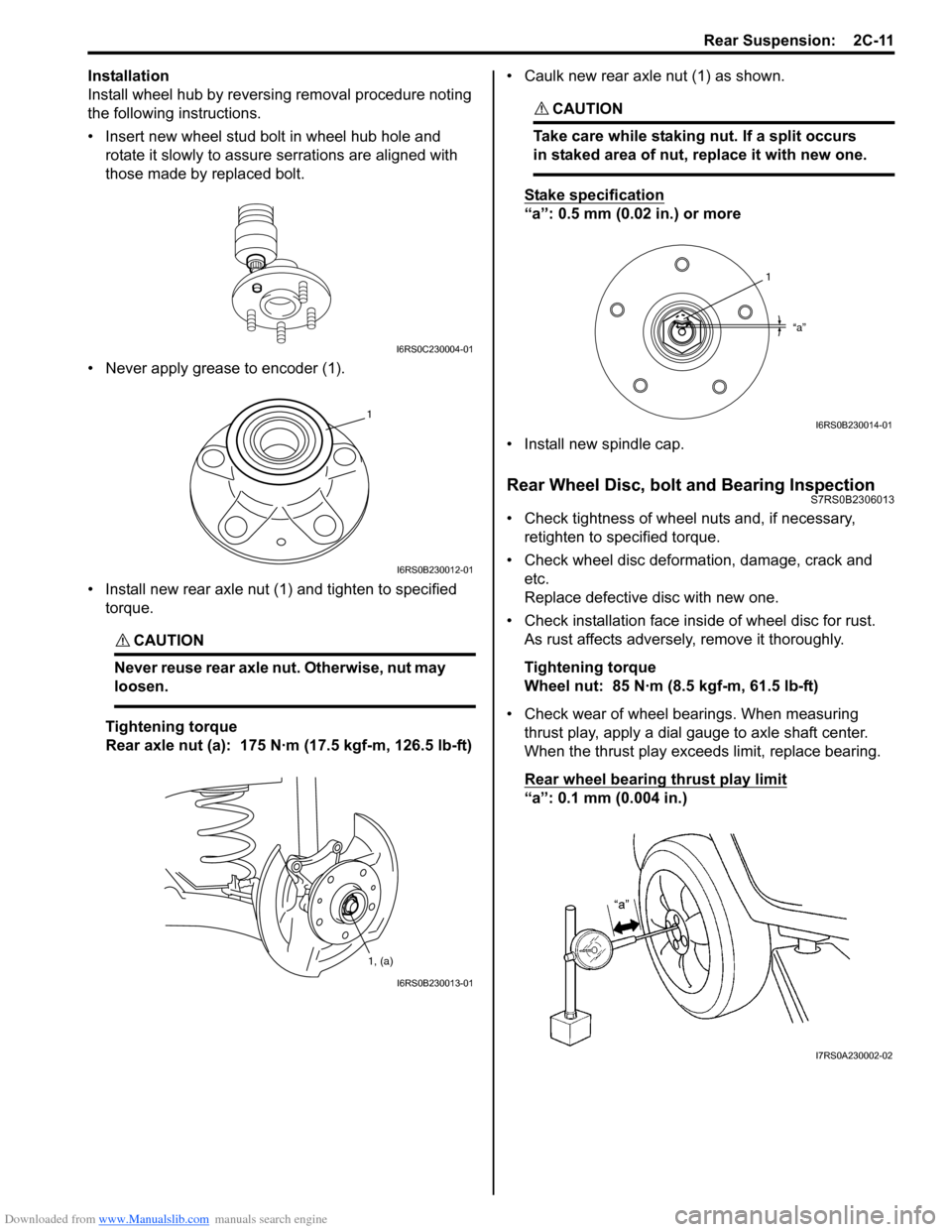

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 465 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-11

Installation

Install wheel hub by reversing removal procedure noting

the following instructions.

• Insert new wheel stud bolt in wheel hub hole and rotate it slowly to assure serrations are aligned with

those made by replaced bolt.

• Never apply grease to encoder (1).

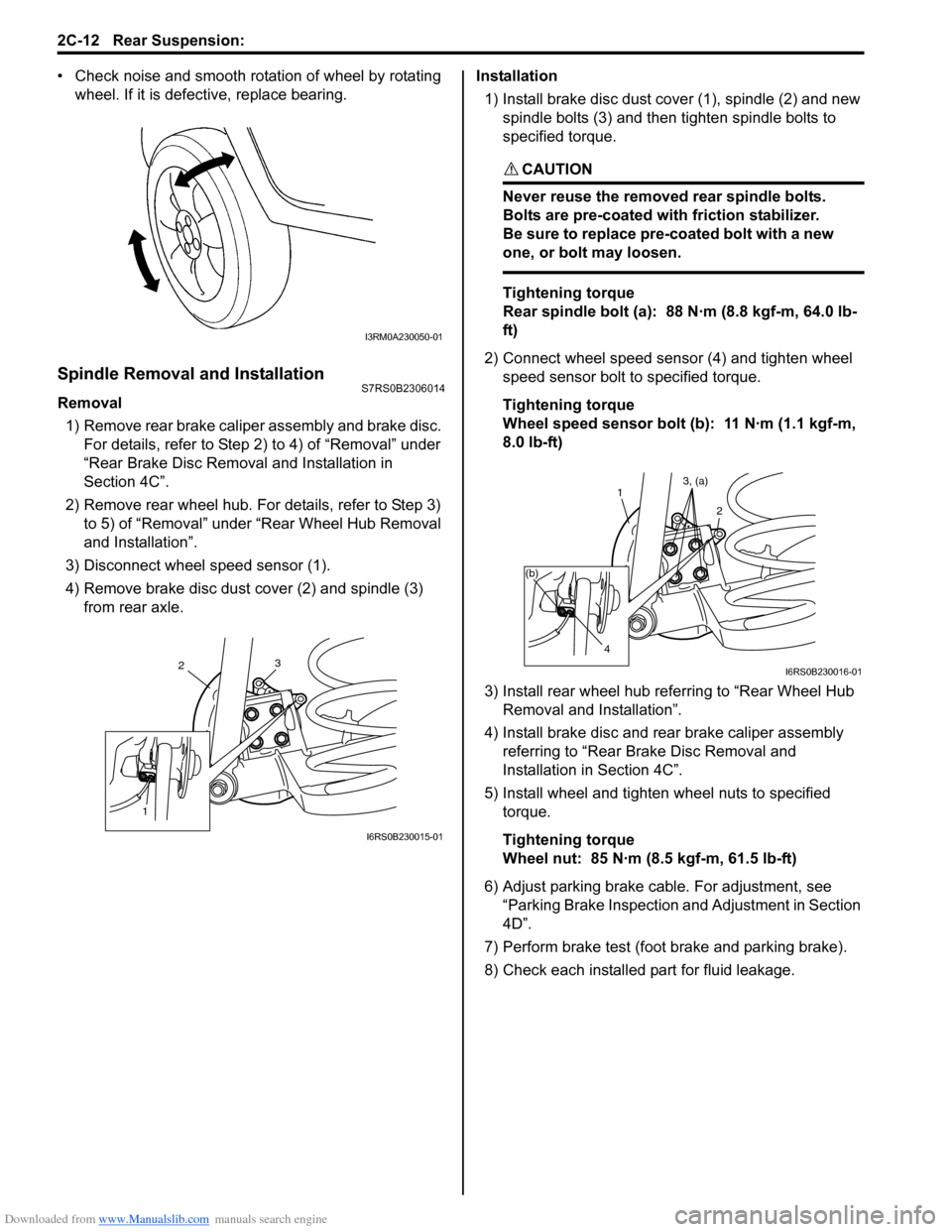

• Install new rear axle nut (1) and tighten to specified torque.

CAUTION!

Never reuse rear axle nut. Otherwise, nut may

loosen.

Tightening torque

Rear axle nut (a): 175 N·m (17.5 kgf-m, 126.5 lb-ft) • Caulk new rear axle nut (1) as shown.

CAUTION!

Take care while staking nut. If a split occurs

in staked area of nut,

replace it with new one.

Stake specification

“a”: 0.5 mm (0.02 in.) or more

• Install new spindle cap.

Rear Wheel Disc, bolt and Bearing InspectionS7RS0B2306013

• Check tightness of wheel nuts and, if necessary, retighten to specified torque.

• Check wheel disc deformation, damage, crack and etc.

Replace defective disc with new one.

• Check installation face insi de of wheel disc for rust.

As rust affects adversely, remove it thoroughly.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearings. When measuring thrust play, apply a dial gauge to axle shaft center.

When the thrust play exce eds limit, replace bearing.

Rear wheel bearing thrust play

limit

“a”: 0.1 mm (0.004 in.)

I6RS0C230004-01

1

I6RS0B230012-01

1, (a)

I6RS0B230013-01

1

“a”

I6RS0B230014-01

I7RS0A230002-02

Page 466 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-12 Rear Suspension:

• Check noise and smooth rotation of wheel by rotating wheel. If it is defect ive, replace bearing.

Spindle Removal and InstallationS7RS0B2306014

Removal

1) Remove rear brake caliper assembly and brake disc. For details, refer to Step 2) to 4) of “Removal” under

“Rear Brake Disc Removal and Installation in

Section 4C”.

2) Remove rear wheel hub. For details, refer to Step 3) to 5) of “Removal” under “Rear Wheel Hub Removal

and Installation”.

3) Disconnect wheel speed sensor (1).

4) Remove brake disc dust cover (2) and spindle (3) from rear axle. Installation

1) Install brake disc dust cover (1), spindle (2) and new spindle bolts (3) and then tighten spindle bolts to

specified torque.

CAUTION!

Never reuse the removed rear spindle bolts.

Bolts are pre-coated wi th friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Rear spindle bolt (a): 88 N·m (8.8 kgf-m, 64.0 lb-

ft)

2) Connect wheel speed sensor (4) and tighten wheel speed sensor bolt to specified torque.

Tightening torque

Wheel speed sensor bolt (b): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

3) Install rear wheel hub re ferring to “Rear Wheel Hub

Removal and Installation”.

4) Install brake disc and rear brake caliper assembly referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) Adjust parking brake cable. For adjustment, see “Parking Brake Inspection and Adjustment in Section

4D”.

7) Perform brake test (foot brake and parking brake).

8) Check each installed part for fluid leakage.

I3RM0A230050-01

2

1 3

I6RS0B230015-01

1

(b)

4

2

3, (a)

I6RS0B230016-01

Page 467 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-13

Spindle InspectionS7RS0B2306015

• Inspect for cracks, deformation or damage.Replace any defective part.

Rear Suspension Fasteners InspectionS7RS0B2306016

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque

referring to the figure in “Rear Suspension Construction”.

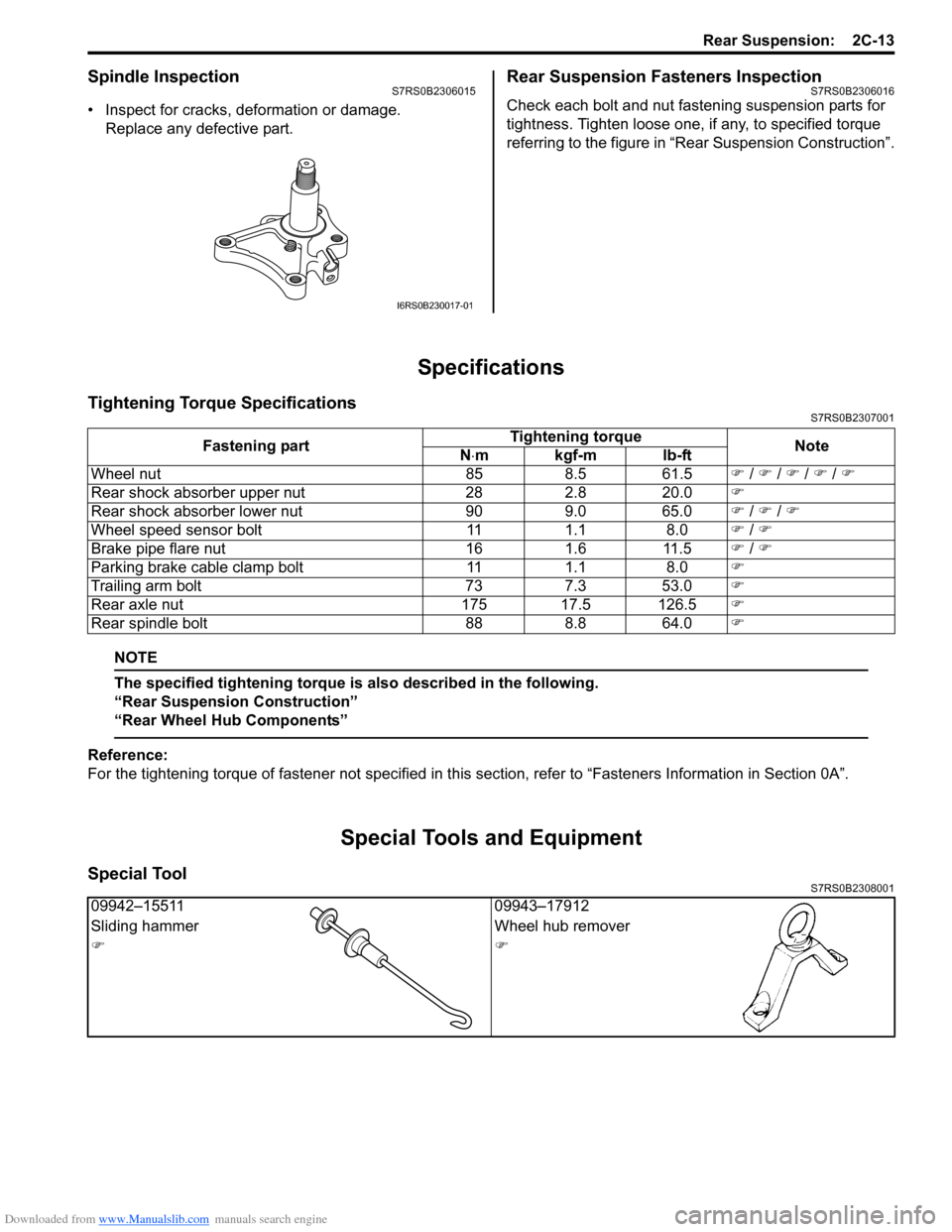

Specifications

Tightening Torque SpecificationsS7RS0B2307001

NOTE

The specified tightening torque is also described in the following.

“Rear Suspension Construction”

“Rear Wheel Hub Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B2308001

I6RS0B230017-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 85 8.5 61.5 �) / �) / �) / �) / �)

Rear shock absorber upper nut 28 2.8 20.0 �)

Rear shock absorber lower nut 90 9.0 65.0 �) / �) / �)

Wheel speed sensor bolt 11 1.1 8.0 �) / �)

Brake pipe flare nut 16 1.6 11.5 �) / �)

Parking brake cable clamp bolt 11 1.1 8.0 �)

Trailing arm bolt 73 7.3 53.0 �)

Rear axle nut 175 17.5 126.5 �)

Rear spindle bolt 88 8.8 64.0 �)

09942–1551109943–17912

Sliding hammer Wheel hub remover

�)�)

Page 474 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-7 Wheels and Tires:

Wheel Removal and InstallationS7RS0B2406003

Removal

WARNING!

Do not removal all of the wheel nuts at once,

because all the wheels of this vehicle are

mounted by the wheel nuts.

Leave a nut at least not to drop the wheel.

Support the wheel and/or tire and then

remove the nut(s) left with the wheel.

1) Loosen wheel nuts by approximately 180° (half a

rotation).

2) Hoist vehicle.

3) Make sure that the vehicle will not fall off by trying to

move vehicle body in both ways.

4) Remove wheel nut except one.

5) Support the wheel and/or tire not to drop the wheel and then remove the nut left with the wheel.

CAUTION!

Never use heat to loosen tight wheel because

the application of heat to wheel causes the

wheel life shorter and the wheel bearing

damage.

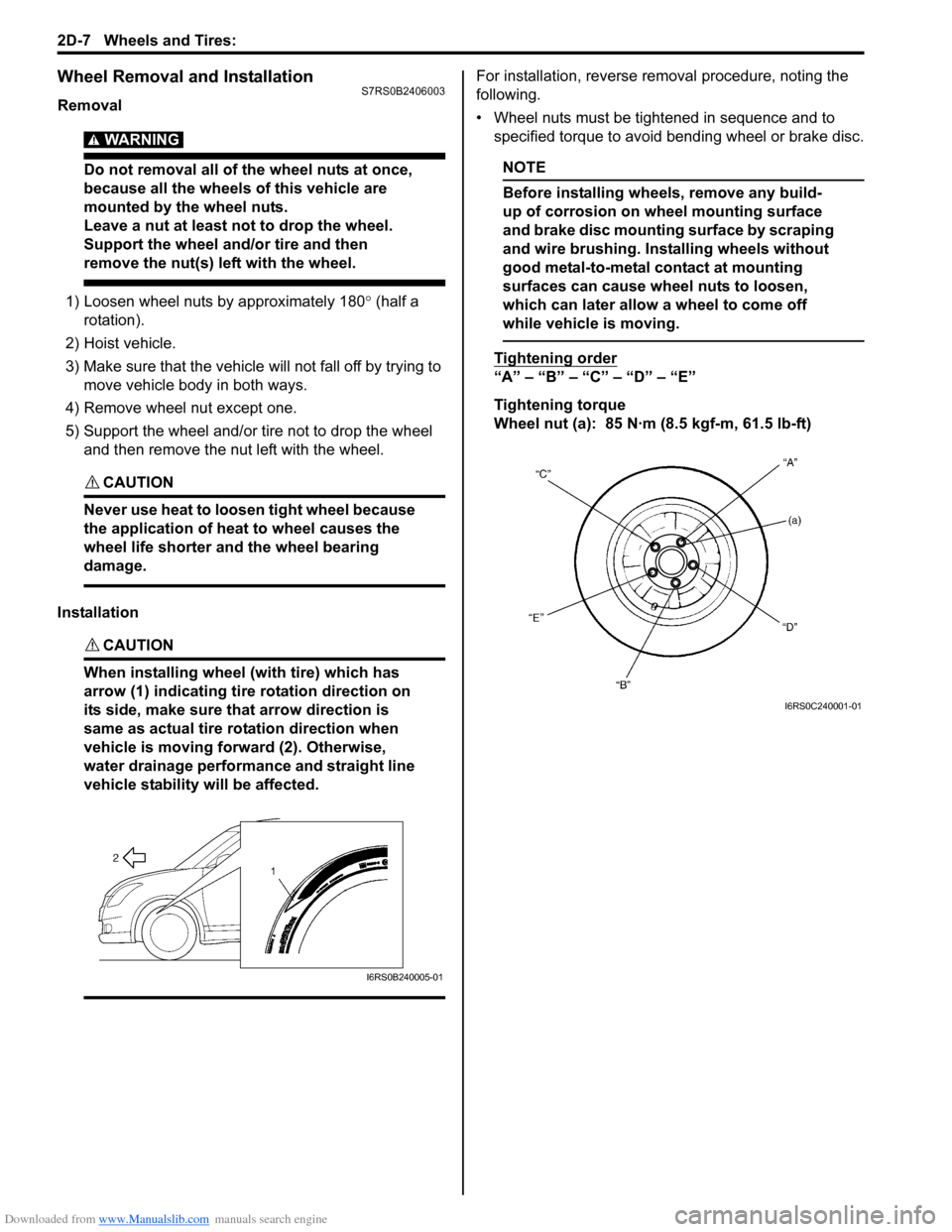

Installation

CAUTION!

When installing wheel (with tire) which has

arrow (1) indicating tire rotation direction on

its side, make sure that arrow direction is

same as actual tire ro tation direction when

vehicle is moving forw ard (2). Otherwise,

water drainage performance and straight line

vehicle stability will be affected.

For installation, reverse removal procedure, noting the

following.

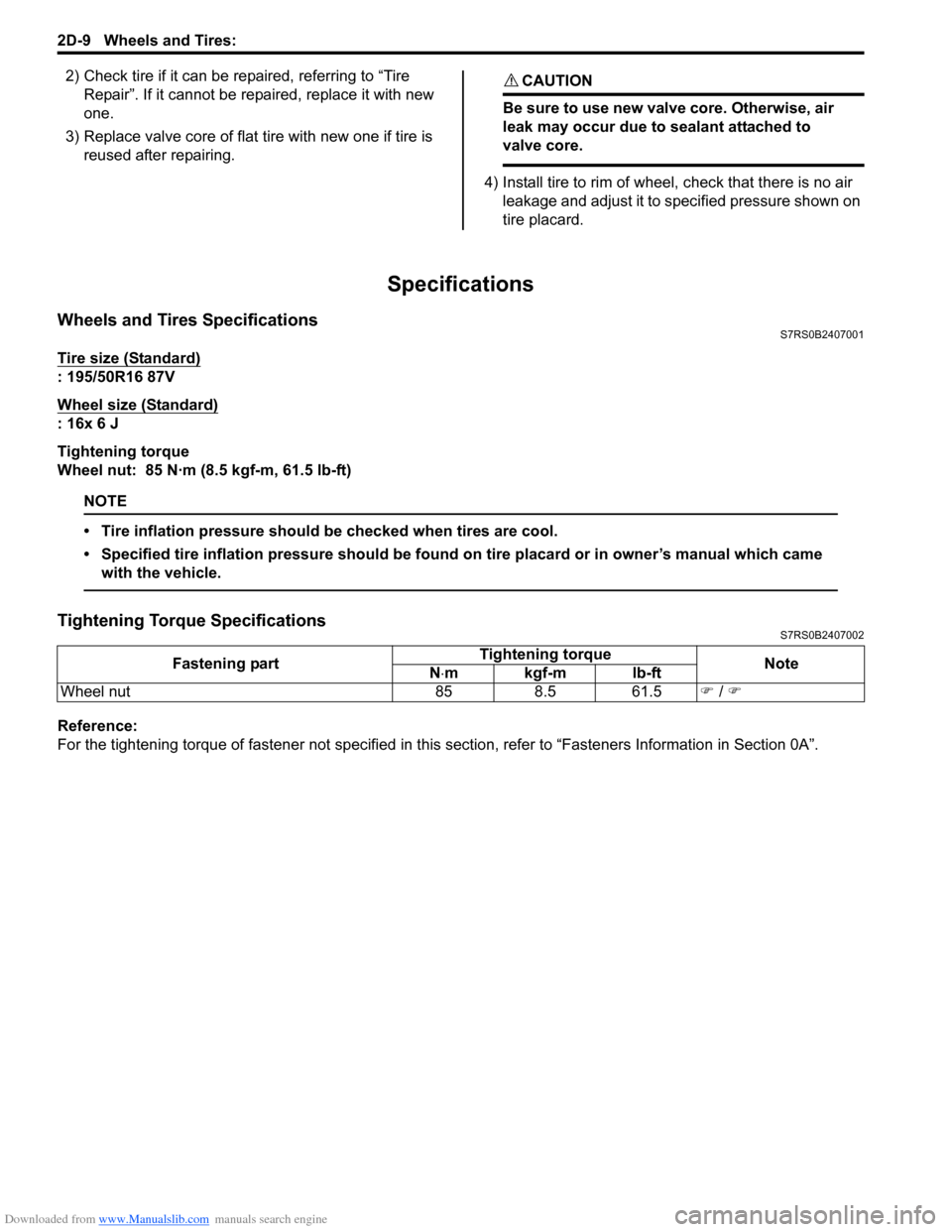

• Wheel nuts must be tightened in sequence and to specified torque to avoid bending wheel or brake disc.

NOTE

Before installing wheels, remove any build-

up of corrosion on wheel mounting surface

and brake disc mounting surface by scraping

and wire brushing. Installing wheels without

good metal-to-metal contact at mounting

surfaces can cause wheel nuts to loosen,

which can later allow a wheel to come off

while vehicle is moving.

Tightening order

“A” – “B” – “C” – “D” – “E”

Tightening torque

Wheel nut (a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

I6RS0B240005-01

I6RS0C240001-01

Page 476 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-9 Wheels and Tires:

2) Check tire if it can be repaired, referring to “Tire

Repair”. If it cannot be repaired, replace it with new

one.

3) Replace valve core of flat tire with new one if tire is reused after repairing.CAUTION!

Be sure to use new valve core. Otherwise, air

leak may occur due to sealant attached to

valve core.

4) Install tire to ri m of wheel, check that there is no air

leakage and adjust it to specified pressure shown on

tire placard.

Specifications

Wheels and Tires SpecificationsS7RS0B2407001

Tire size (Standard)

: 195/50R16 87V

Wheel size (Standard)

: 16x 6 J

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual which came

with the vehicle.

Tightening Torque SpecificationsS7RS0B2407002

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 858.5 61.5 �) / �)