Check engine light comes on SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 43 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-13

Brake

Foot brake

Check the following:

• that brake pedal has proper travel,

• that brake works properly,

• that it is free from noise,

• that vehicle does not pull to one side when brake is applied.

• and that brake do not drag.

Parking brake

Check that lever has proper travel.

WARNING!

With vehicle parked on a fairly steep slope,

make sure nothing is in the way downhill to

avoid any personal injury or property

damage. Be prepared to apply regular brake

quickly even if vehicle should start to move.

Check to ensure that parking brake is fully effective

when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.

Steering

• Check to ensure that steering wheel is free from instability, or abnormally heavy feeling. • Check that the vehicle does not wander or pull to one

side.

Engine

• Check that engine responds readily at all speeds.

• Check that engine is free from abnormal noise and abnormal vibration.

Body, Wheels and Power Transmitting System

Check that body, wheels and power transmitting system

are free from abnormal noise and abnormal vibration or

any other abnormal condition.

Meters and Gauge

Check that speedometer, odometer, fuel meter,

temperature gauge, etc. are operating accurately.

Lights

Check that all lights operate properly.

Windshield Defroster

Periodically check that ai r comes out from defroster

outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan

switch lever to “HI” position for this check.

Specifications

Tightening Torque SpecificationsS7RS0B0207001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Fluids and LubricantsS7RS0B0208001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Engine oil drain plug 35 3.5 25.5 �)

Oil filter 14 1.4 10.5 for reference �)

Engine oilSG, SH, SJ, SL or SM grade (Refer to “Engine Oil and Filter Change” for engine

oil viscosity.)

Engine coolant

(Ethylene glycol base coolant) “Antifreeze/Antico

rrosion coolant”

Brake fluid Refer to reservoir cap of brake master cylinder.

Manual transaxle oil Refer to “Manual Transaxle Oil Change in Section 5B”.

Automatic transaxle fluid Refer to “A/T Fluid Change in Section 5A”.

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 411 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-1

Engine

Charging System

General Description

Battery DescriptionS7RS0B1A01001

The battery has three major functions in the electrical

system.

• It is a source of electrical energy for cranking the engine.

• It acts as a voltage stabilizer for the electrical system.

• It can, for a limited time, provide energy when the electrical load exceeds the output of the generator.

Carrier and Hold-Down

The battery carrier should be in good condition so that it

will support the battery securely and keep it level. Before

installing the battery, the ba ttery carrier and hold-down

clamp should be clean and free from corrosion and

make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the

hold-down bolts should be tight enough but not over-

tightened.

Electrolyte Freezing

The freezing point of electrolyte depends on its specific

gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully

charged condition. If a battery is frozen accidentally, it

should not be charged until it is warmed.

Sulfation

If the battery is allowed to stand for a long period in

discharged condition, the lead sulfate becomes

converted into a hard, cryst alline substance, which will

not easily turn back to the active material again during

the subsequent recharging. “Sulfation” means the result

as well as the process of that reaction. Such a battery

can be revived by very slow charging and may be

restored to usable condition but its capacity is lower than

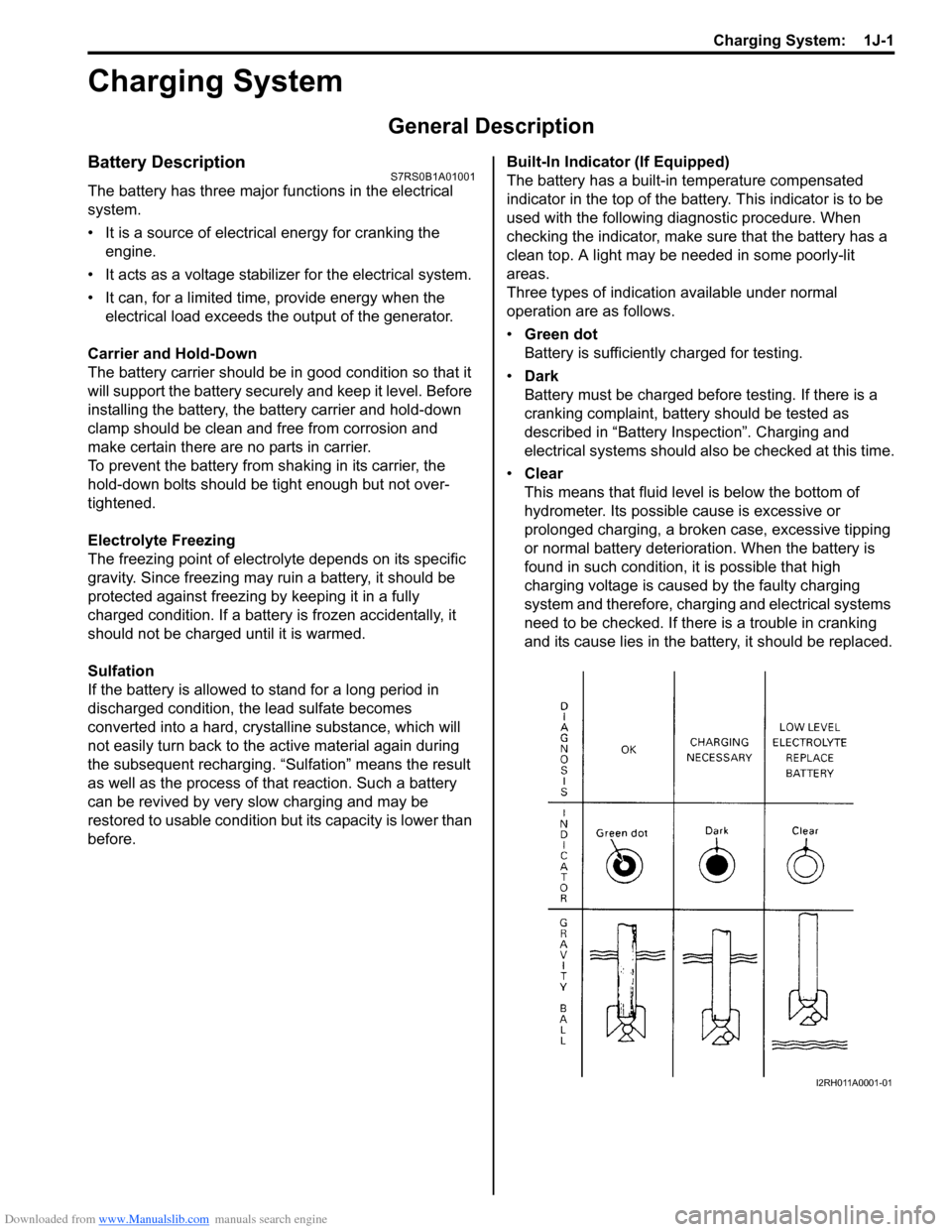

before. Built-In Indicator (If Equipped)

The battery has a built-in temperature compensated

indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When

checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit

areas.

Three types of indication available under normal

operation are as follows.

•

Green dot

Battery is sufficiently charged for testing.

• Dark

Battery must be charged before testing. If there is a

cranking complaint, battery should be tested as

described in “Battery Inspection”. Charging and

electrical systems should also be checked at this time.

• Clear

This means that fluid level is below the bottom of

hydrometer. Its possible cause is excessive or

prolonged charging, a broken case, excessive tipping

or normal battery deteriorat ion. When the battery is

found in such condition, it is possible that high

charging voltage is caused by the faulty charging

system and therefore, charging and electrical systems

need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

I2RH011A0001-01

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

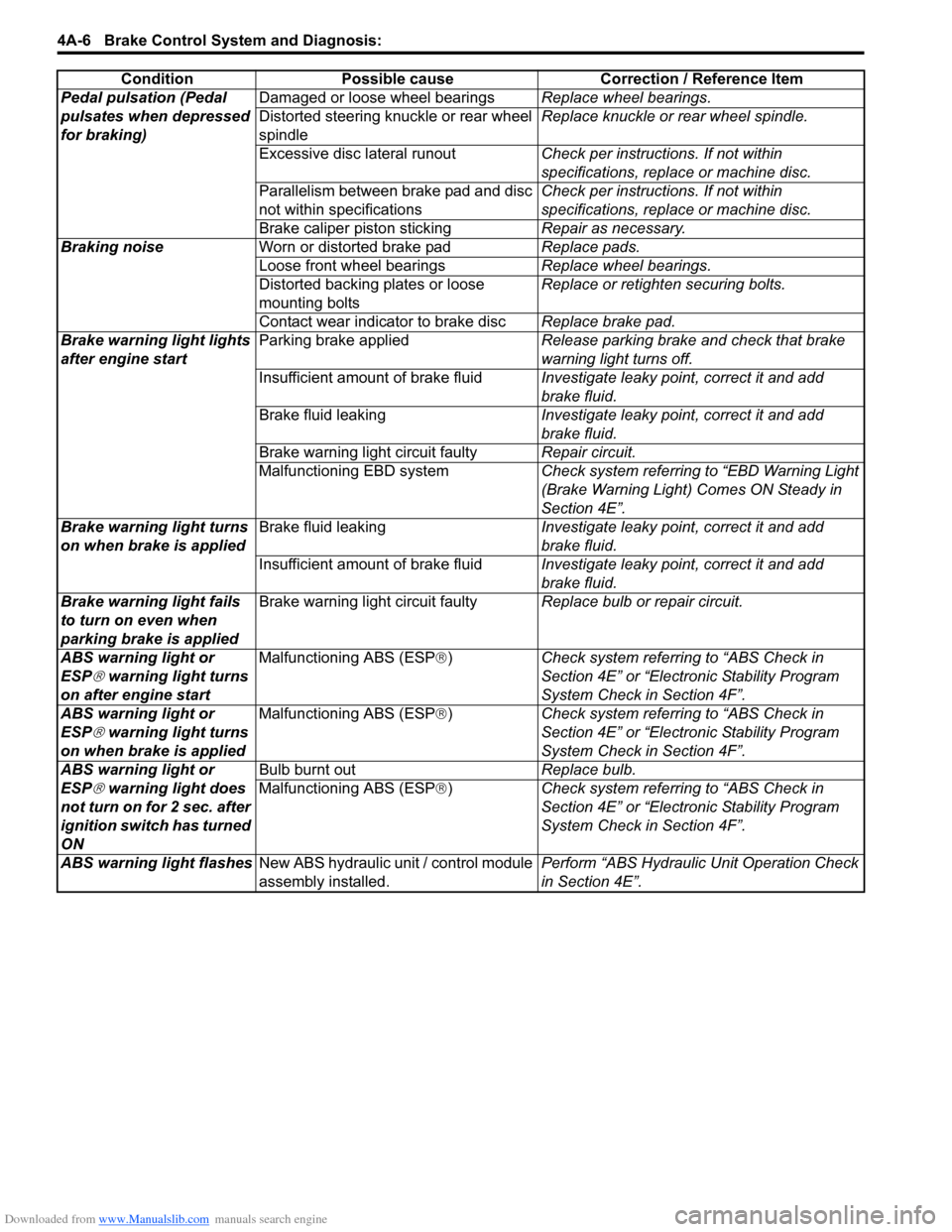

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

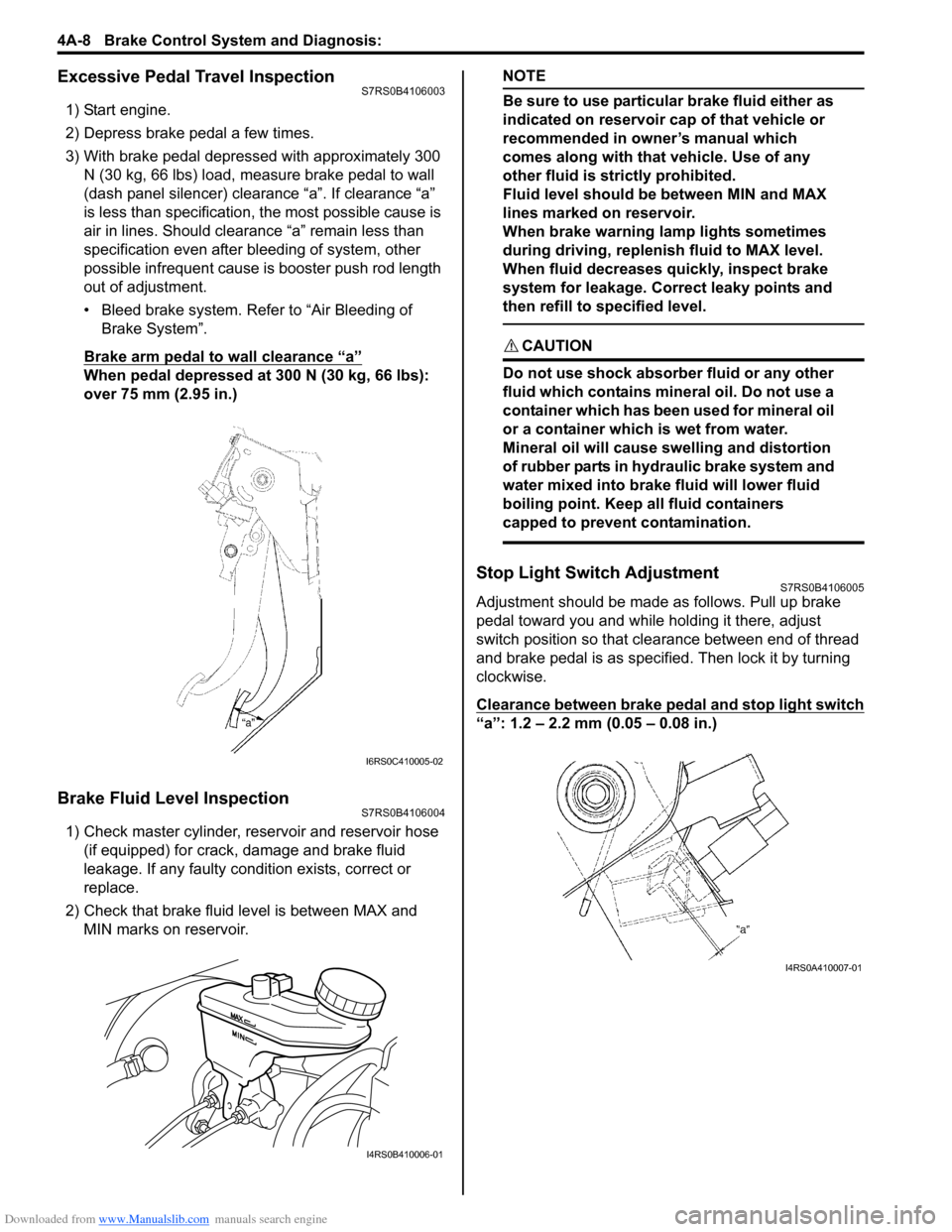

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

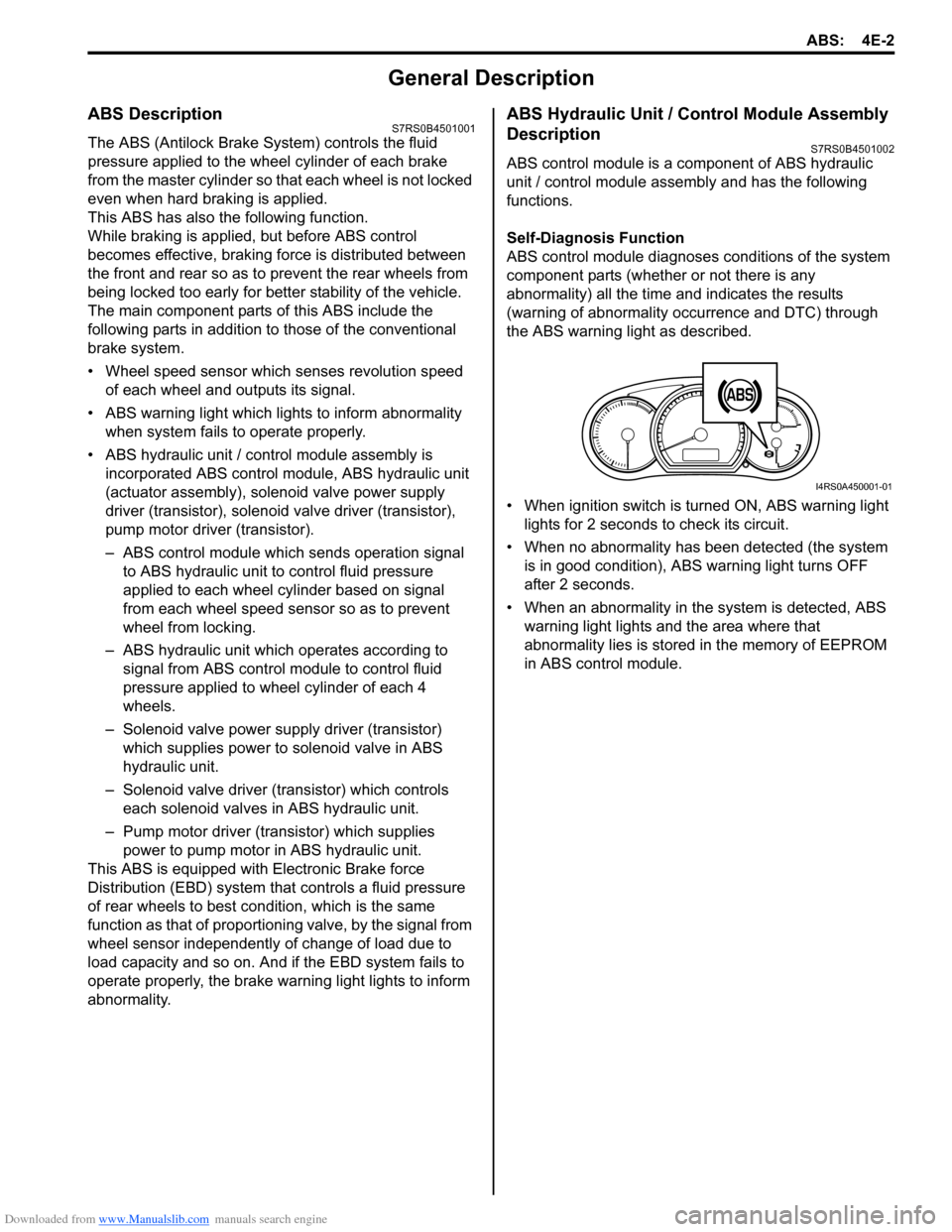

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 541 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

ABS DescriptionS7RS0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

• ABS warning light which light s to inform abnormality

when system fails to operate properly.

• ABS hydraulic unit / cont rol module assembly is

incorporated ABS co ntrol module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supp ly driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportion ing valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. An d if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS Hydraulic Unit / Control Module Assembly

Description

S7RS0B4501002

ABS control module is a component of ABS hydraulic

unit / control module asse mbly and has the following

functions.

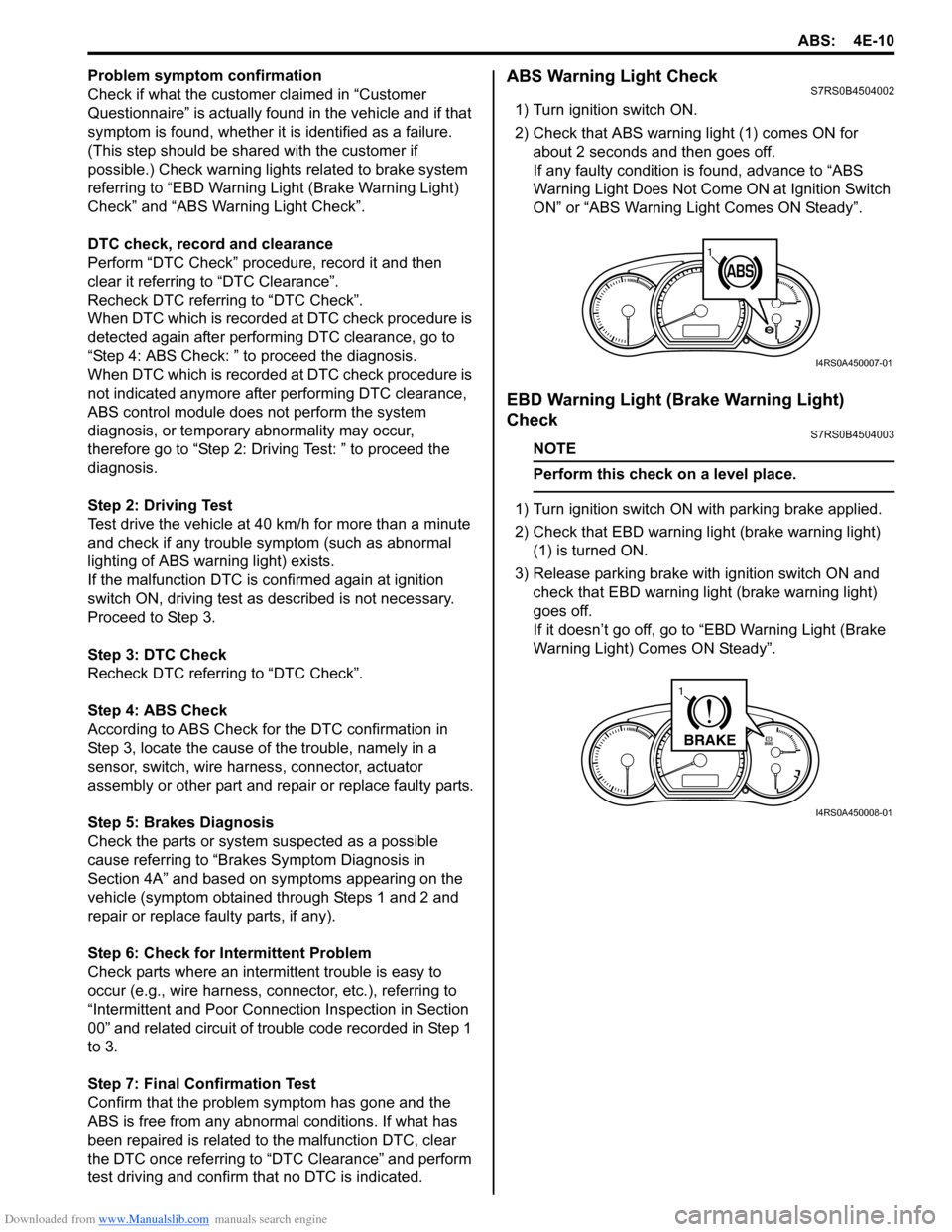

Self-Diagnosis Function

ABS control module diagnose s conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.

• When ignition switch is turned ON, ABS warning light lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in th e system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

1

I4RS0A450001-01

Page 549 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-10

Problem symptom confirmation

Check if what the customer claimed in “Customer

Questionnaire” is actually found in the vehicle and if that

symptom is found, whether it is identified as a failure.

(This step should be shared with the customer if

possible.) Check warning lights related to brake system

referring to “EBD Warning Light (Brake Warning Light)

Check” and “ABS Warning Light Check”.

DTC check, record and clearance

Perform “DTC Check” proced ure, record it and then

clear it referring to “DTC Clearance”.

Recheck DTC referring to “DTC Check”.

When DTC which is recorded at DTC check procedure is

detected again after performi ng DTC clearance, go to

“Step 4: ABS Check: ” to proceed the diagnosis.

When DTC which is recorded at DTC check procedure is

not indicated anymore after performing DTC clearance,

ABS control module does not perform the system

diagnosis, or temporary abnormality may occur,

therefore go to “Step 2: Driving Test: ” to proceed the

diagnosis.

Step 2: Driving Test

Test drive the vehicle at 40 km/h for more than a minute

and check if any trouble symptom (such as abnormal

lighting of ABS warn ing light) exists.

If the malfunction DTC is co nfirmed again at ignition

switch ON, driving test as described is not necessary.

Proceed to Step 3.

Step 3: DTC Check

Recheck DTC referring to “DTC Check”.

Step 4: ABS Check

According to ABS Check for the DTC confirmation in

Step 3, locate the cause of the trouble, namely in a

sensor, switch, wire harness, connector, actuator

assembly or other part and repair or replace faulty parts.

Step 5: Brakes Diagnosis

Check the parts or system suspected as a possible

cause referring to “Brakes Symptom Diagnosis in

Section 4A” and based on symptoms appearing on the

vehicle (symptom obtained through Steps 1 and 2 and

repair or replace faulty parts, if any).

Step 6: Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, con nector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of trouble code recorded in Step 1

to 3.

Step 7: Final Confirmation Test

Confirm that the problem symptom has gone and the

ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once referring to “DTC Clearance” and perform

test driving and confirm that no DTC is indicated.ABS Warning Light CheckS7RS0B4504002

1) Turn ignition switch ON.

2) Check that ABS warning light (1) comes ON for

about 2 seconds and then goes off.

If any faulty condition is found, advance to “ABS

Warning Light Does Not Come ON at Ignition Switch

ON” or “ABS Warning Light Comes ON Steady”.

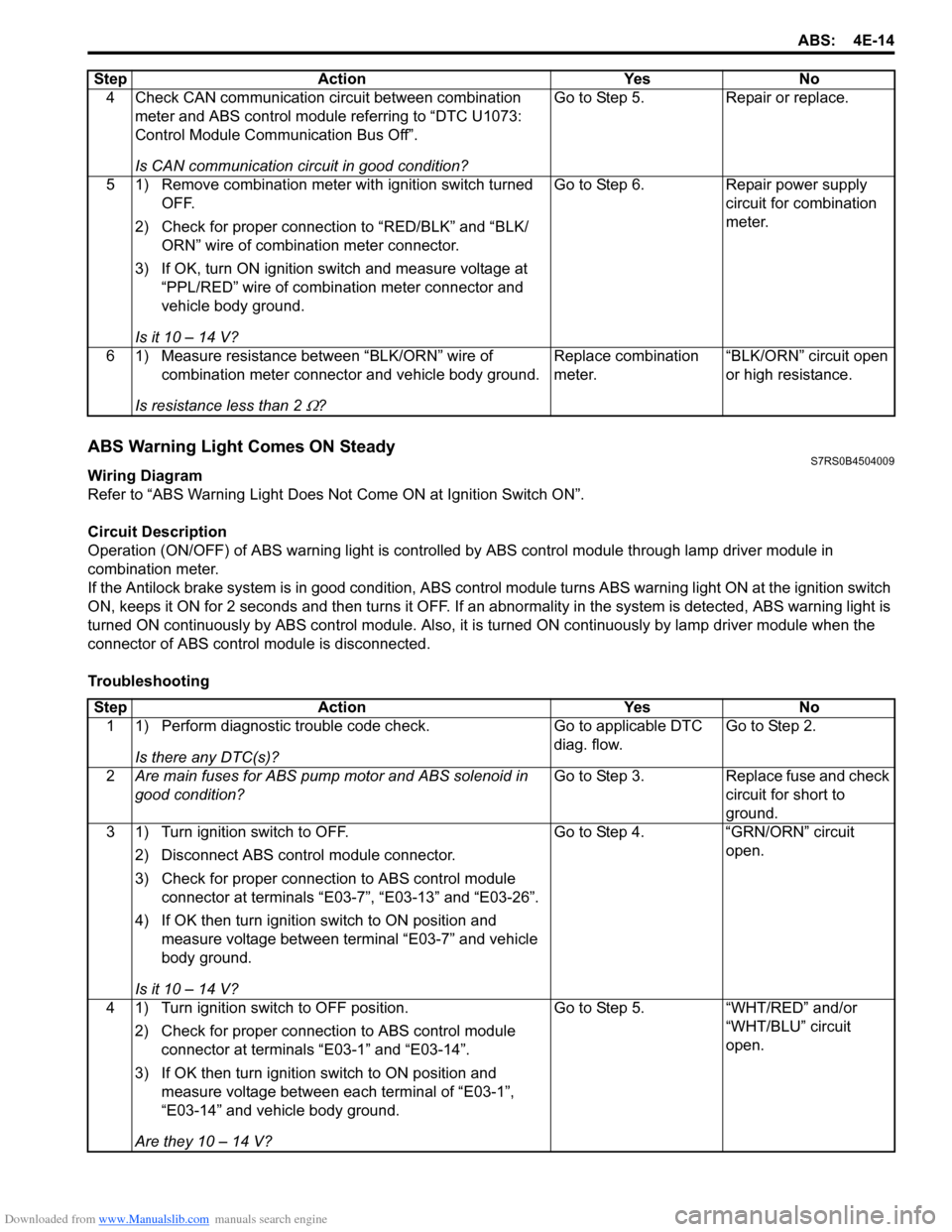

EBD Warning Light (Brake Warning Light)

Check

S7RS0B4504003

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning lig ht (brake warning light)

(1) is turned ON.

3) Release parking brake with ignition switch ON and check that EBD warning lig ht (brake warning light)

goes off.

If it doesn’t go off, go to “EBD Warning Light (Brake

Warning Light) Comes ON Steady”.

11

I4RS0A450007-01

BRAKE

1

I4RS0A450008-01

Page 553 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

ABS Warning Light Comes ON SteadyS7RS0B4504009

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

Operation (ON/OFF) of ABS wa rning light is controlled by ABS contro l module through lamp driver module in

combination meter.

If the Antilock brake system is in good condition, ABS control module turns ABS warning lig ht ON at the ignition switch

ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ABS warning light is

turned ON continuously by ABS c ontrol module. Also, it is turned ON continuously by la mp driver module when the

connector of ABS control module is disconnected.

Troubleshooting 4 Check CAN communication circuit between combination

meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Go to Step 5.

Repair or replace.

5 1) Remove combination meter wit h ignition switch turned

OFF.

2) Check for proper connection to “RED/BLK” and “BLK/ ORN” wire of combinat ion meter connector.

3) If OK, turn ON ignition switch and measure voltage at “PPL/RED” wire of combi nation meter connector and

vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

Repair power supply

circuit for combination

meter.

6 1) Measure resistance between “BLK/ORN” wire of combination meter connector and vehicle body ground.

Is resistance less than 2

Ω? Replace combination

meter.

“BLK/ORN” circuit open

or high resistance.

Step Action Yes No

Step

Action YesNo

1 1) Perform diagnostic trouble code check.

Is there any DTC(s)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Are main fuses for ABS pump motor and ABS solenoid in

good condition? Go to Step 3.

Replace fuse and check

circuit for short to

ground.

3 1) Turn ignition switch to OFF.

2) Disconnect ABS control module connector.

3) Check for proper connection to ABS control module connector at terminals “E03-7”, “E03-13” and “E03-26”.

4) If OK then turn ignition switch to ON position and measure voltage between terminal “E03-7” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” circuit

open.

4 1) Turn ignition switch to OFF position. 2) Check for proper connection to ABS control module connector at terminals “E03-1” and “E03-14”.

3) If OK then turn ignition switch to ON position and measure voltage between each terminal of “E03-1”,

“E03-14” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5.

“WHT/RED” and/or

“WHT/BLU” circuit

open.

Page 554 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-15 ABS:

EBD Warning Light (Brake Warning Light) Comes ON SteadyS7RS0B4504010

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning light (brake warn ing light) is controlled by parking brake switch, brake fluid level switch and ABS

hydraulic unit / control module assembly throug h lamp driver module in combination meter.

EBD warning light turns ON when parki ng brake switch is ON and/or brake fluid level is lower than minimum level.

The information of parking brake switch and brake fluid leve l are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting 5 1) Turn ignition switch to OFF and measure resistance

between each terminal of “E03-13”, “E03-26” and vehicle

body ground.

Is resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 Check CAN communication circuit between combination meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Step Action Yes No

Step

Action YesNo

1 1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK? Go to Step 2.

Release parking brake

completely and/or

replenish brake fluid.

2 1) Turn ignition switch to ON position. Does “ABS” warning light come on steady? Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3 1) CAN communication circuit between combination meter, ABS hydraulic unit / control module and BCM referring to

“DTC U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Page 560 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

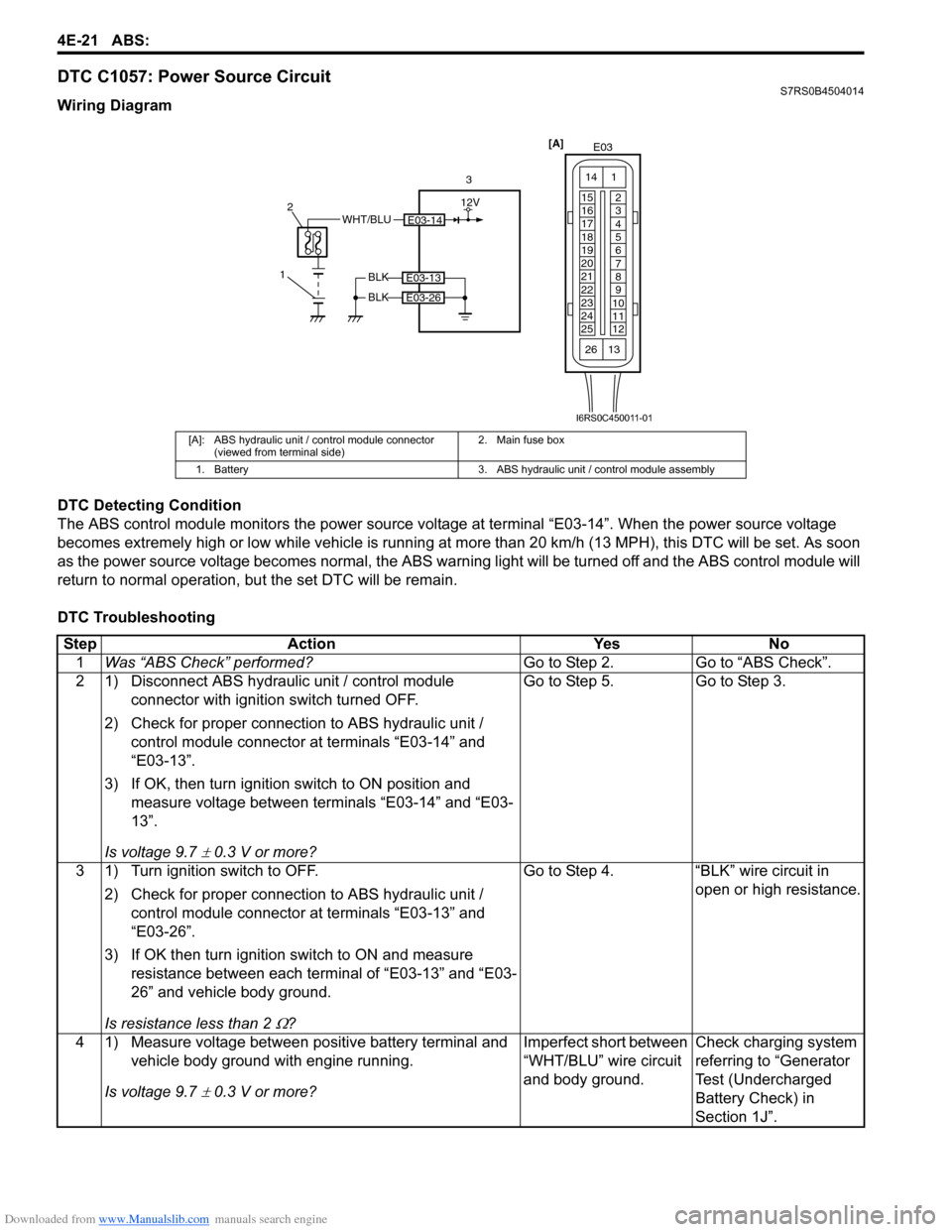

DTC C1057: Power Source CircuitS7RS0B4504014

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the power source voltage at terminal “E03-14”. When the power source voltage

becomes extremely high or low while vehicle is running at more than 20 km/h (13 MPH), this DTC will be set. As soon

as the power source volta ge becomes normal, the ABS warning light will be turned off and the ABS control module will

return to normal operation, bu t the set DTC will be remain.

DTC Troubleshooting

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ABS hydraulic unit / control module assembly

E03-14WHT/BLU

1 2

3

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

12V

I6RS0C450011-01

Step

Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Disconnect ABS hydraulic unit / control module connector with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-14” and

“E03-13”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E03-14” and “E03-

13”.

Is voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 1) Turn ignition switch to OFF. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK then turn ignition switch to ON and measure resistance between each terminal of “E03-13” and “E03-

26” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 1) Measure voltage between positive battery terminal and vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and body ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.