Light control SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 23 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

SAS: Steering Angle Sensor

SDM: Sensing and Diagnostic Module (Air Bag Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multipor t Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position Sensor TVV:

Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bi metal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

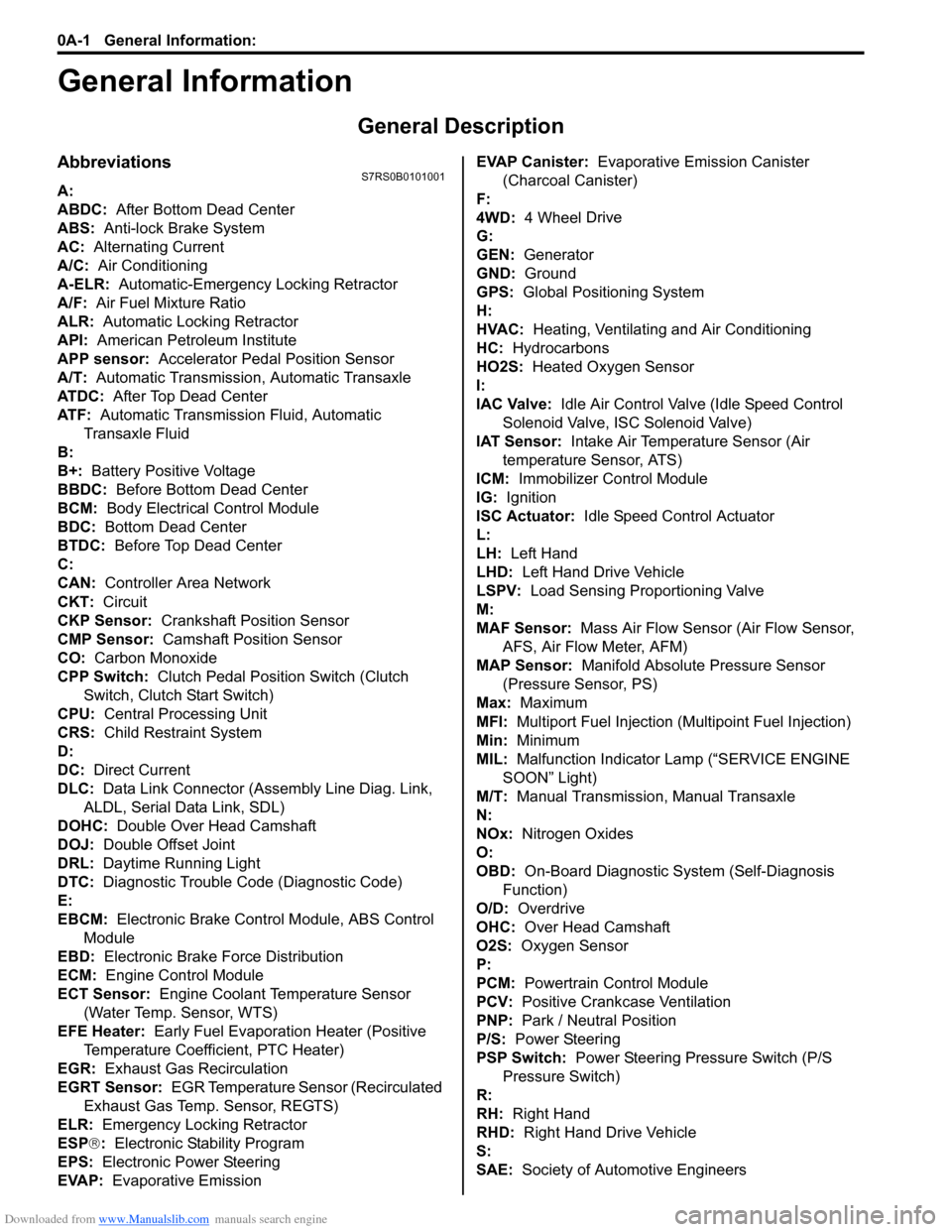

SymbolsS7RS0B0101002

Wire Color SymbolsS7RS0B0101003

Symbol Definition SymbolDefinition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential) Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid) Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030 Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050 Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25121 Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110 Do not reuse

Apply SUZUKI BO ND NO. 1207F

99000-31250 Note on reassembly

Apply SUZUKI BO ND NO. 1217G

99000-31260

Symbol Wire Color SymbolWire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue RRED Red

Br BRN Brown WWHT White

G GRN Green YYEL Yellow

Gr GRY Gray PPNK Pink

Lbl LT BLU Light blueVPPL Violet

Lg LT GRN Light green

Page 37 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-7

Fuel Filter ReplacementS7RS0B0206011

Fuel filter is installed in fuel pump assembly in fuel tank.

Replace fuel filter or fuel pump assembly with new one,

referring to “Fuel Pump Assembly Removal and

Installation in Section 1G” for proper procedure.

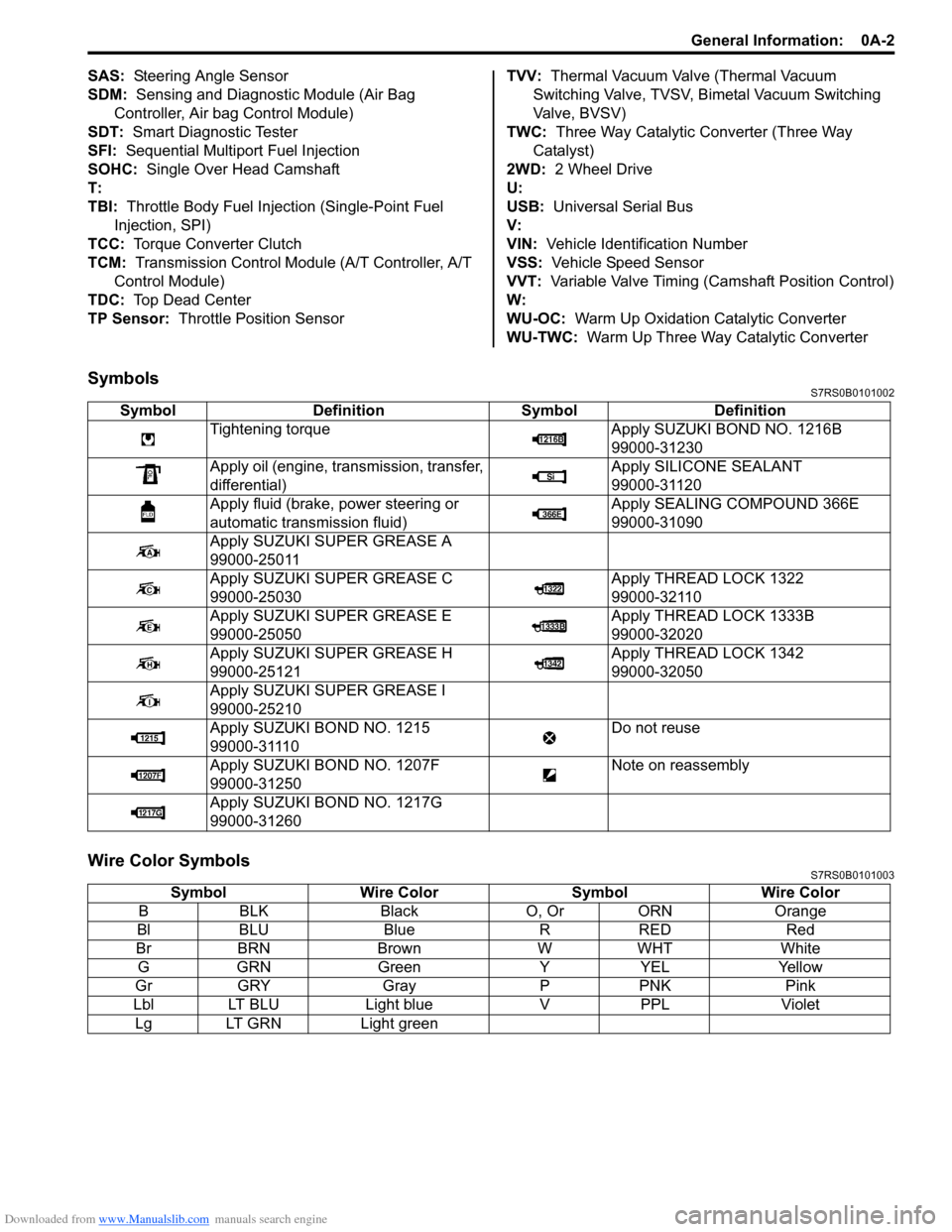

Fuel Tank InspectionS7RS0B0206012

Check fuel tank damage, cracks, fuel leakage, corrosion

and tank bolts looseness.

If a problem is found, repair or replace.

PCV Valve InspectionS7RS0B0206013

Check crankcase ventilation hose and PCV hose for

leaks, cracks or clog, and PCV valve for stick or clog.

Refer to “PCV Valve Inspection in Section 1B” for PCV

valve checking procedure.

Fuel Evaporative Emission Control System

Inspection

S7RS0B0206014

1) Visually inspect hoses for cracks, damage, or excessive bends. Inspect a ll clamps for damage and

proper position.

2) Check EVAP canister for operation and clog, referring to “EVAP Canister Inspection in Section

1B”.

If a malfunction is found, repair or replace.

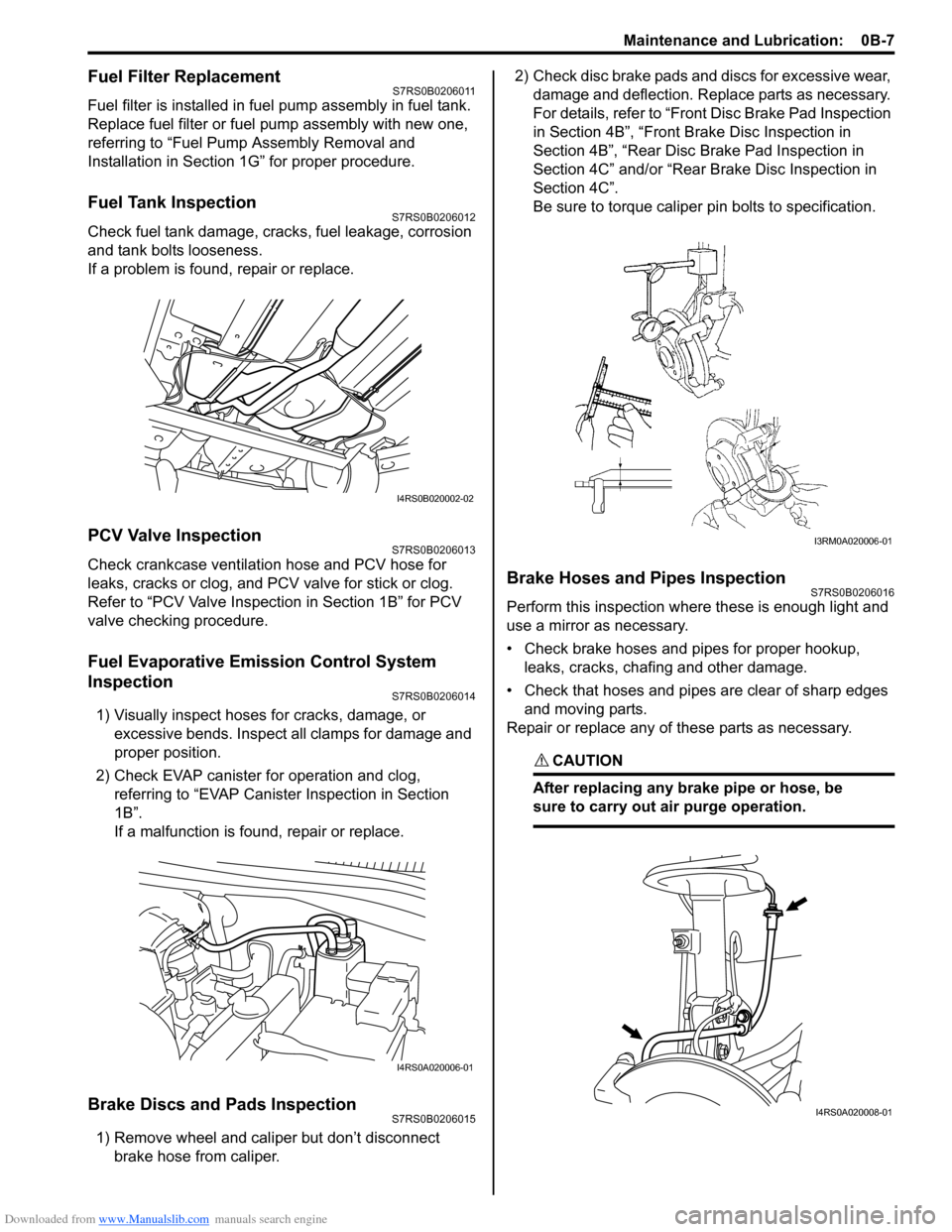

Brake Discs and Pads InspectionS7RS0B0206015

1) Remove wheel and caliper but don’t disconnect brake hose from caliper. 2) Check disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary.

For details, refer to “Front Disc Brake Pad Inspection

in Section 4B”, “Front Brake Disc Inspection in

Section 4B”, “Rear Disc Brake Pad Inspection in

Section 4C” and/or “Rear Brake Disc Inspection in

Section 4C”.

Be sure to torque caliper pin bolts to specification.

Brake Hoses and Pipes InspectionS7RS0B0206016

Perform this inspection where these is enough light and

use a mirror as necessary.

• Check brake hoses and pipes for proper hookup, leaks, cracks, chafing and other damage.

• Check that hoses and pipes are clear of sharp edges and moving parts.

Repair or replace any of these parts as necessary.

CAUTION!

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

I4RS0B020002-02

I4RS0A020006-01

I3RM0A020006-01

I4RS0A020008-01

Page 43 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-13

Brake

Foot brake

Check the following:

• that brake pedal has proper travel,

• that brake works properly,

• that it is free from noise,

• that vehicle does not pull to one side when brake is applied.

• and that brake do not drag.

Parking brake

Check that lever has proper travel.

WARNING!

With vehicle parked on a fairly steep slope,

make sure nothing is in the way downhill to

avoid any personal injury or property

damage. Be prepared to apply regular brake

quickly even if vehicle should start to move.

Check to ensure that parking brake is fully effective

when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.

Steering

• Check to ensure that steering wheel is free from instability, or abnormally heavy feeling. • Check that the vehicle does not wander or pull to one

side.

Engine

• Check that engine responds readily at all speeds.

• Check that engine is free from abnormal noise and abnormal vibration.

Body, Wheels and Power Transmitting System

Check that body, wheels and power transmitting system

are free from abnormal noise and abnormal vibration or

any other abnormal condition.

Meters and Gauge

Check that speedometer, odometer, fuel meter,

temperature gauge, etc. are operating accurately.

Lights

Check that all lights operate properly.

Windshield Defroster

Periodically check that ai r comes out from defroster

outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan

switch lever to “HI” position for this check.

Specifications

Tightening Torque SpecificationsS7RS0B0207001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Fluids and LubricantsS7RS0B0208001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Engine oil drain plug 35 3.5 25.5 �)

Oil filter 14 1.4 10.5 for reference �)

Engine oilSG, SH, SJ, SL or SM grade (Refer to “Engine Oil and Filter Change” for engine

oil viscosity.)

Engine coolant

(Ethylene glycol base coolant) “Antifreeze/Antico

rrosion coolant”

Brake fluid Refer to reservoir cap of brake master cylinder.

Manual transaxle oil Refer to “Manual Transaxle Oil Change in Section 5B”.

Automatic transaxle fluid Refer to “A/T Fluid Change in Section 5A”.

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 55 of 1496

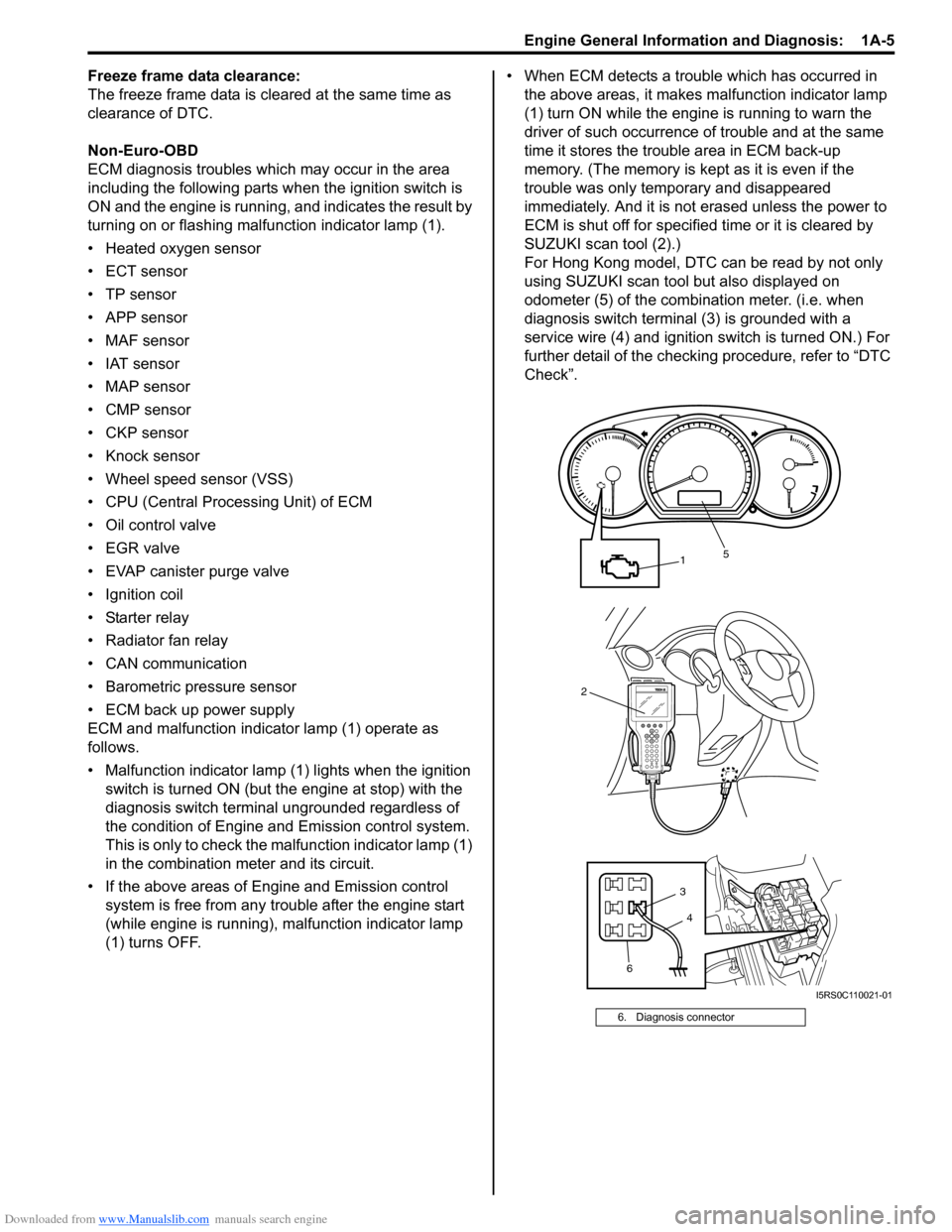

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-5

Freeze frame data clearance:

The freeze frame data is cleared at the same time as

clearance of DTC.

Non-Euro-OBD

ECM diagnosis troubles which may occur in the area

including the following parts w hen the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• Heated oxygen sensor

• ECT sensor

•TP sensor

• APP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor (VSS)

• CPU (Central Processing Unit) of ECM

• Oil control valve

• EGR valve

• EVAP canister purge valve

• Ignition coil

• Starter relay

• Radiator fan relay

• CAN communication

• Barometric pressure sensor

• ECM back up power supply

ECM and malfunction indicator lamp (1) operate as

follows.

• Malfunction indicator lamp (1) lights when the ignition switch is turned ON (but t he engine at stop) with the

diagnosis switch terminal ungrounded regardless of

the condition of Engine and Emission control system.

This is only to check the ma lfunction indicator lamp (1)

in the combination meter and its circuit.

• If the above areas of Engine and Emission control system is free from any trouble after the engine start

(while engine is running), malfunction indicator lamp

(1) turns OFF. • When ECM detects a trouble which has occurred in

the above areas, it makes malfunction indicator lamp

(1) turn ON while the engi ne is running to warn the

driver of such occurrence of trouble and at the same

time it stores the trouble area in ECM back-up

memory. (The memory is kept as it is even if the

trouble was only temporary and disappeared

immediately. And it is not erased unless the power to

ECM is shut off for specified time or it is cleared by

SUZUKI scan tool (2).)

For Hong Kong model, DTC can be read by not only

using SUZUKI scan tool but also displayed on

odometer (5) of the combination meter. (i.e. when

diagnosis switch terminal (3) is grounded with a

service wire (4) and ignition switch is turned ON.) For

further detail of the checking procedure, refer to “DTC

Check”.

6. Diagnosis connector

2

1

6 3

5

4

I5RS0C110021-01

Page 58 of 1496

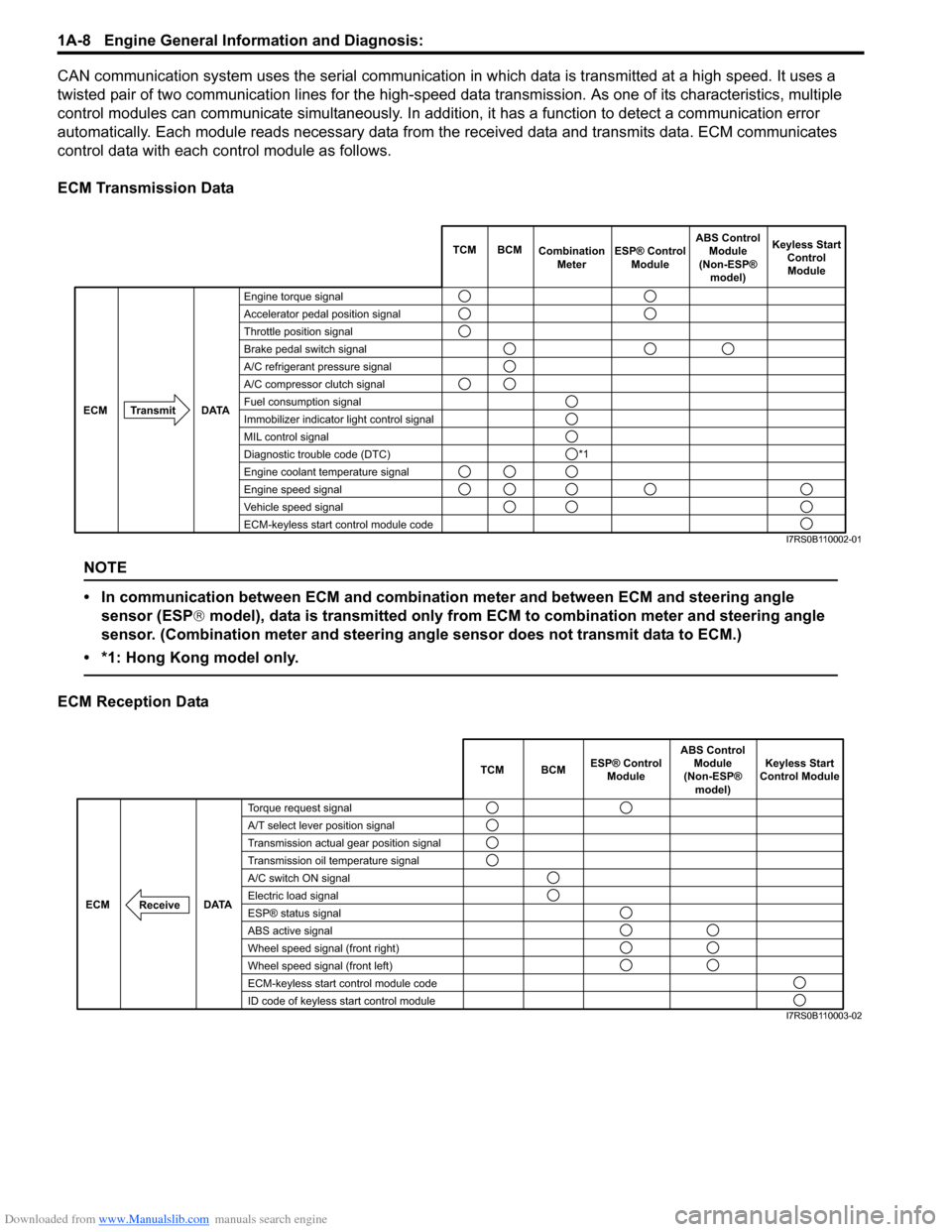

Downloaded from www.Manualslib.com manuals search engine 1A-8 Engine General Information and Diagnosis:

CAN communication system uses the serial communication in which data is transmitted at a high speed. It uses a

twisted pair of two communication lines for the high-speed da ta transmission. As one of its characteristics, multiple

control modules can communicate simultaneously. In addition, it has a function to detect a communication error

automatically. Each module reads necessary data from the received data and transmits data. ECM communicates

control data with each control module as follows.

ECM Transmission Data

NOTE

• In communication between ECM and combination meter and between ECM and steering angle sensor (ESP ® model), data is transmitted only from ECM to combination meter and steering angle

sensor. (Combination meter and steering angle sensor does not transmit data to ECM.)

• *1: Hong Kong model only.

ECM Reception Data

Engine torque signal

Accelerator pedal position signal

Throttle position signal

Brake pedal switch signal

A/C refrigerant pressure signal

A/C compressor clutch signal

Fuel consumption signal

Immobilizer indicator light control signal

MIL control signal

Diagnostic trouble code (DTC)

Engine coolant temperature signal

Engine speed signal

Vehicle speed signal

ECM-keyless start control module code TCM BCM

Combination

Meter Keyless Start

ControlModule

Transmit DATA

ECM

ESP® Control

Module ABS Control

Module

(Non-ESP® model)

*1

I7RS0B110002-01

TCM BCM Keyless Start

Control Module

DATA

ECM

Torque request signal

A/T select lever position signal

Transmission actual gear position signal

Transmission oil temperature signal

A/C switch ON signal

Electric load signal

ESP® status signal

ABS active signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ECM-keyless start control module code

ID code of keyless start control module

Receive

ABS Control

Module

(Non-ESP® model)

ESP® Control

Module

I7RS0B110003-02

Page 61 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-11

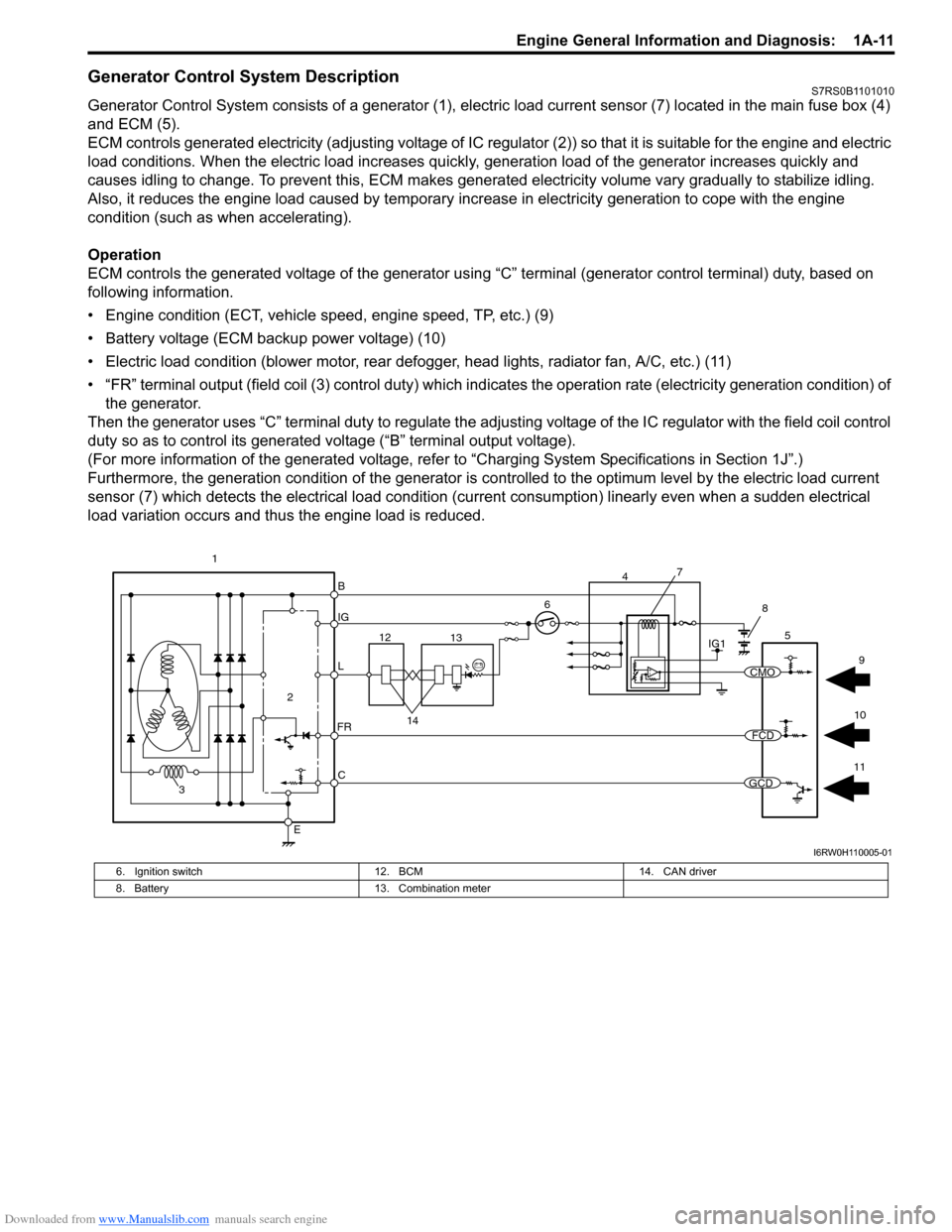

Generator Control System DescriptionS7RS0B1101010

Generator Control System consists of a generator (1), electric load current sensor (7) located in the main fuse box (4)

and ECM (5).

ECM controls generated electricity (adjusting voltage of IC regulator (2)) so that it is suitable for the engine and electric

load conditions. When the electric load increases quickly, generation load of the generator increases quickly and

causes idling to change. To prevent this, ECM makes generated electricity volume vary gradually to stabilize idling.

Also, it reduces the engine load caused by temporary incr ease in electricity generation to cope with the engine

condition (such as when accelerating).

Operation

ECM controls the generated voltage of the generator using “C” terminal (generator control terminal) duty, based on

following information.

• Engine condition (ECT, vehicle speed, engine speed, TP, etc.) (9)

• Battery voltage (ECM backup power voltage) (10)

• Electric load condition (blower motor, rear defogger, head lights, radiator fan, A/C, etc.) (11)

• “FR” terminal output (field coil (3) cont rol duty) which indicates the operation rate (electricity generation condition) of

the generator.

Then the generator uses “C” terminal duty to regulate the adju sting voltage of the IC regulator with the field coil control

duty so as to control its generated voltage (“B” terminal output voltage).

(For more information of the generated voltage, refer to “Charging System Specifications in Section 1J”.)

Furthermore, the generation condition of the generator is co ntrolled to the optimum level by the electric load current

sensor (7) which detects the electrical load condition (cur rent consumption) linearly even when a sudden electrical

load variation occurs and thus the engine load is reduced.

B

IG

L

C

E

6

2

3

FR

5

12 13

14

1IG1

7

4

8

11

10 9

CMO

FCD

GCD

I6RW0H110005-01

6. Ignition switch

12. BCM 14. CAN driver

8. Battery 13. Combination meter

Page 63 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

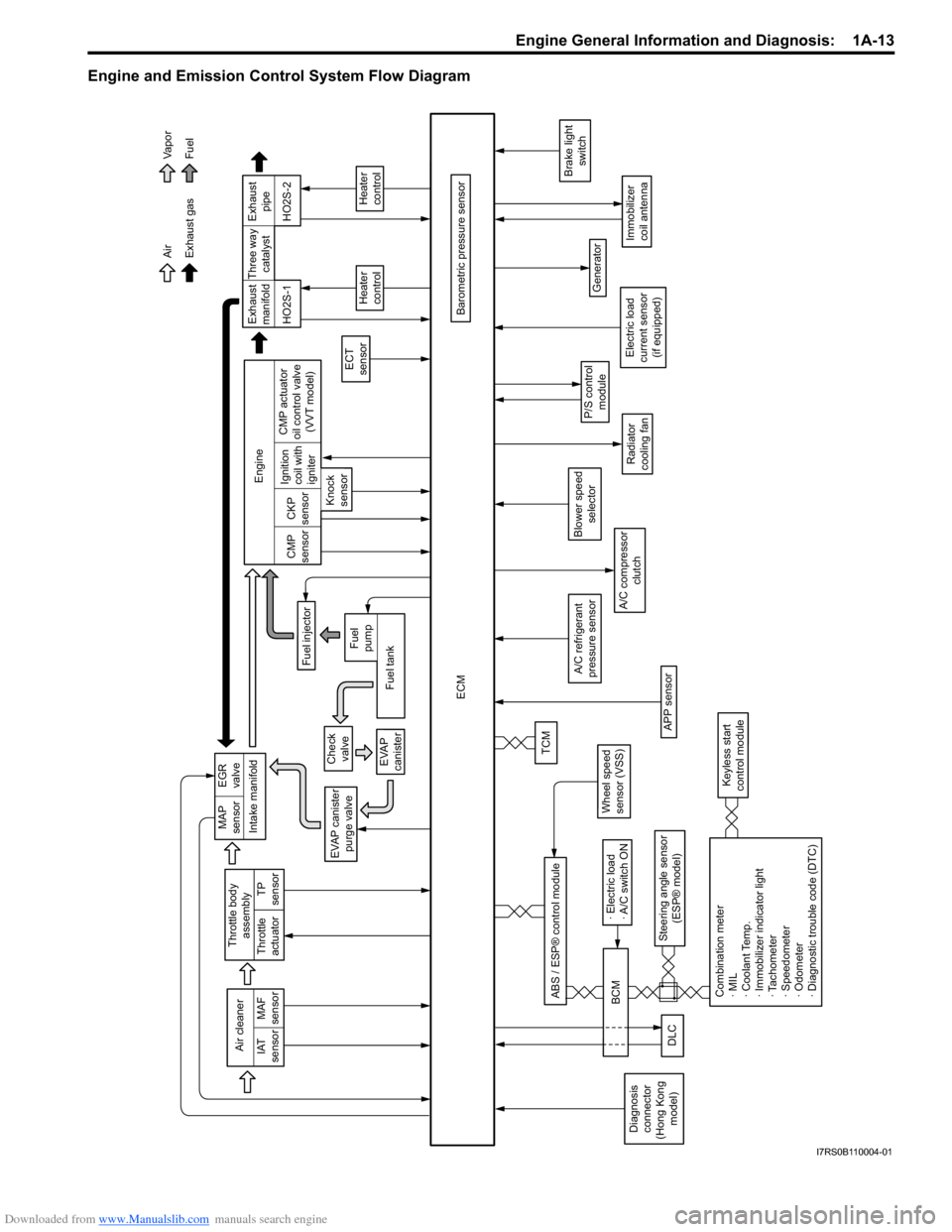

Engine and Emission Control System Flow Diagram

Intake manifold

Exhaust gas AirFuel

Va p o r

EVAP canister purge valve

ECM

Barometric pressure sensor

A/C compressor clutch

Generator

Immobilizer

coil antenna

P/S controlmodule

Brake light switch

Air cleaner

IAT

sensor MAF

sensor

A/C refrigerant

pressure sensor

TP

sensor

Throttle body

assembly

Throttle

actuator

Wheel speed

sensor (VSS)

Steering angle sensor (ESP® model)

ABS / ESP® control module

Blower speed

selector

MAP

sensor EGR

valve

Check valve

EVAP

canisterTCM

Exhaust

manifold Exhaust

pipe

Fuel injector

ECT

sensor

Heater

control

HO2S-1 HO2S-2

Engine

CMP

sensor CKP

sensor

Knock

sensor Ignition

coil with

igniter

Fuel tank

Fuel

pump CMP actuator

oil control valve (VVT model) Three way

catalyst

Heater

control

Radiator

cooling fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Odometer

· Diagnostic trouble code (DTC)

Keyless start

control module

DLC

· Electric load

· A/C switch ON

BCM

Diagnosis

connector

(Hong Kong model) Electric load

current sensor (if equipped)

APP sensor

I7RS0B110004-01