charge SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 49 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-v

Ignition Timing Inspection ................................... 1H-8

Specifications ....................................................... 1H-9

Tightening Torque Specifications ........................ 1H-9

Special Tools and Equipmen t ............................. 1H-9

Special Tool ........................................................ 1H-9

Starting System ................. ........................ 1I-1

Schematic and Routing Diagram ......................... 1I-1

Cranking System Circuit Diagram ........................ 1I-1

Diagnostic Information and Procedures ............. 1I-1

Cranking System Symptom Diagnosis ................. 1I-1

Cranking System Test.......................................... 1I-3

Repair Instructions ............................................... 1I-4 Starting Motor Dismounting and Remounting ...... 1I-4

Starting Motor Components ................................. 1I-5

Starting Motor Inspection ..................................... 1I-6

Specifications ........................................................ 1I-9

Cranking System Specifications........................... 1I-9

Tightening Torque Specifications ......................... 1I-9

Special Tools and Equipment .............................. 1I-9

Recommended Service Material .......................... 1I-9

Charging System ............ .......................... 1J-1

General Description ......... .................................... 1J-1

Battery Description ...............................................1J-1

Generator Descripti on ..........................................1J-2

Diagnostic Information and Procedures ............ 1J-4 Battery Inspection ................................................1J-4

Generator Symptom Diagnosis ............................1J-4 Generator Test (Undercharged Battery

Check) ............................................................... 1J-5

Generator Test (Overcharg ed Battery Check) .... 1J-6

Repair Instructions ........... ................................... 1J-6

Jump Starting in Case of Emergency.................. 1J-6

Battery Dismounting and Remounting ................ 1J-7

Water Pump / Generator Drive Belt Tension Inspection and Adjustment ................................ 1J-7

Water Pump / Generator Drive Belt Removal and Installation .................................................. 1J-8

Generator Unit Co mponents ............................... 1J-9

Generator Dismounting a nd Remounting............ 1J-9

Generator Components........ ............................. 1J-10

Generator Insp ection......................................... 1J-11

Specifications ..................................................... 1J-13 Charging System Specifications ....................... 1J-13

Tightening Torque Specifications ...................... 1J-13

Exhaust System .............. ......................... 1K-1

General Description .............................................1K-1

Exhaust System Description ............................... 1K-1

Diagnostic Information and Procedures ............1K-1 Exhaust System Check ....................................... 1K-1

Repair Instructions ........... ...................................1K-2

Exhaust System Components ............................. 1K-2

Exhaust Manifold Removal and Installation ........ 1K-3

Exhaust Pipe and Muffler Removal and Installation ......................................................... 1K-4

Specifications .................... ...................................1K-5

Tightening Torque Specifications ........................ 1K-5

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 88 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-38 Engine General Information and Diagnosis:

Engine Basic InspectionS7RS0B1104009

This check is very important for troubleshooting when ECM has detected no DTC and no abnormality has been found

in “Visual Inspection”.

Follow the flow carefully.Step Action Yes No 1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Check battery voltage

Is it 11 V or more? Go to Step 3. Charge or replace

battery.

3 Is vehicle equipped with keyless start control system? Go to Step 4. Go to Step 5.

4 Check keyless start control system malfunction

1) Check keyless start control system referring to “Keyless

Start System Operation In spection in Section 10E”.

Is check result satisfactory? Go to Step 5. Keyless start control

system malfunction.

5 Is engine cranked? Go to Step 6. Go to “Cranking System

Symptom Diagnosis in

Section 1I”.

6 Does engine start? Go to Step 7. Go to Step 9.

7 Check idle speed

1) Warm up engine to normal operating temperature.

2) Shift transmission to neutral position for M/T (“P” position

for A/T).

3) Make sure that all electrical loads are switched off.

4) Check engine idle speed with scan tool.

Is it 650 – 800 r/min.? Go to Step 8. Go to “Engine Symptom

Diagnosis”.

I2RH01110005-01

Page 187 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-137

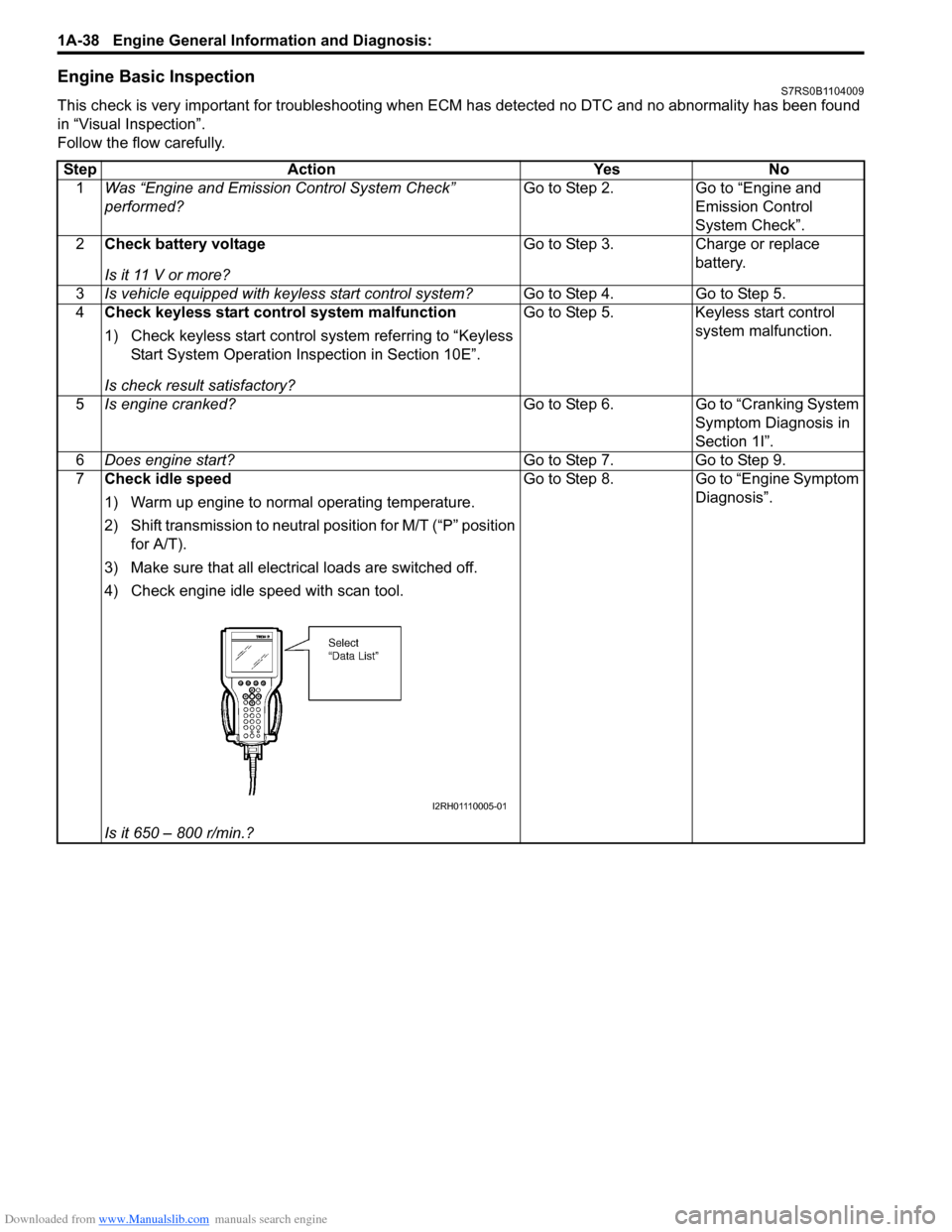

DTC P0620: Generator Control CircuitS7RS0B1104057

System and Wiring Diagram

Generator Control System Description

Refer to “Generator Control System Description”.3

Wire circuit check

1) Disconnect starting motor control relay in individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to starting motor control relay at “RED/WHT”, “RED”, “WHT”, “YEL” (for A/T

model) and “YEL/GRN” (for M/T model) wire terminals.

3) Disconnect connector from starting motor.

4) Measure voltage between “C37-48” terminal of ECM connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 – 1 V? Go to Step 4. For A/T model, “YEL” or

“YEL/GRN” wire is

shorted to power circuit.

For M/T model, “YEL/

GRN” wire is shorted to

power circuit.

If wires are OK,

substitute a known good

ECM and recheck.

4 Wire circuit check

1) Measure voltage between “RED/WHT” wire terminal of

starting motor control relay connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 – 1 V? Check starting motor

control relay. If OK,

substitute a known-

good ECM and recheck.

Faulty ignition switch,

check ignition switch

referring to “Ignition

Switch Inspection in

Section 9C”.

If ignition switch is OK,

check for short circuit

between ignition switch

and starting motor

control relay to power

circuit.

Step Action Yes No

IG

L

C

FR

E 4

2

BRN/BLKC37-8

BLU/YELC37-28

B

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238 1

3 5

I5RS0C110013-01

1. Generator

3. Field coil 5. Ignition switch

2. IC regulator 4. ECM 6. Charge lamp

Page 189 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-139

DTC P0625 / P0626: Generator Field Terminal Circuit Low / HighS7RS0B1104058

System and Wiring Diagram

Refer to “DTC P0620: Generator Control Circuit”.

Generator Control System Description

Refer to “Generator Control System Description”.

DTC Detecting Condition and Trouble Area 3

Generator control circuit check

1) Disconnect connector from generator and ECM with

ignition switch turned OFF.

2) Check for proper connection of wire terminal to generator connector and to ECM connector.

3) If connections are OK, check generator control circuit for

the following.

• Resistance of generator control circuit wire between generator connector and ECM connector is less than

1 Ω (continuity check)

• Resistance between generator control circuit wire of

generator connector and vehicle body ground is

infinity (ground circuit short check)

• Voltage between generator control circuit wire of generator connector and vehicle body ground is 0 V

with ignition switch tuned ON (power circuit short

check)

Are they in good condition? Go to Step 3. Repair or replace

defective wire.

4 Generator check

1) Check for generator output referring to “Generator Test

(Undercharged Battery Check) in Section 1J”.

Is check result satisfactory? Go to Step 4. Repair or replace

generator.

5 Electric load current sensor check

1) Check for electric load current sensor output referring to

“Electric Load Current Sensor On-Vehicle Inspection in

Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric load

current sensor.

Step Action Yes No

DTC detecting condition

Trouble area

P0625:

Generator field coil duty is 0% (high voltage) for more than

specified time even through generator control is minimum

regulation (control duty 0%).

(1 driving cycle detection logic but MIL does not light up)

P0626:

Generator field coil duty is 100% (low voltage) for more than

specified time even through ge nerator control is maximum

regulation (control duty 100%) or Generator field coil duty is 100%

(low voltage) when engine is starting.

(1 driving cycle detection logic but MIL does not light up) • Generator and/or its circuit

•ECM

Page 190 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-140 Engine General Information and Diagnosis:

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switch is tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Turn ON following accessory switch. • Head lights switch.

• Blower motor switch (max position).

• Rear defogger switch.

6) Increase engine speed to 4000 rpm and keep it for 10 sec. or more.

7) Decrease engine speed to idle.

8) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Generator control circuit check

1) Disconnect connector from generator and ECM with

ignition switch turned OFF.

2) Check for proper connection of wire terminal to generator connector and to ECM connector.

3) If connections are OK, check generator control (generator “C” terminal) circuit and field coil monitor

(generator “FR” terminal) circuit for the following.

• Resistance of each generato r control wire and field

coil monitor wire between generator connector and

ECM connector is less than 1 Ω (continuity check)

• Resistance between generator control wire and field coil monitor wire of generator connector is infinity

(insulation check)

• Resistance between each generator control wire and field coil monitor wire of generator connector and

vehicle body ground is infinity (ground circuit short

check)

• Voltage between each generator control wire and field

coil monitor wire of generator connector and vehicle

body ground is 0 V with ignition switch tuned ON

(power circuit short check)

Are they in good condition? Go to Step 3.

Repair or replace

defective wire.

3 Generator check

1) Check for generator output referring to “Generator Test

(Undercharged Battery Check) in Section 1J” and

“Generator Inspection in Section 1J”.

Is check result satisfactory? Substitute a known

good ECM and recheck.

Repair or replace

generator.

Page 284 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-12 Engine Electrical Devices:

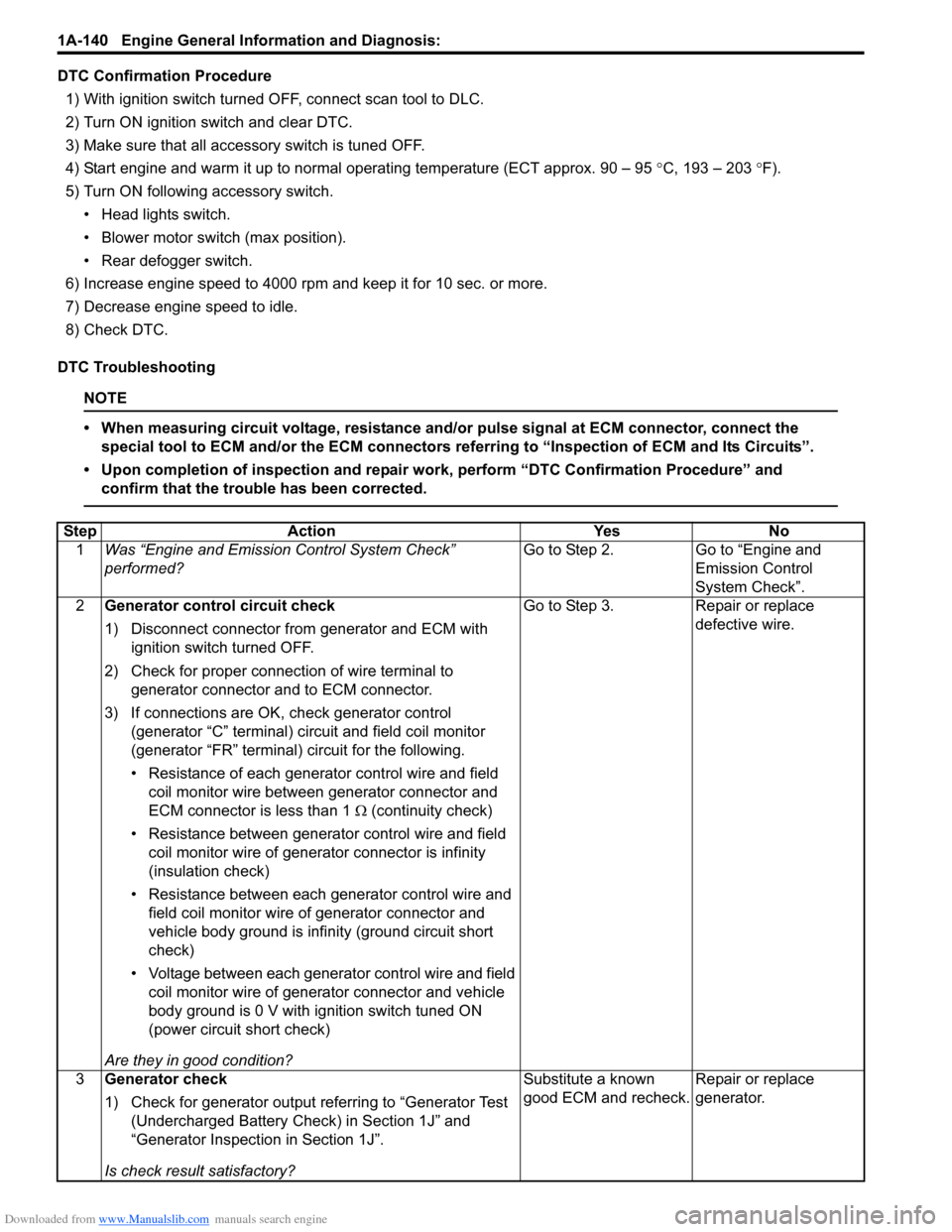

MAF and IAT Sensor InspectionS7RS0B1306020

CAUTION!

Do not heat up MAF and IAT sensor more

than 100 °C (212 °F). Otherwise, MAF and IAT

sensor will be damaged.

• Check sensor O-ring (1) for damage and deterioration. Replace as necessary.

• Blow hot air to temperature sensing part (2) of MAF and IAT sensor (3) using hot air drier (4) and measure

resistance between sensor terminals while heating air

gradually.

If measured resistance does not show such

characteristic as shown, replace MAF and IAT sensor.

IAT sensor resistance

–20 °C (–4 °F): 13.6 – 18.4 k Ω

20 °C (68 °F): 2.21 – 2.69 k Ω

60 °C (140 °F): 0.493 – 0.667 k Ω

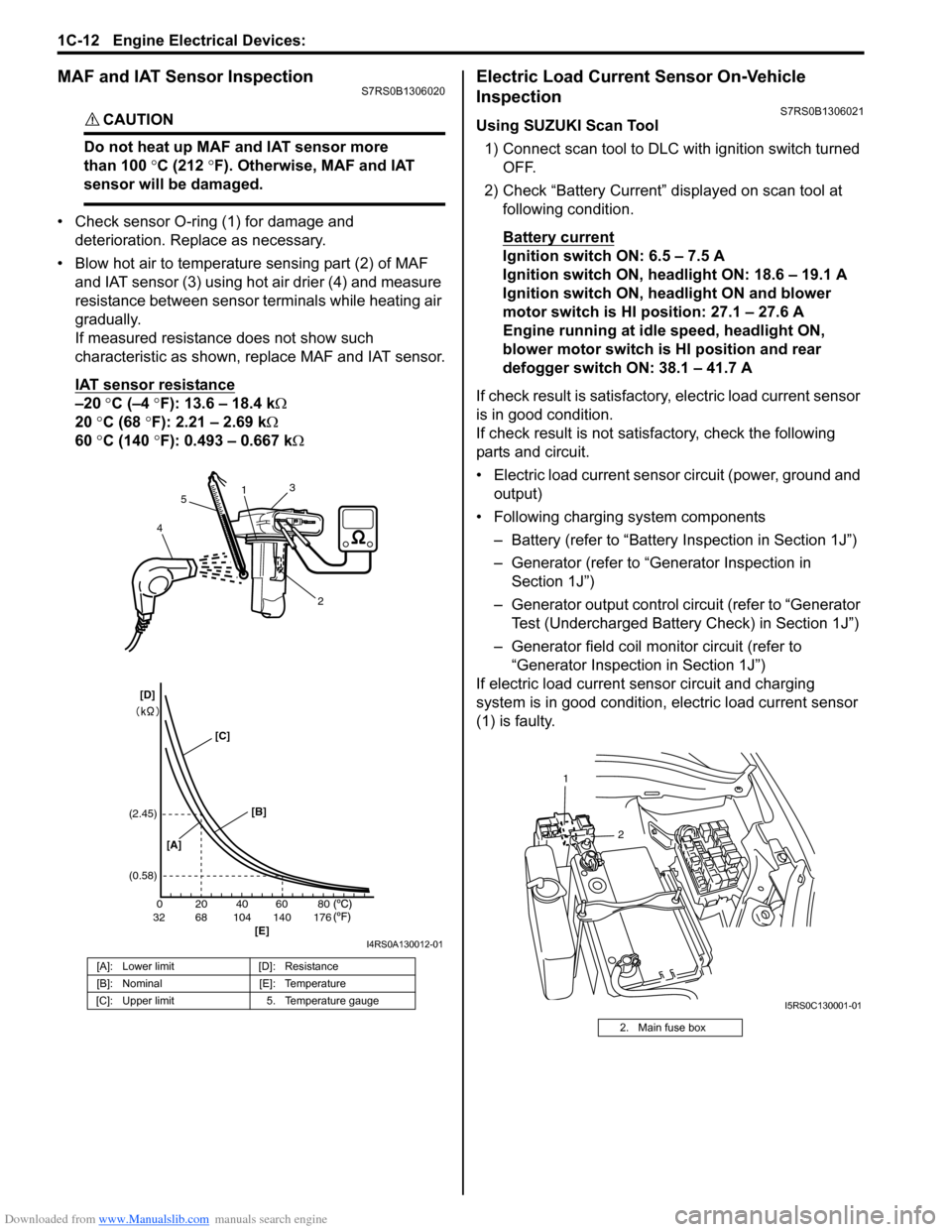

Electric Load Current Sensor On-Vehicle

Inspection

S7RS0B1306021

Using SUZUKI Scan Tool

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Check “Battery Current” displayed on scan tool at following condition.

Battery current

Ignition switch ON: 6.5 – 7.5 A

Ignition switch ON, headlight ON: 18.6 – 19.1 A

Ignition switch ON, headlight ON and blower

motor switch is HI position: 27.1 – 27.6 A

Engine running at idle speed, headlight ON,

blower motor switch is HI position and rear

defogger switch ON: 38.1 – 41.7 A

If check result is satisfactory, electric load current sensor

is in good condition.

If check result is not satisf actory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components

– Battery (refer to “Battery Inspection in Section 1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control ci rcuit (refer to “Generator

Test (Undercharged Battery Check) in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”)

If electric load current sensor circuit and charging

system is in good condition, electric load current sensor

(1) is faulty.

[A]: Lower limit [D]: Resistance

[B]: Nominal [E]: Temperature

[C]: Upper limit 5. Temperature gauge

200

6832104 140 17640 60 80

(2.45)

(0.58)

1

2

3

4 5

[A] [B]

[E]

[C]

[D]

I4RS0A130012-01

2. Main fuse box

2

1

I5RS0C130001-01

Page 285 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-13

Without Using SUZUKI Scan Tool1) Measure sensor voltage between “C37-23” terminal of ECM connector and vehicle body ground referring

to “Inspection of ECM and Its Circuits in Section 1A”.

If check result is satisfactory, electric load current

sensor is in good condition.

If check result is not satisfactory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components – Battery (refer to “Battery Inspection in Section

1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control circuit (refer to “Generator Test (Undercharged Battery Check)

in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”) If electric load current sensor circuit and charging

system is in good condition,

electric load current sensor

(1) is faulty.

Specifications

Tightening Torque SpecificationsS7RS0B1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2. Main fuse box

2

1

I5RS0C130001-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

ECM mounting bolt 8 0.8 6.0 �)

APP sensor assembly nut 5.5 0.55 4.0 �)

ECT sensor 15 1.5 11.0 �)

Heated oxygen sensor 45 4.5 32.5 �)

CMP sensor bolt 10 1.0 7.5 �)

CKP sensor bolt 10 1.0 7.5 �)

Knock sensor 22 2.2 16.0 �)

MAF and IAT sensor screw 1.5 0.15 1.1 �)

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

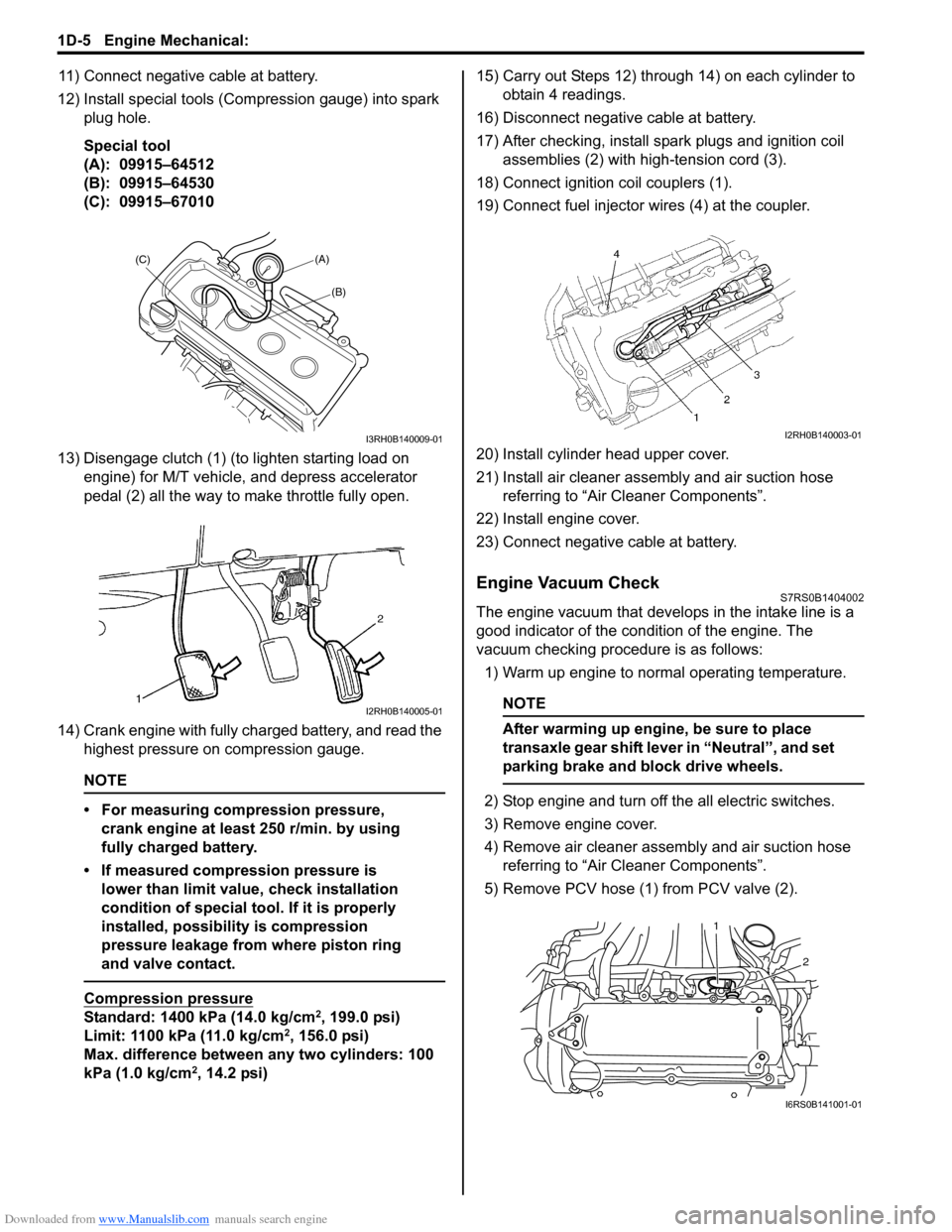

11) Connect negative cable at battery.

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 367 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

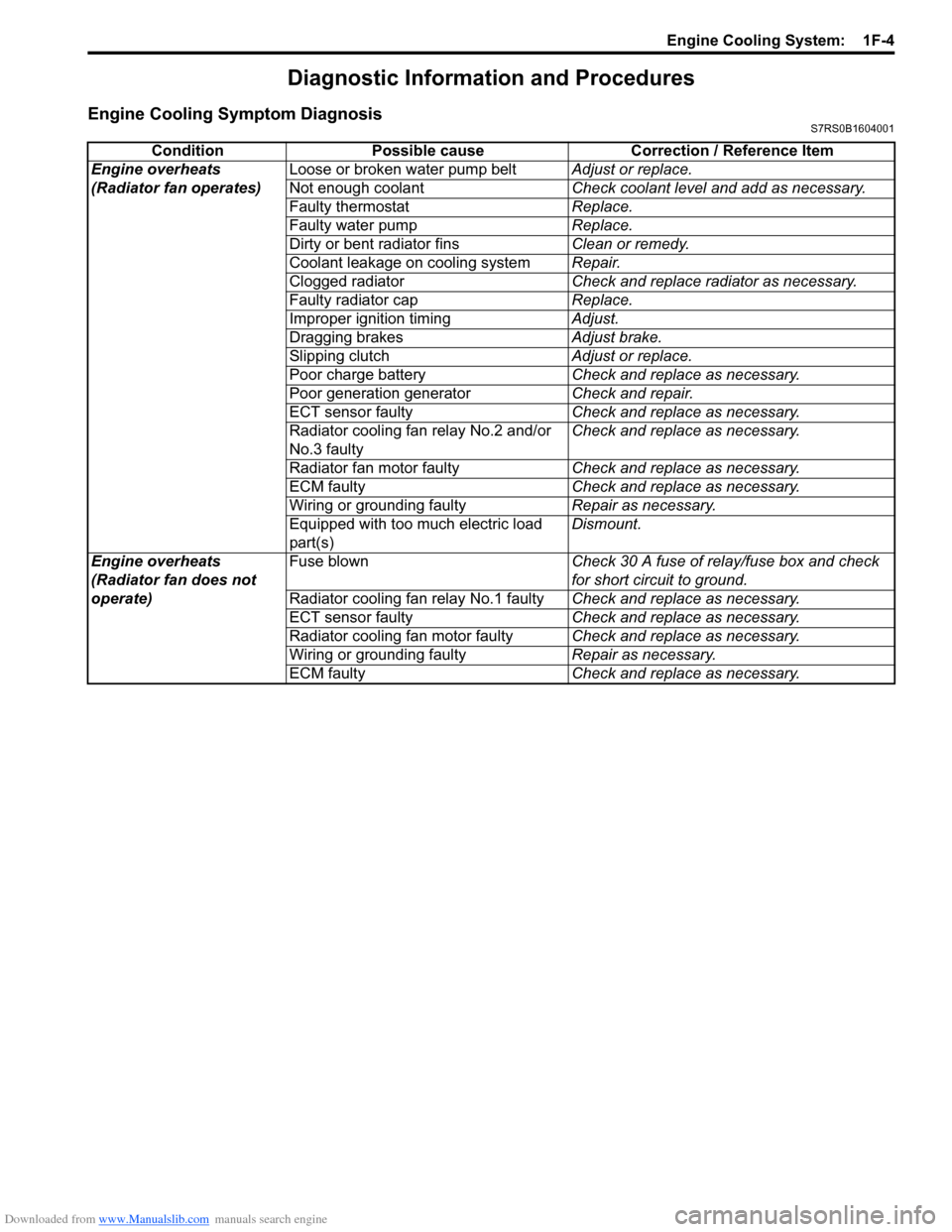

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS7RS0B1604001

ConditionPossible cause Correction / Reference Item

Engine overheats

(Radiator fan operates) Loose or broken water pump belt

Adjust or replace.

Not enough coolant Check coolant level and add as necessary.

Faulty thermostat Replace.

Faulty water pump Replace.

Dirty or bent radiator fins Clean or remedy.

Coolant leakage on cooling system Repair.

Clogged radiator Check and replace radiator as necessary.

Faulty radiator cap Replace.

Improper ignition timing Adjust.

Dragging brakes Adjust brake.

Slipping clutch Adjust or replace.

Poor charge battery Check and replace as necessary.

Poor generation generator Check and repair.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan relay No.2 and/or

No.3 faulty Check and replace as necessary.

Radiator fan motor faulty Check and replace as necessary.

ECM faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

Equipped with too much electric load

part(s) Dismount.

Engine overheats

(Radiator fan does not

operate) Fuse blown

Check 30 A fuse of relay/fuse box and check

for short circuit to ground.

Radiator cooling fan relay No.1 faulty Check and replace as necessary.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan motor faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check and replace as necessary.