head gasket removal SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 91 of 1496

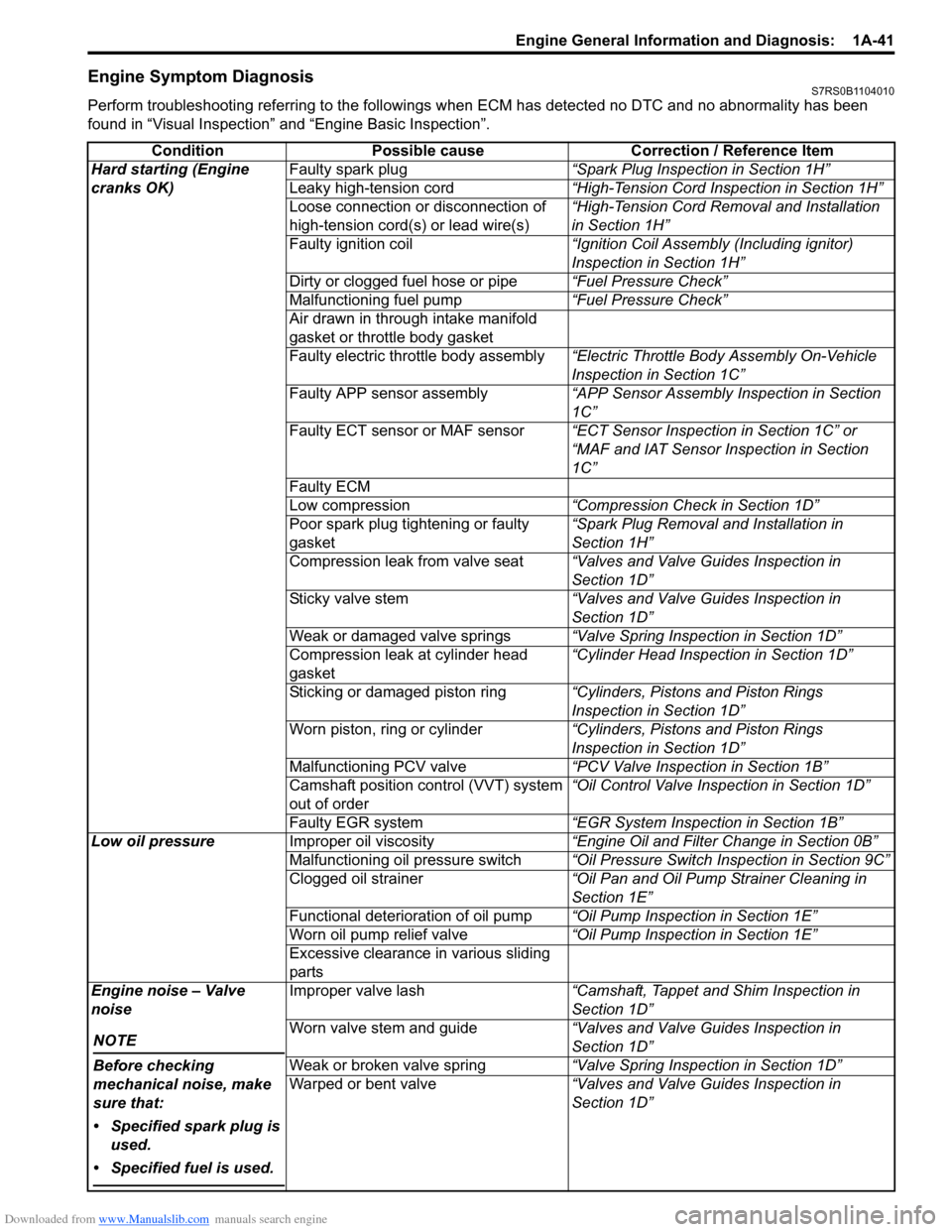

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-41

Engine Symptom DiagnosisS7RS0B1104010

Perform troubleshooting referring to the followings when ECM has detected no DTC and no abnormality has been

found in “Visual Inspection” and “Engine Basic Inspection”.

Condition Possible cause Correction / Reference Item

Hard starting (Engine

cranks OK) Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Loose connection or disconnection of

high-tension cord(s) or lead wire(s) “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Dirty or clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pressure Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECT sensor or MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor spark plug tightening or faulty

gasket “Spark Plug Removal and Installation in

Section 1H”

Compression leak from valve seat “Valves and Valve Guides Inspection in

Section 1D”

Sticky valve stem “Valves and Valve Guides Inspection in

Section 1D”

Weak or damaged valve springs “Valve Spring Inspection in Section 1D”

Compression leak at cylinder head

gasket “Cylinder Head Inspection in Section 1D”

Sticking or damaged piston ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston, ring or cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Faulty EGR system “EGR System Inspection in Section 1B”

Low oil pressure Improper oil viscosity “Engine Oil and Filter Change in Section 0B”

Malfunctioning oil pressure switch “Oil Pressure Switch Inspection in Section 9C”

Clogged oil strainer “Oil Pan and Oil Pump Strainer Cleaning in

Section 1E”

Functional deterioration of oil pump “Oil Pump Inspection in Section 1E”

Worn oil pump relief valve “Oil Pump Inspection in Section 1E”

Excessive clearance in various sliding

parts

Engine noise – Valve

noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Improper valve lash “Camshaft, Tappet and Shim Inspection in

Section 1D”

Worn valve stem and guide “Valves and Valve Guides Inspection in

Section 1D”

Weak or broken valve spring “Valve Spring Inspection in Section 1D”

Warped or bent valve “Valves and Valve Guides Inspection in

Section 1D”

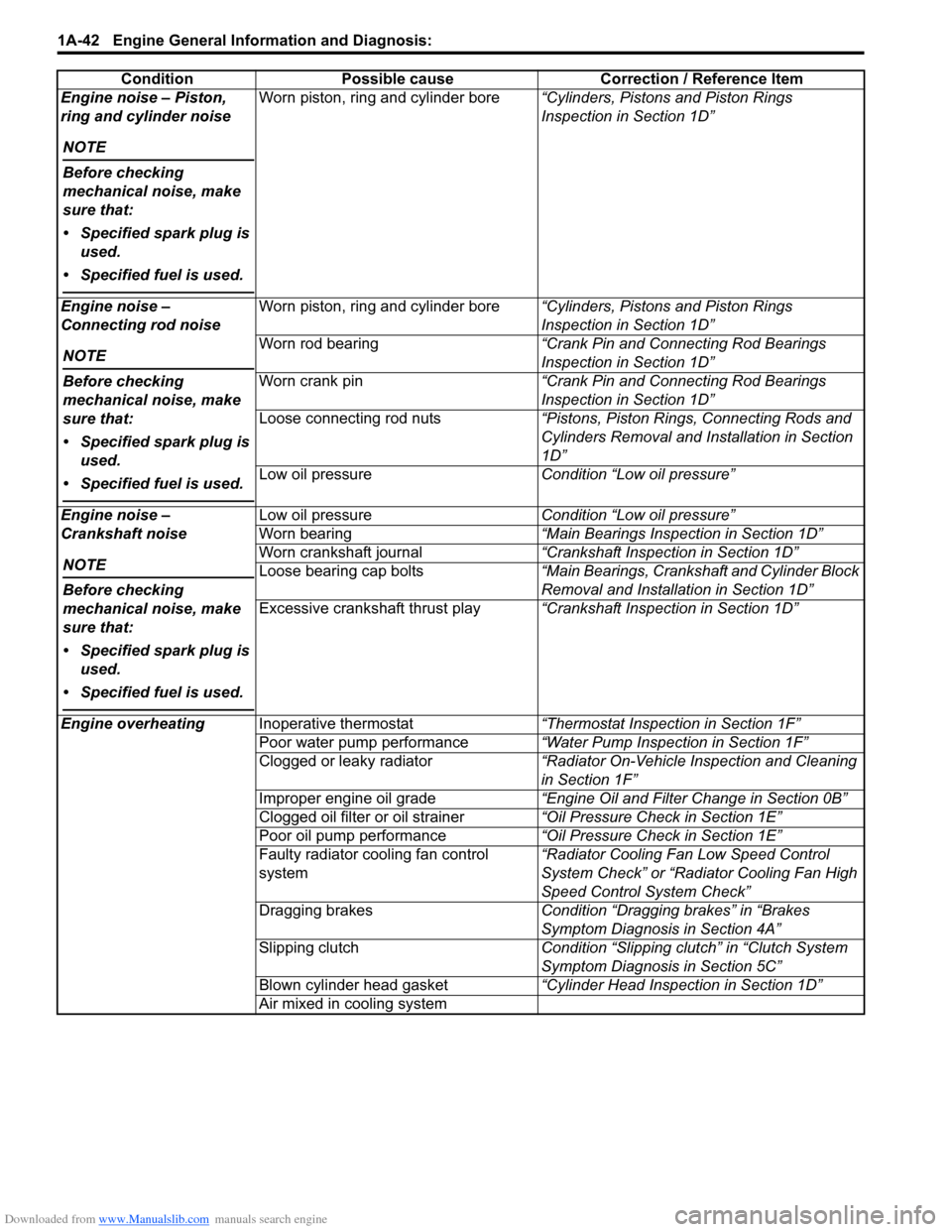

Page 92 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-42 Engine General Information and Diagnosis:

Engine noise – Piston,

ring and cylinder noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Engine noise –

Connecting rod noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn rod bearing “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Worn crank pin “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Loose connecting rod nuts “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation in Section

1D”

Low oil pressure Condition “Low oil pressure”

Engine noise –

Crankshaft noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Low oil pressure Condition “Low oil pressure”

Worn bearing “Main Bearings Inspection in Section 1D”

Worn crankshaft journal “Crankshaft Inspection in Section 1D”

Loose bearing cap bolts “Main Bearings, Crankshaft and Cylinder Block

Removal and Installation in Section 1D”

Excessive crankshaft thrust play “Crankshaft Inspection in Section 1D”

Engine overheating Inoperative thermostat “Thermostat Inspection in Section 1F”

Poor water pump performance “Water Pump Inspection in Section 1F”

Clogged or leaky radiator “Radiator On-Vehicle Inspection and Cleaning

in Section 1F”

Improper engine oil grade “Engine Oil and Filter Change in Section 0B”

Clogged oil filter or oil strainer “Oil Pressure Check in Section 1E”

Poor oil pump performance “Oil Pressure Check in Section 1E”

Faulty radiator cooling fan control

system “Radiator Cooling Fan Low Speed Control

System Check” or “Rad

iator Cooling Fan High

Speed Control System Check”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Blown cylinder head gasket “Cylinder Head Inspection in Section 1D”

Air mixed in cooling system

Condition Possible cause Correction / Reference Item

Page 93 of 1496

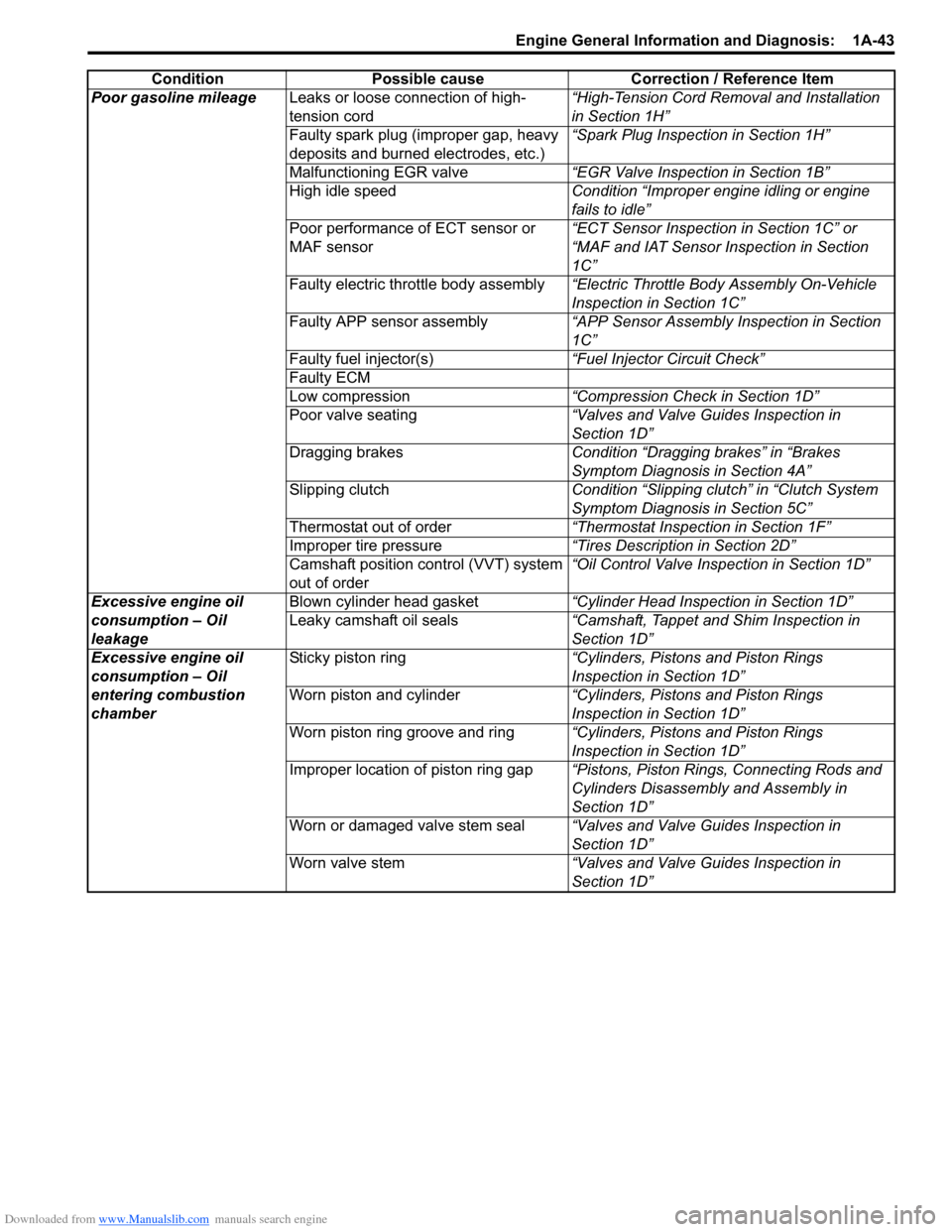

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-43

Poor gasoline mileageLeaks or loose connection of high-

tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.) “Spark Plug Inspection in Section 1H”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

High idle speed Condition “Improper engine idling or engine

fails to idle”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor valve seating “Valves and Valve Guides Inspection in

Section 1D”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Thermostat out of order “Thermostat Inspection in Section 1F”

Improper tire pressure “Tires Description in Section 2D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive engine oil

consumption – Oil

leakage Blown cylinder head gasket

“Cylinder Head Inspection in Section 1D”

Leaky camshaft oil seals “Camshaft, Tappet and Shim Inspection in

Section 1D”

Excessive engine oil

consumption – Oil

entering combustion

chamber Sticky piston ring

“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap “Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal “Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem “Valves and Valve Guides Inspection in

Section 1D”

Condition Possible cause Correction / Reference Item

Page 95 of 1496

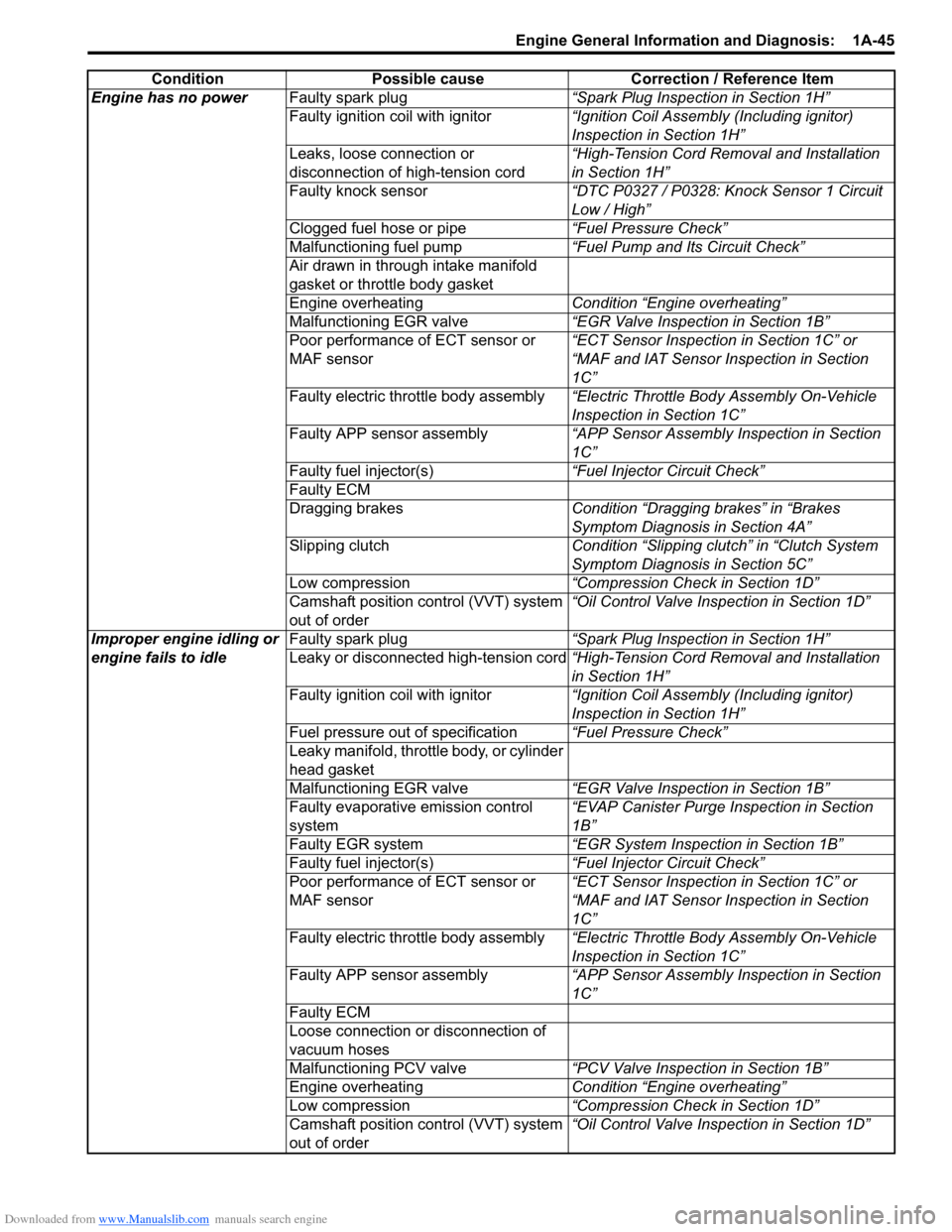

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-45

Engine has no powerFaulty spark plug “Spark Plug Inspection in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Leaks, loose connection or

disconnection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty knock sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”

Clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pump and Its Circuit Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Engine overheating Condition “Engine overheating”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Improper engine idling or

engine fails to idle Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Faulty EGR system “EGR System Inspection in Section 1B”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Loose connection or disconnection of

vacuum hoses

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 271 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-4

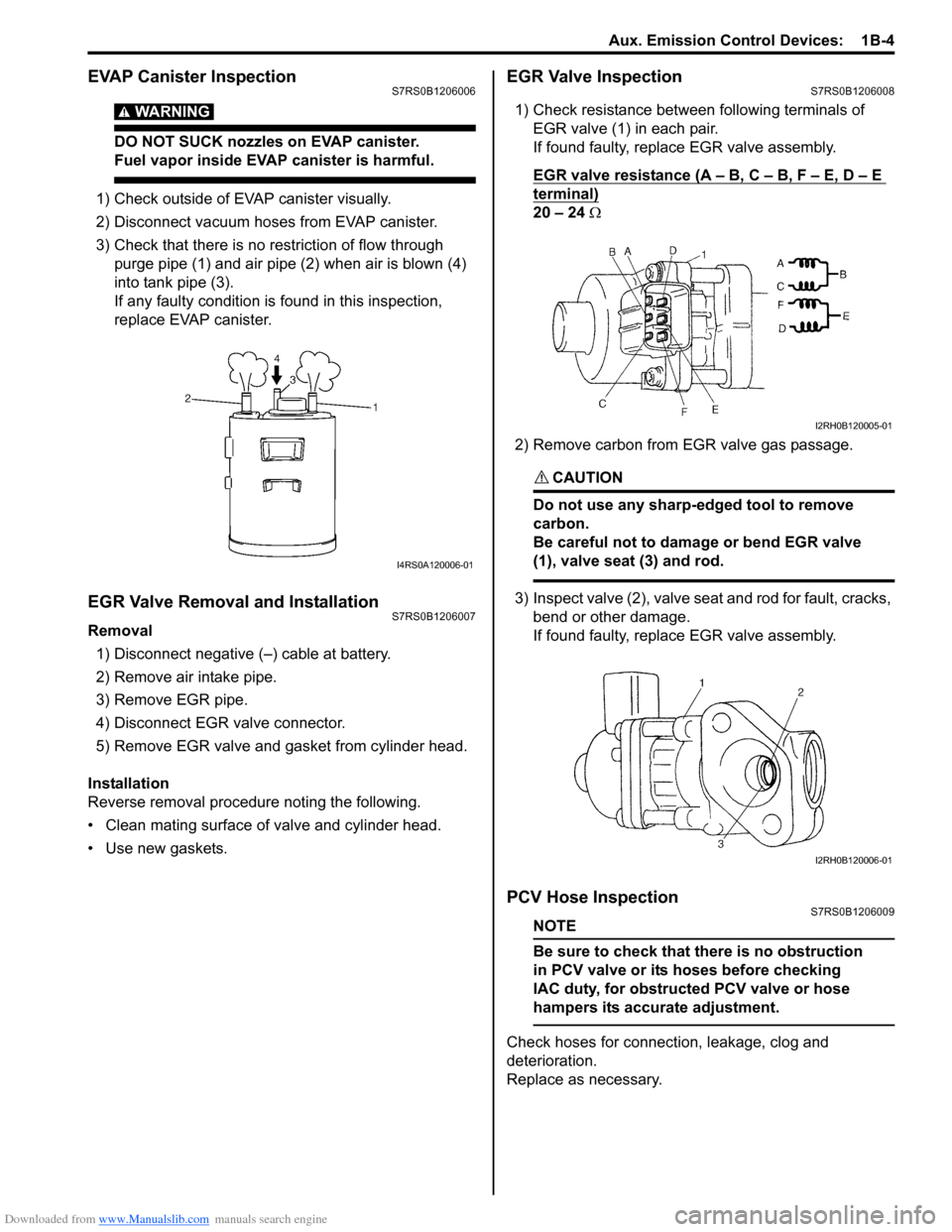

EVAP Canister InspectionS7RS0B1206006

WARNING!

DO NOT SUCK nozzles on EVAP canister.

Fuel vapor inside EVAP canister is harmful.

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there is no restriction of flow through purge pipe (1) and air pipe (2) when air is blown (4)

into tank pipe (3).

If any faulty condition is found in this inspection,

replace EVAP canister.

EGR Valve Removal and InstallationS7RS0B1206007

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from cylinder head.

Installation

Reverse removal procedure noting the following.

• Clean mating surface of valve and cylinder head.

• Use new gaskets.

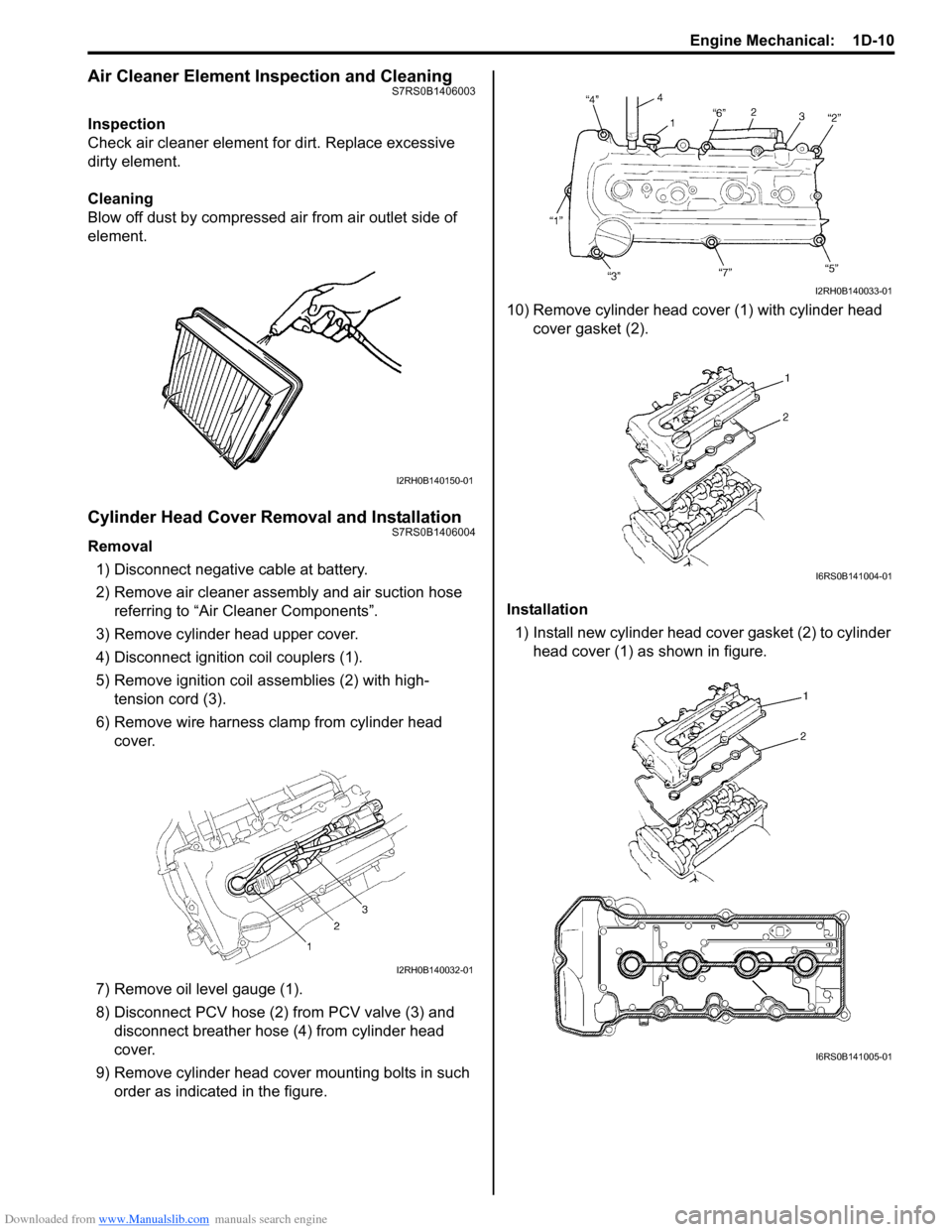

EGR Valve InspectionS7RS0B1206008

1) Check resistance between following terminals of EGR valve (1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance (A – B, C – B, F – E, D – E

terminal)

20 – 24 Ω

2) Remove carbon from EGR valve gas passage.

CAUTION!

Do not use any sharp-edged tool to remove

carbon.

Be careful not to damage or bend EGR valve

(1), valve seat (3) and rod.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or other damage.

If found faulty, replace EGR valve assembly.

PCV Hose InspectionS7RS0B1206009

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

Check hoses for connection, leakage, clog and

deterioration.

Replace as necessary.

I4RS0A120006-01

I2RH0B120005-01

I2RH0B120006-01

Page 295 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-10

Air Cleaner Element Inspection and CleaningS7RS0B1406003

Inspection

Check air cleaner element for dirt. Replace excessive

dirty element.

Cleaning

Blow off dust by compressed air from air outlet side of

element.

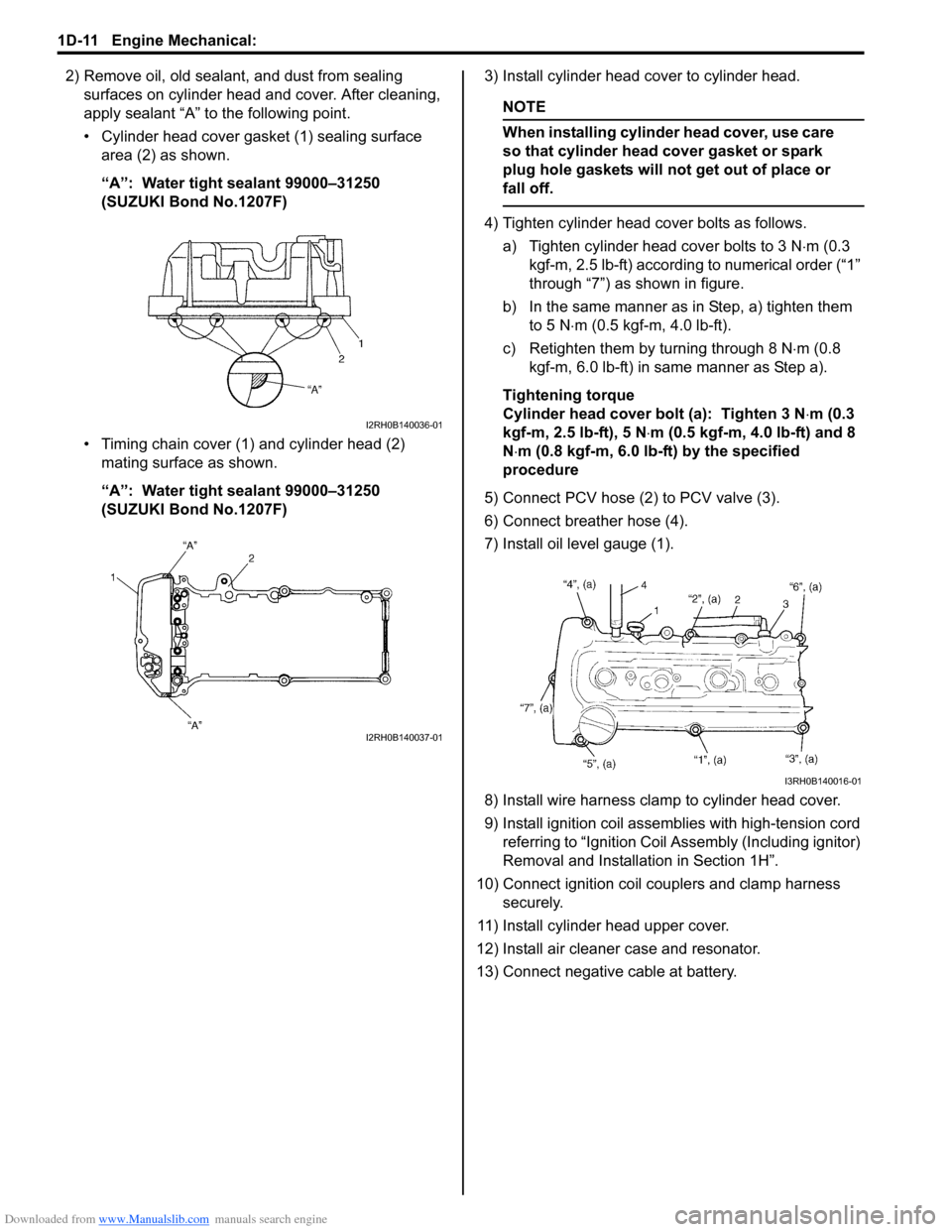

Cylinder Head Cover Removal and InstallationS7RS0B1406004

Removal1) Disconnect negative cable at battery.

2) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

3) Remove cylinder head upper cover.

4) Disconnect ignition coil couplers (1).

5) Remove ignition coil assemblies (2) with high- tension cord (3).

6) Remove wire harness clamp from cylinder head cover.

7) Remove oil level gauge (1).

8) Disconnect PCV hose (2) from PCV valve (3) and disconnect breather hose (4) from cylinder head

cover.

9) Remove cylinder head cove r mounting bolts in such

order as indicated in the figure. 10) Remove cylinder head cover (1) with cylinder head

cover gasket (2).

Installation 1) Install new cylinder head cover gasket (2) to cylinder

head cover (1) as shown in figure.

I2RH0B140150-01

I2RH0B140032-01

I2RH0B140033-01

I6RS0B141004-01

I6RS0B141005-01

Page 296 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-11 Engine Mechanical:

2) Remove oil, old sealant, and dust from sealing surfaces on cylinder head and cover. After cleaning,

apply sealant “A” to the following point.

• Cylinder head cover gasket (1) sealing surface area (2) as shown.

“A”: Water tight sealant 99000–31250

(SUZUKI Bond No.1207F)

• Timing chain cover (1) and cylinder head (2) mating surface as shown.

“A”: Water tight sealant 99000–31250

(SUZUKI Bond No.1207F) 3) Install cylinder head cover to cylinder head.

NOTE

When installing cylinder head cover, use care

so that cylinder head cover gasket or spark

plug hole gaskets will not get out of place or

fall off.

4) Tighten cylinder head cover bolts as follows.

a) Tighten cylinder head cover bolts to 3 N ⋅m (0.3

kgf-m, 2.5 lb-ft) according to numerical order (“1”

through “7”) as shown in figure.

b) In the same manner as in Step, a) tighten them

to 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft).

c) Retighten them by turning through 8 N ⋅m (0.8

kgf-m, 6.0 lb-ft) in same manner as Step a).

Tightening torque

Cylinder head cover bolt (a): Tighten 3 N ⋅m (0.3

kgf-m, 2.5 lb-ft), 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft) and 8

N ⋅m (0.8 kgf-m, 6.0 lb-ft) by the specified

procedure

5) Connect PCV hose (2) to PCV valve (3).

6) Connect breather hose (4).

7) Install oil level gauge (1).

8) Install wire harness clamp to cylinder head cover.

9) Install ignition coil assemb lies with high-tension cord

referring to “Ignit ion Coil Assembly (Including ignitor)

Removal and Installati on in Section 1H”.

10) Connect ignition coil couplers and clamp harness securely.

11) Install cylinder head upper cover.

12) Install air cleaner case and resonator.

13) Connect negative cable at battery.

I2RH0B140036-01

I2RH0B140037-01

I3RH0B140016-01

Page 299 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-14

Throttle Body CleaningS7RS0B1406008

Clean electric throttle body assembly referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

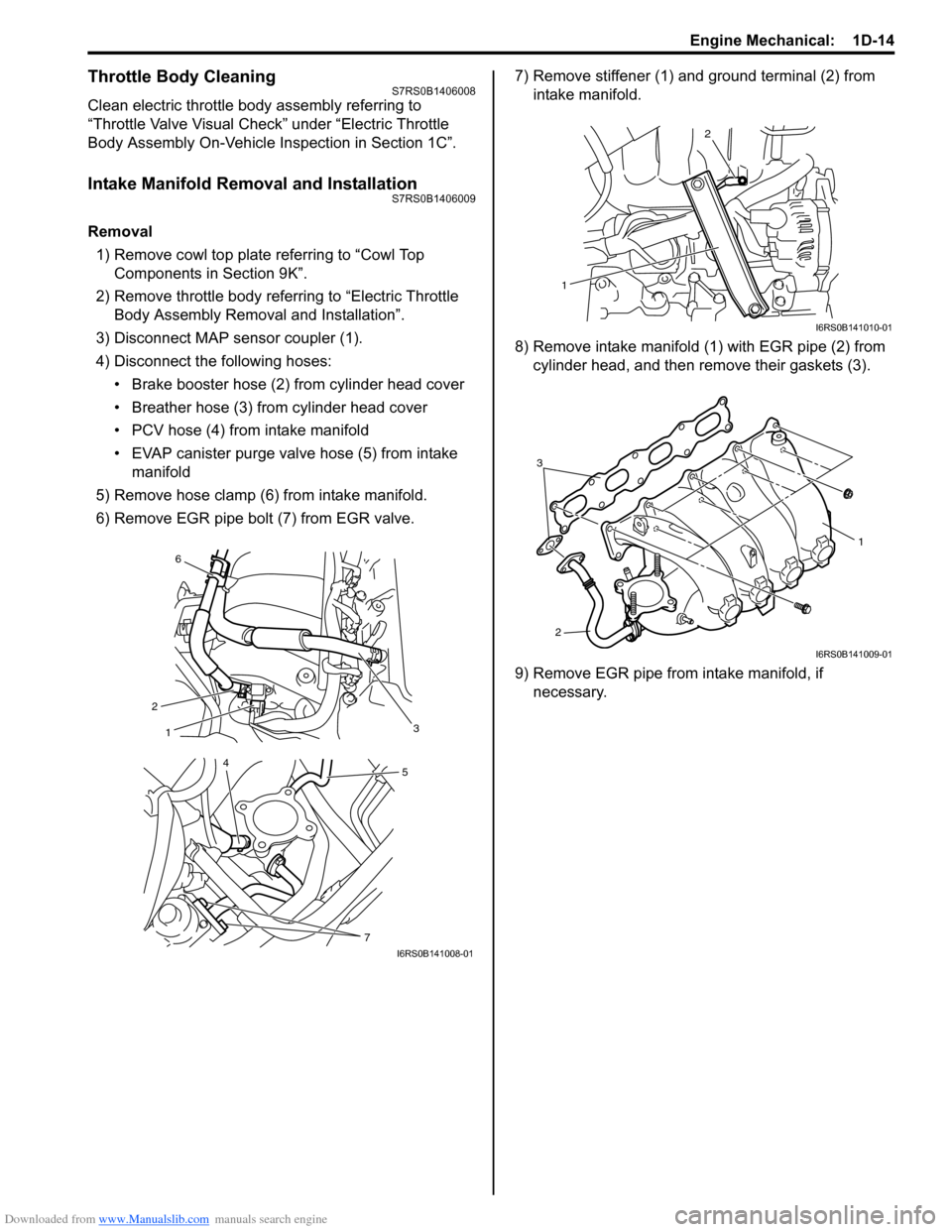

Intake Manifold Removal and InstallationS7RS0B1406009

Removal1) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

2) Remove throttle body referring to “Electric Throttle Body Assembly Removal and Installation”.

3) Disconnect MAP sensor coupler (1).

4) Disconnect the following hoses: • Brake booster hose (2) from cylinder head cover

• Breather hose (3) from cylinder head cover

• PCV hose (4) from intake manifold

• EVAP canister purge valve hose (5) from intake manifold

5) Remove hose clamp (6) from intake manifold.

6) Remove EGR pipe bolt (7) from EGR valve. 7) Remove stiffener (1) and ground terminal (2) from

intake manifold.

8) Remove intake manifold (1) with EGR pipe (2) from

cylinder head, and then remove their gaskets (3).

9) Remove EGR pipe from intake manifold, if necessary.

6

2 1

3

54

7I6RS0B141008-01

1

2

I6RS0B141010-01

3

2

1

I6RS0B141009-01

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

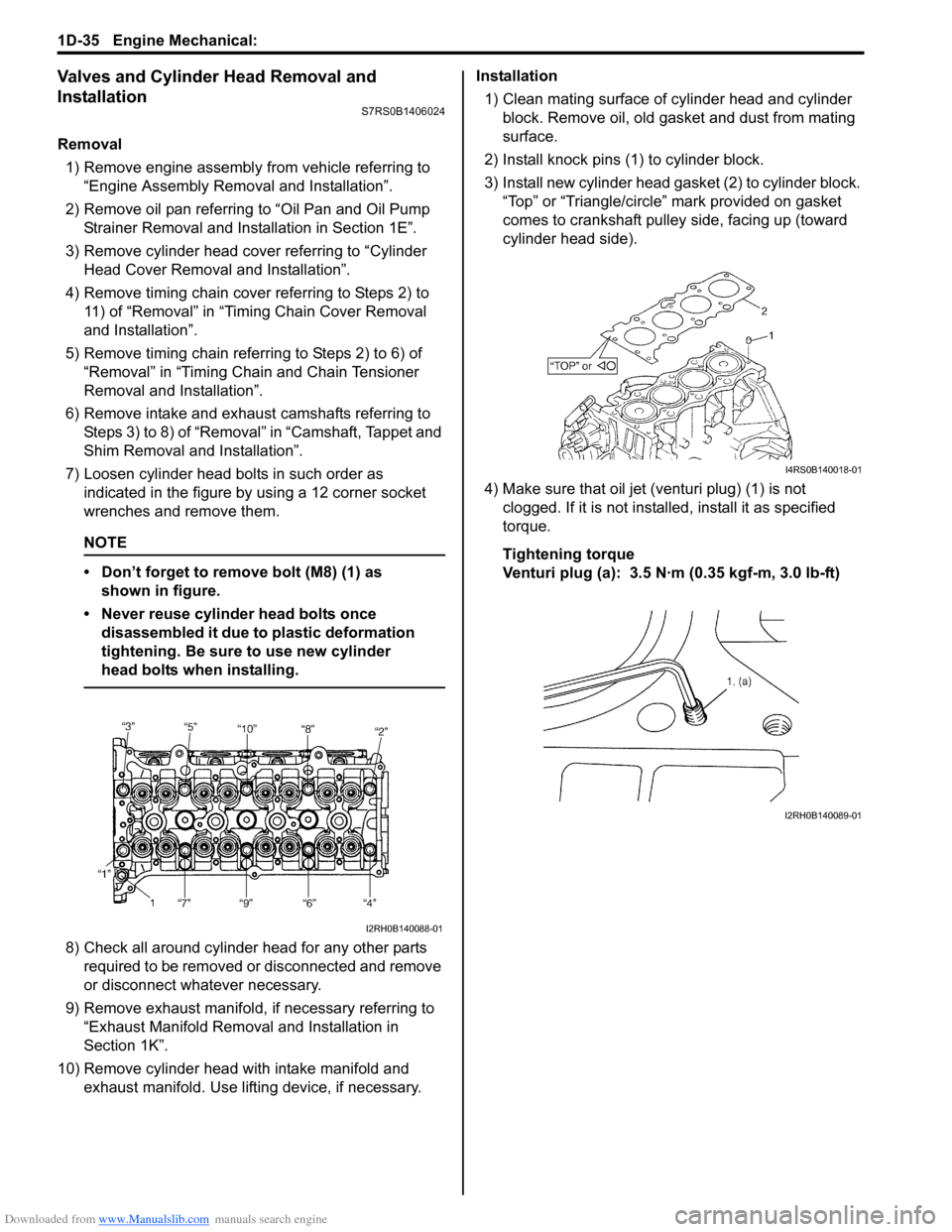

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

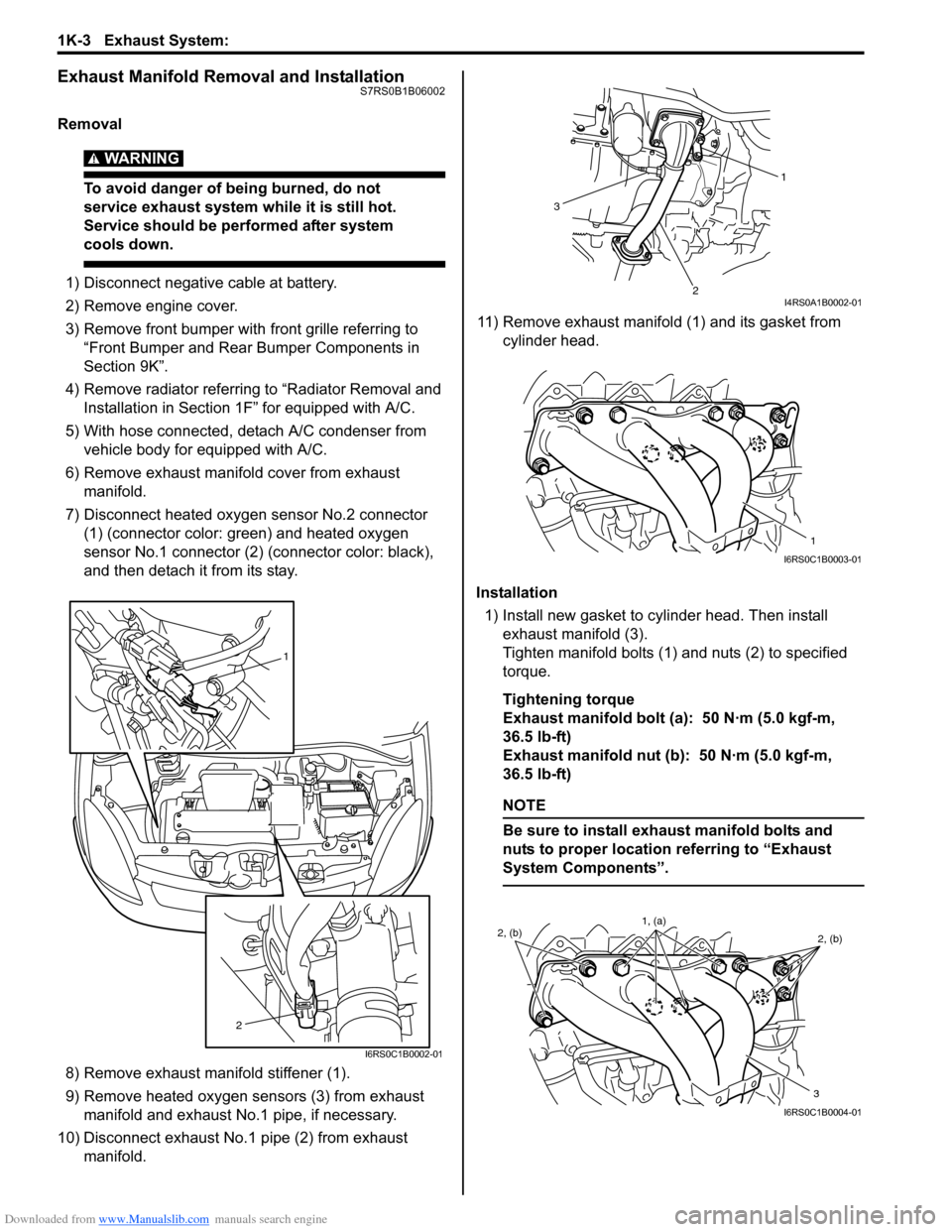

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01