parts diagram SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 157 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-107

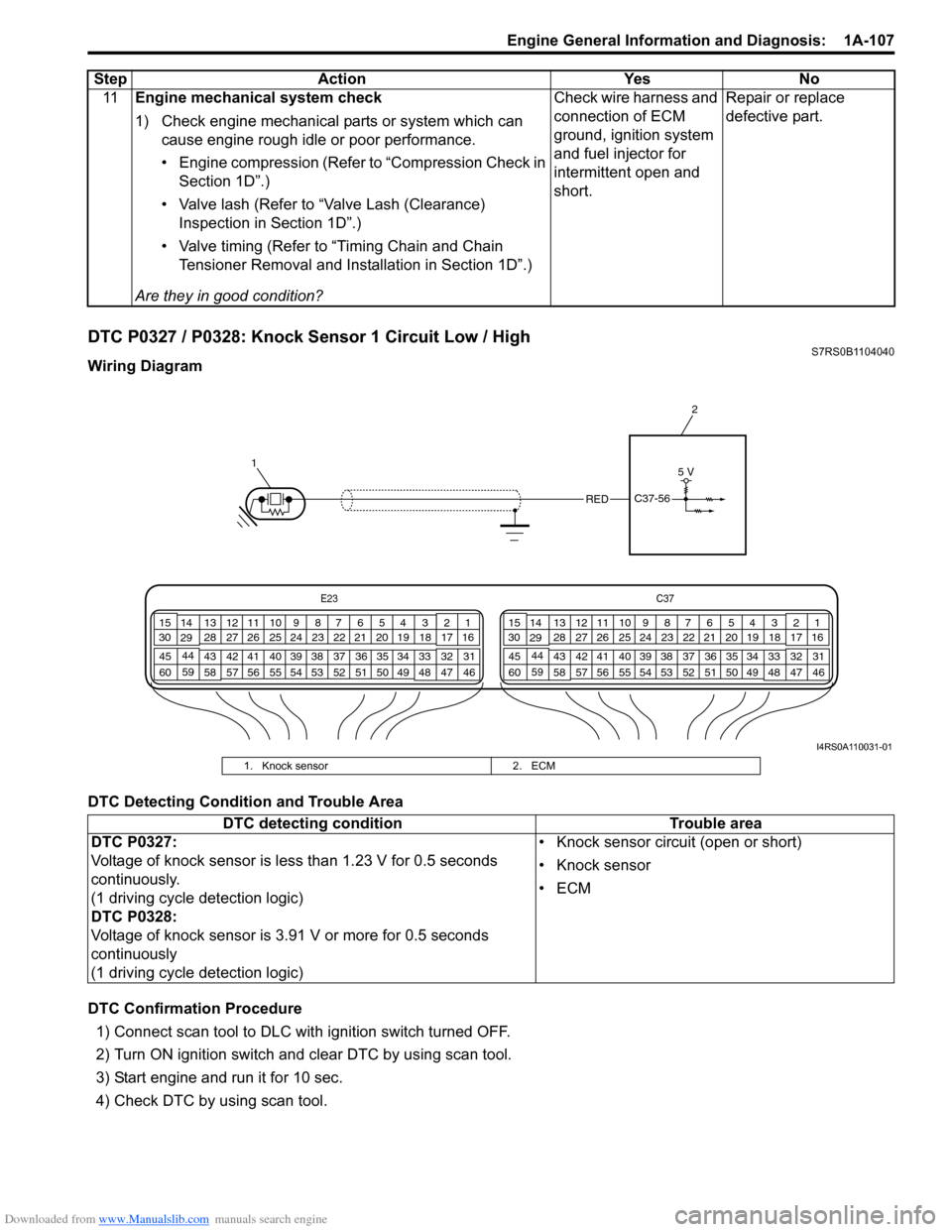

DTC P0327 / P0328: Knock Sensor 1 Circuit Low / HighS7RS0B1104040

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 10 sec.

4) Check DTC by using scan tool. 11

Engine mechanical system check

1) Check engine mechanical parts or system which can

cause engine rough idle or poor performance.

• Engine compression (Refer to “Compression Check in Section 1D”.)

• Valve lash (Refer to “Valve Lash (Clearance) Inspection in Section 1D”.)

• Valve timing (Refer to “Timing Chain and Chain Tensioner Removal and Installation in Section 1D”.)

Are they in good condition? Check wire harness and

connection of ECM

ground, ignition system

and fuel injector for

intermittent open and

short.

Repair or replace

defective part.

Step

Action YesNo

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

1 2

REDC37-56

5 V

I4RS0A110031-01

1. Knock sensor

2. ECM

DTC detecting condition Trouble area

DTC P0327:

Voltage of knock sensor is less than 1.23 V for 0.5 seconds

continuously.

(1 driving cycle detection logic)

DTC P0328:

Voltage of knock sensor is 3.91 V or more for 0.5 seconds

continuously

(1 driving cycle detection logic) • Knock sensor circuit (open or short)

• Knock sensor

•ECM

Page 595 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-21

Stability control (ACTIVE, INACTIVE): This indicates

stability control in acti vation / deactivation.

TCS control (brake) ( ACTIVE, INACTIVE): This

indicates brake function of TCS in activation /

deactivation.

TCS control (engine) (ACTIVE, INACTIVE): This

indicates torque control of TCS in activation /

deactivation. ESP®

off state (cont) (ESP ® ON, ESP ® OFF): State

of ESP ® OFF switch.

Steering angle Sen (Neutral, NON newtral): This

indicates steering wheel angle measured by steering

angle sensor is in straight-ahead or not.

Visual InspectionS7RS0B4604059

Check the following parts and systems visually.

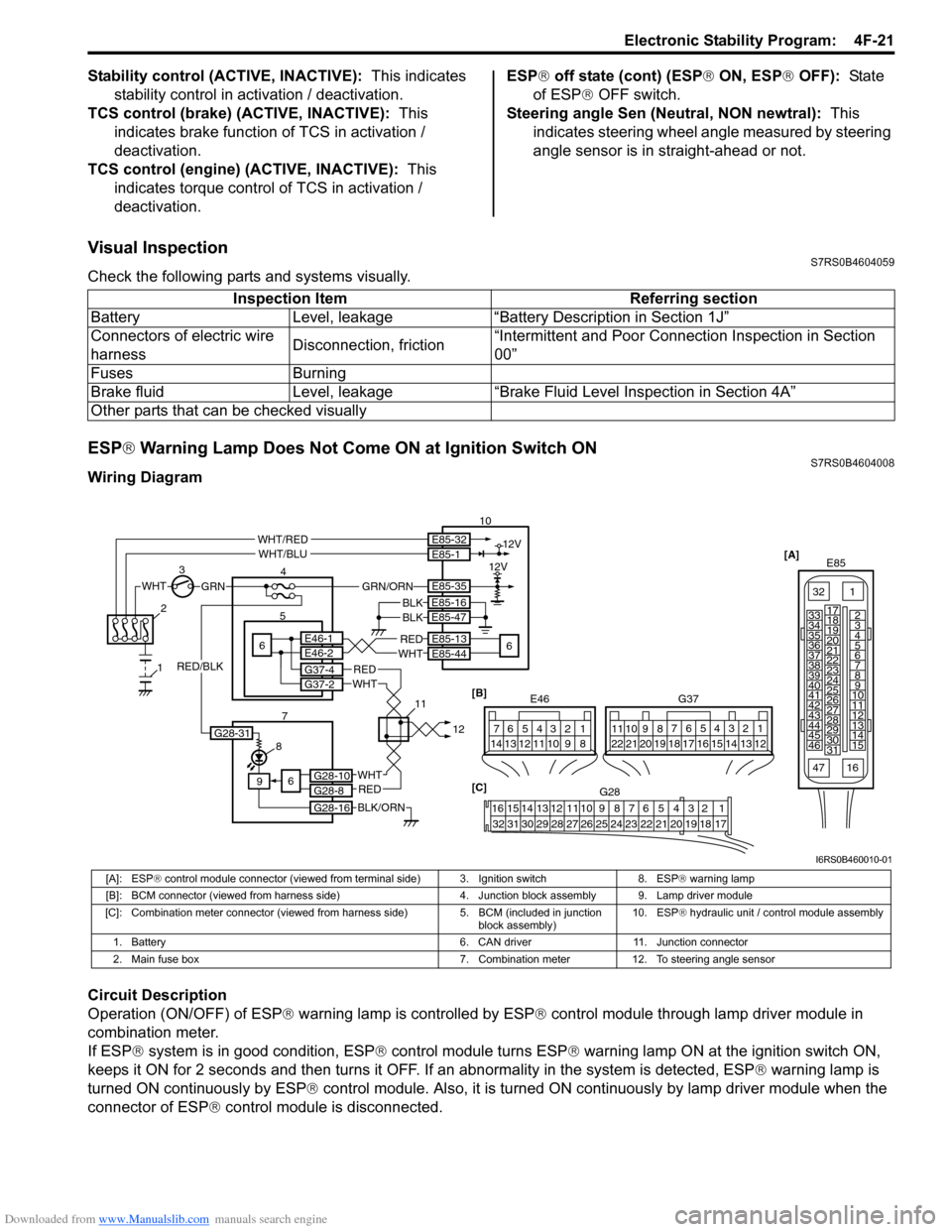

ESP ® Warning Lamp Does Not Come ON at Ignition Switch ONS7RS0B4604008

Wiring Diagram

Circuit Description

Operation (ON/OFF) of ESP ® warning lamp is controlled by ESP ® control module through lamp driver module in

combination meter.

If ESP ® system is in good condition, ESP ® control module turns ESP ® warning lamp ON at the ignition switch ON,

keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ESP ® warning lamp is

turned ON continuously by ESP ® control module. Also, it is turned ON continuously by lamp driver module when the

connector of ESP ® control module is disconnected.Inspection Item Referring section

Battery Level, leakage “Battery Description in Section 1J”

Connectors of electric wire

harness Disconnection, friction“Intermittent and Poor Connec

tion Inspection in Section

00”

Fuses Burning

Brake fluid Level, leakage “Brake Fluid Level Inspection in Section 4A”

Other parts that can be checked visually

[A] E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHTGRN

3

E85-13

E85-44REDWHT6 5E46-1E46-2

4 10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1112[B]

G37

E46124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

G28-31

RED/BLK

I6RS0B460010-01

[A]: ESP ® control module connector (viewed from terminal side) 3. Ignition switch 8. ESP ® warning lamp

[B]: BCM connector (viewed from harness side) 4. Junction block assembly 9. Lamp driver module

[C]: Combination meter connector (viewed from harness side) 5. BCM (included in junction

block assembly) 10. ESP

® hydraulic unit / control module assembly

1. Battery 6. CAN driver 11. Junction connector

2. Main fuse box 7. Combination meter 12. To steering angle sensor

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

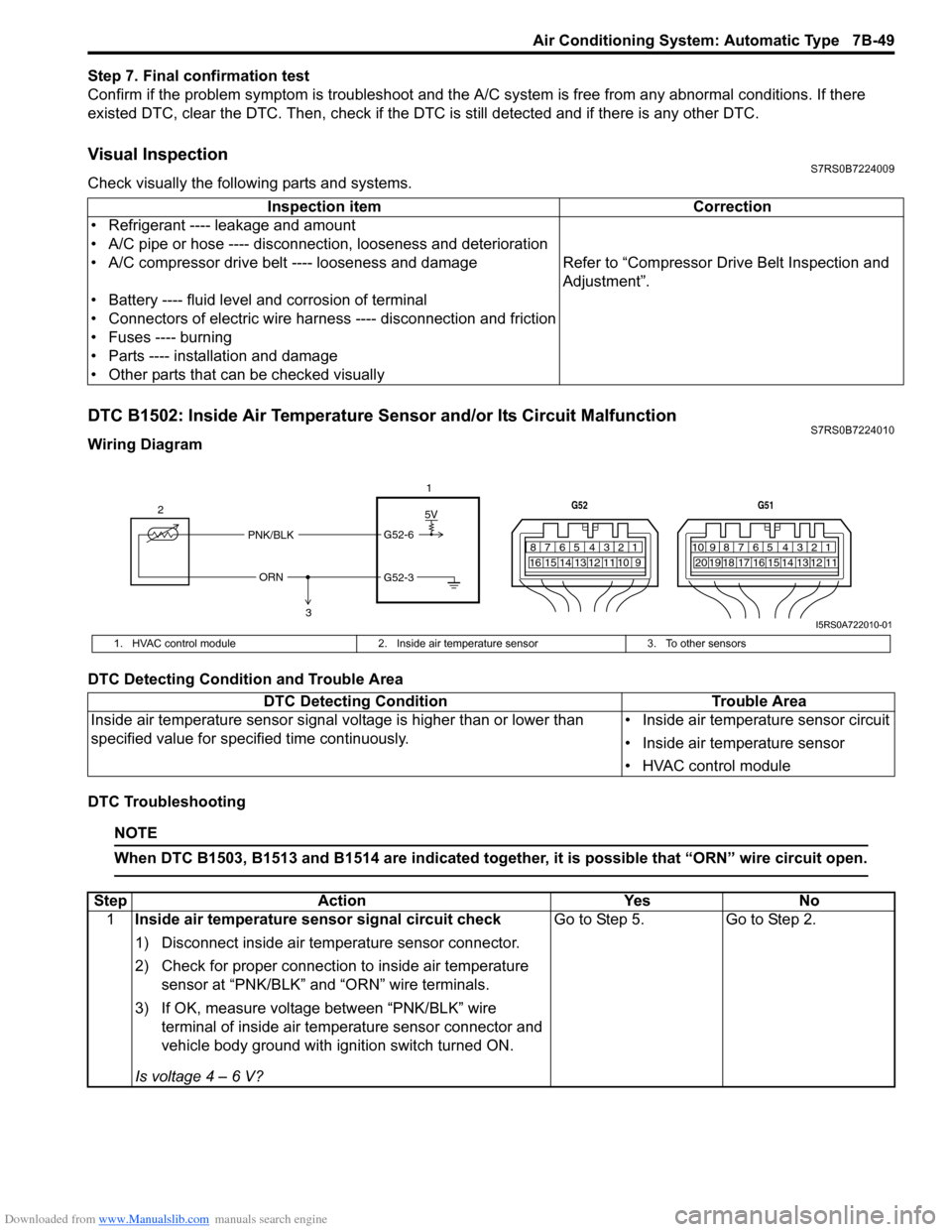

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1167 of 1496

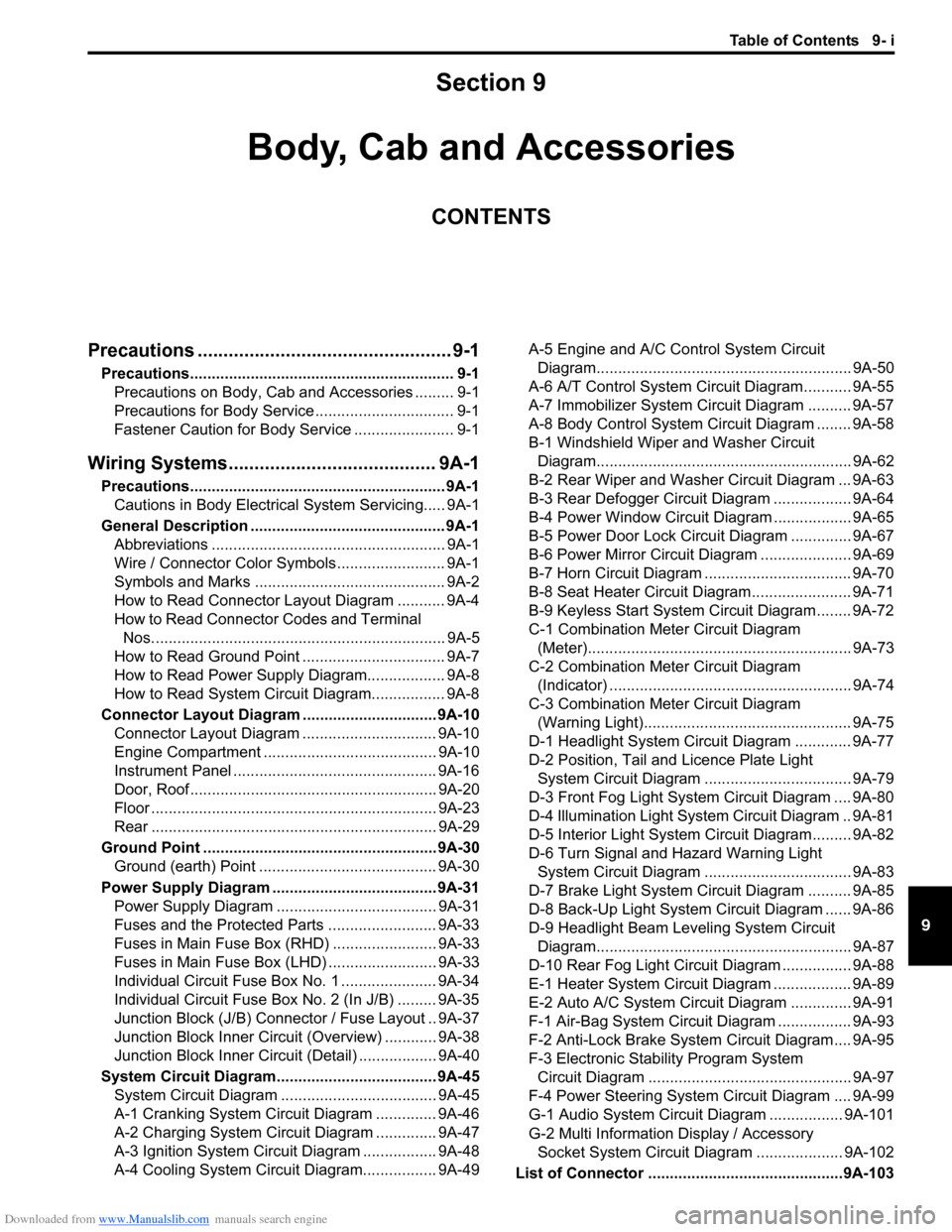

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103

Page 1202 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-31 Wiring Systems:

Power Supply Diagram

Power Supply DiagramS7RS0B910D001

Refer to “Fuses and the Protected Parts”.

Refer to “Fuses in Main Fuse Box (RHD)”.

Refer to “Individual Circuit Fuse Box No. 1”.

Refer to “Individual Circuit Fuse Box No. 2 (In J/B)”.

Refer to “Junction Block (J/B) Connector / Fuse Layout”.

Refer to “Junction Block Inner Circuit (Overview)”.

Refer to “Junction Block Inner Circuit (Detail)”.

Page 1402 of 1496

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

DTC P1615: ID Code Does Not Registered (Vehicle equipped with keyless start system

only) ................................................................10C-9

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system

only) ..............................................................10C-10

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control

Module) (Vehicle equipped with keyless

start system only) ..........................................10C-11

DTC P1621: Immobilizer Communication Line Error ......................................................10C-12

DTC P1622: EEPROM Reading / Writing Error ..............................................................10C-13

DTC P1623: Unregistered Transponder .........10C-13

DTC P1625: Immobilizer An tenna Error..........10C-14

DTC P1636: Immobilizer Information Registration Failure .......................................10C-14

DTC P1638: Immobilizer Information Mismatched ...................................................10C-15

Inspection of Immobilizer Control Module (ICM) and Its Circuit ....... ...............................10C-16

Repair Instructions ........... ...............................10C-18

Immobilizer Control Mo dule (ICM) Removal

and Installation ..............................................10C-18

Registration of the Ignition Key .......................10C-18

Procedure after ECM Replacement ................10C-18

Special Tools and Equipmen t .........................10C-19

Special Tool ....................................................10C-19

Keyless Start System ....... ......................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7 Keyless Start System El ectric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8 Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagn osis Introduction ... 10E-8 Keyless Start System Chec

k ............................. 10E-8

Customer Questionnaire (E xample) .................. 10E-9

Key Indicator Lamp Check .............................. 10E-10

DTC Check...................................................... 10E-10

DTC Table ....................................................... 10E-11

DTC Clearance ............................................... 10E-12

Keyless Start System Symp tom Diagnosis ..... 10E-12

Keyless Start System Operation Inspection .... 10E-13

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC Check ............................................................ 10E-18

Key Indicator Lamp Circuit Check (Key indicator lamp doesn’t light when ignition

knob switch is pushed.) ................................. 10E-20

Keyless Start Control Module Power and Ground Circuit Check .................................... 10E-22

DTC No. 11: Communi cation Error with

Steering Lock Unit ......................................... 10E-23

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-24

DTC No. 21 / No. 22: Internal Error of Keyless Start Control Module (EEPROM reading

error) / (EEPROM writing error) ............ ........ 10E-24

DTC No. 31: Lost Commun ication with BCM .. 10E-25

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-27

DTC No. 51 / No. 52 / No. 53: Driver Side / Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-28

Repair Instructions ............ .............................. 10E-30

Antennas and Request Switches Removal and Installation .............................................. 10E-30

Front Door (Driver and Passenger Side), Rear End Door Request Switch Inspection............ 10E-31

Steering Lock Unit Removal and Installation .. 10E-31

Steering Lock Unit Inspection ......................... 10E-31

Front Door Lock Switch In spection ................. 10E-31

Keyless Start Control Module Removal and Installation ..................................................... 10E-32

Remote Controller Inspection.......................... 10E-32

Replacement of Remote Controller Battery .... 10E-32

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-33

Page 1423 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-20

DTC Troubleshooting

DTC B1157 (No. 1157): Air Bag Deployment Signal InputS7RS0BA204011

Wiring Diagram

Refer to “DTC B1150 (No. 1150): Air Bag Communication Circuit Malfunction”.

DTC Detecting Conditi on and Possible Cause

Flow Test Description

Step 1: Check DTC for SDM.

DTC Troubleshooting Step Action Yes No

1 Check air bag communication circuit

1) Turn ignition switch to OFF position.

2) Disconnect connector from SDM referring to “SDM

Removal and Installation in Section 8B”.

3) Disconnect connector from junction block assembly.

4) Turn ignition switch to ON position.

5) Measure voltage between “L29-37” terminal of SDM connector and vehicle body ground.

Is voltage 0 V? Go to Step 2. Short to power supply in

air bag communication

circuit.

2 Check air bag communication circuit

1) Turn ignition switch to OFF position.

2) Connect connectors to junction block assembly.

3) Turn ignition switch to ON position.

4) Measure voltage between “L04-2” terminal of junction

block assembly connector and vehicle body ground.

Is voltage 4 – 6 V? Go to Step 3.

Short to ground in air

bag communication

circuit. If OK, substitute

a known-good BCM

(included in junction

block assembly) and

recheck.

3 Check air bag communication circuit

1) Measure voltage between “L29-37” terminal of SDM

connector and vehicle body ground.

Is voltage 4 – 6 V? Substitute a known-

good SDM and recheck.

Open or high resistance

in air bag

communication circuit.

DTC detecting condition

Possible cause

Air bag deployment signal is fed from SDM to BCM. • Air bag component parts

• BCM malfunction

StepAction YesNo

1 DTC check of SDM

1) Check DTC stored in SDM re ferring to “DTC Check in

Section 8B”.

Is DTC B1021 detected? Go to “DTC B1021:

Front Air Bag Module

Deployed in Section

8B”.

Substitute a known-

good BCM (included in

junction block

assembly) and recheck.