ECU connection SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 7 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-2

Servicing and Handling

WARNING!

Many of service procedures require

disconnection of “A/BAG” fuse and all air

bag (inflator) module(s) from initiator circuit

to avoid an accidental deployment.

Driver, Passenger, Side and Curtain Air Bag

(Inflator) Modules

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

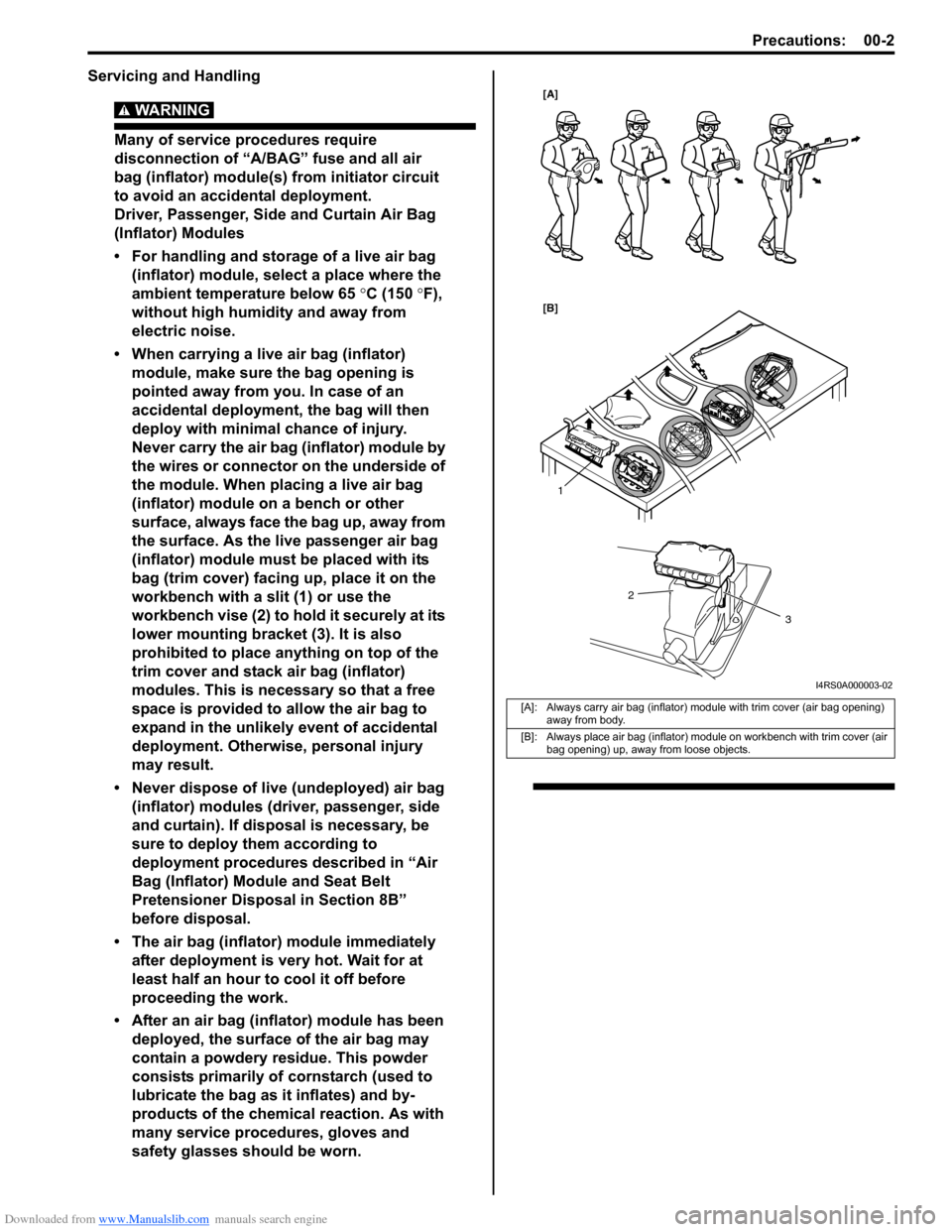

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module. When placing a live air bag

(inflator) module on a bench or other

surface, always face the bag up, away from

the surface. As the live passenger air bag

(inflator) module must be placed with its

bag (trim cover) facing up, place it on the

workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment. Otherwise, personal injury

may result.

• Never dispose of live (undeployed) air bag (inflator) modules (driver, passenger, side

and curtain). If disposal is necessary, be

sure to deploy them according to

deployment procedures described in “Air

Bag (Inflator) Module and Seat Belt

Pretensioner Disposal in Section 8B”

before disposal.

• The air bag (inflator) module immediately

after deployment is very hot. Wait for at

least half an hour to cool it off before

proceeding the work.

• After an air bag (inflator) module has been deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

1

2

3

[A]

[B]

I4RS0A000003-02

Page 36 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-6 Maintenance and Lubrication:

Exhaust System InspectionS7RS0B0206006

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

Any service on exhaust system should be

performed when it is cool.

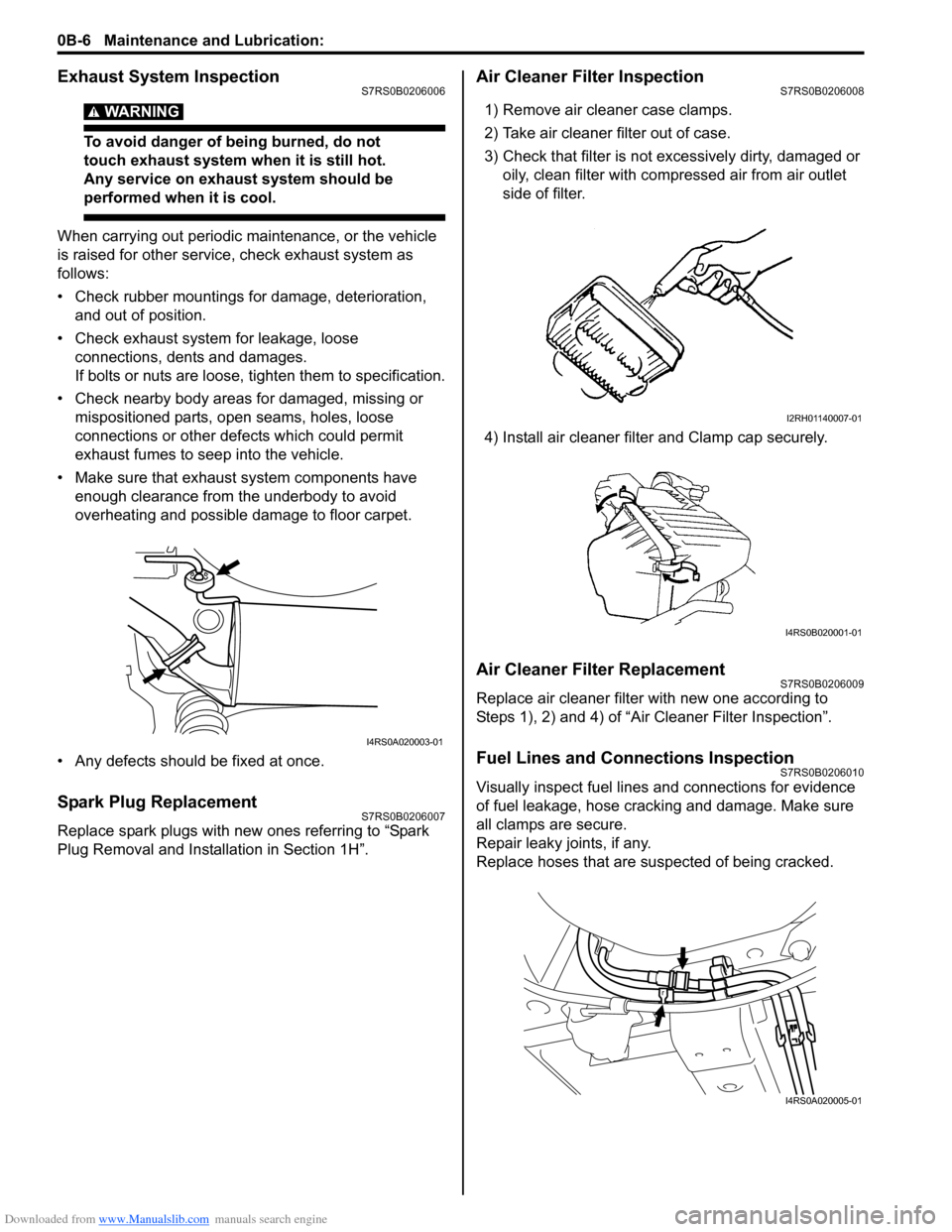

When carrying out periodic maintenance, or the vehicle

is raised for other service, check exhaust system as

follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connections, dents and damages.

If bolts or nuts are loose, tighten them to specification.

• Check nearby body areas for damaged, missing or mispositioned parts, ope n seams, holes, loose

connections or other defects which could permit

exhaust fumes to seep into the vehicle.

• Make sure that exhaust system components have enough clearance from the underbody to avoid

overheating and possible damage to floor carpet.

• Any defects should be fixed at once.

Spark Plug ReplacementS7RS0B0206007

Replace spark plugs with new ones referring to “Spark

Plug Removal and Installation in Section 1H”.

Air Cleaner Filter InspectionS7RS0B0206008

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily, clean filter with compressed air from air outlet

side of filter.

4) Install air cleaner filter and Clamp cap securely.

Air Cleaner Filter ReplacementS7RS0B0206009

Replace air cleaner filter with new one according to

Steps 1), 2) and 4) of “Air Cleaner Filter Inspection”.

Fuel Lines and Connections InspectionS7RS0B0206010

Visually inspect fuel lines and connections for evidence

of fuel leakage, hose cracking and damage. Make sure

all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

I4RS0A020003-01

I2RH01140007-01

I4RS0B020001-01

I4RS0A020005-01

Page 160 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 CKP sensor and connector for proper installation check

Is CKP sensor installed properly and connector connected

securely? Go to Step 3.

Correct.

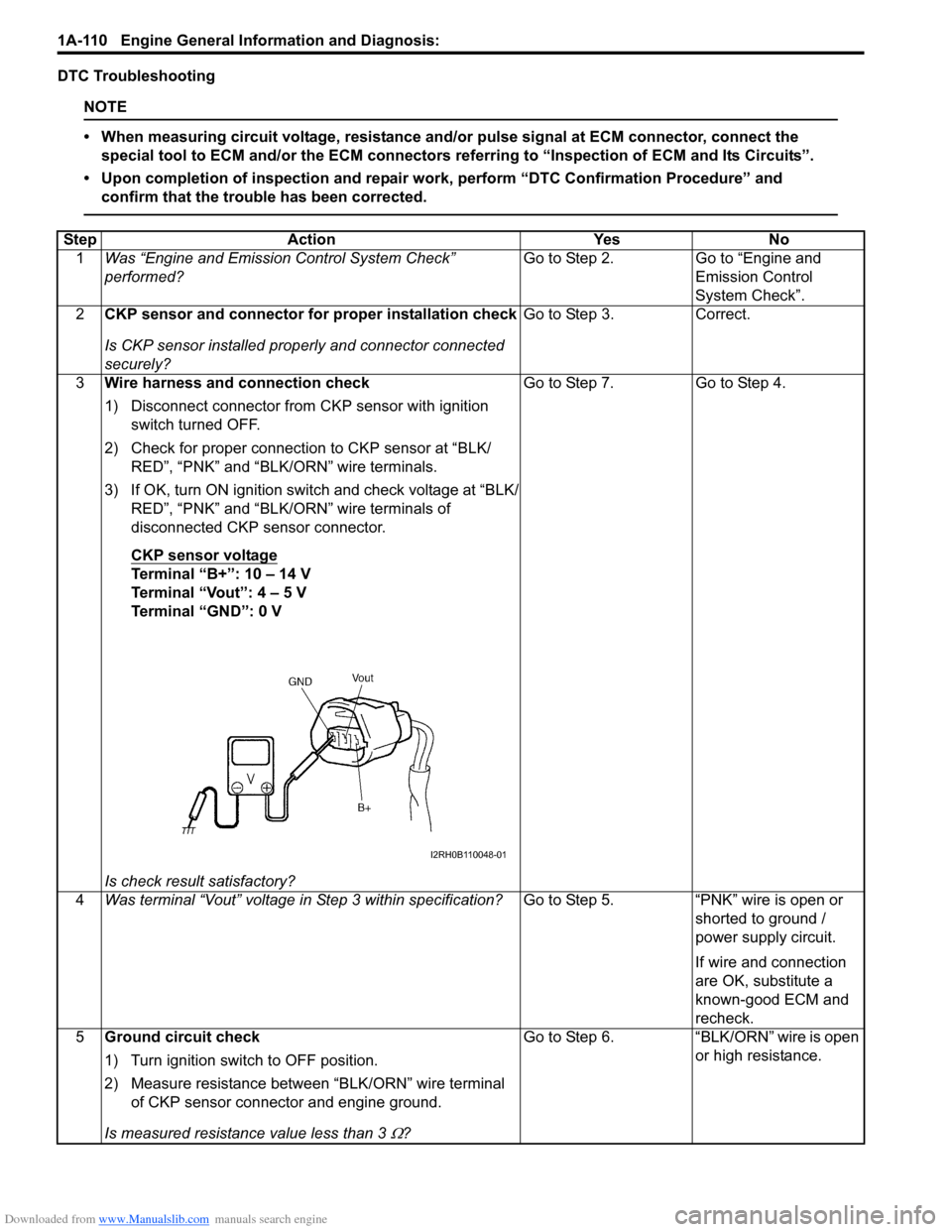

3 Wire harness and connection check

1) Disconnect connector from CKP sensor with ignition

switch turned OFF.

2) Check for proper connection to CKP sensor at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals of

disconnected CKP sensor connector.

CKP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “PNK” wire is open or

shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CKP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance.

I2RH0B110048-01

Page 184 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-134 Engine General Information and Diagnosis:

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control Module

Programming Error / Control Module Performance

S7RS0B1104054

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

DTC P0601:

Data write error or check sum error

(1 driving cycle detection logic)

DTC P0602:

Data programming error

(1 driving cycle detection logic but MIL does not light up)

DTC P0607:

ECM internal processor error

(1 driving cycle detection logic) • ECM power supply circuit and/or

ground circuit

•ECM

Step Action YesNo

1 DTC recheck

1) Clear DTC referring to “DTC Clearance”.

2) Turn OFF ignition switch.

3) Turn ON ignition switch and check DTC.

Is DTC P0601 or P0 607 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 ECM reprogramming check

Was reprogramming of ECM executed? Execute reprogramming

of ECM correctly once

again.Go to step 3.

3 ECM power and ground circuit check

1) Check that ECM power supply circuit and ECM ground

circuit is in good condition referring to “ECM Power and

Ground Circuit Check”.

Are check results OK? Substitute a known-

good ECM and recheck.

Repair ECM power or

ground circuit.

Page 283 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-11

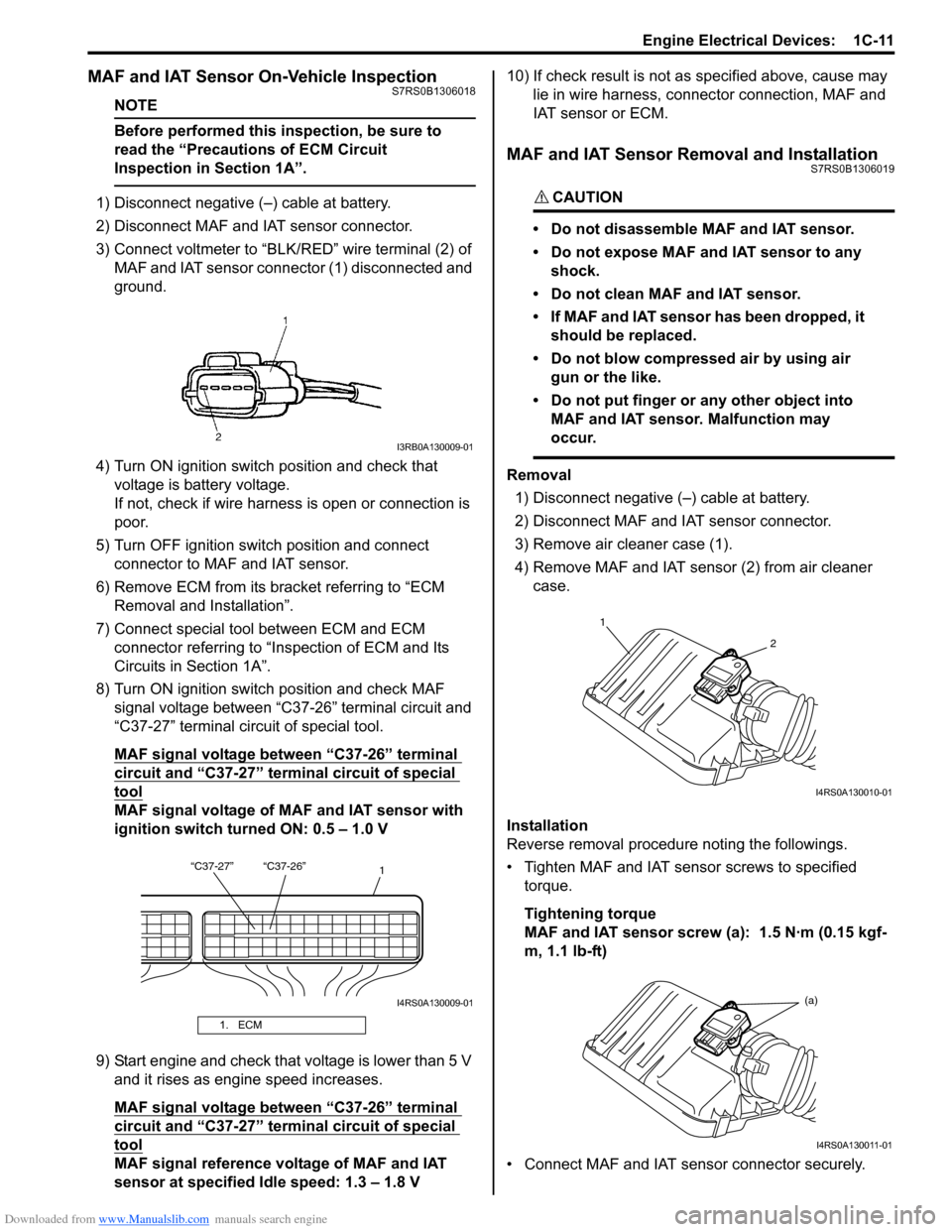

MAF and IAT Sensor On-Vehicle InspectionS7RS0B1306018

NOTE

Before performed this inspection, be sure to

read the “Precautions of ECM Circuit

Inspection in Section 1A”.

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Connect voltmeter to “BLK/RED” wire terminal (2) of

MAF and IAT sensor connector (1) disconnected and

ground.

4) Turn ON ignition switch position and check that voltage is battery voltage.

If not, check if wire harness is open or connection is

poor.

5) Turn OFF ignition switch position and connect connector to MAF and IAT sensor.

6) Remove ECM from its bracket referring to “ECM Removal and Installation”.

7) Connect special tool between ECM and ECM connector referring to “Inspection of ECM and Its

Circuits in Section 1A”.

8) Turn ON ignition switch position and check MAF signal voltage between “C37-26” terminal circuit and

“C37-27” terminal circuit of special tool.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal voltage of MAF and IAT sensor with

ignition switch turned ON: 0.5 – 1.0 V

9) Start engine and check that voltage is lower than 5 V and it rises as engine speed increases.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal reference voltage of MAF and IAT

sensor at specified Idle speed: 1.3 – 1.8 V 10) If check result is not as

specified above, cause may

lie in wire harness, connec tor connection, MAF and

IAT sensor or ECM.

MAF and IAT Sensor Removal and InstallationS7RS0B1306019

CAUTION!

• Do not disassemble MAF and IAT sensor.

• Do not expose MAF and IAT sensor to any shock.

• Do not clean MAF and IAT sensor.

• If MAF and IAT sensor has been dropped, it should be replaced.

• Do not blow compressed air by using air gun or the like.

• Do not put finger or any other object into MAF and IAT sensor. Malfunction may

occur.

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Remove air cleaner case (1).

4) Remove MAF and IAT sensor (2) from air cleaner case.

Installation

Reverse removal procedure noting the followings.

• Tighten MAF and IAT sensor screws to specified torque.

Tightening torque

MAF and IAT sensor screw (a): 1.5 N·m (0.15 kgf-

m, 1.1 lb-ft)

• Connect MAF and IAT sensor connector securely.

1. ECM

I3RB0A130009-01

“C37-27” “C37-26” 1

I4RS0A130009-01

1

2

I4RS0A130010-01

(a)

I4RS0A130011-01

Page 359 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-7

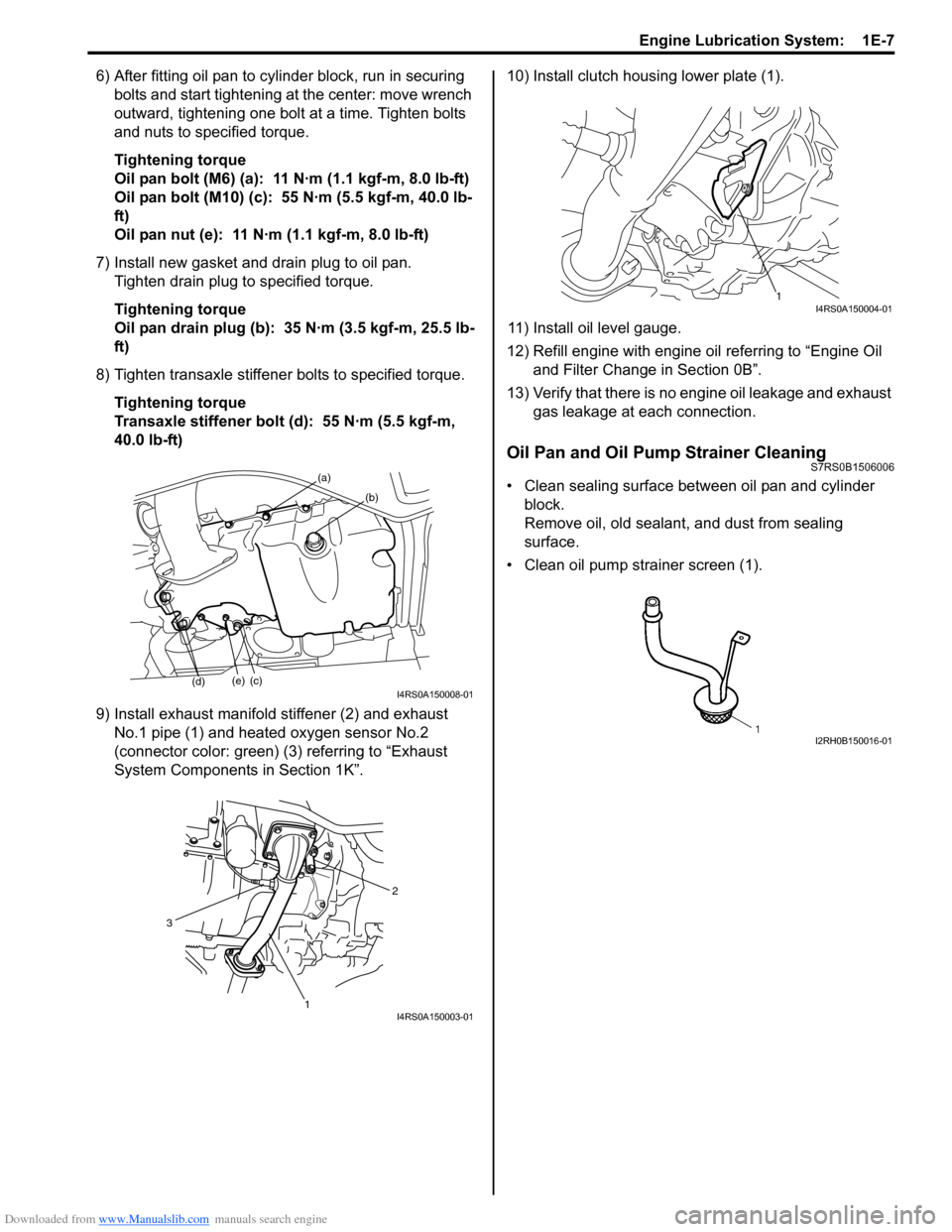

6) After fitting oil pan to cylinder block, run in securing bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) Install new gasket and drain plug to oil pan. Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque. Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)

9) Install exhaust manifold stiffener (2) and exhaust No.1 pipe (1) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 10) Install clutch housing lower plate (1).

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no en gine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS7RS0B1506006

• Clean sealing surface between oil pan and cylinder block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).(a)

(b)

(c)(e)

(d)I4RS0A150008-01

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150016-01

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

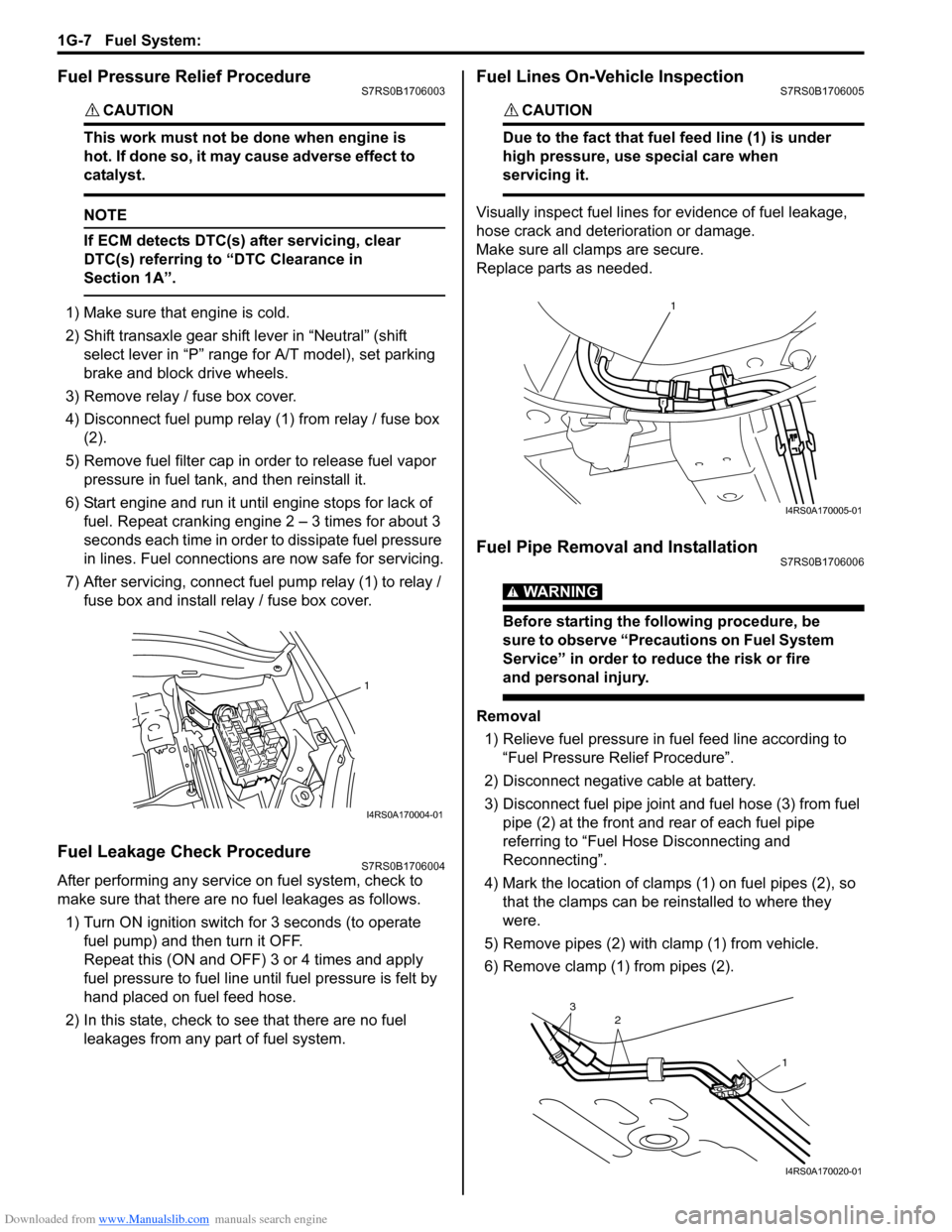

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

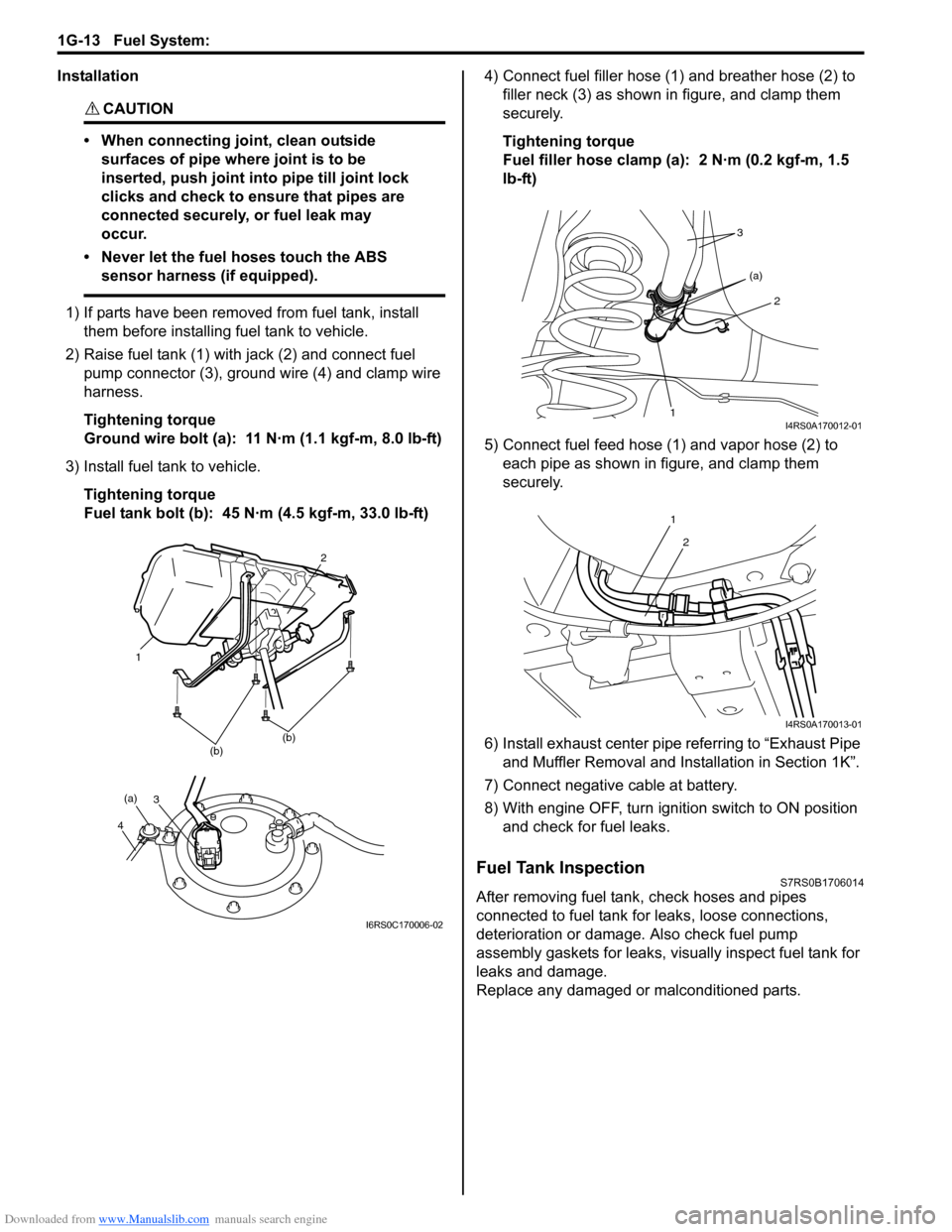

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

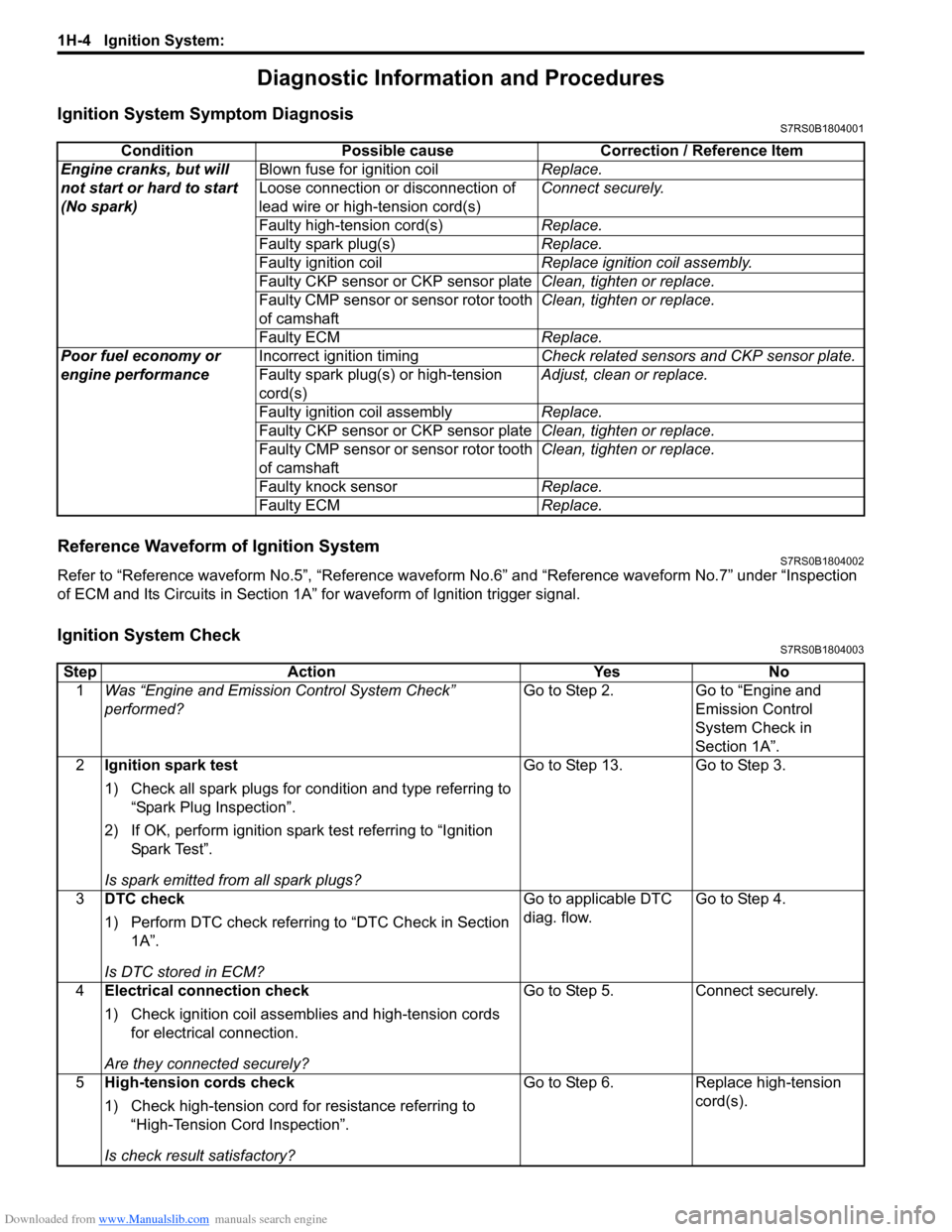

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 548 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-9 ABS:

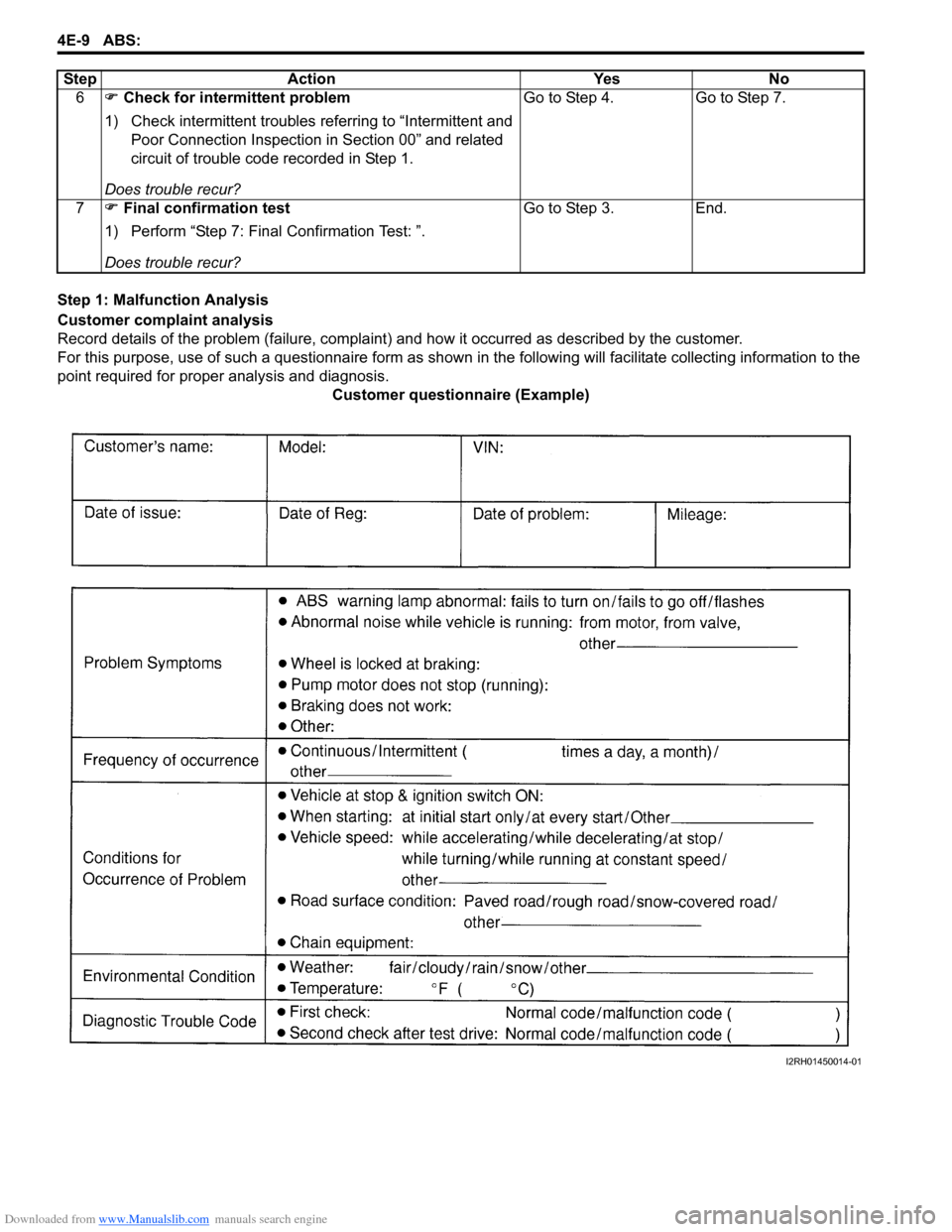

Step 1: Malfunction Analysis

Customer complaint analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in the following will facilitate collec ting information to the

point required for proper analysis and diagnosis. Customer questionnaire (Example)

6

�) Check for intermittent problem

1) Check intermittent troubles referring to “Intermittent and

Poor Connection Inspection in Section 00” and related

circuit of trouble code recorded in Step 1.

Does trouble recur? Go to Step 4.

Go to Step 7.

7 �) Final confirmation test

1) Perform “Step 7: Final Confirmation Test: ”.

Does trouble recur? Go to Step 3.

End.

Step

Action YesNo

I2RH01450014-01