Heater removal SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 47 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-iii

EVAP Canister Purge Valve and Its Circuit

Inspection.......................................................... 1B-2

Vacuum Passage Inspection .............................. 1B-3

Vacuum Hose and Purge Valve Chamber Inspection.......................................................... 1B-3

EVAP Canister Purge Valve Inspection .............. 1B-3

EVAP Canister Inspection ... ................................ 1B-4

EGR Valve Removal and Installation .................. 1B-4

EGR Valve Inspection ......................................... 1B-4

PCV Hose Inspection .......................................... 1B-4

PCV Valve Inspection ......................................... 1B-5

Special Tools and Equipmen t ............................. 1B-5

Special Tool ........................................................ 1B-5

Engine Electrical Devices .. ..................... 1C-1

Repair Instructions .............................................. 1C-1

ECM Removal and Installation ............................ 1C-1

MAP Sensor Inspection ...................................... 1C-2

Electric Throttle Body Assembly On-Vehicle

Inspection.......................................................... 1C-2

Electric Throttle Body System Calibration ........... 1C-5

APP Sensor Assembly On-V ehicle Inspection .... 1C-5

APP Sensor Assembly Removal and Installation ......................................................... 1C-5

APP Sensor Assembly Inspection ...................... 1C-6

ECT Sensor Removal and In stallation ................ 1C-6

ECT Sensor Inspection ....................................... 1C-7

HO2S-1 and HO2S-2 Heater On-Vehicle Inspection.......................................................... 1C-7

HO2S-1 and HO2S-2 Removal and Installation ......................................................... 1C-7

CMP Sensor Removal and In stallation ............... 1C-8

Camshaft Position (CMP) Se nsor Inspection ...... 1C-8

CKP Sensor Removal and Installation ................ 1C-9

CKP Sensor Inspection ....................................... 1C-9

Knock Sensor Removal and Installation ........... 1C-10

Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection....................... 1C-10

MAF and IAT Sensor On-Vehicle Inspection .... 1C-11

MAF and IAT Sensor Removal and Installation ....................................................... 1C-11

MAF and IAT Sensor Inspection ....................... 1C-12

Electric Load Current Sensor On-Vehicle Inspection........................................................ 1C-12

Specifications ..................................................... 1C-13

Tightening Torque Specifications ...................... 1C-13

Engine Mechanical ......... ......................... 1D-1

General Description ............................................. 1D-1

Engine Construction Description ......................... 1D-1

Camshaft Position Control (VVT Variable Valve Timing) System Description .................... 1D-2

Diagnostic Information and Procedures ............ 1D-4 Compression Check ............................................ 1D-4

Engine Vacuum Check ....................................... 1D-5

Valve Lash (Clearance) Inspection ..................... 1D-6

Repair Instructions .............................................. 1D-9 Air Cleaner Components ..................................... 1D-9

Air Cleaner Element Removal and Installation .... 1D-9 Air Cleaner Element Ins

pection and Cleaning ..1D-10

Cylinder Head Co ver Removal and

Installation .......................................................1D-10

Throttle Body and Intake Manifold

Components ....................................................1D-12

Throttle Body On-Vehicle Inspection.................1D-13

Electric Throttle Body Assembly Removal and Installation .......................................................1D-13

Throttle Body Cleaning......................................1D-14

Intake Manifold Removal and Installation .........1D-14

Engine Mountings Components ........................1D-16

Engine Assembly Removal and Installation ......1D-17

Timing Chain Cover Components .....................1D-20

Timing Chain Cover Removal and Installation ..1D-21

Timing Chain Cover Inspection .........................1D-23

Oil Control Valve Removal and Installation .......1D-23

Oil Control Valve Inspection ..............................1D-24

Timing Chain and Chain Tensioner Components ....................................................1D-24

Timing Chain and Chain Tensioner Removal and Installation ................................................1D-25

Timing Chain and Chain Tensioner Inspection ..1D-27

Camshaft, Tappet and Shim Components ........1D-28

Camshaft, Tappet and Shim Removal and Installation .......................................................1D-29

Camshaft, Tappet and Shim Inspection ............1D-31

Valves and Cylinder Head Components ...........1D-34

Valves and Cylinder Head Removal and

Installation .......................................................1D-35

Valves and Cylinder Head Disassembly and Assembly.........................................................1D-37

Valves and Valve Guides Inspection.................1D-40

Cylinder Head Inspection . .................................1D-42

Valve Spring Inspection ....................................1D-43

Pistons, Piston Rings , Connecting Rods and

Cylinders Components ....................................1D-44

Pistons, Piston Rings , Connecting Rods and

Cylinders Removal and Installation .................1D-45

Pistons, Piston Rings , Connecting Rods and

Cylinders Disassembly and Assembly ............1D-46

Cylinders, Pistons and Piston Rings Inspection ........................................................1D-47

Piston Pins and Connecting Rods Inspection ...1D-49

Crank Pin and Connecting Rod Bearings Inspection ........................................................1D-50

Main Bearings, Cran kshaft and Cylinder

Block Components ..........................................1D-53

Main Bearings, Cran kshaft and Cylinder

Block Removal and Installa tion .......................1D-54

Crankshaft Inspection .......................................1D-57

Main Bearings Inspection . .................................1D-59

Sensor Plate Inspection ....................................1D-63

Rear Oil Seal Inspection ...................................1D-63

Flywheel Inspection...........................................1D-63

Cylinder Block Inspection ..................................1D-63

Specifications .................... .................................1D-64

Tightening Torque Specifications ......................1D-64

Special Tools and Equipmen t ...........................1D-66

Recommended Service Material .......................1D-66

Special Tool ......................................................1D-66

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

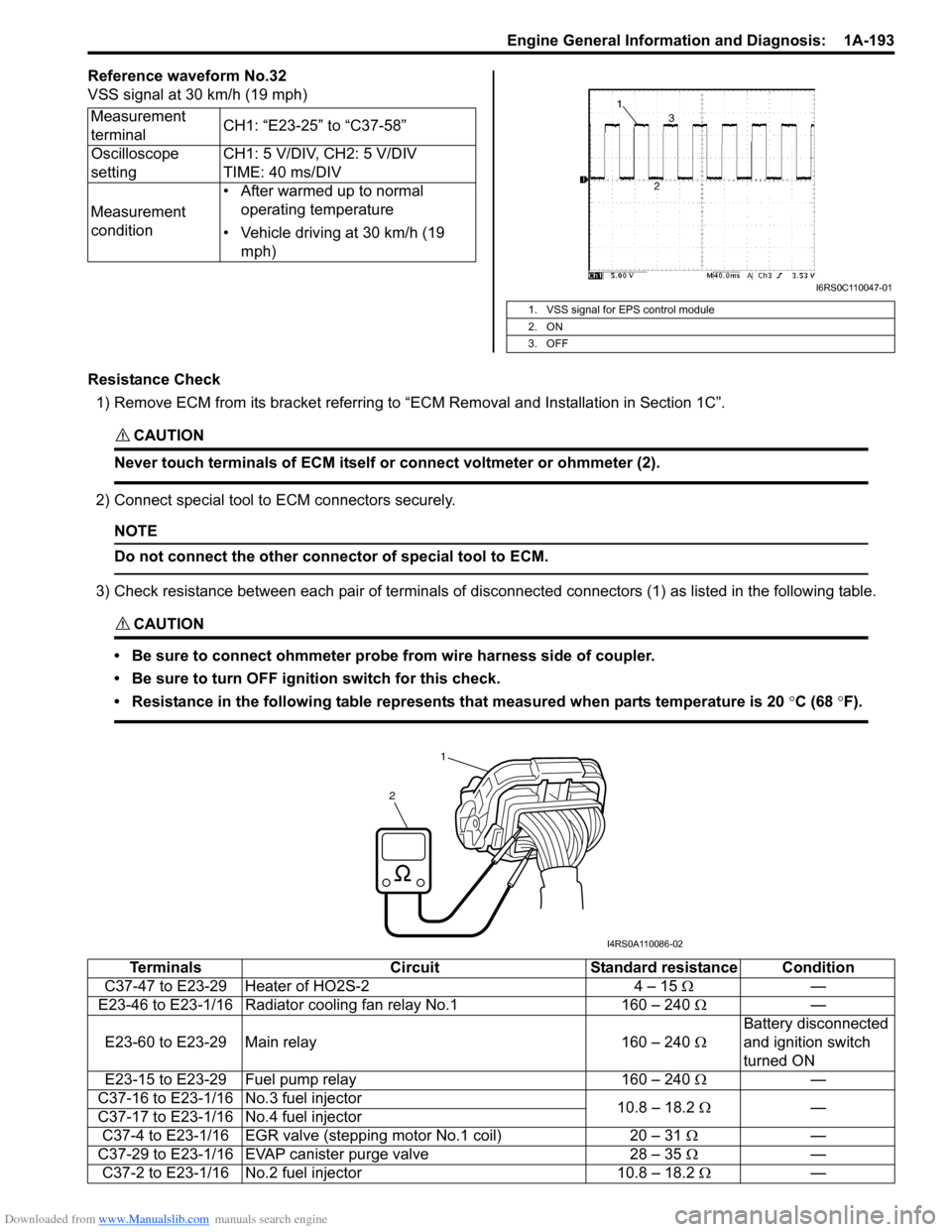

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

Page 279 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and thermostat case.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

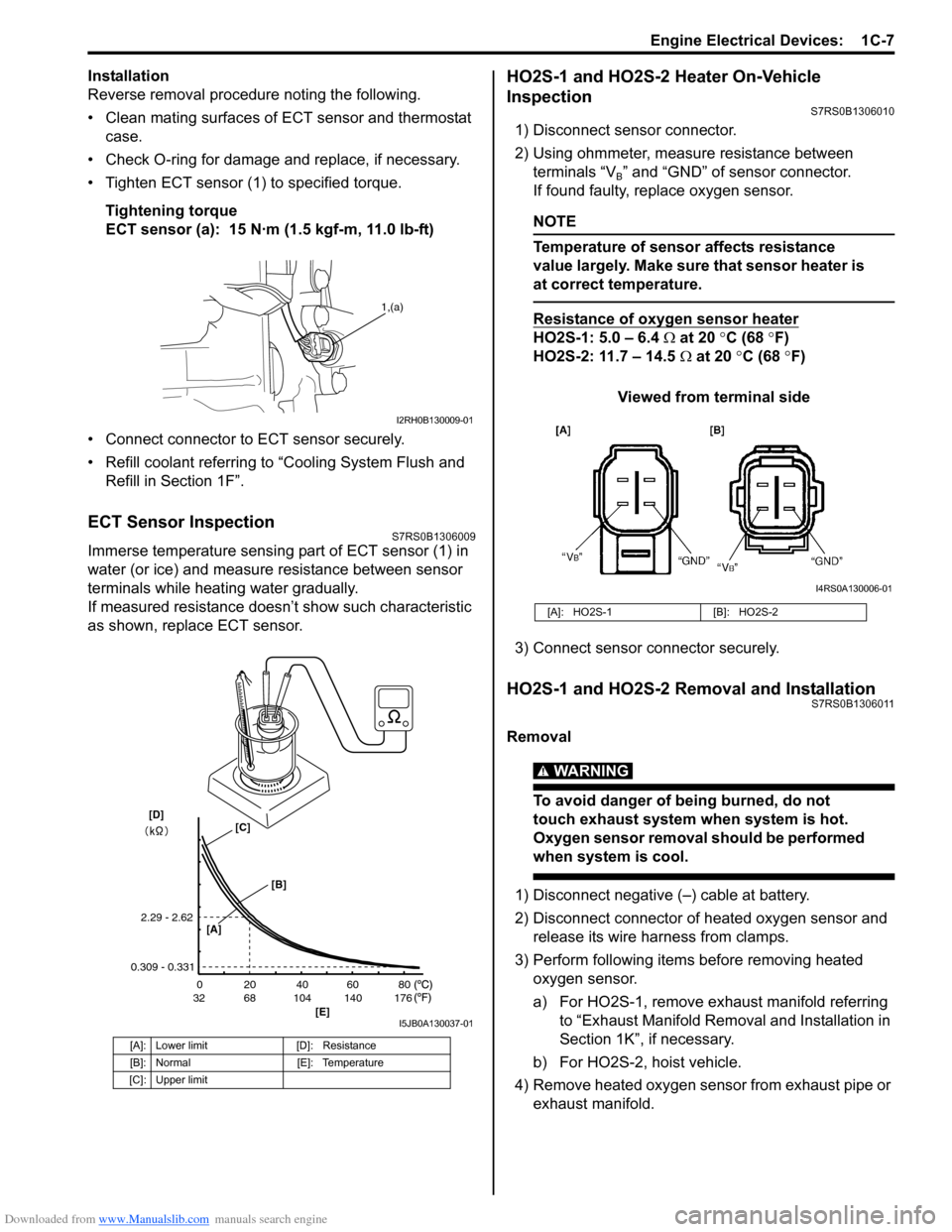

ECT Sensor InspectionS7RS0B1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

HO2S-1 and HO2S-2 Heater On-Vehicle

Inspection

S7RS0B1306010

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals “V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

Resistance of oxygen sensor heater

HO2S-1: 5.0 – 6.4 Ω at 20 °C (68 °F)

HO2S-2: 11.7 – 14.5 Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor co nnector securely.

HO2S-1 and HO2S-2 Removal and InstallationS7RS0B1306011

Removal

WARNING!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Oxygen sensor removal should be performed

when system is cool.

1) Disconnect negative (–) cable at battery.

2) Disconnect connector of heated oxygen sensor and

release its wire harness from clamps.

3) Perform following items before removing heated oxygen sensor.

a) For HO2S-1, remove exhaust manifold referring to “Exhaust Manifold Remo val and Installation in

Section 1K”, if necessary.

b) For HO2S-2, hoist vehicle.

4) Remove heated oxygen sensor from exhaust pipe or exhaust manifold.

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit

1,(a)

I2RH0B130009-01

20

0

68

32 104 140 176 40 60 80

[E]

2.29 - 2.62

0.309 - 0.331

[A]

[B]

[C][D]

I5JB0A130037-01

[A]: HO2S-1 [B]: HO2S-2

I4RS0A130006-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

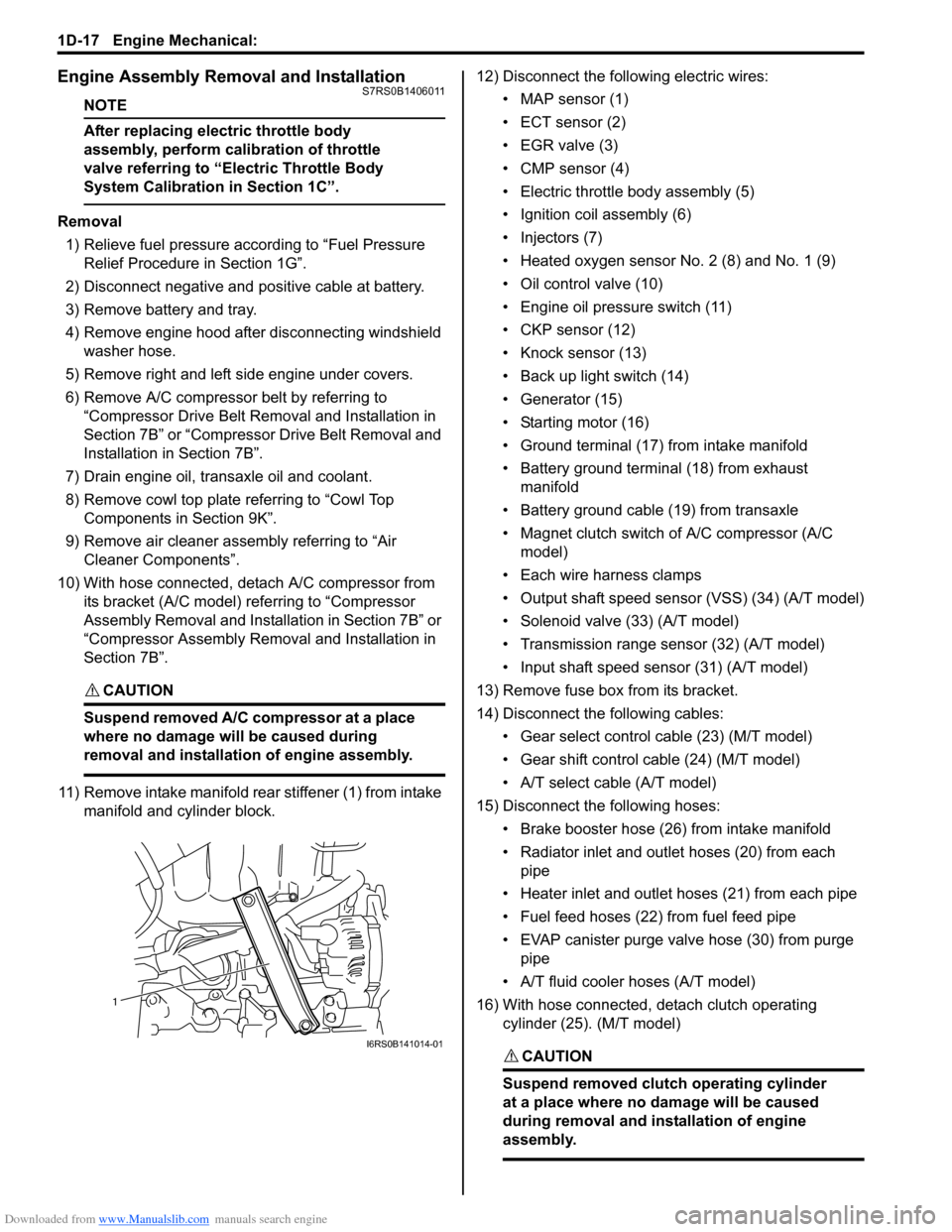

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 371 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-8

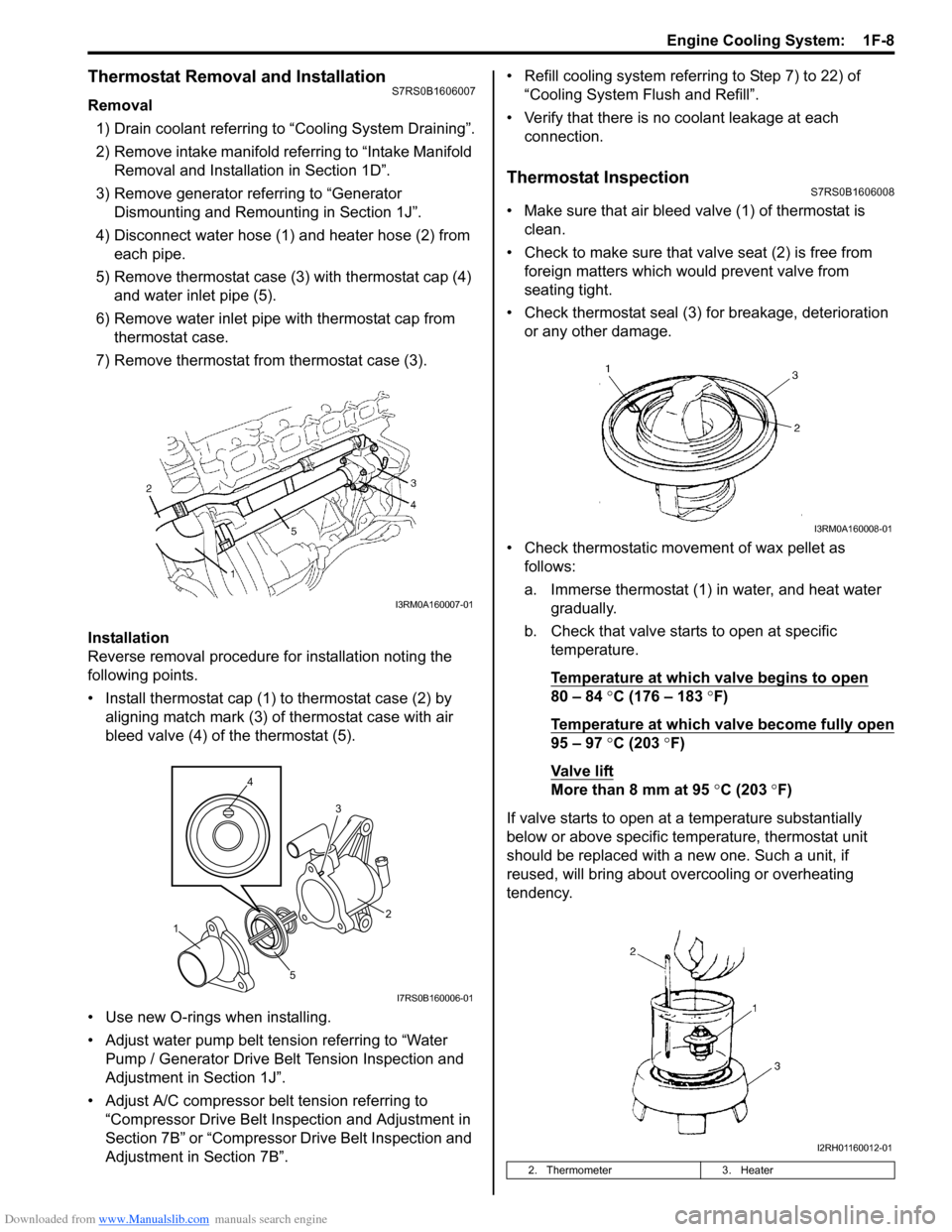

Thermostat Removal and InstallationS7RS0B1606007

Removal1) Drain coolant referring to “Cooling System Draining”.

2) Remove intake manifold referring to “Intake Manifold Removal and Installa tion in Section 1D”.

3) Remove generator referring to “Generator Dismounting and Remounting in Section 1J”.

4) Disconnect water hose (1) and heater hose (2) from each pipe.

5) Remove thermostat case (3) with thermostat cap (4)

and water inlet pipe (5).

6) Remove water inlet pipe with thermostat cap from thermostat case.

7) Remove thermostat from thermostat case (3).

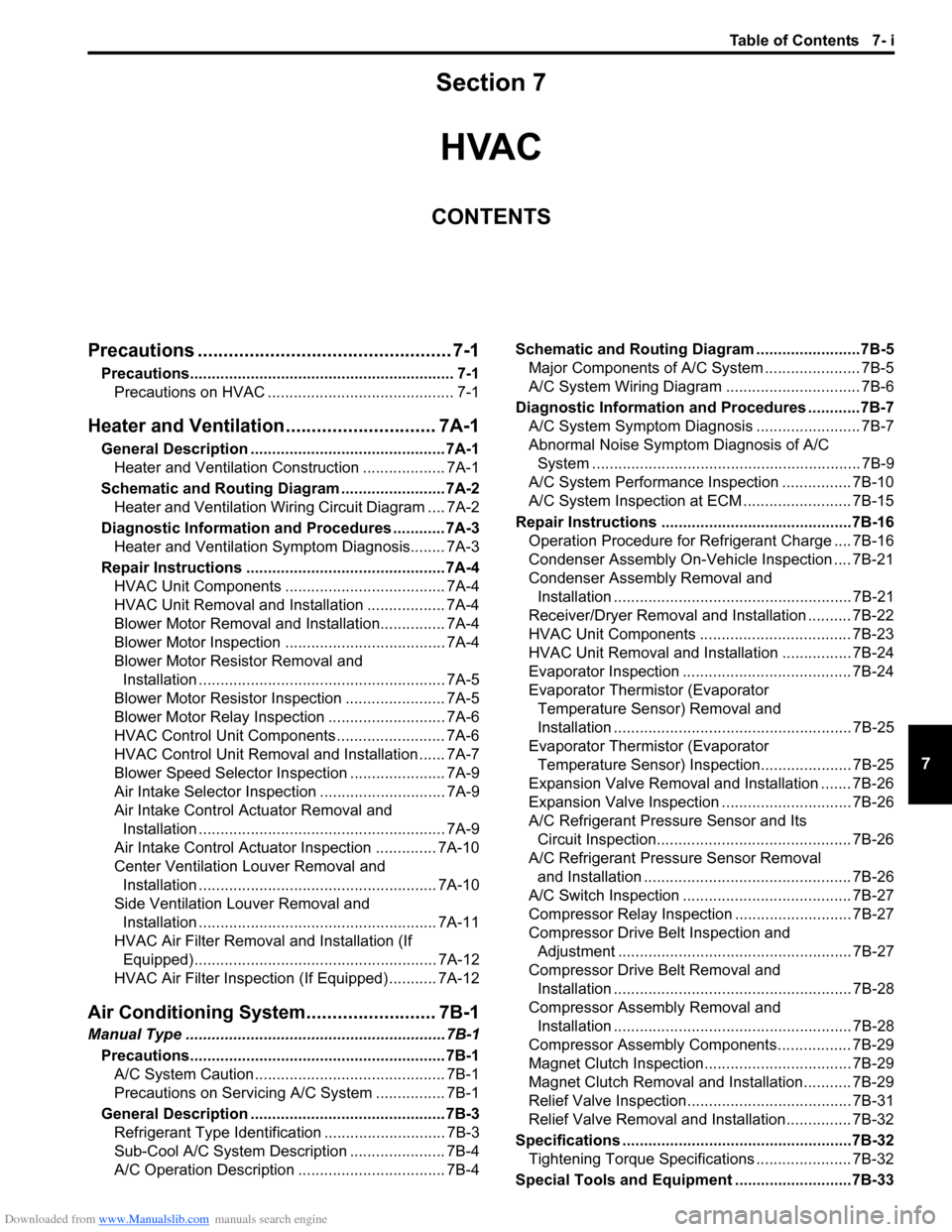

Installation

Reverse removal procedure for installation noting the

following points.

• Install thermostat cap (1) to thermostat case (2) by aligning match mark (3) of thermostat case with air

bleed valve (4) of the thermostat (5).

• Use new O-rings when installing.

• Adjust water pump belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment in Section 1J”.

• Adjust A/C compressor belt tension referring to “Compressor Drive Belt Inspection and Adjustment in

Section 7B” or “Compressor Drive Belt Inspection and

Adjustment in Section 7B”. • Refill cooling system referrin

g to Step 7) to 22) of

“Cooling System Flush and Refill”.

• Verify that there is no coolant leakage at each connection.

Thermostat InspectionS7RS0B1606008

• Make sure that air bleed valve (1) of thermostat is clean.

• Check to make sure that va lve seat (2) is free from

foreign matters which would prevent valve from

seating tight.

• Check thermostat seal (3) for breakage, deterioration or any other damage.

• Check thermostatic movement of wax pellet as follows:

a. Immerse thermostat (1) in water, and heat water gradually.

b. Check that valve starts to open at specific temperature.

Temperature at which valve begins to open

80 – 84 °C (176 – 183 °F)

Temperature at which valve become fully open

95 – 97 °C (203 °F)

Va l v e l i ft

More than 8 mm at 95 °C (203 ° F)

If valve starts to open at a temperature substantially

below or above specific temperature, thermostat unit

should be replaced with a new one. Such a unit, if

reused, will bring about ov ercooling or overheating

tendency.

I3RM0A160007-01

4

5 3

1 2

I7RS0B160006-01

2. Thermometer

3. Heater

I3RM0A160008-01

I2RH01160012-01

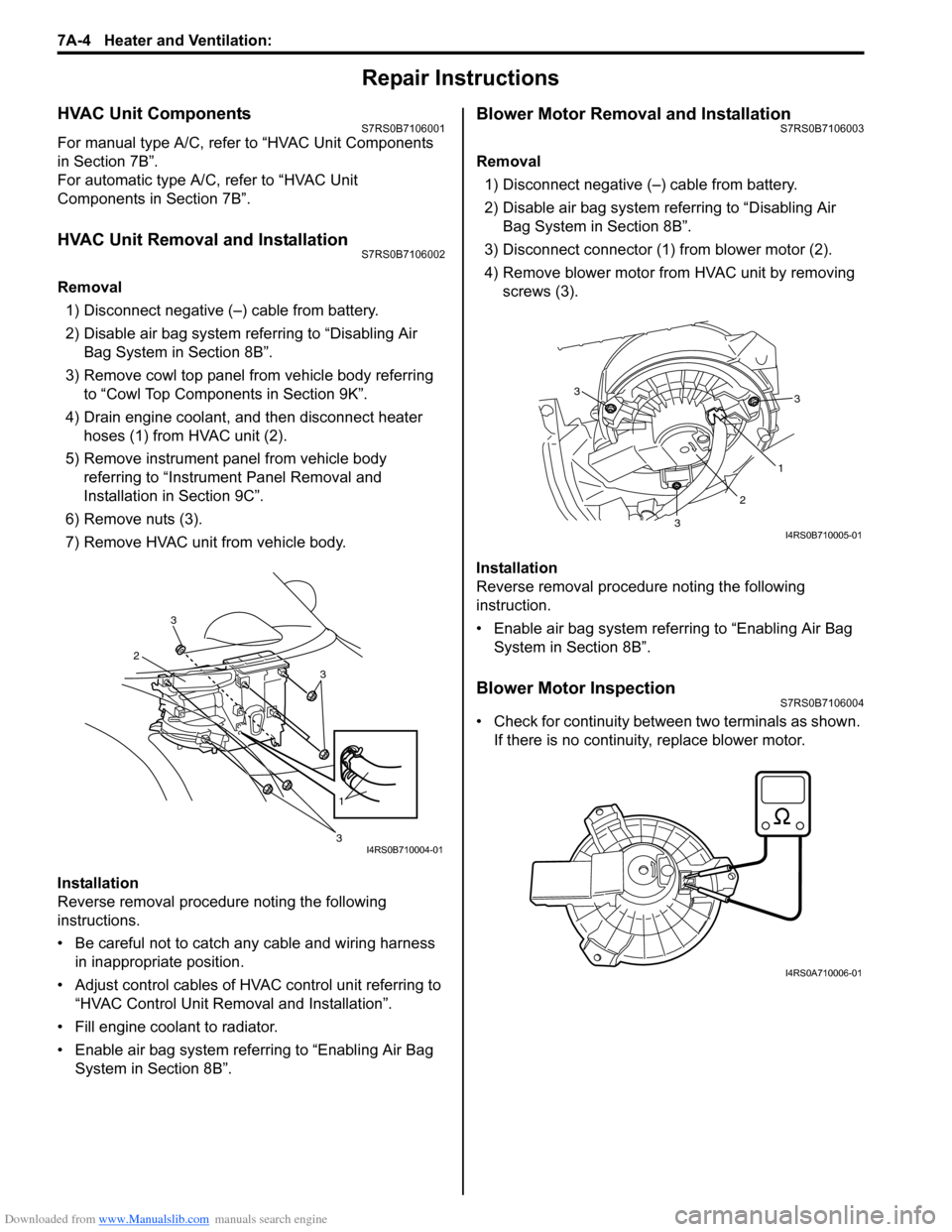

Page 933 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33

Page 940 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-4 Heater and Ventilation:

Repair Instructions

HVAC Unit ComponentsS7RS0B7106001

For manual type A/C, refer to “HVAC Unit Components

in Section 7B”.

For automatic type A/C, refer to “HVAC Unit

Components in Section 7B”.

HVAC Unit Removal and InstallationS7RS0B7106002

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove cowl top panel from vehicle body referring to “Cowl Top Components in Section 9K”.

4) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

5) Remove instrument panel from vehicle body referring to “Instrument Panel Removal and

Installation in Section 9C”.

6) Remove nuts (3).

7) Remove HVAC unit from vehicle body.

Installation

Reverse removal procedure noting the following

instructions.

• Be careful not to catch any cable and wiring harness in inappropriate position.

• Adjust control cables of HVAC control unit referring to “HVAC Control Unit Remo val and Installation”.

• Fill engine coolant to radiator.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

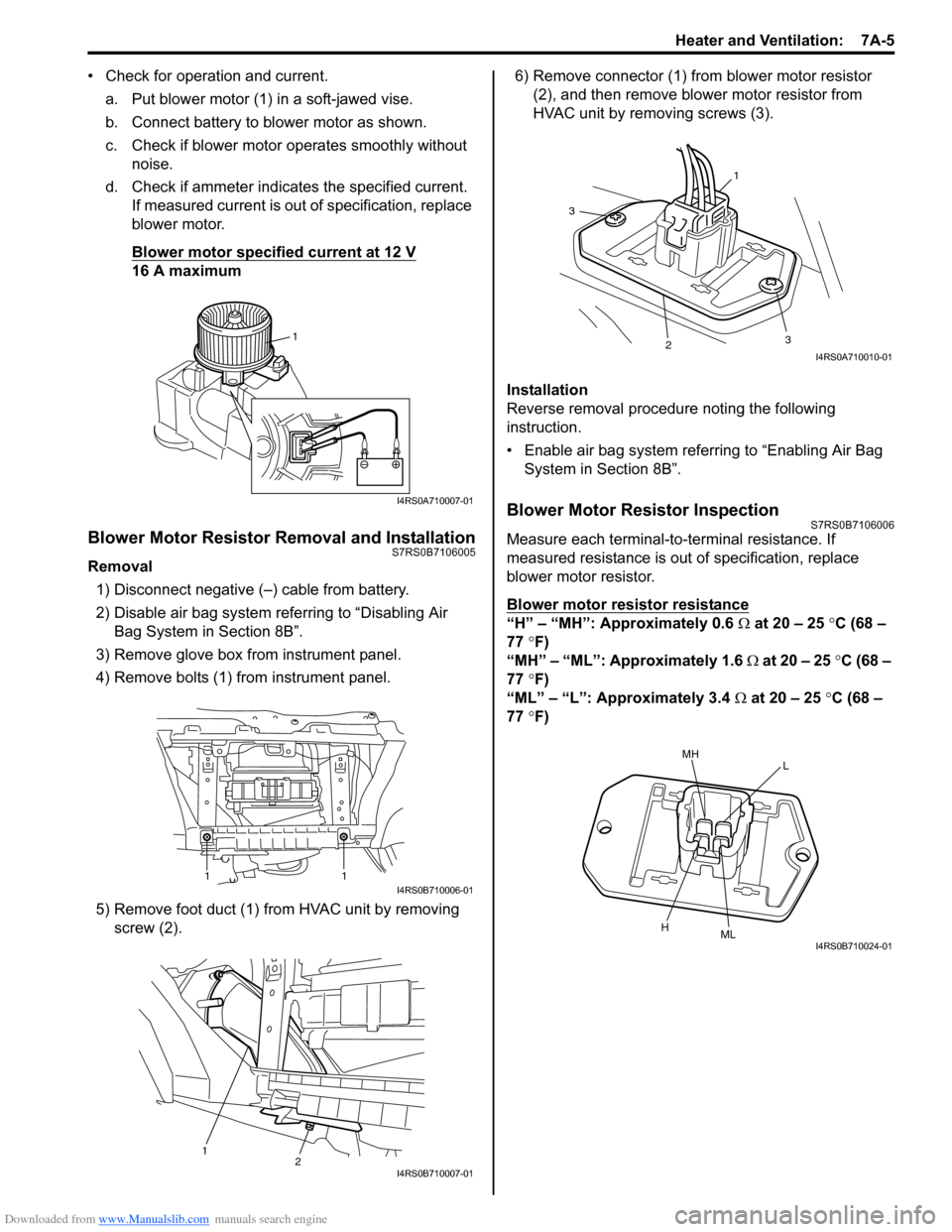

Blower Motor Removal and InstallationS7RS0B7106003

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Disconnect connector (1) from blower motor (2).

4) Remove blower motor from HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor InspectionS7RS0B7106004

• Check for continuity between two terminals as shown. If there is no continuity, replace blower motor.

3

2

3

1

3I4RS0B710004-01

3

1

2

3

3

I4RS0B710005-01

I4RS0A710006-01

Page 941 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-5

• Check for operation and current.a. Put blower motor (1) in a soft-jawed vise.

b. Connect battery to blower motor as shown.

c. Check if blower motor operates smoothly without noise.

d. Check if ammeter indicates the specified current. If measured current is out of specification, replace

blower motor.

Blower motor specified current at 12 V

16 A maximum

Blower Motor Resistor Removal and InstallationS7RS0B7106005

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove bolts (1) from instrument panel.

5) Remove foot duct (1) from HVAC unit by removing screw (2). 6) Remove connector (1) from blower motor resistor

(2), and then remove blower motor resistor from

HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor Resistor InspectionS7RS0B7106006

Measure each terminal-to-terminal resistance. If

measured resistance is out of specification, replace

blower motor resistor.

Blower motor resistor resistance

“H” – “MH”: Approximately 0.6 Ω at 20 – 25 °C (68 –

77 °F)

“MH” – “ML”: Approximately 1.6 Ω at 20 – 25 °C (68 –

77 °F)

“ML” – “L”: Approximately 3.4 Ω at 20 – 25 °C (68 –

77 °F)

1

I4RS0A710007-01

11I4RS0B710006-01

12I4RS0B710007-01

1

3

23

I4RS0A710010-01

MHL

HMLI4RS0B710024-01

Page 942 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-6 Heater and Ventilation:

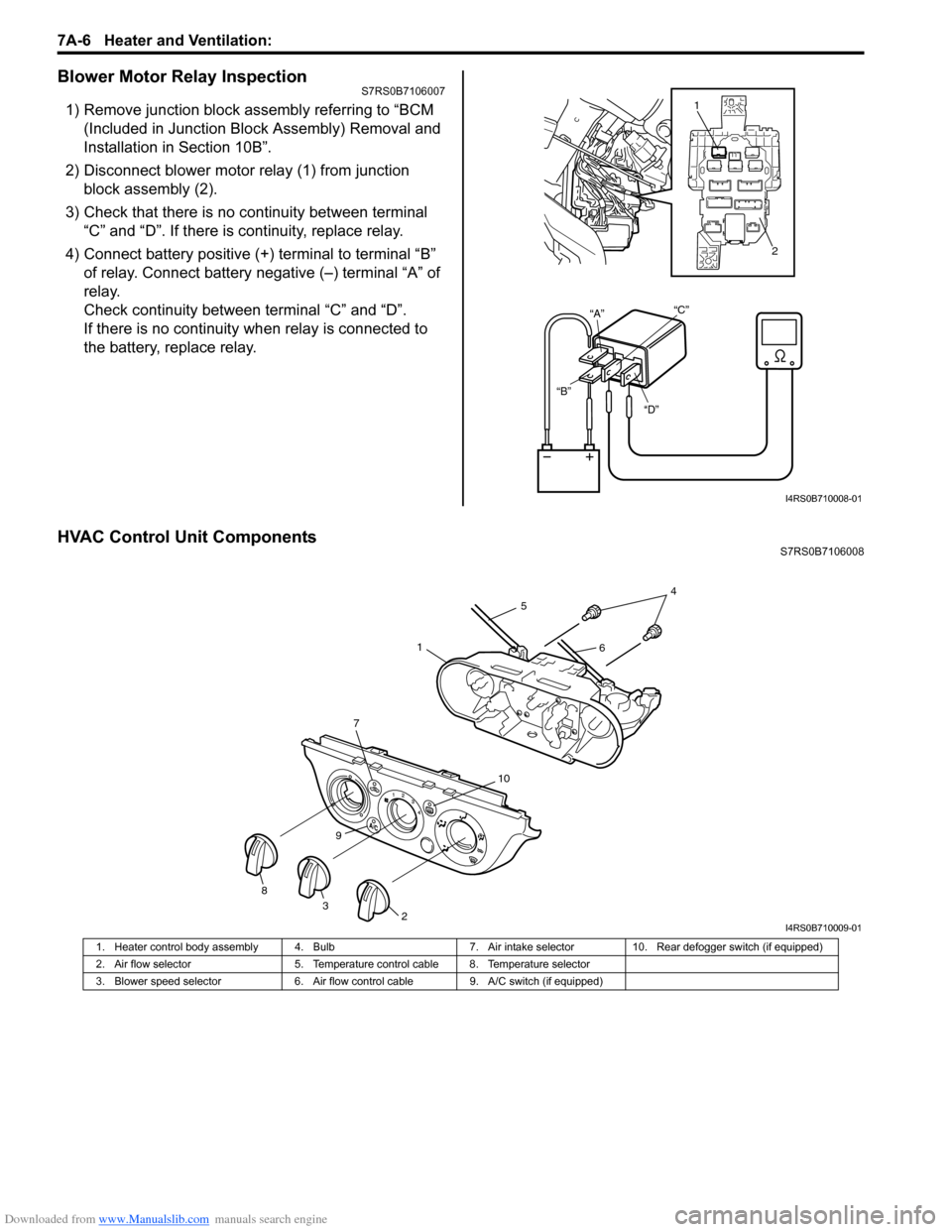

Blower Motor Relay InspectionS7RS0B7106007

1) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

2) Disconnect blower motor relay (1) from junction block assembly (2).

3) Check that there is no continuity between terminal “C” and “D”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “B”

of relay. Connect battery negative (–) terminal “A” of

relay.

Check continuity between terminal “C” and “D”.

If there is no continuity wh en relay is connected to

the battery, replace relay.

HVAC Control Unit ComponentsS7RS0B7106008

“D”

“B” “A”

“C”

1

2

I4RS0B710008-01

45

61

7

10

9

238

I4RS0B710009-01

1. Heater control body assembly 4. Bulb 7. Air intake selector10. Rear defogger switch (if equipped)

2. Air flow selector 5. Temperature control cable 8. Temperature selector

3. Blower speed selector 6. Air flow control cable9. A/C switch (if equipped)

Page 943 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

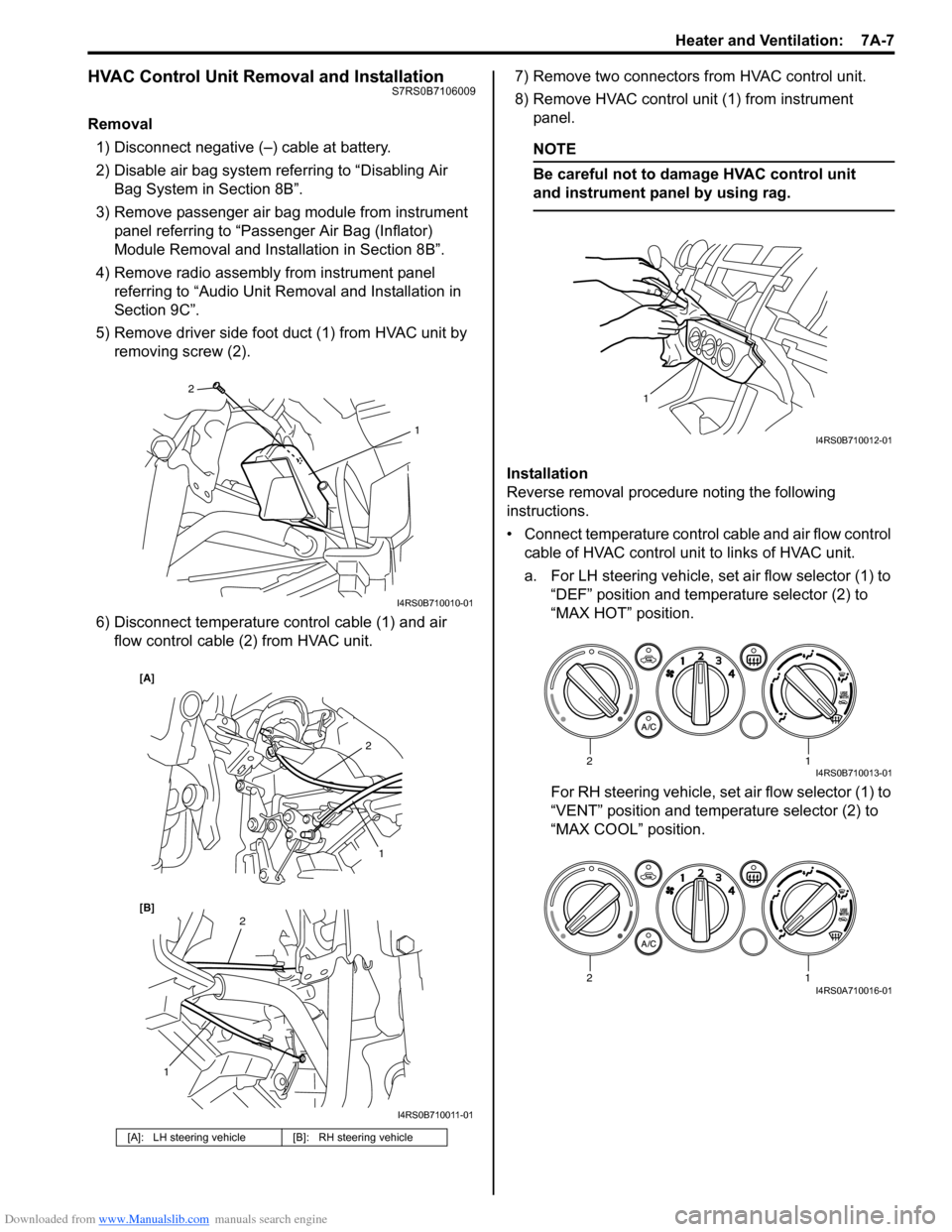

HVAC Control Unit Removal and InstallationS7RS0B7106009

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove driver side foot duct (1) from HVAC unit by removing screw (2).

6) Disconnect temperature control cable (1) and air flow control cable (2) from HVAC unit. 7) Remove two connectors from HVAC control unit.

8) Remove HVAC control unit (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control unit

and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set air flow selector (1) to “DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set air flow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

[A]: LH steering vehicle [B]: RH steering vehicle

2

1

I4RS0B710010-01

2

1

1

2

[B] [A]

I4RS0B710011-01

1

I4RS0B710012-01

12I4RS0B710013-01

12I4RS0A710016-01