time SUZUKI SWIFT 2007 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 565 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-26

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

3 1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair insulation of

CAN communication

line circuit referring to

“Precaution for CAN

Communication System

in Section 00” in related

manual.

4 1) Turn ignition switch to OFF position.

2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC.

IS DTC U1073 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1073 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1073 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1073 is

detected by ABS control

module, go to Step 5.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

5 1) Substitute a know-good BCM and recheck ABS control module for DTC.

IS DTC U1073 detected? Substitute a know-good

ABS control module and

recheck.

End.

Page 566 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-27 ABS:

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4504019

Wiring Diagram

Refer to “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition

Reception error of communication data for ECM is detected more than specified time continuously.

DTC Troubleshooting Step Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check DTC for ABS.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 1) Check DTC for ECM. Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

4 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Check DTC for ABS.

Is DTC U1100 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

5 1) Turn ignition switch to OFF position.

2) Disconnect connectors of ABS control module and ECM

communicating by means of CAN.

3) Check CAN communication circuit between ABS control module and ECM for open, short and high resistance.

Is CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 1) Disconnect connectors of all control modules communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAn communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 1) Turn ignition switch to OFF position. 2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC

IS DTC U1100 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1100 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1100 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1100 is

detected by ABS control

module, go to Step 8.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

Page 567 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-28

Repair Instructions

ABS Hydraulic Unit Operation CheckS7RS0B4506001

1) Check that basic brake system other than ABS is in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if brake dragging occurs. If it does, correct.

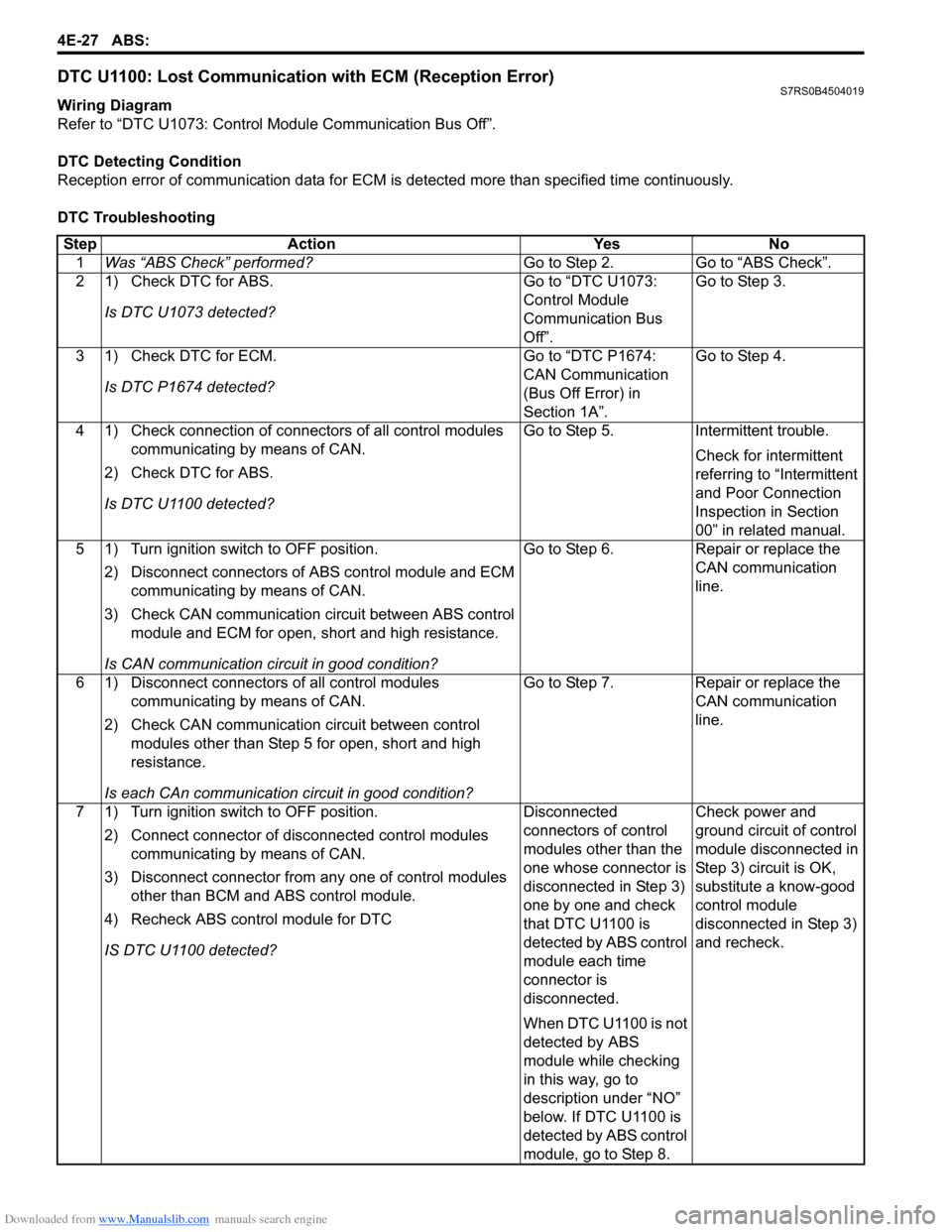

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool 7) Turn ignition switch to ON position and select menu

to “HYDRAULIC CONTROL TEST” under

“miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

8) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then select

testing wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check that:

• Operation sound of solenoid is heard and the wheel turns only about 0.5 sec. (Brake force is

depressurized).

• Operation sound of pump motor is heard and pulsation is felt at brake pedal.

9) Check for all 4-wheels co ndition respectively. If a

faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

8 1) Substitute a know-good BCM and recheck ABS control

module for DTC.

IS DTC U1100 detected? Substitute a know-good

ABS control module and

recheck.

End.

Step Action Yes No

1 (A)I4RS0A450020-01

I4RH01450021-01

Page 570 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-31 ABS:

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage and perform “ABS Hydraulic Un it Operation Check”.

NOTE

For new ABS hydraulic unit / control module

assembly, if “ABS Hydraulic Unit Operation

Check” has not been performed, ABS

warning light may flash when ignition switch

is turned ON position.

Accordingly preform “ABS Hydraulic Unit

Operation Check” to stop flashing of ABS

warning light.

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4506005

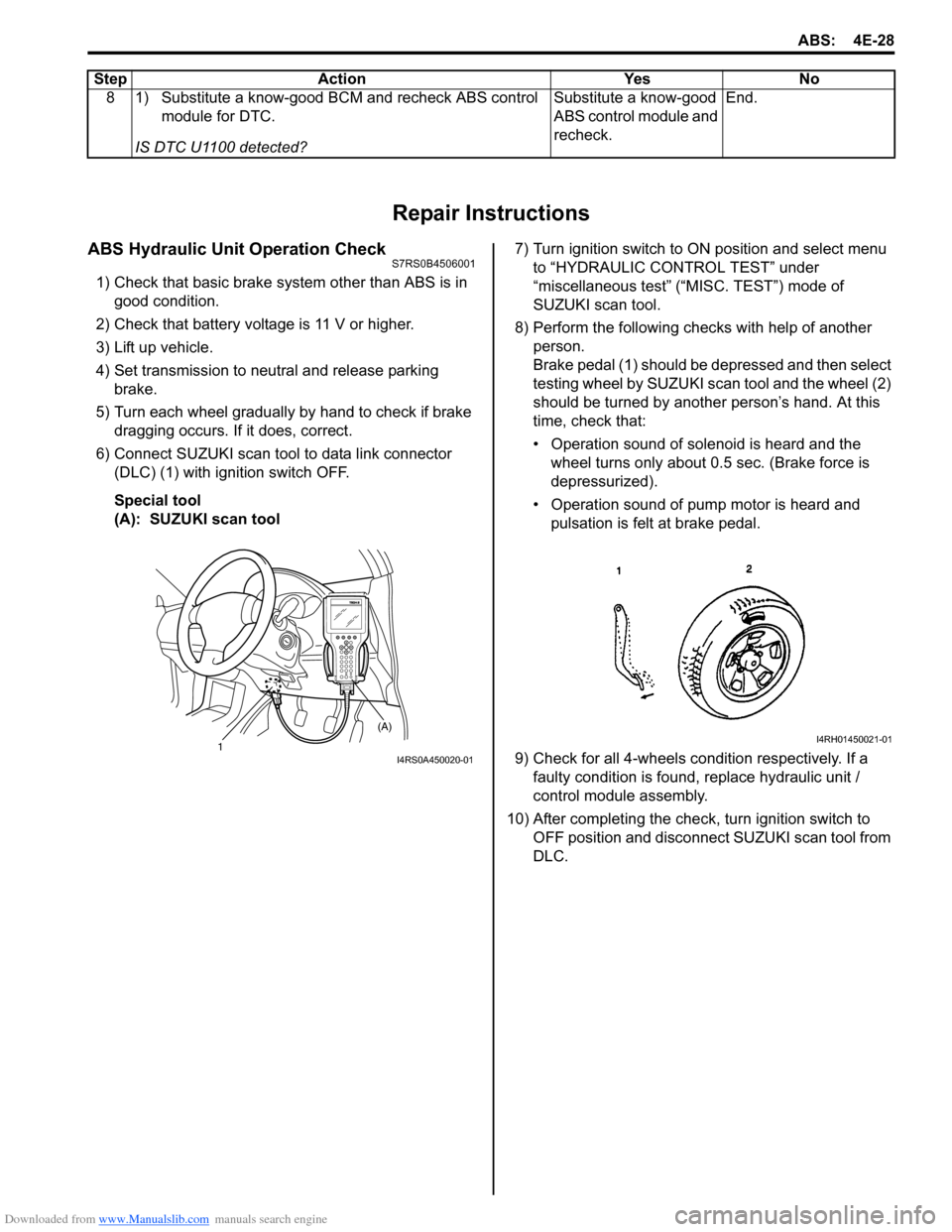

Output Voltage Inspection

1) Disconnect negative cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage to

12 V.

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

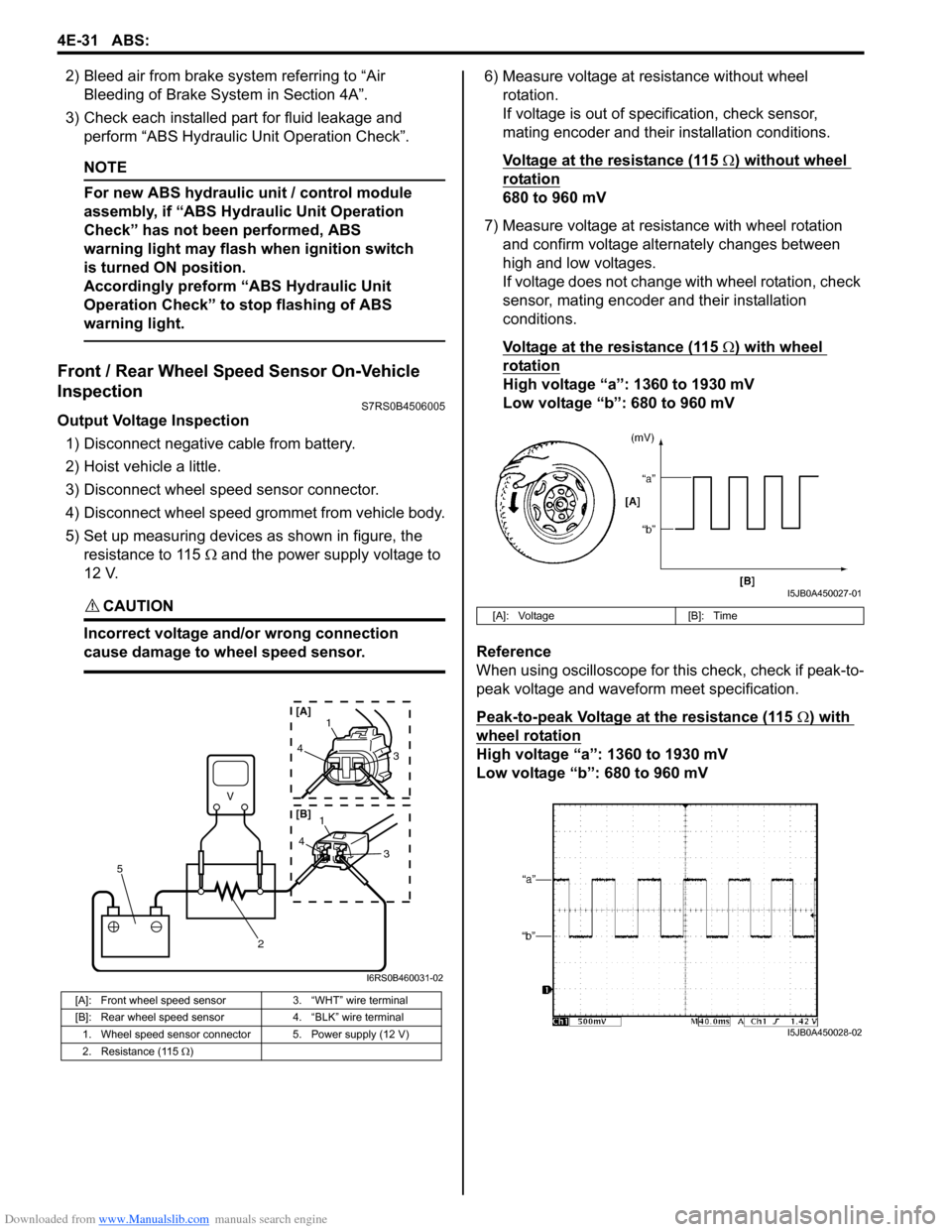

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω )

V

2

5

41

3

43

1

[A]

[B]

I6RS0B460031-02

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

Page 576 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-2 Electronic Stability Program:

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other TestsS7RS0B4600005

When performing speedometer or other tests using speedometer tester or chassis dynamometer, ESP® function must

be deactivated by ESP ® OFF switch or using SUZUKI scan to ol to complete the tests correctly.

When using SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP ® function. Refer to SUZUKI scan tool

operator's manual for further details.

General Description

Electronic Stability Program DescriptionS7RS0B4601006

Electronic Stability Program (ESP ®) is an auxiliary function to enable the vehicle to av oid a danger safely while the

vehicle is running, stopping or turning.

Electronic Stability Program (ESP ®) consists of following functions.

ESP ® is a registered trademark of Daimler Chrysler AG.

Antilock Brake System (ABS)

This system prevents tire locking which may occur when br ake is applied suddenly or on slippery roads. With this

function, as the vehicle body is kept in the stable state an d tires unlocked, the driver can avoid any obstacle by turning

the steering wheel.

Electronic Brake force Distribution (EBD)

This function distributes braking force of front and rear wheels properly according to the vehicle load condition.

With this function, the braking force of the front and rear wheels is controlled for the optimum effect to secure the

maximum braking force regardless of the loadage.

Traction Control System (TCS)

This system controls the engine and brake to prevent the dr iving wheels from spinning at the time of starting and

accelerating. Particularly, this fu nction is helpful for safe driving on muddy or icy roads. When ESP ® control module

detects wheel spinning using information from the yaw rate sensor and wheel speed sensor, it lower the engine torque

by closing the electronic controlled thro ttle and controlling ignition. At the same time, brake is applied to the spinning

tire.

Stability Control

This function controls the vehicle body in the stable state by controlling the engine and braking so as to prevent the

vehicle from over-steering or under-steering while turning.

When under-steering occurs, this function lowers the engine torque and applies brake to the inner rear wheel in the

vehicle forward direction so as to pr event the vehicle from moving outward.

When over-steering occurs, this function applies brake to the outer front wheel in the vehicle forward direction so as to

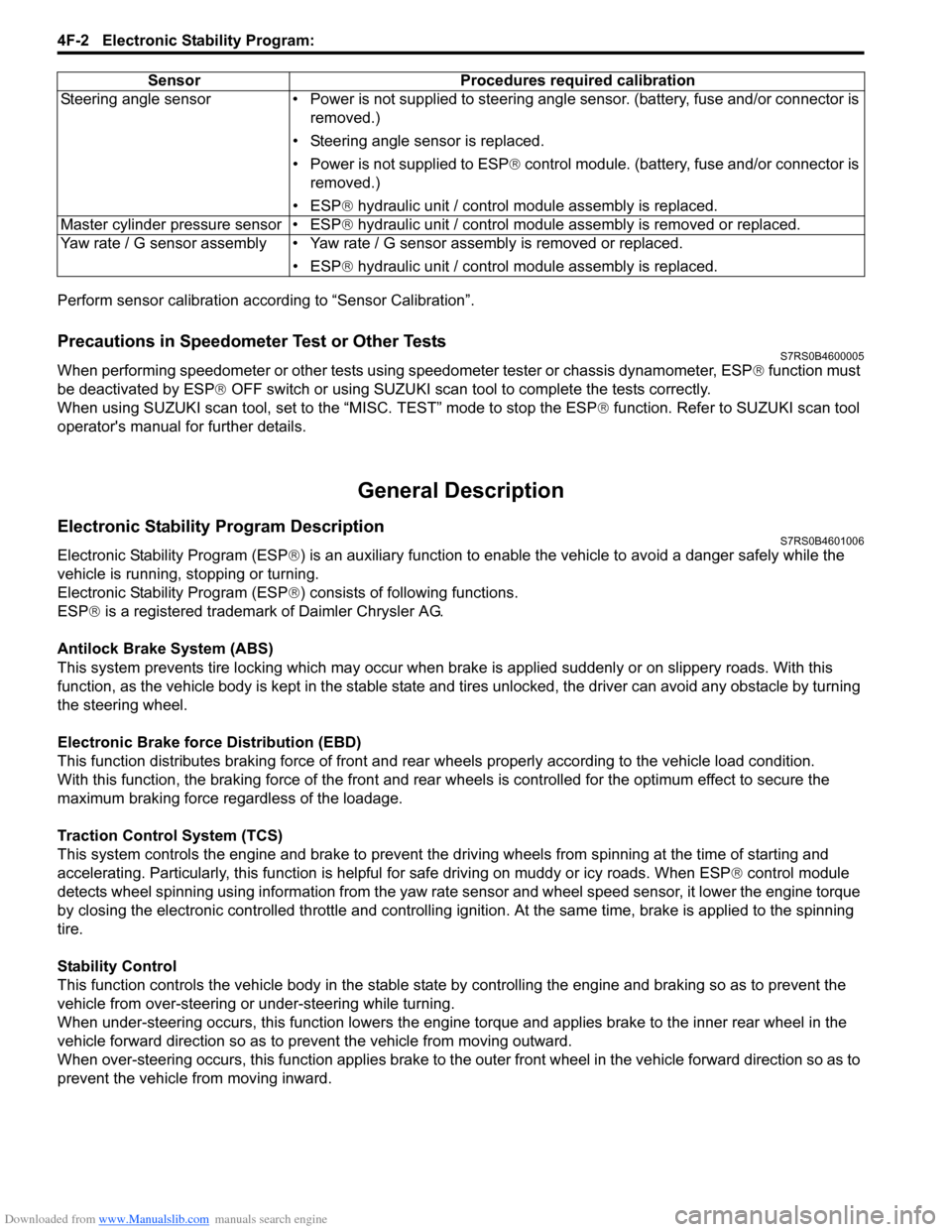

prevent the vehicle from moving inward. Sensor Procedures required calibration

Steering angle sensor • Power is not su pplied to steering angle sensor. (battery, fuse and/or connector is

removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP ® control module. (battery, fuse and/or connector is

removed.)

• ESP® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly • Yaw rate / G sensor assembly is removed or replaced.

• ESP® hydraulic unit / control module assembly is replaced.

Page 589 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-15

EBD Warning Lamp (Brake Warning Lamp)

Check

S7RS0B4604047

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning lamp (brake warning lamp)

(1) is turned ON.

3) Release parking brake with ignition switch ON and check that EBD warning lamp (brake warning lamp)

goes off.

If it doesn't go off, go to “EBD Warning Lamp (Brake

Warning Lamp) Comes ON Steady”.

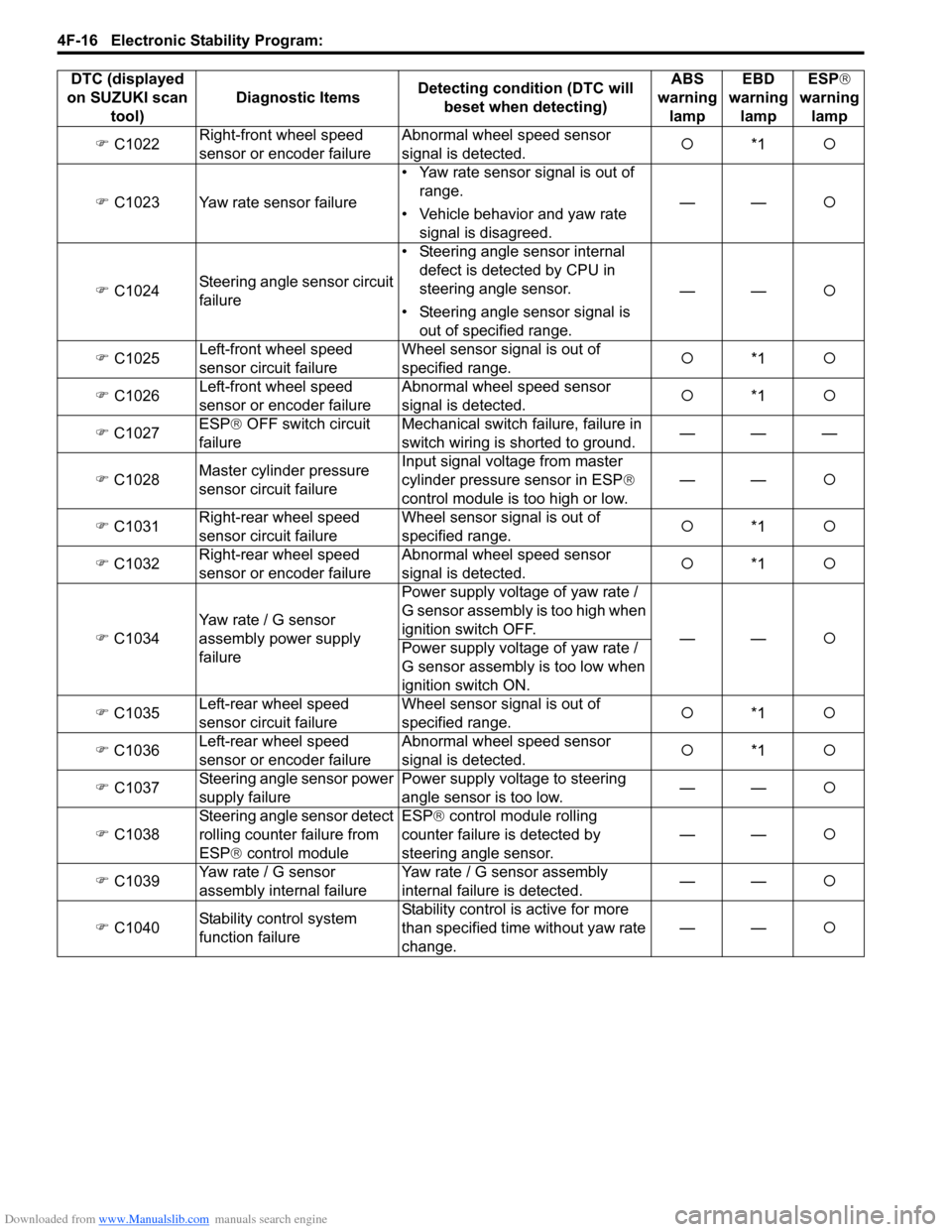

DTC CheckS7RS0B4604004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (1).

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on

SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

NOTE

If SUZUKI scan tool can not communicate

ESP® control module, perform “Serial Data

Link Circuit Check”.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from DLC.

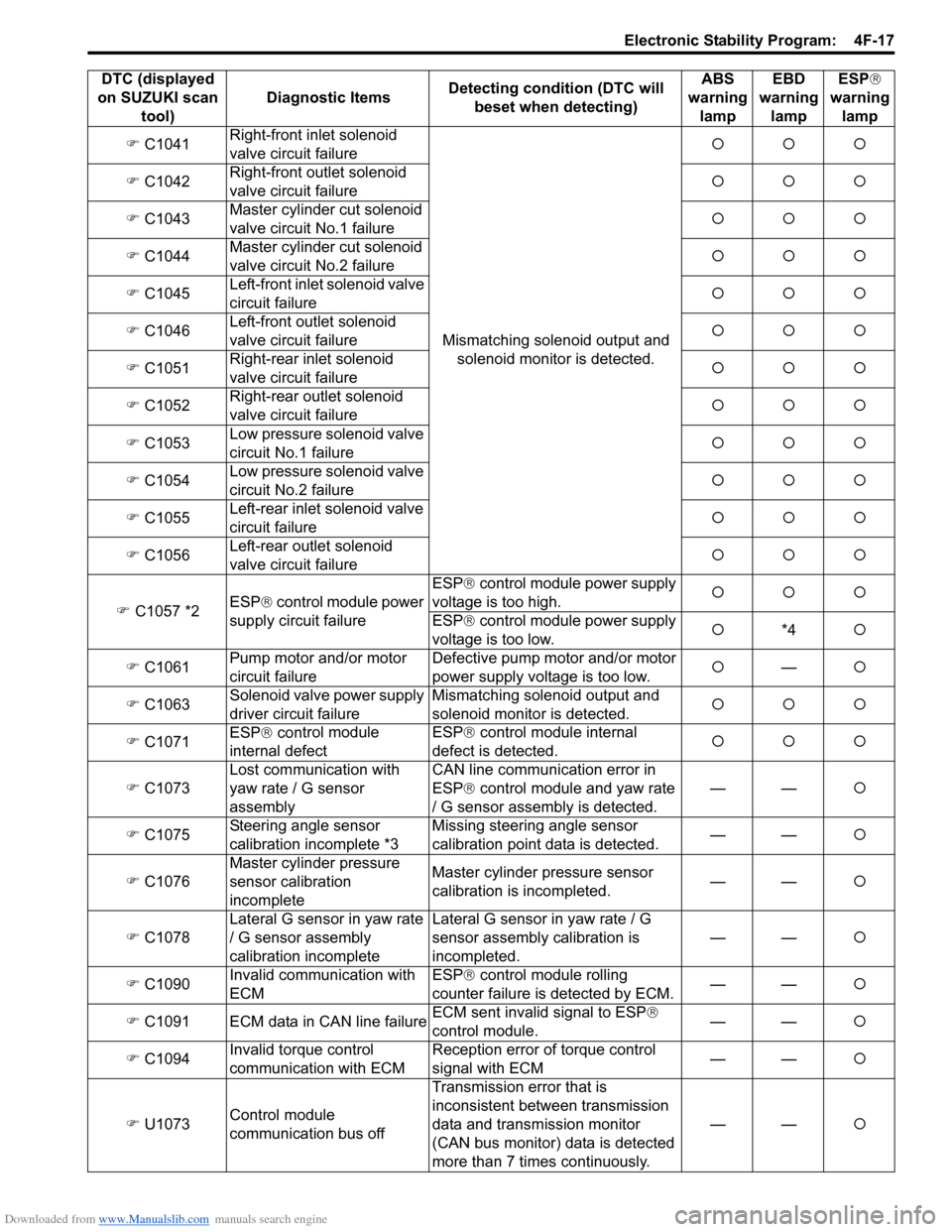

DTC TableS7RS0B4604005

CAUTION!

Be sure to perform “Electronic Stability Program System Check” before starting diagnosis.

BRAKE

1

I4RS0A450008-01

(A)

1

I4RS0B450003-01

DTC (displayed

on SUZUKI scan tool) Diagnostic Items

Detecting condition (DTC will

beset when detecting) ABS

warning lamp EBD

warning lamp ESP

®

warning lamp

NO DTC Normal — — — —

�) C1016 Stop lamp switch failure Vehicle behavior and stop lamp

switch signal is disagreed for

specified time.———

�) C1017 Lateral G sensor range /

performance Lateral G sensor signal is out of

specified range.

——

�{

�) C1018 Brake fluid level switch

failure • Brake fluid level is too low.

• Input signal of brake fluid level

switch to BCM is low level. ——

�{

�) C1020 Master cylinder pressure

sensor power supply failure Power supply volt

age to master

cylinder pressure sensor in ESP ®

hydraulic unit / control module

assembly is out of specification. ——

�{

�) C1021 Right-front wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

Page 590 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-16 Electronic Stability Program:

�) C1022 Right-front wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1023 Yaw rate sensor failure • Yaw rate sensor signal is out of

range.

• Vehicle behavior and yaw rate signal is disagreed. ——

�{

�) C1024 Steering angle sensor circuit

failure • Steering angle sensor internal

defect is detected by CPU in

steering angle sensor.

• Steering angle sensor signal is out of specified range. ——

�{

�) C1025 Left-front wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1026 Left-front wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1027 ESP

® OFF switch circuit

failure Mechanical switch failure, failure in

switch wiring is shorted to ground.

———

�) C1028 Master cylinder pressure

sensor circuit failure Input signal voltage from master

cylinder pressure sensor in ESP

®

control module is too high or low. ——

�{

�) C1031 Right-rear wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1032 Right-rear wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1034 Yaw rate / G sensor

assembly power supply

failure Power supply voltage of yaw rate /

G sensor assembly is too high when

ignition switch OFF.

——�{

Power supply voltage of yaw rate /

G sensor assembly is too low when

ignition switch ON.

�) C1035 Left-rear wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1036 Lef

t-rear wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1037 Steering angle sensor power

supply failure Power supply voltage to steering

angle sensor is too low.

——

�{

�) C1038 Steering angle sensor detect

rolling counter failure from

ESP

® control module ESP

® control module rolling

counter failure is detected by

steering angle sensor. ——

�{

�) C1039 Yaw rate / G sensor

assembly internal failure Yaw rate / G sensor assembly

internal failure is detected.

——

�{

�) C1040 Stability control system

function failure Stability control is active for more

than specified time

without yaw rate

change. ——

�{

DTC (displayed

on SUZUKI scan tool) Diagnostic Items

Detecting condition (DTC will

beset when detecting) ABS

warning lamp EBD

warning lamp ESP

®

warning lamp

Page 591 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-17

�) C1041 Right-front inlet solenoid

valve circuit failure

Mismatching solenoid output and solenoid monitor is detected. �{�{�{

�) C1042 Right-front outlet solenoid

valve circuit failure �{�{�{

�) C1043 Master cylinder cut solenoid

valve circuit No.1 failure �{�{�{

�) C1044 Master cylinder cut solenoid

valve circuit No.2 failure �{�{�{

�) C1045 Left-front inlet solenoid valve

circuit failure �{�{�{

�) C1046 Left-front outlet solenoid

valve circuit failure �{�{�{

�) C1051 Right-rear inlet solenoid

valve circuit failure �{�{�{

�) C1052 Right-rear outlet solenoid

valve circuit failure �{�{�{

�) C1053 Low pressure solenoid valve

circuit No.1 failure �{�{�{

�) C1054 Low pressure solenoid valve

circuit No.2 failure �{�{�{

�) C1055 Left-rear inlet solenoid valve

circuit failure �{�{�{

�) C1056 Left-rear outlet solenoid

valve circuit failure �{�{�{

�) C1057 *2 ESP

® control module power

supply circuit failure ESP®

control module power supply

voltage is too high. �{�{�{

ESP® control module power supply

voltage is too low. �{

*4 �{

�) C1061 Pump motor and/or motor

circuit failure Defective pump motor and/or motor

power supply voltage is too low.

�{

— �{

�) C1063 Solenoid valve

power supply

driver circuit failure Mismatching solenoid output and

solenoid monitor is detected.

�{�{�{

�) C1071 ESP

® con

trol module

internal defect ESP®

control module internal

defect is detected. �{�{�{

�) C1073 Lost communication with

yaw rate / G sensor

assembly CAN line communication error in

ESP®

control module and yaw rate

/ G sensor assembly is detected. ——

�{

�) C1075 Steering angle sensor

calibration incomplete *3 Missing steering angle sensor

calibration point data is detected.

——

�{

�) C1076 Master cylinder pressure

sensor calibration

incomplete Master cylinder pressure sensor

calibration is incompleted.

——

�{

�) C1078 Lateral G sensor in yaw rate

/ G sensor assembly

calibration incomplete Lateral G sensor in yaw rate / G

sensor assembly calibration is

incompleted.

——

�{

�) C1090 Invalid communication with

ECM ESP®

control module rolling

counter failure is detected by ECM. ——

�{

�) C1091 ECM data in CAN line failure ECM sent invalid signal to ESP

®

control module. ——

�{

�) C1094 Invalid torque control

communication with ECM Reception error of torque control

signal with ECM

——

�{

�) U1073 Control module

communication bus off Transmission error that is

inconsistent between transmission

data and transmission monitor

(CAN bus monitor) data is detected

more than 7 times continuously.

——

�{

DTC (displayed

on SUZUKI scan tool) Diagnostic Items

Detecting condition (DTC will

beset when detecting) ABS

warning lamp EBD

warning lamp ESP

®

warning lamp

Page 603 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-29

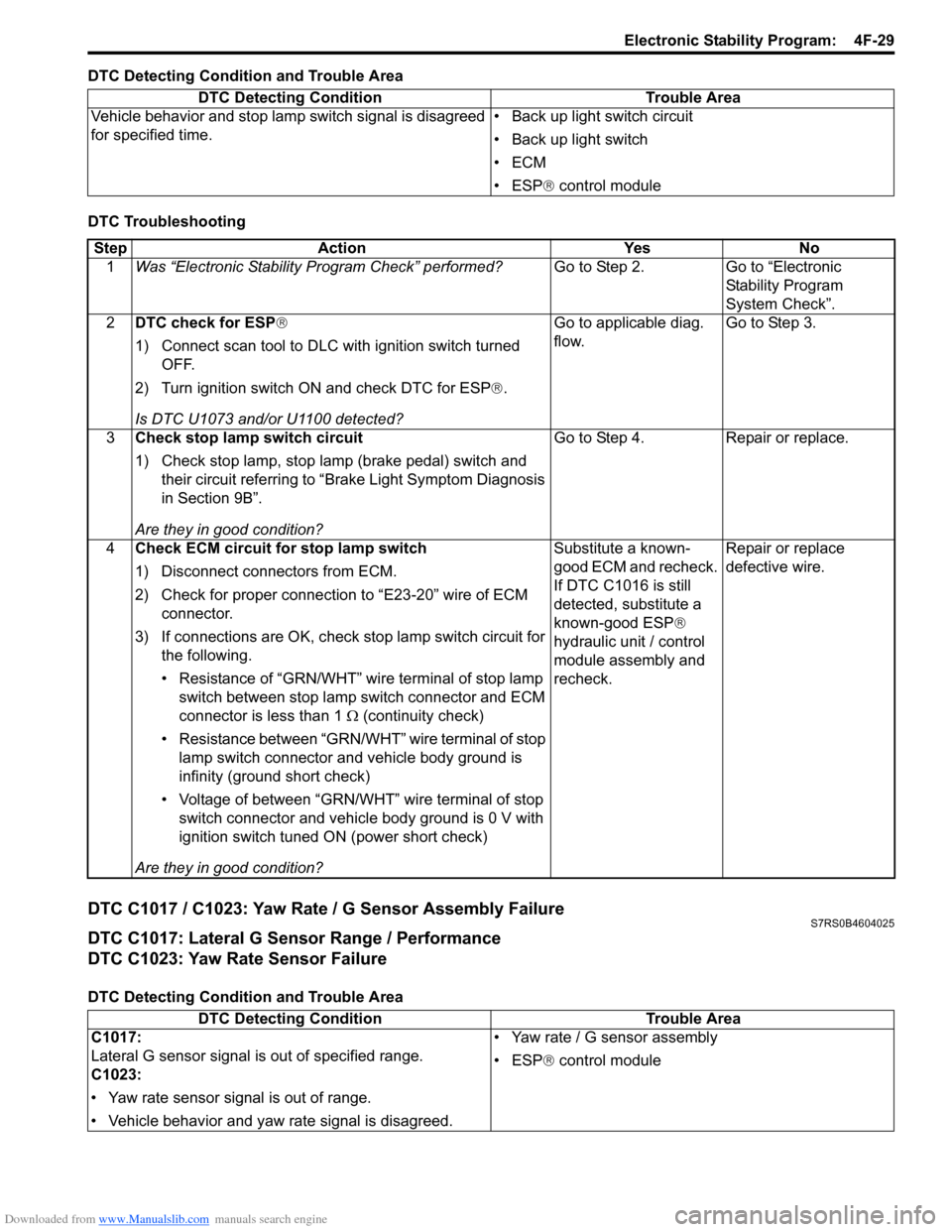

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly FailureS7RS0B4604025

DTC C1017: Lateral G Sensor Range / Performance

DTC C1023: Yaw Rate Sensor Failure

DTC Detecting Condition and Trouble AreaDTC Detecting Condition Trouble Area

Vehicle behavior and stop lamp switch signal is disagreed

for specified time. • Back up light switch circuit

• Back up light switch

•ECM

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Is DTC U1073 and/or U1100 detected? Go to applicable diag.

flow.

Go to Step 3.

3 Check stop lamp switch circuit

1) Check stop lamp, stop lamp (brake pedal) switch and

their circuit referring to “Brake Light Symptom Diagnosis

in Section 9B”.

Are they in good condition? Go to Step 4.

Repair or replace.

4 Check ECM circuit for stop lamp switch

1) Disconnect connectors from ECM.

2) Check for proper connection to “E23-20” wire of ECM

connector.

3) If connections are OK, check stop lamp switch circuit for

the following.

• Resistance of “GRN/WHT” wire terminal of stop lamp switch between stop lamp switch connector and ECM

connector is less than 1 Ω (continuity check)

• Resistance between “GRN/WHT” wire terminal of stop lamp switch connector and vehicle body ground is

infinity (ground short check)

• Voltage of between “GRN/WHT” wire terminal of stop switch connector and vehicle body ground is 0 V with

ignition switch tuned ON (power short check)

Are they in good condition? Substitute a known-

good ECM and recheck.

If DTC C1016 is still

detected, substitute a

known-good ESP

®

hydraulic unit / control

module assembly and

recheck. Repair or replace

defective wire.

DTC Detecting Condition

Trouble Area

C1017:

Lateral G sensor signal is out of specified range.

C1023:

• Yaw rate sensor signal is out of range.

• Vehicle behavior and yaw rate signal is disagreed. • Yaw rate / G sensor assembly

• ESP

® control module

Page 613 of 1496

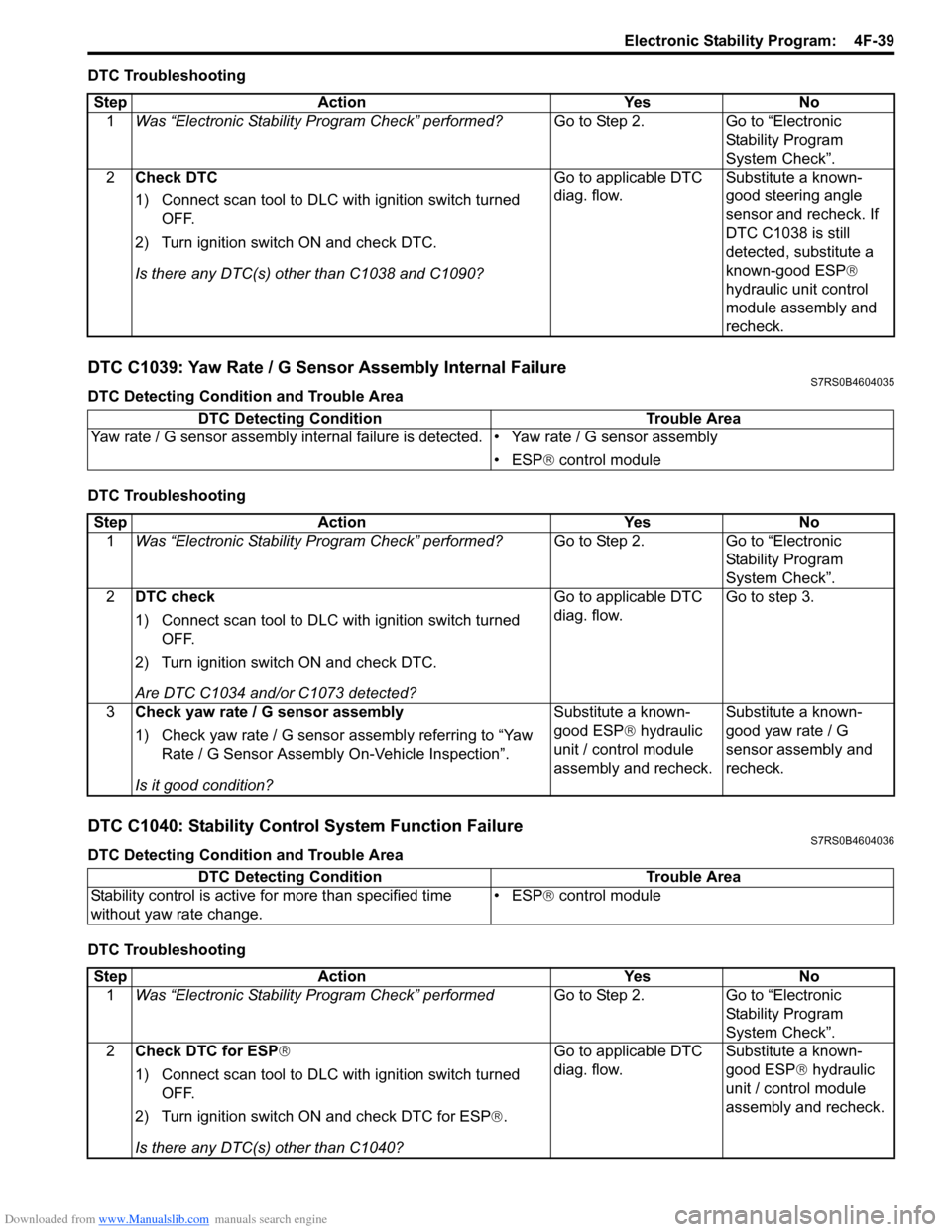

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-39

DTC Troubleshooting

DTC C1039: Yaw Rate / G Sensor Assembly Internal FailureS7RS0B4604035

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC C1040: Stability Control System Function FailureS7RS0B4604036

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 Check DTC

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC.

Is there any DTC(s) other than C1038 and C1090? Go to applicable DTC

diag. flow.

Substitute a known-

good steering angle

sensor and recheck. If

DTC C1038 is still

detected, substitute a

known-good ESP

®

hydraulic unit control

module assembly and

recheck.

DTC Detecting Condition Trouble Area

Yaw rate / G sensor as sembly internal failure is detect ed. • Yaw rate / G sensor assembly

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC.

Are DTC C1034 and/or C1073 detected? Go to applicable DTC

diag. flow.

Go to step 3.

3 Check yaw rate / G sensor assembly

1) Check yaw rate / G sensor assembly referring to “Yaw

Rate / G Sensor Assembly On-Vehicle Inspection”.

Is it good condition? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Substitute a known-

good yaw rate / G

sensor assembly and

recheck.

DTC Detecting Condition

Trouble Area

Stability control is active fo r more than specified time

without yaw rate change. • ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check DTC for ESP ®

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Is there any DTC(s) other than C1040? Go to applicable DTC

diag. flow.

Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck.